Abstract

To improve ore recovery ratio and the quality of medium-length hole blasting in non-pillar sublevel caving method, this study first investigated the effects of brow line failure on rock movement and ore recovery indexes based on rock blasting fragmentation mechanisms, the granular dynamics theory and ore drawing theory. Subsequently, control strategies to enhance blasting quality and reduce brow line failure were explored through energy impact crushing experiments, experiments on the radial rock-breaking effects of blast holes with different detonation velocities, and underground physical simulation experiments using full blast hole length detonating cord blasting. The experimental results indicate that as the degree of brow line failure increases, the ore recovery ratio gradually decreases, while the waste ratio gradually increases. Bottom initiation and the use of the full blast hole length detonating cord were identified as the optimal initiation method and charging structure for medium-length hole blasting in non-pillar sublevel caving method, effectively improving blasting quality and reducing damage to the brow line.

Similar content being viewed by others

Introduction

The non-pillar sublevel caving method is widely used in metal mining production. The characteristics of this mining method include completing preparatory cutting, followed by drilling and ore extraction within the roadway, utilizing medium-length hole blasting. The ore is drawn under the cover of waste1. During ore extracting, the complete boundary line formed on the roof of the extraction roadway after each blasting step is referred to as the brow line. The integrity of the brow line after blasting significantly influences ore recovery ratio, ore dilution ratio, and the safety of subsequent blasting operations. This is especially critical in stopes with soft and unstable ore, where previous blasting steps frequently cause damage to the brow line and blast holes, complicating subsequent blasting and extraction operations2,3. The main causes of brow line failure are threefold: first, the poor stability of the rock, making roadways and blast holes prone to damage; second, unreasonable drilling and blasting parameters, such as insufficient spacing and excessive charge at the collar of blast hole; and third, overly frequent handling of large block rock at the drawpoint or the use of improper secondary blasting methods. Therefore, strengthening the study of ore and rock blastability classification, further optimizing drilling and blasting parameters, and improving secondary blasting methods are essential to fundamentally resolve the issue of brow line failure and eliminate safety hazards in blasting operations4,5,6.

Extensive research has been conducted on the impact of brow line failure on ore loss and dilution. He et al. studied the effect of brow damage on the flowability of caved ore and its subsequent impact on ore loss and dilution7. Zhang et al. proposed selecting and designing the optimal brow line support based on varying mining conditions, considering factors such as rock mass strength, ore drawing height, block size, and drawing rate8. Ren et al. analyzed the causes of brow line failure in the Beiminghe Iron Mine and proposed comprehensive brow line protection measures9,10. Liu et al. suggested protecting the brow line by controlling the length of the uncharged portion of the blast hole11. In the field of research on the mechanisms and experimental methods of rock blasting and fragmentation, the blasting and its effects on rock are highly complex, and the blasting theory remains incomplete12,13,14,15. In recent years, significant progress has been made in the study of blasting mechanisms with the advancement of physical experiments and numerical simulation techniques16,17. Researchers have investigated the mechanisms of rock blasting and fragmentation, as well as the patterns of stress and fracture changes, under different charging structures18,19 and detonation velocities20,21. For massive deposits, ANFO and emulsion explosives are mainly used, and dividing of the deposit into exploitation levels plays an important role in determining the minimum mining loss22,23.

Guided by the ore drawing theory and the granular dynamics theory24,25, experimental research was conducted on the characteristics of ore flow and waste mixing under different degrees of brow line failure during drawing ore under waste. To reduce brow line failure and large block percentage ratio, the study investigated control strategies to enhance the quality of medium-length hole blasting and mitigate brow line failure, focusing on factors such as explosive detonation velocity, initiation methods, and charging structures.

Theoretical analysis

The mechanism of ore dilution and loss following brow line failure

Ore loss includes both mining loss and non-mining loss. Mining loss primarily consists of extracted loss and unextracted loss. The former includes losses due to ore left behind in the stope that cannot be recovered and losses incurred during transportation. The losses caused by brow line failure are classified as extracted loss. The latter includes losses from ore bodies that were designed to be mined but were not extracted, as well as losses from various ore bodies that could not be mined. In Chinese mines, the mining loss rate is typically around 25%. The formula for calculating the ore dilution ratio is as follows:

where: \(\:P\) is the ore dilution ratio, %; \(\:C\) is the industrial ore grade, %; \(\:{C}_{c}\) is the grade of extracted ore (including mixed-in waste),%; \(\:{C}_{y}\) is the grade of mixed-in waste, %.

