Abstract

In an effort to elucidate the fatigue behavior of hydroxyl-terminated polybutadiene (HTPB) propellant with prefabricated cracks under strain-controlled conditions, a comprehensive experimental study was conducted employing an MTS fatigue testing machine. The experimental design included four cohorts of specimens: a control group of un-notched specimens and three experimental groups featuring notched specimens with prefabricated cracks oriented at distinct angles (0°, 45°, and 75°) relative to the horizontal. Throughout the duration of the fatigue tests, an infrared thermographic camera was employed to meticulously monitor the temperature variations across the surface of each specimen. The collected data revealed that an escalation in strain amplitude, when subjected to a constant frequency, is directly correlated with a decrement in the fatigue life of the HTPB propellant. Notably, the fatigue lives of the specimens with prefabricated cracks were observed to be congruent, culminating at approximately 2*10^4 cycles, and maintaining a consistent order of magnitude. Conversely, the un-notched specimens demonstrated a substantially more enduring fatigue life, extending to 1*10^6 cycles, thereby manifesting a cross-order phenomenon.Throughout the fatigue testing, the specimens exhibited a pronounced strain hysteresis effect, which is indicative of their pronounced viscoelastic attributes. Concurrently, the thermal monitoring of the specimens across the four experimental groups uniformly displayed an escalating temperature trend. Intriguingly, a positive correlation was identified between the final surface temperature and the fatigue life of the specimens, suggesting a potential interplay between the heat generated due to viscoelastic dissipation and the material’s resistance to fatigue under cyclic loading.

Similar content being viewed by others

Introduction

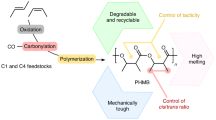

During the transportation of solid rocket motor grains, the mechanical properties of the solid rocket motor will change due to alternating loads such as projectile vibration loads, temperature stress loads, etc., which directly endanger the reliability of the motor grain. During short loading periods, these random loads will not cause macroscopic damage to the grain, but long-term action will deteriorate the mechanical properties of the propellant and cause abnormal operation of the motor. Therefore, it is of great significance to study the fatigue properties and prefabricated fatigue crack growth properties at fatigue test of HTPB propellants under alternating loads for grain life evaluation.

Fatigue and fracture are the main reasons for the failure of engineering structures and components. Today, traditional strength (that is the strength of non-defective materials under static load), the practical experience and accumulation of strength design in engineering are also quite rich, and the ability to control traditional strength has also been greatly enhanced. Therefore, the proportion of failure caused by fatigue and fracture is more and more prominent in engineering. Wei et al.1 predicted the fatigue law and life of HTPB propellant using stress control, and established a fatigue damage evolution model under different stress amplitudes based on the theory of damage mechanics. The original Chaboche model overcomes the inability to explain the cycle. Strain relaxation is a good characterization of the damage evolution law of materials. Gustavo Henrique Murari et al.2 constructed the dynamic mechanical performance curve of propellant based on time and temperature, and verified the application of this curve under alternating load. Historically, the S-N curve (An S-N curve defines the number of cycles to failure, N(S), when a material is repeatedly cycled through a given stress range S.) has been used to express the number of cycles to failure Nfin the form of an exponential relationship between the applied stress σ. Yukitaka Murakami et al.3,4 based on the prediction method of fatigue life and limit of material with defects, and concluded that the fatigue limit decreases with the number of stress cycles and crack growth. Xu et al.5,6 carried out fatigue tests under different loading stresses and loading frequencies for HTPB propellant, and combined with the infrared thermal imaging system to monitor the surface temperature rise of the material during the fatigue test in real time, and analyzed the effect of fatigue damage on the mechanical properties of HTPB propellant. Xin et al.7,8,9,10,11,12 proposed a novel nonlinear viscoelastic constitutive model to describe the mechanical behavior of a polymer matrix composite (HTPB propellant). After implementation into a finite element code, the proposed model is utilized to simulate the stress-strain responses of cyclically loaded HTPB propellant. These results show that the model is capable of capturing the main characteristics of the hysteresis loops during fatigue process. Xin et al.13 conducted a constant stress loading failure experiment in order to analyze the interaction between the creep and fatigue of composite solid propellant, and then used the least squares method to fit the damage accumulation equation and verified it. C. G. Davila14 explored the relationship between fatigue determined usetime and fatigue crack growth rate in composites using a new cohesive damage model. Model parameters are obtained from idealizations of S-N diagrams used in engineering design. The model assumes that the quasi-static cohesion law describing tearing is the envelope of fatigue damage. Fatigue damage within the envelope satisfies the S-N diagram and Miner’s rate-accumulated damage rule for cumulative fatigue.

