Abstract

With the rapid expansion of construction engineering, the demand for traditional materials, particularly natural river sand, has surged, resulting in excessive resource exploitation and significant ecological damage. In response, the use of waste oyster shells as a sustainable alternative for fine aggregates has gained attention. However, limited research has been conducted on the dynamic properties of mortar with this substitution. This study explores the potential of using crushed oyster shell sand (OSS) as fine aggregates in mortar. A series of Split Hopkinson Pressure Bar (SHPB) tests under different gas pressures (pg) (0.2, 0.3, and 0.4 MPa) were carried out on mortar samples with five OSS replacement ratios (Rr) (0%, 20%, 50%, 80%, and 100%), using a water-to-cement ratio of 0.55. The results showed that when the OSS replacement rate (Rr) increased from 0 to 20%, there was a significant increase in peak stress (σmax) and elastic modulus (E), attributed to the filling effect of OSS, which enhanced the absorbed energy (Eab) and strength contribution rate (SCR). However, at Rr above 20%, a sharp decline in σmax and E was observed, primarily due to porous characteristics of OSS. Correspondingly, Eab decreased, reducing the impact resistance of mortar. Moreover, the negative SCR suggests detrimental effects on mortar integrity at higher OSS Rr levels. Predictive relationships for peak stress and elastic modulus across different replacement ratios were established in this study, providing a foundational reference for the design and assessment of the dynamic mechanical response of structures incorporating OSS.

Similar content being viewed by others

Introduction

With the rapid growth of the construction industry, the increasing demand for conventional building materials, such as natural river sand, has led to resource overuse and severe ecological damage1,2. In order to improve this situation, studies have been carried out on partially replacing concrete aggregates with recyclable waste materials. Munir3,4 and Kazmi5 investigated the performance of recycled aggregate concrete based on uniaxial compression and machine learning algorithms, respectively. Deng et al.6 prepared mortar using recycled crumb rubber and recycled glass cullet as fine aggregates with the aim of evaluating their performance. Stel’makh et al.7 found that treating agricultural waste, such as coconut shells, and using them as a partial aggregate replacement has energy-saving effects. Consequently, finding sustainable alternatives for fine aggregates has emerged as a vital focus within the realm of research on construction materials.

Oyster shells (OSs), a type of marine biological debris, have caused environmental problems due to improper disposal, affecting many coastal nations and regions, including China8,9, South Korea10,11, and Taiwan12,13. It is estimated that in 2010 alone, China produced more than 5 million tons of OS, annually14. Therefore, utilizing OS as an alternative aggregate in building materials is a viable and promising approach for making sustainable use of resources.

The utilization of crushed oyster shell sand (OSS) as a fine aggregate in concrete has been the subject of extensive investigation. Yang et al.15 compared the effects of replacing 5–20% of the fine aggregates in concrete with OSS, finding that OSS could improve the 28-day compressive strength of the concrete. However, in terms of long-term performance, it was observed that an increase in the replacement ratio (Rr) of oyster shells impeded the improvement in both the compressive strength and elastic modulus of the concrete16. Chen et al.17 carried out a comparative evaluation between OSS concrete and plain concrete under marine environmental circumstances, identifying that concrete with an 8–10% Rr of oyster shells displayed the least amount of strength loss and showed the most effective resistance to saltwater erosion.

Furthermore, comprehensive studies on OSS mortar have been conducted in recent years. Yoon et al.11 utilized two different sizes of oyster shells to completely replace river sand in mortar and showed that the unconfined compressive strength of OSS mortar was lower than that of ordinary mortar and decreased as the OSS size increased. Subsequent studies by Liao et al.9,14 demonstrated that smaller OSS sizes led to higher compressive strength, flexural strength, and static modulus of elasticity in mortar, irrespective of whether curing occurred at early or late curing ages. This phenomenon is attributed to two main factors. First, larger OSS sizes weaken the bonding capability of the binder, reducing the microstructural integrity of the mortar. Second, finer aggregates enhance the compactness of the mortar, resulting in increased hardness.

