Abstract

The instability and failure processes of coal-rock combinations are accompanied by the release of acoustic emission (AE) and infrared radiation (IR) signals. To investigate the characteristics of AE and IR signals during the failure process in coal-rock combinations with different ratios, and to analyze the effectiveness and applicability of the monitoring methods for these two signals in various specimen ratios. In this paper, the uniaxial compression tests were conducted on seven coal-rock combinations with different ratios by using the rock mechanics loading system and the cooperative monitoring platform of infrared and acoustic emission. The results show that (1) the AE counts for failure precursors in coal-rock combinations are positively correlated with the coal-rock ratio, whereas the AE peak counts are negatively correlated. Moreover, as the coal-rock ratio decreases, the slope of the cumulative AE count curve during the peak failure stage approaches 1. (2) During the elastic and yield stages, the maximum infrared radiation temperature (MIRT) curve fluctuates, and just before peak failure, the curve displays a distinctive “V” shape. This “V” shape becomes more pronounced as the coal-rock ratio decreases. (3) In the monitoring of damage precursors of coal-rock combinations, when the ratio of coal to rock is 1:3 or less, IR monitoring is better than AE monitoring. Conversely, when the ratio of coal to rock is greater than 1:3, AE monitoring is more suitable. Consequently, the combined monitoring of AE and IR signals can increase the reliability and precision of early warning signals for coal-rock assemblage damage precursors.

Similar content being viewed by others

Introduction

As coal mines gradually enter the deep mining stage, the mining environment changes drastically1. Compared with shallow strata, deep mining is associated with a greater frequency of accidents. The deeper coal strata are subject to prolonged geological movements and sedimentation, resulting in complex formations that consist of coal-rock combinations and other composite structures2.

Researchers have recently made significant research advancements regarding the mechanical properties of coal-rock monoliths and artificial assemblages. Zuo et al.3 carried out uniaxial and triaxial mechanical tests on artificially spliced coal-rock combinations, identified their failure strength characteristics and developed nonlinear damage models. They summarized the impact propensity of coal-rock combinations and the factors influencing it. Chen et al.4 examined the mechanical response and deterioration law of a coal-rock combined body under the action of circulating water rock. Chen et al.5 investigated the influence of the coal-rock height ratio on the structural physical characteristics and progressive damage mechanism of the roof sandstone-coal columns under uniaxial compression conditions. Yang et al.6 analyzed the mechanical response characteristics and energy partitioning evolution law of coal-rock combinations with different strength ratios, and revealed the energy-driven mechanism of their destabilization damage. Yang et al.7 explored the mechanical behaviors of coal, rock, and their combinations, concluding that the primary failure modes of the combinations are shear fracture and axial cleavage. They reported that the greater the difference in coal-rock strength, the greater the kinetic energy during failure. Duan et al.8 discovered that the unloading rate has both overall strengthening and local weakening effects on the postpeak loading of the coal-rock combinations.

The rupture of coal-rock bodies results in the release of various physical signals, such as temperature changes and acoustic emissions9. Mature techniques such as acoustic emission (AE) and infrared radiation (IR) can effectively capture the entire process of destabilization and damage in coal-rock bodies. Early on, D. Lockner demonstrated the ability to predict rock failure through AE monitoring (3)10. Hao et al.11 performed uniaxial compression infrared experiments on prefabricated cracked coal bodies with different inclination angles and used infrared monitoring systems to assess the IR characteristics during the damage process. Lai et al.12 used AE technology to examine the energy accumulation and release patterns of brittle porous coal bodies, whereas Li and Yin et al.13,14 analyed the infrared precursors of damage in gas-containing coal. Furthermore, scholars have extensively researched the acoustic and infrared characteristics of coal and rock failure via AE15,16,17,18,19 and IRT20. These studies further elucidate the early warning signals of specimen buckling damage. Liang et al.21 investigated the AE patterns and IRT characteristics of granite, siltstone, and coal during loading damage and analyzed the correlations among these signals. Li et al.22 utilized a coal-rock electric-acoustic-thermal multiparameter experimental system to test and analyze the AE, surface potential, and AIRT signals during the coal and gas outburst damage process.

In previous studies, joint monitoring using AE and IR signals has focused predominantly on individual coal or rock specimens23,24, with limited discussion on the effectiveness of simultaneous multisignal monitoring. Because coal and rock often coexist in practical engineering scenarios, an investigation of coal-rock bodies is essential. Accordingly, in this study, uniaxial compression tests were conducted on seven coal-rock combinations of varying ratios, and synchronized AE and IR monitoring was used to examine the changes in precursor signals. This research specifically investigated how different coal-rock ratios affect the efficiency of both monitoring signals. Based on these results, optimal coal-rock ratios for AE and IR monitoring were identified, representing a key innovation of this study. This research also provides theoretical and experimental support for predicting dynamic disasters in coal-rock formations of varying thickness ratios in engineering applications, which is important.

Test overview

Specimen preparation and specific parameter characterization

The specimens were sourced from the Nanyang Gaoping Coal Mine, and consisted of anthracite coal for the coal samples and fine sandstone from the top plate for the rock samples. Table 1 lists presents the relevant basic parameters of the coal samples. For better monitoring and observation, according to the standards for processing rock samples, the coal-rock combinations were cut and processed into rectangular shapes measuring 50 mm × 50 mm × 100 mm. The error on the specimen end faces did not exceed 0.02 mm. A total of 7 groups of coal and rock assemblages and monoliths with varying coal-to-rock ratios (the coal-rock ratios are used in the latter content to indicate) were fabricated. The ratios (coal: rock) used were 1:0, 3:1, 2:1, 1:1, 1:2, 1:3, and 0:1, with three specimens per group. The anthracite coal samples and sandstone samples were bonded via strong AB adhesive25 and allowed to solidify at room temperature for 24 h. Figure 1 shows some of the specific specimens. For clarity in the analysis, ‘C’ denotes coal, ‘R’ denotes sandstone, and ‘CR’ denotes coal-rock bodies. Table 2 specifies the dimensions of each specific assemblage specimen.

