Abstract

Acoustic emission information can describe the damage degree of rock samples in the process of failure. However, as a discrete non-stationary signal, acoustic emission information is difficult to be effectively processed by conventional methods, while wavelet analysis is an effective method for non-stationary signal processing. Therefore, acoustic emission signal is deeply studied by using wavelet analysis method. In this paper, on the basis of noise reduction of acoustic emission signal, Matlab calculation program is used to decompose the acoustic emission signal of coal sample under the confining pressure test of triaxial unloading, and the singularity detection is carried out. The results show that the time when the Lipschitz index value first appears α negative can be used as the prediction time. However, the corresponding time when the Lipschitz index value is -0.15~-0.31 should be excluded; The absolute range of the difference between the final forecast time and the actual rupture time of coal samples is [5.2s, 17.1s], and the coal samples with the absolute value of time difference within [5.2s, 10.0s] account for 63.6% of the total.

Similar content being viewed by others

Introduction

Under the action of external load, when the internal energy of rock material reaches a certain limit, it will induce the expansion of microfissure, accompanied by the rapid release and propagation of stress waves. For large rock mass, the high frequency part of the stress wave attenuates rapidly, and the signal with high energy but low frequency is usually detected as the microseismic signal1,2,3,4,5. For small-scale rock samples, signals with small energy but high frequency are often obtained, which are acoustic emission signals, and the properties of the two have many similarities. In the process of mine mining, all kinds of mine disasters caused by rock excavation and unloading do not exist in isolation, and there must be some precursor characteristics before they occur. For example, microseismic signals are one of the precursor characteristic information given by them6,7,8,9. Although the scale and microseismic signal energy of rock samples and rock mass are very different, their principles are similar. Conducting acoustic emission tests on rock samples in the laboratory and studying rock fracture prediction methods based on acoustic emission information have important guiding significance for using microseismic monitoring technology to predict mine disasters such as roof fall, water inrush from the top and floor and rock burst10,11,12.

Many scholars have carried out acoustic emission tests of coal and rock samples, and analyzed the acoustic emission characteristics of different samples under different test conditions. The research shows that acoustic emission parameters such as acoustic ringing count rate and energy rate can better describe the damage and rupture of rock samples during the test, and the damage and rupture of rock samples can be predicted by acoustic emission parameters13,14,15,16,17,18,19,20. D. Lockner21analyzed the acoustic emission characteristics during the process of rock fracture; Landis, E.N22. analyzed the correlation between stress waves and frequencies in acoustic emission; Lacidogna, G23. analyzed the acoustic emission law and frequency variation characteristics of concrete in a four point bending test; Aggelis, D.G24. analyzed the variation characteristics and wave distortion of acoustic emission in cementitious materials; Tandon, S25. further studied the crack propagation law during the fracture process of cement-based materials by analyzing the acoustic emission characteristics; Niccolini, G26. further analyzed the relationship between acoustic emission and resistance changes during the failure process of rocks and cement-based materials.

Common methods for processing acoustic emission signals include wavelet packet decomposition, Fourier analysis, and neural network analysis. Among them, wavelet packet decomposition stands out as an excellent time-frequency analysis tool, which can capture the time-frequency characteristics of signals in both time and frequency domains and remove noise from these features. Many scholars use wavelet packet decomposition methods to process acoustic emission signals27,28. Li et al. and He’s research shows that the emission signals of rocks can be divided into low-frequency and high-frequency signals, and the resulting signals can be compared with the original emission signals to analyze the waveform characteristics of rocks over time. Li et al. used wavelet packet decomposition method to perform frequency band decomposition on acoustic emission signals and described the energy distribution patterns of acoustic emission signals in different frequency bands29,30,31,32.

Based on this, on the basis of the confining acoustic emission test of coal sample triaxial unloading, this paper applies the discrete wavelet method to conduct in-depth research on the discrete acoustic emission data series, analyzes the acoustic emission prediction method and prediction index, and explores the internal law of coal rock in the process of confining pressure damage and fracture in the triaxial unloading.

