Abstract

Water injection into a reservoir is a necessary process throughout the reservoir’s lifespan. However, it can lead to certain side effects, such as scale precipitation in production wells and surface facilities due to water incompatibility. This can result in damage to the well, reservoir, and ultimately a decline in production which happened in one of the west of Karoon’s reservoirs and caused the well lost. For solving this problem this case study was conducted with the brine of the reservoir in the reservoir temperature (120 °C) and different economical water samples for water injection. When water combines with the formation water, it can form sediments that cause incompatibility, leading to the precipitation of inorganic scale deposits in surface facilities, flow lines, wells, and even the reservoir itself. Therefore, it is crucial to design the injected water to minimize incompatibility. To address this issue, water compatibility tests should be conducted on the water samples to prevent scale precipitation and ensure successful water injection. In order to investigate this phenomenon, experiments were carried out in both dynamic and static phases. Water samples from the lagoon, mineral water, and synthetic water were mixed with formation water at different temperatures and mixing ratios in static tests. The results indicate that synthetic water (S) was generally incompatible with formation water in most experiments. While mineral water (M) showed compatibility in some mixing ratios and temperatures, lagoon water (L) demonstrated greater compatibility with formation water compared to M water. In cases where M water showed better compatibility, the difference in scale formation between L water and M water was negligible. Based on the availability and the results of this research, L water was chosen as the more compatible water among the three selected samples. Subsequently, tests were conducted using lagoon water and formation water. A glass micromodel with a designed pattern was utilized to observe scaling formation and distribution easily. Photos captured through fluorescent scanning, along with a MATLAB code developed to determine the percentage of reduced porosity, revealed that approximately half of the pores were plugged. To address this reduced porosity, a novel technology involving the use of NaOH in a static situation (jar test) was employed. The jar test was conducted at four different temperatures near the reservoir and well’s temperature (120 °C, 95 °C, 85 °C, and 75 °C) with two percent mixing of lagoon water in contact with the formation water of this case study. These tests were repeated under the same conditions but with the addition of NaOH to the mixing water. The results of this innovative technology showed promising outcomes, as the weight of scales was reduced, and scanning electron microscope (SEM) analysis revealed a transformation to more soluble scales both in dynamic and static tests.

Similar content being viewed by others

Introduction

Water injection is considered one of the most reasonable methods for improved oil recovery when compared with the other available enhanced oil recovery (EOR) methods. It also helps in the disposal of unwanted produced water from oil and gas wells in an environmentally responsible means. Water quality and compatibility play an important role in determining the effectiveness of reinjecting the produced water into the reservoir1,2,3. In addition to observing scales in the laboratory,There is the possibility of mineral deposition inside the reservoir during water reinjection and this leads to damage to the wells and producing facilities. This is one of the key reasons why water injection is not encouraged4,5. This challenge of incompatible water, blocking several wells in Russia and the North Sea has been reported in the literature. Several examples have been stated about the deposition of CaSO4 and SrSO4 in Saudi’s field, El Morgan in Egypt, and Samarta’s field in Indonesia. In all these cases, the result was the loss of their wells which led to other operational problems6,7. Besides water injection, Low-salinity water flooding (LSWF) is an approving and effective method for both improved oil recovery (IOR) and enhanced oil recovery (EOR) strategies at every stage of hydrocarbon production. This technique offers a range of advantages, including cost-effectiveness, minimal environmental impact as well as lots of industry experience with water injection during secondary recovery processes. There is a potential for confusion regarding the classification of LSWF and its intended purpose. Some authors view it as an EOR technique, while others regard it as an IOR method. However, it is better that categorizing LSWF solely as either IOR or EOR may not be advantageous, considering LSWF as a production technology. Researchers from academia and industry have devoted significant attention to studying LSWF, resulting in the publication of numerous scientific papers. It is worth mentioning that the first successful field test was in 2004, yet the number of field projects conducted over the past two decades remains relatively limited due to its side effects; which means that this method considered an experimental rather than a fully operational technique and more studies must be conducted8.

