Abstract

To investigate the propagation mechanisms of stress waves and the characteristics of crack distribution in tunnel structures subjected to explosive effects, an experimental model simulating rock mass using cement mortar was employed. Blasting experiments were conducted at various vertical locations relative to the tunnel. Utilizing ultra-dynamic strain monitoring alongside high-speed digital image recognition, we captured in real time the dynamic evolution of stress waves as well as the precise initiation and expansion paths of cracks. A comprehensive analysis was performed on both stress wave propagation and damage patterns within the refuge structure. Furthermore, the reliability of our numerical simulation algorithm was validated through an examination of fluid-structure coupling algorithms. The results indicated that peak strains at monitoring points within the tunnel increased as detonation points approached it, leading to heightened structural damage. Numerical simulations demonstrated a strong correlation between observed peak strains at critical locations and corresponding damage data from our experimental model. Additionally, it was found that decreasing height between detonation points and the tunnel resulted in increased dynamic response parameters—such as overpressure, velocity, and acceleration—at monitoring sites within the tunnel, thereby exacerbating damage to key areas including vaults and footwall structures. To mitigate potential structural instability within refuges, a full-section molded concrete lining support system was implemented along with supplementary anchor (mesh) spraying in critical regions to ensure long-term operational safety.

Similar content being viewed by others

Introduction

Explosive rock breaking is often used in mining, hydropower station, national defense construction and other fields, and can effectively break rock1,2, but there are certain limitations, such as explosive stress wave damage to underground tunnels. The large amount of high pressure gas generated by the explosion instantaneously compresses the surrounding medium, and produces stress waves propagating outward, which will produce reflected tension waves when encountering a free surface. Stretch waves can cause the expansion of existing cracks and the formation of new cracks in underground structures, resulting in the surrounding rock spalling3,4. As a result, surrounding rock looseness and large deformation are caused, and the overall strength of surrounding rock is further weakened5,6,7,8, which has a significant impact on the safety and stability of underground construction. Therefore, it is of great significance to study the stress wave propagation characteristics of buried deep tunnel under blasting load and the characteristics of key failure sites for ensuring mine safety and realizing efficient production targets in the process of large-scale mining.

At present, various researchers have used experimental and numerical methods to study the dynamic response of underground tunnels under external explosion waves. The basic phenomena and principles of dynamic response and damage of underground structures subjected to external explosion have been studied through field tests. Iwano. et al., Benselama. et al., Anas. et al., Chafi. et al. and Kuster. et al.9,10,11,12,13 conducted experimental research on the propagation and attenuation characteristics of explosion stress waves in rock mass during blasting construction. Mussa. et al.14 studied the dynamic response of buried arch structure under local underground pulse load. Prochazka15 studied the dynamic response behavior of the blast wave in the tunnel model and its influence on the damage of the simulated tunnel lining tube. However, field testing requires a large amount of explosives, which increases the risk and cost of field testing, so laboratory testing and similarity model testing are widely used. Hu. et al.16 used a rectangular prismatic granite sample with a central circular hole to conduct structural model tests to examine the rockburst process acoustic emission characteristics of the borehole. Si. et al., Gong. et al., and Luo. et al.17,18,19 studied the spalling failure process of various tunnel cross-section shapes (i.e., circular, rectangular, and D-shaped tunnels) under different three-dimensional (3D) stress states. Li. et al.20 studied the dynamic effects of large equivalent explosion waves on deep buried tunnels by using the self-developed explosion stress simulation device, and successfully simulated phenomena such as spalling, buckling and block activation.

Numerical modeling serves as a crucial alternative method due to the prohibitive costs, inherent risks, and extended timeframes associated with explosion testing. It effectively accommodates complex boundary conditions and material nonlinearities, significantly enhancing the analysis of explosive responses and damage in underground structures. Xu. et al.21 analyzed the stress distribution of surrounding rock under the action of explosion. Zhang. et al. and Keskin22,23, studied the effects of explosive quantity, shape of underground structure, explosion distance and other factors on the behavior of underground structure under blast shock load. Zhu. et al.24 dynamic response and damage of a cave tunnel are analyzed by stress, deformation, acceleration and velocity of the rock mass and damage morphology of the tunnel.

Current research predominantly emphasizes the macroscopic dynamic responses while lacking a comprehensive exploration of damage mechanisms in critical areas. Furthermore, many existing numerical studies rely on hypothetical scenarios, with the accuracy of their blast load simulations being significantly influenced by various factors such as mesh size and material parameters, often without experimental data validation. In this context, this study conducted four blast modeling tests at varying detonation heights, integrating LS-DYNA numerical analysis to reproduce and validate the experimental findings. Simultaneously, we investigated the effects of detonation height on the propagation of explosive stress waves and crack initiation within tunnel structures. Additionally, we incorporated actual site construction conditions to propose targeted stability control measures aimed at enhancing the tunnel’s resistance to blasts.

Materials and methods

Experimental design

In the blasting model test, the similarity criteria to be met mainly include three aspects: geometric similarity, material similarity and dynamic similarity. Accordingly, the similarity constants of the model test mainly include: geometric similarity constant, material similarity constant and dynamic similarity constant.

