Abstract

Internet of Things (IoT) technologies present transformative opportunities through connectivity of intelligent devices, environmental sensors, and integrated management systems. This study aims to investigate the benefits and impact of IoT implementation on construction sites by analyzing relationships between key factors and outcomes for safety and efficiency. Hypotheses were developed proposing positive correlations between each factor and effective IoT adoption on construction sites. Structural equation modeling analysis on survey data from construction professionals and site reports strongly validated the research hypotheses. Positive path coefficients and high statistical significance confirmed environmental monitoring (0.38), equipment management (0.343), predictive analytics and maintenance (0.222) and safety monitoring (0.369) as crucial enablers for successful IoT integration leading to safer and more productive construction operations. The findings highlight imperative focus areas and provide actionable insights for construction stakeholders on strategies to effectively leverage IoT capabilities.

Similar content being viewed by others

Introduction

The dynamic construction industry constantly seeks to improve operational efficiency and enhance safety in hazardous work environments1,2. Recent advances on the Internet of Things (IoT) enable connectivity between intelligent devices, sensors, and systems through wireless networks. Implementation of IoT technologies presents an unprecedented opportunity to introduce data-driven real-time monitoring and decision-making onto construction sites3,4. This integrated approach has the potential to revolutionize safety practices and unlock significant productivity gains on construction projects5,6. Early case studies demonstrate the transformative impact IoT can have. Predictive maintenance powered by equipment sensor data has reduced downtime incidents by 25–30% and improved asset utilization by 10–15%7,8. Similarly, wearable safety monitoring systems for workers have correlated with 40% reductions in accidents and injuries across multiple sites9,10. Environmental sensing and analysis of air quality, noise levels and other hazards have shown a 15% drop in work-related illnesses, directly contributing to safer conditions11,12. Despite the clear benefits, comprehensive studies examining large-scale IoT implementation specifically for construction sites remain limited. Research has predominantly been fragmented across application areas without holistic understanding of adoption drivers, challenges and best practices contextualized for the unique requirements of the construction industry. In particular, safety improvements represent one of the greatest untapped opportunities, as construction remains one of the most hazardous sectors globally13,14. Existing literature lacks in-depth examination of how emerging IoT technologies like wearables, real-time monitoring systems, and wireless sensor networks can enhance identification and mitigation of worksite hazards to reduce incidents and near-misses15,16. The proper implementation of IoT technologies has immense transformative potential for construction projects. However, real-world deployments at scale remain nascent. There is a pressing need for rigorous academic research and industry collaboration to develop effective strategies and best practices tailored to construction’s unique operating environment17,18. While IoT adoption has been transformative across many industries, construction projects continue to face challenges like cost and schedule overruns, resource wastage, and poor safety records4,19. Comprehensive data-driven solutions enabled by IoT integration hold immense potential to optimize construction performance through real-time monitoring, predictive analytics, and automated workflows16,20. However, more research is critically needed to understand how IoT technologies can be most effectively leveraged for construction site management. Key untapped opportunities exist in using IoT systems to realize significant cost savings, radically improve productivity rates, and dramatically reduce project timelines21,22. This necessitates in-depth investigation of IoT use cases, benefits quantification, implementation strategies, and impact assessment to inform decision-making in construction firms23,24. The aim of this present research study is to provide valuable and actionable insights for the industry by comprehensively analyzing the state of IoT adoption, evaluating demonstrated results on productivity and safety metrics, identifying potential barriers and risks, as well as assessing the business case and environmental impact. Focusing on construction activities in the developing economy context of Pakistan—this research explores the critical yet under-studied area of how pervasive IoT integration affects safety standards and operational efficiency metrics on building project sites. The Mirpur region of Pakistan was selected for this study due to its significant construction activity and rapid urban development, making it an ideal location for examining the impact of IoT on construction safety and efficiency. The region’s diverse construction projects and varied site conditions provide a comprehensive setting for analyzing IoT implementation. Additionally, focusing on a developing region like Mirpur offers valuable insights into the challenges and opportunities of IoT adoption in contexts with similar economic and infrastructural conditions. This makes the findings more relevant and applicable to other developing regions facing analogous challenges. While interest in smart construction is rapidly growing, current deployments have been limited to developing regions that can benefit tremendously from catalytic productivity and safety improvements. Through a rigorous structural equation modelling approach, this study aims to bridge the knowledge gap and establish an analytical framework for understanding the complex interrelationships between IoT system usage, resulting safety outcomes, and operating performance impacts across construction processes.

The Introduction provides background and context for the study, including the selection of the Mirpur region. The Literature Review covers previous research on IoT in construction and sets the stage for the current study. The Methodology section details the research design, data collection, and analysis methods. The Results section presents the findings of the study, followed by the Discussion, which interprets these findings in the context of existing literature. The Conclusion summarizes the key insights and implications of the study, and the References list all sources cited in the manuscript.

Literature review

The construction industry has been slow to adopt new technologies compared to other fields, but the advent of the Internet of Things (IoT) is offering new opportunities to transform traditional construction sites in terms of safety, efficiency, sustainability, and management25,26. Recent literature has explored various promising applications of IoT across all stages of construction projects24,27. Smart helmets equipped with sensors, cameras and communication systems can continuously monitor workers, providing biometric data to assess health and fatigue levels in real-time28,29. They also enable improved safety by detecting potential hazards in the worker’s line of sight and communicating warnings or shutdown commands to vehicles and equipment in the vicinity. Exoskeletons and other body-worn devices provide muscular strength augmentation and injury prevention while gathering data on biomechanics, productivity, and training needs30,31. Handheld devices and augmented reality (AR) headsets allow contextual data gathering and access to 3D visualization overlaid on the workspace, improving work quality, training, and collaboration32,33. Location tracking of vehicles and equipment via GPS and sensors has also seen significant IoT integration on construction sites. Real-time positioning facilitates coordination of vehicle movements, significantly reducing the risk of collisions and resulting injuries, fatalities, and costs34,35. Sensor data enables optimized routing, scheduling, and utilization of machinery. Predictive maintenance reduces equipment downtime and costs through continuous monitoring of usage, vibrations, and other diagnostic metrics36,37. Automated tracking systems can also integrate with building information modeling (BIM) and schedule data for advanced analytics, providing rich insights into fleet management, bottlenecks, and process improvements38,39.

