Abstract

The design of drill pipe joint thread with unequal taper is proposed to investigate the fracture failure of the API NC38 used in the drill pipe joint of the SU36-8-4H2 well. The effect of changes in thread taper on the stress distribution and mechanical properties of drill pipe joints is analyzed and compared with the API standard thread to determine the optimal thread structure with unequal taper. The results reveal highly concentrated stress at the last engaged thread root of API NC38 single-shoulder thread (SUT) may cause early yield failure of the joint threads. Adjusting the unequal taper of the pin thread mitigates uneven stress distribution in NC38 single and double-shoulder threads and enhances connection strength, particularly for SUT-II and DUT-I. However, altering the box thread’s unequal taper modifies the stress concentration slightly in NC38 single and double-shoulder threads. This offers limited tensile and compressive strength improvement. The maximum Mises stress value of SUT-II is reduced by 56.69% compared to SUT. The maximum Mises stress value of DUT-I is reduced by 34.87% compared to NC38 double-shoulder joint thread (DUT). This design approach can guide the optimization of other API threads and enhance joint strength for non-API and specialized taper threads.

Similar content being viewed by others

Introduction

More than 70% of drill pipe failure accidents in China occur at the joint thread connection1,2. Frequent failures of drill pipe connections affect the lifespan and production efficiency of complex oil and gas wells3,4,5,6. Therefore, investigating high-performance joint thread structures is crucial. Numerous scholars have conducted extensive research on the design, optimization, and mechanical behavior of drill pipe joint threads, leading to a better understanding of their mechanical characteristics7. The methods for studying these characteristics can be broadly categorized into three groups.

The first category is the analytical method8,9, which is based on clear mechanical concepts and serves as an important guide for studying the mechanical behavior of threaded structures. However, developing an analytical model can be challenging. Chen et al.10 analyzed the load distribution on P-110 S conic threaded connections under interference fit and axial load conditions, using thick cylinder theory. Their results show that the load on the engaged teeth is uneven, with the maximum concentrated on either the first three or the last two pairs of teeth, while the middle teeth bear minimal load.

The second category of research methods is experimental11,12,13, which is characterized by reliable calculations and visualization of the load-bearing capacity of threads. However, experimental methods are often limited by long test cycles and high costs. Moreover, these methods frequently struggle to accurately capture the internal forces within drill pipe joints14. Oku et al.15 analyzed premium threaded connections through full-scale fatigue tests. At high stress levels, cracks initiated at the thread’s rounded corners due to stress concentration, while at lower stress levels, fretting fatigue caused cracks at the thread root. Similarly, Santus et al.16 conducted fatigue testing of a drill collar threaded connection (5 − 1/2 FH MOD) and found evidence of fatigue cracking at the box’s load engagement thread (LET) before the threads were fully formed.

The third category of research methods is finite element analysis (FEA)17,18,19,20, which can be combined with the previous two methods. This approach can simulate the mechanical properties of threads, quickly evaluate the force characteristics of drill pipe joints, and improve product design efficiency21,22. Dzhus et al.23 proposed a new design and method for simulating the screwing torque of a double-shoulder drill pipe joint thread structure and analyzed its performance using FEA. Chen et al.24 calculated the radial contact compressive stress on thread teeth under make-up torques using a two-dimensional axisymmetric model. The simulation focused on the interference fit between pin and box joints at the effective engagement surface of the thread teeth. Zhu et al.25 and Zhang et al.26 established a three-dimensional finite element model of the drill pipe joint. The performance of the joint threads was analyzed under conditions of wear and fatigue life. Dong et al.18 used FEA and experimental validation to explore the stress state and mechanical behavior of the double-shoulder drill pipe joint thread. Tikhonov et al.27 studied the fatigue behavior of aluminum drill pipe connections for deepwater wells using experiments and FEA. They analyzed stress concentration factors and fatigue life under axial loads, bending, friction, and interference, with full-scale tests verifying the FEA results.

They analyzed the mechanical characteristics of the joint’s thread under the corresponding loads, providing a reference for the research and development of drill pipe joints. However, the structural design primarily focuses on exploring single-shoulder and double-shoulder threads. Only a few investigations have been reported on improving the joint’s mechanical properties by changing the thread taper.

In this paper, two design plans of unequal taper thread are proposed, and 16 unequal taper thread structures are designed based on API NC38 single-shoulder thread (hereinafter referred to as SUT) and NC38 conventional double-shoulder thread (hereinafter referred to as DUT). The elastic-plastic mechanics and finite element analysis are used to compare and analyze the working mechanical behavior and resistance performance of different external loads on the pin and box thread of a drill pipe’s joint thread with an unequal taper and API standard joint thread with the condition of make-up torques, tension, compression, internal and external pressure loads. Furthermore, a selection scheme for drill pipe joint thread parameters with unequal taper is proposed, providing a reference for selecting the thread structure.

