Abstract

The increasing demand for cement has substantially affected the environment, and its manufacturing requires substantial energy usage. However, most countries in the world recently encountered a significant energy problem. So, researchers are exploring the use of agricultural and industrial waste resources with cementitious characteristics to minimize cement manufacturing, cut energy consumption, and contribute to environmental protection. Therefore, this research is performed on roller compacted concrete (RCC) reinforced with 5%, 10%, 15%, and 20% of corn cob ash (CCA) as substitution material with different percentage of cement and 0.25%, 0.50%, 0.75%, and 1% of jute fibre (JF) together for determining the mechanical properties and embodied carbon (EC) by applying response surface methodology (RSM) modelling. The cubical samples were prepared to achieve the targeted strength about 30 MPa at 28 days and then obtained mix proportions were employed for all combinations at various water-cement ratios to maintain roller-compacted concrete’s zero slump. Results showed that at 0.50% JF and 10% CCA, the flexural strength, splitting tensile strength and compressive strengths, and modulus of elasticity of RCC obtained were 5.3 MPa, 3.8 MPa, 32.88 MPa, and 33.11 GPa at 28 days, respectively. Besides, the embodied carbon of RCC is recoded reducing with combined addition of different levels of JF and CCA as compared to control mixture. In addition, the generation of response prediction algorithms was performed using analysis of variance (ANOVA) at a threshold of significance of 95%. The coefficient of determination (R2) readings for the statistical models ranged from 96 to 99%. It is observed that the use of 0.50% of JF along with 10% of CCA as cementitious constituent in RCC provides best outcomes. Therefore, this method is a superior choice for the construction industry.

Similar content being viewed by others

Introduction

For the construction of Pavement, roller compacted concrete (RCC) is mostly used1,2,3,4. RCC is a form of concrete, which is economical, sustainable and unreinforced5. RCC is prepared using aggregates, sand, water and cement. These materials are thoroughly mixed for obtaining the homogeneous zero slump mixture6. The compaction was done in two steps, first compaction carried out using a vibrating steel drum roller, and then compaction is done using rubber tire roller. using a roller to compact using rubber tires7,8. The RCC pavements can be constructed without joints, steel rods, formwork and dowels9,10,11. RCC pavements contain specific features, because of these specific features RCC pavements becomes alternatives for roads, railways, ports, harbours, docks, military sites, warehouses and parking spaces. Environmental aspects and energy demand have driven investigators to look for sustainable enhancement solutions over the past ten years. However cement industry is one the polluted industry12,13. Portland cement (PC) in important constituents of concrete and 5–7% of carbon dioxide (CO2) released during production of PC14. However, the CO2 emissions cause increase of temperature, which cause global warming and climate change15. At present environmental impact becomes favourite topic for researchers in construction industry16. Keeping in mind the innovative materials were used having increased strength, reduced CO2 emissions, large service life, light weight structure17,18,19,20.

There are various technologies to decrease CO2 releases in cement sector, the most operative technology to decrease CO2 emissions is to reduce quantity of clinker used in cement industry. Clinker can be reduced by adding small amount of auxiliary binder21,22. For CO2 reduction constituents used in construction industry are silica fume23,24, PVC waste powder25,26, wheat straw ash27,28, metakaolin29. Agricultural wastes produced daily in huge quantities create landfill and environmental problems30. Agro-industrials ashes possess large quantity of amorphous silica. Agro-industrial ashes are useful for production of pozzolanic as substitution for PC which is utilized in RCC31,32,33. The use of innovative materials and natural aggregates as a substitute for PC is necessary. Therefore, Corn Cob ash (CCA) was used as substitution for PC in RCC, and it reduces detrimental distresses. Besides, Corn cob is an agricultural waste product and round about 50 million tons per year of Corn Cob was generated in United States and other countries and it was incinerated into corn cob ash (CCA)34,35. By use of CCA for RCC mixture waste is handled effectively and it serves as alternative source for RCC mixtures. Moreover, ash has lower value in terms of economy and landfilling of ash cause environmental pollution. But ash can become beneficial, if it is utilized for construction purpose. In addition, C-S-H is produced by the reaction of silica component present in pozzolana with free lime throughout PC hydration36 and the hardened properties of concrete enhanced with C-S-H production. Lot of research carryout out on blending of CCA for PC replacement in concrete. Desai37 suggested that replacement of 10% of CCA as PC could increase flexural strength, splitting tensile strength and compressive strength by 5.92%, 5.67% and 5.90% respectively at 90 days. Adesanya and Raheem38 suggested that as the quantity of CCA increase in concrete, the workability declined. Adesanya and Raheem39 used concrete 1:1.5:3 mix proportion of concrete combined with CCA as substitution for PC and suggested that addition of 15% of CCA as replacement of PC in concrete can cause reduction in weight loss, permeability and water absorption. Owolabi40 suggested that flow of green concrete decrease with rise of CCA in mixture. Further author suggested 5% of PC replaced with CCA has crushing strength after 28 days is 21.44 MPa and 5% of PC replaced with CCA was considered best. Although the resulting ash has a higher concentration of silica and a finer texture compared to PC, CCA is considered a promising supplementary cementing ingredient for improving the strength of hardened concrete35. However, a major limitation of concrete is its weakness when subjected to tensile stress41.

In order to overcome these deficiencies, many types of fibre, including polypropylene fiber42, human hair fiber43, sugarcane bagasse fiber44, polyvinyl alcohol, basalt, steel, nylon, jute, hemp, and coir fiber, are used into concrete mixes45,46,47,48,49,50. In this study, a volume percentage of jute fibre (JF) is included in the RCC. Despite this, the incorporation of JF in concrete composites was thought to be a viable replacement due to their wide availability and affordability as JF is made from annual plants51. These objects made-up of pentagonal or a hexagonal cross as their prominent design, making them an excellent choice for outdoor use due to their UV radiation protection, shielding, and antibacterial qualities52. Jute textiles are excellent choices for reinforcement in laminated and bionic composites due to their enhanced mechanical properties. Jute fabrics can be used for various purposes.

The jute fabric-reinforced composites having low cost and qualify the industrial material criteria with special structure53. Furthermore, Jute is environment friendly, available in huge quantity and biodegradable in nature, Jute possesses high inherent mechanical properties, Jute possesses tensile strength of 250 to 300 MPa. Due to high strength JF is applicable for extensive use in construction sector54. Jute has density 7 times less than steel fibre density54. Lot of research performed to explore the capability and impact properties of Composite of cement, particular attention given on extended, uninterpreted and isolated jute fibres. Addition of JF into concrete results increased composite durability, increase capability to resist external forces, increased ability to resist cracking. Numerous research shows that in concrete jute fibre substituted instead of conventional fibres55. The natural fibre-reinforced concrete (NFRC) properties were affected by parameters such as amount, type and quality of fibre. The infill that is used in composite and hydrophilic properties of fibre also affect NFRC properties. Composites with proper functioning and optimum performance can be achieved by maintaining optimal conditions and suitable proportional of fibre content. As discussed above fibre content has high impact on NFRC characteristics. Countless researchers suggesting use of jute fibre instead of steel fibre. Steel fibre cause thermal expansion and corrosion issues54. However, there no research on use of coconut instead of JF. JF is biodegradable in nature, hence alkalinity, moisture and microorganisms related changes found in concrete within the passage of time. Degradation process can decrease the rigidity and tensile strength and structure of JF. Presence of cement means there is presence of alkalinity in concrete. JF has such structure that it can protect concrete from alkaline environment. Regarding the environmental evaluation of jute fibre, there are several steps involved in its growth and processing, including preparation of the soil, planting, harvesting, retting, and fibre extraction. The utilization of energy sources, transportation, and processing techniques, as well as farming practices, all affect the carbon footprint of the production of jute fibre. JF is environmental fibre, can grow in a variety of climates does not considerable irrigation, requires little number of pesticides. For determining the carbon footprint, the embodied carbon factor can be used as found in the literature. Jawad et al.54 suggested that the incorporation of Jute Fiber can cause greater fibrous surface area, decreased fluidity and elevated abrasiveness in the concrete. Further suggested that accumulation of 2% JF in the concrete provide maximum mechanical strength, FS, STS and CS of the concrete. Addition of 2% of JF in concrete is considered as threshold limit. Above 2% of JF addition can cause degradation of mechanical properties. JF improve concrete’s durability properties, particularly in terms of drying shrinkage, water absorption, density and endurance to acidic conditions.