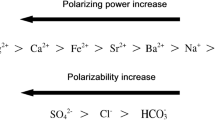

Formation water in the reservoir exists in equilibrium with the surrounding hydrocarbons and rocks, while the injected water is in equilibrium with surface conditions. The temperature and pressure of water on the surface, are lower, and as this water reaches the lower layers in the reservoir, with the increase of temperature and pressure, the system’s thermodynamic equilibrium is lost and the likelihood of depositing scale in the wellbore or the reservoir increases. The deposition of ions contained in the injecting water, which depends on thermodynamic conditions, may occur behind the mixing zone. Also, scales can be deposited when two water frames interact (the mixing zone); these depositions of ions decrease along the reservoir due to their gradual deposition among the reservoir. The scales that are formed in the mixing zone are different from the ones that form behind the mixing zone. The factors in charge of this deposition are pressure reduction or an increase in temperature. Other reasons for scale deposition include turbulence9, mixing two incompatible water bodies, and increasing salt concentration as a result of reservoir water evaporation. This last condition occurs mainly in gas wells with high pressure and temperature. In this state, NaCl is the main scale10. It can also occur near the gas wellbore increasing the CaSO4 scale9. Generally, scales are divided into two categories, organic and inorganic. Organic scales are the deposit of wax, asphaltene, and resins. On the other hand, Inorganic scales include depositions of insoluble salts as a result of ion interactions. The most devastating inorganic scales in a reservoir are CaCO3, CaSO4, SrSO4, and BaSO411. Moghadasi12 identifies several key variables influencing the formation of calcium carbonate (CaCO3): the partial pressure of CO2, temperature, total dissolved salts, and pH. For sulfate groups, pressure and temperature are critical factors. In the case of strontium sulfate (SrSO4) and calcium sulfate compounds such as gypsum (CaSO4·2H2O), hemihydrate (CaSO4·0.5H2O), and anhydrite (CaSO4), total dissolved salts also play a significant role in scale formation. For iron compounds like ferrous carbonate (FeCO3), ferrous sulfate (FeSO4), ferrous hydroxide (Fe(OH)2), and ferric hydroxide (Fe(OH)3), the primary influencing factors include corrosion, dissolved gases, and pH levels.In a study conducted by Mohammadi and Mahani13, the effect of high salinity and low salinity of injected waters were studied in a micromodel, the results indicate that low salinity water performed better in terms of higher recovery factor13. Ghasemian while experimenting in the porous media observed that the salinity of injected seawater has a significant result on the scale precipitation and it was observed that the scale precipitation declined by dilution of sea water10. Based on the conducted tests by Gandomkar, it was observed that there was no precipitation when low-salinity fresh water (1000 ppm) and brine solution containing NaCl (1000 ppm) were mixed with high-salinity fresh water (220,000 ppm) in all the samples. However, precipitation occurred immediately in all samples when high-salinity fresh water (220,000 ppm) was mixed with low-salinity sea water (1000 ppm) and high-salinity sea water (34,000 ppm) along with brine solutions containing single-component salts (1000 ppm), such as MgSO4, KCl, Na2SO4, CaCl2, and MgCl214.

Scales Precipitation solubility changes by various parameters, for example, the solubility of calcium hydroxide is dependent on temperature, PH of the system, Dilution Factor of Injected Brine, and crystal size15. Temperature is one of the key factors in the scale solubility, although their solubility with temperature is not linear and there is an optimum solubility temperature, for instance, Solubility varies with temperature. According to Sanna16 and Azimi17, the solubility of sulfate groups rises as temperature increases, while the solubility of carbonate groups declines with higher temperatures.. Temperature has a significant impact on the formation of scales, but in some studies, different reports about conflicting of temperature impacts were reported. For instance, in studies conducted by Rousseau18,19, it was observed that larger crystals of scales were formed when an increase in temperature occurred. However, Budz et al.20 found that a higher temperature led to a lower nucleation rate. In summary, while temperature has a significant influence on scale formation, its effect can vary depending on the specific system and experimental conditions. The growth rate of crystals generally increases with temperature, but the interfacial supersaturation and nucleation rate can be affected differently, leading to contrasting observations in different studies21.

Another parameter affecting scale deposition and it is proven by several researchers that PH affects forming scales. research conducted by Schierholtz found that nucleation of calcium sulphate dihydrate was affected by PH22. Austin et al. also worked on spontaneous precipitation of calcium sulphate at different ranges of PH and temperature, by increasing PH and temperature hemihydrate phase transformed into anhydrite23. Azizi et.al found by simulation that, at specific mixing ratios, PH was the main parameter that impacted the carbonate scales24. The importance of PH is not only between two water, but also it affects electrostatic interactions between the three phases of oil, brine, and reservoir rock25. A core flooding conducted by Torrijos observed that there is a relationship between increasing oil recovery and increasing PH of producing water26.

Another parameter affecting scale deposition is Dilution Factor of Injected Brine. Studies in the past that had been conducted in the formation damage field used high dilution factors of 100-fold, but recent researchs has demonstrated that by diluting injected water to 2.5-fold dilution the scales can be decreased significantly. However, determining the optimal dilution factor for maximizing recovery remains uncertain due to the lack of comprehensive evaluations in most studies and different reservoir situations. Studies propose that utilizing low-salinity injected water with less than 5000 ppm TDS is advantageous27,28.

Fluid flow through porous media is usually not directly observable, so researchers rely on indirect measurements to understand the processes taking place in this medium. To overcome this limitation, non-invasive imaging methods such as UV, Gamma radiation, X-ray microtomography, and X-ray microtomography are being utilized in porous media research. Additionally, single tubes have been used as a visualization method to study fingering patterns during unsTable displacement, but they are unable to provide pore-scale resolution measurements29,30.

Micromodels are an alternative approach to visualize and simulate porous media, as direct observation of scaling formation and distribution is challenging with other methods. Glass micromodels offer a noTable advantage due to their transparency at the microscopic level, allowing for detailed flow visualization. The use of a glass micromodel that replicates the actual pore structure of a reservoir rock provides valuable experimental evidence at the pore scale, offering useful insights in studying porous media31. Due to pore-scale visualizations, micromodel has a noTable interest32.

In this study, the focus was on addressing the issue of a lost well in the field due to incompatibility between injected water and formation water. The main objective was to determine the compatibility of different water sources with the formation water and identify the types of scales formed in reservoirs for effective removal. The impact of NaOH on the mixing water from the Lagoon wetland and formation water from the west of Karoon’s field was specifically investigated using the jar test method. The aim was to assess whether the increase in pH caused by NaOH would improve the compatibility between the brine and mixing water. Additionally, the study aimed to analyze the influence of temperature on the results obtained. To gain a closer understanding of scale deposition during fluid flow, a unique micromodel was utilized to measure the porosity reduction and determine the compatibility of injecting Lagoon water into reservoir water at a pore-scale level.

Different formation water samples were collected from one of the oil fields in the south of Iran, other water samples include samples collected from Lagoon, Mineral water, and Synthetic water. The compatibility of these water samples with the formation water using different mixing ratios was then evaluated. For the investigation of the compatibility of formation water with the Lagoon water, mineral water, and synthetic water, their chemical composition and the scales produced were determined using X-ray analysis (XRD) and Scanning Electron Microscope (SEM).