1) Geometric similarity: The aim of this paper is to investigate the dynamic response of a deeply buried tunnel under blasting loads. In view of this objective, the analytical model was constructed by scaling the geometry of the model to that of the prototype tunnel to ensure that similarities between the two tunnels were maintained25. The prototype tunnel at Changjiu Shenshan Quarry in Anhui Province, China, was 12 m high, 12 m wide and 6 m high with straight walls, while the model was scaled down to a height of 40 mm, a width of 40 mm and a height of 20 mm with straight walls.

2) Similar power: According to the C-J theory of detonation, taking into account the density of the explosives and the detonation velocity, Φρ∙ΦD = 1 (Φρ and ΦD represent the ratio of density and detonation velocity of the explosives used in the field to the explosives used in the laboratory, respectively) should be satisfied between on-site mixed explosives ( powdered emulsion and ammonium oil explosive ).and the laboratory explosives (No. 8 detonators filled with industrial black soot gold)26. The approximate density ofhe explosives on site is 1100 kg∙m− 3 and the detonation velocity is 3400 m∙s− 1, while the density of the laboratory explosives is 1000 kg∙m− 3 and the detonation velocity is 3800 m∙s− 1. After calculation, Φρ∙ΦD = 0.98, which is basically in line with the requirement of similarity of the dynamics.

3) Similar materials: The results of the researchers showed the suitability of cement mortar or concrete as a similar material for rock27. The uniaxial compressive strength of the prototype limestone was 40.18 MPa and the uniaxial tensile strength was 3.63 MPa.Therefore, 32.5 normal silicate cement and sand were chosen as the raw materials for the similar material.Then the blasting model was made according to the water-cement ratio of cement: sand: water = 1:4:1.The performance indexes of the cement mortar were measured after 28 d of curing, and the uniaxial compressive strength of the model was 21.8 MPa and the uniaxial tensile strength was 1.85 MPa. These indices showed that the tensile and compressive strengths of the model followed almost the same similarity constants with those of the prototype.

In this experiment, the dimensions of the blasting model were 500 mm in length and width, with a tunnel positioned 150 mm above the bottom of the model, extending through both the front and back sides as illustrated in Fig. 1(a). To investigate the impact of blast load on the dynamic response characteristics of the tunnel at varying distances, four sets of blasting models with different detonation heights were established for this study. The vertical distances from the detonator’s base to the top of the tunnel for Models 1 to 4 were set at 600 mm, 450 mm, 300 mm, and 150 mm respectively; corresponding horizontal distances measured at 810 mm, 660 mm, 510 mm are depicted in Fig. 1(b). Each group included a vertical borehole measuring a depth of 150 mm directly above each model. For the purposes of subsequent data monitoring, the prefabricated chamber structure with strain gauges attached to the surface was modelled as a strain brick. The prefabricated tunnel featured a straight arch section with dimensions: length of 400 mm, height of 40 mm, width of 40 mm, and wall thickness of 20 mm as shown in Fig. 1(c).

Specimen preparation

Given the dimensions of the model designed for this blasting test, it is impractical to extract rock from the site and process it into a uniform shape suitable for testing. Additionally, establishing a small-sized tunnel within the rock presents significant challenges. Consequently, 325 ordinary silicate cement and medium sand were utilized as raw materials to fabricate rock-like materials for constructing the blasting model. The procedure for creating the model is outlined as follows:

Step 1: Prefabricated thin-walled structure with tunnel. As illustrated in Fig. 2, a mold is initially fabricated using 3D printing technology, measuring 400 mm in length. The central horseshoe-shaped hollow tube matches the dimensions of the tunnel, while the outer horseshoe-shaped shell is processed to accommodate the side length of the horseshoe-shaped tunnel plus an additional 20 mm. Cement mortar prepared at a ratio of cement: sand: water = 1:4:1 was poured into the mold. During this pouring process, it was placed on a vibrating table to minimize voids. Once the thin-walled structure attained sufficient strength, the mold was removed and subsequently stored in a curing box. After approximately 48 h of curing, the resulting model can be regarded as a thin-walled structure with an integrated tunnel. Subsequently, the strain gauges were pasted in the middle section of the thin-walled structure, and the strain gauges were pasted as shown in Fig. 3. The fabrication of the thin-walled structure is now complete.

Step 2: Model pouring. A mould 1000 mm long, 500 mm wide and 500 mm high was used as shown in Fig. 4, Two horseshoe-shaped holes matching the size of the tunnel were cut symmetrically 150 mm from one end of the mould. Prior to casting, the inside of the mould was coated with lubricating oil to facilitate the later dismantling of the mould. The prefabricated thin-walled structure was inserted through the horseshoe holes, and the thin-walled structure was fixed in a predetermined position. Subsequently, cement mortar was prepared according to the ratio of cement: sand: water = 1: 4: 1 and poured into the large moulds in batches, and vibrated with a vibrating rod to remove internal air bubbles during the pouring process until the mortar in the moulds was about to overflow, and then the pouring was stopped. The mould was dismoulded after 28 days of curing in the curing room to reach the predetermined material strength. Additionally, a number of 50 mm thick foam sheets were added to the mould lengthwise to control the size of the model, resulting in four sets of blasting models with blast heights of 600 mm, 450 mm, 300 mm and 150 mm from the tunnel, respectively.