The elastic-plastic mechanics model of drill pipe’s joint

Design of the drill pipe joint thread

The SUT used in the drill pipe’s joint fractured and failed during the operation of the SU36-8-4H2 well. It was found that the SUT has a stress concentration problem. SUT parameters are shown in Table 1.

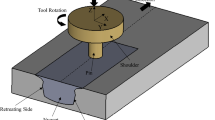

Eight types of drill pipe joints of single-shoulder with unequal taper are designed based on the SUT by changing the diameter of the large end of the pin thread and the small end of the box thread29. The principle of the DUT structure is adding the secondary shoulder based on the SUT, keeping other parameters constant. Moreover, eight types of double-shoulder drill pipe joints with unequal taper are designed by changing the pin and box thread taper based on the DUT. Thread parameters for the pin and the box are shown in Fig. 1. The comparison of the parameters of each structure is shown in Table 2.

In Fig. 1, The tolerance of the pin thread for double-shoulder connections is \(\:{23.35}_{-0.13}^{+0.25}\) mm. The tolerance of the box thread for double-shoulder connections is \(\:{8.5}_{-0.1}^{+0.25}\) mm.

In variable taper threads, the thread’s taper is modified by changing the diameter DE of the large end of the pin thread and the diameter QC of the small end of the box thread, forming different types of variable taper threads.

Unequal taper of the pin thread: Tp = (DE-DC)/Lpc.

Unequal taper of the box thread: Tb = (QE-QC)/LQ.

Mechanical analysis of drill pipe’s joint thread

Joint thread governing equation

The drill pipe joint is usually within the material’s elastic range during downhole operations. High loads are generated due to the scraping between the drill pipe’s system and the well wall during drilling, altering the wellbore track, and screwing the pin and box of the drill pipe’s joint. Consequently, the drill pipe’s joint material enters the plastic state30,31,32. The mechanical analysis of a downhole drill pipe’s joint thread is usually viewed as a complex 3D spatial elastic-plastic problem. The unit governing the equation of a drill pipe’s joint thread can be derived via the principle of virtual work33,34 as follows:

where σij is the Euler stress tensor, Pa; ξij is the infinite strain in the present configuration; δξij is the virtual strain; fi is the unit fire loads vector on the surface, N; δui is the virtual displacement, m; V is the volume in the present configuration, m3; A is the surface area in the present configuration, m2.

The loading and force analysis of the drill pipe’s joint thread

The equivalent loading and force characteristics of the three-dimensional thread model under external torques are shown in Fig. 2.

Force characteristics of drill pipe’s joint under make-up torques. (a) Single shoulder, (b) Double shoulder. Note: ⊕ represents the force acting vertically inward on the paper; ⊙ represents the force acting vertically outward on the paper; △ represents the built-in boundary; P is the total stress, MPa; FP is the force on the main shoulder, N; TT is the main shoulder torques, N·m; Fs is the force on the sub-bench shoulder, N; Fn is the force on each thread tooth of the pin, (n = 1, 2, 3, …), N; \(\:{F}_{n}^{{\prime\:}}\) is the force on each thread tooth of the box.

According to the relevant API RP 7G standard35, the API drill pipe joint under make-up torques can be calculated as follows:

Single shoulder:

Double shoulder can be obtained as follows35:

Where:

where T is a single-shoulder drill pipe joint under make-up torques; \(\:{T}^{{\prime\:}}\) is a double-shoulder drill pipe joint under make-up torques; S is the API recommended level of make-up torques; A is the smaller value of the cross-sectional area at the root of the last engagement thread; P is the thread pitch; f is the friction coefficient of the effective engagement tooth contact surface between the pin and the box joint; θ is half the thread angle; D0 is the outer diameter of the drill pipe joint, in; Dc is the bore diameter of the drill pipe joint; C is the base level pitch diameter; tpr is the taper; LPC is the length of the external thread.

The make-up torque for SUT was calculated according to API RP 7G, based on the recommended levels of make-up torque for drill pipe joints. Each parameter was substituted into Eq. (3), obtaining the value of approximately 21.5 kN·m. The make-up torque for DUT was calculated by bringing the values of each parameter into Eq. (4), obtaining the value of approximately 45 kN·m. In the finite element model, the make-up torque is applied by simulating an interference fit between the threads, representing the actual torque. According to the formula proposed by Yan36 et al., for single-shoulder drill pipe joints, the applied make-up torque of 21.5 kN·m corresponds to an interference of 0.1 mm on the main shoulder. Similarly, for double-shoulder drill pipe joints, a make-up torque of 45 kN·m is applied, with 30.44 kN·m acting on the main shoulder and 14.56 kN·m on the sub-shoulder, corresponding to an interference of 0.116 mm for the main shoulder and 0.04 mm for the sub-shoulder.