The studies primarily focus on specific materials and models without addressing the broader applicability of these findings across different engineering contexts, which limits their generalizability. Additionally, the reliance on traditional fatigue models may overlook emerging complexities in material behavior under varying environmental conditions and loading scenarios.

Based on the virtual crack closure method (VCCT) and the generalized Paris formula, Kong Lingyun et al.15 studied the fatigue crack growth life of the composite tunnel pavement. Tong Xin et al.16 conducted multi-frequency fatigue tests on a composite propellant under different strain amplitudes, and used a non-contact infrared radiation device to synchronously collect the surface temperature of the propellant specimen under cyclic loading, and discussed the frequency and strain influence. The effect of two factors of magnitude on the energy dissipation of composite propellants has been discussed. Yadong Guo et al.17,18 proposed a new viscoelastic damage model for fatigue cracking and optimized the fatigue cracking model of asphalt concrete. Yizhuang David Wang et al.19 proposed the use of a new fatigue parameter Sapp’, which can represent the damage capability of the mixture and is based on viscoelastic continuum damage theory. Sapp’ is a good way to evaluate the fatigue resistance of viscoelastic materials with different properties. Ran Wang20,21 launched a method assesses friction-induced thermal safety of solid rocket motors under ultrahigh overloads, using a validated model to predict ignition and temperature distribution, highlighting ignition likelihood at the propellant grain’s bottom surface. Qinwei Hu22 examines viscoelastic damage properties of NEPE solid propellant, presenting a model that accurately predicts creep and fatigue damage evolution and fatigue life under various stress ratios.

Sumit Bhowmik23 studied the fatigue behavior and fatigue performance of natural fiber polymer composites (NFPC) based on loading conditions, stress concentrations, and physical, mechanical, and wear properties. He believes that the use of NFPC can provide a lightweight material with higher specificity, stiffness, stability, and sustainability, which has greater potential for use in medium-load bearing and structural applications than conventional and synthetic composites. In bone tissue engineering, many studies focus on evaluating the static strength of polymer scaffolds, but their fatigue properties are rarely studied. Hamed Bakhtiari24,25 presents a force- and corrosion-based fatigue damage evolution of polymer scaffolds and compares it with the behavior observed in natural bone. Nanoreinforcements in carbon fiber reinforced polymers (CFRP) have been shown to enhance mechanical properties considering quasi-static and fatigue loading, and CFRP is a promising option in terms of performance optimization. Xingwen Qin26,27,28,29 focuses on investigating the fatigue damage mechanism of tire rubber materials through various research methods, including experimental design, visual analysis, theoretical modeling, and numerical simulation. The study successfully predicts the fatigue life of tire rubber materials using a comprehensive set of evaluation means, validating the accuracy of the thermo-mechanical coupling model in predicting fatigue life under different conditions. John Montesano30 utilized thermography to investigate the fatigue behavior of a braided carbon fiber polymeric composite plate. The thermographic approach successfully determined the fatigue threshold and provided insights into the damage mechanisms and heat dissipation, establishing a correlation between the thermographic technique and conventional test methods for determining the fatigue stress-life curve of the composite plate.

R. López31,32analysis investigates the fatigue crack growth behavior of composite solid propellants from a two-stage rocket, revealing differences in critical energy release rate values and micromechanisms of failure between the booster and sustainer motors. Li Yao33 investigates the effect of pre-fatigue on the mechanical properties of modified double-base propellant, revealing strain rate correlation and changes in elastic modulus, yield strength, tensile strength, and elongation at break with varying cycle numbers. Wenqin Zhang12 investigates the impact of long-term fatigue loading on NEPE solid propellant grains, revealing the evolution law of microdamage and proposing an improved fractional derivative constitutive model to predict low-frequency fatigue behavior, emphasizing the significance of stress-softening behavior, the Mullins effect, and strain-modification in assessing structural integrity.

Qiang Guo et al.34. developed a scaling theory to describe that the dissipation associated with viscoelasticity and crack growth is governed by the coupling between three time-dependent processes: cyclic loading, crack growth, and viscoelastic creep. In the limit of slow crack growth and slow cyclic loading, a simple integral derivation equation is used to predict the crack growth rate at different cyclic loading frequencies. Jad Khodor et al.35 used configuration mechanics to characterize the growth of fatigue cracks in small-strain linear viscoelastic solids. Huailei Cheng et al.36 analyzed the fatigue behavior of asphalt mixtures under haversine waves based on a pseudo-fixation-based method. The fatigue life of asphalt mixtures is predicted.