Step 3

Drilling, loading and filling. After the maintenance of the blasting model is completed, a hole with a diameter of 10 mm and a depth of 150 mm is drilled in the center of the blast hole. Take No.8 electric detonator of 0.5 g RDX main charge, tie two broken kink enameled wires, and connect them to the strain gauge and high-speed camera trigger wire respectively. When the detonator explodes, the enameled wire melts and short-circuits, triggering the record. Prior to this, the hole was sealed with yellow mud, fine sand and 502 glue. The process of drilling, charging and filling is shown in Fig. 5.

Strain testing with digital image correlation

The device used for strain testing in this test is a dynamic strain testing system consisting of a BFH120-3AA-X30 resistive strain gage, a KD7901 bridge box, a CS-1D resistive strain gauge, and a TST3604 dynamic test analyzer, as shown in Fig. 6.

When the strain testing system is used for testing, the BFH120-3AA-X30 type resistance strain gauge embedded in the measuring point will deform with the strain of the exploded medium, thus inducing its own resistance value to change, while the KD7901 type bridge box can convert the size change of resistance value into measurable voltage signal change. Then, then use the strain gauge and dynamic test analyzer to record the voltage change signal, and finally calculate the strain at the position based on the strain conversion formula:

Where, ε represents the strain of the exploded medium at the measured position; U0 represents the measured voltage signal size; K stands for test sensitivity; Ag stands for gain factor; Ue stands for the supply voltage of the bridge box.

The Digital Image Correlation (DIC) method employs time-domain image matching for non-destructive monitoring and is extensively utilized for measuring material displacement and strain fields due to its advantages of non-contact, full-field measurements with high accuracy28. The high-speed DIC system comprises a high-speed camera (Photron Fastcam SAZ), a standard Nikon lens, a flash-free LED light source (Godox SL-200 W), a synchronized trigger, and a computer, as depicted in Fig. 7(a). Prior to the experiments, white paint was applied around the model tunnel, and a black scattering area measuring 200 mm×200 mm was delineated, as shown in Fig. 7(b). The high-speed camera was configured to capture images at a frame rate of 100,000 fps with a resolution of 256 pixels×280 pixels over an imaging area of 298 mm×356 mm. The analysis software MatchID 2D was set to analyze an area of 255 mm×278 mm using an optimal pixel reference subset of 47 pixels×47 pixels and employed a calculation step size of 5 pixels to enhance accuracy while minimizing error.

Results

Stress wave propagation characteristics

Model blasting is mainly carried out under parts with different initiation heights. To simplify the analysis, assume:

1.The explosive is concentrated in the charge center, and the longitudinal wave length caused by blasting in the model is short.

The P-wave caused by blasting in the model is approximately an elastic compression wave

3.The longitudinal wave caused by blasting and the shear wave and Rayleigh wave caused by the inclined incidence of the longitudinal wave on the free surface are ignored.

Defined as the density ρ1 and wave speed c1 of the first material, and the density ρ2 and wave speed c2 of the second material, according to the one-dimensional stress wave theory, when an elastic wave propagates from the first material to the second material with stress σI and particle velocity vI, the following relationship exists between the stress wave-related parameters in the first material:

Where σR, σT is the inverse, transmission stress, MPa; vR, vT are particle inverse, transmission velocity, m·s− 1; R12 and T12 are inverse, transmission coefficient; ζ12 is the ratio of the wave impedance of the first material to the wave impedance of the second.

Figure 8 shows the propagation characteristics of the explosion stress wave at different initiation positions : after the explosive is detonated, the compressive stress wave propagates rapidly. Regardless of whether the detonation position is less than 150 mm or more than 300 mm from the tunnel, the stress wave reaches the top of the tunnel or both sides of the model and is reflected on the free surface, as shown in Fig. 8 ( a ) and ( b ). Observe the first reflected wave in the area surrounded by model I. This wave of amplitude σAB and particle velocity vAB is formed by the reflection of the original wave of amplitude σI and particle velocity vI. When the explosion stress wave propagates to the free plane, the second material is air, at which point ρ2c2→0, according to Eqs. (5) and (6), get ζ12→∞, reflection coefficient R12 = -1, transmission coefficient T12 = 0. Therefore, from Eq. (2)~(4) we have:

It can be seen from Eq. (9) ~ (12) that there is no transmission phenomenon at the boundary of the free plane model. At the same time, the velocity of particles in the reflected wave is the same as that of the original shock wave, and the size is the same as that of the incident wave. Then the stress wave propagates the interface of II, III and IV respectively, and the reflection forms the tension wave. At this time, the movement direction of the particles in the tunnel is consistent with the direction of the incident wave.