Recent literature highlights the immense potential of IoT technologies to transform safety, productivity, sustainability, compliance, and management on construction sites10,40. The expanded table provides a comprehensive overview of the diverse range of IoT applications and their benefits, while also noting key challenges that must be overcome as shown in Table 1. A major application area is monitoring worker safety and productivity through wearables and handheld devices41,42. These provide real-time visibility into health metrics, fatigue levels, training needs, work quality and collaboration effectiveness. Location tracking of both workers and equipment enables better coordination on congested sites, reduced accidents, and optimized workflows. Sensors on equipment and vehicles allow usage monitoring for preventive maintenance, routing and dispatch optimization, and reduction in collisions43,44. Thermal cameras, lidar and other structural health monitoring technologies facilitate early detection of cracks, deformation, and failures. Gas detection and air quality sensors ensure compliance with safety regulations and help prevent explosions, leakage incidents or worker health impacts from dust and emissions. Noise monitoring enables noise level management and hearing loss prevention42,45. Weather tracking allows proactive planning for work disruptions. Scanners, photogrammetry, and computer vision techniques validate construction quality and progress against specifications22,46. Data security and integration technologies are critical enablers, allowing aggregation of data across diverse systems for unified insights while protecting against cyberthreats39,47. Change management and training must also be addressed to drive adoption across the workforce. Compliance sensors ease regulatory reporting burden in areas like sustainability and worker exposures35,48. Technologies for materials tracking and automated reporting of progress metrics offer further opportunities to enhance construction site operations49,50. While the technologies hold great promise, challenges remain in areas like reliability, interoperability, power, calibration, interference, cost, manual oversight needs and technology limitations for specific use cases. However, the convergence of technologies like cloud computing, 5G connectivity, AI/ML analytics and robotic automation will help overcome many of these barriers18,51.

Environmental monitoring using IoT-enabled sensors allows construction firms to ensure worksite safety, regulatory compliance, and achievement of sustainability targets92,93. Air quality sensors can detect hazardous gases, while particulate matter monitoring protects workers from dust inhalation risks94,95. Acoustic sensors facilitate noise level management to prevent hearing loss. Thermal imaging and other camera systems enable remote structural health monitoring and early detection of failures or weaknesses96. Meteorological sensors and forecast data integration allows for proactive planning and mitigation of weather disruptions. While the literature highlights the challenges of technical complexity, interoperability, cybersecurity and change management with large-scale IoT implementation, it is clear that IoT adoption has become essential for construction firms to gain operational efficiency, comply with regulations, achieve sustainability goals, and maintain a competitive advantage97. The consensus view is that the benefits far outweigh the costs, and construction companies that fail to innovate with IoT technologies will lag behind those leveraging real-time data and analytics to optimize safety, productivity, quality, and resilience on their sites98.

In conclusion, the literature comprehensively highlights the tremendous potential of Internet of Things technologies to transform safety, productivity, compliance, sustainability, and management on construction sites. From wearables for workers to equipment sensors, air quality monitors to structural inspection drones, the possibilities are immense. While challenges like costs, interoperability, cybersecurity, and technology limitations exist, the trends point toward IoT becoming an essential enabler for construction firms to gain competitive advantage through real-time visibility, data-driven insights, and cross-system integration. Companies that fail to sufficiently invest in IoT risk falling behind industry leaders who are aggressively leveraging the power of data. Construction enterprises must therefore focus on building robust IoT infrastructure and analytics capabilities to meet the demands of modern infrastructure projects. The future points toward smarter, safer, and more efficient construction sites enabled by the proliferation of connected technologies.

Research framework

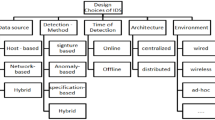

This study involved three major phases. In the first phase, an in-depth literature review was conducted to identify the factors indicating the application of IoT for the safety and efficiency of construction sites to make them smart sites29. In the second phase, the quantitative analysis and the hypothesis are developed. In the last stage, phase depth, SEM analysis is carried out to verify the hypothesis of the studies. The participants in this study were construction professionals working in various roles on site, including project managers, site engineers, safety officers, and labor supervisors. Field professionals who distributed the survey included experienced site supervisors and project managers who were trained to ensure impartiality during the survey process. To mitigate any potential bias, surveys were administered in a confidential manner, ensuring that respondents felt no pressure or influence from their supervisors. The anonymity of responses was emphasized to the participants to reduce the likelihood of response bias. Figure 1 shows the complete theme of the study. Partial Least Squares Structural Equation Modeling (PLS-SEM) was chosen due to its suitability for exploratory research and its ability to handle complex models with small to medium sample sizes effectively. While our size is adequate, PLS-SEM provides robustness against non-normal data and is preferred for its predictive accuracy and flexibility in handling formative constructs, which are key aspects of this study. The questions in the questionnaire were developed based on an extensive literature review and consultation with industry experts. Key factors and indicators relevant to IoT implementation in construction were identified from prior studies, and the questions were designed to capture these variables effectively. The questionnaire was pre-tested with a small group of professionals to ensure clarity and relevance.

Identification of factors

A systematic literature review was conducted to identify key factors for Internet of Things (IoT) implementation on construction sites. The Scopus database was searched using the keywords “IoT” AND “Construction” AND “Sites” OR “Implementation” OR “Safety” OR “Efficiency” in article titles, abstracts, or keywords. This broad search returned 1,618 documents initially. The findings were filtered to only contain English-language documents from 2019 through February 2023 that were categorized as technical papers or review articles in Scopus, in order to concentrate on recent, high-quality publications. This narrowed the results down to 605 relevant documents. Analysis of publication dates showed steady growth in research on this topic. In 2022, 163 papers were published, up from 149 in 2023 and 142 in 2021 as shown in Fig. 2.

The most publications originated from China (212), India (73), United States (47) and United Kingdom (35), indicating significant research interest in these countries as shown in Fig. 3. VOS viewer software was used to visualize bibliometric networks in order to identify technological application areas and analyze keyword usage. Clusters centered on important subjects such wireless sensors, asset tracking, safety, augmented reality, sustainability, and construction productivity were identified by keyword co-occurrence analysis.