Methodology

A Jar test at different temperatures was used to determine the amount, type, and modified mixing ratio of two water samples. The X-ray analysis (XRD) and Scanning Electron Microscope (SEM) were used to identify the minerals and the composition of different samples which comprise the Lagoon water (L), mineral water (M), synthetic water (S), and brine formation water (B). In this study, jar tests were conducted using three different water samples in various mixing ratios (25%, 33.33%, 66.66%, and 75%) of formation water. The mixing ratios were evaluated at different temperatures, including the reservoir temperature of 120 °C, as well as 95 °C, 85 °C, 75 °C, and ambient temperature. Figure 1 summarize all the steps of the experiments and the best results observed.

Materials

Water

In order to assess the compatibility of three water samples with formation water, a combination of Inductively Coupled Plasma (ICP) and Ion Chromatography techniques were employed to determine the components present in the water. Ion Chromatography was specifically used to identify anions, while ICP was utilized to detect cations. The composition of formation water primarily consists of Calcium, Chloride, Sodium, and Potassium.

The water samples used in the compatibility tests included mineral water or freshwater, lagoon water sourced from the nearby lagoon wetland, and synthetic water. These samples varied in their total dissolved solids (TDS) content, with the mineral water having low TDS, lagoon water having median TDS and synthetic water having TDS levels similar to formation water.the PH values were chosen based on the geological and environmental context of the system being studied. The tests were conducted at temperatures ranging from 120 °C, matching the reservoir temperature and simulated the conditions of a well during the production process., to temperatures below that to observe the behavior of the water mixture in the well.

For the synthetic water, de-ionized water served as the base, and salts such as CaCl2, MgCl2, NaCl, KCl, Na2SO4, and NaHCO3 were added while continuously stirring until fully dissolved. The water was then filtered twice using a Millipore filter paper with a 0.45-µm membrane to remove any turbidity. The 0.45-µm membrane filter paper was used to ensure that water samples are filtered effectively, accurately, and reliably, while also meeting regulatory requirements and maintaining high quality.

Among the three water samples, lagoon water emerged as a more accessible and cost-effective option for operational purposes. The major components of each sample are summarized in Table 1, while Fig. 2 illustrates a stiff diagram representing the composition of the formation water.

NaOH

In order to mitigate scale formation, a base, specifically NaOH, was employed in this experiment. The inspiration for using NaOH as a scale inhibitor stemmed from its effectiveness as a corrosion inhibitor, where it helps maintain the solution’s pH at approximately 9 and minimizes corrosion. The NaOH utilized in this study was sourced from MERC and boasted a purity level of 99%. During the mixing process, the homogeneity of the mixture was ensured by using a homogenizer stirrer (HS_30E) at a moderate RPM for a duration of 3 min.

Methods

Static tests

Brine compatibility evaluation

Different ratios of each water sample (L, M, S) have been mixed with the formation water (B) to evaluate the amount and type of possible scales that can be generated by the mixtures. It should be noted that the volume of both brine and injected water in all jar tests was 15 milli-liter in this part of the experiments. Tables 2, 3 and 4 show the mixing ratio and brine percentage at various temperatures in jar tests. At first, a specific amount of the B water was poured into the test jar, then the precise amount of the the lagoon water(L), synthetic water (S) and mineral water(M) was added into the brine formation water(B) at the proportions of 75%, 66.66%, 33.33% and 25% respectively. This mixture was then stirred with a low-speed stirrer for 10 min. In the next step, samples settled in the oven at different temperatures (75 °C, 85 °C, 95 oC, and 120 °C). After two weeks, each sample was filtered through a 0.45-µm filter membrane to verify the weight and scale type by using XRD and SEM analysis. Filtration of each sample was done rapidly to avoid any dissolution of the precipitations.

Dilution of injected water

When a water sample has been diluted, the chance of precipitation dwindles. Dilution of mixed water was used to reduce and eliminate the scale precipitation. Among three mixing water samples (L, S, and M water), L water was chosen, which is easily accessible and more economical than the other water samples. Therefore, this part of the experiment was implemented by diluting L water and mixing it with B water as shown in Table 5, to find out whether a lower volume of the scale was possible to achieve. The L water was diluted at four different ratios: 1.5 time dilution (0.666L), 2 time dilution(0.5L), 3 time dilution (0.33L) ,and 4 time dilution (0.25L). Table 6 indicates water components after dilution. The volume of water was 20 milli-liter and it contained B water and diluted mixing water. The reason for using these DFs ( dilution factor) is to reach the TDS of the injected water to less than 5000 ppm, and experiment the ranges of almost 5000 ppm to less than 2000.

Secondary Jar test

Since L water was chosen in the initial jar test to proceed with the experiments, The secondary jar test was employed to assess the compatibility between B water and Lwater, as well as to investigate the impact of NaOH on their compatibility. The procedure involved gradually adding NaOH to the Lagoon water until it reached a pH level of around 8. A specific quantity of B water was then poured into a beaker, followed by the addition of the mixture of L water and NaOH. The contents were stirred using a homogenizer stirrer (HS_30E) for 3 min at a medium RPM. Subsequently, the beaker contents were transferred to a jar, which was sealed with paraffin paper. The sealed test tubes were then placed in an oven at different fixed temperatures, each sample for a duration of two weeks. After this period, the water mixture was filtered using a 0.45-µm membrane filter paper. The dried scales on the filter paper were weighed and analyzed using a scanning electron microscope. Table 6 provides an overview of the jar test conditions, including the test temperature and the percentage of mixing waters.