Furthermore, adopting response surface methodology (RSM) as an optimisation tool56,57,58 to examine the properties of RCC offers distinct advantages over other techniques. Relative to techniques such as the Taguchi approach, RSM demonstrates greater efficiency by yielding valuable findings with a reduced number of experimental trials. This optimizes the investigative process and conserves resources. Moreover, RSM’s flexibility in modelling facilitates the depiction of complicated, non-linear relationships between input factors and output responses, which is crucial for understanding the complex characteristics of concrete59,60. Moreover, RSM’s focus on particular optimisation allows accurate adjustments towards optimal solutions, particularly beneficial in concrete investigations where little alterations may significantly influence outcomes. The interpretability of RSM algorithms enhances their worth by allowing researchers to figure out the effects of each element and their interactions on particular characteristics61,62. Integrating RSM with meticulously constructed experimental designs allows a systematic exploration of the design space, yielding reliable and applicable results. In conclusion, RSM demonstrates reliability and effectiveness in improving the properties of RCC. It offers a comprehensive strategy that integrates model adaptability, empirical performance, and interpretive proficiency.

Limited research available on analysis of combined effect of JF and CCA on hardened state of RCC. Furthermore, limited research available on environmental impact (embodied carbon) of combined JF and CCA as Cementous materials on RCC. Aim of this work is to evaluate the combined effect of JF and CCA on RCC mechanical properties and environment and to analyse statistically sound models. The purpose of this investigation is to analyse combined effect of JF and CCA on mechanical properties (compressive strength, splitting tensile strength, flexural strength and modulus of elasticity), embodied carbon of roller compacted concrete by using RSM modelling and optimization. This research will help in promoting the practical usage of combined JF and CCA in RCC, and further help to predict the strength of RCC containing JF and CCA with different percentages and statistical equations also used.

Significance of the study

The integration of jute fibre and corn cob ash (CCA) into roller-compacted concrete (RCC) mixes provides substantial benefits for practical infrastructure applications by improving sustainability and performance. CCA, sourced from agricultural waste, offers a sustainable, renewable substitute for a fraction of the cement content, hence decreasing cement use and mitigating CO₂ emissions linked to cement manufacturing. This material, when included in RCC, facilitates waste utilization and engages in pozzolanic reactions, generating supplementary calcium silicate hydrate (C-S-H), which enhances the concrete matrix over time, thereby augmenting its durability and compressive strength. Jute fiber enhances the tensile and flexural strengths of RCC by bridging microcracks, improving crack resistance, and providing a natural, biodegradable alternative to synthetic fibers. CCA and jute fiber together provide resilience to shrinkage and cracking, which is essential for structures designed to endure substantial loads and fluctuating weather conditions. Moreover, jute fibers provide a certain level of thermal insulation, assisting in the reduction of thermal cracking in regions with significant temperature fluctuations. The use of inexpensive, locally sourced components such as jute and CCA makes RCC mixes a more economical option for extensive projects, especially in regions where cement is expensive or requires importation. The combination of qualities renders RCC with jute and CCA suitable for applications like low-traffic pavements, highways, and embankment dams, where durability, stability, and little maintenance are critical. The integration of jute fiber and CCA in RCC is a sustainable and efficient approach for infrastructure that demands durability, cost-effectiveness, and sustainable practices.

Materials and methods

Materials

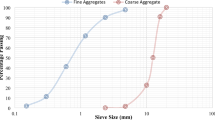

The corn cob was collected, and then burned for five hours at controlled temperature in order to create corn cob ash (CCA). The obtained ash was passed from a 75 μm mesh to remove bulky particles, and utilized as a substitute for cement in RCC. As a binding agent, Portland Cement (PC) was added to the RCC mixture. The oxide compositions of PC, and CCA are revealed in Table 1. However, Jute Fiber (JF) is a natural fibre widely available in tropical areas. JF possess high tensile strength, available in large quantity with reasonable price. JF range in length from 10 to 20 mm and have a 0.10 mm diameter. Additionally, crushed stone was applied as coarse aggregates (CA) with a 20 mm size, and hill sand was served as fine aggregates (FA) and it sieved from a #4 mesh. Table 2 mentioned the aggregates’ physical properties. The aggregate’s bulk density was determined by using ASTM C29-9763 and the sieve analysis of fine and coarse aggregates was carried out using ASTM C13664. By using ASTM C127-9365 and C128-9366 the water absorption and specific gravity of fine and coarse aggregates were determined, correspondingly. Additionally, the mixing and curing processes were done using tap water.

Mix proportions generated by RSM Modelling

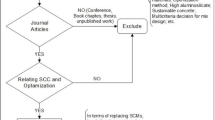

This research methodology adopted on RCC combined with different percentage as 0%, 5%, 10%, 15% and 20% of CCA as replacement for PC and 0%, 0.25%, 0.50%, 0.75%, and 1.0% of jute fiber together, as input parameters by apply RSM modelling. In result, sixteenth different mixtures were prepared for making RCC. One mixture was prepared from PC only for making the RCC, which is called the control mixture, which establishes a baseline for comparing the modified mixtures, and the rest mixtures were prepared with the addition of 5–20% of CCA as a replacement for PC and 0.25–1.0% of JF together in the RCC. Various concrete mixture trials were conducted to produce the desired strength of 30 MPa at 28 days. When targeted strength of RCC achieved, the concrete samples like prisms, cylinders and cubes were cast for determining the flexural, tensile and compressive strength of RCC. Moreover, the cylindrical samples (300 mm x 150 mm) were cast for determining the modulus of elasticity of RCC. The slump value of all combinations was maintained at zero by adjusting the w/c ratio correspondingly. Details of all prepared mixtures were specified in Table 3. Furthermore, the flow chart for this study as shown in Fig. 1.

Measuring techniques

Slump test

It was conducted in order to assess the workability of the freshly prepared materials of RCC addition with several concentration of CCA as SCM and JF in the construction industry or at laboratory scale using BS EN 2350-2 standard67. This test was performed through slump cone apparatus. The slump was kept zero for all mixtures.

Mechanical characteristics

Cubical samples (100 mm x 100 mm x 100 mm) of RCC accumulated using different ratios of combined CCA as SCM and JF for compressive strength analysis of RCC using BS EN 12390-3 standard68 after 28 days. Compressive strength (CS) is a crucial factor to consider during construction of buildings. It is tested on hardened concrete for determining the material’s capacity to resist loads. Engineers frequently evaluate the performance of emerging constructions using the compressive strength of concrete. Similarly, the cylinders (200 mm x 100 mm) were utilized for checking tensile strength of RCC containing CCA as SCM and JF using the standard BS EN 12390-669 after 28 days. This is indirect method of tensile strength measurement. In this method, a specimen is taken length wise. The axial direction force is applied on the surface of cylinder. A vertical fracture will be observed across its diameter. The flexural strength of RCC samples combined with CCA as SCM as JF (500 mm x 100 mm x 100 mm) was conducted prism using standard BS EN 12390-570 after 28 days. Flexural strength determines the amount of load necessary to bend a beam by applying circumstances of three-point loading. The modulus of elasticity of RCC combined with CCA as SCM and JF using the standard BS EN 1992-1-1:2004 after 28 days. Moreover, these all testing were performed on UTM.

