Abstract

Coal, a vital strategic resource, facilitates industrial development and socio-economic progress. Ensuring the high-quality development of the coal industry is crucial for national energy security and safety. Coal and gas outbursts are frequent hazards in coal mining processes. This research delves into the impact of heterogeneous coal seam strength on hydraulic fracturing propagation, utilizing both physical experimentation and the ABAQUS finite element approach. Experimental findings reveal distinct variations in water injection pressure profiles and fracturing fluid distribution patterns within coal seams of varying strengths, in contrast to those exhibiting uniform strength. When fractures propagate from a weaker to stronger coal seam region, a notable increase in pressure build-up effect is observed, leading to higher water injection pressure, wider fracture widths, augmented coal body displacement, and an elevated rate of rigidity reduction. In this study, the physical test results and numerical simulation results are verified with each other. After fractures propagate across the interface, zone with higher coal seam strength experience decreased fracture width, lower coal body displacement, and slower rates of rigidity decline compared to weaker seam zone. When fractures propagate from high to low coal seam areas, the fracture experiences instantaneous cross-boundary extension, resulting in a decrease in pore pressure, increased coal body displacement, and an elevated rate of rigidity decline.

Similar content being viewed by others

Introduction

As surface resources dwindle, attention pivots towards deeper reserves, prompting a shift in mining practices from shallow to deep exploitation, with mining depths escalating annually1,2,3. Deep mining faces numerous challenges, including rock bursts, stress relief, increased permeability in coal seams, coal and gas outbursts, and gas drainage problems, all of which increase the intricacy of mining activities4,5,6. To mitigate coal and gas outbursts and enhance coalbed methane recovery, hydraulic fracturing is utilized to augment coal reservoir permeability, fostering safer mining practices and elevating production efficiency7,8,9,10. However, hydraulic fracturing’s ability to create a complex fracture network significantly impacts coalbed methane extraction efficiency, with the formation of high-diversion fractures in coal seams being pivotal to its success11. Hydraulic fracturing enhancements enhance coal seam permeability, boost coalbed methane extraction, and reduce dust through coal body wetting. Furthermore, it weakens coal seams, modifying their mechanical attributes12. In China, variations in coal seam depth, metamorphic grade, and geological conditions can result in parameter disparities within seams. These strength differences influence hydraulic fracture propagation and fracturing outcomes13. Hence, it is imperative for the coal industry to explore the impact of varying coal seam strength on the patterns of hydraulic fracture propagation.

Research confirms that hydraulic fracturing boosts fracture density, connectivity, gas desorption, and migration in coal seams, improving permeability, extraction efficiency, and preventing outburst accidents, ensuring safe deep coal mining14,15. Therefore, many researchers have extensively studied the initiation and propagation patterns of hydraulic fractures, as demonstrated by Li et al.16 Researchers utilized a triaxial loading system to investigate the impact of pulse frequency on the propagation and extension of hydraulic fractures. The study revealed that lower frequencies resulted in more complex fracture patterns, whereas higher frequencies promoted easier formation of fractures. Liu et al.17 Studying the impact of natural fractures on propagation using artificial samples with varying angles showed that high inclination angles facilitate crack propagation, while lower angles hinder it. Tan et al.18 Researchers utilized a genuine triaxial testing system to investigate the initiation and propagation of hydraulic fractures in both vertical and directional wells.They discovered that propagation mode is governed by both azimuth angle and in-situ stresses. Zhao et al.19 Laboratory experiments investigated fracture morphology, scale, and penetration ability in multi-layer joint fracturing of thin coal seams. Fan et al.20 Hydraulic fracturing experiments in coal mines under true triaxial conditions revealed that splint governs crack initiation and propagation paths, while in-situ stress dictates the fracture direction. Chen et al.21 A downhole pulse and constant velocity fracturing method was suggested to tackle the issue of hard coal rock mass weakening. This method involved the development of specialized equipment, which was subsequently utilized in practical settings. The outcomes of this approach demonstrated an 18% enhancement in the recovery efficiency of the top coal layer. While physical experiments explored hydraulic fracture propagation, numerical simulation remains essential for elucidating fracture laws.

Numerical simulations play a crucial role in the study of hydraulic fracturing propagation, making use of methods like the extended finite element method, discrete element method, and boundary methods22,23,24,25,26. At the same time, it can be divided into two-dimensional and three-dimensional models, which complement and verify physical experimental research27,28,29. Therefore, many scholars have adopted simulation methods for their research. For example, Wang et al.30 Utilizing 2D PFC software, hydraulic fracturing in coal seams was simulated, exploring the interplay between mechanical and injection parameters across scales, and fracture propagation trends. Li et al.31 DDM was employed to simulate hydraulic fracture-natural fracture interactions, revealing that reservoir heterogeneity influences crack propagation. Qin et al.32 Established was a three-dimensional hydraulic fracturing model to investigate the interaction between hydraulic fracturing fractures and natural fractures in three-dimensional space, highlighting the disparities between two-dimensional and three-dimensional models. Luan et al.33 Explored the natural fractures and cavities in fracture-cavity reservoirs by employing hydraulic fracturing propagation simulation based on continuous damage theory. Pump rates were adjusted to effectively link natural fractures and cavities. Xie et al.34 Systematically investigated the impacts of inherent fractures on injection pressure, fracture geometry, and fluid capacity35. Similar materials are proposed to simulate various inhomogeneities in coal seams as a way to study the effect of inhomogeneities on hydraulic fracture extension36. Uneven stress in the coal reservoir is not favourable for the formation of multiple fractures and fracture extension, and fractures at the boundaries increase as the horizontal stress coefficient increases. Despite advancement in understanding hydraulic fracture propagation, current studies primarily focus on homogeneous reservoirs, with limited exploration of hydraulic fractures in heterogeneous reservoirs, limiting our understanding of the penetration propagation law in such environments. Hence, it is essential to investigate the cross-border propagation behavior of hydraulic fractures in heterogeneous reservoirs to enhance the permeability of low-permeability coal seams.