Various chemical treatments have been employed to improve the mechanical properties of OSS mortar. Yoon et al.11 evaluated the impact of fly ash as an additive and ethylbenzene (EB) solution as a treatment agent on the compressive strength of OSS mortar and noted that fly ash significantly boosted the long-term strength, whereas the EB solution reduced the strength of OSS mortar. Wang et al.12 used a 1:1 mass ratio of fly ash and OSS to substitute 5–30% of fine aggregates in mortar, demonstrating an increase in compressive strength over a 120-day curing period. This is attributed to the pozzolanic reaction of fly ash, which not only compacted the mortar samples but also promoted bonding between the aggregates and mortar. These findings are consistent with those of Yoon et al.11 findings. Nevertheless, the enhancement was modest (only 2% –14%), which seems contradictory to the results of Yoon et al.11, possibly because Yoon employed a higher water-to-cement ratio that better activated the hydration and pozzolanic reactions of cement and fly ash, respectively. Chen et al.18 compared the mechanical strength of OSS mortar with fly ash and blast furnace slag substituting 20–40% of the cement in the mortar, showing that both materials led to reductions in the flexural and compressive strength of OS mortar, with blast furnace slag contributing more to the strength due to its higher pozzolanic activity. Subsequently, Chen et al.19 compared the shear strength of masonry blocks strengthened with two types of modified OSS mortar, illustrating their potential in construction engineering applications. Liu et al.20 treated OS particle surfaces with polyvinyl alcohol (PVA) and sodium silicate (SS). The SS solution treated OSS mortar exhibited higher compressive and flexural strengths compared to the control mortar, while the PVA solution treatment reduced the strength of the OSS mortar. Nonetheless, both factors significantly improved the durability of OSS concrete, including reducing permeability, water absorption, and chloride ion penetration. These findings were confirmed by Liu et al.8 in subsequent research that used different concentrations of PVA solution on the mechanical and durability properties of OSS mortar. By treating OSS with a hydrophobic agent, Song et al.21 improved the resistance of OSS mortar to erosion, thereby reducing its water absorption.

Currently, OSS has already found applications in various fields, including new construction materials, roadbed backfill engineering and marine engineering. Chiou et al.22 and Li et al.23 have shown that the bricks prepared after high-temperature calcination treatment of OSS mortar meet the relevant strength requirements at 28 days. Kuo et al.24 investigated the feasibility of applying OSS to preparing controlled low strength material for use in fields, such as channel backfilling and road repair. Similarly, Uddin et al.25 and Kong et al.26,27 validated the feasibility of using OSS concrete for artificial reefs in marine engineering applications. However, when applying OSS concrete and mortar in marine and coastal engineering settings, it is crucial to consider the impact of dynamic loads, such as waves and ships. Thus, it is essential to explore the dynamic properties of them. In previous study, the dynamic properties of OSS concrete have been studied and proved the possibility of application of OSS concrete28. As such, this study is mainly concentrated on the influence of OSS content on the dynamic characteristics of the OSS mortar using series of split Hopkinson pressure bar (SHPB) tests.

Materials and methods

Raw material

Cement

In this study, according to standard ASTM C15029, ordinary Portland cement (P.O. 42.5), which was manufactured by Conch Cement Co., Ltd., China, was adopted as the bonding material. Table 1 shows the details of the oxide components of the P.O. 42.5 cement.

