Abstract

This study investigates the combined use of waste glass powder and nano titanium dioxide (TiO2) on the mechanical and durability properties of the concrete. Waste glass being one of the major municipal wastes going into the landfill sites can be used as a pozzolanic material in the concrete, in this study cement is replaced with waste glass powder by 10% along with nano TiO2, it is used as an addition to cementitious material by 0.5%, 1% and 1.5%. Fresh and mechanical properties like setting time, workability, compressive strength and flexural strength is evaluated along with durability properties such as sorptivity, acid, sulphate and chloride attacks, elevated temperature test. Scanning electron microscope is done to understand the morphology of the blended concrete. Combined use of glass powder and nano TiO2 is found beneficial in mechanical and durability parameters whereas addition of nano TiO2 has resulted in decreased workability of the concrete.

Similar content being viewed by others

Introduction

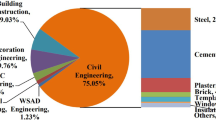

The advancement in the field of infrastructure of a country results in the extensive use of construction materials, concrete is most widely used construction material and in fact concrete is the second most material used in the world only behind water1. The construction sector has a significant impact on the environment in terms of releasing carbondioxide gas which is termed as greenhouse gas in the atmosphere2,3. Cement being one of the important materials which plays the vital role in binding all other ingredients in concrete, its production process releases approximately 0.9 tons of carbondioxide to produce 1 ton of cement4,5. Due to the release of enormous amount of carbondioxide gas in the atmosphere researchers all around the world are trying to find the alternatives to the cement which can either replace cement partially or completely in the production of the cement6,7,8. Incorporating nano materials in the concrete has increased lot of attention in the last two decades, nanotechnology has influenced the performance parameters in terms of mechanical and durability properties of the materials9. A natural or artificial material in which at least 50% of the particles have one or more external dimensions between 1 and 100 nm is referred to as a “nanomaterial,” according to the definition provided by the European Union Commission in the Official Journal of the European Union10. Due to the ultrafine size in terms of nano scale has gained lot of applications in the field of engineering along with construction industry11. Nanoparticles of aluminum oxide, iron oxide, silicon dioxide, and zinc oxide have demonstrated a notable capacity in the process of producing concrete, suggesting that they could be instrumental in achieving the desired results12,13,14. There have been studies shown the photocatalytic and self-cleansing properties to great extent with the inclusion of nano TiO2and cement-based materials15,16.

Supplementary cementitious materials (SCM’s) such as fly ash (FA)17,18, ground granulated blast furnace slag (GGBFS)19,20, silica fume21, rice husk ask ash22have been tried to lower the cement content and to some extent it has been successful approach to minimize cement in the manufacture of concrete. Waste glass (WG) disposal has been a problem for environmentalists from very long time23. Environmentally speaking, waste glass is primarily considered municipal solid waste. Glass waste can take many different forms, such as furniture, containers, facades, bottles and much more in packaging. In 2018, United States Environmental Protection Agency stated that 5.2% of all municipal solid waste that was landfilled was made up of the approximately 7.6 million tons of waste glass that were received for disposal24which is considered to be a high volume of landfill. Researchers have been interested in glass because of its pozzolanic properties, which attempt to react with water and calcium hydroxide to form more calcium silicate hydrate25,26. WG can be considered as a good source of SCM provided it is finely ground to have pozzolanic properties27,28. The use of WG can significantly reduce the landfill problems and also cement can be saved from the consumption in the production of concrete which directly minimizes the carbondioxide percentage released into the atmosphere. Zeybek et al. studied the mechanical properties by partially replacing the cement with waste glass powder (WGP) with different percentages ranging from 10 to 50% and found the optimum replacement level of WGP to be 10%29. Ahmad et al. studied the effects of WGP along with recycled concrete aggregates with proportion of 10%, 20%, 30% and 20%, 40% and 60% respectively, the WGP was adopted primarily to fill the voids and they noted 20% of glass powder and recycled aggregates gave the highest compressive strength (CS) results at the end of 56 days of curing in water30. Paul et al. investigated the use of finely ground WGP with an average particle size distribution (PSD) as 31.57 μm and 7.8 μm in the manufacture of M30 and M40 grade of concrete and wide range of mechanical and durability properties were studied and found 30% of WGP achieves the desired result31. Peng et al. studied the effect of WGP in enhancing corrosion resistance of recycled aggregate concrete, they found no more than 20% of WGP increased the CS of the recycled aggregate concrete but the corrosion resistance of steel was observed for higher replacement percentages32. Jain et al. studied the durability characteristics of WGP concrete blended with granite powder, they performed series of durability tests such as water absorption, acid attack, sulphate attack, permeability and rapid chloride penetration tests on the concrete and also microstructure analysis, WGP was varied from 5 to 25% with 5% incremental increase, they noticed significant improvement in the durability performance of glass induced concrete along with waste granite, 15% of WGP performed well in all the durability tests performed on the concrete33. Khan et al. conducted similar studies on the cement replacement with WGP from 0 to 35% with 5% incremental increase for each combination, the influence of WGP is evaluated in terms of mechanical strength of the concrete, they noticed increase in CS till 25% replacement at the end of 28 days of curing and also noted there was again increase in strength by 5% at the end of 84 days of curing which suggests longer duration of curing is essential for pozzolanic action of the WGP34. Yu et al. examined the effects of nano titanium dioxide (TiO2) on the CS of the concrete and found that 2% of nano TiO2increases the CS up to 7%35. Rawat et al. studied the influence of nano TiO2 as a partial replacement of cement, they varied nano TiO2 in 0.5% incremental order staring from 0 to 3%, they noted decrease in slump values as percentage of nano TiO2 increased and tested compressive, flexural and tensile strengths which gave 1.5% of nano TiO2 as the optimum percentage followed by microstructural properties which showed nano TiO2acts as a filler material in the concrete matrix36. Amor et al. investigated the photocatalytic properties by partially replacing cement by nano TiO2 and nano zinc oxide, the percentage was varied from 0 to 3% and found addition of nano TiO2gave better reactivity with the hydration products resulted from portland cement which is also responsible for photocatalytic process37. Though nano TiO2 has various advantages in the concrete its initial cost is major hurdle for the practical applications in the real-world projects, but use of nano TiO2 in small proportions or combining nano TiO2 with other low-cost materials provides a path to achieve an economical and durable concrete which tends to lower the expenses required for the long-term structures. Some studies report using nano sized TiO2 may have impact on health but using it with precautions it can be minimized. Concrete incorporating WGP and nano TiO₂ may significantly improve resistance to environmental degradation, such as acid rain, pollution, and ultraviolet (UV) radiation. this makes the concrete more suitable for structures exposed to harsh environmental conditions, such as bridges, tunnels, high-rise buildings, and coastal structures. These applications benefit from reduced maintenance costs and extended service life due to increased durability.