This study employs physical experiments and numerical simulations to examine how heterogeneous coal seam strengths affect hydraulic fracture cross-boundary propagation. By analyzing tracer paths, fracture widths, numbers, coal displacements, stiffness decline, and pore pressure changes, we assess the impact of seam strength disparities. Findings are crucial for enhancing deep coal mining safety.

Experimental materials and methods

Experimental protocol

To explore the impact of heterogeneous coal seam strength on the propagation of hydraulic fractures, this study utilizes specimens made from identical materials, with dimensions of 600 × 600 × × 300 mm (length, width, and height, respectively). The coal seam has a thickness of 100 mm, with roof and floor thickness also measuring 100 mm each. The ratio of similar materials in the coal seam is coal:cement:gypsum = 3:3:1 (strength 1), coal:cement:gypsum = 5:3:1 (strength 2), coal:cement:gypsum = 5:2.5:1.5 (strength 3), and the ratio of similar materials to the roof and the bottom plate is sand:gypsum:cement = 4:2:5. The ash-water ratio for the similar material mimicking the coal seam is 2:1, while for the rock strata, it is 3:1. Under simulated triaxial loading conditions with stress components of \({\sigma }_{1}\) = 3.3 MPa, \({\sigma }_{2}\) = 3 MPa, and \({\sigma }_{3}\)= 2.1 MPa, the coal seam is subjected to hydraulic fracturing with an injection displacement of 80 mL/min. The experimental scheme parameters are detailed in Table 1.

To investigate the correlation among pore pressure, displacement, stiffness reduction rate, and fracture propagation in coal seams with heterogeneous strength during hydraulic fracturing, and to validate the results of physical experiments, this study employs the ABAQUS numerical simulation software. The key parameters employed in this research are summarized in Table 2. Fracture report on the gas-bearing stratigraphic test of Jinsha HF1 well, a test for the exploration and evaluation of the ‘three gases’ resources in Permian coal beds in northern Qianbei, China.

Experimental materials and equipment

In this study, sand and coal powder (below 60 mesh) are chosen as aggregate materials, and clear water, gypsum, and cement are used as cementing materials, as shown in Fig. 1. Secondly, according to the principle of similar material proportioning, the parameters such as specimen size (length × width × height) and the proportion of aggregate, cementing material, and clear water, and the quality of aggregate, cementing material, and clear water are determined.

Experimental materials

Using a proprietary multifunctional true triaxial hydraulic fracturing test system, this experiment explored hydraulic fracture propagation and cross-boundary extension in heterogeneous coal seams. This apparatus comprises a main frame, computer, acoustic emission system, fracturing pump, data acquisition system, triaxial loading mechanism, specimen mold, tracer (green ink), and other components, as illustrated in Fig. 2.

Experimental equipment

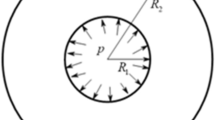

To study the effect of the horizontal heteroogeneity of a single coal seam on the horizontal extension of hydraulic fracturing cracks, the experiment adopts the distribution of coal seams, as shown in Fig. 3 to cast specimens. Originally, the coal seam was divided into three sections (Zone 1, 2, and 3), where the inherent horizontal strength of the coal seam was mimicked by adjusting the characteristics within these sections. In order to replicate the authentic stress conditions of the coal seam, a proprietary true triaxial hydraulic fracturing device was employed to exert stress loading in three directions. consequently, high-pressure water was injected to collect the data on water pressure changes in the fracturing holes. After completing the fracturing process, the specimens were incised to examine the propagation of cracks, and the expansion pattern of hydraulic cracks between interfaces of various coal seams was analyzed. The experimental procedure is detailed in Fig. 4.

-

(1)

Deeply penetrate into the coal mine site, collect geological data and take coal samples and rock samples;

-

(2)

Process coal samples and rock samples to create standardized specimens for testing the fundamental mechanical properties of both coal and rock.

-

(3)

According to the mechanical parameters of coal samples and rock samples and the principle of similar material proportioning, determine the proportion of each material;

-

(4)

Preparing experimental materials. Such as cement, sand, gypsum and coal powder, etc., grinding and screening coal powder;

-

(5)

Design the experimental scheme, weighing, mixing and stirring the similar materials, adding them into the mould in turn, tamping and levelling and pre-burying the fracturing pipe. Insert 3 mm diameter wire into the fracturing pipe to simulate the bare eye section in the real fracturing process;

-

(6)

Demould the specimen, pull out the wire in the fracturing tube, and then maintain it for 28 d according to the standard;

-

(7)

Move the specimen to the self-developed true triaxial fracturing test device, slowly load the three-way stress, and connect the fracturing pipe and data acquisition system;

-

(8)

Turn on the data acquisition equipment and fracturing pump in turn until the end of fracturing, and turn off the fracturing pump and collector. The specimen is slowly unpressurised and moved out;

-

(9)

Dissect the specimen, observe the crack expansion in the specimen, collate and analyse the experimental data and summarize the law of boundary-penetration expansion;

Results and discussion

Experimental results and analyses of hydraulic fracturing of coal seams with non-homogeneity in strength

Analysis of water injection extension in strongly inhomogeneous coal seams

The experiment used pure water and tracer (green ink) as the fracturing fluid, with an injection rate of 80 mL/min. When the specimens with different coal seam strength combinations were fractured under three-way loading stress conditions, the variation curves of water injection pressure versus time are shown in Fig. 5. The fracturing process can be categorized into three main stages: the initial stage involving water injection and pressure maintenance, the following stage of propagation and expansion, and finally, the stage marking the end of the fracturing process.

