Abstract

Geothermal energy, oil industry, and underground gas storage technology require deep drilling. Although oil-based drilling fluids have been widely used, they cause environmental issues. Environmentally friendly Aphronic fluid has emerged as an alternative to oil-based drilling fluid. Despite various investigations on Aphron’s performance, the effect of temperature has not yet been comprehensively studied. In this study, Aphronic fluid was developed with xanthan gum (XG) as a polymer and alpha-olefin sulfonate (AOS) as a surfactant. Furthermore, another Aphronic fluid was developed with xanthan gum (XG) as a polymer and sodium dodecyl sulfate (SDS) as a surfactant. This study evaluates their rheological properties, including shear rate (ranging from 0.1 to 10 s− 1), across a range of temperatures (25 ℃, 49 ℃, 71 ℃, and 93 ℃). Stability testing was conducted at ambient temperature, and rheology tests were performed at various temperatures. It was found that the rheological properties decrease as the temperature increases. An increase in the temperature and shear rate decreases the viscosity of the drilling fluid. AOS demonstrated higher stability and less reduction in rheological properties at elevated temperatures than SDS. This difference can be attributed to SDS’s tendency to denature the XG polymer, leading to a notable decrease in viscosity. Maintaining viscosity is crucial for fluid stability and enhancement of rheological properties. Moreover, the best stability was achieved at 1.5 times the critical micelle concentration (CMC). This behavior is consistent with the Gibbs elasticity theory, indicating that the optimal concentration for both AOS and SDS surfactants is 1.5 times the CMC. Deviation from this optimal concentration resulted in decreased system stability. The determination of the CMC value showed a broader region rather than a singular point, potentially confirming the Gibbs-Marangoni theory. The implications of this research underscore the importance of selecting the appropriate Aphronic fluid formula for drilling operations to ensure stability and rheological properties conducive to overcoming reservoir pressure and accurately facilitating the cutting transfer process. This research highlights the need to choose the right Aphronic fluid formula for drilling. Using the right formula helps in drilling to ensure stability and rheological properties conducive to overcoming reservoir pressure and accurately facilitating the cutting transfer process.

Similar content being viewed by others

Introduction

In the oil industry and new environmentally friendly processes such as geothermal technology, drilling deep wells is unavoidable to access natural energy resources. Drilling is a complex and expensive process, with various systems working collectively to achieve underground targets1,2,3. One of the most important parts of the drilling process is the drilling fluid circulation system, which requires fluids with high viscosity (drilling fluid) to operate steadily4. Hence, the rheological properties of the drilling fluid must be continuously evaluated and controlled to successfully perform the optimal and economical drilling operation and to control the wellbore hydraulics5.

In modern drilling operations, these measurements are performed using drilling fluid testing guidelines and equipment that can determine the relationship between shear stress and shear rate (up to 600 rpm (10 s− 1), as standardized by the American Petroleum Institute (API 13D)6. Emulsion-based drilling fluids have a high ability to stabilize oil and gas wells, especially in Shale formations. Fresh water in contact with clay causes the clay to swell. In boreholes, especially in shale layers that contain much clay, this drives swelling of the clay and loosening of the borehole wall, which can influence the collapse of the borehole wall. Therefore, a water-in-oil emulsion is used to break the bond between the water and the wall and prevent contact. This makes the walls of oil and gas wells more stable. Other advantages of emulsion fluids include good lubrication, low torque and stress, and the ability to be used in conditions where contamination is limited7.

An emulsion is formed by the dispersion of a given amount of liquid in another liquid. Emulsions generally fall into two categories based on the continuous phase: oil-in-water (O/W) and water-in-oil (W/O) types8. Emulsion-based drilling fluids have higher thermal stability and are highly contamination-resistant9. Moreover, the lower compressibility of emulsion-based muds makes them attractive for drilling under balanced conditions (UBD)10. In a colloidal Aphron fluid, the inner core of the system is usually a liquid11. Colloidal emulsion Aphrons refer to Aphrons with a water core in the oil phase12. Colloidal gas Aphrons (CGA) are progressively used in various technical fields because of their special properties. The composition of CGA involves microbubbles that are spherical and have diameters ranging from 10 to 100 micrometers. In contrast to conventional foams, Aphrons possess a thicker water protective film, which renders them appropriate for various practical uses, particularly in drilling fluids13.

The concept of Aphrons was first introduced by Seba in 1987. Aphrons are spherical bubbles of micrometer size with colloidal properties. The most remarkable feature of these microbubbles is the lack of cohesion of Aphrons. It was also mentioned that Aphrons are different from ordinary foams, in Aphrons the tiny bubbles are stabilized in the liquid by polymers and surfactant14. The particular structure of Aphrons in the system of suspensions containing CGA provides a new type of fluid variety possessing distinct filtration and rheological characteristics that fulfill the specific needs of the oil drilling sector. Because the bubbles are non-cohesive, Aphrons can be cleaned and reinjected into the wellbore and are not seriously affected by wellbore conditions15. One way to prevent the swelling of clay and the collapse of the borehole wall is to use salt, nanoparticles, and surfactants in the drilling fluid. Aphron drilling fluid has a high potential to prevent clay swelling because of the presence of surfactants, which have a negative charge, making the borehole wall stable. In several experiments conducted by researchers, the aphronic fluid moved from the fluid within the formation to the wellbore with the lowest pressure and emerged from the porous environment. Therefore, it has been reported that the Aphronic fluid has a good permeability recovery ability and does not damage the formation. However, because the aphronic fluid penetrates the high-permeability zones and the bubbles are separated by a thin polymer layer, only a small amount of the polymer can adhere to the wall, but the Aphronic fluid leaves the porous medium very easily. From this, it can be concluded that Aphrons can minimize formation damage because they cover zones with high permeability16. Moreover, reducing the problem of logging tools from the wellbore conditions and performing the cleaning process of the borehole with a suitable quality are among the other benefits of CGA17.

