Abstract

This paper discusses the seismic performance of five reduced-scale shear walls, including one cast-in-place (CIP) concrete shear wall, two precast concrete (PC) shear walls with overlapping U-bar loop connections, and two PC shear walls with modified form-overlapping U-bar loop connections combined with extruded sleeve connections. A quasi-static test was conducted to evaluate the reliability of the overlapping U-bar loop connections and the modified form by comparing the corresponding mechanical parameters of PC specimens with those of the CIP specimen. Moreover, the differences in seismic performance between the CIP specimen and PC specimens with different connection methods were also analyzed in terms of damage process, hysteretic loops and skeleton curves, load carrying capacity, ductility, equivalent stiffness, and energy dissipation. The experimental findings indicated that the mechanical performances of PC specimens with the modified connection form outperformed those of PC specimens with pure overlapping U-bar loop connections, closely resembling the properties of cast-in-place specimens; the failure mode of PC specimens was consistent with that of the CIP specimen; the generation, distribution and development of cracks in PC specimens were also similar to those in the CIP specimen. Furthermore, although the load-bearing capacity and peak displacement of PC specimens were lower than those of the CIP specimen due to the failure of the post-casted concrete strength to meet the requirements, the ductility, equivalent stiffness, and energy dissipation of PC specimens with the modified connection form closely matched that of the CIP specimen.

Similar content being viewed by others

Introduction

Background and previous investigations

The development of precast buildings represents a significant shift in construction methods, offering benefits such as resource and energy conservation, reduction of construction-related pollution, and the promotion of deeper integration between the construction industry and information industrialization1,2,3,4. Consequently, the application and mechanical properties of PC structures have garnered considerable attention, leading to extensive research on their seismic performance. Among PC structures, the PC shear wall structure has been particularly well-studied and widely implemented in both public and residential buildings5,6,7,8,9,10,11,12,13,14,15. A critical issue in the research and development of PC structures is understanding how different prefabricated components interact and transfer forces effectively. Specifically, the focus must be on investigating the structural measures and steel bar connection methods at precast joints to ensure the integrity and the seismic performance of PC structures.

Currently, grouted splice sleeve connections, pore-forming grouted lap-spliced connections, and unbonded post-tensioned connections have become widely adopted methods for connecting steel bars in PC structures, each having been applied in various practical engineering projects. Grouted splice sleeve connections are particularly effective for connecting steel bars in PC structures subjected to both tension and compression. This method ensures efficient vertical stress transfer within the steel bars, resulting in failure modes that closely resemble those of CIP structures16,17,18,19,20,21,22. However, the complexity of the grouted splice sleeve connection process, along with potential defects in sleeves, grouting materials, and construction quality, can negatively impact the mechanical properties of joints. For pore-forming grouted lap-spliced connections, installation of spliced steel bars does not require high precision compared with that of grouted splice sleeve connections. PC shear walls with this connection showed equivalent mechanic performance to CIP shear walls in many aspects. However, PC shear walls exhibit a more evident pinch effect than CIP shear walls due to the bond-slip of the spliced bars. The seismic performance of shear walls with lap splice by a reserved expanded metal mesh is slightly inferior to the shear walls by metal bellow23,24,25,26. For unbonded post-tensioned prestressing connections, PC structures with this connection method are easier to repair than the traditional CIP structure and PC structures with other connection methods. In addition, the precast structures have good self-recovery ability after large repeated nonlinear deformation, that is, the final residual deformation is very small27,28,29. However, in the construction process, it is required to accurately locate the unbonded prestressed tendon, strictly control the position error, exposed length and tensile stress, and check the elongation value. These factors put forward strict technical requirements for construction.

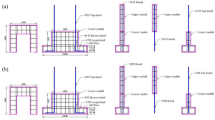

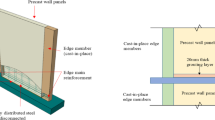

Although the aforementioned connection methods offer distinct advantages that enable their effective application in precast concrete (PC) structures, they also present drawbacks that can negatively impact the mechanical properties of the structures or increase construction costs, difficulty, and complexity. Therefore, based on a comprehensive assessment of the advantages and disadvantages of current connection methods, combined with a series of studies, our research team innovatively proposes new connection technologies - overlapping U-bar loop connection and the modified form-overlapping U-bar loop connection combined with extruded sleeves connection30,31,32,33,34,35,36,37,38,39, which aims to provide an alternative and effective solution for the assembly of different components in PC shear wall structures. While ensuring that the critical mechanical properties such as bearing capacity, stiffness, ductility, and energy dissipation of PC structures are close to those of CIP structures, the method effectively avoids many complex construction operations such as sleeve grouting and prestressed steel bars tensioning, demonstrating significant application advantages. Figure 1 provides specific details for these two connection forms. Vertical steel bars are distributed across the PC shear wall to create U-bar loops. During assembly, U-bars from the upper and lower PC walls overlap to form closed rectangular loops. Subsequently, four transverse steel bars are inserted at the corner of closed loops to enhance the U-bar loop connection. The major difference between the modified form and the original pure overlapping U-bar loop connections lies in how the longitudinal steel bars in the confined boundary zone of the shear wall are connected. In the pure overlapping U-bar loop connection, the longitudinal steel bars are connected through overlapping U-bar loops, whereas with the modified form, extruded sleeves are employed for this purpose. As a mechanical connection method for steel bars, the extruded sleeve connection is formed by inserting the ends of two steel bars into the same sleeve and using a hydraulic press to compress the steel sleeve, causing plastic deformation and tight interlocking with the ribbed steel bars. The combination of the overlapping U-bars, four additional transverse steel bars, and the concrete surrounded by these bars constructs a concealed beam that facilitates load transfer, with the shear force primarily borne by this beam. Moreover, the surfaces of PC components contacting with the post-cast concrete were roughened to amplify the friction, which is more conducive to resisting shear force.