As illustrated in Fig. 5a, initially, when water was introduced into the fracture crevice, no pressure was registered due to the unfilled crevice, resulting in a pressure reading of zero within the crevice. Subsequently, as the crevice gradually fills up, a pressure buildup phenomenon ensues, causing a significant surge in pressure. Once the pressure reaches 3.97 MPa, equivalent to the failure strength of the coal seam, the hole wall ruptures, allowing high-pressure water to propagate and develop along weak joints and fractures within the fracturing hole wall. This cause the crack to expand forward, increasing water storage capacity and rapidly decreasing water pressure. Then, with the increasing injection volume, water rapidly fills the fracture, causing another rise in water pressure and further expansion in the fracture. Upon reaching Zone 2, where the coal seam strength increased, cracks temporarily extended, and the water pressure rose rapidly. At 3.69 MPa, pressure reaches the destructive strength of the coal seam, extending across the boundary to the coal seam in Zone 2, causing a drop in water pressure. The water re-filled the cracks, the water pressure rose again, and the cracks further expanded forward. As the fracture reaches Zone 3, water pressure exceeds the strength of the coal seam in this Zone, enabling the fracture to propagate across the boundary into Zone 3. This results in a sharp drop in pressure. With continuous water injection, the fracture continued to propagate until the specimen fails, causing a rapid decrease in pressure. Subsequently, the hydraulic fracturing pump was shut down.

As shown in Fig. 5b, after the water injection pump was turned on, the pressure rose rapidly and reached the destructive pressure of the coal seam, initiating crack development and expansion from the fracture hole wall, and the pressure was decreased. As water continues to be injected, the pressure rises again, causing cracks to expand, and the water injection pressure–time curve shows a “sawtooth” pattern. As cracks propagate and widen, their water-holding capacity escalates, enabling high-pressure water to promptly infiltrate, thereby decreasing crack pressure. As water injection proceeds, pressure mounts until it surpasses the coal seam’s rupture threshold, prompting repeated crack advancements until the specimen ultimately fails.

As shown in Fig. 5c, upon activating the water injection pump, the water pressure within the fracturing hole escalates in tandem with the increasing water injection rate. At a pressure threshold of 3.85 MPa, minute cracks gradually form, leading to a slight reduction in fracturing activity. Subsequently, continuous water injection results in a progressive pressure surge, causing the cracks to expand continuously until reaching a peak pressure of 4.77 MPa. When the cracks penetrate into the Area 2 coal seam, a sudden drop in pressure is observed. This phenomenon arises from the comparatively lower strength of the Region 2 coal seam relative to the Region 1 coal seam, resulting in the water pressure surpassing the destructive threshold of the Region 2 coal seam. Consequently, the crack propagation becomes more extensive, leading to a larger water storage capacity within the cracks and a substantial decrease in water pressure. Upon the extension of the crack boundary from the Area 2 coal seam to the Area 3 coal seam, a pressure surge is experienced, culminating in the crack traversing the boundary and entering the Area 3 coal seam when the pressure reaches 3.68 MPa. This transition is primarily attributed to the superior strength of the Region 3 coal seam compared to the Region 2 coal seam, necessitating a higher pressure for coal seam rupture. The enhanced high-pressure water retention effect within the fracture further promotes crack propagation within the Region 3 coal seam upon reaching the destructive pressure threshold. The disparity in strength between adjacent coal body zone amplifies the pressure retention effect within the fractures during boundary expansion. Therefore, a notable correlation exists between variations in water injection pressure and the consequential fluctuation amplitude in the fracturing curve, accentuating the impact of coal body strength differentials on fracture propagation.

Analysis of fracture extension in coal seams with non-homogeneous strengths

After the end of fracturing, the specimen was slowly depressurized and left to stand for 12 h. After the tracer (green ink) was dried and adsorbed in the cracks, the specimen was split along the cracks, and the distribution of the tracer and the cracks after the fracturing of the specimen is shown in Fig. 6. The tracer creates a visible mark as it follows the path of the high-pressure water expanding within the hydraulic fractures in the coal seam. This enables us to determine the extent of fracture propagation by analyzing the tracer’s movement.Therefore, the presence of tracers indicates the areas that have been fractured. The 3D reconstruction of the tracer distribution pattern and geometrical characteristics after fracturing is shown in Fig. 7, with green representing the horizontal trace of the fracturing fluid traversing the boundaries within the specimen.

As shown in Fig. 6, fractures initiate from the weak joint locations on the wall of the fracturing hole due to the high-pressure water. As the injection pressure increases, these fractures develop into cracks and propagate along the weak joint locations. Due to the restriction of the roof and floor strata on the vertical extension of fractures, fractures primarily propagate within the coal seam, with limited extension into the roof and floor. When splitting the specimen, cracks were observed to expand through the boundary in the direction of the maximum principal stress. As the crack extension path is influenced by the combination of the three-way loading stress and the internal pores of the specimen, a smaller angle of deflection is produced. At the same time, there are a certain number of secondary cracks near the prominent cracks, which are located on both sides of the prominent cracks, similar to the distribution of a “fishbone” distribution. The abundance of secondary fractures adjacent to the prominent cracks is more pronounced in zone with robust coal seams. In contrast, locales with weaker coal seam integrity exhibit fewer secondary fissures in proximity to the primary ones. This phenomenon arises from the disruption of the coal seam’s initial mechanical equilibrium under the combined influence of triaxial loading stress and liquid injection pressure, leading to the generation of internal tension within the pores. Owing to its elevated tensile strength and higher storage pressure within the fracture, the enhanced capacity release of the more robust coal seam results in a heightened formation of secondary fractures in the vicinity of the primary crack. Conversely, coal seams with lower seam strength have fewer secondary cracks.

The crack width inversely correlates with coal seam strength: stronger seams yield narrower cracks, weaker seams wider ones. This stems from fracture propagation dynamics; as the crack tip reaches zone of higher Seam strength, the water pressure fails to reach failure thresholds, causing pressure buildup in pre-existing fractures, widening them. Conversely, when the tip encounters weaker coal, water pressure surpasses failure thresholds, accelerating propagation, releasing pressure, and limiting further crack expansion. Hence, coal seam strength directly impacts crack width.