Brow line failure occurs when the roof at the end of the ore-drawing roadway collapses and cracks due to blasting or other external forces. Due to the use of fan-shaped blast holes in the non-pillar sublevel caving method, the blast holes are densely concentrated at the collar, and there are two free surfaces. As a result, brow line failure is relatively common26. Moreover, since drilling, blasting, and ore extraction operations in the non-pillar sublevel caving method are all conducted within the ore-drawing roadway, brow line failure has a significantly more detrimental impact on the mining operations.

When the roof stability of the ore-drawing roadway is poor and joints and fractures are well-developed, the brow line is prone to failure along the joint planes after blasting. The concentrated blasting energy at the collar of medium-length holes often causes substantial damage to the brow line and the roof between blast hole rows. Furthermore, as the collar spacing of blast holes decreases from the sides towards the center of the roof, the extent of the damage progressively increases. After brow line failure, the roof of the ore-drawing roadway is raised, causing the isolated extraction zone (IEZ) to become elongated. This results in the earlier exposure of the top waste, an increased proportion of drawn low-grade ore, and a higher dilution ratio27,28. Sometimes, brow line failure can block the rear blast holes, negatively affecting the charging operations and ore breaking quality.

Rock breaking mechanism in medium-length hole blasting

In Chinese mines using the non-pillar sublevel caving method, the safety technical standards for medium-length hole ore drawing generally define medium-length holes as blast holes with a diameter of 50–75 mm and a depth of 5–20 m.

The rock-breaking mechanism of blasting without stress superposition is as follows: the shock wave generated by the explosion initially forms a crushed zone in the area surrounding the blast hole. As the shock wave attenuates into a stress wave, it propagates through the surrounding rock mass as an elastic wave. Consequently, the rock particles experience radial displacement, with the radial compressive stress generating tangential tensile stress, resulting in the formation of radial fractures that connect with the pulverized zone. Under the expansion, compression, and gas wedge action of the detonation gases, radial fracture networks form. Subsequently, the rock mass releases the elastic deformation energy accumulated during compression, leading to the formation of annular fractures. As these fractures form, expand, and interconnect, the rock mass is fragmented into pieces of varying sizes, ultimately forming the fracture zone29.

Due to the longer length of columnar charges in medium-length holes, a time delay occurs along the detonation propagation direction after initiation, resulting in the formation of a stress superposition zone. The columnar charge within the blast hole is divided into a finite number of spherical charges for stress superposition analysis. Analyze two adjacent hypothetical spherical charges, A and B, with the detonation propagation direction from A to B. The stress waves intersect orthogonally at C, with the distances from A and B to point C being \(\:{r}_{1}\) and \(\:{r}_{2}\), respectively. During stress superposition, the stress waves may intersect either perpendicularly or obliquely. To facilitate the analysis of the stress process, and given the time interval between the explosions of the two hypothetical charge, the experiment assumes that the two stress waves intersect perpendicularly.

As the propagation distance of the stress wave increases, the pressure exerted on the rock mass gradually attenuates. According to the attenuation law, when the stress wave reaches point C, the following relationships exist: \(\:{\sigma\:}_{{r}_{1}}={\sigma\:}_{1}/{\left({r}_{1}/{r}_{0}\right)}^{\alpha\:}\) and \(\:{\sigma\:}_{{r}_{2}}={\sigma\:}_{2}/{\left({r}_{2}/{r}_{0}\right)}^{\alpha\:}\). In these equations, \(\:{\sigma\:}_{1}\) and \(\:{\sigma\:}_{2}\) is the pressures exerted on the blast hole walls at A and B, respectively, MPa; \(\:{r}_{0}\) represents the radius of the blast hole, mm; and \(\:\alpha\:\) is the stress attenuation index.