Motivation

To further verify the reliability and effectiveness of the overlapping U-bar loop connections and the modified form, as well as to study the seismic performance of PC shear walls with these connection methods. This article introduces an experimental project on PC shear walls characterized by the connection methods proposed. Five reduced-scale specimens were designed, including one CIP shear wall, two PC shear walls with pure overlapping U-bar loop connections, and two PC shear walls with the modified form. A quasi-static test was carried out to study the mechanical properties of PC and CIP specimens under low reversed cyclic loads. Based on the test results, some important indicators such as load carrying capacity, deformation, ductility, stiffness, and energy dissipation performance of PC shear walls were compared with those of the CIP shear wall to validate the suitability of these connection forms in PC shear wall structures. In addition, the seismic performance of PC specimens with different connection forms was also compared with each other to evaluate the connection performance of these two connection forms.

Experimental program

The specimens

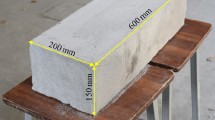

Five reduced-scale specimens, with a scale ratio of 6.5:10, were designed for the quasi-static test. The monolithic cast-in-place (CIP) shear wall, serving as the control specimen, was designated as XJQ1. The PC specimens with overlapping U-bar loop connections were labeled ZPQ1 and ZPQ2, while those with the modified connection form were labeled ZPQ3 and ZPQ4. In the modified connection specimens, all vertical steel bars, except for the two outermost bars with a 14 mm diameter in the confined boundary zone, were connected using overlapping U-bar loops; the outermost bars were connected via extruded sleeves. Apart from the differences in connection methods, the steel bar layouts and geometric dimensions of all five specimens were identical. The axial loads were applied through the reinforced concrete (RC) hidden beam located at the top of each shear wall, which measured 130 mm in width and 260 mm in height. Figure 2 provides detailed dimensions and the steel bar layout for the CIP specimen, while Fig. 3(a), 3(b), and 3(c) illustrate the connection methods and assembly construction procedures for the PC specimens. The details of the extruded sleeve connection and the overlapping U-bar loop connection are shown in Figs. 4 and 5, respectively.

Material properties

Concrete cube specimens with dimensions of 150 × 150 × 150 mm were used to conduct compressive strength tests, with the results presented in Table 1. The precast elements in the PC specimens were designed with a nominal compressive strength of 35 MPa, consistent with that of the CIP specimen. While the post-cast concrete used in the assembly region was intended to have a design compressive strength of 40 MPa. However, the actual compressive strength of the post-cast concrete did not meet the required design value significantly due to the presence of an expansion agent during the production process. The details of concrete mix proportions are shown in Table 2. Relevant mechanical parameters of steel bars with different diameters are also listed in Table 3 respectively.

For reinforced concrete structures, the compressive strength of concrete is an important factor affecting the load carrying capacity. When the strength of the post-cast concrete is significantly lower than the design value, the load carrying capacity of PC shear walls will not reach the design value in results, and the corresponding stiffness will also be reduced accordingly, which means that the structure is more prone to deformation when subjected to horizontal loading. Moreover, when the compressive strength of the post-cast concrete decreases, the corresponding tensile strength also decreases, which makes the cross section of the shear wall specimen more prone to cracking. Although the compressive strength of the post-cast concrete failed to meet the design requirements, this article provides valuable insights and practical guidance for future experimental studies aimed at improving the assembly of PC shear wall structures by comparing and analyzing the seismic performance of the PC shear wall specimens with those of the CIP specimen.

Test setup and loading method

Test setup

The experiment was carried out in the static laboratory of the National Engineering Research Center of High-Speed Railway Construction Technology. Details of the test setup are presented in Fig. 6. The base of specimens was fixed on the laboratory floor by six anchored threaded bars to prevent the movement of the specimen base. When loading, An axial load was applied to the loading distribution steel beam placed on the top of the shear wall using a 20,000 kN hydraulic actuator for uniform load transfer. while a low reverse cyclic load was applied to the top of the specimen using a 500 kN hydraulic actuator. To efficiently transfer the load to the specimen, a load transfer steel beam was attached to the actuator due to the distance between the specimen and the actuator exceeding the actuator’s maximum stroke, whilst the other side of the load transfer steel beam was fixed at the top of specimens by screws. Additionally, four linear variable displacement transducers (LVDTs) were mounted on the LVDT stand to measure the horizontal displacement at various points of the shear wall.