The current study investigates the combined use of WGP and nano TiO2.The main aim to use WGP in this study is because WGP is normally being produced from waste glass, using it as a SCM will benefit in terms of waste management. WGP will contribute to reduce cement content in a concrete mix due to its pozzolanic properties which reduces the overall carbon footprint of the concrete production. Similarly, usage of nano TiO2 enhances the mechanical and durability properties of the concrete due to its ability to fill pores in the matrix. In this study, cement is replaced with 10% of WGP by weight and kept constant as most of the literature has shown to give optimum results at 10%, whereas nano TiO2 is additional added by weight of cementitious material by varying the percentages from 0.5%, 1% and 1.5%. Studies on how WGP and nano TiO2 work together to improve the mechanical and durability qualities of concrete have not been reported in the existing literature. The goal of this research is to create sustainable concrete by bridging the gap between the combined effects of nanomaterials and additional cementitious materials.

Experimental program

Materials

In this experimental study ordinary portland cement (OPC) is used which satisfies the specifications stipulated in IS 811238. Table 1presents the physical properties of OPC. Natural river sand and coarse aggregates with basalt composition is adopted as fine aggregates (FA) and coarse aggregates (CA) respectively, ultimate size of FA is 4.75 mm and of CA is kept 20 mm conforming to the limits of IS 38339 Physical properties of FA and CA is shown in Table 2 along with PSD curve which is shown in Fig. 1. WGP was supplied by Heera chemicals Mumbai, it is white in colour and will be used as SCM having average size 40 μm. The chemical composition of OPC and WGP is shown in Table 3. Nano TiO2 was supplied by AdNano Technologies Pvt. Ltd., Shivamogga, Karnataka, India. Specifications of nano TiO2 given by AdNano Technologies is given in Table 4. Nano TiO2 used in this study is water soluble therefore no special base was required to dissolve it. Figure 2 (a), (b) and (c) shows nano TiO2in packed, powder and dissolved in water respectively. MYK Arment super plasticizer conforming to IS 910340 is used in this study to have the needed workability. Normal tap water was used for concrete mixing and curing processes.

Concrete mixture design and mixture proportions

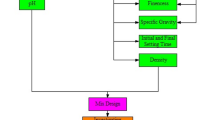

Mix design of normal concrete mixture was calculated with the stipulations given in IS 10,262 − 201941. A concrete grade of M35 is designed in this experimental study, according to IS 456–200042 the minimum concrete grade for a severe exposure criterion is M30 thus satisfies the clause. The cement content is worked out to be 365 kg/m3 with fixed water binder ratio 0.42 which also satisfies minimum OPC criteria of 320 kg/m3 and maximum limit of water to binder ratio 0.45 for severe exposure condition. 1% super plasticizer is used by weight of OPC to achieve required workability of 100 mm throughout all the designed mixtures. In this laboratory work three combinations have been worked out keeping WGP 10% constant as replacement to cement and with varying levels of nano TiO2 from 0.5 to 1.5% with incremental rise of 0.5%. Due of workability concerns at higher percentages, the upper level of nano TiO2 is fixed at 0.5%. This is because the larger surface area of the nano particles increases water demand, which in turn decreases workability. Additionally, there is a high risk of nano particle agglomeration, which occurs when the nano particles tend to clump and reduce the expected results. Designation of all the mixture combinations with WGP and nano TiO2 is shown in Table 5 and the quantities of materials required to cast the said combinations are tabulated in Table 6.

Preparation of samples

To guarantee consistency in the materials, OPC, FA, CA, and WGP are purchased from the same vendor. The required materials are determined by taking into account the specimens that need to be cast for each mix. A concrete mixer is used to thoroughly combine all the ingredients of the concrete. First, the CA and FA are blended to ensure uniform distribution of the aggregates. Next, cement is added to create a dry mix of CA, FA, and OPC. Water, which is pre-mixed with a superplasticizer, is then introduced to the dry mixture. Similarly, the nano TiO₂ is dispersed in water before being added to the mix to ensure even distribution, resulting in a uniform fresh concrete mix. A set of 120 cubes of size 150 mm along with 24 beams of size 500 mm×100 mm×100 mm were casted in a steel casing. After 24 h of casting, concrete was properly set and unpacked from the steel casing and carefully placed in a water curing tank for 7, 28 and 90 days for appropriate water curing of the samples. Figure 3 shows the casted cube and beam specimens along with samples kept for curing in a curing tank.

Test methodology

Initial and final setting times of the binder

In accordance with IS 4031 (Part 5)43, experiment is conducted to ascertain the initial setting time (IST) and final setting time (FST). For every percentage of nano TiO2 inclusion, assessment is done to ascertain changes in both IST and FST, alongside establishing standard consistancy. The primary objective was to observe any alterations in setting time resulting from the progressive addition of TiO2 nano-particles along with constant glass powder in the mix. Vicat apparatus was used to determine IST and FST.

Workability (slump cone test)

This test involves the use of a conical mould known as a slump cone, with dimensions adhering to the IS 119944. Freshly mixed concrete is compacted in three layers within the slump cone which is supported on a base plate, with each layer receiving 25 tamping rod strokes for proper compaction to remove voids. Subsequently, the cone is carefully lifted in a vertical manner, allowing the concrete to settle and slump. The extent of this slump is measured by determining the variation in height amid the original cone height and the highest point of the slumped concrete.

Compressive strength test

Compressive strength (CS) is one of the major characteristics of hardened concrete, it was performed in accordance with the guidelines given in IS 51645. This test helps in determining the load carrying ability of concrete under axial loading conditions. The method involves subjecting a cubical concrete specimen to progressively rising compressive load until failure. Compression testing machine of maximum capacity 2000KN was used to test casted 150 mm cubes at 7, 28, and 90 days of curing. The applied compressive force was kept perpendicular to the specimen’s surface and the value of loading was uniformly maintained at 140 kg/cm2/min. For each set of curing 3 samples were tested and mean of 3 samples was taken to determine compressive load. Test setup is shown in Fig. 4 (a). The equation given below is used to calculate CS of hardened concrete.