The resultant force in the AC direction is:

where: \(\:{\sigma\:}_{{r}_{1}}\) is the radial compressive stress at C along the \(\:{r}_{1}\) direction, Pa; \(\:{\sigma\:}_{{r}_{2}}\) is the radial compressive stress at C along the \(\:{r}_{2}\) direction, Pa; \(\:\mu\:\) is the Poisson’s ratio of the rock, with \(\:\gamma\:=\frac{\mu\:}{1-\mu\:}\); \(\:{\sigma\:}_{{\theta\:}_{1}}\) is the tangential compressive stress applied by \(\:{\sigma\:}_{1}\) at C along the \(\:{r}_{2}\) direction, Pa; \(\:{\sigma\:}_{{\theta\:}_{2}}\) is the tangential compressive stress applied by \(\:{\sigma\:}_{2}\) at C along the \(\:{r}_{1}\) direction, Pa.

Let \(\:{\sigma\:}_{1}\)=\(\:{\sigma\:}_{2}\). When 当\(\:\theta\:\in\:\left(0, arctan\left({\gamma\:}^\frac1{\alpha\:}\right)\right)\), \(\:{F}_{AC}\) and \(\:{F}_{BC}\) are tensile stress and compressive stress, respectively. This leads to the formation of fractures along the BC direction, promoting the gradual increase in fracture width and development. Additionally, the action of detonation gases further facilitates the destruction of the rock mass. Let \(\:{\sigma\:}_{1}\)=\(\:{\sigma\:}_{2}\). When \(\:\theta\in\:\left(0, arctan\left(\gamma^\frac1\alpha\right)\right)\), \(\:{F}_{AC}\) is tensile stress, while \(\:{F}_{BC}\) is compressive stress. This stress state induces the formation of fractures along the BC direction and promotes the gradual increase in fracture width and development. Combined with the action of detonation gases, these factors make the rock mass more susceptible to fragmentation.

In summary, when the initial detonation pressure increases, the radial pressure along the BC direction and the tensile stress along the AC direction will also increase, resulting in wider and more extensive fractures that facilitate rock fragmentation. Therefore, adopting an appropriate initiation method, charge structure, and explosive detonation velocity can effectively enhance the blasting quality in medium-length hole blasting.

Experimental part

A medium-sized iron mine in China, which utilizes non-pillar sublevel caving method, was used as the research subject. The effects of brow line failure on ore and rock movement and ore recovery ratio were investigated. Furthermore, control strategies to enhance the quality of medium-length hole blasting and reduce brow line failure were studied.

Physical simulation experiment of ore drawing under brow line failure

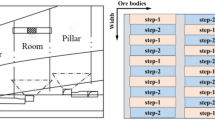

Experimental geometric similarity ratio is set to 1:30. Based on the stope structural parameters from actual mining practice, the ore drawing experiment included three degrees of brow line failure: intact brow line, brow line failure angle of 45°, and brow line failure angle of 60°. The design of the physical similarity simulation experiments for brow line damage is illustrated in Fig. 1.

The simulation materials for top waste and waste ahead were dyed different colors. Under different angles of brow line failure, the quantities of ore, top waste, and waste ahead that were loaded and drawn can be measured and calculated. The particle size distribution of the simulated blasted ore and waste materials was determined based on the particle size distribution data from the mining area under study.

The drawing of ore is a process where the surface of the isolated extraction zone gradually shrinks until the particles on the surface simultaneously reach the drawpoint and are drawn. Based on this theory, labeled markers were placed at specific intervals within the ore simulation materials and front waste rock simulation materials in the model. By statistically analyzing labeled markers recovered during the ore drawing process, the maximum linear cross-sectional profile of the isolated extraction zone surface at various heights can be reconstructed and illustrated.

In the simulation experiment, crushed rock and gravel that are similar to the fragmented ore and waste in the actual caving site were selected as simulated loose materials. The densities of the loose ore and loose waste rock materials were 1.8 t/m³ and 1.6 t/m³, respectively. Based on the statistical results of the ore size after blasting on site: ore smaller than 30 cm accounted for 98.4% of the total blasted volume, ore between 30 and 60 cm accounted for 1.5%, and ore larger than 60 cm accounted for 0.2%. The size of the simulated materials in the experiment was scaled down according to the simulation ratio. The experimental materials were loaded in layers. A layer of labeled markers was placed every 3 cm along the height of the model, and a labeled marker was placed every 1 cm along the width of the model. After loading, the materials were compacted by gravity to the designed density. Considering the size of the mining loader bucket, the excavation tools used for material extraction in the experiment were also scaled down proportionally.

