Abstract

Guided by the goal of improving the heat transfer efficiency of geothermal cement, the development of high thermal conductivity fillers is urgently needed. Considering the drawbacks of carbon-based fillers in deteriorating the strength and fluidity of cement, this study proposes the use of green and low-cost deep eutectic solvents (DES) loaded with graphene oxide to form nanofluids (GONF) to improve the connection between graphene oxide and cement. The thermal conductivity and basic properties of GONF-cement under thermal storage conditions (60–100 °C, 0–36%NaCl) were reported, and the influence mechanism of nanofluids was analyzed. The following interesting conclusions were found: (1) The oxygen-containing functional groups on the surface of graphene oxide were connected to active sites of DES through the formation of the hydrogen bond network, forming thermal stable nanofluids. (2) Nanofluids was proven to be a low-cost (reduce material costs of graphene oxide by 90%) and effective material for enhancing the thermal conductivity and mechanical properties of geothermal cement while maintaining appropriate fluidity and low variation of density. (3) The synergistic mechanism between nanofluids and cement is due to the fact that nanofluids promotes hydration process by providing stable reaction sites, significantly reducing the porosity and pore size of cement. The dense structure enhances compressive strength and shortens the heat transfer path. This study enriches geothermal cementing technology and provides support for the low-cost application of graphene oxide in exploration engineering.

Similar content being viewed by others

Introduction

Under the advocacy of developing green and low-carbon energy, geothermal energy plays a notable role in the transition from fossil fuels, as it is independent of weather changes in daily/seasonal and unpredictable fluctuations in international commodity prices. Nowadays, geothermal resources are a reliable source of heating and/or electricity in 90 countries1,2,3.

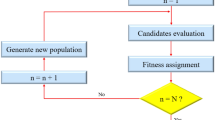

As Fig. 1 shows, building a reliable wellbore channel in the reservoir is the main way to explore and develop geothermal resources. Thermal reservoir drilling faces challenges such as low formation pressure, highly developed pores/fractures, and poor wellbore stability. Typically, cementing engineering is required, which pumps cement into the annular space between the casing and the formation to isolate loose4,5. Cementing is the key to determining the stability, service life, and production capacity of the entire life cycle of wells. Inappropriate drilling plans and cementing issues have resulted in an average exploration time of 56.4 days longer for 21 geothermal wells in the western United States than oil and gas wells6. Therefore, cement systems for geothermal cementing are actively being developed.

Brookhaven National Laboratory (BNL) is dedicated to the development of geothermal cement and has reported modified fly ash calcium aluminate blend cement with ultra-high temperature resistance7, sodium silicate-activated slag cement with acid resistant8, and thermal insulation and shock resistance calcium aluminate cement with composite fly ash cenospheres9. Pacific Northwest National Laboratory and National Energy Technology Laboratory developed a heat-stable cement with self-healing properties for geothermal wells using thermosetting disulfide epoxy resin and H-grade cement10. Continuous studies ensure successful exploration in extremely harsh geothermal environments such as high temperatures, corrosive gas pollution, and low pressures. These studies focused on the strength, fluidity, and solidification characteristics of cement.

However, with the deepening of research on the properties of geothermal cement, researchers have realized that the performance of geothermal wells also depends on the effective heat transfer between the working fluid extracted to the surface and the underground rocks. Based on the layered heat transfer model of medium/deep casing geothermal wells, thermal conductivity is the major factor affecting the heat extraction power of geothermal wells11,12. When the thermal conductivity of cement is the same as that of the formation, the heat generation power at 120 days increased by 10.29%. As the geothermal gradient and well depth increase, the influence of cement thermal conductivity on the system’s heat extraction efficiency deepens13. Song et al. also conducted similar numerical simulation studies, pointing out that the thermal conductivity of insulation pipes and cement has a significant impact on heat recovery efficiency, and proposed that using high thermal conductivity cement is beneficial for improving heat exchange efficiency14. Some works have been done on heat transfer intensifications for geothermal cement.

Narattha et al. proposed a thermal conductivity prediction model based on the linear relationship between thermal conductivity and temperature of cement used in geothermal sites in Mexico15. Liu et al. determined the priority of factors affecting cement thermal conductivity based on partial correlation analysis16. Zhang et al. constructed a mesoscale model for predicting the thermal conductivity of cement and analyzed the influence of factors such as aggregate saturation, volume fraction, and load level on the thermal conductivity17. The cement thermal conductivity model established based on the coupled series model and Maxwell-Eucken model discussed the influence of particle size, spacing, and curing temperature of thermal conductive fillers on the thermal conductivity of cement18. These simulation studies provide guidance for the design of high thermal conductivity cement.

In experimental research, Song et al. found that graphite increased the thermal conductivity of cement by 5% with the optimal ratio in the range of 0.05–0.15, but it also significantly reduced the compressive strength (CS) of cement from ~ 60 MPa to ~ 15 MPa19,20. Wang et al. found that the dosage of graphite or silicon carbide was significantly negatively correlated with cement strength. 30% graphite reduced cement strength to an unacceptable level of < 5 MPa21. Bao et al. developed high thermal conductivity cement for a ground source heat pump (GSHP) system based on expanded graphite and graphite nanosheet composites and also found a 40–50% reduction in CS value22. Yang et al. added graphite, iron powder, and quartz sand to G-grade cement, achieving an increase in thermal conductivity of 69.5%. However, as the filler content increased, the harmful porosity of the cement increased, and the flowability and strength continued to decrease. The 15% filler made the fluidity of the cement decrease to < 15 cm and the CS value < 10 MPa23. Similarly, in the cement composite with graphite/alumina/steel slag, a 77% increment in thermal conductivity is also accompanied by a decrease in CS24.

In short, it’s found that carbon-based fillers have achieved significant results in enhancing the thermal conductivity of cement, but at the same time, their deteriorating effect on the mechanical properties and pumpability of cement cannot be ignored. This is mainly due to their hydrophobicity and large specific surface area, which make them easily agglomerate in cement slurry and inhibit hardening25. In some heat-related engineering applications, materials such as natural flake graphite26, steel fibers27,28, copper powder29, silicon nitride and micro-silica powder30 have been proven to be fillers for enhancing the thermal conductivity of cement. However, these studies did not take into account the engineering environment of high-temperature and highly mineralized fluids in geothermal wells.

It can be seen that improving the thermal conductivity of geothermal casing cement is urgent and valuable. This paper innovatively proposes a composite based on deep eutectic solvents (DES) and graphene oxide (GO). GO was first chosen as a thermal conductive filler due to its extremely high thermal conductivity. Graphene-based materials with a perfect structure have almost the highest thermal conductivity among all known materials (> 5000 W/m K that is on par with diamond materials)31. Meanwhile, it exhibits poor dispersibility, interfacial and contact thermal resistance due to its 2D morphology and high aspect ratio, and the development of its composite materials has received high attention. Recently, DES have been regarded as the superior alternative for ionic liquids with similar properties but with much simpler synthesis, lower cost, and toxicity. Generally, DES is formed by mixing two to three compounds that provide hydrogen bond donors (HBD) and hydrogen bond acceptors (HBA) in a certain proportion. The lattice energy is reduced and the lattice structure is destroyed through hydrogen bonding between the compounds, resulting in a melting point of the product lower than that of any compound raw material32,33,34. The oxygen-containing functional groups on the surface of GO can connect with DES active sites by forming a hydrogen bond (HB) network. Hence, it is speculated that DES is a good solvent for GO to achieve the target of improving the dispersibility and reducing the dosage of GO. Therefore, the synergistic effect between GONF material and cement is also unknown and promising.