Strain gauge measurements

The voltage signal collected by the ultra-dynamic strain gauge can be converted into the circumferential strain of each monitoring of the tunnel through the corresponding relationship between the two. The detonator initiation can cause electromagnetic emission, which may cause considerable noise in the measured strain signal, which has been observed in this experiment. Therefore, a 10 MHz low-pass filter is used to filter out the high-frequency noise in the original signal. Figure 9 is the time history curve of the strain response of the monitoring point of the tunnel under each model.

The compressive stress wave formed rapidly after the detonation of the explosive propagates in the model. When the stress wave reaches the monitoring point outside the tunnel, the particle movement direction in the model is consistent with the propagation direction of the compressive stress wave, resulting in compressive strain at each measuring point. It can be seen from Fig. 9 that the dynamic response speed of the structure caused by the shock wave is extremely fast, and almost the monitored data instantaneously reaches the maximum deformation, and then rebounds. The strain time history curve caused by the shock wave stage is basically V-shaped. Subsequently, when the stress wave reaches the side of the tunnel, it reflects and forms a tensile wave, which causes the particles inside the tunnel structure to move towards the interior of the tunnel, resulting in a tensile normal strain on the strain gauge at the monitoring point. Subsequently, with the continuous reflection, propagation and attenuation of stress wave in the model, the strain time history curve of each monitoring point in the tunnel shows a trend of first oscillation and then flattening.

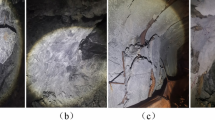

Crack distribution and surface strain field provided by DIC

In this study, four models were designed to investigate the effect of the detonation height of the packages on the stability of underground tunnels, with the key factor being the distance between the packages and the tunnels. When the distance between the packages and the tunnel was 600 mm, 450 mm and 300 mm for Models 1–3 respectively, the strain test results showed that there were no explosive cracks in the vicinity of the tunnel and low strain values. This suggests that the tunnel was able to remain stable at the higher distances. When the distance was reduced to 150 mm, a significant increase in strain was observed in the vicinity of the tunnel, and significant cracks were observed, as shown in Fig. 10. These cracks were mainly in the vault and lower left side of the tunnel, indicating that the structure was severely impacted and the stability of the tunnel was reduced, making it difficult to ensure safety.

Due to the small strains and lack of cracking in the tests of Models 1 to 3, no significant changes in the scattering of the surface of the tunnel were observed during the DIC technique. However, for model 4, the evolution of the strain field in the full field of Von Mises on the surface of the refuge, as observed by the DIC technique, is shown in Fig. 11. As can be seen in Fig. 11. 0 µs corresponds to detonation. At 60 µs after detonation, it can be observed that the maximum strain concentration on the surface of the specimen begins to appear in the upper left part of the tunnel. At 90 µs, a significant concentration of strain was observed in the upper left of the tunnel, and a strain field was observed along the lower left vertical corner of the tunnel, suggesting that the stress wave generated by the detonation was gradually affecting and altering the strain distribution on the surface of the specimen. As the wave propagates, the loads in the vicinity of the tunnel increase, and significant strain concentrations are formed at the top and lower left corners of the tunnel. The appearance of these zones suggests that the specimen is experiencing high levels of stress and deformation in these areas. At 300 µs the strain path above the tunnel shifted from the upper left shoulder to a position closer to the top of the arch, and the lower left corner of the tunnel became more concentrated. Subsequently, the maximum strains peaked above the vault and in the lower left corner of the tunnel in a number of stress concentration zones. This series of peak strains signalled that cracking of the specimen was imminent in these areas.

Numerical simulation

In this section, the finite element blasting simulation of underground cavern is carried out by using numerical simulation technology to verify the experimental results and analyze the dynamic response characteristics of the key failure parts of the cavern.

Numerical model

It was observed that there was no damage to the rock in the vicinity of the tunnel at a distance of 300 - 600 mm from the charge, so the tunnel was modelled at a distance of 300 mm and a distance of 150 mm from the charge, and a comparative analysis was carried out. Two sets of models were constructed in ANSYS/LS-DYNA using the solid unit 3D SOLID-164, and the top of the models were set up with 150 mm deep and 10 mm diameter holes, as shown in Fig. 12. The bottom of the hole is filled with 30 mm high RDX (detonator main charge), and a detonation point is set at the centre of the explosive with the help of the *INITIAL_DETONATION keyword, with a detonation time of 0 µs. In addition, a non-reflective boundary condition is applied to the surfaces except the top surface by using the *SET_SEGMENT keyword combined with the *BOUNDARY_NON_REFLECT keyword to avoid the reflection on the model boundary. boundary conditions on all surfaces except the top surface to avoid wave reflection phenomenon at the model boundary, which will affect the accuracy and reliability of the simulation results. At the same time, through the *MAT_ADD_EROSION keyword to set the compressive and tensile strength of concrete as the failure criterion of the unit, which can be obtained under the action of the explosion damage and destruction of concrete history29.

Where PJ represents the blast pressure of the explosive. Ae, Be, R1, R2 and ωe represent the material constants of the explosive, E0 stands for the initial internal energy of the blast products, and Ve is the ratio of the blast products to the volume of the cohesive phase explosive. The explosive parameters are shown in Table 1.