Aphrons combine gas, liquid, and surfactant, and their attributes are affected by factors such as the type of gas, formulation of base liquid, temperature, pressure, type, and concentration of surfactant. Hence, most physical and chemical properties, including the filtration and rheology properties of Aphron fluids, exhibit greater complexity than those of straightforward liquids13. The stability of Aphron fluids is highly dependent on the thickness and viscosity of the fluid between the bubbles. Therefore, xanthan gum polymer is commonly used for the better preparation of Aphron fluids, especially in the gas and oil industry18. Some of the most important studies on Aphron are presented as follows:

In Arabloo et al. in 2013, the properties of Aphron drilling fluid were investigated using xanthan gum and biopolymer. The researchers found that increasing the concentration of the biopolymer xanthan gum led to a decrease in the bubble diameter, whereas increasing the surfactant concentration increased the bubble diameter. Furthermore, augmented concentrations of polymer and surfactant resulted in amplified apparent viscosity, yield point, and plastic viscosity of Aphron drilling fluids19. Arabloo and Shahri examined the rheological characteristics of CGA drilling fluids developed with xanthan gum (XG) and sodium dodecyl sulfate (SDS). They introduced a novel mathematical model to characterize rheological behavior within the temperature range of 25–45 °C20.

It should be mentioned that the complexity of the impact on foam stability arises from the different types of interactions in the system of mixed surfactants and nanoparticles. Consequently, the combined influence of surfactants and nanoparticles on foam stability is complex. With Aphronic fluids, this issue becomes more intricate as the polymer plays a crucial role in their stability. The presence of nanoparticles can influence Aphronic fluids in three manners: (1) a decrease in surfactant concentration caused by nanoparticle absorption phenomena, (2) an increase in viscosity, and 3) enhancement of the stability of the delicate layer separating the gas and liquid components21.

Pasdar et al. 2018 used the polymer xanthan gum and the surfactant sodium dodecyl benzene sulfonate SDBS to prepare the Aphron fluid, and the results of their work showed that the size of the bubbles decreased with increasing concentration of the polymer and surfactant. These researchers reported that as the polymer concentration increases, the penetration of air into the base fluid becomes more difficult. Moreover, the best stability of the Aphron fluid was found at a polymer concentration of 6810 mg/L and a surfactant concentration of 799 mg/L22.

The loss of fluid for CGA fluid was investigated by Zhu et al. The fluid loss for the CGA fluid reached 66 mL at 150 °C, exceeding API standards due to stabilizer failure23. A stabilizing agent is crucial in the formulation of CGA fluids, serving a significant function in enhancing fluid viscosity and maintaining the stability of microbubbles24,25. Research indicates that optimizing and blending biopolymers fails to meet the demands for creating high-temperature-resistant CGA fluids. Graft copolymerization modification is an effective approach for developing polymer composite materials. This method allows the combination of polymers with diverse structures and properties on the main chain of macromolecules, resulting in the creation of new materials with enhanced utility26,27,28. The primary factor restricting the use of XG is its inadequate resistance to elevated temperatures. When the heating temperature exceeds the transformation threshold (typically 90 °C), XG undergoes a transition into a disordered and unstable structure. This transformation leads to significant viscosity deterioration (> 50%) as the temperature increases, contributing to substantial fluid loss in drilling fluid29,30. Aphrons serve as excellent bridging materials capable of enduring prolonged exposure to harsh conditions, including pressures exceeding 4000 psi. They diminish in size to match the dimensions of pores or fractures under elevated pressures. Shortly after the initiation of invasion, a stable bubble band forms at the fluid front, impeding or slowing down fluid infiltration31.

Khazwarsi et al. 2019 applied three types of surfactants together with xanthan gum to prepare aphronic fluid and investigated the stability of Aphronic fluid half-life and bubble-size experiments. The results of this research show that the half-life of the aphronic fluid increased with increasing concentration of xanthan gum. Furthermore, these researchers found that as the surfactant concentration increases, the volume and half-life of Aphronic fluid increases (even at high CMC concentrations)32. In another study, Pasdar et al. 2020 used a xanthan gum polymer and two surfactants to prepare an Aphron on fluid and reported that the size of the bubbles was strongly influenced by the concentration of the xanthan gum and surfactant. The stability of the Aphron fluid was investigated by measuring the bubble size and its frequency, and it was reported that both Aphron fluids became stable with increasing polymer concentration33.

In previous works and studies, the SDS surfactant has been mentioned as the best surfactant. However, because it has a very high Hydrophilic-Lipophilic Balance (HLB) number, it has the problem of being absorbed on carbonate rock surfaces. Therefore, in this study, we are looking for an alternative surfactant whose structure is different from the structure of the surfactants used in previous studies and has better performance. However, the effect of temperature on the drilling fluid has not been investigated. The only work that has been performed is at very high shear rates, which is not based on the API standard. Note that the rheological properties are highly dependent on the shear rate. Therefore, it must be checked up to 600 rpm for the Aphron fluid using drilling fluid. Moreover, one of the main differences in this study is that it specifies the mechanisms of the Aphronic systems, which was not mentioned in previous studies.

In this study, two types of anionic surfactants with different structures and behaviors were used in the presence of xanthan gum. The purpose of this study was to compare Alpha Olefin Sulphonate (AOS) and Sodium dodecyl sulfate (SDS) to investigate the rheological behavior and stability of Aphron. Furthermore, the effect of temperature and the interaction of surfactant and xanthan gum on the stability and behavior of Aphron are investigated. Moreover, the impact of temperature and surfactant concentration on the rheological behavior of the Aphron fluid was analyzed. The investigation encompasses temperatures ranging from 25 °C to 93 °C, surfactant concentrations varying from 0.25 CMC to 2 CMC, and polymer concentrations ranging from 3430 to 10,290 mg/L. Furthermore, a thorough examination of Aphron fluid stability is conducted throughout 7000 h. Finally, the alterations in bubble size under a microscope were analyzed over a 3-h period.