Flexural strength test

Flexural strength (FS) test on concrete is a method to determine tensile strength of the concrete, it is also called as modulus of rupture test, 4-point bending test is adopted in this which is performed as per IS 51645 guidelines. The bed of the testing apparatus is put up with 2 rollers on which the beam is supported, the rollers are spaced apart at center-to-center distance of 600 mm for 150 mm sample specimens. The load is put through two similar rollers with a third point at the system of loading, the load shall be equally distributed through two rollers. Test setup is presented in Fig. 4 (b). FS is calculated using the equation.

where, P = Max load applied to the beam, L = Supported length, b = Width of the beam, d = Depth of the beam.

Sorptivity test

Sorptivity test is performed according to ASTM C 1585 guidelines46. This test is helpful to determine initial capillary absorption of water. The concrete cubes cured for 90 days are used to undergo sorptivity test. The test specimens are oven dried in an oven to remove excess moisture content at a temperature around 600C until the constant weight is achieved. Weight is noted accurately as initial measurement of the test. The specimen is partially submerged in water to a depth of 5 mm and level of immersion is controlled carefully, in this test specimens were immersed for 60 min, the increase in weight is noted carefully after 15, 30, 45 and 60 min of immersion. Test setup is represented in Fig. 4 (c). Sorptivity (S) is calculated by using the following equation.

Where a = cumulative water absorbed per unit c/s area of the concrete. t = time elapsed in minutes.

Acid, sulphate and chloride resistance tests

Concrete specimens were subjected to aggressive environment to test the durability characteristics, the tests performed are acid attack, sulphate attack and chloride attack as per ASTM C26747. The concrete cube specimens cured for 28 days are used in these tests, a 3% solution was prepared of sulphuric acid, sodium sulphate and sodium chloride for acid, sulphate and chloride attack respectively. Concrete specimens are fully submerged into these solutions for 90 days while maintaining constant concentration of the solutions, specimens are removed from the solution it is cleaned with distilled water to remove loose particles. CS was performed to find out what will be the strength reduction of the specimens after submerging into the aggressive solutions for 90 days. CS loss was computed using the formula.

where F = Initial CS of concrete, F1 = CS after immersion in solution for 90 days.

Elevated temperature test

Elevated temperature test is done to assess concrete when exposed to higher temperatures. In this test concrete cubes are kept in muffle furnace and exposed to a different temperature, the temperature at which the concrete was tested is 150 ºC, 300 ºC and 500 ºC, after exposing to high temperature concrete was kept to cool under normal conditions and then crushed the specimens in a compression testing machine to note down the changes in the CS after exposing to higher temperatures. Figure 5 shows muffle furnace used in the elevated temperature test.

Results and discussions

Initial and final setting time

During this experimental work, changes in IST and FST was observed with the inclusion of WGP and nano TiO2. There was a delay in setting times observed for GT1 but GT2 and GT3 showed retarding setting time. Figure 6 shows the results of setting times. Delay in GT1 is due to the glass content and lower amount of nano TiO2 which dint influence much on setting times, there are reported studies which shows inclusion of glass powder delays the setting time48,49. Delay is due to glass being nonabsorbent in water and takes part in hydration at later stage. But whereas it is also noticed there is retarding effect once the dosage of nano TiO2 is increased50, this is due to large surface available which enhances the chance of more nucleation sites which ultimately results in quicker hydration51.

Workability

Slump test is performed to know the effects of WGP and nano TiO2 on the workability of fresh concrete. It is found that normal concrete is having highest workability without addition of WGP and nano TiO2, GT1 shows a slight decrease by about 4.76% slump value compared to NM, more decrease in slump values is noted for GT2 and GT3 around 12.38% and 16.19% compared to NM, glass powder in concrete tends to have more workability as reported by studies49,52 due to glass being water repellent material therefore water is not utilized by glass during initial stage of mixing, it is because of this reason GT1 has decreased by only 4.76% and this decrease is due to the inclusion of nano TiO2 and also it is observed that as nano TiO2 is increased there is a sharp decline in the workability of the concrete as more water is absorbed by TiO2being a nano material with high surface area and directly impacts on workability of the concrete53,54. Figure 7 presents results of workability of different combinations.

Compressive strength

Figure 8shows 7, 28 and 90 days cured specimens’ CS results. It is noted that there is small increment in the compressive test results in the initial 7 days, GT1 shows an increment of 1.5% followed by 3.18% and 2.90% of GT2 and GT3 respectively compared to normal concrete. At the end of 28 days curing, it is observed that CS values have increase by 3.38%, 6.90% and 8.92% of GT1, GT2 and GT3 respectively. The results of 90 days old concrete specimens peaked as the number of curing days increased, it is observed 12.78% increase of GT1 samples, 18.36% and 19.18% increase of GT2 and GT3 compared to NM samples. This is due to the fact that WGP tends to contribute to the CS at the later stage of the concrete age as compared to initial days of the concrete, glass being rich in silica and pozzolanic material it reacts with calcium hydroxide a byproduct of hydration of cement and this reaction contributes to have higher strength at a later stage, studies carried out on WGP have shown the similar trend of results of the CS55,56. The quantity of WGP being constant we have observed the CS increase as the nano TiO2 quantity is increased in the mixture, this clearly illustrates the importance of nano TiO2 in obtaining a higher CS, this is due to the fact that TiO2being a nano material, particle packing density is improved which results in the reduction of pores in the matrix57,58, also it can be noted that there is no much increase in GT2 and GT3 values this proves that addition of more nano TiO2 will not result in more strength and the extra nano TiO2will act as inert material59.

