Abstract

Aluminium and its alloys, especially Al6061, have gathered significant interest among researchers due to its less density, great durability, and high strength. Due to their lightweight properties, the precise machining of these alloys can become expensive through conventional machining operations for intricate products. Therefore, non-traditional machining such as electric discharge machining (EDM) can potentially be opted for the cutting of Al6061. EDM is often criticized due to its low machining rates, therefore, in the current work, cryogenic treatment (CT) has been performed on the brass electrode to evaluate the improvement in the machining rates. In addition, kerosene oil (KO) has been engaged in traditional EDM which is replaced with the deionized water (DI) based dielectric as a sustainable alternative. The machining variables such as spark voltage (SV), pulse-on-time (PON), peak current (IP), and Al2O3 powder concentration (CP) have been chosen to determine the material removal rate (MRR), surface roughness (SR), and specific energy consumption (SEC) while comparing non-treated (NT), and cryogenically treated (CT) brass electrodes during EDM. The results were analyzed through optical micrographs, scanning electron microscopy (SEM) analysis, energy dispersive x-ray (EDX) examination, and 3D surface plots. An artificial neural network (ANN) has been constructed for the better prediction of output responses. Moreover, multi-response optimization through the non-dominated sorting genetic algorithm (NSGA-II) has also been performed. The magnitudes of MRRCT, SRCT, and SECCT obtained by multi-response optimization are 64.82%, 27.45%, and 46.60% are better than the values obtained by un-optimized settings of CT brass electrodes. However, the optimal magnitudes of processing parameters are IP = 24.85 A, SV = 2.18 V, PON = 119.11 µs, and CP = 1.05 g/100 ml.

Similar content being viewed by others

Introduction

Several industries, including the aviation, marine, automotive, and healthcare sectors, have a strong preference for aluminium alloys, particularly Al6061. This particular aluminium alloy’s exceptional qualities—such as its lightweight, amazing pliability, superior electrical and thermal conductivity, extraordinary ability to be molded, and corrosion resistance—have led to its widespread adoption1,2. However, conventional machining techniques are difficult to apply to this alloy due to its propensity for chip adherence and edge distortion. This could therefore result in unfavourable effects including high EWR (expensive tooling), less surface finish, and more OC3,4. SR evaluates the surface’s quality, EWR show the electrodes that are wearing over time, and overcutting guarantees correct dimensional accuracy. Electrically conductive materials are cut using a stochastic method EDM die sinking which does not have mechanical interactions of tooling with the workpiece5,6,7. In addition to its mechanical qualities, EDM shows promise in producing complex geometries with accurate tolerances and reliable repeatability8,9,10,11. Die sinking EDM’s basic idea is to remove material from the workpart by creating a series of electric discharges between the tool, which is the cathode, and the specimen, which is the anode6,12,13. A power supply is what first generates high-voltage pulses. The dielectric fluid deteriorates and sparks between the conducting surfaces when the voltage is beyond a particular threshold, vaporizing minute amounts of material from the workpiece and the electrode14,15. The dielectric fluid then solidifies these removed particles over the machined cavity. Traditionally, KO is considered as a dielectric medium for a long time, even though it releases dangerous gases, vapours, and fumes that are hurtful to the environment and operator health16,17. This is explained by the intrinsic qualities of KO, which include low viscosity, high flammability, increased toxicity, and non-biodegradability18. Several research works have examined the negative consequences linked to the use of paraffin oil. For instance, Ming et al19. discovered that aerosol by-products and hazardous vapours are released during EDM using KO, affecting the health of the operator and the purity of the air. Hydrocarbon-based dielectrics, such as KO, are known to release hazardous materials such as benzene, dust, aerosols, and volatile particles (Tonshoff et al20).

EDM is criticized because of its limitations, such as less MRR, high EWR, poor surface quality, and more OC21,22. To fix this, scholars recommend adding powders to dielectric oil23,24. Nano-powder in the dielectric medium boosts the reactions above and enhances the values of the abovementioned response measures. Nano-additives in dielectric media generate many ionized particles at high voltage, and acceleration and random movement of particles enhance work-electrode distance and electric discharge dispersion. This increased distance causes the current to bridge, stabilizing and speeding up machining25,26. Researchers also suggest adding surfactant to fix this issue27. Previous research has demonstrated that nano-powder improves EDM’s efficacy. Chaudhari et al.28 improved the response measures for Nitinol shape memory alloy using Al2O3powder and EDM fluid. Hosni and Lajis29 studied the surfactant (Span-20) and chromium (Cr) content that affected AISI D2 steel during EDM, emphasizing their importance in improving output characteristics. Abbas et al30. evaluated surface roughness achieved on AISI D2 steel during electric discharge machining process. A titanium alloy machining through EDM using graphite powder and surfactant was presented by Kolli and Kumar31. Researchers argued that surfactant (Span-20) reduced erratic sparks and particle aggregation in the dielectric oil, improving response measures. Paswan et al32. investigated the DI and graphene nano-powder affected Inconel 718 EDM machining performance. The authors also used waveform analysis to study spark phenomena, and employed RSM for optimizing the machine variable as per given factors. Significant improvements in MRR, EWR, and SR values were 20.1%, 2%, and 14%, respectively. In addition, the findings of said analysis showed that discharges in nano-graphene mixed dielectric were more stable than standard EDM.

Cryogenic Treatment (CT), a key material microstructure improvement method, is widely used to improve electro-mechanical characteristics, including durability, grain size, thermal, and electrical conductivities33,34. Choudhary et al35. applied Taguchi’s design utilizing DCT and NT copper electrodes for EDM on Hastelloy C-4. They examined gap voltage, spark duration, and current in relation to SR and EWR. Compared to NT electrodes, CT electrodes demonstrated reduced EWR and improved SR. Papazoglou et al6. evaluated EDM cutting performance in a dielectric medium for Ti-alloy grade 2. Spark-on duration affected EWR during EDM machining, but IPprimarily affected MRR. Kumar and Sharma36 employed EN-31 magnetic field-assisted EDM to assess MRR, EWR, and OC. Input parametric settings such as PON (10 µs), POFF (10 µs), IP(3.18 A), and magnetic field (0.3 T) yielded maximum MRR and minimal EWR and OC. Meena et al37. optimized multi-response EDM of commercially pure Ti-alloy using GRA. They assessed MRR, EWR, and OC based on current, frequency, and pulse width. For response measures like MRR, EWR, and OC, current is most critical. Ramaswamy and Perumal38 manufactured a hybrid composite LM13 Al-alloy and carried out machining. Pulse current, PON, and POFF were adjusted to evaluate MRR, EWR, and OC. The investigation showed that current and PON were most relevant for MRR, EWR, and OC.

The impact of machining Al6061 alloy using NT and CT brass tools, combined with Span-20 and an alumina mixture in DI, is not evaluated. In the present study, four processing parameters such as IP, SV, PON, and CP have been used for the evaluation of response measures such as MRRNT, SRNT, SECNT, MRRCT, SRCT, and SECCT during the EDM process of Al6061. To further evaluate the process, EDX, SEM, 3D profilometry, and microscopic investigations have all been carried out. Analysis of Variance (ANOVA) has been conducted to recognize the critical input factors that have a direct impact on MRR, SR, and SEC for both types of electrode materials. To achieve the sustainable EDM, carbon footprints have been evaluated in terms of % reduction of CO2 for DI water based dielectric compared to the kerosene oil based dielectric. Moreover, an ANN has been built for the better prediction of output responses and evaluate the correlation among the predicted and the experimental values. Multi-response optimization using the NSGA-II has also been used. To further highlight the novelty of work, the details are as follows:

-

There is no comprehensive work available which explains discrepancy of cutting performance of aerospace alloy considering the process’s physical features.