Dynamic tests

Syringe pump

To facilitate the injection of water into the micromodel at a consistent rate, a syringe pump was employed. Figure 3 illustrates the specific syringe pump utilized in this experiment, which allowed for the controlled flow of water samples through a needle into the micromodel. The syringe diameter used for injection in this experiment was 8 mm, and the injection rate of the syringe pump was determined based on its properties, as indicated by Eqs. 1 and 2. The injection rate, in this case, was set at 0.1 ml per hour to ensure that the injection process was not too rapid, allowing sufficient time for reactions between the water samples to occur and The flow rate of 0.1 mL/h corresponds to a laminar flow regime, which is suitable for micromodel tests. The calibration of the syringe pump was verified using a standard method. During this process 6 PV of L water was injected into the micromodel to ensure all pores came in contact with the injected water.

Micro-model

Designing micromodel

Figure 4 indicates a pattern that with Corel draw application was modeled, and it was a complex, heterogenic structure of the reservoir rock. A 2-mm (thickness) glass was used because of the obviousness of this kind of glass, and the taken photos had more resolution. Also, less deposition in the etch depth occurred, so finding porosity reduction would be easier and more realistic.

Fussing process

Flat glass for fussing on the pattern was needed. The flat glass had holes on both sides of it, for the input and output of fluids. The non-patterned glass was fixed on top of the patterned glass and set in a furnace for 180 min to reach a setpoint at 695 °C, then it rested at this temperature for about 17 min; finally, it was cooled down gradually until its temperature was the same as ambient temperature. this temperature of fussing glasses was found by trial and error based on the glass diameter, material, and structure.

Characterization of physical properties

For the Characterization of physical properties, etch depth was calculated from Eq. 333 in Which 'a' and 'b' which are coefficients depended on the values of resolution ratio and engraving speed , were calculated by Moghadasi et.al (2013), and shown in Table 7. Also, 'D' and '\({P}_{f}\)' are etched depth in micrometers, and dimensionless fractional laser power respectively and a and b are coefficients that strongly depend on the values of engraving speed and resolution ratioThe porosity of the micromodel was measured by MATLAB code, before and after injection to evaluate porosity reduction. A photograph of the image was taken, and the resulting image was then analyzed using MATLAB code to measure the porosity of the rock . The physical properties of the micromodel are shown in Table 8.

Properties of injected water

To determine the most compatible injected water with the brine in static phase, six distinct water samples which had the most promising results from previous jar test experiments with L water were prepared. Each sample was individually injected into the micromodel, and the porosity was quantified using the MATLAB code. Following the porosity calculation, another code was utilized to visualize the difference between the initial porosity and the porosity after water injection. Detailed information on the injected water conditions is presented in Table 9.

SEM analysis

SEM analytical techniques, along with X-ray diffraction (XRD) analysis, are a cheap and non-destructive way to analyze materials for the characterization of the physical and chemical solid materials34,35. Using the EDS (Energy Dispersive Spectroscopy) detector, the relative values of the elements with atomic numbers six and above can be determined using the heights of the peaks. The intensity of the peaks in the EDS indicates the type of elements36.

XRD analysis

X-ray diffraction is a non-destructive method of studying the structure of crystalline materials (through the processing and analysis of X-rays returning from the surface of the sample). This technique was discovered in 1912 by von Lowe and used by William Henry Bragg and William Lawrence Bragg to study crystals37.To find the type of element or salt, the peaks must be matched with the reference patterns, although sometimes there is a slight difference in the angles of the peaks from the XRD test with reference patterns, which is due to the error of the laboratory device and can be ignored37.

Results and discussion

Initial Jar test results

Scale deposition occurs at various chemical and physical conditions such as different temperatures, pressures, mixing ratios, and PH. In this research, the effect of these three parameters was evaluated concurrently. It should be noted that there is always an optimum percent of each water which is highly dependent on the type of mixing water and temperature and finding the optimum percent of mixing ratio at different temperatures of the reservoirs is essential to avoid any type of damage to that reservoir, wells and surface facilities.

The initial Jar test was conducted at four different temperatures and different mixing ratios of each of the water samples and the brine (test conditions can be seen in Tables 2, 3, and 4), to observe the effect of temperature and mixing ratio on scale deposition in a two week period of testing time, and also the solubility of the scales. The aim of these tests was to find the optimum mixing ratio at different temperatures.

For these tests, the volume of the mixture of water samples was 16 ml (both brine and mixing water). The results of these jar tests are shown in Bar charts in Fig. 5a–d which demonstrate the scale’s weight of each water.

Each bar chart of the following Figures and Tables in Fig. 5 indicates how much scale(gr) occurs while L, M, and S water mix with B water at different ratios of each water (25%, 33.33%, 66.66%, and 75%) and different temperatures (120 °C,95 °C,85 °C,75 °C). From the results in Figs. 5, each mixing water compatibility (L, M, and S water) with B water behaves differently in each percentage of the mixing ratio and temperature. From the literature, when the temperature changes, compatibilities, and solubility will change, some scales can resolve as the temperature changes while some other scales deposit38,39,40.

Weighting the scales after filtering them with 0.45-µm paper and drying them at room temperature to prevent any moisture from accumulating within the scales, helped to determine the quantity of scales deposited. Bar charts in Fig. 6 can provide a good comparison between the weights of scales and show the more compatible water. For instance, at 120 °C which is the reservoir’s temperature the most compatible water was 25 and 33.33 percent M water while at 75c L water with 33.33 percent had the least amount of scales. Also, it has been observed that in most of the experiments S water did not perform well and the mixtures generated the highest quantity of scales. Compared with L water and M water, S water was not compatible with any temeprature and percentages.