Flexural strength

The FS test was carried on beam specimens at the end of 28 and 90 days of curing, FS results are graphically represented in the Fig. 9. In this test it is observed an increase in FS of GT1, GT2 and GT3 by 2.15%, 6.47% and 8.03% respectively for 28 days samples, FS has shown increment for the 90 days samples of GT1, GT2 and GT3 by 10.57%, 16.53% and 18.84% respectively compared to NM. The greater increase is seen for 90 days samples due to glass playing significant role in pozzolanic reaction at the later stage of the curing and also due to fine glass particles which help to fill the pores in the matrix. Elaqra et al. examined effects of glass powder on FS and found 10% of glass gave the optimum result due to denser structure of the matrix which to a great extent eliminates the pores by micro sized glass particles leading to dense microstructure60. Hama et al. conducted studies on reinforced beam with glass powder and found 10% glass powder exhibit higher flexural strength compared to concrete without glass powder61. Nano TiO2 is increased and we notice increase in FS, this is due to the nano size pores are filled with nano TiO2giving rise to much denser concrete which ultimately increases flexural strength, also it should be noted greater amount of nano material will give rise difficulty in dispersing in the concrete which creates a weaker zone due to weak interfacial transition zone and this might lead to decline of the strength62. Orakzai examined the hybrid effect of the nano TiO2and alumina on FS of the concrete and found nano material helps to increase FS63. Selvasofia et al. conducted the studies on the combined effect nano TiO2and nano clay and also noted increase in flexural strength64.

Sorptivity

Sorptivity test on all mix combinations was performed to evaluate the water absorption by capillary action. Specimens were water cured for 90 days to undergo sorptivity test, from this test it is observed that there is decrease in sorptivity values which is very encouraging findings with the combined usage of WGP and nano TiO2. There is a downward trend of 9.59%, 15.86% and 18.08% for GT1, GT2 and GT3 samples compared to NM as indicated in Fig. 10. These values indicate low pores in the matrix as the sorptivity of the concrete is directly associated to the pores in the concrete, low values of sorptivity also suggest non uniform size distribution of pores which can limit the movement of water in the concrete. Use of glass and nano TiO2which are micro and nano material in the matrix fill the pores of micro and nano sizes to give a dense concrete restricting water movement. Similar findings were observed by Matos et al. where the sorptivity declined with the inclusion of WGP65. Ghareeb et al. studied use of glass and nano particles on sorptivity of ultra-high performance self-compacting concrete and they have achieved same trend of results66 which confirms the role played by glass powder and nano particle to improve sorptivity in comparison to normal concrete.

Acid, sulphate and chloride resistance

Assessment of concrete in aggressive environments gives different perspective in the applications of the concrete. In this study 90 days cured concrete cubes are used to conduct acid, sulphate and chloride attack tests on all mix combinations, reduction in CS is recorded after keeping the cubes in the acid, sulphate and chloride solutions for 90 days. All three combinations have shown satisfactory resistance to acid, sulphate and chlorides compared with normal concrete. It is observed strength reduction of normal concrete kept in acid solution is up to 22.91% whereas for GT1, GT2 and GT3 combinations the reduction is 20.89%, 19.43% and 18.89% respectively. In sulphate attack the reduction in strength in normal concrete is around 10.1% and that of GT1, GT2 and GT3 is seen around 8.62%, 6.78% and 6.34% respectively. It is also observed similar trend in the cubes kept in chloride solution for 90 days, strength reduction is observed around 13.57% in normal concrete, 11.4% in GT1, 9.86% in GT2 and 8.95% in GT3. Figure 11 depicts the graphical picture of the strength reduction in percentage of acid, sulphate and chloride attack tests.

Figure 12 shows the concrete specimens after removing from the solutions at the end of 90 days. As it is seen from figure maximum deterioration is seen in acid attack and NM sample shown a layer of decolouration which goes on reducing for GT1, GT2 and GT3 samples and same is reflected in strength loss results. Similarly, a layer of white deposition can be seen on the samples of chloride and sulphate attacks. It can be seen that the mixes with WGP and nano TiO2 reduction in strength has been reduced in all the three tests, this is mainly observed due to dense structure because of WGP and nano TiO2, these materials are responsible in micro level particle packing and reducing the pores which directly prohibits aggressive conditions to have impact and percolate in the concrete. These observations help to understand the significance of the resistance to chloride attacks, chlorides are responsible for the corrosion of steel in reinforced concrete members, by having superior resistance to chlorides the concrete can prevent corrosion for longer time compared to concrete prepared with traditional materials. It is evident from CS test that improved CS results helps to mitigate crack and give less scope for the attack of chlorides. Sulphates present in soil and sea water tries to leach in the concrete which primarily responds with calcium hydroxide and Calcium silicate hydrate to form ettriingite and gypsum, these compounds disintegrate the concrete due to expansion, waste glass powder and nano TiO2 serves excellent alternative to reduce these effects as can been seen with strength reduction results, these materials fill the pores to form a dense microstructure which breaks down the pore structure into non uniform path hence sulphate ions probability of leaching into the concrete decreases. Acid attack mainly occurs where the concrete is exposed to acidic environments such as acid string facilities, acids react with calcium hydroxide to form calcium salts which are mostly soluble causing deterioration of concrete, here in this study acid attack is most severe compared to sulphate and chloride attacks but it can be noted reduction of strength is lower in mixes with WGP and nano TiO2in acid attack which suggests these materials have resistance to acid attacks. Omran et al. investigated effects of WGP in field applications, they found concrete with WGP showed better resistivity to chloride penetration compared to concrete with no WGP67. Amin et al. performed tests on the durability of high strength self-compacting concrete by using WGP as partial substitute to cement and they have noticed the overall durability of the concrete chloride permeability and sorptivity improved with WGP inclusion68. Shalan et al. investigated long term sulphate resistance of concrete which was blended with WGP and noted 10% glass powder concrete shown a good resistance to sulphate attack and performed better compared to normal concrete69. Siad et al. observed enhancement in acid resistance to concrete made with increased WGP content compared to concrete with no glass powder70. Ozkan et al. found in their study that there is decrease in chloride permeability by 17.8%71. Pavoine et al. studies the effect of 20% glass powder on chloride attack and found there is a decrease of 40% chloride permeability72. Harbi et al. found decrease of 6.25% in sulphate resistance test with 25% of WGP73. Jain et al. found 12.67% decrease in strength when exposed to acid attack for 15% of WGP33. Rawat et al. examined the effect of nano TiO2 on the chloride penetration in concrete and they found nano TiO2significantly resisted chlorides penetrating into the concrete74. This is due to the fact that the role played by nano TiO2 in the hydration results in a more compact and dense nature of the matrix which ultimately improves pore structure and hence contributes in resisting aggressive environments, also to be noted that inclusion of more nano TiO2 can be harmful to the durability as distance between nano particles will less and also decreases the calcium hydroxide content which leads less crystal to strengthening gel produced to have a compact structure.