As illustrated in Fig. 8, influenced by the strength of the coal seam, the horizontal propagation patterns of tracers vary among different coal body strength combinations. However, the propagation patterns exhibit a distribution that is symmetrical along the axis of the fracturing pipe, with the direction of maximum in-situ stress serving as the axis of symmetry. As shown in Fig. 7a, the tracer (green ink) exhibits a horizontal cross-sectional trace width in Specimen 1 that is the widest in Region 3, relatively wide in Region 1, and narrowest in Region 2, resulting in a tracer distribution pattern resembling a “dumbbell” shape. As shown in Fig. 7b, the horizontal profile trace width of the tracer in Specimen 2 is the largest width of Region 1, the width of Region 2 is larger, the width of Region 3 is the smallest, and the distribution of tracer is like an “elliptical” shape. As shown in Fig. 7c, the horizontal profile trace width of the tracer in Specimen 3 is the largest in Region 2, the width of Region 3 is larger, the width of Region 1 is the smallest, and the tracer distribution pattern is like a “gourd” . Hence, the dispersion of tracers along the horizontal axis of the coal seam is associated with the coal seam’s strength, consequently influencing the extent of hydraulic fracturing.

The reason for the difference in the distribution of tracers is mainly caused by the difference in coal seam strength when the area with lower coal seam strength expands through the boundary to the area with greater coal seam strength. When the water pressure within the fracture fails to surpass the critical intensity of the coal seam, it results in an augmented pressure containment effect in the cavity. Consequently, the crack widens, and its expansion encompasses a larger area within zone characterized by lower coal seam strength. Upon reaching the failure threshold of the coal seam, the fracture propagates and extends towards Zones with higher coal seam strength. As the region of elevated coal seam strength breaches into the lower strength boundary area, the water pressure within the fracture exceeds the coal failure intensity present in the weaker coal seam section. When the area with greater coal seam strength extends through the boundary to the area with less coal seam strength, the water pressure in the fracture is greater than the coal failure intensity in the area with lower coal seam strength.

Numerical simulation results and analysis

Numerical simulation plays a critical role in hydraulic fracturing research. In this study, two-dimensional finite element analysis using ABAQUS was employed as the primary method. The built-in cohesive unit of ABAQUS was specifically chosen to simulate the initiation and progression of hydraulic fractures, as well as the evolution of reservoir displacement, decrease in stiffness, and pore pressure changes in coal reservoirs characterized by varying strengths. Throughout the hydraulic fracturing process in coal reservoirs, the energy derived from the injection fluid pressure serves as the pivotal driving force behind fracture propagation, facilitating its growth and continuous expansion. Subsequently, the combined fracturing curves corresponding to different Seam strengths were analyzed. The pore pressure curve can reflect the expansion and extension of hydraulic fracturing fractures in coal reservoirs, and the changes of fracturing curves in three different Seam strength combinations are shown in Fig. 8 (1) In the initial stage of fracturing, the pore pressure is 0 MPa. This is attributed to the fact that during the early stage of focused fluid flow, the simulated fracturing fluid has not yet fully filled the fracture aperture, thus failing to establish a pressure build-up effect. (2) Fracturing and pressurization stage. With the increase of injection time, the fracturing fluid fills the fracturing holes, forming a pressure-holding effect, and the pore fracturing increases sharply. (3) The development and extension stage of water fracturing. When the pore pressure reaches the failure strength of the coal seam, cracks are generated at the weak joints of the fracturing hole wall. As the injection process continues, the fissure develops into a fissure and propagates along the weak joint. As the fractures propagate, the storage capacity of the coal seam fractures increases, leading to a rapid influx of fracturing fluid into the fracture pores and subsequently decreasing pore pressure. As more fluid is injected, the pore pressure rises once again. When the pore pressure surpasses the coal failure strength, the coal fractures continue to extend, causing a subsequent drop in pore pressure. This cyclic process persists until fracture failure occurs.

Upon completion of the fracturing process, as the fracturing fluid flows out of the fractures, the pressure containment effect diminishes. Consequently, pore pressure rapidly decreases to zero, signifying the conclusion of the fracturing experiment. As can be seen from Fig. 8, when the region of low Seam strength expands towards the region of high Seam strength, the pore pressure increases. When the pressure rises to the failure intensity of the high-strength coal, the high-strength coal will be damaged, and the cracks will continue to develop and expand. When the area of high Seam strength expands to the area of low Seam strength, when the crack expands to the critical interface, the pore pressure exceeds the failure intensity of the coal seam in the area of low Seam strength. As a result, the fractures will continue to propagate and the pore pressure will drop to fluctuations around the failure intensity of the coal seam in the area of low Seam strength. The larger the variation in Seam strength, the more significant the alteration in pore pressure, leading to a wider fluctuation range in the fracturing curve.

Characteristics of pore pressure of hydraulic fracturing combined with different Seam strengths

The pore pressure (POR) of the hydraulic fracturing process with varying strengths of coal was studied by using ABAQUS simulation software. By studying the pore pressure of heterogeneous coal seams at different stages, the characteristics of hydraulic fracturing fracture crossing propagation with different Seam strength combinations can be observed. Different colors at different locations indicate the pore pressure values for that area. The deformation scaling factor is 200 × in the drawing options, and “Free Edge” is selected in the Visible Edge option, as shown in Fig. 9.

When the fracturing range is within Zone 1, the pore pressure is low. When the fracture propagates in the range of Region 1, the pore pressure does not change much and shows a contour “I” shape. When the fracturing range is extended to Zone 2, the pore pressure increases, the pore pressure value and the influence range of fracturing in Zone 2 expand, and the pore pressure contour is wide-narrow-wide, such as a “dumbbell” type. When the fracturing range is within Region 3, the pore pressure variation range increases, and the pore pressure contour is wider-wider-narrower-wider-wider, similar to the “barbell” type. The reason for this phenomenon is that Area 1 is a coal seam of the same nature, and the failure intensity is the same, so the pore pressure is the same. Because the strength of the coal seam in Area 2 is greater than that in Area 1, the fracture penetrates and extends to the coal seam in Area 2, and the pressure does not reach the failure intensity of the coal seam in Area 2, resulting in pressure holding. Therefore, the pore pressure and the influence range of fracturing increased. With the continuous water injection, when the fracture penetrates and extends to the coal seam in Area 3, the water pressure intensity is greater than the coal seam strength, the pore pressure decreases, and the influence range increases.