Results and discussions

Compressive strength (CS)

Figure 2 displays CS of mixture with 0.25-1% of JF as reinforcement ingredient and 5–20% of CCA as SCM in RCC after 28 days. However, the maximum CS obtained was 39.42 MPa at composition of 0.50% of JF and 10% of CCA and the minimum CS obtained was 21.60 MPa at composition of 1% of jute and 20% of CCA as PC substitutions in RCC after 28 days. Besides, the optimum CS was obtained using 0.50% of JF and 10% of CCA in RCC. This increase in CS is brought on by the JF-associating influence, which prevents transverse deformation from increasing CS71. In addition, high JF accumulation creates voids in concrete, due to which CS reduced72. On the other hand, the outcome was showed that the CS was increased while utilizing JF equal to 0.50% as reinforced components and then fall because of enlarged quantity of voids created by JF addition, which was greater than the maximum level as voids led to non-uniform attachment within the matrix. The same trend showed by Zarakia et al.51. Islam and Ahmed73 stated that there was reduction in CS by use of more than 0.50% of JF as reinforcement ingredient in concrete. Moreover, it was worth noting that addition of 10% of CCA in RCC results cause enhancement in CS, there voids are not so increased, voids are helpful for potential pozzolanic reaction of the CCA. Further CCA addition cause reduction in CS because of effect of dilution of the CCA that results lowering the percentage of calcium hydroxide available for product development. Namdeo and Vidisha74 and Bajad, Modhera and Desai75 suggested the similar kind of investigations. Keerio et al.76 was indicated that after 28 days, the CS was increased when 30% of glass powder added as sand alternative.

Figure 3a,b describes the 2D and 3D surface response plots of combined CCA as SCM and JF in RCC mixtures with various concentrations. The linkage between the input factors and the output properties especially CS are depicted in these diagrams. High compressive strength zones are indicated by the red regions. Regions showing moderate and low compressive strengths are represented by the green and blue patches, respectively. The area bounded by the graph axes and the 35 MPa contour line experienced the strongest reaction.

Splitting tensile strength (STS)

Figure 4 showed that the STS of RCC with addition of (0.25 − 1%) JF and (5 − 20%) of CCA as cement ingredient replacement for 28 days. However, the maximum STS obtained was 3.50 MPa at 0.50% of JF and 10% of CCA while the minimum STS obtained was 2.40 MPa by addition of 1% of JF and 20% of CCA as cement ingredient replacement 28 days. Besides, the optimum STS was obtained using 0.50% of JF and 10% of CCA in RCC. It was extracted that the STS was increased while utilizing 0.5% of JF as reinforced components. Further addition of JF cause large voids. Enlarged voids cause led to non-uniform attachment within the matrix. Additionally, JF can stop the growth of microcracks and finally increase the mixture’s STS. Islam and Ahmed73 suggested same pattern that using JF as a reinforcement material in concrete above 0.50% decreased the STS. It was important to note that 10% addition of CCA improves STS because the specific surface area of CCA is higher than that of other concrete components, further adding more CCA causes a drop in STS. This statement is matched with Bheel et al.77, who claimed that increasing the percentage of metakaolin and GGBFS in concrete up to 10% increase the STS of the material. This similar trend research was suggested by Bheel et al.34. Additionally, as shown in Fig. 5, there is a favourable correlation between the accumulating CS and STS of RCC with combined CCA and JF. While one of their properties is supplied, the equation in Fig. 5 can be applied to compute the CS or STS of RCC.

Figure 6a,b are contour and 3D response surface diagrams, respectively, illustrating the behavior of the RCC when subjected to different amounts of CCA and JF together. The following graph illustrates the correlation between many factors that influence STS.

Flexural strength (FS)

Figure 7 showed that concrete’s flexural strength with addition of (0.25 − 1%) of JF and (5 − 20%) of CCA as PC ingredient substitutions in RCC at 28 days. The maximum FS obtained was 5.60 MPa at 0.50% of JF and 10% of CCA and the minimum FS obtained was 3.07 MPa at 1% of JF and 20% of CCA as PC ingredient substitutions in RCC at 28 days correspondingly. Moreover, the optimum FS was obtained at combined use of 0.50% of JF and 10% of CCA in RCC. This concept was associated with the research of Bheel et al.77 that the maximum FS was obtained by the addition of 10% of metakaolin and 10% of GGBFS in concrete. The outcome showed that maximum FS was obtained 0.50% of JF as reinforced components and further addition of JF strength fall due to enlarge quantity of voids generated by JF addition in concrete. Islam and Ahmed73 suggested same pattern that using JF as a reinforcement material in concrete above 0.50% decreased the FS. It was important to note that 10% addition of CCA improves FS due to presence of iron oxide, aluminium oxide and silica in WSA in huge quantity, further adding more CCA causes a drop in FS due to slow pozzolanic reaction. Dayo et al.78 also suggest same trend that the strength was increased with addition of 10% of sugarcane bagasse ash as sand substitute in concrete after 28 days. This aspect is similar to Bheel et al.79.

Figure 8 describe the connection between the CS and FS of RCC with combined addition of various contents of JF and CCA. In addition, Fig. 8 showed the equation that has link with FS and CS. This equation can be used to determine the FS or CS of RCC by determining one of these parameters. Furthermore, Fig. 9 showed the correlations between the FS and STS of RCC with combined addition of JF and CCA as SCM at different levels. The equation shown in Fig. 9 used to calculate STS or FS of RCC by using one of its parameters.

Figure 10 (a), 10 (b) shows the contour and 3D surface response diagrams respectively showing the influence of JF and CCA as SCM on flexural strength. The red portions of the graph showed high flexural strength in lower input values. As the CCA content rises above 14% and JF content rises above 0.70%, the flexural strength decreased, there is transition of green zone to blue zone shows that intermediate FS reduced to lowest FS. To make RCC of optimum FS, it is emphasized to substitute 14% of PC CCA and 0.70% of JF in concrete as replacement of PC as substitution rate of upper limit.

Modulus of elasticity (ME)

Figure 11 showed that the ME of concrete with addition of (0.25 − 1%) JF and (5 − 20%) of CCA as SCM after 28 days. Maximum modulus of elasticity obtained was 33.11 GPa mm at 0.50% of JF and 0% of CCA. Minimum modulus of elasticity obtained was 18.14 GPa at 1% of JF and a20% of CCA as SCM after 28 days. It was resulted that maximum designated that the modulus of elasticity was obtained by combined utilization of 0.5% of JF and 10% of in RCC. The concept was related with Bheel et al.50 that ME was enhanced with increase of coconut shell ash as replacement for PC in concrete. The maximum ME was obtained at addition of 0.5% of JF as reinforced component in concrete, the concrete form harder as compared with plain concrete. Bheel et al.50 suggest similar research that the ME is increased with increasing the expansion of human hair fiber after 90 days. The enhanced ME is a result of CCA’s finer particle size compared to cement, which fills in any remaining pores and expands the inter-transition zone of concrete, making it stiffer overall. The enhanced ME is a result of CCA’s finer particle size compared to cement, which fills in any remaining pores and expands the inter-transition zone of concrete, making it stiffer overall. Sujatha et al.80, suggested that the stronger interface bond between the aggregate matrix and binder is related to the improvement in ME. It has been claimed that an increase in interfacial bond can improve concrete’s ME81,82,83. After 10% CCA is added as SCM, the ME reduces owing to the buildup of a high CCA content, creating a hard mix. Concrete with a higher CCA as SCM content absorbs more water, resulting hard mixture. Due to a limited water availability as the CCA amount as SCM in concrete enhanced, causing concrete to segregate. ME of RCC is decreased by the segregation of concrete. This characteristic was associated by Foong et al.81 that concrete’s ME increased using 15% of rice husk ash as material for cement after 28 days. Figure 12 describe the correlations between the ME and CS of RCC with combination of different level of JF and CCA. In addition, the equation developed in Fig. 12 is used for determining the relation between ME and CS by recognizing one of the parameters.

Figure 13a,b showed the 2-D contour and 3-D response surface graphs for checking behaviour of the RCC with combined addition of different levels of JF and CCA. Graphs show effect of different variables on ME.