Fine aggregates

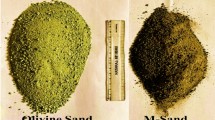

The fine aggregates chosen in this study were in accordance with ASTM C3330. The fine aggregates used in the control mortar samples consisted of river sand with a particle size less than 3 mm and a specific gravity of 2.63. For the OSS mortar samples, fine aggregates were substituted with OSS with the same particle size range, which has a specific gravity of 2.25. The detailed physical properties of the fine aggregates are listed in Table 2. The OSS was prepared in the following three steps. Initially, organic materials were removed from the OS and then washed with purified water. Afterwards, the OS were dried in an oven (Type: 101-00B, 0 ~ 300 °C, Lichen Instrument Technology Co., Ltd., Hangzhou, China) at a temperature of 95 ± 2 °C for more than 24 h. Finally, the dried OS was crushed using a pulverizer (Type: 9QF-320, 5800 rpm, Hengtong Machinery Co., Ltd., Guangzhou, China) to pass through a 3 mm sieve. The chemical compositions of the OSS are displayed in Table 3. The particle size distribution of fine aggregates is shown in Fig. 1, in which OSS showed a finer grading than river sand. Figure 2 shows the morphology of fine aggregates, where river sand has a blocky structure with concave and convex surfaces, while OSS exhibits sheet structure with smoother surfaces. Furthermore, arrangement of OSSs tends to generate a porous structure, which is similar to the observation in Yoon et al.10 study.

Sample preparation

Mixture component

The mortar was designed according to ASTM C30531. The material mixture components for each type are shown in Table 4. In previous studies, the water-to-cement ratios were mainly chosen from the range of 0.45 – 0.55 9,11,12,15,16,18,20,21,24,28,32,33,34, as shown in Table S1 in the supplementary file to this paper. Therefore, considering the wide range of OSS Rr and the high-water absorption of OSS, a water-to-cement ratio of 0.55 was used for all types of mortar. In this study, five volumetric Rr values of 0%, 20%, 50%, 80%, and 100%, respectively were used to replace river sand with OSS.

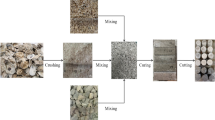

Mixing and casting

First, a given weight of P.O. 42.5 cement, sand, and oyster shells were added to a blender (Type: HJW-60, 48 r/min, Lukejian Test Instrument Co., Ltd., Cangzhou, China) in sequence and stirred for 3 min to ensure that the dry components were well-distributed. Subsequently, the corresponding amount of water was added to the dry mixture in two stages and stirred for 3 min. Next, the mortar was poured into molds measuring 100 × 100 × 300 mm, ensuring that the surface of the mortar was approximately 10 mm higher than the top of the mold. To eliminate air bubbles and increase the density of the mortar, the mold was placed on a vibration table (Type: HZJ-0.8, 2850 r/min, Junfan Test Instrument Co., Ltd., Cangzhou, China) and vibrated until the surface of the mortar appeared smooth. After the surface was leveled, the mortar samples were covered with wet rags for 1 day to reduce the evaporation of moisture.

Curing

After casting for 1 day, the molds were placed into a standard curing cabinet (Type: SHBY-40B, ± 1% RH, Huanan Equipment Co., Ltd., Shaoxing, China) at a temperature of 25 ± 1 °C and a relative humidity of 95% ±1% for another 2 days of curing. After that, to simulate the coastal environment, the samples were removed from the molds and submerged in water at 25 ± 1 °C for an additional 25 days of curing as shown in Fig. 3.

Coring

Following the 28-day curing period, a core-drilling machine (Type: HZ-20, Φ75 × 400 mm, 800 r/min, Qingan Mining Equipment Co., Ltd., Jining, China) was used to extract cylindrical samples of Φ74 × 100 mm. Then, these cylinders were cut into dimensions of Φ74 × 37 mm. To meet the flatness requirements of the SHPB tests, the end faces of the specimens were polished. The whole process is displayed in Fig. 3.

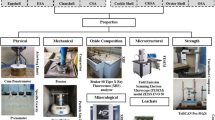

SHPB tests

As depicted in Fig. 4, the SHPB test apparatus (Type: LWKJ-HPKS-Y75, Luoyang Technology Co., Ltd., Luoyang, China) comprises a launching system, a striker bar, an incident bar, a transmission bar, a dashpot, and a data acquisition system, in which the striker bar, incident bar, and transmission bar are made of high-strength alloy steel. To lengthen the rising edge of the incident wave and mitigate high-frequency stress wave oscillations, a circular copper pulse shaper measuring Φ20 × 1.5 mm was selected based on preliminary trials and attached to the front end of the incident bar.