Elevated temperature

In this test slight reduction in the CS was noticed as the temperature was increased from 150oC to 500oC. At 1500C, NM strength was reduced to 1.17% whereas GT1, GT2 and GT3 saw almost same reduction, the noticeable changes were in 300oC and 500oC temperatures, NM strength was reduced by 7.42%, GT1 by 6.98%, GT2 6.83% and GT3 6.62% at 300oC and again dip was observed at 500oC, NM strength was reduced by 12.77% whereas GT1, GT2 and GT3 was reduced by 12.12%, 11.89% and 11.42% respectively. Figure 13 shows the graph of strength reduction at different temperatures for all mix combinations. Inclusion of WGP and nano TiO2 restricts the degradation under elevated temperature to some extent. WGP is high in amorphous silica which reacts with calcium hydroxide to form additional calcium silicate hydrate which contributes to strength and thermal stability. Glass brings the property of thermal stability under heat and also its pozzolanic property which enhances its compressive strength and dense structure contribute during elevated temperatures. Similarly nano TiO2due to its fine size helps to reduce porosity which contributes in the overall densification of the concrete which ultimately resists high temperature. Jiang et al. investigated the cement paste properties at high temperature and found glass to be a suitable supplementary cementitious material at the high temperatures, it resisted high temperature compared to normal cement paste75. Upsurge in the percentage of WGP shown positive resistance to high temperature due to low amount of calcium hydroxide which is a part of pozzolanic reaction of waste glass76. Guler et al. noted that the residual CS at elevated temperature after adding nano particles significantly shown improvement in the interfacial transition zone and had a compact dense concrete microstructure77.

Scanning electron microscope (SEM)

SEM pictures have been taken to comprehend the morphology of the WGP and nano TiO2 incorporated concrete. The magnification is 3000x for all the specimens. Figure 14 (a) illustrates the SEM image of NM, Fig. 14 (b), (c) and (d) shows images of GT1, GT2 and GT3 respectively. It is noticed a dense microstructure in GT1, GT2 and GT3 compared to NM, it is owing to the micro sized WGP and nano sized TiO2 which plays an crucial part in the densification of the concrete. Pores and microcracks are more visible in NM compared to other mixtures, calcium silicate hydrate gel formation is more in GT mixes due to pozzolanic effects of the WGP and TiO2, due to less pores and improved particle packing in WGP and nano TiO2 mixes the mechanical and durability properties were enhanced, proper bonding between aggregate and paste can be seen in the images which improves CS of the concrete. Dense C-S-H gel is evident in GT mixes which enhances probability of high CS as compared to normal mixtures. Micro and nano cracks and pores have been filled by glass powder and TiO2 which is responsible for denser microstructure.

Recommendations for future studies

-

1)

To examine the effectiveness of nano TiO₂ and WGP in conjunction with other SCM’s, such as metakaolin, FA, or GGBFS, to see if there are any synergistic effects in enhancing the durability and mechanical qualities.

-

2)

To analyse the carbonation resistance of the WGP and nano TiO2 induced concrete.

-

3)

Shrinkage and creep behavior studies of concrete incorporating WGP and nano-TiO₂ under different curing conditions.

-

4)

Assessment of the costs and environmental benefits of incorporating WGP and nano TiO₂ into concrete by conducting a life cycle assessment (LCA).

Conclusions

-

1)

Accelerated effect on setting time is observed with the increase of nano TiO2 although WGP is included which tries to prolong setting but due to fixed WGP content and increasing nano TiO2 setting time is accelerated.

-

2)

Decrease in workability is due to the inclusion of nano TiO2 which tends to absorb water and have negative effect on overall workability of the concrete, to mitigate this effect, superplasticizer dosage can be increased.

-

3)

Enhancement in the compressive strength is seen in all the waste glass powder and nano TiO2 mixes compared to normal concrete, inclusion of WGP and TiO2 results in dense concrete which leads to higher compressive strength. GT2 and GT3 have identical compressive strength which suggests more nano TiO2 will not be beneficial in compressive strength.

-

4)

Flexural strength is enhanced of GT mixes compared to normal concrete at the end of 28 and 90 days, Enhancement is seen at 90 days due to delayed pozzolanic effect of WGP and also due to pores filled by nano TiO2 which results in greater flexural strength.

-

5)

Sorptivity is decreased by 9.59%, 15.86% and 18.08% in GT1, GT2 and GT3 respectively which suggests increase in nano TiO2 there is decrease in sorptivity, due to reduced porosity and greater particle packing at micro and nano scale.

-

6)

Good resistance is shown by GT mixes in aggressive environments of acid, sulphate and chloride solutions. Samples were more deteriorated in acid attack compared to sulphate and chloride attack but GT mixes tend to resist these aggressive solutions with decrease in strength reduction compared to normal concrete.

-

7)

GT mixes perform better at elevated temperatures compared to normal concrete.

-

8)

Dense microstructure can be seen through scanning electron microscope which suggests the reduced pores due to the filling of micro cracks and nano pores by WGP and nano TiO2 which ultimately gives increased mechanical and durability properties of concrete.

-

9)

The use of WGP and nano TiO₂ can improve both mechanical and durability properties and this can be particularly beneficial in high-strength concrete applications, such as in skyscrapers, bridges, and heavy-load-bearing structures.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author upon reasonable request.

References

Van Damme, H. Concrete material science: past, present, and future innovations. Cem. Concr Res. 112, 5–24. https://doi.org/10.1016/j.cemconres.2018.05.002 (2018).

Tangadagi, R. B. & Seth, M. M. D. Role of mineral admixtures on strength and durability of high strength self compacting concrete: an experimental study. Mater. (Oxf). 18, 101144. https://doi.org/10.1016/j.mtla.2021.101144 (2021).

Abu Bakr, M. et al. Assessment of the mechanical and durability characteristics of bio-mineralized Bacillus subtilis self-healing concrete blended with hydrated lime and brick powder. Case Stud. Constr. Mater. 19, e02672. https://doi.org/10.1016/j.cscm.2023.e02672 (2023).

Abhijeet Baikerikar A Review on Concept of Sustainable Concrete, in: Recent Advances in Civil Engineering 2018 (RACE-2018), KLE College of Engineering and Technology, Chikodi, Chikodi, Belgaum, (2018).

Meng, Y., Ling, T. C., Mo, K. H. & Tian, W. Enhancement of high temperature performance of cement blocks via CO2 curing. Sci. Total Environ. 671, 827–837. https://doi.org/10.1016/j.scitotenv.2019.03.411 (2019).