In this study, urea and choline chloride (ChCl) were selected as HBD and HBA to synthesize DES. Then, GONF was prepared using ultrasonic dispersion technology and its physicochemical properties were characterized. The laws and influence mechanisms of thermal conductivity, compressive strength, fluidity, density, and salt resistance of geothermal cement based on GONF have been comprehensively discussed to reveal the application potential of GONF. This undoubtedly has extremely important engineering significance and scientific value for improving the thermal energy utilization efficiency of geothermal development.

Materials and method

Materials

In this study, high sulfate resistant G-grade cement (G cement) was used, which was purchased from Qingyun Kangjing Building Materials Co., Ltd. (Dezhou, Shandong). S95 slag powder was purchased from Henan Dingnuo Purification Materials Co., Ltd. (Gongyi, Henan), which was made of blast furnace slag, and obtained by drying, grinding and other processes. Choline chloride (ChCl, AR 98%), and urea (AR 99%) were purchased from Shanghai Aladdin Biochemical Technology Co., Ltd. Nano graphene oxide (GO, 1500 mush) was purchased from Shandong Kangdu Electronic Technology Co., Ltd. Sodium chloride (NaCl, AR) was purchased from Sinopharm Chemical Reagent Co., Ltd.

The Raman spectrum of GO is shown in Fig. 2, with a D peak of 1261 cm−1 (sp3 carbon atom) and a G peak of 1560 cm−1 (sp2 carbon atom). The intensity ratio of the peaks of D and G is denoted as I(D/G), which reflects the degree of oxidation. In this study, the I(D/G) of GO is 0.825, indicating the presence of oxygen-containing functional groups on GO.

Method

Preparation of graphene nanofluids

Figure 3a shows the preparation process of GONF. Based on molecular dynamics simulation, as the proportion of urea increases, the strength of hydrogen bonds continuously increased. The optimal molar ratio of ChCl and urea is 1:2, which can maintain a lower melting point35. Therefore, 13.96 g ChCl and 12.01 g urea were weighed and mixed in a beaker, then the mixture was stirred continuously at 80 °C for 2 h with a magnetic heating stirrer (Model DF-101S, China). A uniform clarified liquid DES was obtained. Then, DES was used as the base solution, nanofluids were prepared by mixing 4 g GO per 100 g of DES. Finally, the mixture of DES and graphene was oscillated at 40 kHz for 30 min by using an ultrasonic disperser, and a graphene oxide nanofluid system was formed, which was recorded as “GONF”. After being left at room temperature for 7 days, GONF remained in a homogeneous fluid state without any layering or precipitation, indicating excellent stability performance.

As mentioned in the introduction, GO exhibits poor dispersion in aqueous solvent system. After placing in clean water and oscillating under the same conditions (40 kHz, 30 min), as shown in Fig. 3b, GO floats on the surface of clean water without any dispersion.

To further compare the improvement effect of hydrophilicity, a contact angle test (Model KRÜSS DSA25, Germany) was conducted between GO/GONF and fresh water. The larger the contact angle, the poorer the wettability of the material to water. Each sample is tested at 3 points and the average value is taken. When the contact angle > 90°, it is considered hydrophobic. As shown in Fig. 3c, The contact angles of GO are 84.3°, 82.3°, and 83.6°, with an average contact angle of 83.4°. Therefore, GO is almost hydrophobic and is difficult to disperse in the cement slurry. GONF significantly improved the hydrophilicity of GO, with the contact angles after treatment being 27.8°, 26.8°, and 29.4°, and the average value being 28.0°. The transition of GO from hydrophobic to hydrophilic makes them more suitable for cement slurry.

Preparation and performance testing of cement

Preparation of cement: The preparation and curing methods of cement refer to the national standard “GB/T 10238-2015”36. Weigh cement and slag in a mass ratio of 6:4. A cement slurry mixer (NJ-160B, China) was used to mix the solid materials and water, and the control group cement with a water-cement ratio of 0.6 was prepared. The cement slurry was poured into a triple mold (40 mm × 40 mm × 40 mm) and cured in a drying oven (Model 101-2BS, China) at 60/80/100 °C for 24 h to simulate the hardening environment in the early stage of cementing. After demolding, it was cured in a water bath (Model HH-600, China) for 48 h to simulate the effect of high-temperature geothermal fluids on cement. Moreover, to simulate the effect of high salinity geothermal water on cement, 5–36%NaCl solution was used to cure the cement samples.

The experimental group cement was added with 1–15% GO or 5–30% GONF as additives to the control group and cured at the same conditions. It should be noted that GO was mixed in the mass ratio of ash materials, while GONF was mixed in the volume ratio of water. For the convenience of calculating the amount of GO, the formula of cement prepared with 100 g ash materials is listed in Table 1.

Thermal conductivity coefficient test: The thermal conductivity tester (Model DRP-II, China) based on the flat plate steady-state method is used to test the thermal conductivity of disc-shaped cement (diameter 13 cm, thickness 1 cm). Record the temperature of the heat dissipation copper plate after stable heat transfer, and use analysis software to calculate the thermal conductivity. The measurement range is 0.1–300 W/(m K), room temperature ~ 110 °C.

Compressive strength test: A micro-controlled electronic universal testing machine (Model WDW-600E, China) was used to record the maximum load borne by the cement test block at a loading rate of 1.2 kN/s. The compressive strength was obtained by dividing it by the contact area. Each group was tested three times and took the average value.

Density test: The mass of the demolded block was weighed and divided by the volume (64cm3) to obtain the average density of the cement.

Fluidity test: The cement fluidity was tested based on the truncated cone mold (36 mm upper mouth diameter, 60 mm lower mouth diameter, and 60 mm height). The cement slurry was poured into the mold and a smooth glass plate was used as a substrate. After removing the mold, the maximum spreading diameter of the cement slurry was recorded.

Characterization of materials and mechanism analysis

Fourier transform infrared spectrometer (FT-IR): The Fourier transform infrared spectrometer Model Bruker Tensor II (Germany) and Model Thermo Fisher Scientific Nicolet iS20, (America) were used to test the FT-IR absorption spectra of solid samples and liquid samples at 4000 ~ 400 cm−1, respectively.

Thermal analysis test (TGA): A differential thermal thermogravimetric analyzer (Model TGA/DSC3+, Switzerland) was used to investigate the thermal stability of DES, GO, GONF, and cement samples in a nitrogen atmosphere at a heating rate of 10 °C/min with a testing temperature range of 25–750 °C.

Scanning electron microscope (SEM) and energy spectrum analysis (EDS): A field emission scanning electron microscopy system (Model JEOL JSM-7610F Plus, Japan) was used to observe the microstructure of the sample. Meanwhile, the mapping images of the samples were scanned and the elemental composition and content were analyzed.

X-ray diffraction analysis (XRD): Mineral analysis of cement powder samples was conducted using an X-ray diffraction analyzer (Model D8-ADVANCE, Germany). The 2θ angle was from 3 to 70° and the scan speed was 4°/min.

Mercury intrusion porosimetry (MIP): Mercury intrusion porosimetry (Model PoreMaster-33, America) was used to test the porosity and pore size distribution of cement test blocks (approximately 0.5 cm in diameter).

Results and discussion

Characterization of materials

FT-IR

Figure 4a and b display the FT-IR of ChCl, urea, and DES, respectively. The characteristic absorption peaks at 3440 cm−1 and 1681 cm−1 represent amino (-NH2) and carbonyl (C=O) groups in urea. The peak at 1478 cm−1 is the bending vibration of methylene (–CH2) in ChCl. The main characteristic peaks of urea and ChCl can be observed in the FT-IR spectrum of DES, indicating that the functional groups were stable after the formation of DES. The functional groups at 869 cm−1 and 953 cm−1 are assigned to symmetric stretching of C–C–O and C–N. Meanwhile, the characteristic peak of –NH2 shifted from 3440 to 3312 cm−1. The tensile vibration of C=O shifted from 1681 cm−1 to a lower wavenumber of 1662 cm−1, and the peak of –CH2 also shifted from 1478 to 1430 cm−1. This typical redshift confirmed the formation of complex hydrogen bonds in DES37,38.