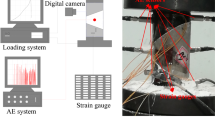

Introduction of experimental equipment parameters

Figure 2 provides a schematic representation of the experimental system, including the loading system, IR monitoring system, and AE monitoring system. The loading system employs an RMT-150B electrohydraulic servo testing machine, which is capable of exerting a vertical maximum force of 1000 kN. The deformation rate loading can be controlled from 0.001 to 500 mm/min, the relative error of the experimental force ≤ ± 0.5%, and the displacement error ≤ ± 0.5%. The IR monitoring system employs a Thermal Imaging Technology Fotric225s model infrared camera, with an infrared resolution of 320 pixels × 240 pixels, a field of view of 24° × 18°, a thermal sensitivity of 0.03 °C, a corresponding spectral band range of 8 –2 μm, an ambient environment temperature range of 10–35 °C when measuring the temperature accuracy is ± 2%, and a maximum image acquisition of 30 Hz. The AE detection system employs the DS2 series full-information AE signal analysis system, the test adopts 2 channels to collect data. The AE probe uses an RS-35 C integrated preamplifier sensor, the sampling frequency is 3 Mhz, and the threshold is set to 300 mV (in the preexperimental tests, below this value, there are useless noise signals to trigger a threshold in advance, which impedes the real signal monitoring of the experiment). The AE probes were positioned on either side of the specimen, with the probes attached to the specimen using petroleum jelly as a coupling agent to fill minor gaps and minimize impedance discrepancies.

Experimental program

During the test, keep the indoor temperature was maintained at 24.5 °C, the test personnel were prohibited from moving around freely during the experiment, and the environment was kept quiet. The tests were conducted in uniaxial displacement-controlled loading mode, starting with preloading to ensure full contact between the loading surface and the specimen. The loading rate was subsequently adjusted to 0.5 mm/min to ensure uniform loading along the vertical direction. AE monitoring and IR monitoring were conducted continuously until the specimen ruptured. Each group of specimens underwent 3 repetitions of the test.

To reduce the influence of the end effect, a lubricant needs to be applied between the specimen and the upper and lower indenters before loading. Additionally, in order to ensure the reliability of the IR camera observation data and AE monitoring should be ensured, and potential interference should be excluded. To minimize the influence of external factors, stable temperature and lighting were maintained throughout the test to minimize interference with the MIRT signal. The experimental environment was kept quiet and unnecessary movement of the tester was prohibited. During AE signal analysis, common filtering techniques are used to eliminate external noise interference effectively while retaining the key frequency components of the AE signal, and relevant experimental measures are implemented for test observations26,27,28. Throughout the loading process, the IR monitoring system and AE system were synchronized and sampled.

Test results and analysis

Experimental results

In accordance with the test program, uniaxial compression tests were performed on seven groups of coal-rock combination specimens, and the basic parameter values of each test group are shown in Table 3. Owing to space limitations, the average level and representative specimens from each group are selected for analysis, to depict the relevant stress-strain curves. The following specimens were selected for analysis within each group: CR-11, CR-22, CR-31, CR-43, CR-52, C-11, and R-12.

Mechanical characterization and analysis

The stress-strain characteristics during uniaxial loading of a coal-rock body can intuitively reflect the mechanical properties of the specimen, and the stress-strain curves of different coal-rock combinations are shown in Fig. 3.

By observing the changes in the stress-strain curves of coal-rock combinations with different ratios, the stress-strain curves can be classified into four stages, namely, compression-tightness, elasticity, yielding, and damage, according to the changes in the curves from nonlinearity to linearity, deviation from linearity, and then a sharp decrease in the curves. Observing of Fig. 3 reveals that the stress-strain curves of each specimen are roughly similar. As illustrated in Fig. 3a,b, the uniaxial compressive strength of the coal monomer is the lowest, reaching 9.94 MPa. The compressive strength of the specimen demonstrates an upward trend as the coal-rock ratio decreases. The uniaxial compressive strength of the rock monomer is the highest, reaching 91.12 MPa, indicating that the uniaxial compressive strength of the specimen is related to the proportion of sandstone in the combination.

The uniaxial compressive strength of the coal-rock combination was fitted to the proportion of sandstone, resulting in Fig. 4. The relationship is described by the equation y = 17.89x + 8.58 (R² = 0.96), which indicates a strong linear correlation between the uniaxial compressive strength of the coal-rock composite and the proportion of sandstone. As the coal-rock ratio decreased from 3:1 to 1:3, the uniaxial compressive strength of the specimens increased by 6.96%, 32.83%, 6.46%, and 11.63%, respectively. This finding suggests that higher proportions of sandstone in the assemblage lead to greater uniaxial compressive strength, which corresponds to the results of a previous study29. Because sandstones typically exhibit greater internal integrity and mass density than coal, fewer internal microcracks and defects, and higher compressive strength and hardness than coal. Increasing the proportion of sandstone enhances the mechanical properties of the assemblage, thereby increasing the uniaxial compressive strength. In contrast, coal has a greater number of primary cracks and is more susceptible to the formation of microcracks when subjected to force due to its non-homogeneity and anisotropy. This results in a reduction in the overall uniaxial compressive strength and an increased probability of failure.