The air is modelled using the *MAT_NULL intrinsic model and its pressure changes are simultaneously elaborated using the *EOS_LINEAR_POLYNOMIAL equation of state31:

Where Pa represents the atmospheric pressure of the air. C0 to C6 are material constants, E1 is the initial internal energy of the air, ρc stands for the current density of the air, ρa represents the ideal density of the air. The specific values of the main material parameters of air are shown in Table 2.

The concrete was modelled using the *MAT_PLASTIC_KINEMATIC intrinsic model, which is a material model that is related to the magnitude of the strain rate, and is a good representation of the rate-dependent effects exhibited by engineering materials under explosive dynamic loading32:

Where σY is the current yield stress, J0 stands for the multiplier of increase, and σ0 is the original yield stress, βr stands for the plastic strengthening parameter, Ep stands for the plastic strengthening modulus, εep stands for the plastic strain; \(\dot \varepsilon\)represents the strain rate, C and P stand for the rate-related parameters; ET is the shear modulus, E stands for the modulus of elasticity, \({\dot \varepsilon _p}\) is the plastic strain rate, and t stands for the total time consumed in generating the plastic strains. The parameters were measured by static mechanical tests on standard specimens of cement mortar prepared in the ratio of cement: sand: water = 1:4:1, as shown in Table 3.

Numerical simulation results

Stress wave propagation

As shown in Fig. 13, the numerical simulation of the explosion at a spacing of 300 mm between the charge and the refuge shows that after the detonation of the explosive, the shock wave instantaneously causes crushing damage to the medium in the near zone, and then rapidly transforms into a stress wave that drives the medium to produce and extend radial cracks in all directions33. At 25 µs after the explosion, a reflected tensile stress wave is formed when the blast stress wave reaches the free surface at the top of the model. At 30 µs, the reflected tensile wave produces tensile laminar fracture damage to the rock near the free surface, while the blast stress wave in the rock continues to propagate around, driving the radial cracks to further expand and extend. With the passage of time, the number of damage cracks gradually increased, and the damage degree gradually increased. At 90 µs, the crack expansion around the charge generated by the explosion basically stagnated. From 90 µs to 160 µs, the distribution of cracks remained almost unchanged, suggesting that the rock mass in the vicinity of the tunnel did not suffer significant stability damage due to the blast. This observation is consistent with the results of the modelling tests and confirms the accuracy of the experimental study.

As shown in Fig. 14, the numerical simulation of the blast at a distance of 150 mm between the charge and the refuge shows that the initial shock wave caused the media in the vicinity of the blast to be crushed, and then rapidly decayed into a stress wave, which drove the rock to produce radial cracks that propagated in all directions. At 70 µs, the cracks extended into the upper part of the tunnel. At 90 µs, cracks began to form in the lower left and lower right corners of the tunnel at the foot of the sidewalls, and then continued to expand. At 120 µs, the cracks in the lower right-hand corner gradually stopped expanding, while the cracks in the lower left-hand corner continued to expand at a high rate until 160 µs, when they completely penetrated the model boundary and formed a significant damage zone. Compared to the model with a detonation height of 300 mm, the model with a detonation height of 150 mm showed a higher number of cracks initiating around the tunnel and a wider range of crack extensions. This suggests that the reduced height of initiation resulted in more energy being utilised to rupture around the tunnel structure.

Strain response characteristics of outdoor wall

According to the arrangement of measuring points 1#, 2# and 3# that are located directly above the arch, on the left spinner and on the left side of the wall foot in the model test, the strain time history curve of the numerical model element grid at the corresponding position of each measuring point is output. The strain time history curve of the measuring point when the distance between charging and the tunnel is 300 mm is shown in Fig. 15. The strain time history curve of the measuring point when the distance between charging and the tunnel is 150 mm is shown in Fig. 16.

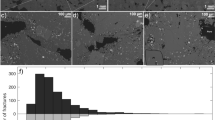

Figures 15 and 16 show that the shock wave action caused the structure to rapidly reach maximum deformation and then rebound, resulting in a V-shaped strain time curve. After reflecting off the free surface of the tunnel, the stress wave was reflected, propagated and attenuated within the model, resulting in an oscillating and then flat strain time-course curve at the monitoring points. For points 1#, 2# and 3#, the peak strains were 1686 µε, 1414 µε and 1540 µε at a distance of 300 mm from the tunnel, and 3695 µε, 3407 µε and 3542 µε at a distance of 150 mm from the tunnel, respectively, and the relationship between the peak strains was also consistent with the relationship of ε1# > ε3# > ε2#.

Figure 17 compares the peak strains between the test and simulation. The peak strains at measurement points 1#, 2# and 3# of the numerical model decreased by 6.34%, 2.68% and 6.54%, respectively, compared with the test with the spacing between the charge and the refuge set at 300 mm spacing; when the spacing was reduced to 150 mm, the rates of change were 2.21%, -1.86% and 0.98%, with a relatively small deviation in the data. These findings reflect the reliability of the numerical simulation and provide strong support for the validation between test and simulation.