Environmental impact assessment of RCC

Embodied carbon (EC)

All construction materials possess an ecological footprint, shown in the emission of greenhouse gases into the surrounding environment91. The procurement of materials for construction entails multiple processes, including extraction, delivery, production, and installation. The substantial reliance on energy sources that are not renewable throughout these processes contributes to the release of greenhouse gases associated with building projects. Embodied carbon refers to the greenhouse gas emissions associated with materials prior to their actual use in building activities. The energy consumption varies per material; nevertheless, throughout industrial production processes, it consistently remains high for each kilogram produced92,93,94. The computation of embodied carbon is predicated on the emission of carbon dioxide per kilogram of material generated, including both industrial operations and all activities related to the extraction and transportation of the material to the building site. Equation 1 is used to compute the embodied carbon of the substance. The primary focus for enhancing sustainability is lowering the amount of embodied carbon; hence, materials with little environmental impact are preferred for building activities95,96. Table 4 clearly indicates that PC has the largest embodied carbon, measuring 0.93 kg of carbon dioxide per kilogram. Alternative materials provide a much-reduced carbon footprint per kilogram, making them more environmentally appropriate than cement. According to conventional values, water exhibits zero kilograms of carbon dioxide emissions due to its ubiquitous presence in the environment and the absence of any processes required for its use in building activities. It is evident that CCA has a minimal embodied carbon value of 0.002, markedly lower than that of cement, suggesting environmental sustainability if CCA is used in RCC with the efficient reduction of cement. Moreover, the CO2 equivalent values for all ingredients used in RCC are mentioned in Table 4. These statistics show the values associated with the production, manufacturing, processing, delivery, and blending processes. Additionally, by calculating the production of CO2 of each raw material per 1 m3 of concrete, the total CO2 emissions of each concrete mixture were determined and then CO2 emissions used in each ingredient were added using Eq. (1)84.

where, \(\:{CO}_{2}\) is total embodied \(\:{CO}_{2}\) of 1 m3 concrete, in kg \(\:{CO}_{2}\)/m3

n is total raw materials in mix,

\(\:{W}_{i}\) is total amount in kilogram of material

i to produces 1 m3 concretes.

\(\:{\:CO}_{2i-e}\)is equivalent \(\:{CO}_{2}\) value of material i in kg \(\:{CO}_{2}\)/kg

Figure 14 shows the EC of RCC combined with CCA as SCM along with JF. However, PC emitted the high embodied carbon as compared to the other elements of RCC as shown in Table 4. The EC in the control specimen is markedly elevated due to its 100% cement composition, devoid of any additional materials. Conversely, the EC of RCC diminishes as the combined amount of CCA and JF increases, as seen in Fig. 14. This reduction in EC is because the cement content has been reduced by 5–20% and is being replaced by CCA in RCC, which ultimately results in reducing the overall embodied carbon of RCC. Figure 14 shows that the EC of RCC is recorded lower with the addition of 5%, 10%, 15%, and 20% of CCA as PC substitute with 0.25–1.0% of JF in RCC as compared to CM. It was shown that an addition of substitutes, minimizes the embodied carbon. Furthermore, the embodied carbon produced from combined 20% CCA and 0.25–1.0% of JF was less than that of CM. The literature87,88,89,15 revealed that by increasing the quantities of binding components as substitute elements in concrete mixtures, embodied carbon levels in concrete can be reduced.

Eco-strength efficiency (ESE)

The concretes ESE was obtained by combination of JF and CCA as SCM in RCC was evaluated using Eq. (2)90. Maximum ESE obtained was 0.114 MPa/kg\(\:{\text{C}\text{O}}_{2}\)/m3 from concrete made from combination of 0.5% of JF and 10% of CCA as SCM. The minimum ESE obtained was 0.068 MPa/kg\(\:{\text{C}\text{O}}_{2}\)/m3 for 20% of concrete made from combination of 1% of JF and 20% of CCA as SCM as shown in Fig. 15. The ESE and strength of concrete follows the same pattern, i.e., both were increase by addition of 10% of CCA as a PC substitution and 0.50% of JF in RCC and further addition of JF and CCA can decrease the ESE and strength. Researchers have discovered that adding SCM and JF decreases the ESE of concrete while replacing 10% of the PC with CCA and 0.5% addition of JF increases ESE. This effect occurs due to high compressive strength and lowest embodied carbon as compared with other combined concretes. Bheel et al.,90,91 suggested that ESE increases when PC in concrete, is developed using 10% of MHA, MK, CBA and SCBA; it decreases further when SCM is added lonely or SCM is added with TCM .

Cost benefit analysis

To assess the viability of CCA as SCMs, its impact on the total cost of concrete must be determined. Although almost all SCMs are waste products available at no cost, the expenses associated with their collection and transportation to the testing facilities where concrete is produced must be included in a comprehensive cost-benefit analysis of employing of the SCMs. Likewise, CCA was gathered, transported from various sources, and subjected to distinct drying, crushing, and sieving procedures. The cost of using 1 kWh is around $0.12, whereas the price of fuel is $0.55 per litre. Additionally, Table 5 displays the local pricing obtained from local suppliers of the various items employed in this study. The overall expense of each concrete mixture was ascertained by computing the cost of each raw material per cubic meter of concrete and then aggregating the price of the various ingredients used in concrete manufacturing, as outlined in Eq. (3)92:

Here,

\(\:{\text{W}}_{\text{i}}\) is total amount of each material in kg i to produce 1 m3 RCC.

n is the number of materials.

\(\:{\text{C}\text{o}\text{s}\text{t}}_{2\text{i}-\text{x}}\) is the cost of materials i, in $/kg.

The widespread acceptability of any substance depends upon its comparative cost. In some locations, cement may be an expensive construction material. The waste components that are commonly used as SCMs are generally available at minimal or no cost. Consequently, they would be advantageous for the partial replacement of PC components in RCC manufacture. Though many of these components are readily available, their preparation and transportation from origin to laboratory or mixing location may incur costs. Consequently, these prices must be assessed and articulated to highlight a distinct disparity in the total expense of the RCC.

Although corn cobs are readily accessible, the preparation of ash entails many procedures, including gathering, grinding, and screening, which incur associated costs. The unit cost of CCA is computed by factoring in power consumption and transportation expenses. Table 5 presents the local unit pricing of materials used in the manufacturing of RCC. The total cost to make 1 m3 of RCC, integrating various percentages of CCA and JF contents, was computed using Eq. (3) and is shown in Fig. 16. Figure 16 indicates that the total cost of control concrete is $ 48.33 per cubic meter of concrete mix. The use of 5%, 10%, 15%, and 20% CCA reduced the overall cost of 1 m3 of RCC by $0.98, $2.15, $3.32, and $4.49 at 0.25% of JF. Similar pattern follows by 0.5%, 0.75%, and 1% of JF along with 5–20% of CCA. It has been observed that the use of CCA increases in RCC that results in reducing the overall cost of RCC, whereas the addition of JF in RCC causes an enhancement in the cost of RCC, but all mixtures of RCC containing CCA and JF provide less cost as compared to the control mixture. This cost reduction of RCC is owing to the lower cost of CCA (0.028 $/kg) as compared to PC (0.096$/kg). Moreover, the use of CCA increases in RCC that results in reducing the overall cost of construction project.

Response surface methodology modelling

Analysis of variance (ANOVA)

Response surface models constructed using RSM. Response surface models evaluated using variance analysis (ANOVA). The RSM modelling and optimization was taken of hardened RCC mixtures with 0 to 1% of JF and 0 to 20% of CCA as PC replacement. Furthermore, quadratic models were considered more suitable for Splitting tensile strength, modules of elasticity, compressive strength and flexural strength. Response of each strength was coded in Eqs. (4)–(7). These Equations can be used to forecast by altering the effecting parameters values. By default, the maximum and minimum values of the components are + 1 and − 1 respectively. Relative response of variables can be estimated utilizing the factor coefficients in coded equations. The input variables of WSA and JF are A and B. The ANOVA’s outcomes are given in Table 6.

Model’s validity can be checked using coefficient of determination (R2). R2 determines at what level model match with the facts. R2 ranges from 0 to 100%. As R2 value reaches near to 100%, more model matches the observation. In the given research, the R2 values for CS was 99.13%, STS was 97% and ME and FS were 99% as given in Table 7 for the validation of model. When there is high coefficient of accuracy, it shows that the model matches the facts quiet well. These results suggest that the models are capable and may be used to predict responses with accuracy.

Where, ME, FS, STS and CS are modulus of elasticity, flexural strength, splitting tensile strength and compressive strength respectively.