The energy impact crushing experiment

Determining the blastability of rock helps in devising more reasonable blasting schemes tailored to different lithologies, thereby improving blasting quality and reducing brow line failure. Rock strength and brittleness are the primary intrinsic factors affecting blastability. Typically, the higher the rock strength, the lower the blastability, while greater rock brittleness facilitates fragmentation. The blastability of rock is classified based on its brittleness.

The experiment utilizes the energy impact crushing test method, which uses physical impact energy to simulate the explosive energy of detonations. In the experiment, ore samples of various lithologies were first crushed into uniformly sized fragments with diameters of 30–40 mm. Then, 600 g of each sample were weighed and placed at the bottom of an impact cylinder. A hammer was allowed to freely fall from the top of the cylinder, impacting the ore six times. The fragmented ore was then sieved, and the mass of the material retained on the sieve was weighed. Finally, the data were analyzed to assess the brittleness of the rock.

Experiment on radial rock breaking effects of blast holes

This study proposes using a detonating cord equal in length to the depth of the blast hole in conjunction with the primary explosive in medium-length holes. Since the detonation velocity of the detonating cord is significantly higher than that of the emulsion ANFO explosive loaded in the hole, this method increases the detonation velocity of the explosive. Using ANSYS/LS-DYNA software, the blasting process of explosives loaded in blast holes is simulated to study the impact of changes in detonation velocity on rock mass damage. This is done to determine the differences between the explosive behavior under initiation method of installing full blast hole length detonating cord and general initiation method.

Based on the detonation velocities of granular emulsion ANFO and detonating cord, numerical simulations were conducted for a low detonation velocity scheme at 3000 m/s and a high detonation velocity scheme at 6000 m/s. The impact of detonation velocity on rock breaking effectiveness was assessed by analyzing the fracture development after blasting. The model dimensions are 500 cm × 500 cm × 500 cm, with the blast hole dimensions being 7 cm × 500 cm, running through the entire model. The coordinate system is defined with the z-axis along the blast hole, ranging from z = -250 cm to 250 cm. The initiation method is bottom initiation, meaning detonation starts at -250 cm. Utilizing the capabilities of ANSYS/LS-DYNA software, observation points are placed at the edges of the horizontal cross-section of the model to monitor the stress variations in the rock. Three model cross-sections at z = -250 cm, z = -49 cm, and z = 147 cm were selected for analysis after blasting.

In the experiment, both the rock and explosive elements were assumed to be homogeneous media. The rock was modeled using a kinematic hardening model (MAT_PLASTIC_KINEMATIC). The key physical and mechanical parameters were as follows: density of 3300 kg/m³, elastic modulus of 97.72 GPa, Poisson’s ratio of 0.21, tensile strength of 10.92 MPa, and compressive strength of 124.77 MPa, The explosive was modeled using the high-performance explosive material model (MAT_HIGH_EXPLOSIVE_BURN), with the JWL equation of state selected to simulate the relationship between detonation pressure and specific volume during the blasting process. The detonation velocities of the explosive were 3000 m/s and 6000 m/s. Non-reflective boundary conditions were applied to the four sides of the model, while the top and bottom surfaces of the model were free surfaces.

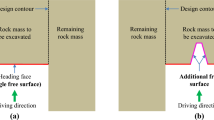

Full blast hole length detonating cord blasting underground physical simulation experiment

When a full blast hole length detonating cord is installed within the blast hole, the detonation velocity of the cord, being significantly higher than the detonation wave velocity of granular emulsion ANFO, approximates simultaneous initiation along the explosive column. To study the effect of full blast hole length detonating cord arrangement within the blast hole on explosive blasting and blast hole damage, physical simulation experiments were designed for both bottom initiation and top initiation methods. Each initiation method included two schemes: installed and uninstalled the full blast hole length detonating cord. Two test samples are used for each scenario.

The experiment utilized a 6 cm × 75 cm steel tube to simulate the blast hole. The experimental equipment and materials also included detonators, nonel tubes, primary explosives, detonating cord, emulsion ANFO explosives, and steel base plates. As shown in Fig. 2.