The measurable scales obtained from various experiments were collected and subjected to analysis using scanning electron microscopy (SEM) and X-ray diffraction (XRD) techniques. The purpose of this analysis was to determine whether these scales were soluble or if they had the potential to cause damage in the reservoir. Additionally, the study aimed to investigate whether similar scales were observed at different temperatures and different percentages.

Analysis of initial Jar test

Given the destructive and damaging impact both on the reservoir and the surface facilities, the elimination of damaging precipitation such as sulfate and carbonate groups is a very critical research area. In this research, all major scales which can be produced from the mixing of the different water samples were evaluated using the XRD and SEM analysis. Due to the amorphous structure and small volumes of some of the precipitates, they could not be analyzed.

SEM analysis of initial Jar test

After putting the mixture of water samples for two weeks in the oven, they were filtered with 0.45-µm filter paper; then, dried and weighed, and they were ready for analysis. For the SEM test, some of the samples were put on a gold paper and then put in their place in the SEM sample chamber. SEM shows the exact morphology of the salts while EDS can help to find the type of scale.

Kα (K-alpha) refers to the characteristic X-ray emission from the K shell (the innermost electron shell) of an atom. When an electron from a higher energy level falls into a vacancy in the K shell, it emits energy in the form of X-rays. Kα radiation has a specific energy unique to each element. Kβ (K-beta) is similar to Kα but originates from transitions involving higher energy levels, specifically the L shell to the K shell. Kβ radiation also provides information about the elemental composition but is usually of lower intensity compared to Kα. keV (kilo-electronvolts is a unit of energy commonly used in the context of X-rays and allows for the characterization of the energy levels involved in the emission of X-rays. 1 keV equals 1000 electronvolts and is used to describe the energy of the emitted X-rays detected in EDS. In an EDS spectrum, the longitudinal axis shows the intensity (in counts) of detected X-ray emissions, while the presence of Kα and Kβ peaks indicates the characteristic X-ray emissions from the elements being analyzed, with keV providing a measure of their energy levels.

When these two methods are interpreted simultaneously, it can provide a solid answer about the kind of scales. Figure 6 shows the SEM and EDS of scales from mixing B water and L water at 120 °C and Fig. 7 illustrates the SEM and EDS of scales of the mixture of B water and S water at this temperature. From Fig. 6a,b, It can be observed that the main component of scale is calcium sulfate in the form of gypsum. Calcium strontium sulfate deposits were also found.

In Fig. 7, two types of scales are shown with numbers 1 and 2 and b1 and b2 represent the EDS of scales at point 1 and point 2. At point 1, the major sediments include calcium chloride and sodium chloride. Also, according to the image and its comparison with reference images, the possibility of sodium oxide is very high. At point 2, the major sediments include chloride oxide as a negative charge, calcium chloride, and sodium chloride. The type of scales in the other percentages and temperatures were almost the same.

XRD analysis of initial Jar test

Using the same methodology as the SEM experiments, the water mixture was also filtered with a 0.45-µm filter paper and some samples did not have a sufficient amount of scale for the XRD tube. From the XRD analysis on Fig. 8 and its peaks, by comparing these results to the reference patterns by using advanced peak shape analysis, the most common salts in A, B, and C are FeCo3, FeS, gypsum, Fe(OH)2, SrSO4, Hemihydrate, Fe (OH)3, anhydride, BaSO4.

Based on the SEM and XRD analysis results, it was found that the scales present in the mixture were predominantly composed of sulphate groups, especially CaSO4, which is known to be highly detrimental and difficult to dissolve. Consequently, in order to address this issue, modifications to the water composition were explored with the aim of either eliminating scales or altering their type.

It was observed that S water proved to be incompatible at all temperatures, exhibiting the strongest scales. Therefore, S water was removed from further experiments.

Comparatively, when considering M and L water, slight differences were noted regarding the type and weight of scales formed. Since L water was sourced from a nearby field and proved to be more economically viable than using B water, To determine the optimal percentage of L water, a bar graph from the data of initial jar test results was generated. Based on Fig. 9, it was identified that the best percentages of L water at different temperatures were 33.33% and 75%. Consequently, the experiments proceeded with L water and these specific percentages.

Micro model setup

In the first step, B water was completely filled into the micromodel with a syringe pump until from the other hole, injected water was poured out. After that, the L Water sample was injected with a syringe pump with a 0.1 ml/hour flow rate for three hours to see depositions and find out the porosity reduction. This chosen flow rate is between min and max flow rates for the used syringe pump and this rate is not too rapid to prevent the reaction between water samples. After the injection was finished, a photo with a Florissant camera was taken from the micromodel to see if pores were plugged, and if they were clogged, what percent of its pores were blocked. Figure 10 shows the micromodel after injection. Although a slight porosity reduction could be neglecTable; the results showed a large amount of scale deposition, which reduced micromodel porosity to almost half (about 50 percent porosity reduction). Porosity reduction by using image processing MATLAB code was done, which was written to show the amount of porosity reduction. The code revealed that the incompatibility of two water caused a porosity reduction of 14.38%. This porosity reduction shows that despite of the small amounts of scales in the static tets, these two waters are highly incompatible in a dynamic situation, and if they interact in the reservoir, it could cause serious damage; so, modifying L water before injection is needed. For this matter, NaOH treatment and dilution of water were used to reduce the incompatibility between waters as may as possible and check wheahter the samples were compatible in static tests.