Furthermore, the models can be considered to fit the observations if difference between the adjusted R2 and predicted R2 is less than 0.2. As shown in Table 7, the gap between adjusted R2 and predicted R2 values was less than 0.2 for each model. Additionally, the acceptable precision value (Adeq. Precision), which must be larger than 4, is used to determine the signal-to-noise ratio. In present research Adeq. Precision values; CS was 35.34, FS was 35.34, STS was 19.97 and ME was 35. These figures show a strong signal and reliable models that might be used to investigate the design space. Figure 17 illustrates actual vs. predicted diagrams used for model inspections for the CS, STS, FS and ME. The linearity of the data points surrounding the line of best fit demonstrated the reliability of the projections in each case when calculating the outcomes. For the diagrams comparing actual vs. predicted results shows how closely the expected and actual responses aligned is shown by the placement of the points on the fitted line. In a similar manner, linear distribution of variables in the best fit lines shows that models were ever best with normal spread of standard errors93.

Assumptions behind the statical models

A comprehensive examination of the assumptions behind the statistical models applied to the RSM technique would enhance the rigor of the research investigation. In implementing RSM, measures were taken to verify essential assumptions to guarantee that the model yielded reliable and accurate outcomes. In particular:

-

The Shapiro-Wilk test was used to assess the normality of residuals, revealing that they conformed to a normal distribution, a crucial requirement for the validity of regression models.

-

The Levene’s test is used to verify the consistency of error variance across measurements. This test confirmed that the assumption of homogeneity of variances was valid, thereby reinforcing the model’s predictive accuracy stability.

-

This analysis examined residual plots to identify patterns suggesting correlation, thereby proving the independence of errors.

-

The linear connection between predictors and responses was evaluated by plotting actual against predicted values, indicating a linear trend appropriate for RSM.

These evaluations facilitated the assurance of the RSM model’s robustness and reliability while also enhancing model validity.

Optimization

Building response models and using RSM provide one challenge is determining most appropriate values for each parameter that is used to produce the intended outcome. As a result, the model’s independent variable was optimized. The set of objectives for parameters and their relative contribution are objective functions in optimization. Same method was used by83,94,95,96,97 to obtain best fit values within the range of 0 to 1. As the desired values approaches one, the response objective function produces good results and the results that have been optimized become more appropriate in choosing the dependent variable. Table 8 describes the input and output factors for enhancing independent variables. It was shown that optimization objectives for dependent variables can change. To increase responses for CS, STS, FS and ME is objective of optimization. In order to find the best solution, the central functions are fed into the optimization system.

Figure 18 describes the optimization’s solution ramp. The results from optimization were maximum CS, STS, FS and ME values of 39.71 MPa, 3.47 MPa, 5.64 MPa, and 33.36 GPa, respectively. As seen in Fig. 19, the 99.30% desirability, based on the model’s variance and response strategy in the findings, implies highly relevant results. The results of the optimization process were as expected results.

Conclusions

The experimental assessment suggest that combine use of CCA as SCM and JF in RCC production delivers the finest outcomes for construction industry. The following are the conclusions of this research:

-

The maximum FS, STS, and CS obtained was 5.60 MPa, 3.50 MPa and 39.42 MPa with combined addition of 0.50% of JF and 10% of CCA as PC substitutions in RCC at 28 days respectively. The growth in strength is instigated by the effect of pore-filling of CCA as SCM’s pozzolanic response. Higher JF and SCM contents, especially JF more than 0.5% and SCM more than 15%, cause adverse effects on the strength of cement.

-

The optimum ME of RCC is recorded by 33.11 GPa at 10% of CCA as SCM and 0.50% JF together in RCC, while the lowest ME is noted by 18.14 GPa at 20% of PC replaced with CCA and 1.0% of JF together in RCC after 28 days, respectively.

-

The combined addition of JF and CCA in RCC has reduced the embodied carbon. Instead of that, the PC releases more embodied carbon than JF and CCA. It was concluded that JF and SCM can become suitable for releasing less embodied carbon. JF and SCM are considered environmentally sustainable. \.

-

Maximum eco-strength efficiency was obtained by the combined addition of 0.5% of JF and 10% of CCA as in RCC while minimum eco-strength efficiency was obtained by the combined addition of 1.0% of JF and 20% of CCA as SCM.

-

The use of CCA increases in RCC that results in reducing the overall cost of RCC, whereas the addition of JF in RCC causes an enhancement in the cost of RCC, but all mixtures of RCC containing CCA and JF provide less cost as compared to the control mixture.

-

The RSM modeling assessed by statistical error analysis demonstrates that the models created are accurate and independent variables shows the major contributions. Mechanical properties were produced and evaluated utilizing ANOVA, response surface models. The model has the R2 values for CS, STS, FS and ME were 99.13%, 99%, 97%, and 99%, respectively.

-

The results provide a fundamental comprehension of how agricultural by-products may significantly enhance the sustainability of concrete components while meeting essential demands in construction for more ecologically responsible and economically viable solutions. This paper provides a framework to utilize CCA and JF in RCC, emphasizing their relevance in buildings that need expedited construction, cost reductions, and environmental advantages.

-

From obtained outcomes, it is noted that the use of 10% CCA as SCM along with 0.50% of JF in RCC provided the optimum outcomes therefore, it is suggested for practical application in construction industry.

Future research directions

This study indicates favourable results; nevertheless, more studies are advised to investigate the longevity of CCA and JF-blended RCC, particularly its resistance to weathering, freeze-thaw cycles, and sulphate attacks. Furthermore, the effects of prolonged exposure on the performance of organic fibres such as JF must be meticulously evaluated to guarantee the blend’s structural integrity throughout time. Examining optimization methods for mixed proportions and fiber treatments may improve material performance and uniformity. By focusing on these aspects, further research may enhance this study’s contributions and promote wider use of sustainable RCC mixes within the building sector.

Drawbacks of the study

To address this, consider include a part in the content outlining the possible constraints when utilising jute fibre and corn cob ash in roller-compacted concrete (RCC). Below are a couple of issues you may address:

-

Challenges in workability The use of jute fibres and CCA can reduce the workability of the RCC mixture, thereby complicating the processes of compaction and finishing. This may affect the uniformity and density of the concrete.

-

Durability considerations Although not the primary focus of the present work, it is important to acknowledge that durability factors—such as freeze-thaw resistance, sulphate resistance, and alkali-silica reactivity—have not been assessed in this mix, potentially restricting its application in certain circumstances.

-

Variation in raw ingredients The characteristics of jute fibres and corn cob ash might differ markedly based on their origin and processing methods. This fluctuation may affect the consistency of the RCC’s mechanical and sustainability performance.

-

Scaling limitations The implementation of jute fibre and corn cob ash-blended RCC on a wider scale may encounter logistical and financial obstacles, particularly in areas where these elements are not easily accessible.

Practical applications and benefits of this study for the construction industry

The application of RCC combined with CCA and JF offers a unique potential for the construction sector to achieve sustainability objectives while maintaining performance standards. This paper proposes a method for decreasing the environmental effect and expense of concrete manufacturing by including low-cost, locally sourced agricultural by-products, which is essential as the sector encounters increasing demand to implement sustainable practices.

-

Environmental sustainability The integration of corn cob ash, an agricultural by-product often considered trash, enables partial cement substitution, thus decreasing the carbon footprint of RCC. Cement manufacture is energy-intensive and significantly contributes to CO₂ emissions; thus, replacing it with CCA facilitates waste utilisation and directly advances environmental sustainability efforts. Likewise, utilising JF—an organic, biodegradable substance—strengthens this environmentally friendly strategy. The integration of CCA and JF adheres to the circular economy paradigm, whereby waste products are transformed into useful building resources, hence facilitating waste reduction and resource conservation.

-

Cost-effectiveness and accessibility In addition to sustainability, the economic advantages are substantial. CCA and JF are comparatively cost-effective in relation to conventional building materials. Areas with significant agricultural production, where corn cobs and jute are prevalent, might especially benefit from cost reductions in material procurement and less reliance on imported resources. The decrease in material expenses, along with the established advantages of RCC such as expedited deployment and diminished formwork requirements, presents a persuasive and economical option for extensive infrastructure initiatives, encompassing roadways, pavements, and industrial flooring.

-

Enhanced performance in certain applications The incorporation of JF in RCC may provide enhanced fracture resistance and ductility in certain applications. Although typical RCC has high compressive strength, it tends to be brittle when subjected to tensile stress. The fibrous composition of jute may provide a more uniform fracture distribution, enhancing the material’s durability under certain pressures and potentially prolonging its lifespan in applications with moderate load-bearing demands.