When the striker bar impacts the incident bar, an incident pulse wave εi(t) is initially generated within the bar. The sample then deforms, subsequently producing a reflected pulse wave εr(t) within the incident bar. Meanwhile, the energy is transmitted through the sample, generating a transmitted pulse wave εt(t) in the transmission bar. The sampling rate in this study was 500 kHz. Based on one-dimensional elastic stress wave theory and uniform stress distribution, the stress (σ), strain (ε), and strain rate (\(\:\dot{{\upepsilon\:}}\)) of the specimen during the impact process can be calculated as shown in Eq. (1)~(3):

where A and As represent the cross-sectional areas of the bars and the sample, respectively. The elastic modulus Eb of the bars is set as 2.1 × 105 MPa, and c0 denotes the elastic wave velocity, calculated from Eq. (4). l0 represents the height of the sample, taken as 37 mm. The density, ρ0, of the bars is 7820 kg/m3. Notably, the sample, the incident bar and the transmission bar must be coaxially aligned to ensure sufficient contact between the sample and the ends of the bars. Furthermore, an appropriate quantity of vaseline should be evenly smeared to both ends of the sample. Moreover, to guarantee the reliability of the results, three samples were tested under the same conditions, with each type of mortar sample subjected to gas pressures (pg) of 0.2, 0.3 and 0.4 MPa, as shown in Table 5.

Results and discussion

Stress-strain curves

Figure 5 shows the dynamic stress-strain curves of the OSS mortar at various pg values. The average of three samples was taken for each curve under the same test condition. The curves exhibited similar characteristics, which can be generally categorized into three typical phases: the elastic stage, the elastoplastic stage and the failure stage. Initially, the curve almost followed a linear increasing trend, indicating the elastic deformation of the samples. Prior to reaching the peak stress (σmax), gradual local yielding occurred, leading to a decrease in the slope of the stress-strain curve and the onset of plastic deformation. Once σmax was reached, the stress decreased as the strain increased, indicating the start of the failure stage.

These observations aligned with the dynamic mechanical properties of calcareous sand mortar investigated by Chen et al.35 using the SHPB technique. The dynamic stress-strain relationship was significantly influenced by pg. As pg increased, σmax achieved by the samples became higher and the strain corresponding to σmax decreased, resulting in a steeper curve during the failure stage. Additionally, with an increase in the Rr at the same pg, the strain at σmax decreased and the ductility decreased.

Peak stress

According to the relationship between the σmax of the OSS mortar and OSS Rr shown in Fig. 6, a distinct inflection point can be observed when OSS Rr reaches 20%. For OSS Rr below 20%, there was an increasing trend in σmax. However, when the OSS Rr exceeded 20%, σmax began to decrease with an approximately exponential trend, although the rate of decrease in σmax gradually slowed down. Specifically, as OSS Rr increased from 0 to 20%, σmax increased from 10.29, 14.01 and 18.61 MPa to 12.16, 16.02 and 20.58 MPa at pg of 0.2, 0.3 and 0.4 MPa, with growth rates of approximately 18.17%, 14.35%, and 10.59%, respectively. These results indicated that a 20% OSS Rr significantly enhanced the dynamic stress of the mortar and showed the highest σmax, similar to the findings of Liao et al.33 regarding static compression and flexural tests on mortar samples partly replacing river sand with OSS as fine aggregates. The finer grading of OSS may facilitate better filling of voids within the samples, resulting in a denser structure. However, as the OSS Rr increased from 20 to 100%, σmax under different pg values showed an approximately exponential decrease. For the 100% OSS Rr mortar samples, σmax decreased to 3.03, 5.95 and 7.71 MPa, with strength reduction rates of 75.08%, 62.86%, and 62.54%, respectively. This indicates that an OSS Rr exceeding 20% led to a significant strength loss, even below that of pure mortar. There are three possible reasons for this phenomenon. First, under the same water-cement ratio conditions, an increase in water absorption with increasing OSS Rr9 reduced the actual amount of water participating in cement hydration reactions, thus diminishing the binding effect of hydrated products, such as C-S-H gel. Furthermore, due to the significantly lower SiO2 content in OSS components than in river sand, approximately 0.57–13.28% 15, 24,36, the pozzolanic reaction was weakened, leading to a further reduction in the formation of C-S-H compounds. Second, the higher proportion of OSS impeded the bonding effect between aggregates and binding material due to the sheet structure and smooth surfaces. Third, the porous characteristics of OSS33 increase its susceptibility to brittle failure.