In the FT-IR spectrum GO (Fig. 4c), the broad peak at 3424 cm−1 is caused by the stretching vibration of –OH. The peak at 1631 cm−1 is the C=C stretching vibration on the benzene-like ring skeleton. The absorption peak at 1400 cm−1 is the vibration of the C–O (H) group on the surface of the GO layer, and the peaks at 1246 cm−1 and 1029 cm−1 belong to the vibration of C–O and C–O–C, respectively39.

The peaks in the FT-IR spectrum of GONF (Fig. 4d) appear from that of DES and GO, however, with some shifts of the peaks. Significantly, the typical peaks of GONF include peaks at 868 cm−1 (C–C–O), and 951 cm−1 (symmetric stretching of C–N). The positions of the C–O–C (1078 cm−1), C–O (1242 cm−1), –CH2 (1429 cm−1), and C=C (1662 cm−1) are slightly shifted. Besides, the O–H band showed a blue shift from 3185 cm−1 in DES to 3189 cm−1 in GONF, indicating that some changes appear in the HBs state of DES on the GO surface. As reported, strong HBs produce higher vibrational band wavenumbers. Hence, it is speculated that the oxygen-containing functional groups on the surface of GO are connected with DES active sites by forming an HB network40, as shown in Fig. 4e.

TGA

As reported, the starting temperatures for the thermal decomposition of Urea and ChCl are 140 °C and 260 °C, respectively. Urea decomposed at 140–376 °C, sequentially forming products such as biuret, cyanuric acid, monoamide, and diamide, ultimately decomposing more completely into gaseous products41. ChCl undergoes strong decomposition at 260–320 °C, producing CO2, H2O, HCl, etc. The sample weight at 320 °C is less than 3%42. Therefore, the estimated initial decomposition temperature of DES based on hydrogen bonding will be higher than Urea, but not exceeding 260 °C.

The thermogravimetric (TG) curve and derivative thermogravimetric (DTG) curve of DES as shown in Fig. 5a, showed thermal stability within 200 °C, with a sample retention rate of 92.317%. DES showed the highest decomposition rate at 281 °C, which was 1.628%/min. At 350 °C, the sample retention rate was only 4.120%, indicating that the thermal decomposition of DES mainly occurred at 200–350 °C, which is consistent with theoretical analysis.

Figure 5b showed that GO had extremely high thermal stability within 600 °C, and the sample retention rate was higher than 99% during the heating process from 25 to 600 °C. As shown in Fig. 5c, the thermal decomposition of GONF occurred at 200–350 °C, with sample retention rates of 92.177% and 3.156% at 200 °C and 350 °C, respectively. The highest thermal decomposition rate at 278 °C was 1.661%/min. In summary, GONF showed a similar thermal decomposition trend to DES, and GO has a relatively low impact on the pyrolysis properties of GONF. GONF can maintain good thermal stability within 200 °C to ensure its applicability in geothermal environments.

SEM

As shown in Fig. 6, the morphology of GO, water-dispersed GO, and GONF were observed by scanning electron microscopy. Figure 6a1-2 showed that the raw material of GO was in the form of layered fragments at room temperature, with an average diameter within 20 μm. At the edge of morphological characterization, it is a little bit thicker rather than in the middle due to oxygen functional groups contained in the GO sample43. The SEM images of GO after ultrasonic dispersion in clean water for 30 min was shown in Fig. 6b1-2. The dispersibility of GO in water was poor, and it aggregated and accumulated to form a large area of block structure, many pores also appeared. This means that GO, as an external admixture, exhibits poor adhesion when mixed with cement and water to form a cement slurry, or even affects the mixing of ash and water.

On the contrary, as shown in Fig. 6c1-2, GO showed good dispersibility and formed a dense morphology in DES solvent. There are no significant pores in the images magnified by × 2000 and ×5000 times. Mapping scanning of Fig. 6c1 was carried out and shown in Fig. 6d. The EDS layered image was highly consistent with Fig. 6c1. Elemental analysis showed that the weight percentages of C and O elements were 97.56% and 2.44%, respectively. In short, DES is a good solvent for GO, and GONF is in a completely dispersed state, which makes it compatible with cement slurry.

Evaluation of thermal conductivity

The thermal conductivity of control group (G-cement), 1–15% GO-cement, and 5–30% GONF-cement were shown in Fig. 7. Figure 7a showed the thermal conductivity of GONF-cement cured at 60/80/100 °C, while Fig. 7b showed the increment in thermal conductivity compared to G-cement. The results showed that the addition of GONF significantly increased the thermal conductivity of cement. After curing at 60, 80, and 100 °C, 5% GONF increased the thermal conductivity of cement from 0.0955 W/m K to 0.1259, 0.1583, and 0.1851 W/m K, respectively, with growth rates of 31.8–120.6%. Overall, with the increase of GONF dosage, the thermal conductivity had an upward trend. The curing temperature had little effect on the thermal conductivity of the control group, and the thermal conductivity of G-cement cured at 60–100 °C fluctuated between 0.0839 and 0.0955 W/m K. However, the influence of temperature on the thermal conductivity of GONF-cement cannot be ignored. When T ≤ 80 °C, the thermal conductivity of 15–30% GONF-cement ranged within 0.2025 W/m K, and the increment of thermal conductivity reached 118.4%. When T > 80 °C, 5% GONF-cement had high thermal conductivity, with an increase in thermal conductivity coefficient of up to 120.6%.

As a comparison, Fig. 7c shows the thermal conductivity of 1–15% GO-cement and the increment after curing at 60 °C. Although GO has extremely high thermal conductivity, increasing the concentration of GO does not always have a beneficial effect on the thermal conductivity of cement. The research of Yang et al. pointed out that the addition of graphite-based carbon materials affected the hardening process of cement slurry and significantly increased the proportion of gel pores and transition pores in cement, while the proportion of large pores decreased. The increase of gel pores and transition pores inhibits the formation of interconnected heat conduction paths in the cement matrix, and the thermal conductivity of air in pores is far lower than that of the cement matrix44. Therefore, when the GO concentration increased from 1 to 5%, the increment of thermal conductivity continuously increased, increasing from 67.9 to 185.8%. When the GO content > 5%, increasing GO further leads to a dominant negative impact on the pore size distribution, and the increment of thermal conductivity begins to decrease. Overall, the improvement ability of GO on thermal conductivity showed a trend of first increasing and then decreasing.

This may be due to poor compatibility between GO and water, as excessive GO affected the uniform mixing and hardening process of the cement slurry. Therefore, 5% GO was the optimal dosage.

However, as listed in Table 1, 5% GO-cement directly mixed GO as an external additive, which was 5 g GO/100 g ash, while the content of GO in 5–30% GONF was only 0.12–0.72 g/100 g ash. In other words, GONF can achieve thermal conductivity equivalent to GO with only about 10% addition. Therefore, GONF has been proven to be an efficient and high-thermal conductive material, greatly reducing the engineering application cost of GO materials.

Evaluation of compressive strength, density and fluidity

The density of cement determines its hydrostatic column pressure, which should be balanced with the formation pressure. Geothermal reservoirs have low pressure and narrow safety density windows. Excessive density causes downhole accidents such as fracturing and severe leakage45,46. The compressive strength and flowability of geothermal cement are related to the stability of the wellbore and the pumpability of the cement. Therefore, the basic properties of 5–30% GONF-cement cured at different temperatures were evaluated, as shown in Fig. 8.