-

The cutting performance of aerospace alloy is not thoroughly optimized for high-speed machining (when compared to conventional process) which advances knowledge towards the key limitation of electric discharge machining systems.

-

The use of design of experiments, artificial intelligence and evolutionary intelligence based multi-objective optimization has not been used to explore the novel process characteristics. Considering the multi-physics nature of process involving thermal, electrical, surface melting and solidification characteristics, deionized water mixed with nano-powders and surfactant, the conventional simulations are limited to present a thorough comparison of cutting performance of the above-mentioned aeronautical alloy.

Experimentation characteristics

Materials and procedures

Al6061 alloy of size (60 mm × 60 mm × 5 mm) has been chosen for assessing the machining performance through EDM setup. The measurement of MRR, SR, and SEC was used to evaluate the cutting performance of Al6061. The dielectric fluid, which was housed in a specially made container, was DI. Table 1 presents the elemental composition of Al6061 as determined by spectrometry, and Table 2lists its physical properties as per manufacturer’s quality sheet (also used in39).

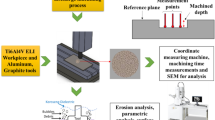

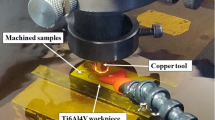

An Al6061 alloy was cut utilizing a brass electrode with a 9 mm diameter under both extensive CT and NT conditions to assess cutting efficiency. Specific electro-physical characteristics of the brass tool are given in Table 340. The brass electrode underwent a 24-hour deep cryogenic treatment in liquid nitrogen, gradually reaching a state of -184 °C about 1 °C per minute. This procedure was performed in a cryogenic compartment. The tool was tempered at 150 °C at the same cooling rate (1 °C/min) following the cooling phase until the electrode eventually attained room temperature. The conductivity increased by 10.70% and the grain size of the tool enhanced by 7.89% after deep CT41. Three different concentrations (0.5, 1, and 1.5 g/100 ml) of alumina (Al2O3) were blended to the DI after initial evaluations. A literature search was also carried out in an effort to lessen the restrictions given by low cutting rates in EDM. The physico-chemical attributes of alumina nanopowder (as per manufacturer) are listed in Table 542, whereas the levels of each variable employed in this research are listed in Table 4. Throughout the EDM process, Span-20 was injected at a consistent concentration of 6% by volume to prevent agglomeration.

The experimental framework adopted in this investigation embraced a Response Surface Methodology (RSM) strategy, specifically the Central Composite Design (CCD). Experiments were conducted utilizing the EDM apparatus,, illustrated in Fig. 1. MRR, quantified in mm3/min, was ascertained by evaluating the variance in weight before and after the EDM operation, and computed using Eq. 1. Conversely, surface roughness was assessed using the 2D roughness meter which slides over the profile in linear fashion recording the movement of pin in the peaks and valleys, and the SEC was assessed using commonly established process energy metric via Eq. 2. To process microscopic images for 3D surface topography investigation, Gwyddion (version 2.63), is utilized.

Within Eq. 1, ‘tm’ denotes the amount of time spent EDM, while ‘WB’ and ‘WA’ stand for the workpiece’s weight prior to and following the machining operation, respectively.

Working schematic of EDM17 (Licensed Open Access).

A graphic explaining the idea of spark production is shown in Fig. 2. Preliminary experiments were operated to identify the best parameter configurations for maximizing MRR and minimizing SR and SEC. After these first trials, parameters showing increased MRR, and decreased SR and SEC were chosen for follow-up workpiece studies with both type of electrodes. The use of these absolute variables reduced the possibility of unnecessary processing costs or damage to tools and workpieces during EDM operations, in addition to resulting in high MRR and decreased SR and SEC. Determining the proper concentration of surfactant in the DI dielectric was a crucial step in the procedure. The final decision was made based on preliminary experimental testing that met predetermined selection criteria, however, an initial reference was taken from the body of existing literature. Preliminary results show that 6% of surfactant concentration complies with the specifications. To make it easier to combine the surfactant with the DI dielectric, a motorized stirrer tank was created specifically for that purpose. Figure 3 outlines the thorough methods used in this investigation.

Analytical computation

An ANN, also known as a “multilayer perceptron,” is a great tool for tying response measures and their predictions to process parameters. Even in systems with inadequate characterizations, the technique mines the complex curvy and quadratic relations in the different input intervals with efficacy43. In the current study, three output variables : material removal rate, surface roughness and specific energy consumption (MRRNT, SRNT, SECNT, MRRCT, SRCT, SECCT) have been investigated using NT and CT brass electrodes. The ANN is used to predict the values of these response measures. When it comes to highly non-linear tasks that depend on bias and weight values, an ANN performs similarly to the human brain. The response measures in this work are modelled using the EBPTA44. Figure 4 displays the ANN structure used in this investigation.

The basic ANN structure has three layers: input, hidden, and output. Figure 4 shows that this study uses three ANN layers. Since the research has been conducted using four process parameters (IP, SV, PON, and CP), these parameters comprise the opening layer, or input layer. Input variables typically range from 1x to 2.5x neurons45,46. Consequently, the learning rate (E-4 to E-1) is compared to a maximal neuron combination set. The hidden layer in this investigation is represented by the 3–10 neurons in the second/middle layer. The performance of ANN models is enhanced with increased model complexity. More neurons in the hidden layer improve the model’s performance and curve spots. Generalization of a model may be constrained by its complex design. The lowest number within a range might lead to data fit issues and mistakes, just like the maximum number of neurons. Thus, the optimal number of neurons is selected with care. For NT and CT brass electrodes, the third and final output layer is made up of six response measurements (MRR, SR, SEC). Nevertheless, only 10% of the data—80% of which was used for training—was utilized for testing and validating the ANN model. The R2 and RMSE formulas are:

Here, \(\:{y}_{i}\) represents the original input value, \(\:{\widehat{y}}_{i}\) the projected value, and \(\:{\stackrel{-}{y}}_{i}\) the average, with \(\:i\) = 1, 2, 3…, and N the total number of observations. \(\:{R}^{2}\) measures accuracy and ranges from 0 to 1.

Results and discussion

The design of experiments for the current study has been compiled in Table 6. The whole discussion and key findings are elaborated with the help of microscopic, SEM images, and EDX profiles. For statistical analysis, ANOVA was also carried out to check which parameter(s) have significance.

Parametric effect analysis

In order to predict the impacts of both type of brass electrode (NT and CT) on the responses obtained during EDM of Al-alloy, parametric effects were examined in this study. Three-dimensional surface plots against the four design factors (IP, SV, CP, and PON) were created for this purpose. It is important to note that two variables are shown to have an influence within their designated ranges in the 3D surface plots, while the other factors are kept at their median values.