As illustrated in Fig. 9a, the Seam strength follows the sequence Zone 3 < Zone 1 < Zone 2. As the fracture propagates from Zone 1 (with high Seam strength) to Zone 2 (also characterized by high Seam strength), there is a corresponding elevation in pore pressure aligned with the enhanced Seam strength. Moreover, the range of variation in coal seam pore pressure widens in tandem with the escalation of Seam strength. When the fracture expands from the coal seam in Region 2 (high strength) to the coal seam in Region 3 (low strength), the influence range of pore pressure in Zone 3 is larger than that in Zone 2, and the pore pressure does not change much. As seen in Fig. 9b, the coal seam strength Zone 1 = Zone 2 = Zone 3; As the fracture propagates within the coal seam, both pore pressure and the affected area gradually increase, leading to the development of a tip effect at the advancing front. As illustrated in Fig. 9c, when the fracture extends from Area 1 (characterized by high strength) to Zone 2 (characterized by low strength) within the coal seam, there is a progressive rise in pore pressure, resulting in a several-fold expansion of the area influenced by pore fracturing. The pore pressure contour showed a distribution pattern of small in the middle and large at both ends. When the fracture extends from the coal body in Zone 2 (low strength) to the coal body in Zone 2 (high strength), the influence range of pore fracturing decreases, and the pore pressure increases.

Displacement characteristics of coal seams fractured by combination of different Seam strengths

The displacement of coal mass during hydraulic fracturing reflects the fracture width and permeability enhancement effect of hydraulic fracturing in coal seams. By investigating the displacement variations during hydraulic fracturing across different coal mass strength combinations, this study aims to explore the influence of coal mass strength on fracture propagation. Figure 10 presents the displacement variation nephograms during hydraulic fracturing for three distinct coal mass strength combinations. The hydraulic fracturing displacement nephograms exhibit a “butterfly-shaped” pattern.

As shown in Fig. 10a, when t = 35.8 s, the fracture propagates across the boundary from Zone 1 to Zone 2. Due to the increase in coal seam strength, the energy accumulates at the fracture tip, requiring a higher pore pressure for the fracture to propagate further. Consequently, as the fracture expands into Zone 2, the displacement of the surrounding coal mass decreases. When t = 140 s, the fracture propagates across the boundary from Zone 2 to Zone 3. The decrease in coal seam strength in this transition allows the energy during boundary crossing to exceed the necessary energy required for the failure of the coal mass in Zone 3. Therefore, the displacement of the nearby coal mass increases. As shown in Fig. 10b, the coal seam’s strength remains constant, and the energy needed for coal mass failure also stays consistent. During the fracture propagation process, the coal mass displacement gradually rises. This phenomenon is attributed to the prolonged duration of the hydraulic fracturing process and the increased fracturing time. As illustrated in Fig. 10c, prior to t = 20.5 s, as the fracture propagates within Zone 1, the displacement of the coal mass slightly increases with the duration of fluid injection. At t = 20.5 s, when the fracture crosses the boundary from Zone 1 to Zone 2, the displacement of the coal mass near the fracture significantly increases. The reason is that the coal seam strength in Zone 1 is greater than that in Zone 2, and the water pressure within the fracture in Zone 1 exceeds the failure pressure of the coal seam in Zone 2. As a result, when fractures propagate, hydraulic pressure causes the coal mass to be torn apart, leading to increased displacement of the fractures. When t = 253 s, the fracture traverses from Zone 2 to Zone 3, resulting in a decrease in the displacement of the coal seam within Zone 3. This phenomenon arises due to the higher strength of the coal seam in Zone 3 compared to that in Zone 2, coupled with the lower water pressure within the fracture in Zone 2, which is insufficient to exceed the failure strength of the coal seam in Zone 3. Consequently, the coal seam in Zone 3 exhibits stronger resistance to failure during fracture propagation, leading to reduced displacement.

Characteristics of hydraulic fracturing stiffness decline rate of different coal seam strength combinations

The rate of decline in coal seam stiffness (SDEG) is determined and assessed through the utilization of the damage factor D. This factor signifies the reduction in stiffness resulting from damage induced by hydraulic fracturing, thereby representing the impact of hydraulic fracturing within the coal seam. The stiffness decline rate of different Seam strength combinations at various stages of fracture propagation was studied, and the fracture propagation law and fracturing effect of hydraulic fracturing were characterized, as shown in Fig. 11. Figure 11a depicts the Stiffness Degradation Evolutionary Grade (SDEG) of hydraulic fracturing on a combined coal body consisting of Zone 1 coal seam (with relatively high strength), Zone 2 coal seam (with the highest strength), and Zone 3 coal seam (with the lowest strength). When the fracture expands in the range of Zone 1, the decline rate of coal seam stiffness gradually increases with the fracture propagation. As the fracture traverses from Zone 1 to Zone 2 coal seams, the latter’s higher strength elevates failure pressure, causing pressure accumulation in Zone 1. This enhances the rate of stiffness decline in Zone 1, thereby improving the effectiveness of fracturing. As the pressure surpasses the failure threshold of Zone 2, the crack expands into this Zone, perpetuating its propagation and increasing the rate of stiffness decline. Upon reaching the interface with Zone 3, where the strength of coal surpasses that of Zone 2, the water pressure in Zone 2 exceeds the failure strength of Zone 3, intensifying the fracturing effects, aiding in propagation, and further amplifying the stiffness decline.