AE characterization of coal-rock combination bodies

AE monitoring parameters of coal‒rock combination bodies

Real-time AE counts were measured through AE monitoring during uniaxial compression of the specimens. Tables 4 and 5 present the frequency of AE counts at each stage, as well as the peak AE counts and cumulative counts for each specimen. Figure 5 depicts the correlation among stress, AE count, and AE cumulative counts over time for various ratios of coal-rock mixtures and monoliths during uniaxial compression.

Characterization of the AE signals for each specimen

As shown in Fig. 5, the coal-rock combinations exhibit four discernible stages (I, II, III, and IV), which correspond to the compression densification, elasticity, yielding, and failure stages in the stress curve during the destabilization and damage process under loading. These stages correlate with AE counting and cumulative counting curves, representing the calm (Stage I, compression densification), gradual growth (Stage II, elasticity), rapid growth (Stage III, yielding), and abrupt escalation (Stage IV, failure) phases.

During Stage I, internal primary cracks close, resulting in a generally low AE count, indicating that the specimen is in the AE calm phase. As the stress level increases gradually, the specimen transitions into Stage II, during which internal cracks begin to slip and microfractures emerge and expand, resulting in a gradual increase in the number of AE events. This is evident from Table 4, which shows that the frequency of AE counts in Stage II is higher than that in Stage I, and the cumulative AE count curve starts to grow slowly. Upon entering Stage III, the slope of the cumulative AE count curve increases significantly, indicating rapid growth in the number of AE events. Furthermore, the frequency of AE counts notably increases in comparison with those in the preceding two stages. By Stage IV, the frequency of AE counts in each group of specimens reaches a maximum of 70.12%, 47.63%, 50.35%, 60.01%, 39.73%, 80.09%, and 98.10%, respectively, and an AE peak count is observed. This stage corresponds to the postpeak destruction phase, wherein the specimens have undergone complete destruction and the elastic energy has been fully released, resulting in an increase in the number of AE events.

In instances of elevated coal-rock ratios, the prevalence of primary fractures results in the onset of multiple instances of minor crack initiation and propagation during the initial phase, with AE events manifesting at an earlier stage. Consequently, the number of AE events is greater, although the energy released per event is relatively low. In contrast, under low coal-rock ratio conditions, fractures in the rock layers are predominantly concentrated in the yield and failure stages. Therefore, before the yield stage, AE events are relatively sparse, but each event tends to be associated with higher energy release, particularly during the failure stage. Figure 5 illustrates that as the coal-rock ratio decreases, the frequency of AE signals decreases as well, indicating a positive correlation between the two variables. From Fig. 5; Table 5, it is also evident that the slope of the cumulative AE count curve in Stage IV is larger than in the first three stages. As the coal-rock ratio decreases, the slope approaches 1, and the AE peak count increases, indicating that the smaller the coal-rock ratio is, the more the AE events are concentrated in the destructive stage. As the proportion of sandstone in a specimen decreases, the number of internal primary cracks also decreases. In the initial stages of loading, the primary cracks close, and new cracks form at a slower rate, resulting in fewer AE events and a period of relative stability. In the stages of yielding and damage that occur at the end of the loading process, the brittle characteristics of the rock become more pronounced than those of the coal. In response to compressive loading, rocks typically release energy through sudden fractures, which in turn generate more AE signals and result in active AE events. Consequently, an increase in the proportion of sandstone results in an increased likelihood of brittle fractures in the coal-rock composite body, which yields a higher AE peak count.

IR characterization of coal-rock combination bodies

Characterization of infrared thermal image evolution

Figure 6 shows the evolution of the infrared thermal image for each specimen subjected to uniaxial loading. Figure 6a show that the temperature distribution of the coal monomer remains relatively uniform during the initial and middle stages of loading. As the load increases, a localized rise in surface temperature is observed at 140 s, accompanied by an anomalous strip of radiation intensity on the right side. At 148 s, a long light-yellow low-temperature strip appears on the surface, which is distinctly different from its surroundings. As the load approaches its peak at 168 s, the low-temperature strip develops and expands, eventually spanning the upper and lower ends of the specimen. Ultimately, the specimen fractured along this low-temperature strip, with the surface temperature reaching a maximum of 22.42 °C.

As shown in Fig. 6c, the infrared thermal image evolution of CR-22 exhibits a pattern comparable to that of C-11, wherein anomalous temperature bands gradually emerge. The sandstone component of the assemblage exhibited no notable alteration in surface temperature throughout the loading process. In contrast, the coal component displays a lack of uniformity in thermal image changes during the loading and compression damage stages.

As shown in Fig. 6b, high-temperature anomaly points appear locally in the middle and on both sides of the sample during the loading process, suggesting an overall increase in temperature. At the peak load of 169 s, the high-temperature points evolve into high-temperature strips, which correspond to the primary crack in the sample. Figure 6d–f clearly reveals anisotropy in the surface temperature field of the specimens, with an evident end effect at the lower position of the coal. The red high-temperature zone gradually expands from the bottom to the top during loading, extending to the coal-rock junction, and the specimen begins to fracture along the high-temperature strip.