Process productivity in terms of material removal rate

In the EDM of Al6061, the MRR was compared to various input variables using NT and CT brass electrodes. Figure 5(a) demonstrates the combined influence of IP and SV on the MRR for the NT brass tool. Figure 5(a) illustrates the removal of material from the specimen as the values of both variables rise. The primary cause of this is the strong discharge energy at high IP and SV values, which causes more material from the specimen to melt and evaporate. As shown in Fig. 5(b), a similar result is also visible when employing the CT brass electrode for Al6061 machining using EDM setup. The CT brass tool’s superior atomic packing and grain refinement led to better wear characteristics, the MRR obtained with it is better than achieved with the NT brass tool. It is further evident from Fig. 6(a) that 33.3% and 90.4% improvements have been predicted in the value of MRR when CT electrode is engaged as compared with the NT electrode at higher state (25 A, 6 V) and lower state (5 A, 2 V), respectively.

The influence of IP and PON on the MRR with NT brass was also assessed for Al6061 alloy, as presented in Fig. 5(c). The surface plot highlights that these factors have a direct impact on the MRR. It means that the MRR raises with the increase of both IP and PON collectively. The reason lies in the formation of spark density in the plasma channel for a longer period, causing the removal of significant material from the workpiece. This material removal is further enhanced when the CT brass electrode is employed due to its improved mechanical and metallurgical properties, as depicted in Fig. 5(d). Hence, the CT brass electrode can be an alternative choice for achieving exceptional MRR values when considering the EDM of Al6061. According to Fig. 6(b), the bar graph shows an increase in MRR of about 2 times at 150µs, 25 A, and 3.2 times at 50µs, 5 A when comparing the CT electrode to the NT electrode.

Figures 5(e) and 5(f) represent the effect of CP and IP on the MRR for NT brass and CT brass, respectively. As long as discussed for the NT brass electrode, the effect of said parameters on MRR shows an increasing trend, and then at higher levels of both parameters, the curve slightly decreases. It specifies that MRR upsurges with the regular change of IP, but depreciation can be noticed in the case of CP after 1 g/100 ml. This is attributed to the generation of agglomerated particles in the dielectric, which reduces the thermal energy over the workpiece, resulting in a drop in the MRR. It is interesting to note that the same trend appears for the CT brass electrode, as shown in Fig. 5(f). However, the value of MRR even at maximum parametric levels is greater than the value found with the NT brass tool, as far as EDM is operated for the cutting of Al6061. This is mainly due to the enhanced surface properties of the CT brass electrode, which generate discharge more uniformly, resulting in the accomplishment of a high MRR. In addition, MRR has significantly improved by 80.8% at the lower state (0.5 g/100 ml, 5 A) and 43.7% at the higher state (1.5 g/100 ml, 25 A) when comparing the CT electrode to the NT electrode, as witnessed in Fig. 6(c).

Part quality in terms of surface roughness

Surface roughness (SR) is another crucial response variable illustrated herein against the given parameters during the EDM of Al6061, as depicted in Fig. 7. Initially, for the NT brass tool, the simultaneous impact of IP and SV on SR is evaluated in a 3D surface plot, as shown in Fig. 7(a). It can be noticed that SR is compromised when either IP or SV increases. The intense heat input available in the plasma at high current and voltage values is the key reason for the machined impression becoming rough. Similarly, for the CT brass electrode, the same trend is noticed. However, for comparison purposes, the CT brass electrode in the EDM of Al6061 provided less SR compared to the NT brass, as evidenced in Fig. 7(b). This is due to the regular discharge phenomenon even at large magnitude of variables, thereby improving surface quality. Mathematical point of view, SR is reduced by 11.49% at 5 A, 2 V and 25.8% at 25 A, 6 V when machining results of CT is compared with the findings of NT electrode, such as displayed in Fig. 8(a).

Figure 7(c) demonstrates the examination of SR by changing the states of IP and PON employing the NT brass tool while EDM of given alloy. It can be highlighted from Fig. 7(c) that SR initially increases with the rise of PON, then it slightly decreases when PON is shifted to 150 µsec, even at all IPlevels. The initial increase in SR is due to prolonged sparking occurring over the target surface. After that, a slight decrease in SR is observed because of the presence of a large number of ionized particles, which hinder discharges and lead to a better surface finish47. As far as IP is taken into account, the value of SR continuously increases with the change of IP, as depicted in Fig. 7(c). On the contrary, for the CT brass electrode, SR increases with the increase of both IP and PON values, as shown in Fig. 7(d). However, SR attained with CT brass is better than that achieved with NT brass due to its better grain structure and prevention of irregular discharges. It is highlighted from Fig. 8(b) that surface finish is enhanced by 11.9% and 33.6% at lower setting (50 µs, 5 A) and higher setting (150 µs, 25 A), respectively, as long as compared the cutting performance of CT with the NT electrode.

Figure 7(d) also demonstrates the impact of two input factors (IP and CP) on the SR in the EDM of Al6061. For both parameters, SR increases with their values. The reason behind this lies in the intensification (due to current) and spreading of sparks (due to CP causing agglomeration) at higher values, which alter the surface micro-impressions and result in a high SR value. However, the 3D surface plot shows different behavior when CP is set to 1.5 g/100 ml and IP changes to 5–25 A. It means that surface finish decreases when IP changes from 5 A to 10 A, then improves again when IP is set at 15 A. Conversely, it has been observed that SR is tremendously improved at higher levels of both IP and CP when the CT brass is employed for the EDM of selected alloy, owing to the high grain refinement. The bar graph in Fig. 8(c) displays the comparative assessment, showing 17.8% and 33.6% reduction in SR at corresponding lower (0.5 g/100 ml, 5 A) and higher (1.5 g/100 ml, 25 A) combinations, when CT electrode is treated in EDM process.

Environmental burden in terms of specific energy consumption

Specific energy consumption (SEC) is thoroughly investigated against machining parameters employing NT brass and CT brass as electrodes, as depicted in Fig. 9. Primarily, the combined effect of SV and IP on SEC for NT brass is explained in Fig. 9(a). According to Fig. 9(a), SEC decreases with the increase in IP. However, SEC slightly deviates downward with the increase of spark voltage. For the combined influence, the magnitude of SEC sharply lowers at large values of both input parameters. This mainly occurs because of the high exclusion of material from the specimen, resulting in the decline of SEC. For the CT brass electrode, the behavior of SEC against the same considered variables is presented in Fig. 9(b). SEC reduces with the increase of IP value, whereas SEC initially decreases and then increases when SV rises to its maximum value. However, their combined interaction yields a low SEC magnitude. For a comparative viewpoint, the SEC from Fig. 9(b) (CT brass electrode) is lower than the value noticed in Fig. 9(a) (NT brass tool) when EDM of Al6061 is taken into account. From Fig. 10(a), it can be predicted that SEC is improved by 27.2% and 18.6% at their respective states, such as lower (5 A, 2 V) and higher (25 A, 6 V), when CT is used during EDM of Al6061.

Figure 9(c) is developed for studying the effect of PON and IP on the SEC when NT brass is utilized in the EDM of the Al6061 process. It can be clearly seen from Fig. 9(c) that the value of SEC decreases with the increase of both aforementioned parameters, even the combined effect of the two parameters also lowers the magnitude of SEC. This is mainly because of proper heat distribution over the machined cavity due to the high-temperature gradient and appropriate gap of the plasma channel. The same behavior can also be noticed for the CT brass electrode in Fig. 9(d), as long as the EDM of Al6061 is taken into account. However, the value of SEC with the CT brass is far less than the value achieved with the NT brass electrode. The primary reason for this shift is the appropriate grain size and structure of CT brass, which effectively utilizes the heat input in the plasma space. Hence, a higher magnitude of input parameters is ideal for getting low SEC while EDM of Al6061. The bar graph in Fig. 10(b) also shows the significance of CT over NT electrode. Mathematically, CT electrode has provided 14.5% and 16.16% lower value of SEC at their respective conditions, such as lower (50 µs, 5 A) and higher (150 µs, 25 A), when comparison is developed with NT brass tool.