The detonation velocity of the detonating cord exceeds 6000 m/s, while the detonation velocity of the granular emulsion ANFO explosive is approximately half of that. The steel tube was welded to the steel base plate, ensuring that the pipe was perpendicular to the plate and maintained stable contact. After connecting the primary explosive to the detonator and nonel tube, the primary explosive and detonating cord were placed inside the steel pipe. The emulsion ANFO explosive was then loaded and compacted. The experimental setup was placed against the roadway wall at the test site. After the detonation, the damaged experimental setup was collected, and the extent of damage to the roadway wall and the base plate at the test site was observed and recorded. The experimental procedure and apparatus is illustrated in Fig. 3.

Based on the extent of damage to the roadway wall and the rock at the bottom of the simulated blast hole near the experimental setup, as well as the plastic deformation around the breach in the steel base plate and the curling of the breach edges, an analysis was conducted on the radial forces exerted on the steel tube (i.e., the radial damage to the roadway wall) and the axial forces on the base plate from the steel tube during blasting.

Results and discussion

Study on the law of ore dilution and loss due to brow line failure

Ore loss during the drawing process includes both the ore left in the stope that cannot be recovered and losses incurred during transportation. During the ore drawing process, once pure ore has been exhausted and waste rock begins to mix in, ore dilution occurs. Following the onset of dilution, in order to maximize ore recovery, ore mixed with waste rock is still extracted until its grade equals cut-off grade of ore drawing, at which point extraction ceases. During the ore drawing simulation, an ore shovel was used to extract ore at the simulated drawpoint. When the ore-to-waste rock mass ratio reaches or exceeds the set value for three consecutive extractions, ore extraction is halted. At this point, the model is in a cut-off state for ore drawing, as shown in Table 1.

The drawn labeled markers were collected and recorded, the approximate shape of the isolated extraction zone was reconstructed based on their initial positions, as shown in Table 1.

The shape of the isolated extraction zone obtained through physical simulation experiments is a laterally symmetrical, longitudinally asymmetrical, partially incomplete ellipsoid with an axis offset. Based on the reconstructed shape of the isolated extraction zone shown in Fig. 6, it can be observed that as the degree of brow failure increases, the height of the isolated extraction zone gradually decreases, and it progressively narrows along the drawpoint direction. Due to the fixed loading depth, the flow range of the ore ahead is limited. Consequently, the increase in residuals ahead reduces the ore recovery ratio. As the axial deviation angle of the isolated extraction zone gradually increases, mathematical modeling shows that under given dilution ratio, the recovery ratio decreases with the increase in the axial deviation angle. Analyzing the recovered ore and waste rock revealed that the primary source of waste is the top waste.

Based on the quantities of ore and waste recorded in the simulated ore drawing experiments, the recovery index values were calculated under various degrees of brow line failure. The optimal parameter was identified as the one with the highest ratio difference between recovery and dilution, are shown in Fig. 4.

As shown in Fig. 4, with constant stope structural parameters such as sublevel height and drawpoint dimensions: as the degree of brow line failure increases, the ore recovery ratio and the ratio difference between recovery and dilution gradually decrease, while the waste ratio gradually increases. The experimental results indicate that brow line failure has a significant impact on ore recovery index values. Analyzing the production data from extraction drifts where brow line failure occurred, the results of the physical similarity simulation experiments were validated.

In conclusion, appropriate protective measures should be implemented for the brow during production operations. When making mining plans, the sequence of operations should be carefully arranged to effectively control ground pressure and minimize its impact on the stability of the roadway roof and surrounding rock. During ore extracting, blasting design parameters and initiation methods suitable for the characteristics of the ore body should be selected to minimize damage to the roof.

Investigating of the blastability of rock

By analyzing the oversize ratios of various lithologies from the energy impact crushing experiment results, the difficulty in breaking the rock can be determined. The impact crushing particle size distribution is shown in Table 2.

The percentage of crushed rock retained on a 10 mm sieve for each lithology is used as the brittleness classification index. A higher value indicates lower brittleness and greater difficulty in breaking the rock. The brittleness is calculated using the following formula:

where \(\:B\) is the brittleness of the rock; \(\:{m}_{s}\) is the mass of the rock retained on the sieve, g; and m is the total mass of the rock, g. The blastability classification standard of the rock is borrowed from the reference29, and the classification results in Table 3.