These studies primarily focus on specific materials and contexts, which may limit the applicability of their findings to broader engineering scenarios, as they often do not consider the interplay of multiple factors influencing fatigue behavior across different environments. Furthermore, while various innovative models and methods are proposed, there remains a lack of comprehensive validation and comparative analysis of these approaches, which could enhance understanding of fatigue mechanisms in diverse materials.

This extensive body of work underscores the importance of investigating the fatigue properties of HTPB propellants under alternating loads. By addressing the underlying mechanisms and predictive models of fatigue damage and crack growth, these studies provide pivotal insights that are not only theoretically profound but also practically vital for ensuring the reliability and longevity of engineering materials used in critical applications such as rocket propulsion systems. This enhancement integrates theoretical advancements and accentuates the broader importance and applications of the research in the realm of engineering reliability and material science .

Experiment and results

Test equipment and methods

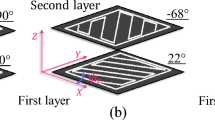

The fatigue test of the HTPB propellant specimen adopts the sine wave loading method, and the fatigue test is carried out on the American MTS(Measure Test Simulate) fatigue testing machine (as shown in Fig. 1). The process adopts strain control. A total of 4 groups of specimens were set up in the test, of which the non-cracked group was group S and the prefabricated crack group was group C. Among them, the crack angle and the horizontal angle α were set to 0°, named C1 group, and the crack angle and the horizontal angle α was 45 named C2, and the angle α between the crack angle and the horizontal is 75°, and it name as C3 group. In the test, ε means strain, εmin was 0, εmax in group S was 0.618, εmax in group C1 was 0.322, εmax in group C2 was 0.335, and εmax in group C3 was 0.410. The strain amplitude εa is (εmax-εmin)/2. In order to ensure the accuracy of the test results, each group of strain (stress) amplitudes were tested three times. The tensile rate is 2 mm/min, and the strain rate is 0.000477s−1. The frequency is 1 Hz.

The test piece was made according to the national standard of the People’s Republic of China (Test Method for Fatigue Performance of Polymer Matrix Composites37), and the shape of the test piece was dumbbell-shaped. Specimen size is accurate to 0.01 mm. Determination has the S-N curve and select at least 4 strain (stress) levels according to the purpose of the test. Generally, the maximum strain (stress) characterization level is obtained according to the fatigue test. The scheme for selecting the strain (stress) level is as follows:

-

a)

The first level has 10^4 cycles;

-

b)

The second level has 10^5 cycles;

-

c)

The third level has 5*10^5 cycles;

-

d)

The fourth level has 1*10^6 to 2*10^6 cycles.

The fatigue test is usually started at the first level, and the strain (stress) level is gradually increased or decreased if the number of cycles differs greatly from that expected(If the number of fatigue failures is lower than expected, increase the number of tests.).

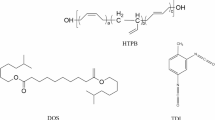

The components of the HTPB propellant used in the test are: aluminum powder (Al) 17%, ammonium perchlorate (AP) is about 70%, matrix HTPB rubber and other components 13%, as is shown in Table 1; Fig. 2. The room temperature in the laboratory is 20℃.

The prefabricated crack of the test piece was made with a self-made crack making tool, the length of the crack was 2 mm, and the width was not counted, as shown in Fig. 3.

Test results

Basic mechanical properties

Under quasi-static uniaxial tension, the maximum failure strain of the specimen without prefabricated crack is 0.62. In the prefabricated crack group, the maximum failure strain of C3 (75°) is the largest, C2 (45°), C1 (0°) is second, but the difference between the maximum failure strains of C1 and C2 is very small. The maximum failure strains of C3 are 0.41, C2 is 0.33, and C1 is 0.32. Compared with the specimen without prefabricated cracks, the ultimate strain of C1 is 51.6% of the S group, C2 is 53.22%, and C3 is 66.13%. Damage resistance S > C3 > C2 > C1 as shown in Fig. 4.