This provided insights into research domains and guided factor selection. Full text review of the filtered literature corroborated the key factors derived from the visualized keyword analysis. The most prevalent factor categories were worker-centered technologies like wearables, handhelds, and exoskeletons to improve safety and productivity. Location tracking of workers, vehicles and equipment was another key focus area in the papers. Environmental monitoring, structural health monitoring, materials management, and data analytics also featured prominently as shown in Fig. 4.

The structured methodology enabled effective identification of a large set of candidate documents for review. Filtration criteria removed low-quality publications and narrowed the focus on construction sites. The bibliometric analysis provided visual guidance to focus the review on papers discussing key factors aligned with major application categories for IoT on sites. This rigorous, transparent, and replicable approach demonstrates systematic literature analysis to derive factors from evidence in the scholarly domain.

The implementation of IoT technology on construction sites could potentially yield several benefits, including enhanced employee welfare, increased adherence to safety regulations, improved renovation scheduling, enhanced device functionality, and ultimately more streamlined operations. The Internet of Things has enabled access to vast quantities of data from construction sites. Heavy equipment that was formerly quiet is now able to open in real time, enabling predictive maintenance plans to prevent issues before they arise. Ensuring worker wellness and regulatory compliance, data is also changing the environment. Wearable technology even makes the human body a source of valuable data, enabling personalized work schedules and tiredness tracking13,14. Data analysis yields insights that improve resource allocation and construction processes15,16. Table 2 also indicates that implementing IoT systems facilitates the administration of energy consumption and enhances operational efficiency. Employee monitoring in real-time ensures safety and expedites emergency response. Integration of IoT into construction sites results in enhanced safety, productivity, and cost-effectiveness.

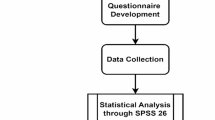

Data collection

Pakistan’s Mirpur region was the focus of a quantitative investigation into the impact of IoT implementation on construction sites. Multiple studies have shown that sample sizes of around 100 can yield reliable results when the sample is representative, and the data is well-analyzed. For instance, studies by Westland99 demonstrate that sample sizes in the range of 100–150 are sufficient for SEM when the data quality is high, and the model is not overly complex100. These studies are applicable to our case as our SEM model is straightforward and the data collected is of high quality. The 188 survey respondents provided 114 valid responses, which were considered for data analysis. Field professionals sometimes delivered the survey by hand in addition to via email3,4. The response rate for the current research was around 60.6%. The survey employed a Likert scale consisting of five points to assess the degree to which respondents concurred or disapproved of specific record-accumulating areas. This scale provided a well-established framework for evaluating the perspectives and opinions of participants regarding the benefits of deploying IoT on production websites. Multiple studies in analogous contexts have demonstrated that effects originating from sample sizes as small as one hundred can still be genuine and precise. It is determined that a sample size of 114 respondents is adequate for the purposes of this investigation. Furthermore, by focusing on the Mirpur region, the statistics become more precise and relevant, thereby enhancing our understanding of the implementation of IoT in the construction sector.

Exploratory factor analysis (EFA) analysis for hypothesis development

The variables identified in the literature were classified into four groups using an exploratory factor analysis (EFA), and hypotheses were developed for this analysis. The EFA analysis made it possible to identify latent patterns and additives within the data and classify the variables according to the characteristics they shared. The EFA evaluation has effectively categorized variables into distinct classes, providing a systematic framework for developing research inquiries and hypotheses. This approach facilitated the elucidation of the interconnections between the variables and provided direction for the subsequent assessment and interpretation of the study’s findings. For EFA evaluation, the subsequent equation is applied.

Where X: variables or signs that were noticed, λ: Factor loadings: the strength of the connection between latent factors and observable variables, Latent variables (basic ideas), E: The variance or error connected to every variable that was observed. The formula shows how the latent factors (LF) affect the observable variables (X) via factor loadings (FL), with the error term (E) taking care of any variation that cannot be explained.

PLS-SEM measurement model

The relationships between the variables of the study were analyzed using Partial Least Squares Structural Equation Modelling (PLS-SEM), which was implemented using the Smart PLS 4 software. Robust statistical methods, such as PLS-SEM, are optimal for examining intricate relationships with limited sample sizes while also facilitating comparisons of model sizes and structures. The investigation encompassed the assessment of both discriminant and convergent validity. The degree to which the signs (observed variables) of each latent construct (underlying element) converge and measure the same concept is convergent validity. In order to reach this conclusion, an analysis was conducted on the composite reliability (CR), average variance extracted (AVE), and indicator loadings for each construct. Determining exceptional convergent validity required indicator loadings to surpass the predetermined threshold, AVE values to exceed 0.5, and CR values to surpass 0.70.

Structural model analysis

Bootstrap resampling techniques were employed to examine the four research hypotheses during the structural model analysis. Determining the significance and direction of the relationships between the latent variables in the study model became the objective of this investigation. Utilizing the bootstrap system, the sample mean (M), standard deviation (STDEV), t-stats, p-values, and original sample (O) could be calculated. The bootstrap method generated a distribution of the path coefficients for each hypothesis through the iterative resampling of the statistics. Using this distribution, the actual sample coefficients (O) have been computed in order to determine the effect size. The calculation of the sample mean (M) and standard deviation (STDEV) was performed to assess the coefficients’ dispersion and significance. Q2 is a statistical metric employed in Partial Least Squares Structural Equation Modelling (PLS-SEM) to evaluate the capability of a research model to make predictions. The metric assesses the accuracy with which the model forecasts outcomes based on latent constructs, unbiased elements, or structured variables. The investigation of the four research hypotheses was conducted using bootstrap resampling techniques.