Elastic modulus

According to Fig. 7, the elastic modulus (E) is determined by the slope of the secant line connecting the 10% and 40% of σmax points on the stress-strain curve, as proposed by Fu et al.37 and represented by Eq. (5):

where σ40 and σ10 represent the stresses at 40% and 10% of σmax, respectively, while ε40 and ε10 are the corresponding strains at σ40 and σ10 respectively. Figure 7 illustrates the relationship between the elastic modulus of OSS mortar and OSS Rr. The trend in E was similar to the changes observed in σmax, where the mortar sample with OSS Rr of 20% exhibited the highest E. As OSS Rr increased from 0 to 20%, under pg of 0.2, 0.3 and 0.4 MPa, E enhanced from 1.10 to 1.74 and 2.31 GPa to 1.39, 2.14 and 2.88 GPa, respectively, which is attributed to the filling effect of OSS mentioned above. However, as OSS Rr further increased from 20 to 100%, E also exhibited an exponential decline, where E decreased from 1.39, 2.14 and 2.88 GPa to 0.46, 0.92 and 1.53 GPa under pg value of 0.2, 0.3 and 0.4 MPa, respectively. This decrease could be explained by the decreasing filling effect of OSS under higher OSS Rr and possibly due to the inherently lower elastic modulus of OSS compared to that of river sand15.

Absorbed energy

In SHPB tests, samples accumulate energy during the impact process. The energy absorbed by the samples, the absorbed energy (Eab) can be calculated by integrating the stress-strain curve, as represented in Eq. (6):

where V is the volume of the mortar sample, which is taken as 0.16 × 10− 9 m3, and εmax is the strain corresponding to σmax. Figure 8 depicts the development of Eab with respect to strain before failure during the SHPB tests.

As OSS Rr increased from 0 to 20%, the maximum Eab increased from 13.1, 14.9 and 16.2 J to 13.9, 16.9 and 18.9 J, respectively. At the same pg, samples with an OOS Rr of 20% exhibit better energy absorption capabilities than the control mortar. This improvement was due to the filling effect of OSS on the pore structure of the mortar33. Liu et al. confirmed that the pore structure significantly affects the impact resistance of concrete37. However, as OOS Rr increased from 20 to 100%, the Eab sharply decreased from 13.9 J, 16.9 J, and 18.9 J to 2.4 J, 3.6 J, and 4.1 J under pg of 0.2, 0.3 and 0.4 MPa, respectively, significantly reducing the impact resistance of the mortar. At lower OSS Rr, higher Eab may be achieved due to both plastic deformation and microcracking. However, as the increase of OSS Rr, these mechanisms gradually become less effective due to the dominant influence of porosity and brittleness of OSS, leading to a sharp decrease in Eab, where porous structure of OSS easily generates cracks, while the brittle nature of OSS particles accelerates crack propagation, jointly reducing the energy-absorbed capacity.