The combined effect of CP and IP on SEC against NT and CT brass tools is shown in Fig. 9(e) and 9(f), respectively. A similar trend of SEC can be observed in the 3D surface plots. For instance, in Fig. 9(e), the value of SEC decreases with increasing IP but remains almost unchanged when CP increases to its maximum level. It is well-known that an increase in powder concentration results in agglomerated material, which blocks discharges and leads to inappropriate machining, thereby increasing SEC. However, an increase in IP also intensifies the spark phenomenon, which increases the MRR, consequently reducing SEC. The same trend can be seen for CT brass during EDM of Al6061 alloy. From the comparison, the values of SEC are higher in the case of NT brass than that of CT. Thus, CT brass is preferred over NT brass electrodes to get low SEC. Figure 10(c) indicates that the CT electrode is more effective during the EDM of Al6061, providing lower values of SEC compared to the NT electrode, with reductions of 28.79% at CP: 0.5 g/100 ml, IP: 5 A, and 22.79% at CP: 1.5 g/100 ml, IP: 25 A.

Topographical analysis

Surface topography analysis has also been performed on the EDMed surfaces of Al6061 against both types of brass electrodes. The impact of changing parametric levels on responses have been investigated by looking at the surface quality of the cut profiles using optical microscopic, SEM, and 3D roughness plots.

The EDMed surface profile using NT brass and CT brass electrodes has been depicted in the form of microscopy and 3D profilometry analysis as shown in Figs. 11(a, b) and 11(c, d), respectively. The NT brass electrode provided a lower MRR due to uneven and non-uniform sparking, whereas the CT brass electrode yielded a higher MRR due to improved grain sizes, as shown by the optimal microscopic image in Fig. 11(c, d). For further analysis, SEM images were also collected with both types of electrodes, as represented in Fig. 12. According to Fig. 11(a, b), and Fig. 12(a), high redeposited melt is found on the machined profile. This is because the NT brass did not properly remove the debris around the machined cavity, which was governed by the uneven sparking and poor flushing. In addition, ionization of dielectric also takes place during sparking, which generates multitude carbon particles, depositing over the machined surface during pulse-off time. The 3D surface topography analysis also revealed the material erosion areas by peaks and valleys. Peaks are highlighted by blue colour and valleys are indicated by red colour. The 3D surface topography analysis (corresponding to Fig. 11(a, b)) has revealed the small heightened peaks and valleys which is the indication of low material erosion for NT brass electrode. An EDX image shown in Fig. 13 highlights the presence of carbon atoms in the workpiece’s surface. Conversely, in Fig. 12(b), less redeposited melt is found with small-size craters, which is an indication of a good flushing phenomenon occurring during machining due to the high grain structure of the CT brass electrode. Moreover, the 3D surface topography analysis for CT brass electrode as shown in the correspondence of Fig. 11(c, d) revealed that deeper, wider, and larger craters have been formed on the surface of Al6061, with smaller amount of melt redeposited.

In Fig. 14(a), shallow craters are evident on the machined surface when the NT brass electrode is used, at low level of process parameters. Moreover, the 3D surface profile depicts a higher blue portion, indicating increased SR. This is mainly due to arcing phenomena and improper flushing effects in the work-electrode zone. Consequently, the surface finish is compromised. The SEM image represented in Fig. 15(a) also indicates the presence of shallow craters with greater redeposited melt. However, when the values of control parameters are changed from small to high levels, no significant change in the magnitude of SR is detected. However, variation in the machined surface topology can be observed in Figs. 14(a) and (b). In both figures, tiny craters with little resolidified melt are found on the machined profile. This occurs due to the widening of the plasma zone, which improves the stability of sparking and reduces the arcing phenomenon, resulting in a somewhat improved surface finish (Fig. 15(b)). The peaks and valleys formed on the surface of Al6061 at the low processing parameters indicating the smaller material erosion, whereas the peaks and valleys formation on the surface of the Al6061 illustrates the larger amount of material erosion during the EDM operation of Al6061.

The micrograph depicted in Fig. 16(a) illustrates shallow and greater redeposited melt on the machined cavity using CT brass electrode for cutting Al6061. This micrograph was captured at low levels of input parameters. Furthermore, the 3D plot exhibits a low peak-to-valley distance, indicating a low SR value. This occurs due to the low discharge density, which partially melts the material from the workpiece. The SEM image highlighted in Fig. 17(a) also reveals the presence of shallow-sized craters. Conversely, Fig. 16(b) displays tiny craters on the machined profile when the process parameters are elevated, while still utilizing the CT brass electrode. Additionally, the surface topography in Fig. 16(b) shows a high peak-to-valley distance, indicating a high SR compared to the one depicted in Fig. 17(a). The generation of high peaks and valleys is primarily caused by the expansion of the plasma channel, delivering poor surface quality (Fig. 17(b)).

For the NT brass electrode, very little material re-solidification is noticed during EDM of Al6061, as depicted in Fig. 18(a). On the opposite side, the impression made with the CT brass tool gives more redeposited melt over the specimen surface, as presented in Fig. 18(b). The 3D surface topography analysis (corresponding to the micrographs (Fig. 18(a, b))) revealed the same scenario of smaller peaks and valleys which is in the favour of smaller material erosion during the machining process. It has already been studied that NT brass provides high SEC due to the arcing effect and uneven distribution of discharges. However, CT brass, owing to better metallurgical properties, provides a minimum value of SEC.

Parametric significance of control variables

The formulated designs have been tested by ANOVA. It is usually applied for identifying the significant parameter and studying the interactions among input variables and individual output. The parametric significance and involvement percentage were examined by p-values and f-values, respectively. It also assists us in determining the statistical validation of the proposed models by computing R2, adjusted R2, and predicted R2 magnitudes.

Material removal rate

The ANOVA results for MRR with both types of electrodes (NT brass and CT brass) are compiled in Table 7. It can be inferred from Table 7 that all four parameters have significance, with p-values less than 0.05. Furthermore, among various combined interactions, IP×SV and SV×PON have p-values smaller than 0.05, showing their importance as model terms. Regarding quadratic effects, all parameters have been found significant except IP². Similarly, for MRR computed against CT brass, all input parameters and their combined interactions, except PON×CP, have p-values smaller than 0.05, portraying their importance as model value. However, in the case of MRR calculated with CT brass, CP² is the only dominant factor among all the given quadratic terms. The R2 values for both types of electrodes are provided in Table 7 to evaluate the reliability of the model. It can be observed that the R2 values for NT brass and CT brass are greater than 0.9, confirming a high level of reliability in the dataset. The predicted models for MRR against NT brass and CT brass are presented in Eqs. 3 and 4, respectively.