Abhijeet & Baikerikar A review on green concrete. J. Emerg. Technol. Innov. Res. 1, 472–474 (2014).

Manjunatha, M., Seth, D., KVGD, B., Roy, S. & Tangadagi, R. B. Utilization of industrial-based PVC waste powder in self-compacting concrete: a sustainable building material. J. Clean. Prod. 428, 139428. https://doi.org/10.1016/j.jclepro.2023.139428 (2023).

Abu Bakr, M. & Singh, B. K. Strength and durability properties of recycled aggregate concrete blended with hydrated lime and brick powder. Eur. J. Environ. Civil Eng. 28, 1259–1283. https://doi.org/10.1080/19648189.2023.2247459 (2024).

Bunea, G., Alexa-Stratulat, S. M., Mihai, P. & Toma, I. O. Use of Clay and Titanium Dioxide nanoparticles in Mortar and Concrete—A state-of-the-art analysis. Coatings. 13, 506. https://doi.org/10.3390/coatings13030506 (2023).

European Commission & COMMISSION RECOMMENDATION of 10. June 2022 on the definition of nanomaterial, Official Journal of the European Union C229/1-C229/5. (2022).

Praveenkumar, T. R., Vijayalakshmi, M. M. & Meddah, M. S. Strengths and durability performances of blended cement concrete with TiO2 nanoparticles and rice husk ash. Constr. Build. Mater. 217, 343–351. https://doi.org/10.1016/j.conbuildmat.2019.05.045 (2019).

Heidarzad Moghaddam, H., Lotfollahi-Yaghin, M. A. & Maleki, A. Durability and Mechanical properties of Self-compacting concretes with Combined Use of Aluminium Oxide nanoparticles and Glass Fiber. Int. J. Eng. 34 https://doi.org/10.5829/ije.2021.34.01a.04 (2021).

Goel, G., Sachdeva, P., Chaudhary, A. K. & Singh, Y. The use of nanomaterials in concrete: a review. Mater. Today Proc. 69, 365–371. https://doi.org/10.1016/j.matpr.2022.09.051 (2022).

Huseien, G. F. A review on concrete composites modified with nanoparticles. J. Compos. Sci. 7, 67. https://doi.org/10.3390/jcs7020067 (2023).

Mostafa, F. E. Z. M. et al. Analyzing the effects of Nano-Titanium Dioxide and Nano-Zinc Oxide nanoparticles on the Mechanical and Durability properties of Self-cleaning concrete. Materials. 16, 6909. https://doi.org/10.3390/ma16216909 (2023).

Fernandes, C. N., Ferreira, R. L. S., Bernardo, R. D. S., Avelino, F. & Bertini, A. A. Using TiO2 nanoparticles as a SO2 catalyst in cement mortars. Constr. Build. Mater. 257, 119542. https://doi.org/10.1016/j.conbuildmat.2020.119542 (2020).

Li, G. et al. Fly Ash Application as supplementary Cementitious Material: a review. Materials. 15, 2664. https://doi.org/10.3390/ma15072664 (2022).

Saadet Gökçe, G. Ö. K. & Kadir, K. I. L. I. N. Ç. Mechanical properties of fly Ash and Blast furnace slag based alkali activated concrete. Kirklareli Univ. J. Eng. Sci. 3, 123–131 (2017).

Ahmad, J. et al. A Comprehensive Review on the Ground Granulated Blast furnace slag (GGBS) in concrete production. Sustainability. 14, 8783. https://doi.org/10.3390/su14148783 (2022).

Gök, S. G., Kilic, I. & Sengul, O. Properties of alkali-activated roller compacted concretes produced from waste aggregates. Cem. Wapno Beton. 26, 352–363. https://doi.org/10.32047/CWB.2021.26.4.7 (2021).

Hamada, H. M. et al. Effect of silica fume on the properties of sustainable cement concrete. J. Mater. Res. Technol. 24, 8887–8908. https://doi.org/10.1016/j.jmrt.2023.05.147 (2023).

Liu, C. et al. Recycled aggregate concrete with the incorporation of rice husk ash: mechanical properties and microstructure. Constr. Build. Mater. 351, 128934. https://doi.org/10.1016/j.conbuildmat.2022.128934 (2022).

Abu Bakr, M., Singh, B. K. & Hussain, A. Experimental investigations on MICP-based autonomous crack-healing recycled aggregate concrete: a sustainable approach for enhancing the strength and durability. Sustain. Resilient Infrastruct. 1–28. https://doi.org/10.1080/23789689.2024.2329390 (2024).

Baikerikar, A., Mudalgi, S. & Ram, V. V. Utilization of waste glass powder and waste glass sand in the production of eco-friendly concrete. Constr. Build. Mater. 377, 131078. https://doi.org/10.1016/j.conbuildmat.2023.131078 (2023).

Jani, Y. & Hogland, W. Waste glass in the production of cement and concrete – a review. J. Environ. Chem. Eng. 2, 1767–1775. https://doi.org/10.1016/j.jece.2014.03.016 (2014).

Gok, S. G. & Sengul, O. The use of waste glass as an activator in alkali-activated slag mortars. Proc. Institution Civil Eng. - Eng. Sustain. 174, 120–130. https://doi.org/10.1680/jensu.19.00070 (2021).

Li, Q., Qiao, H., Li, A. & Li, G. Performance of waste glass powder as a pozzolanic material in blended cement mortar. Constr. Build. Mater. 324, 126531. https://doi.org/10.1016/j.conbuildmat.2022.126531 (2022).

Gok, S. G. & Sengul, O. Mechanical properties of alkali-activated slag based SIFCON incorporating waste steel fibers and waste glass. Constr. Build. Mater. 408, 133697. https://doi.org/10.1016/j.conbuildmat.2023.133697 (2023).

Zeybek, Ö. et al. Burduhos-Nergis, Influence of Replacing Cement with Waste Glass on Mechanical properties of concrete. Materials. 15, 7513. https://doi.org/10.3390/ma15217513 (2022).

Ahmad, J. et al. Concrete with Partial Substitution of Waste Glass and recycled concrete aggregate. Materials. 15, 430. https://doi.org/10.3390/ma15020430 (2022).

