Abstract

Reflector antenna has been widely used in deep space exploration, radar warning, and other fields, all of which requires high pointing accuracy. The antenna elevation bearings are the key component that guarantees its pointing accuracy, while any degradation or fault can seriously affect the antenna’s performance, leading to deviations in antenna pointing and instability during operation. However, the relationship between the antenna elevation bearing fault and its pointing accuracy remains unclear because there is insufficient experimental faulty transmission data and pointing error collected from the test-rig simultaneously. Therefore, this paper aims to establish a deep learning model-based relationship to reveal the underlying relationship between the antenna transmission faults and its pointing accuracy. By linking the two, transmission faults in key components can serve as a substitute for pointing accuracy as one of the criteria for antenna maintenance decisions, vibration signals, serving as a basis for fault diagnosis, can be collected and processed in real-time without the need for equipment shutdowns, undoubtedly bringing convenience to antenna maintenance providing a theoretical basis for the development of antenna maintenance strategies. In order to overcome the problem of insufficient data, this paper has established an antenna elevation system dynamic simulation model containing pre-defined transmission faults. Furthermore, to link antenna fault diagnosis with antenna pointing errors, a mathematical model for antenna axis error analysis has been established. Finally, labeled fault data and antenna pointing errors have been put into the deep neural network model for training to obtain the prediction model for predicting antenna axis error. The results showed that faults in the key transmission components have a significant impact on antenna pointing errors and the proposed deep neural network learning model exhibits a high predictive accuracy.

Similar content being viewed by others

Introduction

The fully steerable large reflector antenna is an electro-mechanical equipment used to detect spatial targets using the electromagnetic wave. It can actively perform target acquisition, aiming, and tracking, playing a significant role in various fields such as deep space exploration, telemetry tracking, navigation, manned spaceflight, and so on1. During the large antenna service period, the degradation or fault in its transmission system can significantly affect their performance, further impacting the pointing accuracy and operational stability. Common key components of large antennas include elevation bearings, elevation axes, and the azimuth drive system to ensure the antenna can rotate in all directions. Among them, the elevation bearing is the only supporting structure between the antenna reflector and the azimuth frame, playing an extremely important role in ensuring antenna accuracy. However, defects such as wear in the bearing interface can inevitably occur during its operation and these failures can inevitably affect the pointing accuracy2. Timely evaluating and monitoring the pointing accuracy of the antenna can help antenna maintenance engineers effectively formulate preventive maintenance strategies and extend its service life.

Numerus studies have been carried out for studying the mechanism of transmission faults3. Based on the physical parameters of the transmission system, the mathematical model can be established and then, its dynamic response can be obtained with experimental data to refine the model4. Many scholars have conducted in-depth researches on the failure mechanisms of key components in mechanical systems. P.K. Gupta5,6,7,8 proposed one of the most representative bearing dynamic models to study the bearing vibration response. Based on Gupta’s work, the following researchers have established various models to study rotor bearing system with faulty components. Yang et al.9 developed a nonlinear rolling bearing model considering Hertz contact, time-varying characteristics, clearance, and slippage, and simulated local faults including outer race faults, inner race faults, and rolling element faults. Patil et al.10 established a dynamic model of localized faults in bearing races based on nonlinear contact theory, studying the effects of race defect size and position on bearing vibration characteristics. Pang and Wang et al.11 established a dynamic model rotor-bearing system with bearing outer ring fault, taking into account the torsional vibration in the model. Hongrui et al.12 provided a comprehensive review of modeling methods for rolling element bearings, summarizing the basic principles and characteristics of five types of rolling bearing models, and proposed a coupling modeling method between bearing models and rotor models. Even though these transmission dynamic models can be applied in the antenna transmission directly, its impact on the pointing error has been neglected.

On the other hand, researchers have investigated the factors affecting antenna pointing accuracy. Liang et al.13 proposed a reconstruction method of the vibration-deformation-induced pointing error for the main reflector via optimized acceleration measurement points. Xu14 has established an antenna structural dynamic model and a control-oriented pointing error analysis model based on modal superposition method to study pointing errors caused by environmental loads. Latifzade et al.15 presented mathematical model and simulation of mono-pulse pointing system using an analytic approach. He16 and others analyzed the impact of satellite disturbance-induced antenna pointing errors on Space Terahertz communication based on satellite disturbance models and Gaussian channel models. However, in these studies, antenna transmission fault17 and antenna pointing errors18 have been investigated separately. The underlying relationship between the antenna transmission fault and its pointing errors remains unclear.

Deep learning models have been proved to be effective in sorting out nonlinear relationship in engineering problems, such as abnormal detection, object detection, pattern recognition, semantic segmentation, social network analysis, and video recommendations19,20,21,22, leveraging its powerful feature extraction capability and nonlinear expression ability to learn deep features from various information and achieve classification through deep structures. Currently, models such as Convolutional Neural Networks (CNN) and Recurrent Neural Networks (RNN) have been widely applied23,24. Wen et al.25 transformed one-dimensional signals into two-dimensional images and utilized CNN to extract features from the transformed images for motor bearing, centrifugal pump, and hydraulic pump fault recognition. Stender et al.26 combined CNN with RNN for brake noise detection and prediction, finding that the combined model can overcome the limitations of traditional methods. These methods have demonstrated promising results in solving engineering problem. However, the application of deep learning in engineering classification requires abundant fault data, while large antennas are specialized equipment, lack of sufficient fault data sample. The transmission dynamic model can simulate the fault data by pre-defined various fault scenarios in a low-cost way, which can provide the required abundant dataset for the deep learning network training.