Loading method

The specimen was subjected to a vertical axial force applied at the top of the shear wall through a 20,000 kN vertical actuator. According to relevant codes40,41,42,43,44,45, the axial compression ratio is defined as the ratio of the design value of the axial force to the product of the gross cross section area and the design value of concrete compressive strength, which can be expressed as formula 1. Specially, the design value of axial force is equal to the standard value multiplied by the factor 1.2 according to the “Load code for the design of building structures“45.

Where n represents the axial compression ratio design value. According to the codes mentioned above, 0.3 was selected as the axial compression ratio of the test. fc represents the design value of concrete compressive strength; Aw is the cross section area of specimens; N represents the standard value of axial force. Based on Eq. 1, the standard axial force imposed on the top of the shear wall was calculated to be 876 kN and remained constant during the test.

Meanwhile, the low reversed cyclic load was applied to the top of the shear wall using a hybrid force and displacement control system, as shown in Fig. 7. The loading process began with force control and transitioned to displacement control mode after the specimen yielded. The initial and base loading displacements (Δ) were determined based on the maximum positive and negative displacements of the 500 kN hydraulic actuator at yielding. Furthermore, the loading displacement of each step in the displacement-controlled stage was increased by Δ. The test was concluded when the horizontal resistance of the specimen decreased to 85% of the peak load or when significant and severe damage to the specimen was observed.

Load carrying capacity prediction

Before the test was conducted, the horizontal load carrying capacity of the shear wall specimens was estimated. According to the relevant provisions of the “Technical Specification for concrete structures of tall buildings“40, the compressive bearing capacity of reinforced concrete shear walls, when considering the combined effects of seismic actions, can be calculated using formulas 2 to 6. The definitions of the parameters adopted in these formulas are presented in Table 4. Based on these equations, the maximum bending moment that the shear wall can resist was determined to be 1692.225 kN·m, resulting in a calculated peak horizontal load carrying capacity of 897.732 kN for the shear wall.

If \(x\leq\xi_{b}h_{w0}\)

If \(x\leq\xi_{b}h_{w0}\)

Where

Measurement items

The primary measurements included the loads at each loading step, horizontal displacements of the shear walls, steel bar strains, and the propagation and distribution of cracks. As shown in Fig. 8(a), a total of four linear variable displacement transducers (LVDTs) were installed on a stand along the central axis of the shear walls, from top to bottom, to measure horizontal displacements at different locations of the specimens. LVDT 1 was positioned at the top of the shear walls to record the horizontal displacement of the specimens, which served as the control displacement used to generate hysteretic loops and skeleton curves. LVDT 4 was placed at the bottom of the specimens to ensure that any movement at the base was successfully constrained.

As depicted in Fig. 8(b), dozens of strain gauges were attached to the steel bars within the shear walls to monitor the strain variations at different positions as the load increased. In addition to placing strain gauges in the same positions as those in the CIP specimen, several gauges were also positioned on the corresponding steel bars in the overlapping U-bar loop connections and the modified connections in the PC specimens. This arrangement was intended to measure the strain changes in the steel bars within the connection zone. The layout of the strain gauges in the connection zones of the PC specimens is illustrated in Fig. 8(c) and 8(d).

Experiment results and discussion

According to the “Specification for Seismic Test of Buildings”44, definitions of relevant mechanical characteristics can be illustrated as follows. The cracking load (Fcr) and cracking displacement (Δcr) refer to the load and deformation at the onset of cracking, respectively. Referring to the corresponding parameters of steel bars shown in Table 3, the specimen was deemed to have yielded when the maximum strain of the longitudinal steel bars reached 2210 µε, or the specimen showed a sudden increase in deformation rate, the corresponding load and deformation were defined as yield load (Fy) and yield displacement (Δy) severally. The peak load (Fp) and peak displacement (Δp) are the maximum load and corresponding displacement during testing. Following the peak load, the specimen’s horizontal resistance decreased with increasing displacement and loading. Generally, the specimen was considered to have reached its peak state when the horizontal resistance was reduced to 85% of the peak load or when visible damage occurred. The load and displacement at this moment were defined as ultimate load (Fu) and ultimate displacement (Δu) severally.

Damage process and failure mechanisms

Observations for the XJQ1 specimen

During the force-controlled phase, each load level was applied with a single cycle of reciprocation. Initial cracking at the bottom of the shear wall was observed when the horizontal load reached 450 kN. As the load continued to increase, multiple horizontal cracks began to form along the height of the shear wall, with the original cracks also extending. Upon reaching a horizontal load of 550 kN, the outermost reinforcement in the confined boundary zone yielded, accompanied by a significant increase in horizontal displacement at the top of the wall. This was identified as the yield point for specimen XJQ1, at which point the loading mode was switched to displacement control.

When the horizontal displacement reached 2Δa, cracks started to develop diagonally, and the width of the original cracks increased significantly. During the loading process of 3Δa cycles, there were no new cracks occurred, whereas the original cracks developed and extended dramatically, with the primary diagonal crack nearly penetrating the entire wall. Additionally, slight spalling of the concrete at the bottom of the shear wall was observed. By the time the displacement reached 4Δa, the load carrying capacity of the specimen had reached its peak, and significant crushing and spalling of the concrete occurred. Due to the extensive damage sustained by the specimen, the test was terminated at this stage.