Secondary jar test: Dilution of water

As L water was selected for experimentation, it was observed during the dynamic test that the results were not promising in terms of scale formation. Therefore, a decision was made to modify this water sample in order to alter the type of scales and minimize their quantity. The L water samples were diluted into 0.25 L, 0.33L, 0.5L, and 0.66L as shown in Table 6 to reduce its TDS to 5000 ppm and less than that( TDS range of L water in these tests were between 7780 and 1970 mg/l). The samples were mixed with B water at 75% and 33.33% of the L water, these specific percentages were chosen as it resulted in minimal scaling during the initial jar tests. The experiments were conducted at a temperature of 120 °C, which represents the field temperature. The results are shown in Fig. 12 which indicates that diluted water in 0.5L and 0.33L leads to less scale.

The results, illustrated in Fig. 11, demonstrate the effects of different mixing ratios on scale formation. It is observed that a 75% mixing ratio of L water leads to scale formation exceeding 1.3 g, while a 33.33% mixing ratio results in approximately 0.8 g of scale. Furthermore, the graph reveals that increasing water dilution does not necessarily guarantee a reduction in scale deposition. An optimum dilution point was identified for each mixing ratio and temperature condition. For the 75% L water, the optimum dilution was observed at 0.66 L (indicated by the dotted trend line), while for the 33.33% L water, the most compatible water was found at 0.5 L (look at the trend line).

Clearly depicted in Fig. 12, there is no direct correlation between increased dilution and reduced scale formation.

Tertiary Jar test: NaOH treatment

During the addition of NaOH to the injected water, an ion exchange process takes place. CaSo4, which is one of the hardest scales, undergoes a significant reaction with NaOH, as demonstrated by Eq. 4.

The salts that were constructed by this reaction are calcium hydroxide and sodium sulphate; sodium sulphate is soluble and its solubility changes with temperature, also calcium hydroxide is partly soluble, they both are less devastating than caso4. the reaction of calcium sulfate scale with sodium hydroxide solution at high temperatures involves the dissolution of the scale and the formation of soluble calcium and sulfate complexes. The strong basic nature of NaOH and the elevated temperatures facilitate the reaction, potentially leading to the removal of calcium sulfate scale.

In the following step by using NaOH, substantially it was found that the weight of the scale was reduced in most tests, and the type of precipitated scales was much more soluble than scales without NaOH in L water or partly soluble which by shaking the test tube some of them were solved in the water again. Also, scales from the mixing water with NaOH had an amorphous soluble structure and were hard to gather for SEM analysis.

Figures 12 and 13 indicate the weight of scales between Lagoon water and formation water at four different temperatures (120 °C, 95 °C, 85 °C, 75 °C), and 33.33 and 75 percent(the chosen percentages from initial jar test) of L water in the presence and without NaOH. Also, as can be seen in the graphs the comparison between the best diluted water samples from secondary jar test (0.66 L at 75%L and 0.5 L at 33.33%L) with NaOH is shown in the bar chart. In both graphs, although NaOH in most experiments caused a lesser scale, there is the same trend of precipitation, it has a maximum amount of scale at a temperature at each percent of Lagoon water (mixing water). Due to the results, it is clear that injected water with NaOH performs better, especially at a lower percentage of diluted mixing water. From the graph, it can be seen that at the reservoir temperature adding NaOH to 33.33% of injected 0.5 L water can lead to less scale.

For analyzing scales, a specific amount of scales were needed. In most experiments, the amount of scales was not sufficient to evaluate, or they were amorphous, and had slight coherence on the filter paper; so, SEM analysis was used to evaluate two samples that had more scales and they were easy to gather. The first sample was the scales of 33.33 percent L water and 75 percent of B Water at 95 °C, and the second sample was 33.33 percent of L water with NaOH on 75 percent of B Water at 95 °C.

The results are shown in Figs. 14 and 15. By analyzing SEM and EDS of Lagoon water and formation water, it can be realized that there is only one type of scale (due to SEM), and calcium soulphate is the dominant scale. While the SEM of the Lagoon water with NaOH and formation water scale shows that three types of scales are present and due to EDS and the shape of scales crystal in SEM dominant precipitations are slightly calcium sulphate, calcium hydroxide, and sodium sulphate, sodium chloride. The comparison of type of scales and their forming condition are listed in Table 10.

Micro model results

After promising results at secondary and tertiary jar tests, micromodel tests were repeated at different injection modified water samples.

Tests were accomplished in four different circumstances by different lagoon samples at different PHs. After injection of the lagoon without changing the water properties, most of the pores were clogged. The difference between initial porosity and injected lagoon at micromodel is demonstrated in Fig. 16 in this photo that is provided from MATLAB code, the black color stands for plugged pores and the white color reveals the path that fluid can flow. As depicted in Fig. 16, a significant portion of the pores are observed to be blocked. This is a matter of concern as it could result in great damage throughout the entire operation if it occurs in the reservoir. It is noteworthy that the majority of scale precipitation takes place in the first half of the micro model, indicating a reduction in ion concentration during the injection process. Additionally, it is observed that the larger pores tend to get blocked more rapidly. Tests were continued to eliminate the plugged pores; the results are shown in Table 11. Based on the results obtained from these tests, several key observations can be made.

Firstly, it can be determined that the pH and TDS of the injected water have a significant impact on the porosity of the micromodel. Specifically, when the injected water is 2 times diluted lagoon with NaOH, the pH reaches 7.9 and the TDS is less than 5000 ppm, the porosity decreases to 0.2563. However, when the lagoon is used directly with NAOH, resulting in a pH of 8.1, the porosity decreases further to 0.2452. This indicates that an increase in PH leads to a reduction in porosity.