Figure 8a1 and a2 showed the effects of GO and GONF on the compressive strength (CS) of cement, respectively. GO as a nanomaterial, due to its small size and strong van der Waals forces and hydrogen bonds, is prone to agglomeration when directly mixed with cement ash, forming large aggregates and reducing specific surface area, making it difficult for GO-cement to achieve expected performance and even reducing cement mechanical properties47. In this study, the addition of GO reduced the CS of cement, which is consistent with the report by Zhu et al48. Then, the CS of cement continued to improve as the concentration of GO increased. When the dosage of GO ≥ 10%, the CS value exceeds the control group. This is because by continuing to increase the GO concentration, more GO participated in the hydration reaction of cement, and the cement’s total porosity remains within a relatively stable range, but the pore size distribution is different. According to the harmful pore theory, pore size < 100 nm has no effect on cement strength, while > 100 nm is harmful44,49. With the increase of GO concentration, the proportion of gel pores and transition pores in cement increases, while the content of macropores (> 1000 nm) decreases. Therefore, the cement strength shows an upward trend.

Based on the analysis in Section “Evaluation of thermal conductivity”, under the optimal concentration, the CS value of GONF- cement cured at different temperatures is consistently higher than that of the control group. For 15–25% GONF-cement cured at 60 °C, the CS value ranges from 26.4 to 29.3 MPa, which is higher than that of the control group (23.2 MPa). The CS value of 15–25% GONF cement cured at 80 °C is equivalent to that of the control group, ranging from 19.4 to 21.9 MPa. The CS of 5% GONF cement cured at 100 °C is 20.4 MPa, which is also higher than the control group (18.7 MPa). Therefore, GONF exhibits a synergistic enhancement effect on the mechanical properties of cement. After adding GONF, the oxygen functional groups (–COOH) react with Ca2+ to form COO–Ca–OOC, providing reaction sites for different hydration units. Meanwhile, the GO layer adsorbs free water, accelerating the hydration rate50,51. GONF significantly reduces the porosity and harmful pore content of cement by promoting the hydration process, and the dense cement matrix corresponds to an increase in compressive strength, as demonstrated in detail in Section “Chemistry and microstructure analysis”. In addition, GONF cement is much higher than the requirements for geothermal cementing (≥ 10.3 MPa). Taking into account the application cost of GONF and its impact on the thermal conductivity and mechanical properties of cement, the optimal dosage of GONF is 15–25% when T ≤ 80 °C, and 5% when T > 80 °C.

Figure 8b1 and b2 showed the effects of GO and GONF on the density of cement, respectively. The density of 1–15% GO-cement fluctuated between 1.528 and 1.617 g/cm3. With the increase in GO concentration, the cement density exhibited an upward trend. The density of GONF-cement first increased and then decreased as the concentration of GONF increased. When T ≤ 80 °C, the density of 15–25% GONF-cement ranged from 1.477 to 1.586 g/cm3. Compared with G-cement, the changes at 60 °C and 80 °C were 1.87–2.26% and 0.92–3.4%, respectively. At T > 80 °C, the density increment of 5% GONF-cement was 5.47%. Overall, in low-pressure formations with narrow safety windows, GONF-cement still has wide applicability52,53.

Figure 8c1 and c2 showed the effects of GO and GONF on the fluidity of cement. GO had a significant adverse effect on the pumpability of cement. When the concentration of GO was higher than 3%, the fluidity rapidly and continuously decreased. When the dosage of GO ≥ 5%, the fluidity of GO-cement decreased to 14.5 cm, far below the standard requirements of geothermal cement. On the contrary, GONF improved the cement fluidity. The fluidity of GONF-cement gradually increased from 20.3 to 23.7 cm with the increase of GONF. The fluidity of 5–30% GONF-cement ranged from 21 to 23.7 cm, highly meeting the optimal fluidity range required by the specifications54. This is also a significant advantage of GONF.

Pollution resistance of salt ion

Based on hydro-chemical analysis of geothermal fluids in multiple regions of China, the geothermal aquifer is characterized by high TDS contents and with Na-Cl facies due to the dissolution of halite and feldspar55,56,57. Therefore, GONF-cement was cured with NaCl solution (from 10% to saturated) at 60 °C to simulate the erosion of geothermal water. As shown in Fig. 9, the thermal conductivity, mechanical properties, and density of GONF-cement were studied. As the fluidity of cement was conducted before solidification, it is not discussed here.

As shown in Fig. 9a, compared with G-cement, the thermal conductivity increments of GONF-cement cured at 10%, 20%, and 30%NaCl were 17.6%, 27.3%, and 29.8%, respectively. As the concentration of NaCl increased, the thermal conductivity of GONF-cement continues to decrease, and it was lower than the control group in saturated salt solution (36% NaCl). Figure 9b indicated that the addition of GONF has no significant negative effect on the mechanical properties of cement, and the compressive strength of GONF-cement was equivalent to G-cement at different NaCl concentrations. The CS value of GONF-cement cured with 10–36% NaCl fluctuated between 22.9 and 25.7 MPa, which was lower than that of GONF-cement cured with fresh water (29.3 MPa), but much higher than the requirements of cementing standards (≥ 10.3 MPa). Similarly, the density of GONF-cement in Fig. 9c ranged from 1.512 to 1.541 g/cm3, which was also lower than that of GONF-cement cured with water (1.568 g/cm3). As reported, an appropriate amount of NaCl can react with cement hydration products (C3A, Ca(OH)2) through the Friedel’s salt and Kuzel’s salt equations to form chloroaluminate compounds, which have no expansion and are absorbed to the calcium silicate58. However, research also pointed that, Cl− vie with sulfate ions to react with tricalcium aluminate (C3A, 3CaO·Al2O3) and produce ettringite (AFt), resulting in disruptive expansion and cement disintegration into an incoherent granular mass59,60. When the expansion stress is greater than the tensile stress inside the cement, it leads to deterioration, cracking, and reduced strength of the cement61. Obviously, under the high mineralization conditions of this study, Cl- leads to the formation of an expanded loose structure in geothermal cement, which further leds to a decrease in thermal conductivity, density, and compressive strength.

In short, NaCl reduces the density and CS value of cement to a certain extent. From the perspective of mechanical properties, the salt resistance of GONF-cement can reach 36% NaCl, and it has the advantage of improving the thermal conductivity of cement under ≤ 30% NaCl conditions.

Chemistry and microstructure analysis

XRD and FT-IR analysis of cement powder

XRD and FT-IR analysis was used to investigate the various crystal phases present in G-cement and GONF-cement cured at 60/80/100 °C, as shown in Figs. 10a–c, 11a–c. In the XRD curves, the peak at 2θ of ~ 12° belongs to un-hydrated C4AF. The peaks belonging to ettringite (AFt) appeared at 2θ of ~ 29.3°. The peaks at 2θ of ~ 29°, ~ 32°, ~ 41° relate to un-hydrated C2S and C3S. CaCO3 showed peaks at 2θ of ~ 23°. In GONF-cement, the characteristic peak of CaCO3 may be overlapped by GO at ~ 22.7°62. The peaks related to the Ca(OH)2 were identified at 2θ of ~ 18°, 28°, 34°, 47°, 50°, and 54°63,64,65. GONF-cement had the same hydration products as G-cement, mainly including calcium silicate hydrate (C–S–H gel, Ca5Si6O16(OH)·4H2O), un-hydrated dicalcium silicate (C2S, 2CaO·SiO2) and tricalcium silicate (C3S, 3CaO·SiO2), Ca (OH)2, AFt, etc., which indicated that the addition of GONF did not induce additional crystal hydration products.