Results and analysis

Demographic details

Table 3 provides specifics on the categories, classifications, frequencies, and percentages of the respondents. According to profession, the respondents included quantity surveyors (6.9%), architects (9.1%), civil engineers (23.4%), M&E engineers (5.1%), project managers (14.3%), and others (6.9%). In terms of organization, the respondents represented Contractors (25.1%), Consultants (21.7%), and Clients (18.2%). In the construction business, 23.4% of respondents had no experience, 18.9% had, 11.4% had 11–15 years, 4.6% had 16–20 years, and 6.8% had more than 20 years. 61.7% of respondents said they were knowledgeable about digital technologies (IoT), while 3.4% said they weren’t/may not be. The table offers a thorough analysis of respondent characteristics, which will facilitate understanding of the study’s conclusions and ramifications.

EFA analysis

The EFA analysis was conducted to investigate the variables’ underlying factors, as shown in Table 4. The analysis revealed that the eigenvalues for the components were greater than 1, indicating that these components account for a considerable portion of the data’s variance24,26. Loading values greater than 0.60 were deemed significant, indicating a robust relationship between the variables and their respective components27,28.

The variables were labelled IOT-SE01, IOT-SE02, IOT-SE03, etc., to represent specific items related to the construction industry IoT focus of the study. Variables with loading values below 0.60 were excluded from the analysis because they lacked a significant association with any component15,16. Principal Component Analysis was used for data extraction, which helps identify the underlying factors that explain the variance in the data14,18. Varimax with Kaiser Normalization was used as the rotation method, which aids in attaining simplified and more interpretable factor structures3,7. The EFA analysis revealed the presence of significant components and their respective variables while excluding one factor. Cronbach’s alpha values evaluated the internal consistency within each component, bolstering the analysis’s credibility.

Based on the results of the EFA and the classification of variables into four groups, four hypotheses concerning the significant relationships between these groups and the implementation of IoT on construction sites were formulated, which are described in Fig. 5.

-

H1: The relationship between environmental monitoring and the implementation of IoT on construction sites is substantial.

-

H2: The relationship between equipment management and the implementation of IoT on construction sites is substantial.

-

H3: There is a significant relationship between predictive analytics and maintenance and the implementation of IoT on construction sites.

-

H4: There is a significant relationship between safety monitoring and the implementation of IoT on construction sites.

PLS-SEM model development

Table 5 demonstrates the consistency and intensity of the relationships between the observed variables and their respective constructs, as determined by the convergent validity analysis. The variable IOT-SE12 has a high loading of 0.784 for the Safety Monitoring construct, indicating a significant relationship with this construct. This indicates that IOT-SE12 measures the intended construct effectively9,10. The VIF value 1.237 indicates minimal multicollinearity, indicating that the observed variables within this construct are distinct. The Safety Monitoring construct’s internal consistency is supported by a Cronbach Alpha (CA) value of 0.777, indicating high reliability5,22. It is further supported by the Composite Reliability (CR) score of 0.779% that the observed variables in this construct are reliable. The Safety Monitoring construct captures a significant amount of variation in the observed variables, as shown by the Average variation Extracted (AVE) value of 0.54, showing sufficient convergent validity6,21.

The findings of this study indicate that the variables comprising the Safety Monitoring construct consistently recreate consistent relationships and precisely measure the intended construct, thereby contributing to the convergent validity of the assemblages. The absence of HTMT ratios for the Environmental Monitoring construct in Table 6 HTMT ratios hinders the ability to discern how it differs from the other constructs. The fact that environmental tracking is discernible and separate from the other components of the study suggests that it possesses exceptional discriminant validity. A few overlaps between the opposite additives, Safety Monitoring (SMO), Predictive Analytics & Maintenance (PAM), and Equipment Management (EMA), are indicated by the HTMT ratios. It is crucial to remember that the HTMT ratios provide sufficient discriminant validity among those concepts, even if they fall below the critical 0.85 threshold.

Even though there is some overlap between the constructs, the HTMT ratios indicate that the constructs in your study have adequate discriminant validity. This indicates that the constructs are sufficiently distinct to be regarded as separate and independent, supporting the study’s measurement model’s reliability4,19.

The Fornell-Larcker criterion results in Table 7 support the discriminant validity of the measurement model’s constructs. The square root of the average variance extracted (AVE) for each construct is greater than the correlations with other constructs, indicating that the constructs are distinctive. Environmental Monitoring (EMO) demonstrates discriminant validity with an AVE square root 0.76, exceeding correlations with other constructs. This demonstrates that EMO differs from the other variables6,8. Equipment Management (EMA) partially satisfies the criterion because it has a higher correlation with Predictive Analytics & Maintenance (PAM) than with Safety Monitoring (SMO). However, additional analysis is required to establish the full validity of discrimination between EMA and SMO. With a square root of AVE of 0.902, Predictive Analytics & Maintenance (PAM) demonstrates discriminant validity, superseding correlations with other constructs. This demonstrates that PAM differs from the other variables9,21.

Table 8 indicating the cross-loading criterion was used to evaluate the discriminant validity of the measurement model’s variables. It investigates the correlations between each variable and its respective construct and the correlations between the variable and other constructs6,19. The variables are evaluated in the supplied table based on their cross-loadings with the constructs. To establish discriminant validity, a variable’s cross-loadings with its construct should be greater than those with other constructs5,8. The results indicate that most variables have higher cross-loadings with their respective constructs, providing evidence for discriminant validity. For instance, IOT-SE08 has a greater cross-loading with Environmental Monitoring (EMO) than other constructs. Similarly, IOT-SE13 has a greater cross-loading with Equipment Management (EMA), Predictive Analytics & Maintenance (PAM), and Safety Monitoring (SMO) than IOT-SE01 and IOT-SE05.

Most variables demonstrate discriminant validity based on the cross-loading criterion, as they exhibit higher cross-loadings with their respective constructs than other constructs.

Structural model development

A bootstrap analysis was conducted to assess the robustness and dependability of the study’s hypotheses, as shown in Table 9. To generate bootstrap samples, it was necessary to resample the data and calculate statistics for each sample repeatedly. The original sample (O), sample mean (M), standard deviation (STDEV), t-statistics, and p-values are provided to summarize the results of the bootstrap analysis21,22. These statistics aid in assessing the significance of the interrelationships between variables. The bootstrap analysis indicates that all hypotheses have reached statistical significance. The relatively large t-statistics for each hypothesis indicate a robust relationship between the independent and dependent variables6,8. Each hypothesis is reported with a p-value of 0, indicating a statistically significant relationship.