The structure of this paper is arranged as follow. In Sect. 2, the overall flowchart of the proposed method has been given. In Sect. 3, the antenna elevation bearing dynamic model has been established with pre-defined transmission faults. The experimental verification has also been carried out to verify the established dynamic model. In Sect. 4, the antenna pointing error mathematical model has been established and the effect of the transmission fault on the antenna pointing has been studied. In Sect. 5, the GRU-based intelligent prediction model for antenna pointing error has been proposed and trained for the antenna with transmission faults. By this way, the engineer can estimate the pointing error caused by the transmission faults by only measuring the transmission vibration data. In Sect. 6, the conclusion has been summarized.

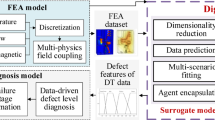

The framework of the intelligent prediction for pointing error

The deep learning based intelligent prediction requires sufficient training data, which is almost impossible for the large antenna currently. Therefore, this research proposed a simulation data driven deep learning approach for the intelligent prediction, where the required training data is generated by the established antenna transmission dynamic model, which mainly includes the elevation bearing and the reflector rotor. In the elevation bearing dynamic model, the motion relationship of each component in the elevation bearing and the time-varying displacement excitations have been considered. In the reflector rotor dynamic model, the motion equations of each degree of freedom of the rotor supported by the bearing have been analyzed. The elevation bearing fault is then incorporated into the antenna transmission dynamic model to investigate the dynamic response. Besides, a faulty experiment platform is built to verify the fault model by comparing the simulated signal with the collected experimental signal. Subsequently, the axial trajectories of the left and right elevation bearings have been extracted from the dynamic model. Furthermore, the relationship between antenna elevation shaft axis error and axial trajectories has been established, and the quantifiable tilt error has been analyzed within the spherical coordinate system under different types of faults. Considering the antenna operational environment, the influence of bearing wear behavior as well as the localized faults have been analyzed. Finally, a GRU neural network model was established to predict the shafting error caused by different types of bearing faults in antenna, and the fault of antenna transmission system was further related to antenna pointing accuracy. The detailed process has been illustrated in Fig. 1.

Antenna elevation transmission system dynamic modeling

For the antenna with reflector, the mechanical system primarily consists of two main structures: the reflector and the antenna pedestal, which are connected each other by the elevation system. The main function of the reflector is to facilitate the reception and transmission of electromagnetic waves. The antenna pedestal is a component to support the whole antenna reflector. The elevation system, including the elevation bearing and elevation shaft, is the key components connecting the reflector and the pedestal and can enable the reflector to rotate in the elevation direction. The structure of the antenna elevation system is illustrated in Fig. 2: The elevation transmission system is driven by a motor to rotate the reflector for elevation adjustment. The elevation motion of the antenna can be estimated as the rotation of the rotor supported rigidly by bearings at both ends around the center, with the reflector’s center of gravity balanced at the center of the elevation axis. The entire antenna reflector structure rotates around the axis within the vertical plane, representing the antenna’s elevation motion process. The primary moving components include elevation bearing and elevation shaft. Therefore, this paper derived a coupled model for the fully movable large-aperture antenna elevation transmission system, mainly including bearing dynamic model, and rotor system model.

Elevation bearing system dynamic modelling

As important supporting components in the antenna elevation transmission system, elevation bearings play a crucial role. In this section, Hertz contact theory was used to model and analyze the elevation bearings and the bearing system configuration is shown in Fig. 3 Elevation bearing model. In the figure, O1 is the geometric center of rotor, O2 is the centroid of rotor, ObL/R is the geometric center of the left or right elevation bearing.

In the configuration, the elevation bearing is connected to the antenna pedestal structure. However, the weight of the antenna pedestal is normally much bigger than the weight of the elevation bearing and the excitation generated by the elevation bearing is hard to excite the antenna pedestal to vibrate. Therefore, when modelling the elevation bearing dynamic model, the antenna pedestal is simplified and treated as the ground for the elevation bearing. Based on the bearing dynamic model by Randall et al.27, the elevation bearing dynamic model has been built. The simplified rotor system of the reflector on the elevation axis is simplified to a Jeffcott rotor system supported by rolling bearings at both left and right ends. It is further simplified into a single mass unit, with the mass concentrated at the center of the rotor. The main assumptions used in the dynamic model are:

(1) The shaft is regarded as an elastic shaft without considering mass, and the disk is in the middle of the rotor, the gyro force of the system is ignored.

(2) The rolling balls are evenly distributed in the raceway and the friction between the ball and the raceway is neglected.

(3) The effects of lubricating oil film, temperature change, and other external factors are ignored in the bearing dynamic model.

(4) The bearing components are regarded as rigid bodies.

The dynamic equation for the left elevation bearing are as follows:

where: mrbL, moL, mpL, are the mass of the left elevation bearing inner raceway, outer raceway and bearing pedestal. xrbL, yrbL, xoL, yoL, xr, yr are the vibration displacement of the left elevation bearing inner raceway, outer raceway, and the disk in the x and y directions respectively. ypL is the vibration displacement of in the y direction. krbL, kopL, kpsL are the stiffness between the left bearing inner raceway and shaft, the stiffness between the left bearing outer raceway and pedestal, the stiffness between the left bearing pedestal and the antenna pedestal. crbL, copL, cpsL are the damping between the left bearing inner raceway and shaft, the damping between the left bearing outer raceway and pedestal, the damping between the left bearing pedestal and the antenna pedestal.