Methods and materials

Material

Drilling fluids based on CGA often contain polymers and surfactants. The drilling fluids presented in this study were developed with a natural polymer and two types of surfactants to investigate the effect of temperature on the rheology and stability of Aphronic fluids. Xanthan Gum (XG) as a polymer, Alpha Olefin Sulphonate (AOS) as an anionic, and sodium dodecyl sulfate (SDS) as surfactants were used in the formulation of drilling fluid based on CGA.

It is proposed that XG-type polymeric materials have high molecular weights and can be used as a viscosifier and stabilizer18,34,35,36,37. A disadvantage of combining xanthan gum with surfactants is its reduced properties. The denaturation process of xanthan gum is accompanied by complicated changes in its molecular configuration, leading to profound changes in its inherent properties and functionality. When surfactants come into contact with xanthan gum, they trigger structural changes, a phenomenon known as denaturation. Xanthan gum, which is classified as a polysaccharide, undergoes chemical interactions and forms hydrogen bonds with the surfactant SDS, which costs the xanthan gum backbone, denaturing it. This disruption in the native structure of xanthan gum decreases its thickening and stabilizing properties38.

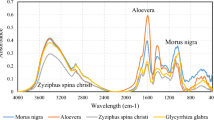

In the formulation of CGA-based drilling fluids, the use of a surface-active agent or surfactant is essential so that bubbles can remain in the fluid. Because of the nature and structure of xanthan gum, cationic surfactants have a great potential to denature it. Denaturation of xanthan gum causes a severe decrease in the stability and rheological properties of the Aphron fluid. Table 1 shows the properties of the surfactants used in this study. Table 2 shows the properties of Xanthan Gum used in this study. Figure 1 shows the chemical structure of SDS, AOS, and Xanthan Gum.

Experimental procedure

CGA Preparation

In 200 ml of deionized (DI) water, xanthan gum, and water were agitated together for 2 min using a homogenizer at 10,000 rpm to prepare the base fluid. We used a normal mechanical rotor-stator homogenizer to produce the Aphronic fluid. This homogenization took 10 min at 10,000 RPM on the base fluid and surfactant mixture. The introduction of air into the base liquid via a homogenizer leads to a substantial reduction in the base fluid’s viscosity, resulting in the creation of an Aphronic fluid. Throughout testing, it was noted that the volume of the final fluid increased by 300%. The inclusion of air bubbles within the Aphronic fluid facilitates its smooth movement, demonstrating exceptional fluidity even under minimal shear stresses. A schematic related to Aphron’s preparation is illustrated in Fig. 2.

Fluid stability experiments

To ensure that a CGA-based drilling fluid can conduct an efficient drilling operation, the drilling fluid must be able to maintain the necessary stability so that bubbles can be prevented from bridging in front of the formation and fluid cannot enter the formation. The evaluation of the CGA drilling fluid stability was conducted at room temperature and under atmospheric conditions. The test procedure described elsewhere involves pouring 100 ml of the CGA fluid into a graduated cylinder and draining the liquid volume33,43. Figure 3 shows the schematic procedure for Aphron stability.

Also, Aphronic fluid is placed under the Fluorescence Microscope and photographed. Then the Fluorescence Microscope Analyst the bubble dimension and counted Fig. 4. shows the schematic procedure for Aphron stability by Microscope method.

Fluid rheology experiments

A mathematical rheology model, and the measurement of shear stress and shear rate, can be used to predict the flow behavior of fluids. Using the MCR 302 rheometer from Anton Paar Company, a rheometer designed for the measurement of viscosity and shear rate in drilling fluids based on CGA was used to determine the shear stress, shear rate, and viscosity of the drilling fluids immediately after Aphronization. A total of 120 different speeds were used to test the rheological properties of the fluids. Figure 5 shows a schematic of the procedure of Aphron rheology.

Results and discussion

In this study, polymer and surfactant were used to study the stability of Aphron. Table 3 lists the specifications for each of the discussed tests.

Furthermore, the effect of temperature on the formation and rheology of Aphron fluid at API standard temperature (i.e., 49, 71, and 93 °C) and ambient temperature was investigated. The stability of the Aphron fluid was assessed at ambient temperature.

Rheological behavior of the aphron

Effect of the polymer concentration

In the first step, it is necessary to specify a base fluid to make subsequent fluids. Therefore, the discussion of the stability and rheology of these types of fluids is important. To improve these properties, natural or synthetic polymers are used. In this study, xanthan gum was applied as a natural polymer to make the Aphron base fluid. According to a previous study, it has been claimed that the concentration of xanthan gum 6860 mg/L in distilled water is the optimal concentration of Aphron fluid44. However, the rheological behavior of the samples was evaluated to determine the optimal viscosity of the base fluid. The results of the tests, as shown in Fig. 6, showed that at low shear rates (up to 40 s− 1), the optimal polymer concentration is 6860 mg/L. Because the shear rate range in the field of drilling mud engineering is up to 10 s− 1 45. According to Fig. 6, the rheological behavior of the base fluid does not significantly change with increasing polymer concentration.

Effect of temperature

In the second step, the rheological behavior of the optimal base fluid was investigated using a rotary viscometer at standard temperatures to determine the effect of temperature on the base fluid. The results obtained from the optimal base fluid rheological tests at standard API temperatures are shown in Fig. 7.

Based on Fig. 7, as the temperature increases, the plastic viscosity and the yield point decrease. In other words, the ability of the fluid to transfer drilling fragments to the surface weakens46,47.

The results of rheology tests for different concentrations of SDS surfactant at a low shear rate are illustrated in Fig. 8, showing that the rheological properties of plastic viscosity and yield point improve as the surfactant concentration increases from 0.25 CMC to 2 CMC.