In Fig. 5, a comparative analysis of crack tip strain is presented, using a stretching rate of 2 mm/min as the baseline. At a stretching rate of 10 mm/min for the 0°crack, the crack tip strain exhibits a growth of 1.55%, corresponding to a growth rate of 5.15%. In contrast, at a stretching rate of 500 mm/min, the crack tip strain growth increases significantly to 21.04%, with a growth rate of 69.73%. For the 45°crack, the strain growth at a tensile rate of 10 mm/min is recorded at −1.23%, indicating that the crack tip strains at the 2 mm/min and 10 mm/min rates are nearly equivalent. At the higher tensile rate of 500 mm/min, the crack tip strain growth reaches 19.17%, with a growth rate of 28.53%. Additionally, at a stretching rate of 10 mm/min, the crack tip strain growth is 4.48%, resulting in a growth rate of 17.42%. At 500 mm/min, the strain growth further escalates to 20.61%, with a growth rate of 80.27%. Notably, the negative strain growth observed at the 10 mm/min stretching rate for the 45°crack suggests a consistent behavior at lower stretching rates (below 10 mm/min), which contrasts sharply with the pronounced effects observed at higher rates(exceeding 500 mm/min).

In the analysis of crack behavior at a 0° orientation, it is observed that as the stretching rate increases from a baseline of 2 mm/min, the crack tip strain growth exhibits a negative trend. Specifically, at a stretching rate of 10 mm/min, the crack tip strain growth is recorded at −1.65%, with a corresponding growth rate of −5.46%. At a higher tensile rate of 500 mm/min, the crack tip strain growth further decreases to −4.50%, resulting in a growth rate of −14.91%.For the 45° crack, similar trends are noted as the tensile rate increases. Starting from the 2 mm/min tensile rate, the crack tip strain growth at 10 mm/min is −4.43%, with a growth rate of −13.97%. At a tensile rate of 500 mm/min, the crack tip strain growth is −1.58%, yielding a growth rate of −4.97%.In the case of the 75° crack, the behavior mirrors that of the previous orientations. With a baseline stretching rate of 2 mm/min, the crack tip strain growth at 10 mm/min is again − 4.43%, maintaining a growth rate of −13.97%. At a stretching rate of 500 mm/min, the crack tip strain growth is recorded at −4.93%, with a growth rate of −9.63%.These findings highlight the consistent negative strain growth across varying crack orientations and stretching rates.

Fatigue failure

The fatigue failure \(\:\text{N}\) refers to the number of cyclic loadings that the material undergoes until fatigue induced fracture in dependence of stress amplitude, as shown in Fig. 6.

It can be seen from the Fig. 6 that the larger the strain amplitude, the smaller the fatigue life, indicating that the larger the strain amplitude, the greater the damage caused by the material per cycle, and the fewer times it takes to reach fatigue fracture. And the relationship between the two can be fitted by a power function.

The parameters are shown in Table 2.

The maximum fatigue limit for unprefabricated cracked specimens has exceeded 1 × 10^6 cycles, while the fatigue life of prefabricated cracked specimens is approximately 2 × 10^4 cycles, with the specimens exhibiting 0° cracks demonstrating the lowest fatigue resistance. These findings align with the research conducted by other scholars, indicating that viscoelastic materials possess notable durability characteristics, enabling them to withstand high stress levels and cyclic loading.

Under conditions of cyclic fatigue loading, viscoelastic materials can endure a greater number of cycles without experiencing significant damage or failure. Their high energy dissipation capacity allows them to effectively absorb and dissipate energy during stress application, which mitigates stress and strain concentrations. This energy dissipation capability is crucial in delaying the onset of fatigue damage.

In contrast, propellant specimens with pre-existing cracks have already sustained damage that leads to localized stress and strain concentrations, thereby accelerating the progression of fatigue damage. Conversely, uncracked propellant specimens exhibit a more uniform distribution of stress and strain, which reduces the formation and development of fatigue damage, allowing for an increased number of fatigue cycles. Typically, uncracked specimens possess a high energy dissipation capacity, enabling them to effectively absorb and dissipate the energy associated with cyclic loads. In contrast, specimens with pre-crack damage demonstrate diminished energy dissipation capabilities, resulting in accelerated fatigue damage propagation localized to the damaged regions.

Load displacement hysteresis curve

Because the HTPB propellant is a viscoelastic material, when subjected to a periodically varying sinusoidal stress, the material produces a periodic sinusoidal strain, but the strain lags the displacement, forming a hysteresis curve.

It can be seen from Fig. 7 that with the increase of the number of cyclic loadings, the hysteresis curve gradually shifts to the right, that is, the strain during the fatigue process continues to increase. At the same time, it is found that the area of the hysteresis curve increases with the increase of cycle times, which indicates that the damage degree of the material increases gradually. At the same time, combined with the uniaxial tensile test results of the prefabricated crack specimens of this propellant, it also conforms to the law that with the increase of the prefabricated damage degree, the fatigue performance also decreases synchronously.