Paul, D., Bindhu, K. R., Matos, A. M. & Delgado, J. Eco-friendly concrete with waste glass powder: a sustainable and circular solution. Constr. Build. Mater. 355, 129217. https://doi.org/10.1016/j.conbuildmat.2022.129217 (2022).

Peng, L. et al. Enhancing the corrosion resistance of recycled aggregate concrete by incorporating waste glass powder. Cem. Concr Compos. 137, 104909. https://doi.org/10.1016/j.cemconcomp.2022.104909 (2023).

Jain, K. L., Sancheti, G. & Gupta, L. K. Durability performance of waste granite and glass powder added concrete. Constr. Build. Mater. 252, 119075. https://doi.org/10.1016/j.conbuildmat.2020.119075 (2020).

Khan, F. A. et al. Development of environment-friendly concrete through Partial Addition of Waste Glass Powder (WGP) as cement replacement. Civil Eng. J. 6, 2332–2343. https://doi.org/10.28991/cej-2020-03091620 (2020).

Yu, X., Kang, S. & Long, X. Compressive strength of concrete reinforced by TiO2 nanoparticles, in: : p. 030006. (2018). https://doi.org/10.1063/1.5075659

Rawat, G., Gandhi, S. & Murthy, Y. I. Strength and rheological aspects of concrete containing nano-titanium dioxide. Asian J. Civil Eng. 23, 1197–1208. https://doi.org/10.1007/s42107-022-00476-2 (2022).

Amor, F. et al. Contribution of TiO2 and ZnO nanoparticles to the hydration of Portland cement and photocatalytic properties of high performance concrete. Case Stud. Constr. Mater. 16, e00965. https://doi.org/10.1016/j.cscm.2022.e00965 (2022).

IS 8112. Ordinary Portland cement specifications, Bureau of Indian Standards, New Delhi., n.d.

IS 383. Specifications for Coarse and fine Aggregates from Natural Resources, Bureau of Indian Standards, New Delhi., n.d.

IS 9103. Concrete admixtures specifications, Bureau of Indian Standards, New Delhi., n.d.

IS 10262. Concrete mix proportioning guidelines, Bureau of Indian Standards, New Delhi, n.d.

IS 456. Plain and reinforced concrete code of practice, Bureau of Indian Standards, New Delhi, n.d.

IS 4031. Method of Physical Tests for Hydraulic Cement, Bureau of Indian Standards, New Delhi, n.d.

IS 1199. Methods of sampling and analysis of concrete, Bureau of Indian Standards, New Delhi, n.d.

IS 516. Methods of tests for strength of concrete, Bureau of Indian Standards, New Delhi., n.d.

ASTM C1585. Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic Cement Concretes., n.d.

ASTM C267. Standard Test Methods for Chemical Resistance of Mortars, Grouts, Monolithic Surfacings and Polymer Concretes, n.d (2012).

Lu, J. X., Zheng, H., Yang, S., He, P. & Poon, C. S. Co-utilization of waste glass cullet and glass powder in precast concrete products. Constr. Build. Mater. 223, 210–220. https://doi.org/10.1016/j.conbuildmat.2019.06.231 (2019).

Aliabdo, A. A., Abd Elmoaty, A. E. M. & Aboshama, A. Y. Utilization of waste glass powder in the production of cement and concrete. Constr. Build. Mater. 124, 866–877. https://doi.org/10.1016/j.conbuildmat.2016.08.016 (2016).

Wang, L., Zhang, H. & Gao, Y. Effect of TiO2 nanoparticles on Physical and Mechanical properties of Cement at Low temperatures. Adv. Mater. Sci. Eng. 2018, 1–12. https://doi.org/10.1155/2018/8934689 (2018).

Lee, B. Y. Effect of titanium dioxide nanoparticles on early age and long term properties of cementitious materials, (2012).

Kim, I. S., Choi, S. Y. & Yang, E. I. Evaluation of durability of concrete substituted heavyweight waste glass as fine aggregate. Constr. Build. Mater. 184, 269–277. https://doi.org/10.1016/j.conbuildmat.2018.06.221 (2018).

Quercia, G., Spiesz, P., Hüsken, G. & Brouwers, H. J. H. SCC modification by use of amorphous nano-silica. Cem. Concr Compos. 45, 69–81. https://doi.org/10.1016/j.cemconcomp.2013.09.001 (2014).

Beigi, M. H., Berenjian, J., Lotfi Omran, O., Sadeghi Nik, A. & Nikbin, I. M. An experimental survey on combined effects of fibers and nanosilica on the mechanical, rheological, and durability properties of self-compacting concrete. Mater. Des. 50, 1019–1029. https://doi.org/10.1016/j.matdes.2013.03.046 (2013).

Soliman, N. A. & Tagnit-Hamou, A. Development of ultra-high-performance concrete using glass powder – towards ecofriendly concrete. Constr. Build. Mater. 125, 600–612. https://doi.org/10.1016/j.conbuildmat.2016.08.073 (2016).

Ramakrishnan, K., Pugazhmani, G., Sripragadeesh, R., Muthu, D. & Venkatasubramanian, C. Experimental study on the mechanical and durability properties of concrete with waste glass powder and ground granulated blast furnace slag as supplementary cementitious materials. Constr. Build. Mater. 156, 739–749. https://doi.org/10.1016/j.conbuildmat.2017.08.183 (2017).

Lee, B. Y., Jayapalan, A. R. & Kurtis, K. E. Effects of nano-TiO2 on properties of cement-based materials. Magazine Concrete Res. 65, 1293–1302. https://doi.org/10.1680/macr.13.00131 (2013).

Reshma, T. V. et al. Influence of ZnO and TiO2 on mechanical and durability properties of concrete prepared with and without polypropylene fibers. Mater. (Oxf). 18, 101138. https://doi.org/10.1016/j.mtla.2021.101138 (2021).

Pathak, S. S. & Vesmawala, G. R. Effect of nano TiO2 on mechanical properties and microstructure of concrete. Mater. Today Proc. 65, 1915–1921. https://doi.org/10.1016/j.matpr.2022.05.161 (2022).

Elaqra, H. A., Haloub, M. A. A. & Rustom, R. N. Effect of new mixing method of glass powder as cement replacement on mechanical behavior of concrete. Constr. Build. Mater. 203, 75–82. https://doi.org/10.1016/j.conbuildmat.2019.01.077 (2019).