In summary, the incorporation of corncob ash and jute fiber in roller-compacted concrete is a viable, ecological, and cost-effective solution for the building sector. This mixture not only corresponds with the industry’s shift toward sustainable construction methods but also provides a realistic and economical substitute for conventional concrete, especially in areas where these by-products are abundantly accessible. Subsequent studies and standardization could enhance confidence in this combination, facilitating a wider use that benefits both the industry and the environment.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author upon reasonable request.

References

Selvam, M., NSSP, K., Kannan, K. R. & Singh, S. Assessing the effect of different compaction mechanisms on the internal structure of roller compacted concrete. Constr. Build. Mater. https://doi.org/10.1016/j.conbuildmat.2022.130072 (2023).

Seav, N., Kim, K. S., Kim, J. H., Lee, S. W. & Kim, Y. K. Effects of Roller compacted concrete incorporating coal bottom Ash as a fine aggregate replacement. Sustainability. https://doi.org/10.3390/su151411420 (2023).

Selvam, M. & Singh, S. Influence of compaction methods on the optimum moisture content and performance of roller compacted concrete pavements. J. Mater. Civ. Eng. https://doi.org/10.1061/jmcee7.mteng-15680 (2023).

Li, L., Wang, Y., Guan, J., Xie, C. & Khan, M. Normal statistical fracture analysis of Roller-compacted concrete on the basis of non-linear elastic fracture mechanics. Compos. Struct. https://doi.org/10.1016/j.compstruct.2023.117543 (2023).

Mohammed, B. S. & Adamu, M. Mechanical performance of roller compacted concrete pavement containing crumb rubber and nano silica. Constr. Build. Mater. 159, 234–251. https://doi.org/10.1016/j.conbuildmat.2017.10.098 (2018).

Saluja, S., Kaur, K., Goyal, S. & Bhattacharjee, B. Assessing the effect of GGBS content and aggregate characteristics on drying shrinkage of roller compacted concrete. Constr. Build. Mater. 201, 72–80. https://doi.org/10.1016/j.conbuildmat.2018.12.179 (2019).

Delatte, N. J. Concrete pavement design, construction, and performance. https://doi.org/10.1201/9781482288483 (2018).

Harrington, D., Abdo, F., Adaska, W. & Hazaree, C. Guide for roller-compacted concrete pavements 104 (Inst. Transp. Iowa State Univerisity, 2010).

Rambabu, D., Sharma, S. K. & Akbar, M. A. A review on suitability of roller-compacted concrete for constructing high traffic resisting pavements. Innov. Infrastruct. Solut. https://doi.org/10.1007/s41062-022-00989-4 (2023).

Pratiwi, D. S. & Albar, A. Review of the implementation of road preservation and road shoulder widening on SP. Lempake - SP3. Sambera - Santan Project. JSE J. Sci. Eng. 1, 1–8. https://doi.org/10.30650/jse.v1i1.3794 (2023).

Zarrin, O. & Shirazi, M. R. Design of Roller compacting concrete pavement. Int. J. Civ. Environ. Eng. 9, 785–788 (2015).

Karbassi, A. R. et al. Reduction of environmental pollution through optimization of energy use in cement industries. Int. J. Environ. Sci. Technol. 7, 127–134. https://doi.org/10.1007/BF03326124 (2010).

Zhang, S., Ren, H., Zhou, W., Yu, Y. & Chen, C. Assessing air pollution abatement co-benefits of energy efficiency improvement in cement industry: A city level analysis. J. Clean. Prod. 185, 761–771. https://doi.org/10.1016/j.jclepro.2018.02.293 (2018).

Kumar, R., Shafiq, N., Kumar, A. & Jhatial, A. A. Investigating embodied carbon, mechanical properties, and durability of high-performance concrete using ternary and quaternary blends of metakaolin, nano-silica, and fly ash. Environ. Sci. Pollut Res. 28, 49074–49088. https://doi.org/10.1007/s11356-021-13918-2 (2021).

Kumar, A. et al. Effect of silica fume and fly ash as cementitious material on hardened properties and embodied carbon of roller compacted concrete. Environ. Sci. Pollut Res. 29, 1210–1222. https://doi.org/10.1007/s11356-021-15734-0 (2022).

Sathanandam, T., Awoyera, P. O., Vijayan, V. & Sathishkumar, K. Low carbon building: Experimental insight on the use of fly ash and glass fibre for making geopolymer concrete. Sustain. Environ. Res. 27, 146–153. https://doi.org/10.1016/j.serj.2017.03.005 (2017).

Cascardi, A., Longo, F., Micelli, F. & Aiello, M. A. Compressive strength of confined column with Fiber Reinforced Mortar (FRM): New design-oriented-models. Constr. Build. Mater. 156, 387–401. https://doi.org/10.1016/j.conbuildmat.2017.09.004 (2017).

Amato, G., Campione, G., Cavaleri, L., Minafò, G. & Miraglia, N. The use of pumice lightweight concrete for masonry applications. Mater. Struct. Constr. 45, 679–693. https://doi.org/10.1617/s11527-011-9789-7 (2012).

Longo, F., Cascardi, A., Lassandro, P. & Aiello, M. A. Thermal and seismic capacity improvements for masonry building heritage: A unified retrofitting system. Sustain 13, 1–16. https://doi.org/10.3390/su13031111 (2021).

Ombres, L. & Verre, S. Shear performance of FRCM strengthened RC beams. Am. Concr Inst. ACI Spec. Publ. 2017-March https://doi.org/10.14359/51702359 (2018).

Yang, K. H., Jung, Y. B., Cho, M. S. & Tae, S. H. Effect of supplementary Cementitious materials on reduction of CO2 emissions from concrete. Handb. Low Carbon Concr 89–110. https://doi.org/10.1016/B978-0-12-804524-4.00005-1 (2017).

Abdul-Wahab, S. A., Al-Dhamri, H., Ram, G. & Chatterjee, V. P. An overview of alternative raw materials used in cement and clinker manufacturing. Int. J. Sustain. Eng. 14, 743–760. https://doi.org/10.1080/19397038.2020.1822949 (2021).

Bheel, N. et al. Effect of low carbon marble dust powder, silica fume, and rice husk ash as tertiary cementitious material on the mechanical properties and embodied carbon of concrete. Sustain. Chem. Pharm. https://doi.org/10.1016/j.scp.2024.101734 (2024).

Buller, A. S. et al. Effect of silica fume on fracture analysis, durability performance and embodied carbon of fiber-reinforced self-healed concrete. Theor. Appl. Fract. Mech. https://doi.org/10.1016/j.tafmec.2024.104333 (2024).

Manjunatha, M., Seth, D. & Balaji, K. V. G. D. Role of engineered fibers on fresh and mechanical properties of concrete prepared with GGBS and PVC waste powder - an experimental study. Mater. Today Proc. 47, 3683–3693. https://doi.org/10.1016/j.matpr.2021.01.605 (2021).

Manjunatha, M. et al. Utilization of industrial-based PVC waste powder in self-compacting concrete: A sustainable building material. J. Clean. Prod. https://doi.org/10.1016/j.jclepro.2023.139428 (2023).

Bheel, N., Chohan, I. M., Alwetaishi, M., Waheeb, S. A. & Alkhattabi, L. Sustainability assessment and mechanical characteristics of high strength concrete blended with marble dust powder and wheat straw ash as cementitious materials by using RSM modelling. Sustain. Chem. Pharm. https://doi.org/10.1016/j.scp.2024.101606 (2024).

Bheel, N. et al. Effect of wheat straw ash as cementitious material on the mechanical characteristics and embodied carbon of concrete reinforced with coir fiber. Heliyon https://doi.org/10.1016/j.heliyon.2024.e24313 (2024).

Bheel, N. et al. Synergistic effect of recycling waste coconut shell ash, metakaolin, and calcined clay as supplementary cementitious material on hardened properties and embodied carbon of high strength concrete, Case Stud. Constr. Mater. https://doi.org/10.1016/j.cscm.2024.e02980 (2024).

Bheel, N. et al. An investigation on Fresh and Hardened properties of concrete blended with rice husk ash as cementitious ingredient and coal bottom ash as sand replacement material. Silicon 14, 677–688. https://doi.org/10.1007/s12633-020-00906-3 (2022).