The surface infrared temperature field of the rock monolith (Fig. 6g) remains relatively uniform and stable during loading. At 210 s, a yellow high-temperature band emerges on the right side, coinciding with the formation and development of cracks. Prior to reaching peak loading at 211 s, a red high-temperature anomaly emerges close to the yellow high-temperature band, with the temperature reaching 20.85 degrees Celsius. At the peak load of 212 s, the anomalous high-temperature point extends into an anomalous red high-temperature band inclined to the right, with a peak temperature of 22.63 °C, which is 7.38 °C higher than the average surface temperature (15.25 °C). Ultimately, the specimen experiences shear damage along the red high-temperature band.

The overall analysis of the data in Fig. 6 reveals that the surface temperature of the specimen increased during the loading process. This temperature increase is primarily attributable to the notion that the strength of the rock is significantly greater than that of the coal, which ultimately results in the coal being the primary factor in the final destruction of the specimen. Therefore, the anomalous high-temperature bands or the anomalous low-temperature bands predominantly manifest on the coal surface. By comparing the thermal field distribution and migration, the evolution and differentiation characteristics of the infrared radiation temperature field on coal and rock surfaces are clearly discernible. These thermal image anomalies serve as early warning indicators, highlighting potential future rupture areas spatially.

Characterization of infrared radiation temperature

The destabilization and rupture of coal-rock specimens are associated with the accumulation and release of energy. Research has indicated30,31 that the maximum infrared radiation temperature (MIRT) is an effective indicator of the loading stage experienced by a specimen. Accordingly, this study extracts the MIRT of each specimen to investigate the characteristics of damage precursors in coal-rock combinations of varying proportions. Figure 7 presents the stress and MIRT versus time for various coal-rock combinations.

In Fig. 7a, the MIRT curves of the coal monomers exhibit fluctuating increases during the initial compaction and elastic stages. Upon entering the yield stage, the MIRT curve slightly decreases, followed by an increase in the postpeak stage as failure occurs. The MIRT curves of the rock monoliths (Fig. 7g) demonstrated a gradual decline during the initial phase of loading. A modest increase was observed at 177 s and 205 s, with increases of 0.21 °C and 0.42 °C, respectively. Upon entering the postpeak stage, the MIRT increases by 4.82 °C before rapidly decreasing. This phenomenon is attributed to the fewer cracks in rock than in coal, resulting in smaller interstitial spaces. The preaccumulated strain energy and elastic energy are strongly released at the moment of destruction, with part of the dissipated energy being emitted as thermal energy32. Furthermore, the instantaneous shear damage that occurs during the rupture process produces a strong frictional thermal effect, resulting in a sudden increase in the local temperature. This temperature then decreases after the destruction has occurred.

In Fig. 7b–f, a reduction in MIRT of varying degrees (0.1–0.25 °C) is evident during the compaction phase. This phenomenon can be attributed to the absorption of heat by the closure of primary microcracks within the specimen, which subsequently results in a reduction in surface temperature. During the closure of these microcracks, some adsorbed gas within the cracks is converted into free gas. Free gas, in conjunction with the surrounding air, is subsequently expelled through fissures and released into the external environment. This desorption process results in the removal of heat, which in turn causes a reduction in surface temperature. During the elastic stage, the MIRT curve begins to fluctuate and then increases. During the yield and damage stages, the formation of macroscopic cracks results in a pronounced increase in the MIRT curve, followed by a slight decrease.

The MIRT curves of the specimens during loading exhibit both ascending and descending trends. When tensile fractures are the predominant form of microfractures during specimen loading, a heat absorption effect is observed, resulting in a reduction in MIRT at the surface. Conversely, if shear fractures are the dominant mode of failure, a frictional exothermic effect is produced, leading to an increasing MIRT. The presence of both tensile and shear cracks causes the MIRT curves to fluctuate during loaded rupture. Notably, the MIRT curve assumes a “V” shape prior to reaching the peak level of damage. As the coal-rock ratio decreases, the fluctuation of the MIRT curve in the yield stage prior to specimen failure increases. The temperature decreases observed ranged from 0.06 to 0.45 °C, with an average of 0.14 °C.

Discussion

Multiparameter normalization analysis

The Integration of AE and IR data enables a comprehensive understanding of the specimen’s state throughout the destabilization and damage process, facilitating effective damage monitoring and early warning. However, the nonuniformity in the dimensions and value ranges of multiple information parameters poses a challenge for rapidly and intuitively assessing the response characteristics of each physical field to a damaged state of a specimen. To address this problem, the stress, cumulative AE count, and MIRT are employed as mechanical, acoustic, and thermal indicators, respectively, for multiparameter normalization. This normalization, with the value range set between 0 and 1, enables the AE and IRT parameters during uniaxial loading of coal-rock combinations to be represented within a unified coordinate system.

Assuming that the data value domain is [xmin, xmax], the normalized expression for the linear function transformation is:

where x and f(x) are the multivariate experimental data of AE and MIRT before normalization and after normalization, respectively, of the linear function, and xmax and xmin are the maximum value and minimum value, respectively, of the multivariate data of AE and MIRT.

After normalization, as shown in Fig. 8, the relative magnitude relationships and trends among the stress, acoustic emission, and thermal parameters remain unchanged after normalization of the linear function, that is, f(x1) < f(x2) for data with x1 < x2.

In Fig. 8, there is a discrepancy between the IR and AE signal anomalies that do not coincide precisely in the damage precursor signals of each group of specimens. During Stage I (the compaction stage), the primary fissures in the specimen undergo compression, which results in gas desorption and varying degrees of cooling. Given the variability of primary fissures, fluctuations in the MIRT curves at this stage do not indicate anomalous precursor signals. The anomalous mutation points of precursor signals typically occur in Stage III (the yielding stage) prior to the onset of damage.