Establishing the calculation model

In the finite element model, the Mises yield surface was utilized to determine the initiation of plastic deformation for elastic plastic material, and the deformation was assumed to be isotropic37,38. The material hardening data, including the plastic strain and corresponding true stress, required in ABAQUS can be obtained from the engineering stress–strain curve as:

Where \(\:{\sigma\:}_{eng}\) and \(\:{\epsilon\:}_{eng}\) refer to the engineering stress and engineering strain respectively, and \(\:{\sigma\:}_{true}\) refers to the true stress. The true stress and true strain of 37CrMnMo are presented in Table 3. The material hardening data were imported into ABAQUS in the tabular form.

The thread angle is relatively small, and the thread joint structure is approximately axisymmetric. Therefore, the thread angle is neglected in the finite element analysis, and an axisymmetric model of the oil casing is established for subsequent simulation calculations. Single- and double-shoulder drill pipe joint thread models are shown in Fig. 3a and b, respectively. The drill pipe’s joint is assumed to be an isotropic and continuous homogeneous body.

The material selected for the drill pipe joint is 37CrMnMo, with an elastic modulus of 210 GPa, Poisson’s ratio of 0.28, yield strength of 931 MPa, and tensile strength of 1035 MPa. The plastic strain of 0.197 is taken as the material’s failure criterion. The CAX4R cell-free mesh is used to mesh the drill pipe’s joint. Moreover, the pin and box joint thread engagement parts’ mesh is refined, as shown in Fig. 3c and d.

Contact conditions change with the engagement and separation of the pin and box threads of the drill rod joint. Contact occurs at the effective engagement of the threads and the main shoulder surfaces. A contact model is established to monitor the changing state of the interaction between the pin and box threads in the drill string connection. The interference adjustment option in the interaction window should be set to automatic shrinkage adjustment, ensuring the convergence of the numerical analysis results. The contact between the pin and box threads is a face-to-face contact with a friction coefficient of 0.0840. The friction formulation is a penalty function. The analysis step time is set to 1 s, and the contact results are shown in Fig. 3e and f.

Fixed boundary conditions are applied to one end of the drill rod joint. In contrast, various force boundary conditions are applied to the other end acting on the drill rod joint. Parameters such as elastic modulus and Poisson’s ratio are selected based on the material characteristics of the drill rod joint and applied to the elements. As shown in Fig. 3g and h, various load conditions must be set for static analysis of the drill string connection threads. Load forms are defined according to the actual working conditions or simulated using equivalent loads to represent the actual working conditions41.

Computational modeling of drill pipe joint threads. (a) Single-shoulder drill pipe joint thread, (b) Double-shoulder drill pipe joint thread, (c) Mesh delineation of single-shoulder drill pipe joint threads, (d) Mesh delineation of double-shoulder drill pipe joint threads, (e) Contact setting of single-shoulder drill pipe joint threads, (f) Contact setting of double-shoulder drill pipe joint threads, (g) Restraint settings for single-shoulder drill pipe joint threads, (h) Restraint settings for double-shoulder drill pipe joint threads.

Mesh convergence study

The edge length of the mesh was reduced from 2 mm to 0.01 mm, and the number of mesh elements was increased from 2324 to 57,351 for single-shoulder drill pipe joint threads and from 3521 to 70,150 for double-shoulder drill pipe joint threads. Seven mesh types were selected to analyze SUT and DUT. Calculated working conditions include a make-up torque of 21.5 kN·m + a tensile load of 1250 kN for single-shoulder joint threads and a make-up torque of 45 kN·m + a tensile load of 1250 kN for double-shoulder threads.

The Mises stress of pin and box threaded joints decreases gradually with an increase in the number of mesh elements. When the number of SUT elements is 16 995, and the number of DUT elements is 24 068, the change in Mises stresses for the pin and box threads is less than 1%. The results are shown in Fig. 4. Therefore, this paper uses these two mesh types to carry out the subsequent corresponding calculations to ensure the calculation accuracy and efficiency.

Validating the model

The numerical simulation of the NC38 thread joint with the same structural parameters is compared with [33] to ensure the model’s reliability. The contact pressure for the effective engagement thread teeth of the pin and the box is solved with the API recommended make-up torque of 21.570 kN·m. The finite element simulation results are compared with the theoretical calculation results in Fig. 5. The contact stress variation of the effective engagement thread is similar, with a maximum error of 8.10%, which is within the allowable error range.

Results and discussions

The effect of make-up torques on single-shoulder thread

Abaqus/Explicit simulation of SUT and eight types of unequal taper thread joints (i.e., SUT-I, SUT-II, SUT-III, SUT-IV, SUT-V, SUT-VI, SUT-VII, and SUT-VIII) can be used to calculate the make-up torque for the drill pipe’s joints. Equation (2) can be used to obtain the make-up torques of NC38 single-shoulder drill pipe joint of 21.5 kN·m. The Mises stress color map of the thread is shown in Fig. 6, and the stress distribution is shown in Fig. 7.