Dynamic response of indoor wall

In order to analyse the dynamic response of the blast wave on the tunnel wall, the monitoring points of the tunnel were arranged as shown in Fig. 18. (with points A, B and C at the top of the arch, the waist of the arch, and the corners of the side walls), using the overpressure, velocity and acceleration as the indexes34. Figure 19 shows the time course curves of the dynamic response at each point under different models. The load distribution characteristics are the basis for studying the dynamic response and destructive effect of the structure. Figure 19 (a) and (d) show that the peak pressure of the blast shock wave is large and the action time is short under different detonation positions. As the detonation position decreases, the overpressure values of each monitoring point in the tunnel increase, and the peak overpressure value of the vault is the most significant. This is because the energy of the explosive shock wave gradually increases with the shortening of the detonation distance, resulting in the increase of overpressure values of each measurement point. This is due to the fact that as the distance between the detonation and the explosion is shortened, the energy of the shockwave increases, resulting in an increase in overpressure at all locations. Velocity and acceleration of the tunnel mass are key to assessing safety35. Figure 19(b) and (e) shows that as the detonation position decreases, the velocity of each monitoring point in the tunnel gradually increases. At the same time, the time for each monitoring point to experience the peak is shortening, which implies that the structure is subjected to a large acceleration during a very short blast time, as shown in Fig. 19(c) and (f). As the detonation position decreases, the acceleration at the monitoring points increases, which may lead to localised stress concentrations in the tunnel structure, increasing the risk of plastic deformation or damage.

Discussion

Effect of blast height on tunnel Stability

The height of detonation is a key parameter in step blasting and has a significant impact on the stability of the tunnel. As the height of detonation decreases, the stress waves generated by the explosive blast act more directly on the structure of the tunnel, resulting in a significant increase in the peak strains at the monitoring points of the tunnel. Figure 20 shows the maximum principal strains at the monitoring points for different detonation heights.It is clear from Fig. 20 that as the detonation position decreases, the strain response at each point in the tunnel increases. This is due to the fact that as the distance between the detonation point and the monitoring points decreases, the intensity of the shockwave generated by the explosion increases, resulting in stronger impacts on the structure of the refuge, which leads to a significant increase in the strain values at each monitoring point. In addition, at the same height of detonation, the relationship between the peak strains at each point was ε1# > ε3# > ε2#. This is because the 1 # measurement point is located in the position of the top of the arch is closer to the explosive package, directly subjected to the most intense compressive stress wave, the maximum strain peak value recorded. In contrast to point 2#, point 3#, which was located at the foot of the tunnel wall, was far from the explosive package, but the right-angled structure led to a concentration of stress, which exacerbated the change in stress and led to an increase in the strain value.

The increased strain response not only exacerbated the damage to the structure, but also facilitated crack initiation and expansion. In particular, as the height of the blast was reduced to a certain distance (e.g. 150 mm in this study), cracks began to appear in key areas such as the vault and the foot of the sidewalls, suggesting that the structure had been subjected to severe impacts and damage in these areas. Numerical modelling results also showed that the dynamic response parameters such as overpressure, velocity and acceleration increased as the height of detonation decreased. The increase in these parameters further demonstrates the significance of the effect of the height of detonation on the stability of the tunnel. At lower detonation heights, the tunnel structure is subjected to higher dynamic loads, making it more susceptible to instability and damage.

Tunnel stability control

These studies have shown that as the height of the steps decreases, the blasting loads pose a serious threat to the stability of the tunnel structure. Therefore, the use of support structures is of particular importance in order to deal with the severe impacts caused by blasting loads and to prevent the risk of instability of the surrounding rock.In the soft rock environment, due to the limited support effect of the traditional anchor rod and cable, the full section molding concrete lining technology is widely used for its excellent stability and bearing capacity brought by the whole pouring. This technology is not only durable, corrosion-resistant and water-resistant, but also has a strong adaptive deformation ability, which plays an indispensable role in maintaining the stability of the tunnel36. In view of this, the underground tunnel studied in this paper chooses full-section molded concrete lining as the supporting structure, as shown in Fig. 21. In addition, according to the results of physical model test and numerical simulation above, it can be found that explosion load will lead to high stress concentration and significant deformation in local areas of the tunnel, especially in key parts such as the vault and the foot of the side wall. This situation will not only greatly reduce the bearing capacity of surrounding rock, but also may lead to the risk of instability and disaster. Therefore, in areas with obvious impact disturbance, the combined support technology of anchor (net) spray and the optimization of bolt parameters can significantly improve the impact resistance of key parts, so as to ensure that the tunnel can maintain the overall stability under strong impact.

Limitation of this study

Significant progress has been made in investigating the propagation characteristics of explosive stress waves in rocky media and the dynamic response of underground tunnels, with a particular focus on in-depth analyses of the structural damage mechanisms of the tunnels. However, the geometry of the prototype tunnels was scaled in order to reduce the difficulty and cost of the modelling tests and to maintain operability, which may have led to a size effect, resulting in discrepancies between the model and the prototype physical processes. At the same time, the simplification of boundary conditions may not fully reflect the real situation, reducing the reliability of the test results. Although cement mortar or concrete with similar properties to the original rock was chosen as similar materials, differences in material properties may still lead to deviations in the results. In view of these limitations, subsequent studies should deeply analyse the mechanism of the size effect, develop compensation strategies to reduce the differences between the model and the prototype; optimise the boundary condition settings and adopt advanced simulation techniques to improve the simulation accuracy; and explore more accurate modelling techniques and similar materials closer to the prototype within the range of cost-effectiveness in order to improve the accuracy and reliability of the tests.