Strength contribution rate

To assess the contribution of OSS in mortar specimens, this study extends the concept of the strength contribution ratio (SCR) introduced by Liao et al.33. The formulas for calculating the SCR are shown in Eq. (7)~(9):

where I and Ic are the relative indices of the OSS mortar and control mortar, respectively. Mo and Mc represent the maximum strength of the OSS mortar and control mortar, respectively. a denotes the weight ratio of river sand to total aggregate. It is worth noting that when OSS completely replaced river sand, the formulas were not applicable. Therefore, test data with an OOS Rr of 100% were excluded from the analysis.

The relationship between the SCR and the OOS Rr under different pg values is illustrated in Fig. 9. With increasing OOS Rr, the SCR gradually shifted from positive to negative. At OOS Rr =20%, the SCRs are 22.0%, 17.5%, and 12.8% under different pg values, indicating that a 20% OSS Rr positively contributes to the dynamic strength of the mortar, which is a similar to the static study results of Liao et al.33. However, when OSS Rr exceeded 20%, the SCR decreased by approximately − 250% (OSS Rr =80%), indicating severe damage to the strength of the control mortar.

Conclusions

This study evaluates the dynamic mechanical properties of OSS mortar under different OSS Rr using SHPB testing to assess the potential of OSS as a sustainable alternative to traditional fine aggregates in construction materials. The outcomes of this study could be concluded as follows:

-

The results showed a significant enhancement in the dynamic properties of the mortar with an OSS Rr of 20%. At this ratio, σmax and E increased considerably, indicating improved strength and energy absorption capabilities. Specifically, σmax increased from 10.29, 14.01, and 18.61 MPa to 12.16, 16.02, and 20.58 MPa at pg of 0.2, 0.3, and 0.4 MPa respectively, with corresponding increases in E from 1.10, 1.74, and 2.31 GPa to 1.39, 2.14, and 2.88 GPa. Meanwhile, Eab increased from 13.1, 14.9 and 16.2 J to 13.9, 16.9 and 18.9 J, respectively. The samples with an OOS Rr of 20% exhibited better energy absorption capabilities than the control mortar. Moreover, the OSS played an important role in the SCR, which was 22.0%, 17.5%, and 12.8% under different pg values. These behaviors are primarily attributed to the filling effect of OSS.

-

When the OSS Rr exceeded 20%, both the σmax and E of the mortar began to exponentially decrease. For the 100% OSS Rr mortar samples, σmax decreased to 3.03, 5.95 and 7.71 MPa, with strength reduction rates of 75.08%, 62.86%, and 62.54% under pg of 0.2, 0.3, and 0.4 MPa, respectively. Moreover, similar to σmax, E decreased from 1.39, 2.14 and 2.88 GPa to 0.46, 0.92 and 1.53 GPa under pg value of 0.2 MPa, 0.3 MPa, and 0.4 MPa, respectively. Correspondingly, the Eab sharply decreased from 13.9 J, 16.9 J, and 18.9 J to 2.4 J, 3.6 J, and 4.1 J, respectively under different pg, while the SCR became negative and decreased to a minimum of approximately − 250%, meaning that higher Rr OSS harms the strength of the mortar. The reasons for these phenomena may be that, on the one hand, a high OSS Rr resulted in decrease in the hydration and pozzolanic reactions, which had a negative effect on the microstructure of the mortar. On the other hand, the porous characteristics of OSS increase its brittleness at a high OSS Rr, further weakening the mechanical properties of the mortar.

Overall, mortar with a 20% OSS Rr is proven to have better dynamic performance, suggesting that OSS can be suitable for applications in construction engineering. This not only provides a sustainable solution for waste oyster shells but also reduces the reliance on natural river sand, mitigating influence on environment.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Eziefula, U. G., Ezeh, J. C. & Eziefula, B. I. Properties of seashell aggregate concrete: a review. Constr. Build. Mater. 192, 287–300 (2018).

Abbara, A. A. et al. Uniaxial compressive stress-strain relationship for rubberized concrete with coarse aggregate replacement up to 100%. Case Stud. Constr. Mater. 17, e01336 (2022).