Observations for ZPQ1

The horizontal cracks occurred initially at the PC-CIP interface (the junction between the precast concrete shear wall and the post-cast concrete) when the horizontal force reached 250 kN. As the loading process continued, these cracks propagated significantly, extending both within the precast wall panel and the post-cast concrete zones. During the 2Δa loading cycles, when the loading displacement was applied to the maximum values in the positive and negative directions respectively, two diagonal cracks developed sequentially, penetrating the wall panel and intersecting with each other. In the duration of the 3Δa loading cycles, the load carrying capacity of the specimen reached its peak value by the time the loading displacement attached 3Δa in the first cycle. At this point, the interface crack width extended dramatically, and noticeable crushing of the bottom concrete occurred. When the loading displacement reached 3Δa in the second cycle, the concrete at both ends of the post-cast zone experienced severe crushing and spalling, leading to the termination of the test.

Observations for ZPQ2

When the horizontal load reached 275 kN, initial cracks formed at the PC-CIP interface. As the load increased, these interface cracks continued to develop and eventually penetrated the interface at a horizontal load of 550 kN, corresponding to the yield load. With the gradual increase in loading displacement, several horizontal cracks appeared along the height of the shear wall, while the original cracks extended further. During the 2Δa loading cycles, two diagonal cracks formed sequentially, penetrating the wall panel and intersecting with each other, indicating clear signs of shear damage in the wall. When the loading displacement reached 3Δa, the specimen reached its peak load carrying capacity, accompanied by a dramatic widening of the interface cracks. Moreover, numerous diagonal cracks emerged in the post-cast zone, the cracks at both ends of the post-cast zone were densely distributed company with significant crushing and spalling of concrete, the test was terminated at this stage.

Observations for ZPQ3

Horizontal cracks first appeared at the PC-CIP interface when the horizontal force reached 225 kN. The specimen yielded as the load approached 550 kN, at which point a horizontal crack formed in the PC wall panel approximately 200 mm above the interface between the PC and CIP concrete. After yielding, cracks developed gradually, with two diagonal cracks penetrating the wall panel and intersecting with each other during the 2Δa loading cycles. During the 3Δa loading cycles, the specimen reached its peak load carrying capacity. Although several short diagonal cracks emerged in the post-cast zone, the crack development did not cause significant damage, with only minor concrete spalling observed.

Observations for ZPQ4

Due to construction defects encountered during the casting of the post-cast concrete, horizontal cracks first appeared at the PC-CIP interface when the horizontal force reached 200 kN, which is lower compared to other specimens. The interface cracks continued to develop and eventually penetrated through the interface when the horizontal load reached 450 kN. The specimen yielded as the load approached 550 kN. During the 2Δa loading cycles, when the displacement was applied to its maximum in the positive direction, significant crushing of the concrete on the right side of the CIP zone was observed. Subsequently, asymmetric damage occurred, with the specimen exhibiting severe damage under positive loads and only minor damage under negative loads. This indicated notable deterioration of the concrete under reversed cyclic loading. When the 3Δa loading displacement was conducted, the load carrying capacity attained its peak value, and the longitudinal bars were bulged and exposed with the serious crushing of the concrete at the bottom of the shear wall.

Propagation and distribution of cracks

The schematic diagram of specimen cracks is presented in Fig. 9. The crack distribution diagram reveals that the crack development in the PC specimens was comparable to that in the CIP specimen, which indicated that the damage morphology of the PC specimens closely mirrored that of the CIP specimen. Both exhibited characteristics of compression-bending failure, which was marked by the buckling of tensile steel bars and the crushing of concrete at the bottom of the beam.

A comparison of crack development and failure modes between the PC specimens and the CIP specimen shows that, except the premature occurrence of cracks at the PC-CIP interface in the PC specimens, the concrete also experienced early crushing and spalling. This premature damage may be caused by the low strength of the concrete in the CIP zone, which failed to meet design requirements and thus could not provide adequate tensile strength and bond strength with the steel bars, impairing effective stress transfer. When comparing ZPQ1/ZPQ2 with ZPQ3/ZPQ4, it was observed that ZPQ1/ZPQ2 exhibited slightly more severe concrete crushing and spalling. In contrast, ZPQ3 and ZPQ4 showed only minor concrete spalling, which may be due to the presence of sleeves weakening the thickness of the protective layer. This indicated that the force transmission efficiency of steel bars connected by extruded sleeves is superior to that of the overlapping U-bar loop connections in the confined boundary zone.