Design of test scheme

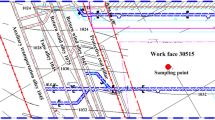

Samples

The test coal sample is taken from 16 coal seam of Yangcun Coal Mine, and the coal seam structure is relatively simple. According to the test method standard of engineering rock mass, the coal block was processed into a standard cylinder specimen of 50 mm× 100 mm (diameter × height), as shown in Fig. 1. In order to reduce the influence of the discreteness of the sample on the test result, the specimen was tested by acoustic wave test, and the specimen with large wave velocity dispersion was excluded, and the specimen with wave velocity in the range of 1900 ~ 2000 m/s was selected for test.

Test scheme

Triaxial loading and unloading tests are carried out on the MTS815.02 electro-hydraulic servo rock mechanics test system of the China University of Mining and Technology. The test system can meet the test requirements under a variety of complex paths, as shown in Fig. 2.

The acoustic emission monitoring adopts the AE21C acoustic emission system, which not only processes conventional acoustic emission parameters, but also comes with a high-speed data acquisition card. It is suitable for monitoring both sudden and continuous acoustic emission waves, and can record 1–2 channels of acoustic emission waveforms for frequency spectrum analysis and wavelet analysis.

During the experiment, according to the characteristics of communication interface of MTS815 electro-hydraulic servo rock mechanics test system, the communication interface of MTS815 rock servo test system was modified so that the AE detector can be placed inside the triaxial chamber and the signal goes smoothly from inside to outside of the triaxial chamber; At the same time, in order to solve the problem that the detector could not withstand the pressure of the hydraulic oil in the triaxial chamber and ensure the working performance of the AE detector, the high confining pressure triaxial AE test head was developed which can seal the AE detector inside the triaxial chamber so that the detector can work normally under high confining pressure. Based on this, the triaxial compression AE test method for rock can be improved and optimized, which is convenient for researchers to use a more reasonable AE test method to carry out the AE test of different loading paths (rock compression, unloading confining pressure and cyclic loading, etc.) under the triaxial condition.

The test plan in this study was as follows.

Loading test: triaxial tests of specimens under different confining pressures were carried out; the confining pressure (4 MPa, 7 MPa and 10 MPa) was gradually applied under hydrostatic pressure. Under constant confining pressure, the axial pressure was increased by axial displacement control at a loading rate of 0.002 mm/s until the specimen failed. The peak stress of specimens under conventional triaxial compression was obtained.

Unloading test: the experiment adopted the unloading path of increasing axial pressure and unloading confining pressure. It’s most dangerous and the failure time of the specimen is shortest under this path. The experiment was divided into three stages:①Increase the confining pressure(σ3) which is gradually increased to a predetermined value(4 MPa, 7 MPa and10MPa) according to the hydrostatic pressure condition. ②Keep the value of σ3 unchange and increase the axial pressure(σ1) to the 80% of compressive peak stress of conventional triaxial test though the stress control method. ③Use the displacement control method to increase the value of σ1,and at the same time, the value of σ3 is removed at a rate (0.02 MPa/s, 0.05 MPa/s, 0.08 MPa/s, 0.11 MPa/s and 0.14 MPa/s) until the specimen is destroyed. Then, the removing of confining pressure is stopped immediately after the specimen is damaged, when the axial pressure is continued to load to the residual strength of the specimen using displacement control method, as shown in Fig. 3.

Acoustic emission characteristics

Figure 1 shows the acoustic emission ringing count rate and energy count rate test results of triaxial unloading confining pressure test of some samples. The numbers in the figure are explained as follows: C stands for “coal”, 4, 7…… Represents different initial confining pressure of unloading (unit: MPa), 0.02, 0.08…… Represents the unloading confining pressure rate (unit: MPa/s); The vertical letter AE-CNT in the figure represents the acoustic emission ringing count rate, as shown in Figs. 4 and 5.

By comparing the acoustic emission ringing count rate and energy count rate curves of coal samples, the regularity of them is similar in each stage of damage and fracture of rock samples. According to the mechanical mechanism of triaxial unloading confining pressure test, the acoustic emission ringing count and energy of coal rock during the experimental process can be divided into four stages, namely compaction stage, elastic-plastic stage, unloading and fracturing stage, macroscopic fracturing stage, and plastic flow stage. Based on the stress-strain curve and the influence of confining pressure unloading, the characteristics of each stage are analyzed.