Rukzon, S. & Chindaprasirt, P. Utilization of bagasse ash in high-strength concrete. Mater. Des. 34, 45–50. https://doi.org/10.1016/j.matdes.2011.07.045 (2012).

Habeeb, G. A. & Fayyadh, M. M. Rice husk ash concrete: The effect of RHA average particle size on mechanical properties and drying shrinkage. Aust J. Basic. Appl. Sci. 3, 1616–1622 (2009).

Cordeiro, G. C., Toledo Filho, R. D., Tavares, L. M. & Fairbairn, E. M. R. Pozzolanic activity and filler effect of sugar cane bagasse ash in Portland cement and lime mortars. Cem. Concr Compos. 30, 410–418. https://doi.org/10.1016/j.cemconcomp.2008.01.001 (2008).

Bheel, N. & Adesina, A. Influence of binary blend of corn cob ash and glass powder as partial replacement of cement in concrete. Silicon https://doi.org/10.1007/s12633-020-00557-4 (2020).

Bheel, N. et al. Utilization of corn cob ash as fine aggregate and ground granulated blast furnace slag as cementitious material in concrete. Buildings. https://doi.org/10.3390/buildings11090422 (2021).

Akhter, M. Experimental Study on Effect of Wood Ash on Strength of Concrete 1252–1254. (2017).

Desai, P. H. Experimental study on corn cob ash powder as partial replacement of cement in concrete. Int. Res. J. Eng. Technol. (2018).

Adesanya, D. A. & Raheem, A. A. A study of the workability and compressive strength characteristics of corn cob ash blended cement concrete. Constr. Build. Mater. 23, 311–317. https://doi.org/10.1016/j.conbuildmat.2007.12.004 (2009).

Adesanya, D. A. & Raheem, A. A. A study of the permeability and acid attack of corn cob ash blended cements. Constr. Build. Mater. 24, 403–409. https://doi.org/10.1016/j.conbuildmat.2009.02.001 (2010).

Owolabi, T. A. Effect of corncob ash as partial substitute for cement in concrete. N.Y. Sci. J. 151, 10–17 (2015).

Okeola, A. A., Abuodha, S. O. & Mwero, J. Experimental investigation of the physical and mechanical properties of sisal fiber-reinforced concrete. Fibers 6, 1–16. https://doi.org/10.3390/fib6030053 (2018).

Dharek, M. S., Vengala, M. M. B. S. J. & Tangadagi, R. B. Performance evaluation of hybrid fiber reinforced concrete on engineering properties and life cycle assessment: a sustainable approach. J. Clean. Prod. https://doi.org/10.1016/j.jclepro.2024.142498 (2024).

Manjunatha, M. et al. Experimental study on the use of human hair as fiber to enhance the performance of concrete: A novel use to reduce the disposal challenges. Mater. Today Proc. 47, 3966–3972. https://doi.org/10.1016/j.matpr.2021.04.039 (2021).

Thejaswi, P., Vengala, J., Dharek, M. S., Manjunatha, M. & Poudel, A. Sugarcane bagasse fibers for enhancing moisture susceptibility properties in Stone Mastic Asphalt. Adv. Mater. Sci. Eng. https://doi.org/10.1155/2023/5378738 (2023).

Singh, S., Shukla, A. & Brown, R. Pullout behavior of polypropylene fibers from cementitious matrix. Cem. Concr Res. 34, 1919–1925. https://doi.org/10.1016/j.cemconres.2004.02.014 (2004).

Vadivambal, R., Chelladurai, V., Jian, F. & Jayas, D. S. Tensile strength and elongation of hemp and sisal ropes at different temperatures. Can. Biosyst Eng. 57, 9–12. https://doi.org/10.7451/CBE.2015.57.3.9 (2015).

Zhang, T., Yin, Y., Gong, Y. & Wang, L. Mechanical properties of jute fiber-reinforced high-strength concrete. Struct. Concr. 21, 703–712. https://doi.org/10.1002/suco.201900012 (2020).

Lee, S. Effect of nylon fiber addition on the performance of recycled aggregate concrete. Appl. Sci. https://doi.org/10.3390/app9040767 (2019).

Manaia, J. P., Manaia, A. T. & Rodriges, L. Industrial Hemp Fibers: Overv. Fibers 7 106. https://doi.org/10.3390/fib7120106. (2019).

Bheel, N. et al. Sustainable composite development: Novel use of human hair as fiber in concrete, Case Stud. Constr. Mater. 13 https://doi.org/10.1016/j.cscm.2020.e00412 (2020).

Zakaria, M., Ahmed, M., Hoque, M. M. & Islam, S. Scope of using jute fiber for the reinforcement of concrete material. Text. Cloth. Sustain. https://doi.org/10.1186/s40689-016-0022-5 (2017).

Wang, X., Chang, L., Shi, X. & Wang, L. Effect of hot-alkali treatment on the structure composition of jute fabrics and mechanical properties of laminated composites. Materials (Basel). https://doi.org/10.3390/ma12091386 (2019).

Song, X. et al. The reinforcement and toughening of jute/PLA (lactic acid) composite material with modified-rubber/SiO2 core-shell particles. Mater. Today Sustain. https://doi.org/10.1016/j.mtsust.2022.100198 (2022).

Ahmad, J. et al. Performance of concrete reinforced with jute fibers (natural fibers): A review. J. Eng. Fiber Fabr. https://doi.org/10.1177/15589250221121871 (2022).

Naik, N. et al. Enhancing the mechanical properties of jute fiber reinforced green composites varying cashew nut shell liquid composition and using mercerizing process. Mater. Today Proc. 19, 434–439. https://doi.org/10.1016/j.matpr.2019.07.631 (2019).

Abdullah, G. M. S. et al. Effect of titanium dioxide as nanomaterials on mechanical and durability properties of rubberised concrete by applying RSM modelling and optimizations. Front. Mater. https://doi.org/10.3389/fmats.2024.1357094 (2024).

Bheel, N., Mohammed, B. S., Ali, M. O. A., Shafiq, N. & Radu, D. Effect of graphene oxide as a nanomaterial on the bond behaviour of engineered cementitious composites by applying RSM modelling and optimization. J. Mater. Res. Technol. 26, 1484–1507. https://doi.org/10.1016/j.jmrt.2023.07.278 (2023).

Bheel, N., Mohammed, B. S. & Woen, E. L. Modelling and optimizing the impact resistance of engineered cementitious composites with multiwalled carbon nanotubes using response surface methodology. Sci. Rep. 14, 24107. https://doi.org/10.1038/s41598-024-75641-5 (2024).

Bheel, N. et al. Enhancing performance and sustainability of GGBFS-based self-compacting geopolymer concrete blended with coal bottom ash and metakaolin by using RSM modelling. Sci. Rep. https://doi.org/10.1038/s41598-024-70800-0 (2024).

Bheel, N. et al. A comprehensive study on the impact of human hair fiber and millet husk ash on concrete properties: response surface modeling and optimization. Sci. Rep. 14 https://doi.org/10.1038/s41598-024-63050-7 (2024).

Bheel, N. et al. A comprehensive study on the impact of nano-silica and ground granulated blast furnace slag on high strength concrete characteristics: RSM modeling and optimization. Structures. https://doi.org/10.1016/j.istruc.2024.106160 (2024).

Bheel, N. & Mohammed, B. S. Modelling and optimization of long-term modulus of elasticity and Poisson’s ratio of graphene oxide based engineered cementitious composites by using response surface methodology. Diam. Relat. Mater. https://doi.org/10.1016/j.diamond.2024.110949 (2024).

ASTM, C. 29/C 29 M. Standard Test Method for Bulk Density (Unit Weight) and Voids in Aggregate, Annual Book of ASTM Standards (1997).

ASTM, C. 136. Standard test method for sieve analysis of fine and coarse aggregates (American Society for Testing and Materials, 2005).

ASTM C127. Standard Method of Test for Specific Gravity and Water Absorption of Coarse Aggregate (American Society for Testing and Materials, 1993).

ASTM C128. Standard Method of Test for Specific Gravity and Water Absorption of Fine Aggregate (American Society for Testing and Materials, 1993).

BS EN 12350-2. Testing Fresh Concrete, Part 2: Slump-Test (BSI, 2009).