The dynamic equations for the right elevation bearing are similar with Eq. (1), as follows:

The dynamic equation for the antenna reflector rotor are as follows:

where: mr is the mass of the disk. kr is the stiffness of the shaft at the disk, cr is the damping of the shaft at the disk.

In the equations, FxL/R, FyL/R respectively represent the contact forces in the x and y directions of the bearing. According to Hertz contact theory, the contact forces between the inner and outer raceways and the single rolling element can be given by the following equation:

In the equations, Nb represents the number of rolling elements, and kb is the contact stiffness between the rolling elements and the inner and outer raceways. The deformation of the j-th rolling element δj, is determined by the total clearance c caused by the displacement between the inner and outer races, the angular position θj of the rolling element, and factors such as oil film and assembly clearances, given by:

The angular position of the ball j including the slippage is expressed as follows:

Considering that compression occurs only for positive values of \(\delta_{j}\), \(\gamma_{j}\)(\(\gamma_{j}\) represent the contact state of \(\delta_{j}\) the rolling elements) is introduced as:

The contact force for each rolling element obtained from the above equation, and the total contact forces in the x and y directions are determined by the following equations.

Transmission fault modeling

Bearings are critical components in the normal operation of the antenna elevation axis transmission system. With internal and external excitations, the failures of the transmission system are unavoidable. Common failures in the bearing system are: localized spalling and raceway wear. By establishing corresponding fault dynamic models, the vibration response characteristics of the system with faults can be obtained, and some validation experiment work has been carried out correspondingly. If faults on the inner/outer raceway are introduced in the bearing model, the total elastic deformation in Eq. (5) can be rewritten as,

where \({C}_{d}\) is the additional displacement caused by the bearing faults. Parameter \({\beta }_{j}\) is the fault switch to simulate the contact loss at the predefined angular position and it determines whether the jth ball/roller is inside the defected zone or not.

(1) Localized fault modelling of the elevation bearing.

Generally, localized fault in rolling bearing mainly occur on the inner and outer raceways. Therefore, this study focuses on defects on the bearing raceways. Figure 4 illustrates the presence of local faults on the bearing raceway. In the figure, W is the defect width, H0 is the defect depth disregarding distributed faults, Hm is the actual distance from the maximum displacement of the rolling element to its descent and ascent surfaces, ψd is the defect angle. When there is a local fault in the bearing, it leads to the appearance of additional radial displacement Clocalized, resulting in impact vibration. To better simulate this situation, it is assumed that the local defects on the inner and outer raceways are rectangular spalling, as shown in Fig. 4(b) and Fig. 4(c):

When there is a local fault on the raceway, the additional displacement of the rolling element caused by the fault can be expressed as:

The radial displacement λd of the rolling element passing through the surface local defect on the raceway is represented as:

From the diagram, the size of the defect angle on the inner and outer raceway can be expressed as:

Therefore, if the j-th rolling element passes through the area of the outer raceway’s local fault, the additional displacement is given by:

If the j-th rolling element passes through the area of the inner raceway’s local defect, the additional displacement is given by:

The outer raceway localized fault is normally fixed in location between θout and θout + ψdo. This normally occurs in the load zone. An inner raceway fault rotates at the same speed as the rotor, i.e. θin = ωst + θino, where θino is the initial starting location of the inner raceway fault.

(2) Wear Fault Modelling of the elevation bearing.

Moving components in machinery undergo wear as operating time increases. The key to studying bearing wear faults lies in analyzing the characteristic relationship between the wear parameters of the bearing-rotor system and the vibration response characteristics of the system. The influence of wear amount is incorporated into the healthy bearing dynamic model to analyze the effect of wear amount on system performance under different time increments. In mechanical components, the actual wear process of friction pairs is highly complex and can manifest in various forms of wear. To accurately simulate various wear processes, corresponding computational models has been established. Regarding the bearing raceway wear situation depicted in Fig. 5, the Archard28 wear model has been widely used in the study of bearing wear, determining the relationship between local wear volume and calculating the wear depth of the bearing raceway.

The Archard formula can be expressed as:

where V represents the wear volume, k is the wear coefficient, Q denotes the radial load, L stands for the relative sliding distance, and H represents the material hardness. With the consideration of V = hAs, the equation to calculate wear depth is,

where h represents the wear depth, As is the sliding area of within the surface contact time, \(\overline{p}\) is the contact pressure. Dividing both sides of Equation by the wear time Δt, the equation can then be rewritten as:

where u is the sliding speed of the contact point. The wear depth in the bearing raceway in different raceway positions can be expressed by the formula:

According to Hertz contact theory, the shape of the contact area between the rolling element and the raceway surface is elliptical. To study the wear evolution process in this area, it is necessary to analyze the variations in contact stress and sliding velocity on the elliptical contact area. The contact pressure is distributed in the area as an ellipsoidal shape, and the contact load in different micro-regions is represented as:

where Qmax is the maximum contact stress between the rolling element and the raceway, ai/o is the semi-major axis of the elliptical contact of the raceway, and bi/o is the semi-minor axis of the elliptical contact of the raceway. Parameter x and y is the position for the contact point and their range is x = [-ao, ao], y = [-bo, bo]。

For the ball bearing, Δui/o is the sliding velocity for the rolling ball-inter raceway and rolling ball-outer raceway respectively, and the detailed calculation is:

where Ri/o is the radius of curvature for the inner raceway and outer raceway, ωm is the rotation speed of the ball around the bearing axis, ωR is the self-rotation speed. The rotation speed of the ball on the inner raceway and outer raceway are,