As shown in Fig. 11 and Table 2, the main peaks of the FT-IR spectrum were attributed to the corresponding functional groups. The Ca(OH)2 exhibited a sharp peak at ~ 3645 cm-1, and it had higher intensity in GONF-cement. The symmetric and asymmetric stretching vibrations of O–H from water molecules and C–S–H showed a broad absorption at ~ 3440 cm−1. The H–O-H bending vibration also exhibited a peak at ~ 1645 cm−1. The asymmetric stretching vibration of SO42− in AFt showed a peak at ~ 1110 cm−1. The sharp peak at 1420 cm−1 and the gentle peak at 1480 cm−1 belong to the asymmetric stretching of CO32− from CaCO3. And the out-of-plane bending at ~ 875 cm−1 corresponded to the fundamental bands of CO32−. The peaks at ~ 526 cm−1 and ~ 456 cm−1 were attributed to the out-of-plane Si–O bending and in-plane Si–O bending from C3S/C2S, respectively65,66,67,68. Moreover, strong band appeared at high frequency centered at ~ 920–980 cm−1 with the formation of xCaO·ySiO2·zH2O (C–S–H). Compared to the G-cement, the characteristic peaks of GONF-cement cured at 60/80/100 °C blue shifted from 968 cm−1, 957 cm−1, 949 cm−1 to 973 cm−1, 964 cm−1, and 966 cm−1, respectively, indicating the formation of more C–S–H products in the GONF-cement69,70,71.

In summary, based on the XRD and FT-IR analysis, after 60/80/100 °C cured, the addition of GONF does not affect the hydration products type of cement, which mainly includes C2S and C3S, C–S–H, AFt, Ca(OH)2, and CaCO3. At 60–100 °C, GONF promoted the transformation of C2S/C3S into C–S–H, which indicates that GONF could promote cement hydration.

TGA

As shown in Fig. 12 and Table 3, the mass loss of G-cement and GONF-cement cured at 60/80/100 °C was determined by TGA technique, and the difference in hydration product content was quantitatively analyzed. Figure 12 showed that GONF-cement exhibited four stages of mass loss transformation within the testing range of 30–750 °C. According to previous research65,72, the dehydration of pore water occurred in the early stage of thermal degradation (30–120 °C), which is also the most intense. The second stage (120–300 °C) represents the decomposition of C–S–H gels, ettringite (AFt), and part of CaCO3. The third stage (300–500 °C) represented the dehydroxylation of Ca(OH)2, which occurred through a hydration reaction. The fourth stage (500–750 °C) represented the degradation of remaining CaCO3. Thanongsak et al. proposed that the total weight loss in TGA can reflect the hydration reaction of cement slurry and is also related to its compressive strength70. The results showed that the total weight loss (30–750 °C) of GONF-cement cured at 60/80/100 °C was 5.342%, 9.766%, and 4.912% higher than that of the control group, respectively. After subtracting pore water from the total mass loss, the total mass of hydration products (C–S–H, AFt, Ca(OH)2, CaCO3, etc.) of GONF-cement cured at 60/80/100 °C were 17.859%, 19.724%, and 16.244%, respectively, which were 4.589%, 6.459%, and 1.976% higher than the control group. This indicated that the addition of GONF promoted the hydration process of cement, which helped to form a dense cement structure and improve the thermal conductivity and mechanical properties.

SEM

Figure 13 showed the SEM images of G-cement and GONF-cement at different magnifications. The hydration products in XRD and FT-IR analysis were found in the cement matrix. The polygonal plate-like, spherical, and needle shaped structures in the images were marked as Ca (OH) 2, CaCO3, and AFt, respectively73,74. The C–S–H gel appeared in the form of honeycomb-shaped coral clusters. In Fig. 13a, G-cement showed a loose structure, and the adhesion between matrix and aggregate was poor, especially the lack of close combination between the C–S–H edge and other products in Fig. 13a3, a4, thus forming a large number of micropores/microcracks in the structure.

The GONF-cement in Fig. 13b had a dense structure. At ×2000 and ×5000, many C–S–H was found. The Ca(OH)2, CaCO3, and AFt were locally dispersed in the cement matrix. Good adhesion was observed in both the hydration products and the hydration products/matrix. As shown in Fig. 13b4, b6, after magnifying the two sites by ×10,000 times, dense C–S–H structures could still be observed. This visually demonstrated that GONF promoted the hardening of cement and the formation of C–S–H, resulting in a denser structure. Moreover, GO was also found in the GONF-cement. As marked in Fig. 13b7-8, the oxygen-containing functional groups of GO interact with the active components in cement to form hydrate crystal nuclei. GO is displayed in the microstructure of layered crystals interlocking and interpenetrating in cement, exhibiting unique flower-shaped crystals.

MIP

The mercury intrusion porosimeter was used to quantitatively characterize the pore distribution of G-cement and GONF-cement, and the results were shown in Fig. 14, Tables 4, 5. Compared with G-cement, the porosity of GONF-cement decreased from 48.6222 to 40.8757%. The mode value characterized the highest value of frequency size distribution, and the addition of GONF shifted the mode value to the left of the coordinate axis, reducing it from 1.653 to 1.087 μm, with a decrease of 34.24%. Based on the pore size, cement pores can be divided into four categories: macropores (> 1 μm), capillary pores (0.1–1 μm), transition pores (0.01–0.1 μm), and gel pores (< 0.01 μm)75,76,77. As Fig. 14a and Table 5 showed, G-cement exhibited continuous peaks (1.65 μm, 7.66 μm, 22.80 μm) in the regions of transition pores and macropores. While the peak of GONF-cement mainly occurred in the regions of 0.02–0.1 μm and 0.5–2 μm, with 67.91% pores of the transition pores and capillary pores. After adding GONF, the content of gel pores decreased from 5.84 to 3.79%, and the proportion of macropores also decreased by 8.04%. As shown in Fig. 14b, the diameter corresponding to 50% mercury injection volume was the median diameter (D50), and the D50 of GONF-cement was 29.57% lower than G-cement.

In short, the MIP results were consistent with the FT-IR, TGA analysis and the SEM observation, that is, the hydration process in G-cement was greatly promoted by GONF, and the hydration products effectively filled the micropores of cement. Therefore, GONF significantly reduced the porosity and pore diameter of cement, simultaneously reduced the number of gel pores and macropores, and optimized the pore size distribution of cement78. Dense cement structure corresponded to higher thermal conductivity and mechanical properties.

Mechanism analysis of the effect of GONF on cement properties

Based on the XRD analysis, the addition of GONF does not form additional crystal hydration products, which mainly include C–S–H gel, C3S, C2S, AFt, Ca(OH)2, and CaCO3. Then, FT-IR and TGA qualitatively and quantitatively confirmed the promotion of GONF on cement hydration. During the hardening process at 60–100 °C, GONF may promote the conversion of un-hydrated C2S/C3S to C–S–H through providing stable reaction sites, effectively filling the cement pores. Therefore, in the MIP test, it was observed that the porosity, pore diameter, the content of gel pores and macro-pores were significantly reduced. Also, the cement matrix and hydration products with good cohesiveness were observed in the SEM images. A dense cement skeleton corresponds to an increase in compressive strength. Meanwhile, it helps to improve the thermal conductivity.

Cement transfers energy from the high-temperature region to the low-temperature region as an inorganic porous medium composite material through lattice vibration, that is, phonon heat transfer26. The thermal conductivity of air (0.026 W/(m K)) is much lower than the phase in cement slurry (C–S–H is 0.98 W/(m K)). Hence, the reduction in pore space is an important factor leading to the improvement in the thermal conductivity of cement79,80. When the total porosity of cement decreases by 22.6%, it will also cause a 43.6% increase in thermal conductivity81,82. Sarkar et al. proposed that when the content of macro-porosity (> 6 μm) in cement increased by 14.2%, the thermal conductivity decreased by 8.3% accordingly83. Due to the Knudsen effect induced by the nanoscale pore, the thermal conductivity in the C–S–H gel pore is also significantly decreased84. As shown in Fig. 15, Given the high thermal conductivity of GO material itself, GONF was evenly dispersed in the cement matrix to form a thermal conduction path. Besides, C–S–H gel filled the pores in the cement skeleton, forming a dense thermal conduction network. Finally, the heat transfer efficiency of cement was improved significantly by shortening the thermal conductivity path85.