In Fig. 8a, the AE count begins to increase slowly at approximately 112 s, with the initial abnormal surge occurring at 140 s, whereas the MIRT shows an abnormal surge at 116 s, indicating that the MIRT anomaly occurs earlier than the AE signal anomaly. In Fig. 8b, the initial surge in the AE count commences at approximately 157 s, whereas the MIRT curve at this time remains unchanged, with the MIRT surge occurring at 169 s. Thus, the AE count anomaly precedes the MIRT anomaly by 11 s. In Fig. 8c, the AE count and MIRT anomalies occur almost simultaneously at approximately 190 s. In Fig. 8d, the AE count begins to increase at approximately 51 s, with the MIRT concurrently demonstrating fluctuations and an increasing trend. However, the MIRT anomaly occurs at 200 s, and the AE count shows an abnormal surge at approximately 210 s, approximately 10 s later. In Fig. 8e, the AE count surge commences at approximately 207 s, whereas the MIRT anomaly appears at approximately 218 s. In Fig. 8f, the AE count shows an abnormal surge near 296 s, with the MIRT anomaly occurring at 273 s, earlier than the AE count anomaly. In Fig. 8g, the MIRT anomalies manifest at approximately 177 s and 205 s, whereas the AE count anomaly occurs at approximately 211 s, indicating that the MIRT anomalies precede the AE signal anomalies.

The analysis of precursor signal anomalies revealed that for specimens C-11, CR-31, CR-52, and R-12, the anomalies in MIRT appeared earlier than those in the AE counts did. In contrast, for specimens CR-11 and CR-43, the anomalies in MIRT manifested subsequent to those in the AE counts. Specimen CR-22 displayed a near-simultaneous occurrence of anomalies in both the MIRT and AE count data.

The analysis of the conclusions indicates that there are differences in the timing of the occurrence of abnormal AE and IR signals among specimens with different ratios. AE signals are associated primarily with the rapid propagation of cracks and the release of energy, whereas IR signals correspond to localized temperature increases, frictional heat, or heat generated at fracture surfaces. The proportion of coal and rock within the coal-rock body directly influences its mechanical properties. The timing of crack propagation and the increase in temperature may not occur simultaneously. For the same sample, the combination of coal and rock is not uniform, with coal exhibiting greater heterogeneity. During failure, the coal is more susceptible to deformation, the generation of microcracks, and stress concentration, which results in the emergence of AE signals at an earlier stage in samples with a higher coal content. In contrast, in samples with a greater proportion of rock, a longer phase of elastic deformation may occur, leading to a relative delay in the appearance of AE signals. Furthermore, the greater porosity of coal than rock results in a greater number of primary cracks due to the presence of internal fractures. The propagation and friction along these cracks generate more localized heat, frictional heat, or heat from fracture surfaces, which results in IR signals appearing earlier than AE signals.

Correlation analysis of destabilizing damage precursor signals of coal-rock combination bodies and stress changes

Figure 8 reveals a notable surge in the IR and AE signals preceding the yield damage of the coal-rock specimens. However, the analysis indicates a lack of consistency in the timing of AE and IR signal appearance during the damage precursor stage across different specimen proportions, which compromises the authenticity and accuracy of the precursor signals. The Pearson correlation coefficient is an effective method for measuring the linear relationship between different sets of correlated data and is easy to calculate and interpret. Accordingly, the Pearson correlation coefficient was used to investigate the relationships between the AE and IR signals and the stress changes. The formula is as follows:

where xi and yi are the sample values of the variables, \(\overline {x}\) and \(\overline {y}\) are the mean values of the variables x and y, respectively.

The magnitude of Pearson’s correlation coefficient, denoted as r, is used to quantify the degree of linear correlation between two variables, with values ranging from − 1 to 1. A positive r value signifies a positive linear correlation, whereas a negative r value indicates a negative linear correlation. As the absolute value of r approaches 1, the strength of the correlation increases. Conversely, an r value near 0 suggests a weak correlation.

As shown in Fig. 9, the AE counts of each specimen exhibit a positive correlations with the stress changes, albeit with correlation coefficients below 0.3 in Stage I, indicating a calm period with minimal AE events. The coefficients begin to increase notably in Stages II and III; however, specimens C-11, CR-52, and R-12 consistently have lower correlation coefficients than the other specimens do, suggesting weaker correlations with stress changes. In Fig. 10, during Stage I, the absolute values of the correlation coefficients for each specimen exceed 0.6, indicating that MIRT has some correlation with stress changes. Throughout Stages II and III, with the exception of CR-11 and CR-43, the absolute values of the correlation coefficients for the other specimens consistently exceeded 0.8, indicating a strong correlation with stress changes. However, the correlation coefficient of CR-43 in Stage III is − 0.632, indicating a weak correlation with the stress changes. In contrast, CR-11 continuously decreases in correlation with stress changes.

The analysis demonstrates that the correlation between MIRT and stress change is notably low for CR-11 and CR-43, which aligns with the conclusion drawn from the “Multiparameter normalization analysis” that “MIRT anomalies of CR-11 and CR-43 appear later than AE count anomalies.” Conversely, the AE counts of C-11, CR-52, and R-12 exhibit a weak correlation with stress changes. Interestingly, CR-31 is strongly correlated with stress changes, contradicting the initial observation documented in the “Multiparameter normalization analysis” where the AE count anomaly of CR-31 was identified as emerging at a later stage. A more detailed analysis is presented below.