According to Fig. 6, under various make-up torques, the SUT has a higher stress on the thread tooth near the main shoulder (i.e., the starting sequence of the effective engagement thread). However, the stress on the thread tooth far from the shoulder is relatively low. A significant stress concentration can be found at the pin and box joints’ last engaged thread (LET) root, i.e., 688 MPa. This may lead to early yield failure of the joint threads. The Mises stress distribution of the drill pipe’s joint is extremely uneven; the torque load is resisted only by the frictional moment generated by a pair of forces acting in opposite directions between the thread tooth and the main shoulder, verifying the assumptions of the fracture analysis.

According to Fig. 7, the Mises stress distribution of effective engagement thread tooth on the API single-shoulder drill pipe joint is nonuniform, with one high and one low side. The Mises stress distribution of the thread tooth of type I, II, III, and IV with pin’s thread unequal taper shows a stress distribution of “small in the middle and large on both sides”. This indicates that effective engagement of the thread tooth near the secondary shoulder also bears a large torque load. The maximum Mises stresses are 324 MPa, 298 MPa, 390 MPa, and 481 MPa. Moreover, the stress distribution of Types I, II, and III is more uniform. The maximum stress value of SUT-II is the smallest, i.e., 56.6% less than that of the SUT. In addition, the SUT-II has the best torque-withstanding properties. The maximum Mises stresses of Types V, VI, VII, and VIII of box thread unequal taper are higher than those of pin thread unequal taper, i.e., 649 MPa, 538 MPa, 615 MPa, and 694 MPa, respectively.

The stresses in a tapered box thread are concentrated on the first and second threaded teeth. Moreover, there is no significant improvement in the stress concentration problem compared with the SUT thread. The stress distribution is more uniform on the thread teeth of the pin’s thread taper, indicating that the pin’s thread taper is more effective than the box thread taper in alleviating the stress concentration problem under the same upward buckling torque.

The effect of tensile loads on single-shoulder thread

The make-up torques are maintained while applying the axial tension of 350 kN-1250 kN in increments of 100 kN, i.e., 10 working conditions. According to Fig. 8 and 9, the maximum Mises stress of nine types of drill pipe joint threads increases with the axial tensile load. Type II has the best tensile properties among the single-shoulder unequal taper. The maximum Mises stresses of the single-shoulder drill pipe joint threads are 791 MPa, 851 MPa, 641 MPa, 744 MPa, and 858 MPa for Types I, II, III, and IV, respectively. When the axial load is less than 800 kN, the tensile properties of the pin and box drill pipe’s joint thread with unequal taper are better than that of the standard drill pipe joint. When the axial load is between 800 kN and 1250 kN, the tensile properties of single-shoulder unequal taper Types II and III are better than that of single-shoulder standard API drill pipe joints.

Figure 9 further depicts that the maximum stress of single-shoulder variable taper Type II is always smaller than the other eight structures under the same conditions. Moreover, the tensile performance of single-shoulder variable taper Type II is the best. Compared with the standard API single-shoulder drill pipe joints, changing the pin thread taper (Types I and IV) and box thread taper (Types V, VI, VII, and VIII) did not result in significant effects as the one in Types II and III.

Because the larger Mises stress of unequal taper thread structure is uniformly distributed in the middle of the pin under tension, the stress distribution on the last engaged thread is not the same as the maximum Mises stress distribution. Under axial tensile loads, the stress concentration of SUT is at the shoulder and at the last engaged thread, while the stress of unequal taper thread is uniformly distributed in the middle of the pin under tension. Under axial tensile loads, the appropriate change in taper is able to reduce the stress of the last engaged thread of the pin, improving the strength of the connection. The best results were obtained with SUT-II.

The distribution of the maximum Mises stress on the effective engagement thread teeth of a single-shoulder pin and box unequal taper joints is shown in Fig. 10. The maximum Mises stress on the effective engagement thread teeth of a single-shoulder box thread drill pipe’s joint with the unequal taper is unevenly distributed; one side is high, and the other side is low, while the stress distribution on the pin thread teeth with unequal taper is uniform. The maximum Mises stress of single-shoulder API drill pipe joint and single-shoulder Types I, II, III, and IV drill pipe joints are 791 MPa, 851 MPa, 641 MPa, 744 MPa, and 858 MPa, respectively, under the compound effect of make-up torques and axial tension of 1250 kN. The maximum Mises stress of single-shoulder Type II with unequal taper (the pin thread) is significantly lower than that of other types and API single-shoulder. In summary, the tensile stability of Type II drill pipe joint thread with unequal taper is the best under the make-up torques and axial tensile loads of 1050 kN, i.e., the result is improved by 18.96%.