Conclusion

-

1.

1. Packet detonation height and strain gage posting position are two important factors affecting the peak strain. As the height of the packet detonation decreased, the peak strain values decreased significantly. For the same height of initiation, there was a relationship of ε1# > ε3# > ε2# between the strains at the top of the vault, at the left shoulder, at point 2# and at point 3# at the foot of the left wall of the tunnel.

-

2.

2. Image analysis showed that the height of detonation significantly affected the generation of macroscopic cracks. As the distance between the charge location and the tunnel was reduced to 150 mm, visible cracks began to appear in key areas of the tunnel, such as the vault and the foot of the sidewalls.

-

3.

3. The maximum strain concentration in the strain field matches well with the actual crack patterns in the monitored tunnels, indicating that the DIC technique can be successfully applied to the detection and development of multiple cracks caused by blasting.

-

4.

4. The simulations showed that as the height of the detonation point from the tunnel decreased, the dynamic response parameters such as overpressure, velocity and acceleration at the tunnel monitoring point increased significantly, and the extent of damage to critical areas increased. The numerical simulations were in good agreement with the experimental data.

-

5.

5. The use of a full-section moulded concrete lining support structure, together with the addition of anchor (mesh) sprays in key areas of the tunnel that are susceptible to damage, will prevent the surrounding rock from destabilising and ensure the safe long-term operation of the tunnel.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Kumar, P. et al. A newly developed blasting cut in tunnels; application of combined method in small to medium-sized tunnels. Tunn. Undergr. Space Technol. 142, 105426 (2023).

Yilmaz, O. & Unlu, T. An application of the modified Holmberg–Persson approach for tunnel blasting design. Tunn. Undergr. Space Technol. 43, 113–122 (2014).

Banadaki, D. M. M. & Mohanty, B. Numerical simulation of stress wave induced fractures in rock. Int. J. Impact Eng. 40–41, 16–25 (2012).

Mitelman, A. & Elmo, D. Analysis of tunnel support design to withstand spalling induced by blasting. Tunn. Undergr. Space Technol. 51, 354–361 (2016).

Salum, A. H. & Murthy, V. M. S. R. Optimising blast pulls and controlling blast-induced excavation damage zone in tunnelling through varied rock classes. Tunn. Undergr. Space Technol. 85, 307–318 (2019).

Silva, J., Worsey, T. & Lusk, B. Practical assessment of rock damage due to blasting. Int. J. Min. Sci. Technol. 29 (3), 379–385 (2019).

De, A. & Zimmie, T. F. Effects of Surface Explosion on Underground tunnel and potential mitigation measures. Transp. Infrastructure Geotechnology. 3 (2), 74–90 (2016).

Xu, T. H., Li, J. & Wang, M. Y. Influence of incident angle on spalling damage of underground tunnels subjected to explosion waves. Tunn. Undergr. Space Technol. 147, 105746 (2024).

Iwano, K. et al. Reduction of tunnel blasting induced ground vibrations using advanced electronic detonators. Tunn. Undergr. Space Technol. 105, 103556 (2020).

Benselama, A. M. et al. A numerical study of the evolution of the blast wave shape in tunnels. J. Hazard. Mater. 181 (1–3), 609–616 (2010).

Anas, S. M., Alam, M. & Umair, M. Air-blast and ground shockwave parameters, shallow underground blasting, on the ground and buried shallow underground blast-resistant shelters: a review. Int. J. Protective Struct. 13 (1), 99–139 (2022).

Chafi, M. S., Karami, G. & Ziejewski, M. Numerical analysis of blast-induced wave propagation using FSI and ALEmulti-material formulations. Int. J. Impact Eng. 36 (10–11), 1269–1275 (2009).

Kuster, G. T. & Toksöz, M. N. Velocity and attenuation of seismic waves in two-phase media: part I. theoretical formulations. Geophysics 39 (5), 587–737 (2012).

Mussa, M. H. et al. Assessment of damage to an underground box tunnel by a surface explosion. Tunn. Undergr. Space Technol. 66, 64–76 (2017).

Prochazka, P. & Jandeková, D. Effect of explosion source location on tunnel damage. Int. J. Protective Struct. 11 (4), 1–20 (2020).

Hu, X. C. et al. Experiment on rockburst process of borehole and its acoustic emission characteristics. Rock Mech. Rock Eng. 52 (3), 783–802 (2019).

Si, X. F. et al. Experimental investigation on rock burst process and characteristics of a circular opening in layered rock under three-dimensional stress conditions. Tunn. Undergr. Space Technol. 127, 104603 (2022).

Gong, F. Q., Wu, W. X. & Li, T. B. Simulation test of spalling failure of surrounding rock in rectangular tunnels with different height-to-width ratios. Bull. Eng. Geol. Environ. 79 (6), 3207–3219 (2020).