These results indicate that the study’s findings are reliable and consistent, as multiple bootstrap samples support them. The bootstrap analysis supports the hypotheses and strengthens the validity of the study’s conclusions. The predictive relevance analysis indicates that the model’s predictive power is moderate. The sum of squares explained (SSO) is 9056.000, indicating that the model accounts for this variation in IoT implementation for safety and efficiency. Table 10 shows the GOF indices for the structural model in addition to the Structural Model Output Standardized Estimates Path Diagram. These indices evaluate the model’s overall fit to the data, ensuring an accurate evaluation of the model’s applicability. The GFI, RMSEA, and Chisq Absolute Fit Indices, among others, all came within acceptable bounds, suggesting a satisfactory fit between the model and the data. The Incremental Fit Indices, such as the TLI and the CFI, which are both above the recommended values, also showed an appropriate fit with respect to the baseline model. The Parsimonious Fit Index, or Chi-square/Degrees of Freedom, or Chisq/df ratio, eventually fell below the recommended cutoff, indicating a modest and well-fitting model.

Figure 6 depicts the path loadings and associated statistical results for each of the study’s hypotheses. It demonstrates the intensity of the relationship between the independent variable the dependent variable (IoT implementation) and pertinent statistical measures. The path loadings are the coefficients that have been normalized to indicate the magnitude and direction of the relationship between the variables. These indices represent the influence of each independent variable on the dependent variable.

Figure 7 illustrates the T-statistics for each hypothesis, which evaluate the significance of the relationship between the independent variables (EMO, EMA, PAM, and SMO) and the dependent variable (IoT implementation). T-statistics quantify the intensity of the relationship between variables, considering sample size and variance7,19. Higher T-statistics indicate a more significant and robust relationship. In this instance, the T-statistics for all four hypotheses (H1, H2, H3, and H4) are relatively substantial, indicating a robust and statistically significant relationship between the independent variables and IoT implementation.

Based on the T-statistics, we can conclude that the data validate the hypothesized relationships and that the independent variables significantly affect IoT implementation.

Discussion

The study examined four hypotheses regarding the relationships between various variables and the implementation of IoT for construction site safety and efficiency. Significant results supported all of the hypotheses. Focusing on the Mirpur region allows for a detailed and context-specific analysis of IoT implementation in construction, which enhances the precision and relevance of the data. The region’s active construction industry and unique challenges provide a rich dataset that reflects real-world conditions, making the findings highly applicable and actionable for similar developing regions. Figure 8 is framework is explaining the all the hypothesis with variables considering their effectiveness in terms of IoT for safety and efficiency in construction site operations.

The path coefficient for Hypothesis 1 (H1), which suggests a relationship between Environmental Monitoring (EMO) and IoT implementation, was 0.38. The original sample was analyzed, and the mean and standard deviation values were calculated accordingly. The T statistic value was 27.405, indicating a highly significant relationship8,10. The validity of Hypothesis 1 was supported by the finding that the P value was 0. Hypothesis 2 (H2)’s route coefficient, which postulated a connection between IoT adoption and Equipment Management (EMA), was 0.343. The statistical study, which included the mean, standard deviation, T statistic value of 32,318 and P value of 0, verified the significance of the link. The third hypothesis (H3) focused on the connection between IoT installation and Predictive Analytics & Maintenance (PAM). The positive correlation within reason is supported by the path coefficient of 0.222. Hypothesis H3 was substantiated by the T statistic of 7.69 and the P value less than 0.005. The fourth and ultimate hypothesis (H4) assessed the relationship between the deployment of IoT and Safety Monitoring (SMO). A significant and favorable correlation was identified through the utilization of the path coefficient of 0.369. The T statistic value of 25.848 and the P statistic value of 0 provided persuasive support for adopting H4. These facts illustrate the importance of every aspect pertaining to the implementation of the IoT regarding the overall efficiency and integrity of construction work sites. By analyzing critical connections, the significance of Environmental Monitoring, Equipment Management, Predictive Analytics & Maintenance, and Safety Monitoring to the successful adoption and utilization of the IoT era by the construction company is determined.

Conclusion

The objective of this investigation was to examine the correlations between various factors and the effectiveness and safety of construction sites utilizing the IoT. The results of the study, which demonstrated a strong correlation between the attributes and IoT adoption, provided support for all four hypotheses. Integrating IoT within a construction zone necessitates an emphasis on environmental monitoring, machine and equipment administration, predictive analytics and protection, and safety monitoring, as demonstrated by the results. The robust route loadings and statistical significance of T records indicate the strength of these interactions. Beneficiaries of these findings include construction professionals, job administrators, and safety stakeholders due to their practical implications. The study emphasizes the criticality of incorporating IoT generation into construction strategies to enhance operational efficiency and safety. Construction sites have the potential to leverage the IoT to enhance efficiency and mitigate risks through environmental monitoring, device management, predictive analytics-driven maintenance, and safety assurance. The studies contribute to the body of knowledge by substantiating the significance of those variables in the context of construction industry. It provides policymakers and practitioners with crucial insights regarding the critical factors that influence the effective implementation of the IoT era. Nonetheless, it is critical to acknowledge the limitations of the examination. The investigation employed a restricted geographic area and a modest sample size. To enhance the reliability of the findings, future research may wish to expand the scope of interest to include more geographical regions and increase the scale of the pattern. Additionally, qualitative research methods can be utilized to gain a more comprehensive understanding of the perspectives and experiences of construction professionals regarding the incorporation of IoT. This examination concludes by emphasizing the significance of environmental monitoring, equipment management, predictive analytics and security, and protection monitoring when utilizing IoT for construction and development efficiency and security. The results enhance the existing body of knowledge and provide practical suggestions for professionals in the field, thereby promoting the environmentally friendly incorporation of IoT technology within the construction site.

Data availability

All data generated or analysed during this study are included in this published article [and its supplementary information files].

References

Abualigah, L. et al. Revolutionizing sustainable supply chain management: a review of metaheuristics. Eng. Appl. Artif. Intell. 126, 106839 (2023).

Sajjad, M. et al. BIM-driven energy simulation and optimization for net-zero tall buildings: sustainable construction management. Front. Built Environ. 10, 1296817 (2024).