The effect of compression loads on single-shoulder thread

The maximum stress color map for the same make-up torques under different axial pressures is shown in Fig. 11, and the stress values are shown in Fig. 12. Among single-shoulder drill pipe joints, the compressive properties of Type II (pin taper 1:6.2) with unequal taper is better than that of Types I, III, IV, and a single-shoulder standard API drill pipe joint.

According to Fig. 11 and 12, the maximum Mises stresses of single-shoulder API drill pipe joint and single-shoulder drill pipe joint with unequal taper under the compound effect of make-up torques and axial pressure of 1250 kN are 890 MPa, 856 MPa, 564 MPa, 703 MPa, and 725 MPa for Types I – V, respectively. The compressive properties of Types I, II, III, and IV single-shoulder drill pipe’s joints with unequal taper are increased by 3.82%, 36.63%, 21.01%, and 18.54%, respectively, compared with API drill pipe’s joint.

Under axial compression loads, the stress of SUT is mainly concentrated at the last engaged thread. Unequal taper thread improves the stress distribution structure by changing the thread taper, so the stress mainly acts on the shoulders of the pin and box, and it is evenly distributed over the thread teeth. Under axial compression loads, unequal taper thread can reduce the stress value of the last engaged thread of the pin and improve the connection strength of the thread.

Figure 12 further depicts that the maximum Mises stress of the threads increases with the axial tensile load by changing the pin thread taper (Types I, II, III, and IV). The maximum Mises stress of the threads decreases and then increases with the increase of axial tensile load by changing the taper of box threads (Types I, II, III, and IV). Compared with API single-shoulder drill pipe joint threads, the maximum stresses of changing pin and box thread tapers are smaller under the same conditions, and the tensile performance results are better.

The effect of internal and external differential pressures on single-shoulder thread

According to Fig. 13 and 14, the stresses on the first threaded teeth of the pin and box variable taper threads are higher compared to the other threaded teeth. In addition, the change in the internal and external differential pressure loads regarding the maximum Mises stresses is smaller for both the pin and box variable taper threads of the single shoulder. The maximum Mises stress value of a single-shoulder pin unequal taper joint becomes slightly higher with a gradual increase in internal and external pressure difference. Moreover, the pin thread stress value is significantly smaller than that of a standard API drill pipe joint, which is the optimal choice. The maximum Mises stress value of single-shoulder box unequal taper joint becomes slightly higher with a gradual increase in the internal and external pressure difference, i.e., 713 MPa, 735 MPa, 751 MPa, and 774 MPa for Types V-VIII, respectively.

Under internal and external pressure, the maximum stress values of single-shoulder variable taper Types I, II, III, and IV are similar; all values are significantly lower than the maximum stress value of single-shoulder standard API drilling column joint thread. Changing the taper of the box thread results in the maximum stresses of single-shoulder variable taper Types V, VI, VII, and VIII being slightly smaller than the maximum stress value of single-shoulder standard API drilling column joint thread. Therefore, considering the effects of top button torque, tensile, compressive, internal, and external pressure differences, single-shoulder variable taper drilled column thread Type II is the best.

The effect of make-up torques on double-shoulder thread

Abaqus/Explicit simulation of DUT and eight types of unequal taper thread joints (i.e., DUT-I, DUT-II, DUT-III, DUT-IV, DUT-V, DUT-VI, DUT-VII, and DUT-VIII) can be used to calculate the make-up torque for the drill pipe’s joints. According to Eq. (3), the make-up torque of the NC38 double-shoulder drill pipe joint is 45 kN·m.

The Mises stress distribution on the thread is shown in Fig. 15. The stress values on the pin and box thread teeth sequences are shown in Fig. 16. According to Fig. 15 and 16, the Mises stress distribution of the thread tooth on a double-shoulder pin thread with unequal taper shows a “small in the middle and large on both sides”, indicating that the effective engagement thread tooth near the secondary shoulder also bears large torques. The stress distribution on the pin and box thread of double-shoulder Type I is the most uniform, solving the stress concentration of double-shoulder drill pipe joints and showing better torque-withstanding properties. Unequal taper drill pipe thread is structurally reduced due to the reduction of box taper. Consequently, the threaded tooth away from the shoulder bears minor changes in contact pressure, and stress concentration still occurs. Even though the uneven stress distribution of standard API drill pipe joint thread is not improved, the stress peak value is reduced.

The effect of tensile loads on double-shoulder thread

The Mises stress color map of drill pipe joint thread under the tension of double-shoulder unequal taper is shown in Fig. 17. The stress values are shown in Fig. 18. The maximum Mises stress of standard double-shoulder drill pipe joint proportionally increases with the axial tensile loads. In addition, the maximum Mises stress of a drill pipe joint with unequal taper also shows an increasing trend when axial tensile loads are increased. Von Mises stresses for a double-shoulder pin thread with unequal taper and Types I, II, III, and IV are 744 MPa, 692 MPa, 787 MPa, 880 MPa, and 900 MPa, respectively.