Rheological behavior of the SDS base aphron

The results obtained from the rotary viscometer for the five SDS concentrations at different temperatures are shown in Fig. 9. According to these graphs, for all samples, the rheological properties of the Aphron fluid decrease with increasing temperature. The only exceptions are the 0.25 CMC and 0.5 CMC concentrations, where after the shear rate of 250 rpm, the graph for 25 °C is slightly lower than that for 49 °C. This different behavior is shown in Fig. 9.

Because the temperature of the underground (well) is higher than the surface, it is necessary to have appropriate rheological properties of the hydraulic fluid at high temperatures48,49. For this purpose, the comparison should be performed at temperatures of 49, 71, and 93 °C (based on the API standard).

In all the samples, the quality of the drilling fluid at 93 °C is severely reduced, among which the highest quality reduction is related to the fluid with CMC concentrations of 1.5 and 2 CMC. For example, with an increase in temperature from 25 °C to 93 °C, the reduction in viscosity for 0.25 CMC is equal to 54%, and for 2 CMC, the reduction rate is 77%. The effect on the yield point is the same as that on viscosity. An increase in temperature destroys the polymer structure of the base fluid and changes the structure of the polymer, and the so-called xanthan gum polymer becomes denatured, which decreases the rheological properties of the fluid. Note that the rheological properties of the polymer improve with decreasing temperature and exhibit reversible behavior. The general changes in viscosity values and yield points are fully collected and visible.

Although the relative decrease in rheological properties with increasing temperature is quite evident, at 93 °C, all samples have unfavorable rheological properties. Furthermore, at a temperature of 71 °C, samples with concentrations of 0.25 CMC and 2 CMC had a greater reduction in quality in terms of rheological properties. Among these, the best performance at 71 °C is related to the concentration of 1 CMC. Based on these results, it can be concluded that Aphornic fluid prepared with SDS surfactant is suitable for drilling wells with a temperature lower than 71 ℃.

Rheological behavior of the AOS base aphron

The results obtained from the rotary viscometer for five concentrations of AOS at different temperatures are shown in Fig. 10. According to these graphs, it can be deduced that for all samples, the rheological properties of the Aphron fluid decrease with increasing temperature.

At concentrations of 0.25 CMC, 0.5 CMC, and 1 CMC, especially at shear rate values higher than 4 s− 1, the graphs for temperatures of 25 °C and 49 °C have slightly different trends, and the rheological properties increased slightly with increasing temperature.

For the practical conditions, a comparison at high temperatures of 71 and 93 °C (according to the API standard) is performed. In all samples, the drilling fluid quality significantly decreased at 93 °C. The lowest reduction in quality was observed with a 0.5 CMC concentration, whereas the highest reduction was associated with a 2-CMC concentration.

For example, with an increase in temperature from 25 to 93 °C, the reduction in viscosity for the sample with 0.5 CMC concentration is equal to 44%, and for the sample with 2 CMC concentration, the reduction rate is about 65%. The effect on the yield point is the same as that on viscosity.

The changes in the rheological properties with increasing temperature could be due to an increase in the size of the bubbles in the Aphron fluid50. As the temperature increases, the size of the bubbles increases, and finally, the small bubbles join together and cause the size of the bubbles to substantially increase. Furthermore, with increasing temperature, the aqueous phase viscosity decreases. Reducing fluid viscosity allows bubbles to coalesce more easily and brings lamellae closer together51. This decreased stability in the Aphronic fluid system leads to bubble migration toward the upper side, resulting in emptying52.

Comparing Aphron’s stability

Stability of Aphron (SDS base)

To assess the stability of the Aphron fluids, 100 ml of the fluid was poured into a graduated cylinder. Over time, the fluid level gradually decreases because of the gravitational separation of air and liquid. Gravitational separation is the main mechanism underlying the instability of Aphron fluids over time53. The changes in the height of the Aphron fluid with time are shown in Fig. 11(left) and 11(right). With time, the bubbles grow larger and eventually reach the top surface. Figure 11 (left) and 11 (right) depict the changes after 24 and 100 h, respectively.

The changes in the height of the Aphron fluid with time are shown in Fig. 12(left) and 12(right). With time, the bubbles grow larger and eventually reach the top surface. In Fig. 12 (left) and 12 (right) depict the changes after 24 and 224 h, respectively.

The greatest reduction in height or fluid instability was observed in the sample with a concentration of 0.25 CMC SDS. Increasing the surfactant concentration in the Aphron fluid from 0.25 to 1.5 CMC results in improved fluid stability. This improvement was observed for both the SDS and AOS-containing fluids and they behaved similarly.

During the stability test using the half-life method, it was observed that a decrease in fluid height occurred simultaneously with an increase in bubble size. The best time stability was associated with a fluid concentration of 1.5 CMC SDS, where no significant height reduction was observed even after 37 h. Figure 13 compares the stability of Aphronic fluids containing SDS.

One of the key factors influencing the half-life of Aphron fluids is the change in bubble size. Smaller bubbles tend to shrink, whereas larger ones grow, contributing to Aphron fluid instability32,50. In general, after a certain period, the bubble size increases to a point where it falls outside the scope of the definition of Aphron, and this fluid can be considered foam54. Figure 14 clearly shows this phenomenon.

After the preparation of the emulsion, foam, Aphron, and suspension, there may be immediate changes in the size of the droplets, bubbles, or dispersed particles. This is the main factor causing instability in emulsions and Aphron fluids. This phenomenon could be mainly due to Ostwald Ripening and is caused by the limited solubility of the dispersed phase55.