Abudayyeh, O. et al. An investigation of management’s commitment to construction safety. Int. J. Project Manage. 24(2), 167–174 (2006).

Rehman, S. K. U. et al. BIM adoption over the entire life cycle of a constructed asset and using ISO standards in Pakistan. in AIP Conference Proceedings. AIP Publishing. (2023).

Achouch, M. et al. On predictive maintenance in industry 4.0: overview, models, and challenges. Appl. Sci. 12(16), 8081 (2022).

Pan, X. et al. BIM adoption in sustainability, energy modelling and implementing using ISO 19650: a review. Ain Shams Eng. J. 15(1), 102252 (2024).

Afzal, M., Shafiq, M. T., Al, H. & Jassmi Improving construction safety with virtual-design construction technologies-a review. J. Inform. Technol. Constr. 26. (2021).

Musarat, M. A. et al. Automated monitoring innovations for efficient and safe construction practices. Results Eng. 22, 102057 (2024).

Ahmed, A. et al. Assessment of the renewable energy generation towards net-zero energy buildings: a review. Energy Build. 256, 111755 (2022).

Musarat, M. A. et al. A survey-based approach of framework development for improving the application of internet of things in the construction industry of Malaysia. Results Eng. p. 101823. (2024).

Alaloul, W. S. et al. Survey evaluation of Building Information Modelling (BIM) for Health and Safety in Building Construction projects in Malaysia. Sustainability. 15(6), 4899 (2023).

Althoey, F. et al. Influence of IoT Implementation on Resource Management in Construction. Heliyon, (2024).

Alawag, A. M. et al. The role of the total-quality-management (TQM) drivers in overcoming the challenges of implementing TQM in Industrialized-Building-System (IBS) projects in Malaysia: experts’ perspectives. Sustainability. 15(8), 6607 (2023).

Pan, X. et al. BIM adoption in sustainability, energy modelling and implementing using ISO 19650: a review. Ain Shams Eng. J. 102252, p (2023).

Alawag, A. M. et al. Critical success factors influencing total quality management in industrialised building system: a case of Malaysian construction industry. Ain Shams Eng. J. 14(2), 101877 (2023).

Maglad, A. M. et al. Bim-based energy analysis and optimization using insight 360 (case study). Case Stud. Constr. Mater. 18, pe01755 (2023).

Antony, J. et al. How does performance vary between early and late adopters of industry 4.0? A qualitative viewpoint. Int. J. Qual. Reliab. Manage. 40(1), 1–24 (2023).

Zhang, J. et al. BIM-based architectural analysis and optimization for construction 4.0 concept (a comparison). Ain Shams Eng. J. 14(6), 102110 (2023).

Aslam, B. et al. Comparison between Machine Learning and Bivariate Statistical Models for Groundwater Recharge Zones. (2023).

Atkinson, A. R. & Westall, R. The relationship between integrated design and construction and safety on construction projects. Constr. Manage. Econ. 28(9), 1007–1017 (2010).

Azamfirei, V., Psarommatis, F. & Lagrosen, Y. Application of automation for in-line quality inspection, a zero-defect manufacturing approach. J. Manuf. Syst. 67, 1–22 (2023).

Waqar, A. et al. BIM in green building: enhancing sustainability in the small construction project. Clean. Environ. Syst. p. 100149. (2023).

Baarimah, A. O. et al. Integration of building information modeling (BIM) and value engineering in construction projects: a bibliometric analysis. in 2021 Third International Sustainability and Resilience Conference: Climate Change. IEEE. (2021).

Abuhussain, M. A. et al. Integrating Building Information Modeling (BIM) for optimal lifecycle management of complex structures. in Structures. Elsevier. (2024).

Bado, M. F. et al. Digital twin for civil engineering systems: an exploratory review for distributed sensing updating. Sensors. 22(9), 3168 (2022).

Alotaibi, B. S. et al. Building information modeling (BIM) adoption for enhanced legal and contractual management in construction projects. Ain Shams Eng. J. 15(7), 102822 (2024).

Baghalzadeh Shishehgarkhaneh, M. et al. Internet of things (IoT), Building Information modeling (BIM), and Digital Twin (DT) in construction industry: a review, bibliometric, and network analysis. Buildings. 12(10), 1503 (2022).

Baghalzadeh Shishehgarkhaneh, M. et al. Application of classic and novel metaheuristic algorithms in a BIM-based resource tradeoff in dam projects. Smart Cities. 5(4), 1441–1464 (2022).

Waqar, A. et al. Impediments to the BIM-Based Safety Management Practices in Residential Construction Projectp. 100848 (Environmental Challenges, 2024).

Bakhoum, E. S. et al. Impact assessment of implementing virtual reality in the Egyptian construction industry. Ain Shams Eng. J. 14(6), 102184 (2023).

Waqar, A. et al. BIM-Driven Energy Simulation and optimization for net-zero tall buildings: sustainable construction management. Front. Built Environ. 10, 1296817 (2024).

Baxendale, T. & Jones, O. Construction design and management safety regulations in practice—progress on implementation. Int. J. Project Manage. 18(1), 33–40 (2000).

Aati, K. et al. Analysis of Road Traffic accidents in dense cities: Geotech Transport and ArcGIS. Transp. Eng. p. 100256. (2024).

Bena, R. M. et al. A Hybrid Quadratic Programming Framework for Real-Time Embedded Safety-Critical Control. in. IEEE International Conference on Robotics and Automation (ICRA). 2023. IEEE. (2023).

Waqar, A. et al. Integration of passive RFID for small-scale construction project management. Data Inform. Manage. 7(4), 100055 (2023).

Berawi, M. A., Miraj, P. & Naomi, F. Formulating smart integrated workspace concept to improve energy efficiency. in IOP Conference Series: Earth and Environmental Science. IOP Publishing. (2018).

Waqar, A. et al. Sustainable Leadership Practices in Construction: Building a Resilient Society. Environmental Challenges, p. 100841. (2024).

Berglund, E. Z. et al. Smart infrastructure: a vision for the role of the civil engineering profession in smart cities. J. Infrastruct. Syst. 26(2), 03120001 (2020).