The tensile properties of double-shoulder unequal taper Type I are better than those of double-shoulder conventional drill pipe joints. In comparison, the Mises stress values of all four threads (Types V, VI, VII, and VIII) are higher than those of double-shoulder conventional drill pipe joints under the box thread unequal taper. Therefore, the box thread’s unequal taper is detrimental to the tensile properties of double-shoulder thread.

The Mises stress of the effective engagement thread tooth on the drill pipe joint with the compound effect and an axial load of 1250 kN are shown in Fig. 19. The Mises stress distribution of the effective engagement thread tooth of the conventional double-shoulder drill pipe joint is high on both sides and low in the middle part. In contrast, a double-shoulder unequal taper drill pipe joint aggravates the uneven stress distribution on both sides under the same loads. The maximum Mises stress of double-shoulder Type I is significantly lower than that of other unequal taper types and conventional double shoulders.

Comprehensively, it can be seen that the joint thread of the double-shoulder Type I drill pipe has the best tensile properties for various make-up torques and axial tensile loads. In contrast, the double-shoulder unequal taper drill pipe joint worsens the uneven stress distribution on both sides under the same loads. Under this compound effect, the maximum Mises stress of double-shoulder Type I is significantly lower than that of other unequal and conventional double-shoulder tapers. Compared with the conventional double-shoulder thread, the tensile properties of double-shoulder Type I drill pipe’s joint thread are the best under the compound effect of make-up torques and an axial tensile load of 1050 kN, improved by 6.98%.

The effect of compression loads on double-shoulder thread

According to Fig. 20 and 21, the maximum Mises stress of double-shoulder pin thread drill pipe’s joints with unequal taper can be sorted from lowest to highest as follows: Type I, Type II, Type III, and Type IV for double-shoulder with unequal taper conventional drill pipe joints under the compound effect of make-up torques and axial pressure. Compared with conventional DUT, the compressive properties of double-shoulder unequal taper-thread drill pipe joints of Types I-IV are increased by 34.48%, 31.03%, 30.29%, and 23.03%, respectively.

The maximum Mises stress of the box thread drill pipe’s joint with an unequal taper can be sorted from lowest to highest as follows: Type V, Type VI, Type VII, and Type VIII for double-shoulder with unequal taper. Under the axial pressure of 650 kN, all stress values are lower and more evenly distributed than those of double-shoulder conventional drill pipe joints. This shows that a double-shoulder drill pipe joint with unequal taper has better compressive performance than a double-shoulder conventional drill pipe joint. According to the conducted investigation, it can be concluded that the double-shoulder unequal-taper Type I has the best compressive performance.

The effect of internal and external differential pressures on double-shoulder thread

The maximum stress color map under different internal and external pressure differences is shown in Fig. 22, and the changes in stresses are shown in Fig. 23. The maximum Mises stress values of conventional double-shoulder drill pipe joints are almost constant, with gradually increasing internal and external pressure differences. The maximum Mises stress of the double-shoulder drill pipe’s joint with unequal taper slightly changed with a gradual increase in the internal and external pressure differences. For example, the maximum Mises stresses increase from 514 MPa, 552 MPa, 727 MPa, and 827 MPa to 627 MPa, 628 MPa, 779 MPa, and 876 MPa for Types I, II, III, and IV, respectively, for a double-shoulder pin thread drill pipe’s joints with unequal taper.

It can be concluded that the differential pressure resistance of a single-shoulder drill pipe’s joint with unequal taper is better than that of a single-shoulder drill pipe’s joint with unequal taper. Type I has the best differential pressure resistance, improving by 19.89%. Regarding the double-shoulder drill pipe joint with unequal taper, only Type I has better differential pressure resistance than the conventional double-shoulder thread, with an improvement of 0.4%. Therefore, the single-shoulder has better resistance to differential pressure than the double-shoulder thread.

The maximum stress values of the double-shoulder variable taper Types V, VI, VII, and VIII obtained by modifying the taper of the box thread are similar and slightly smaller than those of the DUT. Therefore, a comprehensive comparison of the effects of internal and external pressure differences between the DUT and the eight types of unequal taper threads shows that the double-shoulder unequal taper Type I has the best compressive performance.

Conclusions

The uneven distribution of engagement stress in the drill pipe’s joint threads can hardly meet the development of complex drilling technology. Therefore, the structure of the drill pipe’s joint thread with unequal taper was proposed in this paper. The working mechanical properties of drill pipe joint thread with unequal taper were investigated under the make-up torques and compound effect. The following conclusions are drawn:

-

1.

The highly concentrated stress at the last engaged thread root of SUT may cause early yielding failure of the joint threads. The design shall be improved to avoid this situation.