Analysis of the applicability of AE monitoring and IR monitoring

Based on the findings in the preceding section, which revealed that the precursor signals of C-11, CR-11, CR-43, CR-52, and R-12 exhibited a low correlation with stress variations, an analysis of the rate of change in the MIRT and the percentage of AE counts in each stage before failure was conducted for these five specimens. The results are presented in Figs. 11 and 12. As shown in Fig. 11, the MIRT change rate of CR-11 is less pronounced than that of the other specimens, with an average rate of 1.48 × 10 −3 °C/s in the precursor stage. This rate is significantly lower than those observed for C-11, CR-52, and R-12, which were 4.56 × 10 −3 °C/s, 2.12 × 10 −3 °C/s, and 1.7 × 10 −2 °C/s, respectively. Therefore, for CR-11, IR monitoring signals are not an effective method for identifying damage precursors. On the other hand, CR-43 exhibited an average change rate of 2.3 × 10 −3 °C/s (Fig. 11). Despite the delayed appearance of MIRT anomalies compared with that of AE count anomalies during the precursor stage of destruction, the higher rate of change indicates significant monitoring signal variability, validating its role as a precursor signal.

Figure 12 shows that the percentage of AE counts attributable to CR-11 during the damage precursor phase exceeds 50%. This finding indicates that AE events are more active, which compensates for the less conspicuous IR monitoring.

In response to the contradiction between the high AE correlation of CR-31 and the late appearance of anomalies, when the coal-rock ratio is 1:1, the interface between the coal and rock tends to form a stress concentration zone. As the loading progresses, microcrack propagation is accompanied by friction and energy dissipation as heat, which causes the surface temperature to rise. This phenomenon can be detected earlier through MIRT monitoring. Given that AE signals are linked to sudden energy release, the fatigue behavior of coal may explain the delayed appearance of AE anomalies. In the initial phases of loading, coal gradually deforms without substantial energy release. It is only when the fatigue limit is reached and microcracks propagate significantly that the AE signals intensify. Conversely, coal creep may result in the early accumulation of internal damage, which may cause a reduction in the perceptibility of AE anomalies. In contrast, MIRT may facilitate the earlier detection of temperature anomalies.

Figure 12, shows that the AE counts in CR-31 exceeded 50% across the three preceding stages, underscoring the strong correlation between active AE events and stress changes. This finding affirms the effectiveness of AE signals as precursors. Conversely, C-11, CR-52, and R-12 presented AE counts exceeding 70% in Stage IV (Fig. 12), indicating that AE events predominantly occurred during this stage. Anomalous AE signals in the predamage stage were inconspicuous and not promptly monitored, indicating poor correlation with stress changes. Hence, AE signals are unsuitable as early warning precursor signals. In contrast, the high rate of MIRT change demonstrated a strong correlation with stress changes, rendering it suitable as an early warning signal for specimen destabilization and damage. This advantage compensates for the deficiencies in AE monitoring clarity.

In conclusion, it can be observed that when the coal-rock ratio is 1:3 or less, the damage precursor AE signals in the specimens are not prominent, thus necessitating supplementary IR monitoring. AE monitoring is more suitable for specimens with a coal-rock ratio exceeding 1:3. This is because specimens with a coal-rock ratio of 1:3 or lower are susceptible to significant alterations in their material properties, which can cause a notable weakening of the AE signals. Rock exhibits greater compressive strength and elastic modulus, primarily displaying elastic deformation in the initial loading phase, with slow crack propagation, resulting in minimal AE signals. In specimens with a low coal-rock ratio, the rock dominated, resulting in an extended elastic phase and a reduction in the intensity of the AE signals. This diminishes the visibility of the AE signal, making it more challenging to monitor. When the coal-rock ratio is 3:1, the change in the MIRT is not obvious, and the damage precursor of the sample destabilization cannot be accurately determined. In this context, AE monitoring offers more discernible signals and represents a valuable supplementary technique. Consequently, the integration of AE and IR monitoring systems is an effective approach for coal and rock specimens exhibiting specific ratios. This collaborative methodology enhances the precision of damage precursor signals and effectively supports early warning systems.

Conclusion

This study presents the results of uniaxial compression experiments on coal-rock combinations with varying ratios, employing a combination of AE and IR monitoring. The results demonstrated the varying characteristics of the acoustic and thermal signals in response to different proportions. Based on these findings, this study investigated the distinctive variations in AE and IR signals under different coal-rock ratios and evaluated the efficacy of AE and IR monitoring in detecting failure precursors in these samples. The conclusions are as follows:

-

(1)

The strength characteristics of a specimen are influenced by the coal-rock ratio. A reduction in the coal-rock ratio increases the uniaxial compressive strength of the specimen, thereby satisfying the fitting relationship. The coal-rock ratio is positively correlated with the AE count and negatively correlated with the peak AE count. The larger the coal-rock ratio is, the more AE signals there are in the destabilization precursor stage, whereas the peak AE counts decrease, and vice versa. The slope of the cumulative AE count curve during peak failure approaches 1 as the proportion of sandstone increases.

-

(2)

In the infrared thermal image, the relationship between the coal-rock ratio and surface temperature during specimen loading is evident. During the elastic and yield stages preceding peak failure, the MIRT curve displays fluctuates within a 0.5 °C range, forming a distinctive “V” shape. As the coal-rock ratio decreases, the “V” shape becomes more pronounced.