Munir, M. J., Kazmi, S. M. S., Wu, Y. F., Lin, X. & Ahmad, M. R. Development of a novel compressive strength design equation for natural and recycled aggregate concrete through advanced computational modeling. J. Building Eng. 55, 104690 (2022).

Munir, M. J., Kazmi, S. M. S., Wu, Y. F. & Lin, X. Axial stress-strain performance of steel spiral confined acetic acid immersed and mechanically rubbed recycled aggregate concrete. J. Building Eng. 34, 101891 (2021).

Kazmi, S. M. S., Munir, M. J., Wu, Y. F., Lin, X. & Ashiq, S. Z. Development of unified elastic modulus model of natural and recycled aggregate concrete for structural applications. Case Stud. Constr. Mater. 18, e01873 (2023).

Deng, Z., Yang, Z. & Pan, X. Synergetic effects of recycled crumb rubber and glass cullet on the engineering properties of geopolymer mortar. Cem. Concr. Compos. 137, 104907 (2023).

Stel’makh, S. A. et al. Alteration of structure and characteristics of concrete with Coconut Shell as a substitution of a part of Coarse Aggregate. Materials. 16 (12), 4422 (2023).

Liu, R., Fan, J., Yu, X., Zhu, Y. & Chen, D. Properties of mortar containing polyvinyl alcohol pretreated waste oyster shells with various concentrations. Constr. Build. Mater. 363, 129879 (2023).

Liao, Y., Wang, X., Kong, D., Da, B. & Chen, D. Experiment research on effect of oyster shell particle size on mortar transmission properties. Constr. Build. Mater. 375, 131012 (2023).

Yoon, G. L., Kim, B. T., Kim, B. O. & Han, S. H. Chemical–mechanical characteristics of crushed oyster-shell. Waste Manage. 23 (9), 825–834 (2003).

Yoon, H., Park, S., Lee, K. & Park, J. Oyster shell as substitute for aggregate in mortar. Waste Manag. Res. 22 (3), 158–170 (2004).

Wang, H. Y., Kuo, W. T., Lin, C. C. & Po-Yo, C. Study of the material properties of fly ash added to oyster cement mortar. Constr. Build. Mater. 41, 532–537 (2013).

Liu, H. Y., Wu, H. S. & Chou, C. P. Study on engineering and thermal properties of environment-friendly lightweight brick made from Kinmen oyster shells & sorghum waste. Constr. Build. Mater. 246, 118367 (2020).

Liao, Y., Shi, H., Zhang, S., Da, B. & Chen, D. Particle size effect of oyster shell on mortar: experimental investigation and modeling. Materials. 14 (22), 6813 (2021).

Yang, E. I., Yi, S. T. & Leem, Y. M. Effect of oyster shell substituted for fine aggregate on concrete characteristics: part I. Fundamental properties. Cem. Concr. Res. 35 (11), 2175–2182 (2005).

Yang, E. I., Kim, M. Y., Park, H. G. & Yi, S. T. Effect of partial replacement of sand with dry oyster shell on the long-term performance of concrete. Constr. Build. Mater. 24 (5), 758–765 (2010).

Hai-Yan, C. et al. Effects of crushed oyster shell on strength and durability of marine concrete containing fly ash and blastfurnace slag. Mater. Sci. 25 (1), 97–107 (2019).

Chen, D., Zhang, P., Pan, T., Liao, Y. & Zhao, H. Evaluation of the eco-friendly crushed waste oyster shell mortars containing supplementary cementitious materials. J. Clean. Prod. 237, 117811 (2019).

Chen, Z., Tang, Y., Mai, C., Shi, J., Xie, Y. and Hu, H., 2020. Experimental study on the shear performance of brick masonry strengthened with modified oyster shell ash mortar. Case Studies in Construction Materials, 13, p.e00469.

Liu, R., Chen, D., Cai, X., Deng, Z. & Liao, Y. Hardened properties of mortar mixtures containing pre-treated waste oyster shells. J. Clean. Prod. 266, 121729 (2020).