Surface roughness

The ANOVA findings for SR with both NT and CT brass within a predetermined range of input variables are shown in Table 8. All major effect variables for SRNT have p-values smaller than 0.05, demonstrating the importance of these variables as model terms. Furthermore, the significance of these model components is shown by the p-values for interaction parameters, which include IP×SV, IP×CP, SV×CP, and PON×CP, all of which are below 0.05. Only two factors (IP2 and PON2) are determined to be significant in the case of quadratic effects, with p-values less than 0.05. For SRCT, all main effect factors and quadratic effect parameters are significant except IP², with p-values less than 0.0001 and less than 0.05, respectively. Conversely, significance has been observed only in the three combined interactions (IP×CP, SV×PON, and SV×CP). The R2 values for both types of electrodes demonstrate greater reliability in the proposed models. The adequacy precision values for SRNT and SRCT are 37.4301 and 36.4146, respectively. The mathematical models for SR against NT and CT brass electrodes are highlighted in Eq. 5 and Eq. 6, respectively.

Specific energy consumption

The ANOVA findings for SECNT and SECCT are tabulated in Table 9. Concerning NT brass, all main effect parameters except Sv are found to be significant. However, only the interactions IP×CP, SV×CP, and PON×CP are deemed significant with p-values smaller than 0.05. Among the quadratic effects, only Ip² exhibits a p-value less than 0.05, showing its significance in the model. For SECCT, all main effect parameters and combined parameters except IP×CP and SV×CP demonstrate significance with p-values less than 0.05, highlighting their importance in the model. In addition, IP², SV², and PON² show significant effects, while CP² has a p-value very close to 0.05, suggesting some significance. In terms of model reliability, the R2 values for both SECNT and SECCT exceed 0.9, indicating high reliability. The adequacy precision for SECNT and SECCT is 16.6711 and 24.2616, respectively. The mathematical models for SEC for NT and CT brass electrodes are given in Eqs. (7) and (8).

Sustainability and process modelling

Over time, EDM emissions create dangerous compounds that contaminate the air and lead to respiratory illnesses and air pollution. To lessen these effects on the environment and public health, industries must adopt cleaner technologies, strict emission regulations, and ethical waste management.

Sustainable EDM practices with high MRR, low SR, SEC, and CO2 emissions can be achieved through advanced EDM assistive technologies such as, novel electrodes for stable pulse generation establishing controllable erosion, environmentally friendly dielectric fluids and process parametric control etc. These factors determine the effectiveness, economy, and environmental impact of EDM operations. High MRR affects profitability, SR regulates surface quality, SEC limits power consumption during machining, and CO2 emissions guarantee environmentally responsible operation. These emissions are caused by non-biodegradable dielectric fluids, hence sustainable EDM approaches need to reduce them. By reducing their environmental effect and achieving sustainability targets for waste reduction, energy efficiency, and environmental preservation, these techniques enable EDM operations to operate as efficiently as possible. Figure 19 illustrates an overview of sustainability for EDM. However, the scope in this study is emissions based on the consumed electricity.

Sustainable approaches in EDM48 (Licensed Open Access and reused with the permission of author).

When comparing the SEC of KO dielectric with that of DI dielectric used in EDM, significant differences in energy consumption become apparent. KO has an SEC index of 102.523 kJ/mm3, however its DI cousin has significantly lower SEC parameters. Using DI dielectric in EDM operations has the potential to reduce CO2emissions while also producing energy savings. This mitigation effort is evaluated based on adherence to the IPCC’s guidelines49. The proportional decrease in CO2 emissions for both KO and DI dielectrics is shown in Fig. 20. Using DI results in an average CO2 reduction of around 94.81 ± 2.58% for the NT brass electrode and 95.56 ± 1.01% for the CT brass electrode. As a result, in the context of the EDM framework, DI dielectric becomes the model substitute for KO, supporting sustainability goals and providing more control over carbon emissions.

Figure 21 illustrates the relationship between the goal and output values with a total ANN modelling regression coefficient R value of 0.95105. The two primary measures for assessing the effectiveness of machine learning models are R2and RMSE50.

The results from the experiment indicated that the ANN model predicts response measures and that the R2 for each response measure is more than 0.98 with an exception of few. In Fig. 22(a-c), contour graphs are made using NT brass electrode between the number of neuron layers (3 to 10), R2train, R2test, and R2val, and RMSEtrain, RMSEtest, and RMSEval. Figure 22(a) shows MRRNT with R2train > 0.99 and RMSEval = 0.09 mm3/min for 8 neuron layer and E-4 learning rate. Figure 22(b) shows that the R2train value for SRNT is > 0.99 and the RMSEval is 0.032 μm for the 9 neuron layer and E-1 learning rate. As shown in Fig. 22(c), the best SECNT model has 8 neurons, E-3 learning rate, R2train > 0.99, and RMSEval = 0.085 kJ/mm3. In the same way, In Fig. 20(a-c), contour graphs are made using CT brass electrode between the number of neuron layers (3 to 10), R2train, R2test, and R2val, and RMSEtrain, RMSEtest, and RMSEval. Figure 23(a) shows MRRCT with R2train > 0.99 and RMSE_val = 0.07 mm3/min for 9 neuron layer and E-2 learning rate. Figure 23(b) shows that the R2train value for SRCT is also more than 0.99 and the RMSEval is 0.042 μm for the 5 neuron layer and E-1 learning rate. As shown in Fig. 23(c), the best SECCT model has 7 neurons, E-4 learning rate, R2train > 0.99, and RMSEval = 0.11 kJ/mm3. Thus, the ANN model estimates response measure values better than other models. Table 10 summarizes all ANN model results. However, there are still challenges about the generalization and reproducibility of similar performance metric because of inherent limitations of ANN and sensitivity towards data categorization.

Sustainability targeted process optimization

NSGA-II is an evolutionary algorithm which finds a compromise between multiple objectives. Using heuristic techniques or random selection, it first creates a population of viable solutions. Subsequently, every solution is evaluated by means of the established objective functions that encompass the several optimization criteria. Individuals are sorted into several fronts according to their dominance relationship through a process known as non-dominant sorting, in which a person (as an example) performs better than another in one or more objectives without degrading in any other area. The population is thus sorted into fronts, the first of which is made up of people who are independent of all others. The density of surrounding solutions in the objective space is then measured by assigning a crowding distance to each individual within a front. In order to preserve diversity along the Pareto front and favour solutions with larger crowding distances, NSGA-II strikes a balance between exploration and exploitation throughout the selection process by taking into account both non-dominant sorting and crowding distance. To create children for the following generation, a select few undertake genetic procedures like crossover and mutation, which introduce new variations. The best solutions from the previous generation are preserved in the following population through the use of elitism. Decision-makers are presented with a variety of Pareto-optimal solutions that provide trade-off possibilities for multi-objective optimization issues by means of this iterative procedure, which continues until a termination requirement is satisfied. Figure 24 depicts the working schematic of NSGA-II.

NSGA-II working schematic51.

Using NT and CT brass electrodes, the input variable magnitudes are optimized in this study using NSGA-II to find the optimal MRRNT, SRNT, SECNT, MRRCT, SRCT, and SECCT solutions. Equation 11 demonstrates the objective function that was used to maximize the values of the input variables, but Eq. 12 illustrates the objective function’s limits.

Upon successfully executing NSGA-II within the designated restrictions, various solutions for the input variables and output answers are achieved. The process parameters, i.e., IP, SV, PON, and CP values of 24.85 (A), 2.18 (V), 119.11 (µs), and 1.05 (g/100 ml), respectively, should be used, the algorithm concluded, in order to optimize MRRNT, and MRRCT and minimize SRNT, SRCT, SECNT and SECCT. Figure 25(a) illustrates the MRRNT of 8.10 mm3/min, SRNT of 4.16 μm, and SECNT of 4.86 kJ/mm3, and the MRRCT of 11.60 mm3/min, SRCT of 4.08 μm, and SECCT of 3.70 kJ/mm3 as a consequence of the multi-objective function (Fig. 25(b)). Additionally, the ideal parametric configuration recommended by NSGA-II is provided in Table 11. Confirmatory runs have verified the ideal configuration proposed by NSGA-II; the findings are collected in Table 12. NSGA-II was run twice more and confirmatory runs were performed to prove the process’s efficacy. Table 12 also includes the outcomes of these validation runs.