-

(3)

When the coal-rock ratio is greater than 3:1 or less than 1:3, the correlation between the AE counts and stress variations in coal-rock combinations is relatively weak. Similarly, at ratios of 3:1 and 1:2, the correlation between the MIRT and stress variations is also found to be low. During precursor damage detection in coal-rock bodies, IR monitoring is more effective at ratios of 1:3 or less, whereas AE monitoring is preferable for specimens with ratios greater than 1:3. However, at a ratio of 3:1, the IR signal changes are less pronounced, making AE monitoring more suitable as a supplementary signal. Therefore, synergistic AE and IR monitoring can complement each other’s limitations, improving the precision of precursor warning signals for coal-rock combination failures.

Data availability

Data used to support the results of this study are provided under license from the authors and are available upon request from the corresponding author, Guoqing Wang, upon reasonable request.

References

Yuan, L. Research progress of mining response and disaster prevention and control in deep coal mines. J. China Coal Soc.46(03), 716–725. https://doi.org/10.13225/j.cnki.jccs.YT21.0158 (2021).

Li, C. et al. Crack development characteristics and fracture modes of primary coal-rock mass induced by the unloading of confining pressure in deep coal mining. J. China Coal Soc.48(02), 678–692. https://doi.org/10.13225/j.cnki.jccs.2022.1545 (2023).

Zuo, J., Chen, Y. & Song, H. Study progress of failure behaviors and nonlinear model of deep coal-rock combined body. J. Cent. South Univ. (Sci. Technol.)52(08), 2510–2521 (2021).

Chen, G., Li, Y., Li, T., Zhang, J. & Zhang, G. Mechanical response and deterioration mechanism of coal-rock combined body under the action of circulating water-rock. J. Eng. Geol.32(01), 108–119. https://doi.org/10.13544/j.cnki.jeg.2021-0707 (2024).

Chen, S., Yin, D., Zhang, B., Ma, H. & Liu, X. Mechanical characteristics and progressive failure mechanism of roof-coal pillar structure. Chin. J. Rock Mech. Eng.36(07), 1588–1598. https://doi.org/10.13722/j.cnki.jrme.2016.1282 (2017).

Yang, L., Gao, F. & Wang, X. Mechanical response and energy partition evolution of coal-rock combinations with different strength ratios. Chin. J. Rock Mech. Eng.39(S2), 3297–3305. https://doi.org/10.13722/j.cnki.jrme.2020.0456 (2020).

Yang, S., Wang, J., Ning, J. & Qiu, P. Experimental study on mechanical properties, failure behavior and energy evolution of different coal-rock combined specimens. Appl. Sci.9(20), 4427–4444. https://doi.org/10.3390/app9204427 (2019).

Duan, H., Wang, C. & Sun, M. Mechanical characteristics and support mechanism of coal-rock combined body under unload-loading conditions beyond peak strength. J. Min. Saf. Eng.41(02), 372–383. https://doi.org/10.13545/j.cnki.jmse.2023.0078 (2024).

Yang, Z., Ji, L., Guo, W., Liu, P. & Ma, S. Study on the joint monitoring and early warning technology of instability and failure in roadway rock mass based on infrared and acoustic emission. Met Min.11, 33–40. https://doi.org/10.19614/j.cnki.jsks.202111005 (2021).

Lockner, D. The role of acoustic emission in the study of rock fracture. Int. J. Rock Mech. Min. Sci. Geomech. Abstr.30, 883–899. https://doi.org/10.1016/0148-9062(93)90041-B (1993).

Hao, T., Li, F., Tang, Y., Wang, Z. & Zhao, L. Infrared radiation characterization of damaged coal rupture based on stress distribution and energy. ACS Omega7(32), 28545–28555. https://doi.org/10.1021/acsomega.2c03350 (2022).

Lai, X. et al. Failure mode and phased energy accumulation and release law of brittle holey coal samples during loading. J. Min. Saf. Eng.38(05), 1005–1014. https://doi.org/10.13545/j.cnki.jmse.2021.0136 (2021).

Li, Z. et al. Experimental study on the infrared thermal imaging of a coal fracture under the coupled effects of stress and gas. J. Nat. Gas Sci. Eng.55, 444–451. https://doi.org/10.1016/j.jngse.2018.05.019 (2018).

Yin, S. et al. Experimental study on the infrared precursor characteristics of gas-bearing coal failure under loading. Int. J. Min. Sci. Technol.31(5), 901–912. https://doi.org/10.1016/j.ijmst.2021.07.003 (2021).

Khazaei, C., Hazzard, J. & Chalaturnyk, R. Damage quantification of intact rocks using acoustic emission energies recorded during uniaxial compression test and discrete element modeling. Comput, Geotechn.67, 94–102. https://doi.org/10.1016/j.compgeo.2015.02.012 (2015).

Gianni, N., Potirakis, M., Giuseppe, L. & Borla, O. Criticality hidden in acoustic emissions and in changing electrical resistance during fracture of rocks and Cement-Based materials. Matererials13(24), 5608. https://doi.org/10.3390/ma13245608 (2020).

Carpinteri, A., Lacidogna, G. & Pugno, N. Structural damage diagnosis and life-time assessment by acoustic emission monitoring. Eng. Fract. Mech.74(1), 273–289. https://doi.org/10.1016/j.engfracmech.2006.01.036 (2006).

Stergiopoulos, C., Stavrakas, I., Hloupis, G., Triantis, D. & Vallianatos, F. Electrical and acoustic emissions in cement mortar beams subjected to mechanical loading up to fracture. Eng. Failure Anal.35, 454–461. https://doi.org/10.1016/j.engfailanal.2013.04.015 (2013).

Griffiths, L., Lengliné, O., Heap, M. J., Baud, P. & Schmittbuhl, J. Thermal cracking in Westerly Granite monitored ssing direct wave velocity, coda wave interferometry, and acoustic emissions. J. Geophys. Res. Solid Earth.123(3), 2246–2261. https://doi.org/10.1002/2017JB015191 (2018).