Infrared camera temperature monitoring results

In terms of temperature monitoring, the starting temperature of the four groups of specimens is about 20℃ at room temperature. The prefabricated crack group C1\C2\C3 has the same trend. The non-cracked group presents an independent law, which can be seen from temperature monitoring. In prefabricated groups, the temperature change trend of the HTPB propellant specimen during the fatigue test is consistent, and the difference between the each prefabricated crack group is small. The temperature is about 10℃ higher than that of the prefabricated crack specimen. Combined with the fatigue life above, the fatigue life of the prefabricated crack specimen is an order of magnitude higher than that of the specimen without prefabricated cracks, and the temperature change is also consistent with this law. It can be seen that the fatigue life is positively correlated with the surface temperature change of the fatigue specimen. The sudden increase in temperature of group S is mainly due to the fact that the fatigue life is much higher than that of group C1\C1\C3, and its mechanical energy is converted into thermal energy to accumulate more energy, which is reflected in a significant increase in temperature as shown in Fig. 8.

Combined with the temperature monitoring image in Fig. 9, this law can be observed very intuitively. During the test, the middle of the specimen is selected as the key area for temperature monitoring. In the prefabricated crack group, the colors in the center of the specimen and around the specimen are similar, while in the group without prefabricated cracks, whether it is in the center of the specimen or around the specimen, the temperature is significantly higher than that of the prefabricated crack group. This is also consistent with the trend above.

It can be seen from Fig. 8 that when the loading stress is greater than the fatigue limit, the temperature change of the HTPB propellant specimen during the fatigue process can be divided into three stages: the first stage is the initial temperature rise stage (A-B), and point A represents the test At the beginning, the surface temperature of the test piece remains almost the same as that of the surrounding environment. With the increase of the number of cycles, the specimen experienced a rapid temperature rise, cyclic deformation occurred locally in the specimen, and the material released a large amount of heat due to viscous dissipation. The temperature difference between the specimen and the environment was small at the beginning of the test, and the heat loss during the convection process was small. Relatively small, the heat generation rate on the surface of the specimen is greater than the heat exchange rate between the specimen and the environment. Therefore, the surface temperature of the specimen rises rapidly; the second stage is the stable temperature rise stage (B-C), at this time, the heat generation rate on the specimen surface and the heat exchange rate between the specimen and the environment reach a balance, and the temperature change reaches a relatively stable state. The temperature fluctuates in a small range and continues to rise. For particle-filled polymer materials such as HTPB propellants, when fatigue loading reaches a certain stage, “dehydration” begins to appear between the internal matrix of the propellant and the particle interface, resulting in microvoids and other defects. With the increase of the number of cycles, the phenomenon of “dehumidification” between the particles inside the propellant and the matrix increases, the dehumidification points continue to open and close, and the temperature of the specimen fluctuates in a small range, resulting in the continuous expansion of defects. This stage occupies the majority of the fatigue life. The vast majority; the third stage is the rapid temperature increase stage (C-D). In this stage, the specimen initiates cracks and expands rapidly, the crack tip continues to release heat, and the temperature continues to rise. When the temperature reaches the highest point, the specimen fatigue fractures .

Specimen shape after fatigue fracture

Some HTPB propellant specimens during the test are shown in Fig. 9. In the non-prefabricated crack group, the fatigue fracture morphology of the specimen is similar to the fracture morphology during uniaxial tension, and the fracture position is random, and the fracture notch direction (to the left or right) is random. In the C1 (0° crack) group, the fracture positions of the specimens were all near the prefabricated cracks, showing a “one” shape; in the C2 (45° crack) group, the specimen fractures showed a “Z” shape, and the fracture position is also at the prefabricated crack; in the C3 (75° crack) group, the fracture of the specimen presents a relatively inclined “Z” shape, and the fracture position is also at the prefabricated crack as is shown in Fig. 10.

Theoretical analysis

Miner theoretical energy model analysis

The fatigue life of materials, especially the prediction of residual life, is one of the main research contents in the field of engineering design and application. Miner’s linear cumulative damage theory is still widely concerned and generally recognized by the engineering community because of its simple and clear form. According to the assumption of energy limit, the energy model of Miner’s38 linear cumulative damage theory is established. The damage of the material for \(\:{n}_{i}\) cycles under the action of strain\(\:\:{\epsilon\:}_{i}\:\)is,

In formula (2), \(\:{N}_{fi}\:\)is the fatigue life under strain \(\:\:{\epsilon\:}_{i}\).