Figure 11b shows the combined hydraulic fracturing stiffness decline rate (SDEG) of coal with the same seam strength in Zone 1, Zone 2, and Zone 3. With the propagation of fractures, the rate of decline in coal seam stiffness (SDEG) increases. The reason for this lies in the gradual accumulation of energy within the coal seam fractures, which continually disrupts the coal seam in their vicinity. Consequently, the Stiffness Degradation Evolutionary Grade (SDEG) of the coal seam increases.

Figure 11c presents the Stiffness Degradation Evolutionary Grade (SDEG) of hydraulic fracturing for the coal body combination of Zone 1 coal seam (with the highest strength), Zone 2 coal seam (with the lowest strength), and Zone 3 coal seam (with relatively high strength). When the fracture expands in the range of Zone 1, the decline rate of coal seam stiffness gradually increases with the fracture propagation. As the fracture progresses from the most robust coal seam in Zone 1 to the least stable in Zone 2, water pressure exceeds the critical point for failure in Zone 2, leading to an acceleration in its stiffness decline rate (SDEG). In contrast, as the fracture advances from the weakest seam in Zone 2 to the stronger seam in Zone 3, there is a buildup of fracture pressure, further amplifying Zone 2’s SDEG. Once the fracture penetrates the threshold in Zone 3, the resilient properties of Zone 3 curb additional increases in SDEG. These changes in displacement and stiffness validate the underlying dynamics of fracture propagation.

Analysis of the cross-boundary propagation mechanism of strength heterogeneous coal seam

During the process of hydraulic fracturing in coal and rock formations, the application of high-pressure water initiates the formation of fractures that spread along Zones of weakness, ultimately improving permeability through the creation of a network of fractures. Both tensile and shear failure criteria apply, with initiation pressure and fracture angles governed by the principal stress distribution.

Assuming an isotropic, homogeneous elastomer for the fractured coal-rock mass with low permeability, the radial and tangential stresses at the hole wall under compressive stress can be formulated as37:

where \({\sigma }_{H}\), \({\sigma }_{h}\) are the maximum horizontal in-situ stress, the minimum horizontal in-situ stress, MPa; \({\sigma }_{r}\), \({\sigma }_{\theta }\) are radial stress and tangential stress at the hole wall, MPa; θ is the maximum horizontal, the angle of rotation should be in the counter-clockwise direction, /°; P is the pressure of the fracturing hole, MPa.

As the pressure of the fracture hole increases, \({\sigma }_{\theta }\) will become zero or negative, which is the tensile stress. Therefore, the failure mode that may occur at the hole wall could be tensile failure. Based on the maximum tensile stress theory, the rupture pressure of the hole wall is determined38:

where \({p}_{b}\) is the tensile failure pressure of the coal pore wall, MPa; \({\sigma }_{\tau }\) is the uniaxial compressive strength of coal and rock, MPa.

Hydraulic fracturing failure in coal and rock is typically regarded as solely influenced by horizontal in-situ stress, overlooking vertical and radial stress effects. Consequently, the Mohr–Coulomb criterion is applied to ascertain failure modes, formulated as39:

where τ and \({\sigma }_{n}\) are represent shear and normal stresses on the fracture surface, MPa. φ is the internal friction angle of coal and rock, /°; c is the cohesion of coal and rock, MPa; α is the angle between the normal shear stress of the fracture surface and the \({\sigma }_{1}\) direction of the maximum principal stress.

With the geological sedimentation, the permeability and porosity of the coal reservoir change, and many micropores will be generated inside the reservoir. Therefore, coal and rock reservoirs belong to porous media. According to Darcy’s theorem, the fluid flow in a porous medium can be described by the following formula40:

where u represents the local fluid velocity of the pores; \(<{u}_{i}>\) is represents the average flow velocity of the local fluid in the pores; \({k}_{ij}\) denotes the permeability tensor; η is fluid viscosity. The local fluid velocity of the pores is proportional to the pressure gradient on the porous medium by permeability tensor, fluid viscosity, η.

According to elastic mechanics, crack propagation needs to satisfy the following expression41:

where \({\sigma }_{n}\) is the normal stress of the natural fracture, the unit is MPa, \({T}_{0}\) is the unit of tensile strength of coal and rock, the unit is MPa, \(\Delta {p}_{nf}\) is the fluid pressure drop between the intersection point and the fracture end, the unit is MPa, \({p}_{i}\) is the fluid pressure at the intersection of the fracture, the unit is MPa.

Assuming that the liquid injected into the coal reservoir in the Cohesive unit flows continuously as an incompressible Newtonian fluid, the equation governing the tangential flow of the fracturing fluid in the fracture is42:

where τ is the shear stress, \(\frac{{d}_{u}}{{d}_{y}}\) is the shear deformation rate, μ is the viscosity of the fracturing fluid.

where \({q}_{t}\) is the fracturing fluid flow per unit area, w is the fracture width, \(\nabla {p}_{w}\) is the pressure gradient in the fracture direction, \(\frac{{w}^{3}}{12\mu }\) is the permeability or flow resistance.

Fracture propagation hinges on injection pressure, coal seam properties, and in-situ stress. Figure 12 illustrates the impact of coal seam strength on fracture propagation across boundaries during hydraulic fracturing in heterogeneous seams. When fractures propagate from a weaker coal seam to a stronger one, a pressure build-up effect occurs. When the hydraulic pressure reaches the failure strength of the coal seam, fractures extend across the boundary, as shown in Fig. 12b, depicting the pattern of fracture propagation. The crack width becomes smaller, the expansion rate becomes slower, the coal seam displacement decreases, and the stiffness decline rate decreases. Similarly, when fractures propagate from a stronger coal seam to a weaker one, the hydraulic pressure exceeds the failure strength of the coal seam, causing the fractures to propagate across the boundary instantaneously. The fracture propagation pattern is illustrated in Fig. 12c, where the fracture propagation rate increases, displacement magnifies, and the rate of rigidity reduction also intensifies. The experimental results show that the heterogeneity of coal seam strength has an essential influence on the morphology of hydraulic fractures.