There is a difference in solubility between droplets, small bubbles, and particles versus large bubbles. Smaller bubbles have higher solubility because of the effect of curvature on the surface free energy, and this high solubility causes the smaller species to slowly disappear over time and the material solved to be transferred to larger species. Hence, larger droplets, bubbles, or particles tend to become larger while smaller species become smaller56,57. From a stability point of view, this process is almost always unfavorable because larger species will have a higher creaming rate. One method to reduce the Ostwald Ripening rate involves the adsorption of surfactants and polymers at interfaces, which can prevent the incorporation of new molecules into dispersed species. However, there can be an increase in Ostwald Ripening at values above the CMC58,59.

Ostwald Ripening refers to mass transfer between droplets with different curvatures through the continuous medium around them in emulsion fluids. The concentration of the dispersed phase materials on the drop’s surface has an inverse relationship with the radius of curvature. Hence, a small droplet has a higher surface concentration than a large droplet. Therefore, a concentration gradient of the dispersed phase substance is created in the continuous phase. Mass transfer occurs along the concentration gradient from small to large droplets. Therefore, small droplets shrink and eventually disappear, whereas large droplets grow at their expense, leading to phase separation58,59.To check the size change of the bubbles inside the Aphron fluid, microscopic studies were performed. For this purpose, a picture of the Aphronic fluid sample was taken with an optical microscope, and only for the 1 CMC concentration of the Aphronic fluid containing AOS, the changes in the size and shape of the bubbles were investigated over time.

Figure 15 shows a better understanding of the stability of the Aphron fluid and the effect of the bubble size in the base fluid. In general, as time passes, the size of the bubbles increases. This behavior prevails for bubbles located at a sufficient distance from their neighboring bubbles60. However, for bubbles that are attached to a bubble, the behavior is slightly different. When two bubbles are stuck together, the bubble becomes smaller and the big bubble becomes bigger. For example, after only 2 h, bubble G has shrunk to such an extent that it has completely disappeared from the environment. Furthermore, bubble D increases in size after an hour and sticks to its adjacent bubbles (i.e., C and E) and its shrinking process begins. As shown in Fig. 16 the bubbles with a size of less than 100 μm increase in size at a slower rate. Samples A and F remained almost constant after 1 h at the end of the test. However, for samples larger than 100 μm and smaller than 200 μm (B), it was observed that the size gradually increased until the end of the experiment. On the other hand, for bubbles larger than 200 μm in size (C, D, and E), the bubble size changes more rapidly and continuously.

Changes in the size of the bubbles in the Aphronic fluid over time. (A–G) are the bubbles mentioned in Fig. 15.

Stability of Aphron (AOS Base)

Figure 17 shows the results of the stability of Aphronic fluids containing AOS over time. As can be seen, the greatest reduction in height or fluid instability in the AOS containing Aphronic fluid is associated with the sample having a concentration of 0.25 CMC AOS. The fluid stability increased with concentration from 0.25 to 1.5 CMC but decreased again at the highest concentration of 2 CMC AOS. The highest time stability was obtained in Aphronic fluid containing AOS at a concentration of 1.5 CMC, with no height reduction observed after 6 h. A comparison of Figs. 13 and 17 shows that Aphronic fluid containing AOS exhibits significantly greater stability compared to that containing SDS. In both samples, the highest stability is achieved with a concentration of 1.5 CMC.

In general, the Aphron fluid with the AOS surfactant has a much higher stability than that with the SDS surfactant and is recommended as an Aphron drilling fluid.

Figure 16 shows the difference in the drained volume and stability of the Aphron fluids containing SDS and AOS. The values in Fig. 18 are in the first 3000 min of the test. As it is clear in Fig. 18, both Aphronic fluids become more stable by increasing the surfactant concentration up to 1.5 CMC but increasing the surfactant concentration in both Aphronic fluid samples has caused instability of the Aphronic fluids.

Comparison of the rheology of Aphron fluid containing SDS and AOS surfactants

The drilling fluid containing AOS has higher stability than that containing SDS because the drilling fluid containing SDS surfactant denatures the xanthan gum polymer, which is an essential material in maintaining the rheological properties and stability of the Aphron fluid. The rheological properties of AOS compared with those of SDS surfactant decrease with increasing temperature. The stability of the Aphron fluid in the well is equivalent to the height (pressure head) of the drilling fluid inside. On the other hand, AOS has a lower CMC value than SDS; thus, it requires less solid powder to make an Aphronic fluid. Especially offshore, we have limited space for the storage of these materials, and the costs of transporting the materials to the offshore rig are very high.

In general, the rheological properties of the Aphronic fluid decrease with increasing temperature. A comparison of the rheological properties of the Aphronic fluid at the optimum concentration of 1.5 CMC, where it was most stable, for the two surfactants AOS and SDS is shown in Fig. 19. The rheological properties of the Aphronic fluid decrease with increasing temperature. At temperatures of 25 °C, 49 °C, and 71 °C, the rheological properties of the Aphron fluid with the AOS surfactant were higher than those of the Aphron fluid with the SDS surfactant. At 93 °C, the rheological properties of both surfactants decreased. However, the Aphron fluid with the AOS surfactant showed a much smaller decrease than the Aphron fluid with the SDS surfactant. The changes in rheological properties with increasing temperature may be due to the increase in bubble size in the Aphronic liquid. As the temperature increases, the bubbles become larger and larger, and eventually, the small bubbles merge, causing the bubbles to increase significantly in size. Moreover, the viscosity of the aqueous phase decreases as the temperature increases61. The decrease in the viscosity of the liquid causes the bubbles to coalesce more easily because the SDS surfactant can denature xanthan gum, resulting in a drastic reduction in the rheological properties of the Aphron fluid containing the SDS surfactant38.

Considering the anionic nature of both AOS and SDS surfactants and the anionic nature of xanthan gum, and based on previous studies, anionic surfactants do not react with the sub-branch of xanthan gum, and the SDS surfactant wraps around the main branch of xanthan gum, thus causing denaturation of xanthan gum38. It appears that the AOS surfactant cannot wrap around the main branch of the xanthan gum due to its double bond in its structure and is, therefore, unable to denature xanthan gum, which is why the structure of the xanthan gum does not change, and the AOS surfactant can produce a more stable Aphronic fluid with better rheological properties.