-

2.

The pin thread with unequal taper reduces the uneven stress distribution for various make-up torques. The connection strength of single-shoulder Type II (pin thread taper is 1:6.2) is the best, with the maximum Mises stress value reduced by 56.69% compared with the standard single-shoulder joint thread. The bearing performance of double-shoulder Type I (pin thread taper is 1:6.1) is the best, with the maximum Mises stress value reduced by 34.87% compared with conventional double-shoulder joint thread.

-

3.

Under tensile and compressive axial loads, as well as internal and external differential pressure, the pin thread joint with unequal taper can improve the strength of thread connection, reducing the stress concentration phenomenon and leading to a more uniform stress distribution. The box thread joint with unequal taper has good performance under pressure loads. However, the improvement in thread connection strength is limited, and the phenomenon of uneven stress distribution is not improved. Type II has the best overall performance among single-shoulder. In contrast, Type I has the best overall performance among double-shoulder.

Data availability

The data that support the findings of this study are available on request from the corresponding author, upon reasonable request.

References

Tian, D., Chen, Y., Li, Q., Dong, M. & Mou, P. Research status and prospect of drill pipe thread used in coal mine. Coal Geol. Explor. 48, 233–239 (2020).

Chen, S. Research on Mechanical Behavior and Buckle Failure Process in oil pipe Threaded Connection (East China University of Science and Technology, 2013).

Croccolo, D. et al. Failure of threaded connections: a literature review. Machines 11, 212 (2023).

Li, Y. et al. Drill pipe joints fatigue analysis and optimization under special working conditions. J. Phys. Conf. Ser. 2691, 012018 (2024).

Gong, H., Liu, J. & Feng, H. Review on anti-loosening methods for threaded fasteners. Chin. J. Aeronaut. 35, 47–61 (2022).

Di, Q. et al. Research progress on mechanical properties of threaded connection for oil country well pipe tubular goods. J. Shanghai Univ. Sci. Ed. 26, 163–180 (2020).

Liu, H. et al. New design method of unequal taper thread (UTT) pairs and its application in API NC38 thread improvement. Petroleum 9, 439–453 (2023).

He, T. Analysis of Thread Stress of Oil Drilling and Development of Thread Reduction Coatings (Xi’an University of Science and Technology, 2020).

Wu, X., Gao, L. & Yuan, P. Method for calculating make-up torque on petroleum tool joint. Drill. Prod. Technol. 40, 67–70 (2017).

Chen, S., Li, Q., Zhang, Y. & An, Q. Finite element analysis of tooth load distribution on P-110S conic threaded connections. Int. J. Press. Vessels Pip. 88, 88–93 (2011).

Mo, L., Tu, L., Fu, Q. & Wang, L. Study on safety performance of premium thread joint for oil and gas wells. J. Saf. Sci. Technol. 13, 126–133 (2017).

Santus, C., Bertini, L., Beghini, M., Merlo, A. & Baryshnikov, A. Torsional strength comparison between two assembling techniques for aluminium drill pipe to steel tool joint connection. Int. J. Press. Vessels Pip. 86, 177–186 (2009).

Bertini, L., Beghini, M., Santus, C. & Baryshnikov, A. Resonant test rigs for fatigue full scale testing of oil drill string connections. Int. J. Fatigue. 30, 978–988 (2008).

Shi, Q. et al. Investigation on flexural fracture behaviour of bolted spherical joints with crack propagation in screw threads. Materials 16, 3781 (2023).

Oku, Y. et al. Fretting fatigue on thread root of premium threaded connections. Tribol Int. 108, 111–120 (2017).

Santus, C., Bertini, L., Burchianti, A., Inoue, T. & Sakurai, N. Fatigue resonant tests on drill collar rotary shouldered connections and critical thread root identification. Eng. Fail. Anal. 89, 138–149 (2018).

Zhu, X. & Zhang, Z. Design of an ultra-high torque double shoulder drill-pipe tool joint for extended reach wells. Nat. Gas Ind. B. 4, 374–381 (2017).

Dong, L., Zhu, X. & Yang, D. Study on mechanical behaviors of double shoulder drill pipe joint thread. Petroleum 5, 102–112 (2019).

Yang, W., Wang, R., Li, D., Zhang, L. & Xu, P. Three-dimensional mechanical characteristics analysis of double-shoulder tool joint under complex loads. Int. J. Press. Vessels Pip. 209, 105200 (2024).

Cheng, J. et al. Effect of interference magnitude on ultimate strength and failure analysis of aluminium-drill-pipe-body-tool-joint-assemblies with Johnson-Cook model. Eng. Fail. Anal. 137, 106281 (2022).

Gong, H., Liu, J. & Ding, X. Study on local slippage accumulation between thread contact surfaces and novel anti-loosening thread designs under transversal vibration. Tribol Int. 153, 106558 (2021).