Moreover, when the lagoon is diluted 1.5 times with NAOH, the pH lowers to 8, leading to a significant decrease in porosity to 0.2226. Similarly, when the lagoon is diluted 2 times without NAOH, the pH decreases to 6 and the porosity drops to 0.2091.

Lastly, it is observed that the lowest pH value (6.3) is associated with the use of the lagoon without any dilution, resulting in the lowest porosity value of 0.1416.

Conclusion

The injection of water into reservoirs can lead to the mixing of incompatible fluids, such as formation water, sea water, or river water, causing disruptions to their thermodynamic balance. This issue has been observed in various reservoirs worldwide, with the loss of a well during water injection operations serving as a case study for this research.

To address the challenge of water incompatibility, it became essential to investigate the compatibility between mixing water and formation water before utilizing it for activities like enhanced oil recovery (EOR), drilling, or production operations.

Among the three types of water samples, synthetic water (S) showed poor compatibility with formation water in most experiments. While M and L water exhibited compatibility in some mixing ratios and temperatures. Moreover, in cases where M water showed better compatibility, the difference in scale formation between L water and M water was negligible. Therefore, L water was chosen to do more experiments on and modified due to its availability .

Further optimization was achieved by diluting the L water at varying ratios (0.25L, 0.33L, 0.66L, and 0.75L). The diluted water was then mixed with formation water at different ratios and temperatures. The results revealed that the optimum mixing ratio was found to be 33.33%, with 0.5L preventing scale precipitation at temperatures below 120 °C.

To determine the nature of the scales formed and to aid in scale prevention and removal, SEM and XRD analyses were conducted on the precipitated scales. These analyses identified sulfate salts, particularly calcium sulfate, as the predominant and detrimental scale observed in both SEM and XRD analyses.

In addition, a novel NaOH treatment was employed in jar tests to evaluate its impact on scale formation. SEM and EDS analyses confirmed that the addition of NaOH to the injected water resulted in a change in the nature of scale precipitation, making them more soluble, also less scale precipated in these tests.

Porosity reduction emerged as a major concern due to water incompatibility. To investigate this phenomenon and visually observe its effects, a micro model was designed and filled with formation water. Injected water was then pumped into the micro model using a syringe pump. A photo of the micro model was taken, and the porosity reduction was determined using MATLAB code, revealing a significant decrease in porosity of almost half. In order to improve porosity, modifications were made to the injected water.

Micro model tests were repeated, adding NaOH to the injected water, as well as diluting the injected water in certain experiments and adding NaOH to the diluted water in others. The results indicated that NaOH not only reduced scales in jar tests but also proved to be a successful method in micro model tests. Additionally, dilution was found to a possitive effect on scale precipitation. When the optimum diluted water was combined with NaOH, the porosity reduction was negligible. Therefore it was concluded PH and TDS together have a great impact in compatibility of waters. The pH of the injected water was found to directly correlate with the porosity of the micro model.

In conclusion, this research provides valuable insights into water compatibility and its impact on reservoir operations. The study highlights the significance of assessing mixing water and formation water compatibility prior to usage, optimizing mixing ratios through dilution, and employing NaOH treatment to reduce scale formation. The findings also emphasize the crucial role of pH control in preserving reservoir porosity during injection processes. Ultimately, this research contributes to scale prevention and mitigation strategies, enhancing the overall efficiency and performance of reservoir operations.

Data availability

All data generated or analysed during this study are included in this manuscript.

References

Ayirala, S. C., Al-Saleh, S. H. & Al-Yousef, A. A. Microscopic scale interactions of water ions at crude oil/water interface and their impact on oil mobilization in advanced water flooding. J. Pet. Sci. Eng. 163, 640–649 (2018).

Sheng, J. J. Critical review of low-salinity waterflooding. J. Pet. Sci. Eng. 120, 216–224 (2014).

Al-Shalabi, E. W., Sepehrnoori, K. & Pope, G. Mysteries behind the low salinity water injection technique. J. Pet. Eng. 2014, 1–11 (2014).

Younis, S. A. et al. Tailored functionalized polymer nanoparticles using gamma radiation for selected adsorption of barium and strontium in oilfield wastewater. Arab. J. Chem. 13(2), 3762–3774 (2020).

Krueger, R. F. An overview of formation damage and well productivity in oilfield operations. J. Petrol. Technol. 38(02), 131–152 (1986).

Mitchell, R., Grist, D. & Boyle, M. Chemical treatments associated with North Sea projects. J. Pet. Technol. 32(05), 904–912 (1980).

El-Hattab, M. I. GUPCO’S experience in treating Gulf of Suez seawater for waterflooding the El Morgan oil field. J. Pet. Technol. 34(07), 1449–1460 (1982).

Bigdeli, A., Thyne, G. & Ulyanov, V. Low salinity water flooding (LSWF), can we move forward? The economic case. J. Res. Recov. 1(1), 1002 (2023).

Moghadasi, J. et al. Formation damage due to scale formation in porous media resulting from water injection. In SPE International Symposium and Exhibition on Formation Damage Control (OnePetro, 2004).

Ghasemian, J. & Riahi, S. Effects of salinity and ionic composition of smart water on mineral scaling in carbonate reservoirs during water flooding. Pet. Explor. Dev. 48(2), 421–429 (2021).

Al-Taq, A. A. et al. Organic/inorganic deposition in oil producing wells from carbonate reservoirs: Mechanisms, removal and mitigation. In Abu Dhabi International Petroleum Exhibition and Conference (OnePetro, 2015).