Presenting mechanism of the role of surfactant in the stability of Aphron

According to Gibbs Marangoni62,63, the behavior observed in Figs. 13 and 17 can be explained by the same mechanism. The elastic material’s response to applied force is determined by the interface between stress and strain64. It is important that the fluid can resist forces that try to thin the film it consists of and unite bubbles because Aphronic fluid is dependent on the elasticity of its thin liquid film. In foam production and the production of Aphron fluid, elasticity is crucial to ensuring the stability of the liquid film and, consequently, the Aphron fluid53.

The surface tension of liquids changes when surfactants are present, which affects the elasticity of thin films. The Gibbs elasticity coefficient, expressed by the equation EG = dγ /dlnA, where A is the film thickness and γ is surface tension, quantifies this relationship. About the surface tension of the film, a higher elasticity coefficient indicates greater stability. Gibbs elasticity, however, has limitations because it can only be applied to thin liquid films and ignores penetration phenomena65,66.

Surface tension is influenced by the surfactant concentration in the solution. A low concentration of monomers (Fig. 20) results in low elasticity coefficients because monomers are evenly spread out62,63.

The surface tension changes when the film is thinned under these conditions, which easily destroys the fluid bubbles. During film thinning, the surface tension remains relatively unchanged at high concentrations (Fig. 21)62,63.

In Fig. 22, where the elasticity increases with force application, a difference in the monomer concentration and surface tension is observed, which results in optimal stability62,63.

According to the abovementioned cases, there is an optimal concentration value for the stability of Aphron fluid, and at lower and higher concentrations than this value, the stability of Aphron fluid decreases.

Based on Gibbs elasticity theory62,63, in Figs. 13 and 17, the optimal concentrations for the AOS and SDS surfactants are 1.5 CMC. Therefore, the stability of the system decreases at concentrations lower and higher than the optimal state. This can be explained based on Figs. 20 and 21, and 22. Note that based on the obtained results, obtaining the CMC as a point based on the intersection of two lines in the conductivity diagram according to concentration is not a suitable criterion for choosing the stability of the system. In other words, the most suitable stability is in the region of 1–1.5 CMC. That is, there is a region of stability.

Conclusions

In this study, the effects of temperature on the stability and rheological properties of Aphron fluids were investigated to ensure effective transfer of cuttings during drilling. Stability and rheology tests were conducted at room temperature and various elevated temperatures to assess how well the fluid could maintain its structural integrity under different conditions. Given that the unique structure of Aphron fluid is critical for stable coating transfer, it is essential to preserve this stability throughout the process. Thus, the stability of Aphron fluid formulated with SDS and AOS surfactants was examined. The main findings from this investigation are as follows:

Rheological properties and temperature

The rheological properties of Aphron fluids decrease with increasing temperature, although the behavior improves at ambient temperatures with higher surfactant concentrations. In particular, the AOS surfactant maintains better rheological stability at temperatures up to 71 °C compared to SDS, which causes the degradation of xanthan gum, resulting in instability of the liquid.

Stability and surfactant performance

Aphron fluids exhibit stability problems over time due to Ostwald ripening. However, surfactants, especially AOS, mitigate this by preserving the structure of the xanthan gum, unlike SDS, which promotes degradation. The study confirms that stability is higher in the range of 1 CMC to 1.5 CMC, suggesting that surfactant concentration is critical in maintaining fluid integrity.

Significance and future research

The observations showed that the AOS surfactant had minimal impact on the structure and performance of the xanthan gum polymer, preserving its integrity without causing degradation. At high temperatures, stability tests showed that Aphron fluid prepared with AOS exhibited greater stability, making it a more suitable candidate for formulating temperature-resistant Aphron fluids. This study highlights the effectiveness of AOS in maintaining stability under high-temperature conditions, suggesting it as a promising surfactant choice for such applications. Future research should aim to optimize surfactant concentration and explore additional polymers to further improve the fluid’s temperature resilience for high-temperature drilling environments.

Data availability

Data avalibility: The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Churilova, M., Lupuleac, S. & Shaposhnikov, N. Complex Mathematical modeling of the Well drilling process. Appl. Sci. 12, 11369 (2022).

Tabzar, A., Arabloo, M. & Ghazanfari, M. H. Rheology, stability and filtration characteristics of Colloidal Gas Aphron fluids: role of surfactant and polymer type. J. Nat. Gas Sci. Eng. 26, 895–906 (2015).

Riazi, M. et al. Modelling rate of penetration in drilling operations using RBF, MLP, LSSVM, and DT models. Sci. Rep. 12, 11650 (2022).

Wong-Loya, J., Andaverde, J. & del Rio, J. Improved method for estimating static formation temperatures in geothermal and petroleum wells. Geothermics 57, 73–83 (2015).

Caenn, R., Darley, H. C. & Gray, G. R. Composition and Properties of Drilling and Completion Fluids (Gulf professional publishing, 2011).

Vajargah, A. K. & van Oort, E. Determination of drilling fluid rheology under downhole conditions by using real-time distributed pressure data. J. Nat. Gas Sci. Eng. 24, 400–411 (2015).

Yu, B., Yan, C. & Nie, Z. Chemical effect on wellbore instability of Nahr Umr shale. The Scientific World Journal (2013). (2013).

Jha, P. K., Mahto, V. & Saxena, V. K. Study the effect of polymers on the stability and rheological properties of oil-in-water (O/W) Pickering emulsion muds. Korea-Australia Rheology J. 30, 127–136 (2018).

Uzoma, O. G. Extraction and partial characterization of mustard seed (BRASSICA SPP.) OIL 4(3), 177–195 (2014).