Luo, Y., Gong, F. Q. & Zhu, C. Q. Experimental investigation on stress-induced failure in D-shaped hard rock tunnel under water-bearing and true triaxial compression conditions. Bull. Eng. Geol. Environ. 81 (2), 76 (2022).

Li, Z. H. et al. Theoretical and experimental study on ground impact damage effect under large equivalent explosion. Part I: field measurement analysis of ground impact failure phenomenon of deep buried caverns. Chin. J. Rock Mechan. Eng. 41 (5), 865–876 (2022).

Xu, J. H. et al. Dynamic characteristics and safety criterion of deep rock mine opening under blast loading. Int. J. Rock Mech. Min. Sci. 119, 156–167 (2019).

Zhang, Y., Liu, Y. & Tan, X. Effect of Underground stress waves with varied wavelengths on dynamic responses of tunnels. Geotech. Geol. Eng. 35 (5), 2371–2380 (2017).

Keskin, I., Yadgar Ahmed, M. & Taher, R. An evaluation on effects of surface explosion on underground tunnel; availability of ABAQUS Finite element method. Tunn. Undergr. Space Technol. 120, 104306 (2022).

Zhu, J. et al. Decoupled explosion in an underground opening and dynamic responses of surrounding rock masses and structures and induced ground motions: a FEM-DEM numerical study. Tunn. Undergr. Space Technol. 82, 442–454 (2018).

Wu, H., Zhao, G. Y. & Ma, S. W. Failure behavior of horseshoe-shaped tunnel in hard rock under high stress: Phenomenon and mechanisms. Trans. Nonferrous Met. Soc. China. 32 (2), 639–656 (2022).

Du, M. R. et al. Theoretical studies for calculating the detonation products and properties of explosives. Explosion Shock Waves. 35 (4), 449–453 (2015).

Kong, Y., Ruan, H. N. & Wang, Z. C. Selection and mechanical properties testy of similar brittle rock-like model materials of basalt. Chin. J. Geotech. Eng. 45 (11), 2308–2318 (2023).

Berg, N., Hori, T. & Take, W. A. Calculation of 3D displacement and time to failure of an earth dam using DIC analysis of hillshade images derived from high temporal resolution point cloud data. Landslides 17 (3), 499–515 (2020).

Bendezu, M., Romanel, C. & Roehl, D. Finite element analysis of blast-induced fracture propagation in hard rocks. Comput. Struct. 182, 1–13 (2017).

Alia, A. & Souli, M. High explosive simulation using multi-material formulations. Appl. Therm. Eng. 26 (10), 1032–1042 (2006).

Ni, Y. et al. Numerical study on the dynamic fragmentation of rock under cyclic blasting and different in-situ stresses. Comput. Geotech. 172, 106404 (2024).

Chen, Y. F. & Yi, G. X. Dynamic response analysis of the Reinforced concrete column under the Effect of Explosive Impact load. Adv. Mater. Res. 681, 104–199 (2013).

Wang, W. et al. Dynamic extension of mode imicrocracks of rocks under blasting loading. Chin. J. Rock Mechan. Eng. 33 (6), 1194–1202 (2014).

Cui, Y. et al. Research on damage assessment of buried pipelines with circular dent defects subjected to blast loading. Eng. Fail. Anal. 163, 108581 (2024).

Wang, J. X. et al. Study on the propagation and attenuation characteristics of tunnel blasting vibration waves at different blast center distances. J. Appl. Geophys. 220, 105280 (2024).

Petrarola, D. N. et al. Tunnel lining segments with enhanced bearing capacity using hybrid concrete concepts. Tunn. Undergr. Space Technol. 143, 105484 (2024).

Funding

This research was financially supported by the Anhui Key Laboratory of Explosive Energy Utilization and Control (No.BP20240103), Anhui Natural Science Foundation(No. 2408085QA029).

Author information

Authors and Affiliations

Contributions

Jichao Duan, Qi Zong and Haibo Wang designed and performed the experiments. Bing Cheng and Pengfei Gao assisted in performing the experiments. Jichao Duan analyzed the data, and wrote the manuscript. Qi Zong and Haibo Wang collected and authenticated the samples. All authors readand approved the final manuscript. All authors contributed to the article and approved the submitted version.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Duan, J., Zong, Q., Wang, H. et al. Study on stress wave propagation and failure characteristics of key parts in tunnel under blasting load. Sci Rep 14, 29034 (2024). https://doi.org/10.1038/s41598-024-80223-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-80223-6

Keywords

This article is cited by

-

Multi-scale study on dynamic damage characteristics and energy dissipation of deep rock under thermal-hydro-mechanical coupling

Scientific Reports (2026)

-

Study on the damage mechanism of deep ingate lining structure disturbed by cyclic blasting

Scientific Reports (2026)

-

Experimental study on dynamic response of existing tunnel lining structure by adjacent tunnel blasting load

Scientific Reports (2025)

-

Research process and hotspot prediction of deep-hole presplitting blasting technology in China’s mines

Geomechanics and Geophysics for Geo-Energy and Geo-Resources (2025)