Conclusion

In this study, DES was used as a carrier for GO to produce nanofluids (GONF) to improve dispersibility and reduce the use of expensive GO. The potential application of GONF in improving thermal conductivity in geothermal cement was innovatively explored, successfully solving the problems of cement strength weakening and rapid decrease in fluidity caused by the existing high-thermal conductivity materials. The following conclusions can be summarized:

-

1.

The typical redshift observed in the FT-IR spectrum confirmed that ChCl and Urea form DES through hydrogen bonding. The characterization of GONF suggested that the oxygen-containing functional groups on the surface of GO were connected to active sites of DES through the formation of an HB network, forming stable nanofluids. The thermal decomposition trend of GONF was similar to that of DES, and it can maintain good thermal stability within 200 °C, which ensures its applicability in geothermal cement.

-

2.

GONF has been proven to be an efficient and highly thermally conductive material. By adding only about 10% content of GO, a comparable thermal conductivity enhancement effect can be achieved, which greatly reducing the cost of GO materials. When T ≤ 80 °C, the thermal conductivity increment of 15–30% GONF-cement reached 66–118.4%. When T was in the range of 80–100 °C, 5% GONF-cement showed a higher thermal conductivity, with an increase of 120.6% compared to the control group. Moreover, GONF exhibited a synergistic enhancement in the mechanical properties of cement. The flowability of GONF-cement (21–23.7 cm) was within the optimal flowability range. The density variation of GONF cement was controlled within 5.47%, making it applicable in low-pressure formations with narrow safety windows.

-

3.

The presence of Cl- promoted the formation of components that caused destructive expansion, which to some extent reduced the density and CS value of cement. However, GONF-cement has the advantage of improving the thermal conductivity of cement at ≤ 30% NaCl. From the perspective of mechanical properties, the salt resistance of GONF-cement can reach a saturated salt solution (36% NaCl).

-

4.

The addition of GONF does not form novel hydration products in G-cement. However, GONF promoted the hydration process by providing a stable reaction site, so that the cement matrix and hydration products were well combined. The porosity, pore size, gel pores, and macropores in cement were significantly reduced, and the densified cement skeleton corresponded to the increase in compressive strength. Meanwhile, GONF shortened the heat transfer path by forming a dense thermal conductivity network in the cement matrix, significantly improving the thermal conductance of cement.

In summary, GONF has been proven to be a low-cost (reduce material costs by 90%) and effective material for enhancing the application performance of geothermal cement. A breakthrough has been made in controlling the damage caused by traditional carbon-based thermal conductive materials to the physical–chemical properties of cement. Furthermore, the effectiveness of a small amount of graphene loaded with DES was demonstrated in this study, which is expected to support the large-scale application of expensive graphene in exploration engineering. In future research, we will continue to explore the load-bearing capacity of DES prepared from different hydrogen bond donors/acceptors for GO and its synergistic effect on cement.

Data availability

The datasets used and analyzed during the current study are available from the corresponding author on request.

References

Jolie, E. et al. Geological controls on geothermal resources for power generation. Nat. Rev. Earth Environ. 2, 324–339. https://doi.org/10.1038/s43017-021-00154-y (2021).

Soltani, M. et al. Environmental, economic, and social impacts of geothermal energy systems. Renew. Sustain. Energy Rev. 140, 110750. https://doi.org/10.1016/j.rser.2021.110750 (2021).

Zhuanzhuan, W. et al. The characteristics and development of geothermal resources in China. Water Resour. Hydropower Eng. 50, 187–195 (2019).

Bu, Y. et al. Investigating the applicability of novel hydrate dissociation inhibitors in oilwell cement through molecular simulations. Sci. Rep. https://doi.org/10.1038/s41598-024-65935-z (2024).

Zou, Q., Wang, W. & Wang, X. Modification mechanism of calcium lignosulfonate on cementing cement. Sci. Rep. https://doi.org/10.1038/s41598-024-58077-9 (2024).

Arbad, N., Emadi, H. & Watson, M. A comprehensive review of geothermal cementing from well integrity perspective. J. Pet. Sci. Eng. 217, 110869. https://doi.org/10.1016/j.petrol.2022.110869 (2022).

Sugama, T., Weber, L. & Brothers, L. E. Sodium-polyphosphate-modified fly ash/calcium aluminate blend cement: Durability in wet, harsh geothermal environments. MatL 44, 45–53. https://doi.org/10.1016/s0167-577x(00)00002-1 (2000).

Sugama, T. & Brothers, L. E. Sodium-silicate-activated slag for acid-resistant geothermal well cements. Adv. Cem. Res. 16, 77–87. https://doi.org/10.1680/adcr.16.2.77.36256 (2004).

Sugama, T. & Pyatina, T. Hydrophobic lightweight cement with thermal shock resistance and thermal insulating properties for energy-storage geothermal well systems. Materials 14, 6679. https://doi.org/10.3390/ma14216679 (2021).

Childers, M. I. et al. Polymer-cement composites with self-healing ability for geothermal and fossil energy applications. Chem. Mater. 29, 4708–4718. https://doi.org/10.1021/acs.chemmater.7b00344 (2017).

Han, Y. et al. Influencing patterns of multiple factors on the heat transfer performance of moderately deep geothermal wells. Coal Geol. Explor. 52, 104–116 (2024).

Ji, Y. et al. Analysis of the thermal insulation performance of cement with waste glass powder in geothermal well. Sci. Rep. https://doi.org/10.1038/s41598-024-67546-0 (2024).

Li, R. et al. Numerical analysis of the effect of cement sheath on the heat extraction performance of coaxial borehole heat exchangers geothermal system. Build. Sci. 34, 36–40 (2018).

Song, X. et al. Heat extraction performance of a downhole coaxial heat exchanger geothermal system by considering fluid flow in the reservoir. Geoth 76, 190–200. https://doi.org/10.1016/j.geothermics.2018.07.012 (2018).

Narattha, C., Wongkeo, W., Thongsanitgarn, P. & Chaipanich, A. Compressive strength and thermal conductivity of water and air cured portland cement-fly-ash-silica fume mortars. Environ. Eng. Manag. J. 17, 2023–2030 (2018).

Liu, K., Wang, Z., Jin, C., Wang, F. & Lu, X. An experimental study on thermal conductivity of iron ore sand cement mortar. Constr. Build. Mater. 101, 932–941. https://doi.org/10.1016/j.conbuildmat.2015.10.108 (2015).

Zhang, W., Min, H., Gu, X., Xi, Y. & Xing, Y. Mesoscale model for thermal conductivity of concrete. Constr. Build. Mater. 98, 8–16. https://doi.org/10.1016/j.conbuildmat.2015.08.106 (2015).

Yang, Y. et al. Calculation model and influence factors of thermal conductivity of composite cement-based materials for geothermal well. Geotherm. Energy https://doi.org/10.1186/s40517-024-00282-w (2024).

Song, X. et al. Study on thermal conductivity of cement with thermal conductive materials in geothermal well. Geoth 81, 1–11. https://doi.org/10.1016/j.geothermics.2019.04.001 (2019).

Zheng, R. et al. Study on factors affecting thermal conductivity of thermal conductive cement in geothermal well. Acta Energiae Solaris Sinica 42, 10–15 (2021).

Wang, S. et al. Investigation on thermal conductivity property and hydration mechanism of graphene-composite cement for geothermal exploitation. Geoth 104, 102477. https://doi.org/10.1016/j.geothermics.2022.102477 (2022).

Bao, X., Memon, S. A., Yang, H., Dong, Z. & Cui, H. Thermal properties of cement-based composites for geothermal energy applications. Materials 10, 462. https://doi.org/10.3390/ma10050462 (2017).