Eckhout, D. et al. In IADC/SPE Asia Pacific Drilling Technology Conference and Exhibition? SPE-62791-MS (SPE).

Lye, G. & Stuckey, D. Structure and stability of colloidal liquid aphrons. Colloids Surf., a. 131, 119–136 (1998).

Deng, T., Dai, Y. & Wang, J. A new kind of dispersion—colloidal emulsion aphrons. Colloids Surf., a. 266, 97–105 (2005).

White, C. C., Chesters, A. P., Ivan, C. D., Maikranz, S. & Nouris, R. in SPE/IADC Drilling Conference. (OnePetro).

Sebba, F. Foams and biliquid foams–aphrons. vii, 236 pp. (1987).

Brookey, T. in SPE International Conference and Exhibition on Formation Damage Control. SPE-39589-MS (SPE).

Ivan, C. D., Growcock, F. B. & Friedheim, J. E. In SPE Annual Technical Conference and Exhibition? SPE-77445-MS (SPE).

Rosenberg, S., Gala, D. M. & Xu, W. in IADC/SPE Drilling Conference and Exhibition. (OnePetro).

Bjorndalen, H., Jossy, W., Alvarez, J. & Kuru, E. A laboratory investigation of the factors controlling the filtration loss when drilling with colloidal gas aphron (CGA) fluids. J. Petrol. Sci. Eng. 117, 1–7 (2014).

Arabloo, M., Shahri, M. P. & Zamani, M. Characterization of colloidal gas aphron-fluids produced from a new plant-based surfactant. J. Dispers. Sci. Technol. 34, 669–678 (2013).

Arabloo, M. & Shahri, M. P. Experimental studies on stability and viscoplastic modeling of colloidal gas aphron (CGA) based drilling fluids. J. Petrol. Sci. Eng. 113, 8–22 (2014).

Amiri, M. & Sadeghialiabadi, H. Evaluating the stability of colloidal gas aphrons in the presence of montmorillonite nanoparticles. Colloids Surf., a. 457, 212–219 (2014).

Pasdar, M., Kazemzadeh, E., Kamari, E., Ghazanfari, M. H. & Soleymani, M. Monitoring the role of polymer and surfactant concentrations on bubble size distribution in colloidal gas aphron based fluids. Colloids Surf., a. 556, 93–98 (2018).

Zhu, W., Zheng, X. & Li, G. Micro-bubbles size, rheological and filtration characteristics of Colloidal Gas Aphron (CGA) drilling fluids for high temperature well: role of attapulgite. J. Petrol. Sci. Eng. 186, 106683 (2020).

Alizadeh, A. & Khamehchi, E. Experimental investigation of the oil based Aphron drilling fluid for determining the most stable fluid formulation. J. Petrol. Sci. Eng. 174, 525–532 (2019).

Wang, Z. et al. Formation and rupture mechanisms of visco-elastic interfacial films in polymer-stabilized emulsions. J. Dispers. Sci. Technol. 40, 612–626 (2019).

El-Ghazawy, R. A., Atta, A. M. & Kabel, K. I. Modified maleic anhydride-co-octadecene copolymers as flow improver for waxy Egyptian crude oil. J. Petrol. Sci. Eng. 122, 411–419 (2014).

Wang, R., Pu, W., Dang, S., Jiang, F. & Zhao, S. Synthesis and characterization of a graft-modified copolymer for enhanced oil recovery. J. Petrol. Sci. Eng. 184, 106473 (2020).

Zhang, W., Shen, H., Wang, Y. & Dong, Y. Grafting lignite with sulformethal phenoldehy resin and their performance in controlling rheological and filtration properties of water–bentonite suspensions at high temperatures. J. Petrol. Sci. Eng. 144, 84–90 (2016).

Sun, L., Wei, P., Fu, Q., Zhang, J. & Zeng, D. Research advance of xanthan system with temperature resistance and salt resistant in the oilfield development. App Chem. Ind. 43, 2279–2284 (2014).

Ramasamy, J. & Amanullah, M. Nanocellulose for oil and gas field drilling and cementing applications. J. Petrol. Sci. Eng. 184, 106292 (2020).

Hosseini-Kaldozakh, S. A., Khamehchi, E., Dabir, B., Alizadeh, A. & Mansouri, Z. Rock wettability effect on Colloidal Gas Aphron invasion near wellbore region. J. Petrol. Sci. Eng. 189, 106766 (2020).

Keshavarzi, B., Javadi, A., Bahramian, A. & Miller, R. Formation and stability of colloidal gas aphron based drilling fluid considering dynamic surface properties. J. Petrol. Sci. Eng. 174, 468–475 (2019).

Pasdar, M., Kazemzadeh, E., Kamari, E., Ghazanfari, M. H. & Soleymani, M. Insight into selection of appropriate formulation for colloidal gas aphron (CGA)-based drilling fluids. Pet. Sci. 17, 759–767 (2020).

Bjorndalen, N. & Kuru, E. Physico-chemical characterization of aphron-based drilling fluids. Journal Can. Petroleum Technology 47 (2008).

Kuru, E., Bjorndalen, N., Jossy, E. & Alvarez, J. Reducing formation damage with microbubble-based drilling fluid: understanding the blocking ability. J. Can. Petroleum Technol. 47(11), 63–69 (2008).

Ziaee, H., Arabloo, M., Ghazanfari, M. H. & Rashtchian, D. Herschel–Bulkley rheological parameters of lightweight colloidal gas aphron (CGA) based fluids. Chem. Eng. Res. Des. 93, 21–29 (2015).

Dehaghani, A. H. S. & Elyaderani, S. M. G. Experimental investigation of the impact of sugarcane molasses on the properties of colloidal gas aphron (CGA) drilling fluid. Petroleum (2021).