Then there is the Miner cumulative damage criterion:

Then based on the energy accumulation theory, the damage accumulation rate can be expressed by the energy accumulation rate:

In formula (4), \(\:\varDelta\:{W}_{i}\) is the steady-state hysteretic energy of the material under strain \(\:{\epsilon\:}_{i}\), and \(\:{E}_{c}\) is the ultimate energy of the material.

The relationship between hysteresis energy and steady temperature rise based on the law of energy conservation was derived by V. Crupi39:

In formula (5), \(\:{N}_{si}\) is the number of cycles when the temperature is stable under strain \(\:{\epsilon\:}_{i}\), \(\:\varDelta\:{T}_{si}\) is the stable temperature rise, \(\:\rho\:\) is the material density, and \(\:{c}_{p}\) is the specific heat capacity.

According to the energy limit assumption,

In the formula 6), \(\:\phi\:\) is the energy parameter, and the formula (3) (4) is substituted into the formula (2) to obtain the energy expression of the fatigue damage:

Then there is the Miner damage accumulation criterion expressed in energy:

Under different loading sequences, cyclic strain is applied to the unprefabricated cracked specimen, and its residual life is predicted. Table 3 shows the prediction results and error analysis using the Miner energy model (Formula 8). The results show that the loading sequence has a certain degree of influence on the fatigue life of HTPB propellants, which is mainly due to the sudden increase of the crack density under the loading mode of first low and then high, while from high to low loading, the crack density .There will be no sudden increase, from the perspective of energy accumulation, the energy model of Miner theory is simple and clear, with clear physical meaning, and is suitable for the prediction of the residual life of HTPB propellants.

Analysis of load-displacement hysteretic curve of HTPB propellant

Because the HTPB propellant is a viscoelastic material, when subjected to a periodically changing sinusoidal stress, the material produces a periodic sinusoidal strain, but the strain lags behind the displacement, forming a load-displacement hysteresis curve. The load-displacement hysteresis curve can not only show the actual loading path, that is, the entire strain and stress history experienced by the material, but also reflect the energy absorbed and released by the material during the entire cycle.

Viscoelastic materials dissipate energy during loading and unloading. The area of the hysteresis curve represents the dissipation capacity of the material, and the larger the area, the higher the energy dissipation capacity of the material; the hysteresis curve reflects the deformation delay of the material in the process of stress loading and unloading. That is, during the unloading process, the deformation of the material does not completely return to the initial state, resulting in a deviation between the rising branch on the hysteresis curve and the loading branch; the slope of the hysteresis curve represents the stiffness of the material, that is, the material’s response to the stress during the loading process response speed. The larger the slope, the more rigid the material, and the opposite, the softer the material. The curve shape and slope changes on the hysteretic curve can also reflect the viscous properties of the material, that is, the time dependence of the material on the application of stress.

According to Figs. 11 and 12, as the number of cyclic loading increases, the hysteretic curve of the propellant will move to the right, indicating that the strain during the fatigue process will continue to increase. In addition, as the number of cycles increases, the area of the hysteresis curve also increases, which means that the damage of the material will gradually increase. At the same time, combined with the uniaxial tensile test results of the prefabricated cracked specimens of this propellant, it is also consistent with the law that the fatigue performance of the propellant decreases with the increase of the degree of prefabricated damage.

The hysteresis loop area reflects the energy dissipation of a material or structure under cyclic loading. A larger hysteresis loop area indicates a material or structure with a greater ability to dissipate energy, which generally means better fatigue resistance and durability. The hysteresis loop areas of the three groups of pre-cracked specimens have the same trend. The hysteresis loop areas of the 0° cracked, 45° cracked and 75° cracked specimens reached 99.47, 115.87 and 121.31mm2 respectively, while the hysteresis loops area of the specimens without prefabricated cracks reached 176.71mm2. This is also consistent with the fact that the uncracked specimen has the best fatigue resistance among the four groups of specimens.

Conclusion

-

(1)

An increase in strain amplitude at the same frequency reduces fatigue life. The fatigue life of the three prefabricated crack specimen types is similar and within the same order of magnitude; surface temperature monitoring shows that all four specimen groups experienced a temperature rise; there is a positive correlation between the final surface temperature and the fatigue life.

-

(2)

All four specimen groups exhibited an increase in surface temperature over time. There is a positive correlation between the final surface temperature and fatigue life; specimens without prefabricated cracks had higher fatigue life and showed greater temperature increases compared to those with prefabricated cracks; as the number of cycles increases, specimens with better fatigue resistance experience more pronounced strain and temperature rise.