The relative sliding speed at the contact point in the x and y directions are,

Therefore, the relative speed at the contact point is,

During the operation of the bearing, the contact stress and sliding velocity experienced by the rolling element vary over time. Therefore, it is not sufficient to only consider fixed values of Q and u, it is necessary to construct a wear life calculation model based on kinematic analysis of the rolling bearing. The wear volume for the whole contact area within one time step is :

The contact area for the jth rolling ball can be calculated as,

In the large antenna elevation bearing application, the bearing outer raceway is fixed while the bearing inner raceway is rotating. During the inner raceway rotation, its force comes from all the rolling balls and therefor, the wear depth for the inner raceway is uniform along the whole contact area. After the operating time t, the wear depth for the inner raceway can be calculated as:

where \(\Delta V_{mij}\) is the wear volume of the jth rolling ball-inner raceway wear interaction.

The wear depth for the outer raceway is non-uniform along the whole contact area and after the operating time t, the wear depth for the outer raceway can be calculated as:

where \(\Delta V_{moj}\) is the wear volume of the jth rolling ball-outer raceway wear interaction.

Experiment verification

Figure 6 shows a test-rig constructed for the elevation drive system, used for experimental validation. This experimental platform mainly consists of a servo stepper motor, a two-stage gear reducer, an angle encoder, a rotor shaft system, and a brake, among other components. The motor provides the driving torque, while the brake can act as a load to provide resistance torque. The experiments can simulate several basic bearing faults scenarios under different speeds. In the experiment, a YMC143A50 three-axis voltage output accelerometer sensor was used, with a sensitivity of up to 50 mV/g and a range of ± 100 g. It was connected to an NI-9230 data acquisition card (3 channels, input voltage ± 30 V, maximum sampling rate 12.8 kS/s) and connected to a computer via a USB interface. LabVIEW software was used on the desktop for data acquisition management and storage, with a sampling frequency set to 10 kHz, consistent with the model solution. The acquired TDMS-type data was directly opened using Excel after installing the corresponding plugin, and the required effective data was extracted for visualization processing in MATLAB.

For the validation of the bearing localized fault model, the output speed was set to 300 r/min. Since the outer race of the bearing is fixed to the bearing seat ring and the defect on the outer raceway is located at the lower down position, with defect dimensions: defect width W = 1 mm, defect depth H = 0.5 mm.

After simulating the bearing dynamic model, the simulated bearing signals for the localized faults and raceway wear can be obtained, as shown in Fig. 7. When there are localized defects on the inner and outer raceways of the bearing, in the time domain response, distinct periodic pulse responses can be observed compared to the time domain plot under normal conditions. After performing envelope analysis on the signal, an envelope spectrum analysis plot was obtained. Under healthy condition, the bearing exhibits rotational frequency fs. When a fault occurs on the inner race, additional response frequencies such as the fault characteristic frequency of the inner race fbpfi, the rotational frequency fs and frequencies fbpfi ± fs appear in the simulation results. These additional frequencies are due to the interaction of the bearing with other components in the entire model. When the fault occurs on the outer race, the characteristic frequency of the outer race fault fbpfo appears, and the second harmonic frequency 2fbpfo of the fault frequency is also clearly visible. This demonstrates the consistency between the simulated signal results and the calculated results.

The experimental conditions and parameters of the bearing used in the experiment were consistent with those of the simulation model. The vibration signals collected by the accelerometer sensor were analyzed in both the time domain and the frequency domain envelope, the experimental results are shown in Fig. 8. The time-domain waveforms and frequency-domain envelope analysis of the signals simulated by the model were essentially consistent with those obtained from the experiment. The fault characteristic frequencies of the inner and outer races were determined to be 114.8 Hz and 75.9 Hz, respectively. The frequency error between the experimental and simulated results was approximately 2.02%, validating the accuracy of the model. Therefore, this model can be utilized for the study of bearing localized faults and other types of faults.

Antenna pointing error modelling

In order to analyze the influence of typical faults on the axis error of large antenna, it is necessary to investigate the relationship between various error and the antenna pointing error. In the antenna structure, the reflector mounted on the antenna pedestal, and it’s mechanical axis has a bottom orthogonal axis that can rotate left and right, called the azimuth axis, and a top axis that can reciprocally rotate up and down, called the elevation axis. In azimuth-elevation antennas, these two axes are perpendicular to each other, and the accurate positioning and tracking of targets by the antenna mainly depend on these two axes. Angular measurement accuracy is one of the key indicators for the antenna equipment, with higher accuracy values indicating better performance. The vibration response of key components in the elevation axis structure will directly affect the accuracy of angular measurement. In order to study the mechanism of how bearing fault affects angular measurement accuracy, and analyze the causes of elevation axis error, the mathematical model for calculating axis error has been proposed.

Antenna pointing error analysis

Typically, a spherical coordinate system is used to describe the position of a target tracked by the antenna, as shown in Fig. 9(a). When the antenna points to any target in space, with the antenna’s current position as the origin O, the target position T can be determined by the target distance R, azimuth angle A, and elevation angle E. For the elevation-azimuth antenna mount, the elevation axis system error refers to the error caused when the elevation axis deviates from the ideal azimuth axis. This error leads to the misalignment between the elevation axis and the azimuth axis, affecting the pointing performance of the antenna. As shown in Fig. 9(b), assuming the azimuth axis is vertical, and the mechanical axis is perpendicular to the elevation axis, ideally, the mechanical axis of the antenna would move with the elevation axis in the YOZ plane. When there is a deviation δ in the horizontal plane of the elevation axis, the mechanical axis moves within the inclined plane YOZ`, resulting in an error between the antenna position and the target position.

where:

O: The intersection point of the antenna’s azimuth axis, elevation axis, and mechanical axis.