Yang, Y. et al. Investigation on the preparation, properties, and microstructure of high thermal conductive cementing material in 3500m-deep geothermal well. Geoth 100, 102322. https://doi.org/10.1016/j.geothermics.2021.102322 (2022).

Ji, Y. et al. Performance evaluation of geothermal cementing materials based on orthogonal tests. J. Mater. Sci. Eng. 40, 1018–1024 (2022).

Su, X. et al. Thermal conductivity of cement stone modified with superfine graphite. China Powder Sci. Technol. 29, 61–71 (2023).

Wang, S., Jian, L., Shu, Z., Chen, S. & Chen, L. A high thermal conductivity cement for geothermal exploitation application. Nat. Resour. Res. 29, 3675–3687. https://doi.org/10.1007/s11053-020-09694-4 (2020).

Sang, G. et al. Development of a novel sulphoalumitate cement-based composite combing fine steel fibers and phase change materials for thermal energy storage. Energy Build. 183, 75–85. https://doi.org/10.1016/j.enbuild.2018.10.039 (2019).

Liu, K., Wang, F. & Wang, X. Influence factor of thermal conductivity of cement concrete and its prediction model. J. Build. Mater. 15, 771–777 (2012).

Bae, J.-H., Woo, B. H., Kim, H. G. & Ryou, J.-S. Enhancing the thermal properties of cement composites through substitution of the fine aggregate using metallic material. Int. J. Pavement Eng. https://doi.org/10.1080/10298436.2022.2144311 (2023).

Xiang, J. et al. Nano composite cement material with synergistic enhancement of consolidation/thermal conductivity comprises base cement material, nano-synergistic enhanced material, additive and water, where basic cement material includes thermal conductivity and strength enhancement materials. CN116730662-A.

Huang, X. et al. Thermal conductivity of graphene-based polymer nanocomposites. Mater. Sci. Eng. R-Rep. 142, 100577. https://doi.org/10.1016/j.mser.2020.100577 (2020).

Paiva, A. et al. Natural deep eutectic solvents-solvents for the 21st century. Acs Sustain. Chem. Eng. 2, 1063–1071. https://doi.org/10.1021/sc500096j (2014).

Li, X. & Row, K. H. Development of deep eutectic solvents applied in extraction and separation. J. Sep. Sci. 39, 3505–3520. https://doi.org/10.1002/jssc.201600633 (2016).

El Achkar, T., Greige-Gerges, H. & Fourmentin, S. Basics and properties of deep eutectic solvents: A review. Environ. Chem. Lett. 19, 3397–3408. https://doi.org/10.1007/s10311-021-01225-8 (2021).

Sun, H., Li, Y., Wu, X. & Li, G. Theoretical study on the structures and properties of mixtures of urea and choline chloride. J. Mol. Model. 19, 2433–2441. https://doi.org/10.1007/s00894-013-1791-2 (2013).

Administration, C. N. S. Vol. GB/T 10238–2015 (2015).

Fan, X. et al. Deep eutectic solvent intercalation graphene oxide with strong interfacial adsorption capacity towards efficient lubrication. Carbon 216, 118508. https://doi.org/10.1016/j.carbon.2023.118508 (2024).

Lin, H. et al. Graphene-based deep eutectic solvent nanofluids with high photothermal conversion and high-grade energy. Chem. Eng. J. 405 (2021).

Gang, W. et al. Determination of the oxidizability on the surface of the graphene oxide layer by infrared spectroscopy. Spectrosc. Spectr. Anal. 40, 1722–1727 (2020).

Lin, H. et al. Nanoconfined deep eutectic solvent in laminated MXene for efficient CO2 separation. Chem. Eng. J. 405, 126961. https://doi.org/10.1016/j.cej.2020.126961 (2021).

Chong-huan, Q., Chun-lan, M., Ming-ru, J. & Wen-cong, W. Comparativeanalysis of thermogravimetric test of urea deposits under different heating rates. J. Guangxi Univ. 46, 394–404 (2021).

Zhu, W. & Zheng, X. Biodegradable lubricant with high-temperature and ioniccontamination resistance: Deep eutectic solvent ChCl-PEG. ACS Omega 7, 38380–38388 (2022).

Handayani, M. et al. In 2nd International Seminar on Metallurgy and Materials (ISMM). (2019).

Yu, Y. et al. Preparation, properties and structure of high heat conduction and low density cementing materials for geothermal wells. Drill. Fluid Complet. Fluid 38, 93–101 (2021).

Hamid, A., Setiati, R. & Santoso, A. In 4th Annual Applied Science and Engineering Conference (AASEC). (2019).

Tan, H. et al. Light-weight temporary-sealing cement for medium temperature geothermal wells by using polyvinyl alcohol fibers and fly ash cenospheres. J. Pet. Sci. Eng. 215, 110704. https://doi.org/10.1016/j.petrol.2022.110704 (2022).

Korayem, A. H., Tourani, N., Zakertabrizi, M., Sabziparvar, A. M. & Duan, W. H. A review of dispersion of nanoparticles in cementitious matrices: Nanoparticle geometry perspective. Constr. Build. Mater. 153, 346–357. https://doi.org/10.1016/j.conbuildmat.2017.06.164 (2017).

Linlin, Z. Controllable Dispersion of Graphene Oxide and its Impact on Structure and Properties of Cement-based Composites Master’s degree thesis, Shaanxi University of Science and Technology, (2018).

Cuizhen, X., Aiqin, S. & Yinchuan, G. Prediction model for the compressive strength of concrete mixed with CWCPM based on pore structure parameters. Mater. Rep. 33, 1348–1353. https://doi.org/10.11896/cldb.18040075 (2019).

Wang, M., Wang, R., Yao, H., Wang, Z. & Zheng, S. Adsorption characteristics of graphene oxide nanosheets on cement. Rsc Adv. 6, 63365–63372. https://doi.org/10.1039/c6ra10902k (2016).

Sharma, S., Kothiyal, N. C. & Chitkara, M. Enhanced mechanical performance of cement nanocomposite reinforced with graphene oxide synthesized from mechanically milled graphite and its comparison with carbon nanotubes reinforced nanocomposite. Rsc Adv. 6, 103993–104009. https://doi.org/10.1039/c6ra23421f (2016).

Jian, Z., Dewei, G. & Haibing, Y. A early-strengthh and Low-denstiy cement slurry system used to improve cementing in low-pressure thief zones. Nat. Gas Ind. 32, 72–74 (2012).

Zhang, W., Wei, R., Yang, H., Liu, P. & Niu, G. Application of cement slurry with ultra-low density: A case study from Well Baiquan 1, Junggar Basin. Nat. Gas Ind. 32, 69–71 (2012).

Liming, J., Sheng, W., Liyi, C. & Zhihong, S. In The 20th National Exploration Engineering (Geotechnical Drilling and Excavation Engineering) Academic Exchange Annual Conference 233–239 (Qinghai, China, 2019).

Duan, R., Li, P., Wang, L., He, X. & Zhang, L. Hydrochemical characteristics, hydrochemical processes and recharge sources of the geothermal systems in Lanzhou City, northwestern China. Urban Clim. https://doi.org/10.1016/j.uclim.2022.101152 (2022).

Li, X., Huang, X., Liao, X. & Zhang, Y. Hydrogeochemical characteristics and conceptual model of the geothermal waters in the Xianshuihe Fault Zone, Southwestern China. Int. J. Env. Res. Public Health 17, 500. https://doi.org/10.3390/ijerph17020500 (2020).

Yin, H. et al. Hydrochemical characteristics and genetic mechanism of porous sandstone geothermal water in northern Jinan, Shandong, China. Environ. Sci. Pollut. Res. https://doi.org/10.1007/s11356-024-32714-2 (2024).

Li, G., Zhang, A., Song, Z., Liu, S. & Zhang, J. Ground granulated blast furnace slag effect on the durability of ternary cementitious system exposed to combined attack of chloride and sulfate. Constr. Build. Mater. 158, 640–648. https://doi.org/10.1016/j.conbuildmat.2017.10.062 (2018).