-

(3)

The study focuses on the mechanical properties and stress-strain behavior of HTPB propellant. During cyclic loading, the material shows distinct changes in fracture morphology and mechanical response. Initial stage: Rapid surface temperature rise due to viscous dissipation highlights critical heat exchange dynamics. Intermediate stage: Surface temperature stabilizes as heat generation balances with heat loss; final stage: Rapid crack initiation and propagation cause a sharp temperature increase, leading to fracture. Under both fatigue and quasi-static conditions, fracture morphology remains consistent. Non-prefabricated crack specimens show random fracture positions and smooth notches. The Miner theoretical model confirms the relationship between hysteretic energy and material fatigue characteristics.

Data availability

All data generated or analysed during this study are included in this published article.

References

Liang, W., Chen, X. & Xu, J. S. Study on fatigue damage and life of HTPB propellant under stress control. New. Chem. Mater. 46 (11), 4 (2018).

Murari, G. H. & Calciolari, F. L. Nunes De Almeida. Dynamic mechanical characterization of composite solid propellant for propellant grain structural integrity assessment. Macromol. Symposia. 383 (1), 1800050 (2019).

Murakami, Y. et al. Essential structure of SN curve: prediction of fatigue life and fatigue limit of defective materials and nature of scatter. Int. J. Fatigue. 146, 106138 (2021).

Xiao, Y. et al. Multiscale modeling for dynamic compressive behavior of polymer bonded explosives. Int. J. Mech. Sci. 242, 108007 (2023).

Xu, J. S. et al. Experimental Investigation on Fatigue Properties of HTPB Propellant (Chinese Journal of Explosives&Propellants, 2021).

Range, A. R. The thermomechanical response of particulate composite energetic materials under mechanical vibration (Purdue University, 2019).

Tong, X. et al. A nonlinear viscoelastic constitutive model for cyclically loaded solid composite propellant. Int. J. Solids Struct. 198, 126–135 (2020).

Tong, X. et al. The mechanical response of a composite propellant under harsh conditions. Int. J. Mech. Mater. Eng. 11, 1742–1746 (2017).

Tong, X. et al. The heat build-up of a polymer matrix composite under cyclic loading: Experimental assessment and numerical simulation. Int. J. Fatigue. 116, 323–333 (2018).

Xu, J. et al. Thermo-damage-viscoelastic constitutive model of HTPB composite propellant. Int. J. Solids Struct. 51 (18), 3209–3217 (2014).

Wang, T. et al. Crack propagation velocity and fracture toughness of hydroxyl-terminated polybutadiene propellants with consideration of a thermo-viscoelastic constitutive model: experimental and numerical study. Theor. Appl. Fract. Mech. 124, 103732 (2023).

Zhang, W. et al. Research on the low-frequency fatigue behavior of NEPE solid composite propellant based on fractional derivative constitutive model. Int. J. Solids Struct., : 112931. (2024).

Wang, X., Zhao, R. & Yang, M. Study on constitutive equation of cumulative damage of HTPB Propellant, IOP conf. Series: Earth Environ. Sci. IOP Publ. 358 (5), 052006 (2019).

Dávila, C. G. From SN to the Paris law with a new mixed-mode cohesive fatigue model for delamination in composites. Theor. Appl. Fract. Mech. 106, 102499 (2020).

Kong, L. Y. et al. Numerical simulation study on fatigue crack propagation of composite pavement. J. Chongqing Jiaotong Univ. (Naturnal Science). 40 (4), 8 (2021).

Tong, X. et al. Energy dissipation of composite propellant under cyclic loading. Acta Aeronautica et Astronaut. Sinica. 39 (11), 9 (2018).

Guo, Y., Onifade, I. & Birgisson, B. A mass specific volume-based viscoelastic damage model to characterize fatigue damage in asphalt mixtures. Constr. Build. Mater. 325, 126729 (2022).

Li, J., Dong, W., Zhao, X. & Li, H. Investigation on fracture properties of concrete considering the viscoelastic characteristics. Constr. Build. Mater. 426, 136044 (2024).

Wang, Y. D., Underwood, B. S. & Kim, Y. R. Development of a fatigue index parameter, Sapp, for asphalt mixes using viscoelastic continuum damage theory. Int. J. Pav Eng. 23 (2), 438–452 (2022).

Wang, R. et al. Friction-induced ignition study of HTPB propellant based on a coupled chemo-mechano-thermodynamic model under ultrahigh acceleration overload conditions. Case Stud. Therm. Eng. 52, 103708 (2023).

Wang, R. et al. Experimental study on self-heating phenomena of CMDB/HTPB propellant under intermediate strain rate compression load. J. Phys. : Conf. Ser. IOP Publ. 2478 (3), 032030 (2023).