R: The straight-line distance OT from the antenna pointing to the target position T.

A: Azimuth angle, the angle between the projection line of OT and the Y axis on the horizontal plane XOY. When the azimuth angle is 0°, the Y-axis points to true north.

E: Elevation angle, the angle between the line OT and the projection line OD on the azimuth plane ZOD.

As shown in the figure, assuming the azimuth angle of the antenna is A, and the elevation angle is E. The azimuth angle error is ΔA and the elevation angle error is ΔE. By employing the formulas for spherical trigonometry, the azimuth angle error can be expressed as:

where δ is the total axis error. Due to the small magnitude of the error, typically under the condition E < 80°, sinΔA≈ΔA and tanδ≈δ can be approximated. Therefore,

In the spherical coordinate, the elevation angle error can be calculated as,

In the above equation, \(E-E^{\prime}\)= ΔE, which represents the elevation angle error, can be expressed as:

The total axis error δ can be divided into two parts: the elevation axis tilt error \(\Delta_{1}\) and the elevation axis wobble error \(\Delta_{2}\).The total axis error δ can be calculated as

Assuming that the distance supported between the bearings at the left and right support of the elevation axis is L, and the height difference between the two bearing rotation centers is ΔZ, the elevation axis tilt error δ1 can be calculated as,

The elevation axis wobble error \(\Delta_{2}\) can be further decomposed into two error components: axial error ΔS, and radial error δ2, as shown in Fig. 10. The axial error ΔS is normally quite small and can be neglected. In order to more accurately reflect the rotation process of the elevation shafting, it is necessary to measure the elevation axis along two orthogonal directions, The wobble error \(\Delta_{2}\) can be derived as:

where ΔC1 and ΔC2 are the elevation bearing radial offset along the x and y axes.

Effect of transmission fault on pointing error

(3) The impact of local bearing faults on pointing error

By incorporating local bearing faults (W = 2 mm, H = 1 mm) into the left-end bearing inner and outer races, based on the previously described elevation bearing dynamic model and the mathematical model of the axis error, the trajectory of the bearing axis can be obtained, as shown in Fig. 11 and Fig. 12.

From the figures, it can be observed that, with faults present in both ends’ elevation bearings, the vibration response along the axis trajectory is significantly changed when a local fault is introduced in the left-end bearing. When the defect occurs on the outer raceway, the displacement at the position of the local defect exhibits the most severe response. However, systems with inner race defects present a considerably wider margin circle in the axis trajectory. The right-end bearing is influenced by the bearing inner excitation, resulting in a trajectory with lacking in prominent impulse excitation response. Through analysis of the motion trajectories under local faults in the left and right bearings, the tilt error and wobble error of the elevation axis system can be obtained, and the axis error is calculated as shown in Table 1.

From the analysis of the results in the table above, it can be concluded that the faults mainly affect the radial runout error of the bearings, resulting in variations in the rotational angle error due to the faults on one side of the bearing. After calculating the axis deviation of the elevation axis system under the influence of different types of faults, an analysis was conducted to obtain the angular measurement errors of the antenna in azimuth and elevation directions as shown in Fig. 13 Azimuth and elevation angle errors under inner and outer race local faults, with changes in the elevation angle under different fault conditions.

(2) Impact of Bearing Wear Faults on Angular Measurement Accuracy.

To investigate the impact of wear on the system, an analysis of bearing raceway wear based on the Archard wear model established in the previous sections was conducted. Since the amount of wear on the bearings is a gradual process, different time increments need to be set. Figure 14 illustrates the relationship between different time increments and the depth of wear on the inner and outer raceways of the bearings. From the figure, it can be observed that the depth of wear gradually increases over time, and the wear depth on the inner raceway of the bearing is significantly higher than that on the outer raceway at the same time interval. This is due to the contact area between the inner race of the bearing and the rolling elements is small, resulting in higher pressure.

Based on the theoretical analysis and simulation results above, dynamic simulations were conducted after introducing time-varying wear. To investigate the effect of bearing wear on errors, it is assumed that both sections of the bearing wear at the same rate. The dynamic response of the bearings was analyzed after 500 h, 1200 h, 3000 h, 6000 h, 10,000 h, and 15,000 h of operation, respectively.

Figure 15 and Fig. 16 respectively depict the axis trajectories of the bearings at both ends of the elevation axis under different time increments of wear. As mentioned earlier, after wearing out, leading to clearances between bearing raceways. Changes in geometric dimensions will further alter dynamic behavior. Therefore, as shown in the trajectories in the figure, the axis trajectories after wear at different time intervals cannot maintain stable circular motion.

Through analysis of the motion trajectories, the tilt error and wobble error of the elevation axis system under different operating conditions were obtained, and the axis errors were calculated as shown in Table 2

Due to the varying depths of wear on the inner and outer raceways of the elevation bearings under different time increments of operation, the analysis of axis errors under different wear time was conducted. The angular measurement errors in azimuth and elevation directions are depicted in Fig. 17.