The important improvements made achievable by including NSGA-II in the confirmation investigations are shown in Table 12. In particular, the maximum percentages for MRR increased by 77.75%, SR fell by 31.80%, and SEC improved by roughly 43.02% for the NT brass electrode in the confirmatory experiment. In the experiment, MRR increased by 64.82%, SR lowered by 27.45%, and SEC improved by roughly 46.60% for the CT brass electrode, respectively, for the greatest percentages.

Conclusions

This article reports the multi-response examination of Al6061 machined via EDM against different sets of control parameters. The findings have been thoroughly illustrated with optical micrographs, SEM, EDX, 3D surface plots, and bar graphs. ANOVA has also been applied to determine the significance of parameters. Multi-response optimization through the NSGA-II has been performed for the set of processing parameters, and response measures. The key points of this study have been concluded below:

-

The maximum MRR (10.42 mm³/min) was achieved with the CT brass at 25 A, 2 V, 150 µs, 0.5 g/100 ml, which is almost 25% higher than the MRR (8.32 mm³/min) observed with the NT brass tool. This improvement is primarily due to the enhanced characteristics of the CT electrode. On average, the maximum MRR (10.08 mm³/min) was achieved with the CT electrode at a combination of 150 µs and 25 A. Compared to the NT brass tool, this MRR value is approximately twice as high under the same parametric conditions.

-

MRR is found to be higher when IP, SV, and PON are increased to 25 A, 6 V, and 150 µs due to the intensification of sparks at these higher parameter values, resulting in greater material erosion from the specimen’s surface. Additionally, MRR is significantly influenced, with an increase of 80.8% at low conditions (CP: 0.5 g/100 ml, IP: 5 A) and 43.7% at high conditions (CP: 1.5 g/100 ml, IP: 25 A) when comparing CT performance with the NT electrode.

-

According to the findings, SR is reduced by 11.49% at low settings (5 A, 2 V) and 25.8% at high settings (25 A, 6 V) with the CT brass electrode compared to NT brass, due to more consistent discharge phenomena and better surface quality even at higher current and voltage levels. CT brass also improves SR by 17.8% at low (0.5 g/100 ml, 5 A) and 33.6% at high (1.5 g/100 ml, 25 A) settings, owing to its refined grain structure, which minimizes irregular discharges and enhances surface finish in the EDM process. Moreover, the CT brass electrode enhanced surface finish by 11.9% and 33.6% at 50 µs, 5 A and 150 µs, 25 A, respectively.

-

In the case of SEC, the minimum value (2.25 kJ/mm³) is achieved with the CT electrode at the parametric setting of (25 A, 2 V, 150 µs, 0.5 g/100 ml) during the EDM of Al6061. This value is approximately 1.07 times lower than the Sect. (2.41 kJ/mm³) obtained with the NT brass electrode. On average, the minimum Sect. (3.34 kJ/mm³) is observed with the CT electrode at the parametric combination of (150 µs and 25 A). This improvement is due to proper heat distribution over the machined cavity, attributed to the high-temperature gradient and the appropriate gap of the plasma channel. Additionally, at this combination, the SEC is 16.16% lower compared to the Sect. (3.88 kJ/mm³) achieved with the NT brass tool.

-

Surface morphology obtained with CT brass is somewhat better than that obtained with NT electrode. The improved grain refinement in the CT brass is the key reason for providing improved microstructure. However, the surface topology provided by NT brass is due to the unstable arcing effect, causing large peak-to-valley height.

-

The ANOVA analysis revealed that all the parametric effects are significant in the case of CT brass, showing their p-value less than 0.05, whereas only SV remains insignificant when NT brass is utilized during EDM of Al6061. Moreover, the magnitude of R2 in each response was larger than 0.9, which highlights a close connection between the actual value and the proposed value.

-

An ANN has been constructed for the better forecast of output responses. It has been found that the R2 for almost each response measure is greater than 0.99 which shows the close relationship among the predicted and the experimental values. Moreover, the respective RMSE magnitudes are lower, which is in the favour that ANN has better predict the values and predict the close relationship between the experimental and predict values. The values given by the ANN models for different response measures for RMSE are within the desired range for the EDM setup.

-

Multi-response optimization has been performed through the NSGA-II for each response measure. It has been found that the NSGA-II has recorded the better results for all the response measures. The magnitudes of MRRCT, SRCT, and SECCT obtained by multi-response optimization are 64.82%, 27.45%, and 46.60% are better than the values obtained by un-optimized settings of CT brass electrodes. However, the optimal magnitudes of processing parameters are IP = 24.85 A, SV = 2.18 V, PON = 119.11 µs, and CP = 1.05 g/100 ml.

Data availability

All data analysed during this study is included in this published article.

Abbreviations

- Aluminium 6061:

-

Al6061

- KO:

-

Kerosene oil

- EWR:

-

Electrode Wear Rate

- SR:

-

Surface Roughness

- NT:

-

Non Treated

- IP :

-

Peak Current

- PON :

-

Pulse On Time

- RLT:

-

Recast Layer Thickness

- CCD:

-

Central Composite Design

- SEM:

-

Scanning Electron Microscopy

- ANOVA:

-

Analysis of Variance

- EDM:

-

Electric Discharge Machining

- DI:

-

Deionized water/dielectric

- OC:

-

Overcut

- MRR:

-

Material Removal Rate

- CT:

-

Cryogenic Treatment

- CP :

-

Powder Concentration

- SV :

-

Spark Voltage

- RSM:

-

Response Surface Methodology

- R2 :

-

Coefficient of Determination

- IPCC:

-

Intergovernmental Panel on Climate Change

- EBPTA:

-

Error Back Propagation Training Algorithm

References

Yoo, S. C. et al. Enhanced mechanical and wear properties of Al6061 alloy nanocomposite reinforced by CNT-template-grown core–shell CNT/SiC nanotubes. Sci. Rep. 10, 12896. https://doi.org/10.1038/s41598-020-69341-z (2020).

Samuel, A. U., Araoyinbo, A. O., Elewa, R. R. & Biodun, M. B. Effect of Machining of Aluminium Alloys with Emphasis on Aluminium 6061 Alloy – A Review. IOP Conference Series: Materials Science and Engineering 1107:012157. (2021). https://doi.org/10.1088/1757-899X/1107/1/012157

Zaidi, S. R. et al. Statistical Analysis of Machining Parameters on Burr Formation, Surface Roughness and Energy Consumption during Milling of Aluminium Alloy Al 6061-T6. Materials. 15, 8065. https://doi.org/10.3390/ma15228065 (2022).

Hassan, A. et al. Machinability investigation in electric discharge machining of carbon fiber reinforced composites for aerospace applications. Polym. Compos. 43, 7773–7788. https://doi.org/10.1002/pc.26878 (2022).

Akıncıoğlu, S. & TAGUCHI OPTIMIZATION OF MULTIPLE PERFORMANCE CHARACTERISTICS IN THE ELECTRICAL DISCHARGE MACHINING OF THE TIGR2. FU Mech. Eng. 20:237. https://doi.org/10.22190/FUME201230028A (2022).