Song, Q. et al. Properties of water-repellent concrete mortar containing superhydrophobic oyster shell powder. Constr. Build. Mater. 337, 127423 (2022).

Chiou, I. J., Chen, C. H. & Li, Y. H. Using oyster-shell foamed bricks to neutralize the acidity of recycled rainwater. Constr. Build. Mater. 64, 480–487 (2014).

Li, G., Xu, X., Chen, E., Fan, J. & Xiong, G. Properties of cement-based bricks with oyster-shells ash. J. Clean. Prod. 91, 279–287 (2015).

Kuo, W. T., Wang, H. Y., Shu, C. Y. & Su, D. S. Engineering properties of controlled low-strength materials containing waste oyster shells. Constr. Build. Mater. 46, 128–133 (2013).

Uddin, M. J., Smith, K. J. & Hargis, C. W. Development of pervious oyster shell habitat (POSH) concrete for reef restoration and living shorelines. Constr. Build. Mater. 295, 123685 (2021).

Kong, J., Ni, S., Guo, C., Chen, M. & Quan, H. Impacts from waste oyster shell on the durability and biological attachment of recycled aggregate porous concrete for artificial reef. Materials. 15 (17), 6117 (2022).

Kong, J. et al. Recycling of waste oyster shell and recycled aggregate in the porous ecological concrete used for artificial reefs. Constr. Build. Mater. 323, 126447 (2022).

Lin, Y., Ren, Y., Ge, T. et al. Effects of waste oyster shell replacing fine aggregate on the dynamic mechanical characteristics of concrete. Sci Rep. 14, 19800 (2024). https://doi.org/10.1038/s41598-024-70505-4.

ASTM-C150. Standard Test Method for Portland cement, West Conshohocken, PA, United States, (2016).

ASTM-C33, Standard specification for concrete aggregates, West Conshohocken, PA, United States., (2008).

ASTM-C305. Standard Test Method for mechanical mixing of hydraulic cement pastes and mortars of plastic consistency, West Conshohocken, PA, United States, (2014).

Liao, Y. et al. The mechanical and durability indices for mortar containing crushed waste oyster shells. Magazine Concrete Res. 74 (20), 1027–1038 (2022).

Liao, Y. et al. Influence of the usage of waste oyster shell powder on mechanical properties and durability of mortar. Adv. Powder Technol. 33 (3), 103503 (2022).

Eo, S. H. & Yi, S. T. Effect of oyster shell as an aggregate replacement on the characteristics of concrete. Magazine Concrete Res. 67 (15), 833–842 (2015).

Chen, X., Xu, D., Shen, J., Wei, H. & Wang, R. Effect of particle size and particle distribution pattern on dynamic behavior of cemented calcareous sand. Mar. Georesources Geotechnology. 41 (4), 412–424 (2023).

Fu, Q. et al. Impact characterization and modelling of cement and asphalt mortar based on SHPB experiments. Int. J. Impact Eng. 106, 44–52 (2017).

Liu, J., Ren, Y., Chen, R., Wu, Y. & Lei, W. The effect of pore structure on impact behavior of concrete hollow brick, autoclaved aerated concrete and foamed concrete. Materials. 15 (12), 4075 (2022).

Author information

Authors and Affiliations

Contributions

Y L: Conceptualization, Methodology, Investigation, Validation, Writing-original draft, Y R: Conceptualization, Methodology, Investigation, Data curation, Writing-original draft. T G: Investigation, Validation, Data curation. M A: Investigation, Validation, Writing-review & editing. Y X: Investigation, Writing-review & editing. A A M S M: Validation, Writing-review & editing. L M: Resources, Writing-review & editing. L H : Investigation, Writing-review & editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Lin, Y., Ren, Y., Ge, T. et al. Dynamic properties of mortar with oyster shell sand replacement. Sci Rep 14, 28500 (2024). https://doi.org/10.1038/s41598-024-77133-y

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-77133-y