The pointing error intelligent prediction model

Recurrent Neural Networks (RNNs) are a significant branch of neural networks, known for their robust fitting capabilities in handling time-series data, but they also have certain inherent limitations. Consequently, Gated Recurrent Units (GRU) and Long Short-Term Memory (LSTM)29 networks have been developed, which to a certain extent, mitigate the issues of vanishing and exploding gradients that are prevalent in RNN30. Compared to LSTMs, GRUs have a simpler architecture with fewer parameters, making them more tractable to train, significantly enhancing training efficiency, and reducing the risk of overfitting31. Empirical evidence suggests that GRU perform comparably to LSTM, and in some cases, they exhibit superior performance when dealing with smaller datasets. For the vibration signals of bearings, data is primarily collected using interval time sampling, which imbues the samples with a temporal sequence. Therefore, a GRU model is selected for prediction due to its suitability for modeling such sequential data. The internal structure of the model is shown in Fig. 18.

Based on the model structure of GRU, the update gate can be used to control information from the previous moment, deciding how much past information to retain in the current time step, while the reset gate decides how much past information needs to be forgotten, with values limited between 0 and 1. The GRU network computation process is mainly divided into four steps:

(1) First, calculate the update gate zt:

(2) Similar to the update gate structure, then calculate the reset gate rt:

(3) Next, calculate the candidate hidden state value h̃t for the current moment:

(4) Finally, calculate the hidden layer output ht at time t:

xt is the input vector information at time t, Wz,Wr and Wh̃ represent the weights for the update gate, reset gate, and candidate hidden layer, respectively, bz, br, and bh represent the corresponding biases, ht-1 is the hidden layer information at time t-1, and σ represents the Sigmoid function.

Dataset and model training

In this section, the fault models have been established, and through the analysis of antenna axis error, the angular measurement errors of the antenna in azimuth and elevation directions caused by bearing faults have been obtained. The GRU network was selected to establish a prediction model for antenna angular measurement errors under different fault conditions. Inherently, this involves using the regression model of GRU network to fit the process of the effect of faults on azimuth and elevation errors. Based on the simulated data, the sample space is constructed to establish the prediction model, which ultimately predict the antenna pointing error.

In this model, one-dimensional vibration signals will be directly used as inputs. The vibration signals from the left-end bearing will continue to be used for model training and prediction. Three different datasets, S1, S2, and S3, are constructed to represent three different types of faults. By inputting different relevant variables, different datasets are constructed to establish the mapping relationship between different faults and errors. This is illustrated in Table 3.

(1) For inner race local faults, varying the size of the defect to simulate and generate inner race local fault bearing signal datasets, defined as S1.

(2) For outer race local faults, varying the position and size of the defect to simulate and generate outer race local fault bearing signal datasets, defined as S2.

(3) For bearing wear faults, varying the time increment of wear to simulate and generate bearing wear fault bearing signal datasets, defined as S3.

According to the provided fault parameter ranges for the three types of faults in Table 3, different fault vibration signals are simulated and generated, followed by axis error analysis to calculate the corresponding axis error quantities under each fault condition. The model is then subjected to batch simulation calculations, with a simulation time set to 20 ms and a sampling frequency maintained at 10 kHz. The sizes of the S1 and S2 simulation datasets are both 8,000, while the size of the S3 simulation dataset is 16,000. Each dataset is divided, with 70% of the data used as the training set and 30% used as the test set. The data used for training the GRU neural network and model validation are shown in Table 4, Table 5, and Table 6.

From the table, it is evident that as the fault size increases, the resultant axis error also increases as well. This is mainly due to the variation of bearing radial runout error, which causes the axis error, evolving with the fault. However, the original vibration signals obtained from the dataset are time series data, which are high-dimensional and processing them directly would result in a complex calculation process. The feature extraction technique based on time-domain, frequency-domain, and time–frequency domain can be used to deal with the original signal. In order to obtain information about the bearing in various states and characterize the time–frequency features of the signal, ten different features were extracted from the time-domain, frequency-domain, and time–frequency domain as a data preprocessing module before inputting the original signal into the network model.

Once the dataset of "fault type-angular error" for the bearings is obtained, the process of building the prediction model can be carried out. Figure 19 illustrates the modeling process of the GRU model network. The model primarily consists of an input layer, hidden layer, and output layer, where the output results in the axis error quantity. The output range of the regression layer is set between 0 and 1. The GRU1 and GRU2 layers are both set to 50 units. This choice is based on experimental evidence and common practices in the literature, where the number of units should neither be too large nor too small to balance the model’s learning capacity and the risk of overfitting. Forty training epochs are set. This number is based on the principle of early stopping, which stops training when performance on the validation set no longer improves to prevent overfitting. Forty is an initial estimate. The learning rate is set to 0.001, which is a common starting value suitable for many deep learning tasks. The Adam optimizer combines the advantages of RMSprop and Momentum, two optimization algorithms, and can adaptively adjust the learning rate for each parameter, typically leading to faster convergence and better performance. Mean Squared Error (MSE) is used as the loss function because it is suitable for regression problems and can effectively measure the difference between predicted and actual values. The structural parameters of the GRU error prediction model are set as shown in Table 7.

The steps for GRU error prediction are as follows:

Step 1: Data preprocessing: Normalize the obtained dataset, allocate training and testing data in a certain proportion, and extract time–frequency features from the data.

Step 2: Establish the GRU prediction model: Use the features of bearing signal data as input and the error quantity as output. Begin training with three different fault types and set model parameters.