At present, domestic coalbed methane resources exist in the deep part, and the geological conditions restrict their development and utilization. This study underscores the significance of coal seam strength heterogeneity in fracture propagation. Hence, pre-determining coal seam strength distribution is crucial for hydraulic fracturing in heterogeneous seams. Therefore, by appropriately arranging the fracturing hole spacing, fracturing flow rate, and fracturing pressure based on the distribution of coal seam strength, the scale and distribution density of the fracture network are enhanced, leading to improved efficiency in coalbed methane extraction.

Conclusions

This study systematically examined hydraulic fracture penetration and propagation across varying Seam strength combinations using lab experiments and numerical simulations. The influence of coal seam strength on fracture propagation was explored, discussing its characteristics and rules. Validation was achieved by analyzing pore pressure decline, displacement, and stiffness data during fracturing with different Seam strengths. The study reveals the macroscopic mechanism of combined Seam strength differences on hydraulic fracture development and propagation, concluding:

-

(1)

During hydraulic fracturing, water injection pressure–time curves, fracturing extent, and tracer distribution vary across coal seam strength combinations. Higher coal seam strength areas exhibit broader fracturing ranges and narrower cracks, whereas lower strength areas show wider cracks and narrower ranges. Secondary fractures proliferate on both sides of primary fractures in stronger coal seams, while weaker seams have fewer secondary fractures.

-

(2)

As the crack propagates from low to high coal seam strength, water injection pressure rises, widening the crack in the weaker area. When pressure surpasses coal seam strength, fracture propagation extends into the stronger region. Conversely, from high to low strength, the fracture’s water pressure exceeds coal damage intensity, causing instantaneous expansion, increased water storage, and a marked pressure drop in the new fracture.

-

(3)

The crack propagation is influenced by the tip effect. As the fracture extends from a region with lower coal seam strength to a region with higher strength, there is a rise in pore pressure. This leads to a reduction in coal seam displacement and an increase in the rate of decline of coal seam stiffness. As the fracture propagates from a region characterized by high coal seam strength to a region with lower coal seam strength, the pore pressure diminishes, leading to an increase in coal seam displacement. Simultaneously, the rate of decrease in coal seam rigidity gradually intensifies as the fracture continues to expand.

Data availability

All data used during this research are available from the corresponding author by reasonable request.

References

Sun, H., He, N. & Gurkalo, F. Application and research of microseismic monitoring system and hydraulic fracturing technology in coal mines. Water 16, 1062 (2024).

Mou, P. et al. Influences of hydraulic fracturing on microfractures of high-rank coal under different in-situ stress conditions. Fuel 287, 119566 (2021).

Li, F. et al. Stress relief and permeability enhancement with hydraulic fracturing in overlying key strata of deep and soft coal seams. Acs Omega 8, 12183–12193 (2023).

Lu, Y., Yang, Z., Li, X., Han, J. & Ji, G. Problems and methods for optimization of hydraulic fracturing of deep coal beds in China. Chem. Tech. Fuels Oils 51, 41–48 (2015).

Wang, G., Huang, T., Yan, S. & Liu, X. Experimental study of the fracturing-wetting effect of ves fracturing fluid for the coal seam water injection. J. Mol. Liq. 295, 111715 (2019).

Kang, H., Gao, F., Xu, G. & Ren, H. Mechanical behaviors of coal measures and ground control technologies for china’s deep coal mines—a review. J. Rock Mech. Geotech. Eng. 15, 37–65 (2023).

Zhao, J. et al. Effect of Sio2–H2O nanofluids on wettability of pulverized coal and the modification mechanism. Fuel. 359, 130396 (2024).

Chen, Y., Nagaya, Y., Ishida, T., Barla, G. & Zang, A. Observations of fractures induced by hydraulic fracturing in anisotropic granite. Rock Mech. Rock Eng. 48, 1455–1461 (2015).

Zhang, X. et al. Numerical simulation of hydraulic fracturing and associated seismicity in lab-scale coal samples: A new insight into the stress and aperture evolution. Comput. Geotech. 160, 105507 (2023).

Lu, Y., Ge, Z., Yang, F., Xia, B. & Tang, J. Progress on the hydraulic measures for grid slotting and fracking to enhance coal seam permeability. Int. J. Min. Sci. Technol. 27, 867–871 (2017).

Zou, Y. S., Zhang, S. C. & Zhang, J. Experimental method to simulate coal fines migration and coal fines aggregation prevention in the hydraulic fracture. Transp. Porous Media. 101, 17–34 (2014).

Zhao, J. et al. Study on the mechanism of Sio2–H2O Nanofluid enhanced water injection in coal seam. Appl. Surf. Sci. 658, 159843 (2024).

Xue, Y., Liu, J., Ranjith, P. G., Liang, X. & Wang, S. Investigation of the influence of gas fracturing on fracturing characteristics of coal mass and gas extraction efficiency based on a multi-physical field model. J. Pet. Sci. Eng. 206, 109018 (2021).

Liu, Y., Zhang, Z., Xiong, W., Shen, K. & Ba, Q. The influence of the injected water on the underground coalbed methane extraction. Energies 13, 1151 (2020).

Jiao, A., Tian, S. & Lin, H. Study on crack penetration induced by fatigue damage of low permeability coal seam under cyclic loading. Energies 15, 4761 (2022).

Li, Q., Lin, B. & Zhai, C. The effect of pulse frequency on the fracture extension during hydraulic fracturing. J. Nat. Gas Sci. Eng. 21, 296–303 (2014).

Liu, Y. et al. Influence of natural fractures on propagation of hydraulic fractures in tight reservoirs during hydraulic fracturing. Mar. Pet. Geol. 138, 105505 (2022).

Tan, P. et al. Experimental investigation on fracture initiation and non-planar propagation of hydraulic fractures in coal seams. Pet. Explor. Dev. 44, 470–476 (2017).