Yu, H., Wang, H. & Lian, Z. An assessment of seal ability of tubing threaded connections: a hybrid empirical-numerical method. J. Energy Resour. Technol. 145, 052902 (2023).

Dzhus, A. P., Faflei, O. Y., Deineha, R. O., Yurych, L. R. & Dorokhov, M. A. Design of double-shoulder threaded joints of drilling string elements. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 60–65 (2023).

Chen, S., Gao, L. & An, Q. Calculation method of load distribution on pipe threaded connections under tension load. Front. Mech. Eng. 6, 241–248 (2011).

Zhu, X., Zhang, Z., Chang, X. & Li, L. Three-dimensional mechanical behavior of worn casing connecting thread in complex structural well. Acta Pet. Sin. 36, 748–753 (2015).

Zhang, Z. & Zhu, X. Multiaxial fatigue life of drill pipe joint. Acta Pet. Sin. 40, 839–845 (2023).

Tikhonov, V. et al. Application, calculation and experimental evaluation of SCF for aluminum drill pipe with steel connector. In 29th International Conference on Ocean, Offshore and Arctic Engineering: Volume 5, Parts A and B 29–35 (ASMEDC, 2010).

Institute, A. P. Specification for Threading and Gauging of Rotary Shouldered Thread Connections (American Petroleum Institute, 2008).

Thakur, J. Design and analysis of non-threaded drill pipe connector. (Robert Gordon Univ. (2022).

Onysko, O., Kopei, V., Kusyj, Y., Kornuta, O. & Schuliar, I. Turning of NC10 threads for drill pipes: theoretical study of the designed profile. In Design, Simulation, Manufacturing: The Innovation Exchange 356–366 (Springer, 2023).

Mei, M., Hou, H., Huang, T., Liu, S. & Zhao, Y. Numerical simulation and experimental investigation of coating influence on extrusion tap wear. Sci. Rep. 14, 18259 (2024).

Hu, F. et al. Fracture analysis of butt welding area of 5″ drill pipe internal thread end in an oilfield. J. Phys. Conf. Ser. 2463, 012040 (2023).

Chen, F. et al. The influence of clearance of secondary shoulder on performance of double shoulder drill pipe joint. Eng. Mech. 30, 353–357 (2013).

Kopei, V. B., Onysko, O. R., Panchuk, V. G., Odosii, Z. M. & Kusyi, Y. M. Increasing the fatigue strength of threaded joints of oil and gas equipment by plastic deformation of the thread under high load before make-up. J. Phys. Conf. Ser. 2540, 012033 (2023).

API RP 7G. Recommended practice for drill stem design and operating limits. (1998).

Yan, T., Fan, S. & Shi, D. A study on load distributional a drill collar threaded connection. Acta Petrolei Sinica. 3, 116–122 (1996).

Shi, C., Tan, L., Zhu, X., Chen, K. & Cheng, F. Fracture failure analysis and research on solid expandable tubular with joint thread. Eng. Fail. Anal. 129, 105658 (2021).

Xu, S., Wang, S., Meng, W., Wang, C. & Sun, Z. Study of the effect of the expansion cone on the expansion process in solid expandable tubulars with thread joints. J. Pet. Sci. Eng. 158, 175–185 (2017).

Hou, S. Analysis on Working Mechanical Properties of Variable Taper drill String Connection Thread (Yangtze University, 2022).

Gao, L., Jiao, W., Dong, Q. & Yuan, P. Torsion performance analysis of new dill pipe connection HLBT-8A. J. East. China Univ. Sci. Technol. 39, 115–120 (2013).

Cheng, X. & Hou, Y. Analysis of the influence of thread parameter deviation on the sealing performance of drill pipe joint under axial load. Acad. J. Sci. Technol. 10, 316–324 (2024).

Acknowledgements

The authors gratefully acknowledge the financial support from the National Natural Science Foundation of China (No. 51974035) and the Key R&D Program of Hubei Province (No. 2020BAB055).

Author information

Authors and Affiliations

Contributions

Hangming Liu planned the research content and revised the manuscript. Yongpeng Song established the finite element model. Shenghua Hu conducted the numerical simulation. Yuxian He wrote the main manuscript text and performed data analysis. Jifang Wan conducted the experiments. Xianzhong Yi handled data curation. Song Hou supervised the work. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Liu, H., Song, Y., Hu, S. et al. Design and mechanical properties analysis of drill pipe’s joint thread with unequal taper under complex loads. Sci Rep 14, 30856 (2024). https://doi.org/10.1038/s41598-024-81691-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-81691-6

Keywords

This article is cited by

-

Research on the Ultrasonic Phased Array Detection Method for Thread Defects of Drill Pipe Female Joints

Journal of Failure Analysis and Prevention (2025)