Step 3: Model optimization: Adjust model parameters during training to obtain the optimal GRU model.

Step 4: Reverse normalization: Perform reverse normalization on the error output results obtained from the optimal prediction model to establish the mapping relationship between bearing signal data and angular measurement errors under different types of faults.

Results discussion

Using the previously established GRU error prediction model, the vibration signals from the three datasets were used to predict the antenna axis error quantities. The predicted results for the test set are shown in the following figures.

In Fig. 20, when the bearing is in a state of inner race local fault, as the size of the fault defect increases, the trend of the resulting axis error quantity gradually becomes less steep. In Fig. 21, when the bearing is in a state of outer race local fault, the variation of the axis error quantity increases initially with the increase of the fault defect size and then begins to decrease. This is because the outer race local fault is influenced by the position of the defect, with the maximum impact occurring at the 6 o’clock position under the same fault size. In Fig. 22, when the bearing is in a state of wear fault, the degree of wear increases rapidly with time, resulting in a rapid increase in the axis error quantity. The predicted values of the test samples for the three types of faults generally follow the same trend as the true values, with the red line and blue line almost overlapping, indicating that the GRU network model can accurately predict the axis error quantity.

To evaluate the predictive performance of the model on pointing error, root mean square error (RMSE) and coefficient of determination (R2) are selected as evaluation metrics for the prediction model, as shown in Table 8.

The coefficient of determination R2 clearly reflects the reliability of the GRU neural network model. A value closer to 1 indicates a higher fitting accuracy of the model and more accurate results. The maximum R2 value in the sample data is 0.9214. Based on the RMSE and R2 values for prediction errors, it can be demonstrated that the GRU network prediction model proposed in this paper can achieve rapid and accurate prediction of error quantities through neural network modeling.

Conclusion and discussion

This paper has established an intelligent prediction method to reveal the underlying relationship between the antenna transmission faults and its pointing accuracy. During the prediction process, the dynamic model of the antenna elevation bearing with localized faults and wear fault has been established. As the antenna pointing error has been significantly impacted by the elevation bearing conditions, the mathematical model for the antenna pointing error has also been established. All these simulated data have been used as the labeled fault data and antenna pointing errors in the deep neural network model for training to obtain the prediction model for predicting antenna axis error. The results showed that faults in the key antenna transmission have a significant impact on antenna pointing errors and the proposed deep neural network learning model exhibits a high predictive accuracy, which can be more than 0.9. This paper has laid a promising foundation for antenna maintenance to develop reasonable maintenance strategies for large antenna transmission component.

Regarding the research methods of this paper, the approach involves establishing corresponding models, validating the accuracy of these models through experiments, and predicting a certain target value using a data-driven approach. The main methods can be roughly divided into three categories:

-

1.

Simulation modeling is used to generate simulated data, which is then processed and input into a neural network for training the prediction model.

-

2.

A portion of the data is obtained through simulation modeling, and another portion is collected under actual working conditions. Transfer learning32 is applied to combine these two types of data for training, resulting in new data that is then used to train the prediction model within a neural network.

-

3.

Similar to the second method, adversarial learning33 is used to integrate real-world data with simulated data, creating new data that is subsequently input into a neural network for training the prediction model.

It is evident that the latter two methods are superior because the new data resulting from their integration more closely resembles actual data, offering higher credibility, which is also a focus of our next phase of work.

Data availability

The data that support the findings of this study are available from the corresponding author, upon reasonable request.

References

Rahmat-Samii, Y. & Haupt, R. Reflector Antenna Developments: A Perspective on the Past, Present and Future. IEEE Antennas Propag. Mag. 57, 85–95 (2015).

Randall, R. B. Vibration-based condition monitoring: industrial, aerospace and automotive applications (John Wiley & Sons Ltd, 2021).

Liu, Z. et al. Dynamic analysis and modeling of ball screw feed system with a localized defect on the support bearing. J. Braz. Soc. Mech. Sci. Eng. 45, 367 (2023).

Wang, M. et al. Effects of deformations and angular ring misalignment on dynamic properties for ball bearing under different preload mechanisms. J. Braz. Soc. Mech. Sci. Eng. 45, 274 (2023).

Gupta, P. K. Dynamics of rolling-element bearings—Part I: Cylindrical roller bearing analysis. J. Lubr. Technol. 101, 293–302 (1979).

Gupta, P. K. Dynamics of rolling-element bearings—Part II: Cylindrical roller bearing results. J. Lubr. Technol. 101, 305–311 (1979).

Gupta, P. K., Dill, J. F., Artuso, J. W. & Forster, N. H. Ball bearing response to cage unbalance. J. Tribol. 108, 462–466 (1986).

Gupta, P. K. Cage unbalance and wear in ball bearings. Wear 147, 93–104 (1991).

Yang, Y., Yang, W. & Jiang, D. Simulation and experimental analysis of rolling element bearing fault in rotor-bearing-casing system. Eng. Fail. Anal. 92, 205–221 (2018).

Patil, M. S., Mathew, J., Rajendrakumar, P. K. & Desai, S. A theoretical model to predict the effect of localized defect on vibrations associated with ball bearing. Int. J. Mech. Sci. 52, 1193–1201 (2010).

Pang, B., Wang, B., Sun, Z. & Hao, Z. Torsional and lateral vibration analysis of wind turbine generator bearing outer ring fault considering unbalanced magnetic pull. Eng. Fail. Anal. 161, 108251 (2024).