The experimental results indicate that the main lithology of this ore body, garnet magnetite quartzite, is difficult to blast. Optimization of the charging structure is required to improve blasting quality.

Research on the relationship between explosive detonation velocity and rock breaking

To analyze the damage to the rock mass under different detonation velocities, the fracture generation effects of the cross-sections from various experimental schemes were compared. The cross-sections of the rock mass models are shown in in Table 4.

As shown in Table 4, when bottom initiation occurs, both experiments exhibit minimal fracture development and a limited detonation wave impact range, and the crushing zone of the high detonation velocity scheme is slightly larger. As the detonation wave propagates to the middle of the borehole, the damage in this area significantly increases. In the high detonation velocity scheme, the extent of the crushed and fractured zones is noticeably larger than in the low detonation velocity scheme. In the high detonation velocity scheme and the low detonation velocity scheme, the proportions of the volume of the blast hole and failed units relative to the total model volume were 1.354% and 0.722%, respectively. In summary, the high detonation velocity scheme, more closely approximates simultaneous initiation along the explosive column. This scheme generates higher detonation pressure, which helps expand the range of fracture formation. However, the higher detonation velocity tends to increase damage at the blast hole collar, requiring a corresponding increase in the length of the blast hole stemming. It can be inferred that in medium-length hole blasting, the higher the explosive’s detonation velocity, the more it tends to exhibit the characteristics of columnar charge blasting, significantly increasing the radial damage range.

The stress curves obtained from the monitoring points in both schemes are shown in Figs. 5 and 6.

According to the data from different schemes, the high detonation velocity scheme reaches the stress peak first, while the peak stress of the low detonation velocity scheme is only 52.9% of that of the former. Within the monitoring period, both the maximum and minimum stress values in the high detonation velocity scheme are higher than those in the low detonation velocity scheme, indicating that the high detonation velocity scheme exerts greater force on the rock, facilitating its breakage. Shear stress is the main cause of fracture formation, and in the experiments, the shear stress–time curve are similar to the stress-time curve. The peak shear stress in the high detonation velocity scheme is only 46.9% of that in the high detonation velocity scheme.

Since fractures play a critical role in the rock-breaking process, increasing the detonation velocity facilitates the initial breakage of the rock. As radial compressive stress increases, tangential tensile stress also increases, resulting in the generation of more and larger fractures, which in turn aids the further breakage of the rock by detonation gases. The higher the detonation velocity, the more the damage characteristics of the blast hole resemble those of columnar charge blasting. Experimental data indicate that high-velocity explosives are significantly superior to low-velocity explosives in terms of stress exertion, fracture formation, and damage effects. A well-designed charging structure can enhance the efficiency and effectiveness of medium-length hole blasting operations in the non-pillar sublevel caving method.

Study on blasting quality control strategies

In the underground physical simulation blasting experiment, a steel pipe with a diameter of 60 mm, matching the blast hole diameter, was used to simulate the blast hole. The emulsion ANFO explosive, detonating cord, and initiation charge were identical to those used in production blasting. The damage is observed in the form of breaches and the surrounding plastic deformations. A nearly circular breach forms at the center of the base plate of the experimental setup, with a plastic deformation area around the breach. The statistical results of the physical simulation blasting experiments are shown in Table 5.

As shown in Table 5, the results of the blast hole top initiation experiments indicate that the steel base plate breach diameter is larger in the scheme without the detonating cord, and the plastic deformation around the breach is more chaotic. This suggests that this charging structure did not form a stable detonation wave, resulting in unstable detonation direction and pressure. In contrast, the scheme with the full blast hole length detonating cord resulted in a smaller breach diameter and more orderly plastic deformation around the breach. The damage to the roadway wall was more severe, with distinct imprints, indicating that the detonation wave formed by this charging structure was more stable. Consequently, less detonation wave energy impacted the steel base plate, with more blasting energy acting in the radial direction.