Hysteretic loops and skeleton curves

As illustrated in Fig. 10(a)−(e), the hysteretic curves under positive loading are noticeably fuller compared to those under negative loading during the displacement loading phase. This discrepancy may be attributed to two factors: Firstly, an installation gap between the lateral loading device and the specimen likely led to asymmetric loading displacements applied to the specimen. Secondly, the loosening of the anchored threaded bars that secured the specimens to the laboratory floor contributed to the asymmetric horizontal movement of the specimen under lateral loading. The hysteretic properties of all specimens were relatively similar. Before yielding, the specimens exhibited nearly constant stiffness, with horizontal displacement increasing approximately linearly with lateral force. After yielding, the stiffness of specimens decreased rapidly with the increase of the horizontal displacement. The CIP specimen displayed a slight pinching effect, while the hysteresis curves of the PC specimens were fuller and did not exhibit a pronounced pinching effect.

The skeleton curves of the five specimens, as compared in Fig. 10(f), show that the curves for ZPQ3 and ZPQ4 closely matched that of XJQ1 prior to the peak cycle. In contrast, the skeleton curves for ZPQ1 and ZPQ2 exhibited significantly lower stiffness compared to XJQ1. Moreover, the load carrying capacity of the PC specimens was lower than that of the CIP specimen, likely due to the insufficient strength of the post-cast concrete, which did not meet the design requirements.

Load carrying capacity, deformation and ductility

The resistance and deformation of all specimens at different character loading steps are shown in Table 5. The yield load of PC specimens was very close to that of the CIP specimen. However, the obvious difference lay in the fact that the cracking load and peak load of PC specimens were significantly lower than those of the CIP specimen. The difference in cracking load may be caused by the presence of the PC-CIP interface weakening the integrity of the PC shear wall, while the difference in peak load may be due to the actual strength of the post-cast concrete being much lower than the design value, which cannot provide sufficient compressive bearing capacity, resulting in premature collapse of the concrete at the bottom of the shear wall. In terms of deformation, except for the yield displacements of ZPQ1 and ZPQ2 were significantly larger than those of the CIP specimen, while the yield displacements of ZPQ3 and ZPQ4 were much closer to those of the CIP specimens, the characteristic displacements of PC specimens in the cracking cycle and peak cycle were significantly lower than those of the CIP specimen. Moreover, considering that specimens had already been severely damaged when the peak load were reached and could not continue to withstand the load to obtain ultimate displacement, the ratio of the peak displacement Δp to the yield displacement Δy was defined as the ductility coefficient Δp/Δy to characterize the deformation capacity of specimens. It can be seen from Table 5 clearly, that the ductility of PC specimens was significantly smaller than that of the CIP specimen, but the ductility coefficients of ZPQ3 and ZPQ4 were closer to those of the CIP specimen.

Equivalent stiffness

Formula 7 defines the equivalent stiffness of each step as Ki under low reversed cyclic loading. In this formula, Fi represents the peak load of the step, Δi denotes the peak displacement of the step, and “+” and “-” indicate positive and negative directions, respectively. As illustrated in Table 6, the equivalent stiffness values of ZPQ3 and ZPQ4 were larger than those of the CIP specimen, while the stiffness of ZPQ1 and ZPQ2 was significantly lower than that of the CIP specimen. Moreover, by fitting these stiffness data of the five specimens, Fig. 11 demonstrates the variation pattern of equivalent stiffness with increasing displacement for the five specimens. It was evident that all specimens exhibited a similar degradation trend as displacement increased.

Energy dissipation performance

The energy dissipation properties of all specimens under low reversed cyclic loading are illustrated in Figs. 12 and 13. The energy dissipated per cycle is represented by the area enclosed within each corresponding load-displacement hysteretic loop. As shown in Fig. 12, ZPQ3 and ZPQ4 exhibited slightly lower energy dissipation than the CIP specimen, while ZPQ1 and ZPQ2 demonstrated the lowest energy dissipation overall. However, the trend in energy dissipation across the PC specimens was consistent with that of the CIP specimen, with ZPQ3 and ZPQ4 displaying a dissipation rate nearly equivalent to the CIP specimen.

In order to analyze the evolution of energy dissipation, the normalized energy dissipation w/Wwas introduced for further examination46. Figure 13 presents the normalized energy dissipation per cycle and its evolution trend derived by fitting the data across all samples. It is evident that the energy dissipation trend of the CIP specimen aligned closely with that of the PC specimens. Before yielding, the energy dissipation was minimal but increased approximately linearly with displacement. After yielding, the energy dissipation rate surged, contributing significantly to the total energy dissipation. As the peak phase approached, the energy dissipation rate gradually stabilized.

Rebar strain analysis

Strain gauges were mainly employed to measure the strain in vertical steel bars at the bottom of the shear wall, providing a reference for determining whether the specimen had reached the yield state. Additionally, the effectiveness of different connection methods in transmitting force could be assessed by examining the strain development in the corresponding steel bars of the PC specimens. The layout of the strain gauges is illustrated in Fig. 7. At the connection position of vertical steel bars in the confined boundary zone, if the strain development forms of the corresponding steel bars connected by extruded sleeve or overlapping U-bar were similar to each other, and the maximum strain is approximate, it would indicate that the connection method is reliable and capable of effectively transmitting stress. As depicted in Fig. 14, the force-strain curves of all specimens exhibit an approximate linear distribution before yielding, with the curve progression of the PC specimens closely resembling that of the CIP specimen. Moreover, the shape of the force-strain curves of the corresponding steel bars at the connection position in the PC specimens was consistent across the different specimens. It should be noted that although the force-strain curves of ZPQ1 displayed notable differences from the other specimens that may caused by the damage of the strain gauges or installation defects, the force-strain shape of the corresponding steel bars in ZPQ1 remained similar. These findings indicated that both connection methods are reasonable and reliable.