Hama, S. M., Mahmoud, A. S. & Yassen, M. M. Flexural behavior of reinforced concrete beam incorporating waste glass powder. Structures. 20, 510–518. https://doi.org/10.1016/j.istruc.2019.05.012 (2019).

Li, H., Zhang, M. & Ou, J. Abrasion resistance of concrete containing nano-particles for pavement. Wear. 260, 1262–1266. https://doi.org/10.1016/j.wear.2005.08.006 (2006).

Atiq Orakzai, M. Hybrid effect of nano-alumina and nano-titanium dioxide on mechanical properties of concrete. Case Stud. Constr. Mater. 14, e00483. https://doi.org/10.1016/j.cscm.2020.e00483 (2021).

Anitha Selvasofia, S. D. et al. Study on the mechanical properties of the nanoconcrete using nano-TiO2 and nanoclay. Mater. Today Proc. 50, 1319–1325. https://doi.org/10.1016/j.matpr.2021.08.242 (2022).

Matos, A. M. & Sousa-Coutinho, J. Durability of mortar using waste glass powder as cement replacement. Constr. Build. Mater. 36, 205–215. https://doi.org/10.1016/j.conbuildmat.2012.04.027 (2012).

Ghareeb, K. S., Ahmed, H. E., El-Affandy, T. H., Deifalla, A. F. & El-Sayed, T. A. The novelty of using Glass Powder and Lime Powder for Producing UHPSCC. Buildings. 12, 684. https://doi.org/10.3390/buildings12050684 (2022).

Omran, A. & Tagnit-Hamou, A. Performance of glass-powder concrete in field applications. Constr. Build. Mater. 109, 84–95. https://doi.org/10.1016/j.conbuildmat.2016.02.006 (2016).

Amin, M., Zeyad, A. M., Tayeh, B. A. & Agwa, I. S. Effect of Glass Powder on High-Strength Self-compacting concrete durability. Key Eng. Mater. 945, 117–127. https://doi.org/10.4028/p-w4tcjx (2023).

Shalan, A. H. & El-Gohary, M. M. Long-term sulfate resistance of blended cement concrete with Waste Glass Powder. Pract. Periodical Struct. Des. Constr. 27 https://doi.org/10.1061/(ASCE)SC.1943-5576.0000731 (2022).

Siad, H., Lachemi, M., Sahmaran, M. & Hossain, K. M. A. Effect of glass powder on sulfuric acid resistance of cementitious materials. Constr. Build. Mater. 113, 163–173. https://doi.org/10.1016/j.conbuildmat.2016.03.049 (2016).

Özkan, Ö. & Yüksel, İ. Studies on mortars containing waste bottle glass and industrial by-products. Constr. Build. Mater. 22, 1288–1298. https://doi.org/10.1016/j.conbuildmat.2007.01.015 (2008).

Pavoine, A., Harbec, D., Chaussadent, T., Tagnit-Hamou, A. & Divet, L. Impact of alternative Cementitious material on mechanical and transfer properties of concrete. ACI Mater. J. 111 https://doi.org/10.14359/51686828 (2014).

Harbi, R., Derabla, R. & Nafa, Z. Improvement of the properties of a mortar with 5% of kaolin fillers in sand combined with metakaolin, brick waste and glass powder in cement. Constr. Build. Mater. 152, 632–641. https://doi.org/10.1016/j.conbuildmat.2017.07.062 (2017).

Garima Rawat, S., Gandhi, Y. I. & Murthy Durability aspects of concrete Containing Nano- Titanium Dioxide. ACI Mater. J. 120 https://doi.org/10.14359/51738490 (2023).

Jiang, X., Xiao, R., Bai, Y., Huang, B. & Ma, Y. Influence of waste glass powder as a supplementary cementitious material (SCM) on physical and mechanical properties of cement paste under high temperatures. J. Clean. Prod. 340, 130778. https://doi.org/10.1016/j.jclepro.2022.130778 (2022).

Yang, S., Lu, J. X. & Poon, C. S. Recycling of waste glass in cement mortars: mechanical properties under high temperature loading. Resour. Conserv. Recycl. 174, 105831. https://doi.org/10.1016/j.resconrec.2021.105831 (2021).

Guler, S., Türkmenoğlu, Z. F. & Ashour, A. Performance of single and hybrid nanoparticles added concrete at ambient and elevated temperatures. Constr. Build. Mater. 250, 118847. https://doi.org/10.1016/j.conbuildmat.2020.118847 (2020).

Acknowledgements

The authors extend their appreciation to Taif University, Saudi Arabia, for supporting this work through project number (TU-DSPP-2024-33). Authors gratefully acknowledge the Sophisticated Analytical Instrument Facility (SAIF), Karnatak University, Dharwad for rendering the support in conducting micro structural investigations.

Funding

This research was funded by Taif University, Saudi Arabia, Project No. (TU-DSPP-2024-33).

Author information

Authors and Affiliations

Contributions

Abhijeet Vidyadhar Baikerikar: Conceptualization, Methodology, Investigation, Validation, Writing - Original Draft, Visualization, Supervision. Vinayak Ganachari: Methodology, Investigation, Visualization. Veerendrakumar Khed: Investigation, Validation, SupervisionNaraindas Bheel: Formal analysis, visualization, methodology; Writing - Review & Editing.Ahmed Saleh Alraeeini: Formal analysis; Data analysis; visualization; Writing - Review & Editing.Hamad Almujibah: Visualization; Formal analysis; Funding Acquisition; Writing - Review & Editing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Baikerikar, A.V., Ganachari, V., Khed, V.C. et al. Synergistic effects of nano titanium dioxide and waste glass powder on the mechanical and durability properties of concrete. Sci Rep 14, 27573 (2024). https://doi.org/10.1038/s41598-024-79263-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-79263-9

Keywords

This article is cited by

-

Synergistic effects of fly ash, ground granulated blast furnace slag, and graphene oxide in low-carbon concrete: modelling, optimization, and sustainability assessment

Scientific Reports (2025)

-

Mechanical, microstructure, durability, and economic assessment of nano titanium dioxide integrated concrete

Scientific Reports (2025)

-

Optimization of durability characteristics of engineered cementitious composites combined with titanium dioxide as a nanomaterial applying RSM modelling

Scientific Reports (2025)

-

Modelling and Optimization of Waste Glass Sand in the Production of Sustainable Concrete Using Response Surface Methodology

Iranian Journal of Science and Technology, Transactions of Civil Engineering (2025)