Zhao, H., Liu, C., Xiong, Y., Zhen, H. & Li, X. Experimental research on hydraulic fracture propagation in group of thin coal seams. J. Nat. Gas Sci. Eng. 103, 104614 (2022).

Fan, T., Zhang, G. & Cui, J. The impact of cleats on hydraulic fracture initiation and propagation in coal seams. Pet. Sci. 11, 532–539 (2014).

Cheng, Q. et al. Combination of pre-pulse and constant pumping rate hydraulic fracturing for weakening hard coal and rock mass. Energies 13, 5534 (2020).

Zhang, J. & Bian, X. Numerical simulation of hydraulic fracturing coalbed methane reservoir with independent fracture grid. Fuel 143, 543–546 (2015).

Xu, B. et al. A new method and application of full 3D numerical simulation for hydraulic fracturing horizontal fracture. Energies 12, 48 (2019).

Yan, C. & Zheng, H. A two-dimensional coupled hydro-mechanical finite-discrete model considering porous media flow for simulating hydraulic fracturing. Int. J. Rock Mech. Min. Sci. 88, 115–128 (2016).

Yang, P. et al. Numerical simulation of integrated three-dimensional hydraulic fracture propagation and proppant transport in multi-well pad fracturing. Comput. Geotech. 167, 106075 (2024).

Dong, Y., Tian, W., Li, P., Zeng, B. & Lu, D. numerical investigation of complex hydraulic fracture network in naturally fractured reservoirs based on the Xfem. J. Nat. Gas Sci. Eng. 96, 104272 (2021).

Peng, S. et al. Hydraulic fracture simulation with hydro-mechanical coupled discretized virtual internal bond. J. Pet. Sci. Eng. 169, 504–517 (2018).

Secchi, S. & Schrefler, B. A. A method for 3-D hydraulic fracturing simulation. Int. J. Fract. 178, 245–258 (2012).

Zou, J., Chen, W., Yuan, J., Yang, D. & Yang, J. 3-D numerical simulation of hydraulic fracturing in a Cbm reservoir. J. Nat. Gas Sci. Eng. 37, 386–396 (2017).

Wang, T. et al. Simulation of hydraulic fracturing using particle flow method and application in a coal mine. Int. J. Coal Geol. 121, 1–13 (2014).

Li, Y. et al. Numerical simulation of hydraulic fracturing process in a naturally fractured reservoir based on a discrete fracture network model. J. Struct. Geol. 147, 104331 (2021).

Qin, M., Yang, D. & Chen, W. Three-dimensional hydraulic fracturing modeling based on peridynamics. Eng. Anal. Bound. Elem. 141, 153–166 (2022).

Luan, H. et al. numerical study of hydraulic fractures propagation in deep fracture-cavity reservoir based on continuous damage theory. Front. Energy Res. 12, 1377400 (2024).

Xie, J. et al. Numerical investigation of effect of natural fractures on hydraulic-fracture propagation in unconventional reservoirs. J. Nat. Gas Sci. Eng. 54, 143–153 (2018).

Baev, M., Khyamyalyaynen, V. & Shevtsov, A. Geomechanical assessment of the effect of inhomogeneities on the propagation of hydrofractures in coal seams. E3S Web Conf. 105, 1046 (2019).

Jiang, T. et al. Crack Initiation and propagation in coalbed gas reservoir during hydraulic fracturing. Sādhanā 44, 1–9 (2019).

He, H., Cheng, R., Zhao, J., Men, Z. & Mu, Z. Research on the initiation pressure criterion of directional hydraulic fracturing in coal mine. Heliyon 9, e17638 (2023).

Zhengzheng, C. et al. Fracture propagation and pore pressure evolution characteristics induced by hydraulic and pneumatic fracturing of coal. Sci Rep. 14, 9992 (2024).

Schwartzkopff, A. K., Sainoki, A., Bruning, T. & Karakus, M. A conceptual three-dimensional frictional model to predict the effect of the intermediate principal stress based on the Mohr-Coulomb and Hoek-Brown failure criteria. Int. J. Rock Mech. Min. Sci. 172, 105605 (2023).

Barbati, A. C., Desroches, J., Robisson, A. & McKinley, G. H. Complex fluids and hydraulic fracturing. Annu. Rev. Chem. Biomol. Eng. 7, 415–453 (2016).

Ge, Z. et al. Modeling and experiment on permeability of coal with hydraulic fracturing by stimulated reservoir volume. Rock Mech. Rock Eng. 52, 2605–2615 (2019).

Huang, B., Wang, Y. & Cao, S. cavability control by hydraulic fracturing for top coal caving in hard thick coal seams. Int. J. Rock Mech. Min. Sci. 74, 45–57 (2015).

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (52264015), which are gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

D.H.: Conceptualization, Investigation, Visualization, Software, Data curation, Writing—original draft, Writing—review & editing. X.K.: Conceptualization, Methodology, Formal analysis, Writing—review & editing, Supervision, Funding acquisition. Z.X.: Investigation. C.R.: Formal analysis, Writing—review & editing. Y.L.: Investigation, Formal analysis. P.C.: Investigation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Huang, D., Kang, X., Xu, Z. et al. Influence of strength inhomogeneity on transboundary expansion characteristics of hydraulically fractured fractures in coal seams. Sci Rep 14, 29094 (2024). https://doi.org/10.1038/s41598-024-80588-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-80588-8

Keywords

This article is cited by

-

Simulation and analysis of fracture evolution in repeated unloading mining based on fault structure

Bulletin of Engineering Geology and the Environment (2026)

-

Research on the main controlling factors of low permeability coal seam under the action of high-pressure water jetting

Scientific Reports (2025)

-

Study on the evolution mechanism of damage to overburden fissures of repetitive mining of close coal seam groups by positive faults

Scientific Reports (2025)

-

Study on the range of influence of faults on overburden fissures in the working face under repetitive mining action

Scientific Reports (2025)