Conclusions

In this study, five reduced-scale shear wall specimens were designed and tested under low reversed cyclic loading. A comparison of the seismic performance of the PC specimens with the CIP specimen was conducted, focusing on failure mode, load carrying capacity, ductility, equivalent stiffness, and hysteretic behavior. The following conclusions can be drawn:

-

(1)

The failure modes of PC specimens were consistent with those observed in the CIP specimen, characterized by the yielding of tensile steel bars, buckling of compression steel bars, and the crushing of concrete. The generation, distribution and propagation of cracks in PC specimens mirrored those in the CIP specimen. However, cracking at the PC-CIP interface in PC specimens was more pronounced compared to other regions.

-

(2)

The mechanical properties of PC specimens with overlapping U-bar loop connections combined with extruded sleeves connections (ZPQ3 and ZPQ4) more closely resembled those of the CIP specimen compared to PC specimens with only overlapping U-bar loop connections (ZPQ1 and ZPQ2). This similarity was observed in aspects such as ductility, stiffness, energy dissipation, hysteretic loops, and skeleton curves. However, the cracking load of PC specimens was significantly lower than that of the CIP specimen, which may be caused by the weakening of shear wall integrity at the PC-CIP interface. Additionally, The peak load of PC specimens was significantly lower than that of the CIP specimen, possibly attributed to the actual strength of the post-cast concrete being much lower than the design value, thus insufficient to provide adequate compressive bearing capacity.

-

(3)

Both the overlapping U-bar loop connection and the modified form-overlapping U-bar loop connection combined with extruded sleeve connections are reliable and feasible methods for application in PC structures effectively. Among these, the modified form (ZPQ3 and ZPQ4) exhibited superior overall mechanical properties. Nonetheless, further experimental validation is necessary to confirm that the mechanical performance of PC structures utilizing this connection method meets seismic requirements.

Data availability

The data used to support the findings of this study are included within the article.

References

The data used to support the findings of this study are included within the article.Y. C et al. Seismic-resistant precast concrete structures: state of the art. J. Struct. Eng. 144 (4). https://doi.org/10.1061/(ASCE)ST.1943-541X.0001972 (2018).

Mo Sha, P., Liu, J. & Gao, H. M. Research status and application of prefabricated concrete frame joints. E3S Web of Conferences. 2021; 260. (2021). https://doi.org/10.1051/e3sconf/202126003025

Chen, F. et al. Study on the Bond-Slip Numerical Simulation in the analysis of Reinforced concrete Wall-Beam-Slab Joint under cyclic Loading[J]. Constr. Build. Mater. 449, 138266. https://doi.org/10.1016/j.conbuildmat.2024.138266 (2024).

Biswas, R. K. et al. An Experimental and Numerical Investigation on the Flexural strengthening of full-scale corrosion-damaged RC columns using UHPC layers. Constr. Build. Mater. 449, 138269. https://doi.org/10.1016/j.conbuildmat.2024.138269 (2024).

Nigel Priestley, M. J. Overview of PRESSS research program. Pci J. 36 (4), 50–57. https://doi.org/10.15554/PCIJ.07011991.50.57 (1991).

Dong, Y. H. et al. Comparing carbon emissions of precast and cast-in-situ construction methods – a case study of high-rise private building. Constr. Build. Mater. 99, 39–53. https://doi.org/10.1016/j.conbuildmat.2015.08.145 (2015).

Zhang, F. et al. Effect of strand debonding on the Shear Strength of existing pretensioned PC Hollow Slab. Eng. Struct. 291, 116417. https://doi.org/10.1016/j.engstruct.2023.116417 (2023).

Lachimpadi, S. K. et al. Construction waste minimisation comparing conventional and precast construction (mixed system and IBS) methods in high-rise buildings: a Malaysia case study. Resour. Conserv. Recycling. 68 (4), 96–103. https://doi.org/10.1016/j.resconrec.2012.08.011 (2012).

Jun, S. et al. Experimental and Numerical Investigation of Seismic Response of Access floors Based on Shake-table tests using 2-Story Steel Moment Frame. J. Building Eng. 77, 107474. https://doi.org/10.1016/j.jobe.2023.107474 (2023).

Eom, T. et al. Experimental and Analytical Investigation of Bracket Moment connection for precast concrete Beam-to-composite column joints. J. Building Eng. 96, 110593. https://doi.org/10.1016/j.jobe.2024.110593 (2024).

Brunesi, E. & Nascimbene, R. Experimental and numerical investigation of the seismic response of precast wall connections. Bull. Earthq. Eng. 15 (12), 5511–5550. https://doi.org/10.1007/s10518-017-0166-y (2017).

Ioani, A. M. & Tripa, E. Structural behavior of an innovative all–precast concrete dual system for residential buildings. Pci J. 57 (1), 110–123. https://doi.org/10.15554/pcij.01012012.110.123 (2012).