Waqar, A. et al. Complexities for adopting 3D laser scanners in the AEC industry: structural equation modeling. Appl. Eng. Sci. 16, 100160 (2023).

Bharadiya, J. P. A comparative study of business intelligence and artificial intelligence with big data analytics. Am. J. Artif. Intell. 7(1), 24 (2023).

Bishay, P. L. et al. 3D-Printed Bio-inspired mechanisms for Bird-like morphing drones. Appl. Sci. 13(21), 11814 (2023).

Waqar, A., Khan, A. M. & Othman, I. Blockchain empowerment in construction supply chains: enhancing efficiency and sustainability for an infrastructure development. J. Infrastructure Intell. Resil. 3(1), 100065 (2024).

Boffino, C. C. et al. Fear of heights: cognitive performance and postural control. Eur. Arch. Psychiatry Clin. NeuroSci. 259, 114–119 (2009).

Waqar, A. et al. Limitations to the BIM-based safety management practices in residential construction project. Environ. Challenges. 14, 100848 (2024).

Boje, C. et al. Towards a semantic construction Digital Twin: directions for future research. Autom. Constr. 114, 103179 (2020).

Bown, C. P. China Bought none of the Extra $200 Billion of US Exports in Trump’s Trade deal8 (Peterson Institute for International Economics, 2022).

Chandramowleeswaran, G. et al. Implementation of Human Robot Interaction with Motion Planning and Control Parameters with Autonomous Systems in Industry 4.0. in. Second International Conference on Augmented Intelligence and Sustainable Systems (ICAISS). 2023. IEEE. (2023).

Chauhan, R., Ali, H. & Munawar, N. A. Building performance service through transformational leadership analysis, work stress and work motivation (empirical CASE study in stationery distributor companies). Dinasti Int. J. Educ. Manage. Social Sci. 1(1), 87–107 (2019).

Chaurey, S. et al. A review on the identification of total productive maintenance critical success factors for effective implementation in the manufacturing sector. J. Qual. Maintenance Eng. 29(1), 114–135 (2023).

Waqar, A. et al. Examining the impact of BIM implementation on external environment of AEC industry: a PEST analysis perspective. Developments Built Environ. 17, 100347 (2024).

Chen, L. Coordinated Development of Smart City and Regional Industrial Economy under the Background of Internet of Things. Mobile Information Systems, 2022. (2022).

Lee, P. et al. Trends in smart helmets with multimodal sensing for health and safety: scoping review. JMIR mHealth uHealth. 10(11), e40797 (2022).

Abuhussain, M. A. et al. Integrating building information modeling (BIM) for optimal lifecycle management of complex structures. Structures, 60. (2024).

Di Pasquale, V. et al. Smart operators: how augmented and virtual technologies are affecting the worker’s performance in manufacturing contexts. J. Ind. Eng. Manag. 15(2), 233–255 (2022).

Asif, U. et al. Predictive modeling and experimental validation for assessing the Mechanical properties of Cementitious composites made with silica fume and ground granulated blast furnace slag. Buildings, 14(4). (2024).

Shirowzhan, S. et al. An integrated GIS and Wi-Fi based Locating system for improving construction labor communications. in ISARC. Proceedings of the International Symposium on Automation and Robotics in Construction. IAARC Publications. (2017).

Bageis, A. S. et al. Evaluation of factors affecting the Competitive Advantage of Organizations in establishing sustainable Project Management Post Covid-19. J. Eng. 2023, p1–24 (2023).

Pradhananga, N. & Teizer, J. Automatic spatio-temporal analysis of construction site equipment operations using GPS data. Autom. Constr. 29, 107–122 (2013).

Carlier, R., Dabbagh, M. & Krarti, M. Energy Performance of Integrated Wall and Window Switchable Insulated systems for residential buildings. Energies, 15(3). (2022).

Ahn, C. R., Lee, S. & Peña-Mora, F. Application of low-cost accelerometers for measuring the operational efficiency of a construction equipment fleet. J. Comput. Civil Eng. 29(2), 04014042 (2015).

Lee, M. J. & Zhang, R. Human-centric Artificial Intelligence of things–based indoor environment quality modeling Framework for supporting Student Well-being in Educational facilities. J. Comput. Civil Eng., 38(2). (2024).

Lu, M. et al. Positioning and tracking construction vehicles in highly dense urban areas and building construction sites. Autom. Constr. 16(5), 647–656 (2007).

Saad Alotaibi, B. et al. Building information modeling (BIM) adoption for enhanced legal and contractual management in construction projects. Ain Shams Eng. J., 15(7). (2024).

Ni, Y., Wong, K. & Xia, Y. Health checks through landmark bridges to sky-high structures. Adv. Struct. Eng. 14(1), 103–119 (2011).

Sajjad, M. et al. BIM-driven energy simulation and optimization for net-zero tall buildings: sustainable construction management. Front. Built Environ., 10. (2024).

Yang, C. T. et al. Construction and application of an intelligent air quality monitoring system for healthcare environment. J. Med. Syst. 38, 1–10 (2014).

Waqar, A. et al. Impediment to implementation of internet of things (IOT) for oil and gas construction project safety: structural equation modeling approach. Structures, 57. (2023).

Risojević, V. et al. Accurate indoor sound level measurement on a low-power and low-cost wireless sensor node. Sensors. 18(7), 2351 (2018).

Waqar, A. et al. Evaluation of Challenges to the Adoption of Intelligent Transportation System for Urban Smart Mobility51 (Research in Transportation Business & Management, 2023).

Cheriyan, D. & Choi, J. Estimation of particulate matter exposure to construction workers using low-cost dust sensors. Sustainable Cities Soc. 59, 102197 (2020).

Waqar, A. et al. Evaluation of success factors of utilizing AI in digital transformation of health and safety management systems in modern construction projects. Ain Shams Eng. J., 14(11). (2023).

Devaraju, J. et al. Wireless portable microcontroller based weather monitoring station. Measurement. 76, 189–200 (2015).

Waqar, A., Bheel, N. & Tayeh, B. A. Modeling the effect of implementation of artificial intelligence powered image analysis and pattern recognition algorithms in concrete industry. Developments Built Environ., 17. (2024).