Hu, Q. et al. Study on the Viscoelastic Damage Properties of NEPE Solid Propellant with Different Cyclic Stress Ratios47e202100342 (Propellants, Explosives, 2022). 5.

Bhowmik, S., Kumar, S. & Mahakur, V. K. Various factors affecting the fatigue performance of natural fiber-reinforced polymer composites: a systematic review. Iran. Polym. J. 33 (2), 249–271 (2024).

Bakhtiari, H. et al. Fatigue behaviour of load-bearing polymeric bone scaffolds: a review. Acta Biomater., (2023).

Mrzljak, S. et al. Effect of carbon nanofibre orientation on fatigue properties of carbon fibre-reinforced polymers. J. Compos. Mater. 57 (6), 1149–1164 (2023).

Qiu, X. et al. Development of fatigue life model for Rubber materials based on fracture mechanics. Polymers 15 (12), 2746 (2023).

Mukherjee, S. et al. Modeling and Simulation of Dynamic Response of a Composite Solid Propellant.

Zhang, J. et al. An experimental and modeling investigation on the effects of temperature and strain rate on the tensile-deformation behavior of TB991 weld sealant. Mech. Time-Dependent Mater. 27 (1), 119–138 (2023).

Xue, X. & Yu, Y. Numerical study on wake flow field characteristic of the base-bleed unit under fast depressurization process. J. Energetic Mater. 35 (2), 213–232 (2017).

Montesano, J., Fawaz, Z. & Bougherara, H. Use of infrared thermography to investigate the fatigue behavior of a carbon fiber reinforced polymer composite. Compos. Struct. 97, 76–83 (2013).

López, R., Salazar, A. & Rodríguez, J. Fatigue crack propagation behaviour of carboxyl-terminated polybutadiene solid rocket propellants. Int. J. Fract. 223 (1), 3–15 (2020).

López, R. et al. Structural integrity of aged hydroxyl-terminated polybutadiene solid rocket propellant. J. Propuls. Power. 34 (1), 75–84 (2018).

Yao, L., Chang-sheng, Z. & Xiu-min, Y. Effect of pre-fatigue on mechanical properties of modified double-base propellant. J. Phys. : Conf. Ser. IOP Publishing. 2478 (3), 032049 (2023).

Guo, Q. et al. Dynamic effect in the fatigue fracture of viscoelastic solids. Extreme Mech. Lett. 54, 101726 (2022).

Khodor, J. et al. Fatigue fracture characterization by cyclic material forces in viscoelastic solids at small strain. Int. J. Fract., : 1–21. (2022).

Cheng, H. et al. Analysis of fatigue behaviors of asphalt mixture under actual loading waveforms using pseudo-strain-based approaches. Int. J. Pav Eng., : 1–14. (2022).

Test method for. fatigue properties of polymer matrix composite materials.GB/T 35465.1–2017.

Amiri, M. & Khonsari, M. M. Life prediction of metals undergoing fatigue load based on temperature evolution. Mater. Sci. Eng. : A. 527 (6), 1555–1559 (2010).

Crupi, V. An unifying approach to assess the structural strength. Int. J. Fatigue. 30 (7), 1150–1159 (2008).

Acknowledgements

This study was funded by the Science and Technology Research Program of Chongqing Municipal Education Commission (KJQN202201311),(KJZD-K202301307).The postdoctoral fund of Chongqing Natural Science Foundation (CSTC2021JCYJ-BSHX0210).Chongqing Natural Science Foundation (CTSC2021 JCYJ-MSXM-0639).The Science and Technology Research Program of Chongqing Municipal Education Commission (KJQN202101344).Research on strategies to improve road traffic resilience in Chongqing Smart City(21SKGH215).Research on key technologies for the construction of rural industrialized farmhouses in Yongchuan District based on prefabricated straw concrete structure technology(2021YC-JCKX20010). Industrial Technology Innovation Project of Inner Mongolia Academy of Science and Technology (2024RCYJ02003).

Author information

Authors and Affiliations

Contributions

G. L., Writing the entire text. B. G., modify. H. H., Obtaining macroscopic experimental data. R. C., Obtaining macroscopic experimental data. J. F. Assist in data analysis. J. H., Assist in data analysis.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Li, G., Gao, B., Hu, H. et al. Fatigue failure of prefabricated crack HTPB(hydroxyl-terminated polybutadiene) propellant under strain control. Sci Rep 15, 5542 (2025). https://doi.org/10.1038/s41598-024-80482-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-80482-3