Kim, H. et al. Cyclic loading test for joints between concrete-filled U-Shaped Steel beams and Bolt-Connected Steel Angle Composite columns. J. Building Eng. 96, 110553. https://doi.org/10.1016/j.jobe.2024.110553 (2024).

Guan, D. et al. Development and seismic behavior of precast concrete beam-to-column connections. J. Earthquake Eng. 22 (1–2), 234–256. https://doi.org/10.1080/13632469.2016.1217807 (2018).

Ding, F., Wu, X., Xiang, P. & Yu, Z. New damage ratio Strength Criterion for concrete and lightweight aggregate concrete. ACI Struct. J. 118 (6), 165–178. https://doi.org/10.14359/51732989 (2021).

Liu, D. Hou Jia-Yu. Comparative analysis of reinforcement connection method of precast members in residential industrialization. J. Jilin Jianzhu Univ. 33 (1), 35–38 (2016). (in Chinese) CNKI:SUN:JLJZ.0.2016-01-009.

Shahi, R. et al. Seismic performance behavior of cold-formed steel wall panels by quasi-static tests and incremental dynamic analyses. J. Earthquake Eng. 21 (3), 411–438. https://doi.org/10.1080/13632469.2016.1160007 (2017).

Sorensen, J. H., Hoang, L. C. & Poulsen, P. N. Keyed shear connections with looped U-Bars subjected to normal and Shear forces Part I: experimental investigation. Struct. Concrete. 22 (4), 2418–2431. https://doi.org/10.1002/suco.202000727 (2021).

Lim, W. Y., Kang, H. K. & Hong, S. G. Cyclic lateral testing of precast concrete T-Walls in fast low-rise construction. Aci Struct. J. 113 (1), 179–189. https://doi.org/10.14359/51688200 (2016).

Wei Guo, Z., Zhai, Y., Cui, Z., Yu, X. & Wu Seismic performance assessment of low-rise precast wall panel structure with bolt connections. Eng. Struct. 181, 562–578. https://doi.org/10.1016/j.engstruct.2018.12.060 (2019).

Wei Guo, Z., Zhai, Z. & Yu Experimental and Numerical Analysis of the bolt connections in a low-rise Precast Wall Panel structure system. Adv. Civil Eng. 1–22. https://doi.org/10.1155/2019/7594132 (2019).

Xu, G. et al. Seismic performance of precast shear wall with sleeves connection based on experimental and numerical studies. Eng. Struct. 150, 346–358. https://doi.org/10.1016/j.engstruct.2017.06.026 (2017).

Akin, A. & Sezer, R. A study on strengthening of reinforced concrete frames using precast concrete panels. KSCE J. Civ. Eng. 20 (6), 2439–2446. https://doi.org/10.1007/s12205-016-0188-z (2016).

Yang, X., Jiang, Y. & Lin, F. Experimental study on Direct Shear Resistance of Horizontal grouted joints in PC shear walls under Compression and in-plane bending moment. J. Building Eng. 90, 109419. https://doi.org/10.1016/j.jobe.2024.109419 (2024).

Lu, Y., Jiang, L. & Lin, F. Seismic performance of precast concrete Shear Wall using Grouted Sleeve connections for Section Steels Reinforced at Wall ends. Structures. 57, 105068. https://doi.org/10.1016/j.istruc.2023.105068 (2023).

Haber, Z. B., Saiidi, M. S. & Sanders, D. H. Seismic performance of precast columns with mechanically spliced column-footing connections. Aci Struct. J. 111 (3), 639–650. https://doi.org/10.14359/51686624 (2014).

Ameli, M. J., Parks, J. E., Brown, D. N. & Pantelides, C. P. Seismic evaluation of grouted splice sleeve connections for reinforced precast concrete column–to–cap beam joints in accelerated bridge construction. Pci J. 60 (2), 80–103. https://doi.org/10.15554/pcij.03012015.80.103 (2015).

Parks, J. E., Papulak, T. & Pantelides, C. P. Acoustic emission monitoring of grouted splice sleeve connectors and reinforced precast concrete bridge assemblies. Constr. Build. Mater. 122, 537–547. https://doi.org/10.1016/j.conbuildmat.2016.06.076 (2016).

Ameli, M. J., Brown, D. N., Parks, J. E. & Pantelides, C. P. Seismic column-to-footing connections using grouted splice sleeves. Aci Struct. J. 113 (5), 1021–1030. https://doi.org/10.14359/51688755 (2016).

Ameli, M. J. & Pantelides, C. P. Seismic analysis of precast concrete bridge columns connected with grouted splice sleeve connectors. J. Struct. Eng. 143 (2). https://doi.org/10.1061/(ASCE)ST.1943-541X.0001678 (2017). 04016176-1-04016176-13.

Jiang, H. et al. Influence of Friction-Bearing devices on seismic behavior of PC shear walls with End columns. Eng. Struct. 210, 110293. https://doi.org/10.1016/j.engstruct.2020.110293 (2020).