Kalyan, T. S. et al. Construction quality assessment using 3D as-built models generated with Project Tango. Procedia Eng. 145, 1416–1423 (2016).

Waqar, A. et al. Sustainable leadership practices in construction: building a resilient society. Environ. Challenges, 14. (2024).

Gou, Q. et al. Construction and strategies in IoT security system. in. IEEE international conference on green computing and communications and IEEE internet of things and IEEE cyber, physical and social computing. 2013. IEEE. (2013).

Waqar, A., Mateen Khan, A. & Othman, I. Blockchain empowerment in construction supply chains: enhancing efficiency and sustainability for an infrastructure development. J. Infrastructure Intell. Resil., 3(1). (2024).

Shelden, D. R. et al. Data standards and data exchange for Construction 4.0, in Construction 4.0. Routledge. pp. 222–239. (2020).

Waqar, A. et al. Overcoming implementation barriers in 3D printing for gaining positive influence considering PEST environment. Ain Shams Eng. J., 15(3). (2024).

Amoah, K. B. Web-Based Building Information Modeling Data Exchange Standardization Protocols for the Architectural, Engineering, and Construction Industry.

Waqar, A. et al. Modeling relation among implementing AI-based drones and sustainable construction project success. Front. Built Environ., 9. (2023).

Amaral, R. E. et al. Waste management and operational energy for sustainable buildings: a review. Sustainability. 12(13), 5337 (2020).

Waqar, A. et al. Modeling the relation between Building Information Modeling and the success of Construction projects: a structural-equation-modeling Approach. Appl. Sci., 13(15). (2023).

Kasim, N., Latiffi, A. A. & Fathi, M. S. RFID Technology for materials management in construction projects—a review. Int. J. Constr. Eng. Manage. 2(4A), 7–12 (2013).

Waqar, A. et al. Complexities for adopting 3D laser scanners in the AEC industry: structural equation modeling. Appl. Eng. Sci., 16. (2023).

Yang, J. et al. Construction performance monitoring via still images, time-lapse photos, and video streams: now, tomorrow, and the future. Adv. Eng. Inform. 29(2), 211–224 (2015).

Waqar, A. et al. Analyzing the success of adopting Metaverse in Construction Industry: structural equation modelling. J. Eng. 2023, 1–21 (2023).

Teizer, J. Wearable, wireless identification sensing platform: self-monitoring alert and reporting technology for hazard avoidance and training (SmartHat). J. Inform. Technol. Constr. (ITcon). 20(19), 295–312 (2015).

Waqar, A. et al. Evaluating the critical safety factors causing accidents in downstream oil and gas construction projects in Malaysia. Ain Shams Eng. J., 15(1). (2024).

Majumder, S., Mondal, T. & Deen, M. J. Wearable sensors for remote health monitoring. Sensors. 17(1), 130 (2017).

Waqar, A. et al. Modeling of success factors of using PU coats in concrete construction projects. Heliyon. 10(7), e28908 (2024).

D’Agostino, D. et al. How will future climate impact the design and performance of nearly zero energy buildings (NZEBs)? Energy. 240, 122479 (2022).

Waqar, A. et al. Examining the impact of BIM implementation on external environment of AEC industry: a PEST analysis perspective. Developments Built Environ., 17. (2024).

da Silva, N. P., Eloy, S. & Resende, R. Robotic construction analysis: simulation with virtual reality. Heliyon. 8 (10), e11039 (2022).

Zaki, S. & Hagag, A. The role of value engineering job plan in prioritizing finishing flooring selection criteria. JES J. Eng. Sci. 51(6), 522–546 (2023).

De Simone, M. C., Lorusso, A. & Santaniello, D. Predictive maintenance and structural health monitoring via IoT system. in 2022 IEEE Workshop on Complexity in Engineering (COMPENG). IEEE. (2022).

Do, H. T., Blanchini, F. & Prodan, I. Enhancements on a saturated control for stabilizing a quadcopter: adaptive and robustness analysis in the flat output space. arXiv preprint arXiv:2308.15177, 2023.

Edirisinghe, R. & Woo, J. BIM-based performance monitoring for smart building management. Facilities. 39(1/2), 19–35 (2021).

Westland, J. C. Lower bounds on sample size in structural equation modeling. Electron. Commer. Res. Appl. 9(6), 476–487 (2010).

Molwus, J. J., Erdogan, B. & Ogunlana, S. O. Sample size and model fit indices for structural equation modelling (SEM): The case of construction management research, in ICCREM 2013: Construction and Operation in the Context of Sustainability. pp. 338–347. (2013).

Acknowledgements

The authors extend their appreciation to Taif University, Saudi Arabia, for supporting this work through project number (TU-DSPP-2024-33).

Funding

This research was funded by Taif University, Saudi Arabia, Project No. (TU-DSPP-2024-33).

Author information

Authors and Affiliations

Contributions

Conceptualization: Ahsan Waqar (AW), Abdul Mateen KhanMethodology: Ahsan Waqar (AW), Abdul Mateen KhanFormal analysis: Ahsan Waqar (AW), Hamad AlmujibahInvestigation: Ahsan Waqar (AW), Khaled A AlrasheedData curation: Ahsan Waqar (AW), Khaled A AlrasheedWriting - Original Draft: Ahsan Waqar (AW)Writing - Review & Editing: Abdul Mateen Khan, Hamad Almujibah, Omrane BenjeddouSupervision: Abdul Mateen Khan and Khaled A Alrasheed.

Corresponding author

Ethics declarations

Competing interests

The author(s) declare(s) that there is no conflict of interest regarding the publication of this paper.

Ethical approval

All methods were carried out in accordance with relevant guidelines and regulations issued by Department of Civil Engineering, International Islamic University, Islamabad. The experimental protocols were approved by Department of Civil Engineering, International Islamic University, Islamabad.

Informed consent

Informed consent was obtained from all participants prior to their participation in the study.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Khan, A.M., Alrasheed, K.A., Waqar, A. et al. Internet of things (IoT) for safety and efficiency in construction building site operations. Sci Rep 14, 28914 (2024). https://doi.org/10.1038/s41598-024-78931-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-78931-0