He, M. C., Gong, W. L., Zhai, H. M. & Zhang, H. P. Physical modeling of deep ground excavation in geologically horizontal strata based on infrared thermography. Tunn Undergr Sp Tech.25(4), 366–376. https://doi.org/10.1016/j.tust.2010.01.012 (2010).

Liang, P., Zhang, Y., Tian, B. & Liu, X. Experimental study on correlation and characteristics of acoustic emission and infrared radiation in rock failure process. Min. Res. Dev.35(03), 57–60. https://doi.org/10.13827/j.cnki.kyyk.2015.03.016 (2015).

Li, Z., Lou, Q., Wang, E., Liu, S. & Niu, Y. Study on acoustic–electric–heat effect of coal and rock failure processes under uniaxial compression. J. Geophys. Eng.15(1), 71–80 (2018).

Li, M. et al. Acoustic emission-infrared characteristics of model specimen and evolution of rockburst under gradient stress. J. Shandong Univ. Sci. Technol. (Nat. Sci.).41(02), 31–41. https://doi.org/10.16452/j.cnki.sdkjzk.2022.02.004 (2022).

Yang, Z., Ji, L., Guo, W., Liu, P. & Ma, S. Study on the joint monitoring and early warning technology of instability and failure in roadway rock mass based on infrared and acoustic emission. Met. Mine.11, 33–40. https://doi.org/10.19614/j.cnki.jsks.202111005 (2021).

Zuo, J., Xie, H., Meng, B. & Liu, J. Experimental research on loading-unloading behavior of coal-rock combination bodies at different stress levels. Rock Soil Mech.32(05), 1287–1296. https://doi.org/10.16285/j.rsm.2011.05.028 (2011).

Tang, Y., Hao, T., Li, F., Zhao, L. & Liu, J. Energy evolution and infrared radiation characterization of coal rocks considering strain rate effect. Chin. J. Rock Mech. Eng.41(06), 1126–1135. https://doi.org/10.13722/j.cnki.jrme.2021.0952 (2022).

Hao, T., Li, F., Tang, Y., Wang, Z. & Zhao, L. Infrared radiation characterization of damaged coal rupture based on stress distribution and energy. ACS omega.7(32), 28545–28555. https://doi.org/10.1021/acsomega.2c03350 (2022).

Xiao, F., He, J., Liu, Z., Shen, Z. & Liu, G. Analysis on warning signs of damage of coal samples with different water contents and relevant damage evolution based on acoustic emission and infrared characterization. Infrared Phys. Technol.97, 287–299. https://doi.org/10.1016/j.infrared.2019.01.007 (2019).

Chen, G. et al. Mechanical properties and failure mechanism of combined bodies with different coal-rock ratios and combinations. J. Min. Strata Control Eng.3(02), 84–94. https://doi.org/10.13532/j.jmsce.cn10-1638/td.20210108.001 (2021).

Liu, S. et al. Quantitative analysis method of infrared radiation temperature field variation in rock loading process. Chin. J. Rock Mech. Eng.34(S1), 2968–2976. https://doi.org/10.13722/j.cnki.jrme.2014.0656 (2015).

Ma, L., Hai, S., Yao, Z., Hu, H. & Zhang, C. The role of stress in controlling infrared radiation during coal and rock failures. Strain54(6), e12295. https://doi.org/10.1111/str.12295 (2018).

Cao, K. et al. A comprehensive model for evaluating infrared radiation and acoustic emission characteristics of sandstone fracture. Eng. Fract. Mech.283, 109217. https://doi.org/10.1016/j.engfracmech.2023.109217 (2023).

Acknowledgements

This work was performed at the School of Safety Science and Engineering, Henan Polytechnic University. We thank our professors for their support and help in this project. Additionally, I thank my colleagues for their tireless efforts in this work.

Funding

This work was funded by the Infrared Radiation Response Mechanism of Destabilization and Damage Process of Defecting Damaged Coal Bodies, the Natural Science Foundation of Henan Province (No. 242300420025), supported by “the Fundamental Research Funds for the Universities of Henan Province” (NSFRF240804), the Natural Science Foundation of Henan Province of China (Grant No. 242300420317), and the Open Fund Project of Henan Provincial Key Laboratory of Gas Geology and Gas Governance--Provincial-Ministry Jointly-Built National Key Laboratory Cultivation Base (WS2023B08) Study on the Damage Evolution Mechanism and Multiparameter Fusion Early-Warning of Deep Gas-bearing Coal-Rock Combined Body.

Author information

Authors and Affiliations

Contributions

T.H.: provided the original idea; G.W.: wrote the main manuscript text and prepared all figures; F.L.: assisted in experimentation, supervision, and inspection; Y.T.: data curation and visualization. M.Y.: investigation, validation. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hao, T., Wang, G., Li, F. et al. Study on the characteristics of acoustic-thermal precursors of destabilization damage in coal-rock combination bodies with different proportions. Sci Rep 14, 25661 (2024). https://doi.org/10.1038/s41598-024-77170-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-77170-7

Keywords

This article is cited by

-

Study on influencing factors and prevention measures of coal-rock-gas compound dynamic disaster in deep coal mine mining

Scientific Reports (2025)

-

Research on multi-source information responses and instability warning in the deformation and failure process of coal and rock

Scientific Reports (2025)

-

Influence of prefabricated fissure angles on mechanical and infrared properties of red sandstone and failure prediction based on deep learning

Scientific Reports (2025)