Wu, D. et al. The development and experimental test of a new pore-forming grouted precast shear wall connector. KSCE J. Civ. Eng. 20 (4), 1462–1472. https://doi.org/10.1007/s12205-015-0071-3 (2016).

Zhao, Y. et al. Experimental study of the shear behaviour of concrete-grout-concrete joints. J. Building Eng. 43, 103095. https://doi.org/10.1016/j.jobe.2021.103095 (2021).

Zhi, Q. et al. Quasi-static test and strut-and-tie modeling of precast concrete shear walls with grouted lap-spliced connections. Constr. Build. Mater. 150, 190–203. https://doi.org/10.1016/j.conbuildmat.2017.05.183 (2017).

Feng, C. et al. Experimental investigation of seismic performance of precast concrete Wall–Beam–Slab joints with overlapping U-Bar Loop connections. Materials. 16 (9), 3318. https://doi.org/10.3390/ma16093318 (2023).

Yu, Z. et al. Peng Xiao-dan, Guo Wei. Seismic Performance of Precast Shear Wall with U-type reinforcements ferrule connection. Journal of Zhejiang University (Engineering Science), 49(05): 975-984. (in Chinese) (2015). https://doi.org/10.3785/j.issn.1008-973X.2015.05.024

Yu, Z. et al. Peng Xiao-dan, Guo Wei. New node connection mode and seismic performance of precast concrete shear wall structure. Journal of Xi’an University of Architecture & Technology (Natural Science Edition), 47(02): 160-164 + 191. (in Chinese) (2015). https://doi.org/10.15986/j.1006-7930.2015.02.002

Yu, Z. et al. Peng Xiao-dan, Guo Wei. Research on anchorage performance of U-shaped ferrule reinforcement connections in precast shear wall. Journal of Railway Science and Engineering, 12(04): 879-886. (in Chinese) (2015). https://doi.org/10.1016/j.istruc.2023.105544

Zhiwu Yu, X., Lv, Y., Yu, F., Ding, X. & Peng Seismic performance of Precast concrete columns with improved U-type reinforcement ferrule connections. Int. J. Concrete Struct. Mater. ,2019,13(1). https://doi.org/10.1186/s40069-019-0368-6

MOHURD (Ministry of Housing and Urban-. Rural Development of the People’s Republic of China), Technical Specification for Concrete Structures of tall Building (China Architecture and Industry, 2010). (in Chinese).

MOHURD (Ministry of Housing and Urban-. Rural Development of the People’s Republic of China), Code for Design of Concrete Structures (China Architecture and Industry, 2010). (in Chinese).

MOHURD (Ministry of Housing and Urban-Rural Development of the People’s Republic of China). Code for Seismic Designs of Buildings, GB 50011 – 2010 (China Architecture and Industry, 2016). (in Chinese).

MOHURD (Ministry of Housing and Urban-Rural Development of the People’s Republic of China). Standard for test Method of Mechanical Properties on Ordinary Concrete, GB/T 50081 – 2002 (China Architecture and Industry, 2002). (in Chinese).

MOHURD (Ministry of Housing and Urban-. Rural Development of the People’s Republic of China), Specification for Seismic test of Buildings, JGJ 101–2015 (China Architecture and Industry, 2015). (in Chinese).

MOHURD (Ministry of Housing and Urban-Rural Development of the People’s Republic of China). Load code for the Design of Building Structures. JB50009-2012 (China Architecture and Industry, 2012). (in Chinese).

Shan, Z., Yu, Z., Chen, F., Li, X. & Gao, J. Experimental investigation of mechanical behaviors of self-compacting concrete under cyclic direct tension. Materials. 12, 1047. https://doi.org/10.3390/ma12071047 (2019).

Author information

Authors and Affiliations

Contributions

Conceptualization, Feng Chen, Zhiwu Yu and Zheng Li; methodology, Feng Chen, Zhiwu Yu and Zheng Li; software, Feng Chen, Yalin Yu, Chenxing Cui and Guangwen Zhang; validation, Feng Chen, Zheng Li, Sheng Cheng, Chenxing Cui and Guangwen Zhang; formal analysis, Feng Chen, Yalin Yu, Zheng Li and Sheng Cheng; investigation, Feng Chen, Zheng Li, Yalin Yu, Sheng Cheng, Chenxing Cui and Guangwen Zhang; resources, Zhiwu Yu and Zheng Li; data curation, Feng Chen, Yalin Yu, Zheng Li, Sheng Cheng, Chenxing Cui and Guangwen Zhang; writing—original draft preparation, Feng Chen and Zheng Li; writing—review and editing, Feng Chen, Yalin Yu, Zheng Li; visualization, Sheng Cheng, Chenxing Cui and Guangwen Zhang; supervision, Zhiwu Yu and Zheng Li; project administration, Zhiwu Yu and Zheng Li.; funding acquisition, Zhiwu Yu and Zheng Li.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Chen, F., Yu, Z., Yu, Y. et al. Experimental investigation of seismic performance of precast concrete shear walls with overlapping U-bar loop connections. Sci Rep 14, 26240 (2024). https://doi.org/10.1038/s41598-024-78223-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-78223-7