Papazoglou, E. L., Karmiris-Obratański, P., Leszczyńska-Madej, B. & Markopoulos, A. P. A study on Electrical Discharge Machining of Titanium Grade2 with experimental and theoretical analysis. Sci. Rep. 11, 8971. https://doi.org/10.1038/s41598-021-88534-8 (2021).

Nieslony, P. et al. Relationship between energy consumption and surface integrity aspects in electrical discharge machining of hot work die steel. Sustainable Mater. Technol. 36, e00623. https://doi.org/10.1016/j.susmat.2023.e00623 (2023).

Gouda, D. et al. Recently evaluated Electrical Discharge Machining (EDM) process performances: A research perspective. Materials Today: Proceedings 44:2087–2092. (2021). https://doi.org/10.1016/j.matpr.2020.12.180

Rathod, R., Kamble, D. & Ambhore, N. Performance evaluation of electric discharge machining of titanium alloy-a review. J. Eng. Appl. Sci. 69, 64. https://doi.org/10.1186/s44147-022-00118-z (2022).

Seshaiah, S. et al. Optimization on material removal rate and surface roughness of Stainless Steel 304 Wire Cut EDM by Response Surface Methodology. Adv. Mater. Sci. Eng. 2022, 1–10. https://doi.org/10.1155/2022/6022550 (2022).

Jampana, V. N. R., Ramana Rao, P. S. V. & Kumar, A. Bi-objective optimization of process parameters in Electric Discharge Machining of SS630 using Grey Relation Analysis. J. Nanomaterials. 2022, 1–11. https://doi.org/10.1155/2022/1165750 (2022).

Mohije, R., Titre, H., Gohil, V. & Babruwan Meshram, D. A study in EDM electrode manufacturing using additive manufacturing. Materials Today: Proceedings. (2023). https://doi.org/10.1016/j.matpr.2023.01.044

Hassan, S. et al. Parametric Analysis and Multi-objective Optimization for Machining Complex Features on D2 and DC53 steels for Tooling Applications. J. Materi Eng. Perform. https://doi.org/10.1007/s11665-024-09828-2 (2024).

Sari, M. M., Noordin, M. Y. & Brusa, E. Evaluating the electrical discharge machining (EDM) parameters with using carbon nanotubes. IOP Conference Series: Materials Science and Engineering 40:012019. (2012). https://doi.org/10.1088/1757-899X/40/1/012019

Ishfaq, K. et al. A systematic study to achieve cleaner and sustainable manufacturing process by using bio-degradable dielectrics. Sustainable Mater. Technol. 37, e00685. https://doi.org/10.1016/j.susmat.2023.e00685 (2023).

Dzulkifli, N. F., Mamat, A. & Choudhury, I. A. The potential of Water-In-Oil Emulsion of Canola Oil as Dielectric Fluid for EDM process. J. Adv. Res. Fluid Mech. Therm. Sci. 72, 129–141. https://doi.org/10.37934/arfmts.72.2.129141 (2020).

Umar Farooq, M. et al. On the Investigation of Surface Integrity of Ti6Al4V ELI Using Si-Mixed Electric Discharge Machining. Materials 13(7), 1549. https://doi.org/10.3390/ma13071549

Muttamara, A. & Kanchanomai, C. Effect of Carbon in the Dielectric Fluid and Workpieces on the characteristics of Recast Layers Machined by Electrical Discharge Machining. Metall. Mater. Trans. A. 47, 3248–3255. https://doi.org/10.1007/s11661-016-3452-4 (2016).

Ming, W. et al. Research on EDM Performance of Renewable Dielectrics under Different Electrodes for Machining SKD11. Crystals 12:291. (2022). https://doi.org/10.3390/cryst12020291

Tönshoff, H. K., Egger, R. & Klocke, F. Environmental and Safety aspects of Electrophysical and Electrochemical processes. CIRP Ann. 45, 553–568. https://doi.org/10.1016/S0007-8506(07)60510-1 (1996).

Al-Amin, M. et al. Powder mixed-EDM for potential biomedical applications: a critical review. Mater. Manuf. Processes. 35, 1789–1811. https://doi.org/10.1080/10426914.2020.1779939 (2020).

Ishfaq, K., Farooq, M. U. & Pruncu, C. I. Reducing the geometrical machining errors incurred during die repair and maintenance through electric discharge machining (EDM). Int. J. Adv. Manuf. Technol. 117, 3153–3168. https://doi.org/10.1007/s00170-021-07846-1 (2021).

Talla, G., Gangopadhayay, S. & Biswas, C. State of the art in powder-mixed electric discharge machining: A review. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture 231:2511–2526. (2017). https://doi.org/10.1177/0954405416634265

Baroi, B. K. & Jagadish, Patowari, P. K. Effect of boric acid in powder mixed EDM of Ti-6al-4V ELI. Materials and Manufacturing Processes 1–14. (2023). https://doi.org/10.1080/10426914.2023.2195907

Jampana, V. N. R., Ramana Rao, P. S. V. & Sampathkumar, A. Experimental and thermal investigation on powder mixed EDM using FEM and Artificial neural networks. Adv. Mater. Sci. Eng. 2021, 1–12. https://doi.org/10.1155/2021/8138294 (2021).

Sulakhe, V. N. et al. Influence of powder-mixed dielectric on MRR and TWR in EDM process. In: Proceedings of the 1st International Conference on Mechanical and Materials Science Engineering. AIP Conference Proceedings, Maharashtra, India, p 020021 (2018).

Reddy, V. V., Valli, P. M., Kumar, A. & Reddy, C. S. Multi-objective optimization of electrical discharge machining of PH17-4 stainless steel with surfactant-mixed and graphite powder–mixed dielectric using Taguchi-data envelopment analysis–based ranking method. Proc. Institution Mech. Eng. Part. B: J. Eng. Manuf. 229, 487–494. https://doi.org/10.1177/0954405414530904 (2015).

Chaudhari, R. et al. Multi-response optimization of Al2O3 nanopowder-mixed Wire Electrical discharge machining process parameters of Nitinol shape memory Alloy. Materials. 15, 2018. https://doi.org/10.3390/ma15062018 (2022).

Hosni, N. A. J. & Lajis, M. A. Multi-response optimization of the machining characteristics in electrical discharge machining (EDM) using span-20 surfactant and chromium (cr) powder mixed. Materialwiss. Werkstofftech. 50, 329–335. https://doi.org/10.1002/mawe.201800204 (2019).

Abbas, M. A. et al. Influence of additive materials on the roughness of AISI D2 steel in electrical discharge machining (EDM) environment. Materialwiss. Werkstofftech. 51, 719–724. https://doi.org/10.1002/mawe.201900243 (2020).

Kolli, M. & Kumar, A. Surfactant and graphite powder–assisted electrical discharge machining of titanium alloy. Proc. Institution Mech. Eng. Part. B: J. Eng. Manuf. 231, 641–657. https://doi.org/10.1177/0954405415579019 (2017).

Paswan, K., Pramanik, A. & Chattopadhyaya, S. Machining performance of Inconel 718 using graphene nanofluid in EDM. Mater. Manuf. Processes. 35, 33–42. https://doi.org/10.1080/10426914.2020.1711924 (2020).