The results of the bottom initiation experiments indicate that in the scheme without the detonating cord, the steel base plate breach diameter is smaller, and the plastic deformation around the breach is more orderly. The detonation wave reflected from the ground did not cause curling at the breach edges, and the damage to the roadway wall was minimal. In contrast, the scheme with the full blast hole length detonating cord resulted in a larger breach diameter and more severe plastic deformation around the breach. This indicates that, after initiation with the full blast hole length detonating cord, the high detonation velocity rapidly generated a large amount of high-temperature, high-pressure gas and produced significant detonation pressure. After initiation, the booster charge quickly detonated the explosive in the blast hole, creating an extremely strong detonation wave that penetrated the steel base plate. The rebounding detonation wave then acted on the steel base plate again, causing curling around the breach. The damage to the roadway wall suggests that significant radial forces were generated. Compared to the scheme without the full-length detonating cord, the initial stage more closely aligns with the characteristics of a spherical wave propagation from the end of a columnar charge, with an increased spherical wave damage diameter. Additionally, the increased detonation pressure led to greater radial forces at the breach edges, thereby enlarging the breach diameter and the degree of curling around the breach edges.

In conclusion, the scheme with the full blast hole length detonating cord generates greater detonation pressure and has a larger damage range compared to the scheme without the detonating cord. It also causes more severe radial damage to the steel tube and the roadway wall. However, this experiment used a steel tube to simulate a borehole, which significantly differs from the actual production conditions of non-pillar sublevel caving method. To fully validate that the bottom initiation scheme with the full blast hole length detonating cord can effectively improve the quality of medium-length hole blasting, further field experiments are necessary.

A field industrial experiment was conducted using the full blast hole length detonating cord combined with bottom initiation. A total of 72 blast holes in 8 rows were charged and blasted. The statistical analysis showed a significant reduction in the oversize fragmentation rate, which decreased from 13.91% using the traditional initiation method to 7.33% with the full-length detonating cord. This effectively enhanced ore flow and reduced the damage to the brow caused by secondary blasting of large fragments.

Conclusions

The impact of different degrees of brow line failure on the loss and dilution of ore was study. The results of the physical simulation experiment on ore drawing indicate that as the degree of brow line failure increases, the ore recovery ratio and the ratio difference between recovery and dilution gradually decrease, while the waste ratio gradually increases. To reduce the failure to the brow line caused by production blasting and secondary blasting of large blocks, blasting quality control strategies for medium-length hole blasting in sublevel caving mining is studied. Energy impact crushing experiments show that the main lithology of the orebody, garnet magnetite quartzite, has poor blastability, requiring optimization of the charging structure to improve blasting quality. The experimental procedure and apparatus were designed to conduct underground physical experiments on the mechanisms of rock blasting and fragmentation, as well as the patterns of stress and fracture changes under different initiation methods and charging structures. The study concluded that bottom initiation and the use of the full blast hole length detonating cord are the optimal initiation method and charging structure for medium-length hole blasting in non-pillar sublevel caving method.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Mao, S. L. & Ming, J. Ore Drawing Theory and application[M].Beijing (Metallurgical Industry, 2019).

Xiao, W. F. Study on the protection method and failure mechanism of sublevel caving brow line. J. Guiyang Coll. Nat. Sci. (Quarterly). 9 (3), 54–56 (2014).

Zhang, Y. D. Experimental Research on Mullock Movement and Control Methods under Overburden (University of Science and Technology Beijing, 2016).

Wu, A. X. et al. Study on structural parameters of sublevel caving. J. Cent. South. Univ. (Science Technology). 43 (5), 1845–1850 (2012).

Castro, R. Study of the mechanisms of gravity flow for block caving PhD thesis. (University of Queensland, 2006).

Castro, R., Trueman, R. & Halim, A. A study of isolated draw zones in block caving mines by means of a large 3D physical model. Int. J. Rock. Mech. Min. Sci. 44(6), 860-870 (2007).

He, R. X. & Ren, F. Y. Influences of blasting effect on ore loss and dilution in non-pillar sublevel caving. Min. R&D. 32 (6), 17–19 (2012).

Zhang, X. B. The support design of ore drawing point eyebrow line. J. Nonferrous Mines. 6, 58–59 (1995).

Liu, Q. Y. Beiminghe iron mine eyebrow line protection comprehensive measures. Morden Min. 28 (7), 65–66 (2012).