Nnyigide, O. S., Nnyigide, T. O. & Hyun, K. The degradation of xanthan gum in ionic and non-ionic denaturants studied by rheology and molecular dynamics simulation. Carbohydr. Polym. 251, 117061 (2021).

Jing, J. et al. Preparation and rheological properties of a stable aqueous foam system. RSC Adv. 7, 39258–39269 (2017).

Jadav, M., Pooja, D., Adams, D. J. & Kulhari, H. Advances in xanthan gum-based systems for the delivery of therapeutic agents. Pharmaceutics 15, 402 (2023).

Elarbi, F. M., Ettarhouni, Z. O., Abdussalam-Mohammed, W. & Mezoughi, A. B. Study on the effects of biologically active amino acids on the micellization of anionic surfactant sodium dodecyl sulfate (SDS) at different temperatures. Chemistry 4, 146–155 (2022).

Mehrjoo, H., Riazi, M. & Norouzi-Apourvari, S. A comprehensive review on the use of eco-friendly surfactants in oil industry. Chem. Meth., 357–399. https://doi.org/10.1016/B978-0-12-821931-7.00009-2 (2022).

Pourbehzad, A., Ranjbar, M. & Zabihi, R. Application of response surface methodology for a feasibility study of producing stable semi-aphron fluids using natural materials. Energy Sources Part A: Recovery Utilization Environ. Effects. 44, 4740–4762 (2022).

Pasdar, M., Kamari, E., Kazemzadeh, E., Ghazanfari, M. H. & Soleymani, M. Investigating fluid invasion control by Colloidal Gas Aphron (CGA) based fluids in micromodel systems. J. Nat. Gas Sci. Eng. 66, 1–10 (2019).

Agwu, O. E. et al. A critical review of drilling mud rheological models. J. Petrol. Sci. Eng. 203, 108659 (2021).

Abdullah, A. H. et al. A comprehensive review of nanoparticles: Effect on water-based drilling fluids and wellbore stability. Chemosphere 308, 136274 (2022).

Chu, Q. & Lin, L. Synthesis and properties of an improved agent with restricted viscosity and shearing strength in water-based drilling fluid. J. Petrol. Sci. Eng. 173, 1254–1263 (2019).

Zhao, S., Yan, J., Shu, Y. & Zhang, H. -x. Rheological properties of oil-based drilling fluids at high temperature and high pressure. J. Cent. South. Univ. Technol. 15, 457–461 (2008).

Ye, Y., Fan, H. & Liu, Y. A New Approach for Predicting the Rheological Properties of Oil-Based Drilling Fluids under high temperature and high pressure based on a parameter-free method. Appl. Sci. 13, 8592 (2023).

Geng, X., Hu, X. & Jia, X. Recirculated aphron-based drilling fluids. J. Petroleum Explor. Prod. Technol. 4, 337–342 (2014).

Kamat, P. M., Anthony, C. R. & Basaran, O. A. Bubble coalescence in low-viscosity power-law fluids. J. Fluid Mech. 902, A8 (2020).

Zhu, W., Zheng, X., Shi, J. & Wang, Y. A high-temperature resistant colloid gas aphron drilling fluid system prepared by using a novel graft copolymer xanthan gum-AA/AM/AMPS. J. Petrol. Sci. Eng. 205, 108821 (2021).

Belkin, A. et al. In SPE Annual Technical Conference and Exhibition? SPE-96145-MS (SPE).

Larmignat, S., Vanderpool, D., Lai, H. K. & Pilon, L. Rheology of colloidal gas aphrons (microfoams). Colloids Surf. A: Physicochemical Eng. Aspects. 322, 199–210 (2008).

Schramm, L. L. Emulsions, Foams, and Suspensions: Fundamentals and Applications (Wiley, 2006).

Ratke, L. & Voorhees, P. W. Growth and Coarsening: Ostwald Ripening in Material Processing (Springer Science & Business Media, 2013).

Loth, E. Fluid Dynamics of Particles, Drops, and Bubbles (Cambridge University Press, 2023).

Jiao, J. & Burgess, D. J. Ostwald ripening of water-in-hydrocarbon emulsions. J. Colloid Interface Sci. 264, 509–516 (2003).

Tadros, T. F. Industrial applications of dispersions. Adv. Colloid Interface Sci. 46, 1–47 (1993).

Zenit, R. & Rodríguez-Rodríguez, J. The fluid mechanics of bubbly drinks. Phys. Today. 71, 44–50 (2018).

Ewell, R. H. & Eyring, H. Theory of the viscosity of liquids as a function of temperature and pressure. J. Chem. Phys. 5, 726–736 (1937).

Tadros, T. F. Applied Surfactants: Principles and Applications (Wiley, 2006).

Pugh, R. Foaming, foam films, antifoaming and defoaming. Adv. Colloid Interface Sci. 64, 67–142 (1996).

Marrett, R. & Peacock, D. C. Strain and stress. J. Struct. Geol. 21, 1057–1063 (1999).

Ivanov, I. Thin liquid films. (2023).

Craster, R. V. & Matar, O. K. Dynamics and stability of thin liquid films. Rev. Mod. Phys. 81, 1131–1198 (2009).

Author information

Authors and Affiliations

Contributions

Mohsen Riazi: Investigation, Data curation, Methodology, Writing original draft; Abdolhossein Hemmati-Sarapardeh: Supervision, Methodology, Validation, Writing-Review & Editing; Mahin Schaffie: Validation, Methodology, Writing-Review & Editing; Reza Zabihi: Methodology, Visualization, Writing-Review & Editing; Masoud Riazi: Conceptualization, visualization, Writing-Review & Editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Riazi, M., Hemmati-Sarapardeh, A., Schaffie, M. et al. A comparative analysis of alpha olefin sulfonate and dodecyl sulfate in aphronic fluid containing xanthan gum in a wide range of temperatures. Sci Rep 15, 2507 (2025). https://doi.org/10.1038/s41598-024-80475-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-80475-2