Harsha, S. & Dasharath, S. M. Effect of cryogenic heat treatment & ageing on ultra fine grained aluminium–lithium alloy- A review. Materials Today: Proceedings 45:338–348. (2021). https://doi.org/10.1016/j.matpr.2020.10.1009

Dong, N., Sun, L., Ma, H. & Jin, P. Effects of cryogenic treatment on microstructures and mechanical properties of Mg-2Nd-4Zn alloy. Mater. Lett. 305, 130699. https://doi.org/10.1016/j.matlet.2021.130699 (2021).

Choudhary, R., Garg, H., Prasad, M. & Kumar, D. Effect of Cryogenic Treatment of Tool Electrode on the Machining Performance and Surface Finish during Electrical Discharge Machining of Hastelloy C-4. Mater. Today: Proc. 4, 1158–1166. https://doi.org/10.1016/j.matpr.2017.01.132 (2017).

Kumar, A. & Sharma, R. Multi-response optimization of magnetic field assisted EDM through desirability function using response surface methodology. J. Mech. Behav. Mater. 29, 19–35. https://doi.org/10.1515/jmbm-2020-0003 (2020).

Meena, V. K., Azad, M. S., Singh, S. & Singh, N. Micro-EDM multiple parameter optimization for cp titanium. Int. J. Adv. Manuf. Technol. 89, 897–904. https://doi.org/10.1007/s00170-016-9130-2 (2017).

Ramaswamy, A. & Perumal, A. V. Multi-objective optimization of drilling EDM process parameters of LM13 Al alloy–10ZrB2–5TiC hybrid composite using RSM. J. Braz Soc. Mech. Sci. Eng. 42, 432. https://doi.org/10.1007/s40430-020-02518-9 (2020).

Sana, M. et al. Machine learning for multi-dimensional performance optimization and predictive modelling of nanopowder-mixed electric discharge machining (EDM). Int. J. Adv. Manuf. Technol. https://doi.org/10.1007/s00170-024-13023-x (2024).

Kassem, M. G. A., Ahmed, A-M-M., Abdel-Rahman, H. H. & Moustafa, A. H. E. Use of Span 80 and tween 80 for blending gasoline and alcohol in spark ignition engines. Energy Rep. 5, 221–230. https://doi.org/10.1016/j.egyr.2019.01.009 (2019).

Mohanty, C. P., Satpathy, M. P., Mahapatra, S. S. & Singh, M. R. Optimization of cryo-treated EDM variables using TOPSIS-based TLBO algorithm. Sādhanā. 43, 51. https://doi.org/10.1007/s12046-018-0829-7 (2018).

Hasçalık, A. & Çaydaş, U. Electrical discharge machining of titanium alloy (Ti–6Al–4V). Appl. Surf. Sci. 253, 9007–9016. https://doi.org/10.1016/j.apsusc.2007.05.031 (2007).

Ali, M. A. et al. Enhancing High-Speed EDM Performance of Hybrid Aluminium Matrix Composite by Genetic Algorithm Integrated Neural Network Optimization (Journal of Materials Research and Technology, 2024).

Sana, M., Khan, A., Farooq, M. U. & Anwar, S. Artificial neural networks-based modelling of effects of cryogenic electrode treatment, nano-powder, and surfactant-mixed dielectrics on wear performance and dimensional errors on superalloy machining. J. Braz Soc. Mech. Sci. Eng. 46, 539. https://doi.org/10.1007/s40430-024-05100-9 (2024).

Sana, M., Farooq, M. U., Anwar, S. & Haber, R. Predictive modelling framework on the basis of artificial neural network: a case of nano-powder mixed electric discharge machining. Heliyon e22508. (2023). https://doi.org/10.1016/j.heliyon.2023.e22508

Ehsan S, Ali MA, Khan SA, et al. Understanding the effects of cutting conditions on vibrations, surface integrity, machining temperature and tool wear mechanisms in end milling of AISI D2 Steel. Tribology International 198, 109894. https://doi.org/10.1016/j.triboint.2024.109894 (2024)

Asif, N., Saleem, M. Q. & Farooq, M. U. Performance evaluation of surfactant mixed dielectric and process optimization for electrical discharge machining of titanium alloy Ti6Al4V. CIRP J. Manufact. Sci. Technol. 43, 42–56 (2023).

Sana, M. et al. Sustainable electric discharge machining using alumina-mixed deionized water as dielectric: process modelling by artificial neural networks underpinning net-zero from industry. J. Clean. Prod. 441, 140926. https://doi.org/10.1016/j.jclepro.2024.140926 (2024).

Krey, V. et al. Annex 2 - Metrics and Methodology (Cambridge University Press, 2014).

Suvarna, M. et al. Predicting biodiesel properties and its optimal fatty acid profile via explainable machine learning. Renew. Energy. 189, 245–258. https://doi.org/10.1016/j.renene.2022.02.124 (2022).

Chang, Y., Bouzarkouna, Z. & Devegowda, D. Multi-objective optimization for rapid and robust optimal oilfield development under geological uncertainty. Comput. Geosci. 19, 933–950. https://doi.org/10.1007/s10596-015-9507-6 (2015).

Acknowledgements

The authors acknowledge Researchers Supporting Project number (RSPD2025R685), King Saud University, Riyadh, Saudi Arabia. Authors wish also to thank the projects “Self-reconfiguration for Industrial Cyber-Physical Systems based on digital twins and Artificial Intelligence. Methods and application in Industry 4.0 pilot line (SELFRECO)”, Spain, grant ID PID2021-127763OB-100 supported by MICINN and NextGenerationEU/PRTR and the European Project GA 101135707 “Multi-Modal and Multi-Aspect Holistic Human-Robot Interaction (FORTIS)”. Authors also acknowledge the lab development works carried out during 2019-2020 at Department of Industrial and Manufacturing Engineering, University of Engineering and Technology Lahore. The authors also acknowledge the use of ChatGPT by OpenAI for enhancing the clarity and readability of the manuscript.

Author information

Authors and Affiliations

Contributions

Muhammad Sana: Conceptualization, Methodology, Software, Validation, Data curation, Formal analysis, Writing – original draft, Writing– review & editing, Project administration, Supervision. Muhammad Asad: Methodology, Visualization, Writing – original draft, Writing – review & editing. MuhammadUmar Farooq: Methodology, Visualization, Investigation, Writing – original draft, Writing – review & editing, Formal analysis. Mehdi Tlija: Validation, Writing – review &editing, Funding acquisition. Rodolfo Haber: Writing – review & editing, Funding acquisition.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sana, M., Asad, M., Farooq, M.U. et al. Sustainability metrics targeted optimization and electric discharge process modelling by neural networks. Sci Rep 15, 3375 (2025). https://doi.org/10.1038/s41598-024-78883-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-78883-5

Keywords

This article is cited by

-

Machinability analysis in wire-EDM of cryogenically treated Ti6Al4V alloy and multi-objective optimization using MOAVOA and MOGA

Scientific Reports (2025)

-

Performance evaluation and multi-objective optimization of EDM parameters for Ti6Al4V using different tool electrodes

Scientific Reports (2025)

-

EDM-based analysis of Fe-based shape memory alloys using Cu-W electrodes with multiple output optimization and microstructural validation

Scientific Reports (2025)

-

A state-of-the-art review of soft computing-based monitoring and control in the machining of hard alloys

Discover Applied Sciences (2025)

-

A comprehensive review on powder mixed electrical discharge machining: advances in dielectric enhancement and machining efficiency

Discover Applied Sciences (2025)