Ren, F. Y., He, R. X., Li, A. G. & Bai, W. X. Experimental study on improving charge structure of blast hole in Beiminghe iron mine. Metal mine. 40 (2), 9–12 (2011).

Liu, N., Ren, F. Y., He, R. X. & Liu, Y. Approach of ore loss and dilution control in sublevel caving method. Metal mine. 45 (11), 10–15 (2016).

Zhu, J. J. et al. Experimental test and damage characteristics of sandstone under uniaxial impact compressive loads. J. Cent. South. Univ. (Science Technology). 43 (7), 2701–2707 (2012).

Zuo, J., Yang, R., Ma, X., Yang, L. & Zhao, Y. Explosion wave and explosion fracture characteristics of cylindrical charges. Int. J. Rock. Mech. Min. Sci. 135, 104501 (2020).

Chandrakar, S., Paul, P. & Sawmliana, C. Influence of void ratio on blast pull for different confinement factors of development headings in underground metalliferous mines. Tunn. Undergr. Space Technol. 108, 103716 (2021).

Ding, Z. et al. Experimental study and application of medium-length hole blasting technique in coal-rock roadway. Energy Sci. Eng. 8, 1554–1566 (2020).

Zhang, S. et al. Equivalent modeling of energy dissipation in impact and rock blasting fragmentation of frozen sandstone. Chin. J. Rock Mechan. Eng. 43 (5), 1255–1269 (2024).

Yang, R. S. et al. Experimental study on evolution of strain field of explosion stress wave passing through a heterogeneous interface based on the DIC method. Explosion Shock Waves. 42 (12), 52–67 (2022).

Gao, P. et al. Investigation on cutting blasting efficiency of hard rock tunnels under different charge diameters. Appl. Sci. 12, 9906 (2022).

Li, X. Y. Research progresses on influence of initiation charge location for blasting effect. China Acad. J. Electron. Publishing House. 38 (7), 38–41 (2009).

Xie, S. D. et al. Ma. Effect of internal phase particle size on properties of site mixed emulsion explosive at plateau environment. Sci. Rep. 14, 8549 (2024).

Eugie Kabwe. Velocity of detonation measurement and fragmentation analysis to evaluate blasting efficacy. J. Rock Mech. Geotech. Eng. 10 (3), 523–533 (2018).

Krzystof Skrzypkowshi, K. & Zagórski Anna Zagórska & Fhatuwani Sengani. Access to deposits as a stage of mining works. Energies. 15, 8740 (2022).

Krzysztof Skrzypkowski, R., Gómez, K. & Zagórski Anna Zagórska & Roberto Gómez-Espina. Review of underground mining methods in world-class base metal deposits: experiences from Poland and Chile. Energies. 16, 148 (2023).

Wang, C. H. Ore Drawing (Metallurgical Industry Press, 1982).

Liu, X. G. Theoretical Basis of ore drawing[M]. Beijing (Metallurgical Industry Press, 1995).

Reng, F. Y., Wang, W. J. & Han, Z. Y. The blasting mechanism of fan-patterned holes and its application in Sublevel Caving. J. Northeastern Univ. (Natural Science). 27 (11), 1267–1270 (2006).

Zhang, W. Y. Research on 3D modeling low dilution for ore drawing PhD thesis. (Harbin Institute of Technology, 2013).

Guo, J. P., Liu, D. & Li, R. F. Reconstruction of moving transition equation for ellipsoid drawing theory. Metal Mine. 44 (10), 37–40 (2015).

Xie, J. P. Research on Control Technology for Extrusion Blasting ore Breaking Quality of medium-length hole (University of Science and Technology Beijing, 2015).

Acknowledgements

This research was supported by the National Natural Science Foundation of China (No. 52374115).

Author information

Authors and Affiliations

Contributions

JIAN MING, JINGPENG XIE and ZHIHUI LI wrote the main manuscript text.YUEHAO PAN and RONGHUA GUO prepared all figures and tables.All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ming, J., Pan, Y., Xie, J. et al. Study on the law of ore dilution and loss and control strategies under brow line failure in sublevel caving mining. Sci Rep 14, 26195 (2024). https://doi.org/10.1038/s41598-024-77064-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-77064-8