Cao, H., Niu, L., Xi, S. & Chen, X. Mechanical model development of rolling bearing-rotor systems: A review. Mech. Syst. Sig. Process. 102, 37–58 (2018).

Liang, W., Huang, J., Zhang, J., Tang, X. & Zhang, Y. Reconstruction of vibration-deformation-induced pointing error via optimized acceleration measurement points for large reflector antennas. Proc. Inst. Mech. Eng. Part C: J. Mech. Eng. Sci. 233, 3417–3428 (2019).

Xu, Q., Zhang, J., Wang, Z.-Y. & Pan, H.-Z. Analysis and compensation of the reflector antenna pointing error under wind disturbance. Res. Astron. Astrophys. 21, 150 (2021).

Latifzade, M. A., Arvan, M. R. & Armaki, H. M. Monopulse antenna-pointing system modelling and simulation. IET Radar Sonar Navig. 13, 646–652 (2019).

He, Y. & Ma, C. Analysis of the effect of antenna pointing error caused by satellite perturbation on space terahertz communication. Appl. Sci. 12, 10772 (2022).

Prajosh, K. P., Ranganathan, S. S., Ferranti, F. & Khankhoje, U. K. Efficient mutual-coupling aware fault diagnosis of phased array antennas using optimized excitations. IEEE Antennas Wirel. Propag. Lett. 21, 1906–1910 (2022).

Xu, Q., Xue, F., Wang, H. & Yi, L. Measurement and correction of pointing error caused by radio telescope alidade deformation based on biaxial inclination sensor. Micromachines 14, 1283 (2023).

Nguyen, T. T. et al. Deep learning for deepfakes creation and detection: A survey. Comput. Vis. Image Underst. 223, 103525 (2022).

Dong, S., Wang, P. & Abbas, K. A survey on deep learning and its applications. Comput. Sci. Rev. 40, 100379 (2021).

Ni, J., Young, T., Pandelea, V., Xue, F. & Cambria, E. Recent advances in deep learning based dialogue systems: a systematic survey. Artif. Intell. Rev. 56, 3055–3155 (2023).

Piccialli, F., Somma, V. D., Giampaolo, F., Cuomo, S. & Fortino, G. A survey on deep learning in medicine: Why, how and when?. Inf. Fusion 66, 111–137 (2021).

Zhao, X. & Luo, W. A deep intelligent hybrid model for fault diagnosis of rolling bearing. J. Vib. Eng. Technol. 11(2), 721–737 (2023).

Shang, Z., Zhang, J., Li, W., Qian, S. & Gao, M. A domain adversarial transfer model with inception and attention network for rolling bearing fault diagnosis under variable operating conditions. J. Vib. Eng. Technol. 12, 1–17 (2022).

Wen, L., Li, X., Gao, L. & Zhang, Y. A new convolutional neural network-based data-driven fault diagnosis method. IEEE Trans. Ind. Electron. 65, 5990–5998 (2018).

Stender, M. et al. Deep learning for brake squeal: Brake noise detection, characterization and prediction. Mech. Syst. Sig. Process. 149, 107181 (2021).

Sawalhi, N. & Randall, R. B. Simulating gear and bearing interactions in the presence of faults: Part II: Simulation of the vibrations produced by extended bearing faults. Mech. Syst. Sig. Process. 22(8), 1952–1966 (2008).

Yu, G. et al. Wear-life analysis of deep groove ball bearings based on Archard wear theory. J. Mech. Sci. Technol. 32, 3329–3336 (2018).

Hong, S. & Zeng, Y. A health assessment framework of lithium-ion batteries for cyber defense. Appl. Soft Comput. 101, 107067 (2021).

Lee, J.-H. & Hong, J.-K. Comparative performance analysis of RNN techniques for predicting concatenated normal and abnormal vibrations. Electronics 12, 4778 (2023).

Zarzycki, K. & Ławryńczuk, M. Advanced predictive control for GRU and LSTM networks. Inf. Sci. 616, 229–254 (2022).

Han, Y. et al. Dual-drive RUL prediction of gear transmission systems based on dynamic model and unsupervised domain adaption under zero sample. Reliab. Eng. Syst. Saf. 253, 110442 (2024).

Gao, Y., Liu, X. & Xiang, J. Fault detection in gears using fault samples enlarged by a combination of numerical simulation and a generative adversarial network. IEEE/ASME Trans. Mechatron. 27, 3798–3805 (2021).

Funding

This work was supported by the National Key Research and Development Program of China (Grant No. 2021YFC2203600), National Natural Science Foundation of China (Grant No. 52475278 and 52275269), the Fundamental Research Funds for the Central Universities (Grant Nos. ZYTS24030, ZYTS24024), The Project about Building up "Scientists + Engineers" of Shaanxi Qinchuangyuan Platform under No. 2022KXJ-030.

Author information

Authors and Affiliations

Contributions

Lihui Chen: Methodology, Writing- Original draft preparation. Song Xue: Conceptualization, Supervision, Writing- Reviewing and Editing. Peiyuan Lian: Visualization, Investigation. Qian Xu: Software, Validation. Software, Validation. Meng Wang: Software, Visualization. Congsi Wang: Supervision, Writing- Reviewing and Editing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare that there is no conflict of interest regarding the publication of this paper.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Chen, L., Xue, S., Lian, P. et al. A deep learning approach for predicting the antenna pointing error caused by transmission faults with simulation data. Sci Rep 14, 31824 (2024). https://doi.org/10.1038/s41598-024-83103-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-83103-1