BS EN 12390-3. Testing Harden Concrete. Compressive Strength of Test Specimens (BSI, 2009).

British Standards Institute. BS EN 12390-6 tensile splitting strength of test specimens. BSI Stand. Publ (2009).

BSI, BS EN 12390-5. Testing hardened concrete. Flexural strength of test specimens, Br. Stand. Inst. (2000). (2000).

Yan, L. & Chouw, N. Natural FRP tube confined fibre reinforced concrete under pure axial compression: A comparison with glass/carbon FRP. Thin-Walled Struct. 82, 159–169. https://doi.org/10.1016/j.tws.2014.04.013 (2014).

Mello, E., Ribellato, C. & Mohamedelhassan, E. Improving concrete properties with fibers addition. Int. Sch. Sci. Res. Innov. 8, 245–250 (2014).

Islam, M. S. & Ahmed, S. J. Influence of jute fiber on concrete properties. Constr. Build. Mater. 189, 768–776. https://doi.org/10.1016/j.conbuildmat.2018.09.048 (2018).

Yogyta, N. & Vidisha, M. P. Experimental study on partial replacement of fine aggregate with Sawdust for M30 Grade concrete. 6 98–110 (2019).

Bajad, M. N., Modhera, C. D. & Desai, D. K. Effect of glass on strength of concrete subjected to sulphate attack. Int. J. Civ. Eng. Res. Dev. (2011).

Keerio, M. A. et al. Effect of silica fume as cementitious material and waste glass as fine aggregate replacement constituent on selected properties of concrete. Silicon 14, 165–176. https://doi.org/10.1007/s12633-020-00806-6 (2022).

Bheel, N. et al. Fresh and hardened properties of concrete incorporating binary blend of metakaolin and ground granulated blast furnace slag as supplementary cementitious material. Adv. Civ. Eng. https://doi.org/10.1155/2020/8851030 (2020).

Dayo, A. A. et al. Effect of sugarcane bagasse ash as fine aggregates on the flexural strength of concrete. In 2nd Int. Conf. Sustain. Dev. Civ. Eng. 130–133 (MUET Jamshoro, 2019).

Bheel, N., Memon, F. A. & Meghwar, S. L. Study of fresh and hardened properties of concrete using cement with modified blend of millet husk ash as secondary cementitious material. Silicon 13, 4641–4652. https://doi.org/10.1007/s12633-020-00794-7 (2021).

Sujatha, E. R., Dharini, K. & Bharathi, V. Influence of groundnut shell ash on strength and durability properties of clay. Geomech. Geoeng. 11, 20–27. https://doi.org/10.1080/17486025.2015.1006265 (2016).

Foong, K. Y., Alengaram, U. J., Jumaat, M. Z. & Mo, K. H. Enhancement of the mechanical properties of lightweight oil palm shell concrete using rice husk ash and manufactured sand. J. Zhejiang Univ. Sci. A. 16, 59–69. https://doi.org/10.1631/jzus.A1400175 (2015).

Ramezanianpour, A. A., Mahdikhani, M. & Ahmadibeni, G. The effect of rice husk ash on mechanical properties and durability of sustainable concretes. Int. J. Civ. Eng. 7, 83–91 (2009).

Waqar, A. et al. Effect of Coir Fibre Ash (CFA) on the strengths, modulus of elasticity and embodied carbon of concrete using response surface methodology (RSM) and optimization. Results Eng. https://doi.org/10.1016/j.rineng.2023.100883 (2023).

Yang, K. H., Song, J. K. & Song, K. I. Assessment of CO2 reduction of alkali-activated concrete. J. Clean. Prod. 39, 265–272 (2013).

Zhu, Q. CO2 abatement in the cement industry 121–127 (Industry IEA Clean Coal Centre, 2011). https://www.usea.org/publication/co2-abatement-cement-industry-ccc184 (2011).

Singh, A. K., Kumar, M. & Mitra, S. Carbon footprint and energy use in jute and allied fibre production. Indian J. Agric. Sci. 88, 1305–1311. https://doi.org/10.56093/ijas.v88i8.82579 (2018).

Turner, L. K. & Collins, F. G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 43, 125–130. https://doi.org/10.1016/j.conbuildmat.2013.01.023 (2013).

Sahoo, S., Parhi, P. K. & Chandra Panda, B. Durability properties of concrete with silica fume and rice husk ash. Clean. Eng. Technol. https://doi.org/10.1016/j.clet.2021.100067 (2021).

Keerio, M. A. et al. The effect of local Metakaolin developed from natural material soorh on selected properties of concrete/mortar. Silicon 14, 1807–1816. https://doi.org/10.1007/s12633-021-00993-w (2022).

Bheel, N., Khoso, S., Baloch, M. H., Benjeddou, O. & Alwetaishi, M. Use of waste recycling coal bottom ash and sugarcane bagasse ash as cement and sand replacement material to produce sustainable concrete. Environ. Sci. Pollut Res. 29, 52399–52411. https://doi.org/10.1007/s11356-022-19478-3 (2022).

Bheel, N., Ali, M. O. A., Tafsirojjaman, S. H., Khahro, M. A. & Keerio. Experimental study on fresh, mechanical properties and embodied carbon of concrete blended with sugarcane bagasse ash, metakaolin, and millet husk ash as ternary cementitious material. Environ. Sci. Pollut Res. 29, 5224–5239. https://doi.org/10.1007/s11356-021-15954-4 (2022).

Jhatial, A. A., Kumar, A., Bheel, N., Sohu, S. & Goh, W. I. Assessing the sustainability and cost-effectiveness of concrete incorporating various fineness of eggshell powder as supplementary cementitious material. Environ. Sci. Pollut Res. 29, 84814–84826. https://doi.org/10.1007/s11356-022-21635-7 (2022).

Bheel, N. et al. Effect of calcined clay and marble dust powder as cementitious material on the mechanical properties and embodied carbon of high strength concrete by using RSM-based modelling. Heliyon. https://doi.org/10.1016/j.heliyon.2023.e15029 (2023).

Jayasinghe, A., Orr, J., Hawkins, W., Ibell, T. & Boshoff, W. P. Comparing different strategies of minimising embodied carbon in concrete floors. J. Clean. Prod. https://doi.org/10.1016/j.jclepro.2022.131177 (2022).

Shah, I., Li, J., Yang, S., Zhang, Y. & Anwar, A. Experimental investigation on the mechanical properties of natural fiber reinforced concrete. J. Renew. Mater. 10, 1307–1320. https://doi.org/10.32604/jrm.2022.017513 (2022).

Jayasinghe, A., Orr, J., Ibell, T. & Boshoff, W. P. Minimising embodied carbon in reinforced concrete flat slabs through parametric design. J. Build. Eng. https://doi.org/10.1016/j.jobe.2022.104136 (2022).

Bheel, N. et al. Utilization of millet husk ash as a supplementary cementitious material in eco-friendly concrete: RSM modelling and optimization. Structures 49, 826–841. https://doi.org/10.1016/j.istruc.2023.02.015 (2023).

Acknowledgements

The authors extend their appreciation to Taif University, Saudi Arabia, for supporting this work through project number (TU-DSPP-2024-32).

Author information

Authors and Affiliations

Contributions

Naraindas Bheel: Conceptualization; Data analysis; Investigation; methodology; Writing - Original Draft; Writing - Review & Editing.Dileep Kumar: Conceptualization; Formal Analysis; methodology; Writing - Review & Editing.Fouad Ismail Ismail: Formal analysis; Visualization; methodology; Writing - Review & Editing.Waleligne Molla Salilew: Formal analysis; Data analysis; visualization; Writing - Review & Editing.Mamdooh Alwetaishi: Formal analysis; Funding Acquisition; visualization; Writing - Review & Editing.Sahl Abdullah Waheeb: Conceptualization; Formal analysis; visualization; Writing - Review & Editing.Loai Alkhattabi: Formal analysis; data curing; visualization; Writing - Review & Editing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Bheel, N., Kumar, D., Ismail, F.I. et al. Combined effect of jute fiber and corn cob ash on sustainability assessment and mechanical properties of roller compacted concrete using RSM modelling. Sci Rep 14, 29724 (2024). https://doi.org/10.1038/s41598-024-81345-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-81345-7