Shaheen, F. & Pradhan, B. Role of chloride ion and cation type accompanied by sulfate ion on durability performance of concrete in conjoint chloride-sulfate environment. J. Mater. Civ. Eng. 32, 1–21. https://doi.org/10.1061/(asce)mt.1943-5533.0003319 (2020).

Wang, K. J., Nelsen, D. E. & Nixon, W. A. Damaging effects of deicing chemicals on concrete materials. Cem. Concr. Compos. 28, 173–188. https://doi.org/10.1016/j.cemconcomp.2005.07.006 (2006).

Mingjing, Y., Jianheng, S., Yang, X. & Junlin, W. Analysis of influence from iron tailings powder on sulfate corrosion resistance of concrete and its mechanism. Water Resour. Hydropower Eng. 53, 177–185 (2022).

Xu, S., Liu, J., Xue, Y., Wu, T. & Zhang, Z. Appropriate conditions for preparing few-layered graphene oxide and reduced graphene oxide. Fuller. Nanotub. Carbon Nanostructures 25, 40–46. https://doi.org/10.1080/1536383x.2016.1247268 (2017).

Wang, R., Yao, L. & Wang, P. Mechanism analysis and effect of styrene-acrylate copolymer powder on cement hydrates. Constr. Build. Mater. 41, 538–544. https://doi.org/10.1016/j.conbuildmat.2012.12.028 (2013).

Zhang, G., Zhao, J., Wang, P. & Xu, L. Effect of HEMC on the early hydration of Portland cement highlighted by isothermal calorimetry. JTAC 119, 1833–1843. https://doi.org/10.1007/s10973-014-4346-6 (2015).

Tan, H., He, W., Ye, Y., Chen, Y. & Zheng, X. Influence of polyvinyl alcohol coated porous Al2O3 ceramic waste particles on cement properties in geothermal applications. Constr. Build. Mater. 376, 1–11. https://doi.org/10.1016/j.conbuildmat.2023.131046 (2023).

Trezza, M. A. Hydration study of ordinary portland cement in the presence of zinc ions. Mater. Res. 10, 331–334. https://doi.org/10.1590/s1516-14392007000400002 (2007).

Kupwade-Patil, K., Palkovic, S. D., Bumajdad, A., Soriano, C. & Buyukozturk, O. Use of silica fume and natural volcanic ash as a replacement to Portland cement: Micro and pore structural investigation using NMR, XRD, FTIR and X-ray microtomography. Constr. Build. Mater. 158, 574–590. https://doi.org/10.1016/j.conbuildmat.2017.09.165 (2018).

Yousuf, M., Mollah, A., Parga, J. R. & Cocke, D. L. An infrared spectroscopic examination of cement-based solidification/stabilization systems-Portland types V and IP with zinc. J. Environ. Sci. Health Part A Environ. Sci. Eng. Toxic Hazard. Subst. Control 27, 1503–1519. https://doi.org/10.1080/10934529209375809 (1992).

Tao, S., Zeping, Y. & Liwei, Z. FTIR spectra for early age hydration of cement-based composites incorporation with CNTs. AcMCS 34, 653–660 (2017).

Nochaiya, T., Sekine, Y., Choopun, S. & Chaipanich, A. Microstructure, characterizations, functionality and compressive strength of cement-based materials using zinc oxide nanoparticles as an additive. JAllC 630, 1–10. https://doi.org/10.1016/j.jallcom.2014.11.043 (2015).

Chen, X. et al. Improved low-carbon magnesium oxysulfate cement pastes containing boric acid and citric acid. Cem. Concr. Compos. 134, 104813. https://doi.org/10.1016/j.cemconcomp.2022.104813 (2022).

Tantawy, M. A. Effect of high temperatures on the microstructure of cement paste. J. Mater. Sci. Chem. Eng. 5, 33–48. https://doi.org/10.4236/msce.2017.511004 (2017).

Rui, Z. et al. Study on factors affecting thermal conductivity of thermal conductive cement in geothermal Well. ACTA Energiae Solaris Sinica 42, 10–15 (2021).

Yang, Y. et al. Study on the performance and mechanism of high thermal conductivity and low-density cementing composite for deep geothermal wells. Energy 285, 129429. https://doi.org/10.1016/j.energy.2023.129429 (2023).

Park, B. & Choi, Y. C. Hydration and pore-structure characteristics of high-volume fly ash cement pastes. Constr. Build. Mater. 278, 122390. https://doi.org/10.1016/j.conbuildmat.2021.122390 (2021).

Chen, X. et al. Effect of silicic acid on water resistance of magnesium oxysulfate cement. J. Chin. Ceram. Soc. 51, 2017–2026 (2023).

Chen, X. et al. Improved mechanical strength of magnesium oxysulfate cement using ferric sulfate. J. Build. Eng. 67, 106007. https://doi.org/10.1016/j.jobe.2023.106007 (2023).

Zeng, Q., Li, K., Fen-chong, T. & Dangla, P. Pore structure characterization of cement pastes blended with high-volume fly-ash. Cem. Concr. Res. 42, 194–204. https://doi.org/10.1016/j.cemconres.2011.09.012 (2012).

Hochstein, D. P. & Meyer, C. Measurement and prediction of thermal conductivity of cement paste. ACI Mater. J. 113, 317–322. https://doi.org/10.14359/51688643 (2016).

Du, Y. & Ge, Y. Multiphase model for predicting the thermal conductivity of cement paste and its applications. Materials 14, 4525. https://doi.org/10.3390/ma14164525 (2021).

Kim, D., Kim, G. & Baek, H. Thermal conductivities under unsaturated condition and mechanical properties of cement-based grout for vertical ground-heat exchangers in Korea—A case study. Energy Build. 122, 34–41. https://doi.org/10.1016/j.enbuild.2016.02.047 (2016).

Shihao, D. et al. Prediction model of thermal conductivity of cement-based grouts for ground source heat pump. Fluid Machin. 50, 22–31 (2022).

Sarkar, P. K. & Mitra, N. Thermal conductivity of cement paste: Influence of macro-porosity. Cem. Concr. Res. 143, 106385. https://doi.org/10.1016/j.cemconres.2021.106385 (2021).

Liu, C., Liu, Q., Gao, J. & Zhang, Y. Numerical modelling of effective thermal conductivity of hardened cement paste. Comput. Concr. 32, 567–576. https://doi.org/10.12989/cac.2023.32.6.567 (2023).

Fengyan, Z. & Lixin, L. Research status and prospect of thermal transfer performance of cement in geothermal wells. Drill. Eng. 48, 54–64 (2021).

Acknowledgements

This research has been funded by the China Postdoctoral Science Foundation (Grant No. 2023M730947), Key Scientific Research Project of Higher Education Institutions in Henan Province (Grant No. 25B440001), Sichuan Science and Technology Program (Grant No. 2023NSFSC0781), and the National Natural Science Foundation of China (Grant No. 22306103).

Funding

China Postdoctoral Science Foundation, 2023M730947, Key Scientific Research Project of Higher Education Institutions in Henan Province, 25B440001, Sichuan Provincial Science and Technology Support Program, No. 2023NSFSC0781, National Natural Science Foundation of China, 22306103.

Author information

Authors and Affiliations

Contributions

Wenxi Zhu: Fund acquisition, Manuscript writing Bingjie Wang: Data acquisition Shengkai Cui: Data processing Huijing Tan: Fund acquisition Shiwei Yang: Fund acquisition Declaration: All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhu, W., Wang, B., Cui, S. et al. Study on the improvement of geothermal cement properties by nanofluid composed of deep eutectic solvent and graphene oxide. Sci Rep 14, 29071 (2024). https://doi.org/10.1038/s41598-024-80012-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-80012-1