Moghadasi, J. et al. Scale formation in Iranian oil reservoir and production equipment during water injection. In International Symposium on Oilfield Scale (OnePetro, 2003).

Mohammadi, M. & Mahani, H. Direct insights into the pore-scale mechanism of low-salinity waterflooding in carbonates using a novel calcite microfluidic chip. Fuel 260, 116374 (2020).

Gandomkar, A. & Rahimpour, M. R. Investigation of low-salinity waterflooding in secondary and tertiary enhanced oil recovery in limestone reservoirs. Energy Fuels 29(12), 7781–7792 (2015).

Peppler, R. B. & Wells, L. S. The system of lime, alumina, and water from 50 to 250 C. J. Res. Natl. Bureau Stand. 52(2), 75 (1954).

Sanna, A. & Maroto-Valer, M. M. CO2 sequestration using a novel Na-salts pH swing mineral carbonation process. Energy Procedia 63, 5897–5903 (2014).

Azimi, G., Papangelakis, V. & Dutrizac, J. Modelling of calcium sulphate solubility in concentrated multi-component sulphate solutions. Fluid Phase Equilib. 260(2), 300–315 (2007).

Rousseau, R. & Yin, M. Inhibition of contact nucleation and growth of secondary nuclei in solutions of mixed solutes. Ind. Crystal. 81, 71–77 (1982).

Rousseau, R. & Woo, R. Effects of Operating Variables on Potassium Alum Crystal Size Distribution (1980).

Budz, J., Karpiński, P. & Nuruć, Z. Effect of temperature on crystallization and dissolution processes in a fluidized bed. AIChE J. 31(2), 259–268 (1985).

Amjad, Z. & Demadis, K. D. Water-Formed Deposits: Fundamentals and Mitigation Strategies (Elsevier, 2022).

Schierholtz, O. The crystallization of calcium sulphate dihydrate. Can. J. Chem. 36(7), 1057–1063 (1958).

Austin, A. et al. Precipitation of calcium sulfate from sea water at high temperatures. Desalination 16(3), 331–344 (1975).

Azizi, J. et al. Archive of SID petroleum engineering. Iran. J. Oil Gas Sci. Technol. 7(3), 18–31 (2018).

Sohal, M. A., Thyne, G. & Søgaard, E. G. Review of recovery mechanisms of ionically modified waterflood in carbonate reservoirs. Energy Fuels 30(3), 1904–1914 (2016).

Piñerez Torrijos, I. D. et al. Experimental study of the response time of the low-salinity enhanced oil recovery effect during secondary and tertiary low-salinity waterflooding. Energy Fuels 30(6), 4733–4739 (2016).

Ayirala, S. & Yousef, A. Injection water chemistry requirement guidelines for IOR/EOR. In SPE Improved Oil Recovery Conference? (SPE, 2014).

Yang, J., Dong, Z. & Lin, M. The impact of brine composition and salinity on the wettability of sandstone. Pet. Sci. Technol. 33(4), 430–436 (2015).

Peters, E. & Cavalero, S. The fractal nature of viscous fingering in porous media. In SPE Annual Technical Conference and Exhibition (OnePetro, 1990).

Ni, W., Hornof, V. & Neale, G. Radial fingering in a porous medium. Revue de l’Institut français du pétrole 41(2), 217–228 (1986).

Sun, W. et al. Characterization of water injection in low permeable rock using sandstone micro-model. In SPE Western Regional Meeting (SPE, 2004).

Emadi, A. & Sohrabi, M. Visual investigation of low salinity waterflooding. In International Symposium of the Society of Core Analysts (2012).

Mohammadi, S. et al. On the control of glass micro-model characteristics developed by laser technology. Energy Sources Part A 35(3), 193–201 (2013).

Thipse, S. S., Schoenitz, M. & Dreizin, E. L. Morphology and composition of the fly ash particles produced in incineration of municipal solid waste. Fuel Process. Technol. 75(3), 173–184 (2002).

Vassilev, S. V. & Vassileva, C. G. Methods for characterization of composition of fly ashes from coal-fired power stations: A critical overview. Energy Fuels 19(3), 1084–1098 (2005).

Kutchko, B. G. & Kim, A. G. Fly ash characterization by SEM–EDS. Fuel 85(17–18), 2537–2544 (2006).

Ermrich, M. & Opper, D. XRD for the analyst. In Getting Acquainted with the Principles, 2nd edn (Panalytical Co, 2013).

Abdi, A. et al. Smart water injection. In Chemical Methods 313–356 (Elsevier, Berlin, 2022).

Chong, T. & Sheikholeslami, R. Thermodynamics and kinetics for mixed calcium carbonate and calcium sulfate precipitation. Chem. Eng. Sci. 56(18), 5391–5400 (2001).

Gullikstad, J. S. A review of experimental solubilities and a general correlation between the temperature-dependent solubility and solute and solvent molar masses for binary n-alkane mixtures. arXiv e-prints. arXiv: 1807.08514 (2018).

Author information

Authors and Affiliations

Contributions

Ghazal Amiri wrote the main manuscript and did the investigations. Hamidreza Jahangiri was the supervisor.All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Amiri, G., Jahangiri, H.R. & Jalalpoor, M. Evaluating water injection compatibility and scale-formation reduction in a middle east reservoir using direct pore-scale visualization and NaOH treatment. Sci Rep 15, 12925 (2025). https://doi.org/10.1038/s41598-024-80965-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-80965-3

Keywords

This article is cited by

-

Influence of inorganic scale formation on asphaltene behavior during water injection

Scientific Reports (2025)