Compaction stage OA: When the primary fissure inside the rock sample is closed in the compaction stage, sporadic acoustic emission phenomenon will be caused, and its frequency and energy value are very small. If the sample has high strength and few internal main cracks, the degree of crack propagation in the elastic stage is low, and there are few acoustic emission events. If the strength of the sample is low and there are many primary cracks inside, the rock cracks will propagate during the elastic stage, accompanied by sporadic acoustic emissions. Similarly, when the confining pressure is high, it has a strong inhibitory effect on the deformation and failure of the specimen, and there are fewer acoustic emission events; When the confining pressure is low, the inhibitory effect on the sample is weak, and at this time, there will be an increase in acoustic emission events.

Elastoplastic stage AB: In the early stage of elastoplastic stage, there is basically no acoustic emission activity. With the increase of axial stress, the energy accumulation in the rock sample gradually increases, and the primary cracks begin to produce slip friction, resulting in acoustic emission phenomenon, but the acoustic emission events are still low on the whole. The main reason for this stage is also the inhibitory effect of confining pressure on the failure of the specimen. Under axial load, the specimen accumulates energy, but due to the inhibitory effect of confining pressure, the degree of crack propagation in the specimen is relatively low at this time.

In the stage of confining pressure relief and rupture BD: After the confining pressure relief begins, cracks of larger scale and more number appear inside the rock sample, and the acoustic emission activities are further enhanced. With the continuous increase of load and the continuous reduction of confining pressure, there is a period of “relative silence”. After the relative silence period, the rock sample reaches the peak stress point C, and then enters the fracture stage. At this time, the cracks inside the rock sample begin to expand rapidly, converge and penetrate, and the acoustic emission events increase rapidly until the rock sample suddenly fails.

Macro fracture stage DE: In this stage, the cracks continue to develop, and further converge and penetrate to form a macro fracture plane. The acoustic emission ringing number is large and the energy rate is high. Continue to load, the crushed block extrusion deformation, the rock sample into the residual crushing process, ringing count and energy gradually reduce.

Plastic flow stage: After point E, the rock sample produces macroscopic slip and enters the plastic flow stage. With the development of plastic deformation, the rock sample is further loosened and broken into the residual strength stage, in which the acoustic emission ringing count and energy are greatly reduced. In the later stage of the residual stage, the acoustic emission events of some rock samples even disappear.

The main reason for the difference in acoustic emission characteristics between the macroscopic fracture stage (DE) and the plastic flow stage is the effect of unloading confining pressure. After unloading confining pressure begins, the inhibitory effect of confining pressure on the rock sample weakens, and the crack propagation of the rock sample is obvious, which is significantly different from the elastic-plastic stage.

In addition, it can also be seen that the time of the maximum acoustic emission ringing count rate of rock samples is slightly behind its peak stress when the confining pressure is discharged from the triaxial unloading.

It can be seen from the above analysis that the process of compression, deformation and failure of coal and rock is closely related to the evolutive process such as the generation, expansion and penetration of new compaction cracks of the primary cracks in coal and rock. Acoustic emission information contains abundant precursor information of progressive damage and failure of coal and rock. The acoustic emission prediction method of coal and rock fracture can be found by processing and analyzing the acoustic emission information of coal and rock.

Wavelet analysis method

Determination of wavelet analysis method

Wavelet is a special waveform with limited length and zero average value, that is, the wave in a small region.Wavelet analysis is developed and deepened on the basis of Fourier analysis. In the process of analysis, the construction of wavelet basis and analysis results are related to Fourier analysis, and the two complement each other.

Commonly used wavelet basis functions include Morlet, Mexican hat, Meyer, Haar, Daubechies(N), Symlets(N), Coiflets(N). The main properties of each wavelet basis function are different. It is mainly manifested in compact support, orthogonality, symmetry, vanishing moment and whether it can be used for discrete wavelet transform, etc. Therefore, different wavelet basis functions should be selected for different signals.

Acoustic emission signal data of rock samples are large and sudden and transient. At the same time, due to the internal structure of rock samples, acoustic emission signals also contain a lot of noise. Therefore, the following conditions should be met when selecting wavelet basis function: The wavelet basis function should be able to better characterize the internal defects of rock samples and restrain external interference; In order to effectively remove the noise and judge the singularity inside the signal, the wavelet basis function should have a certain vanishing moment; In order to ensure no distortion of acoustic emission signal and certain local analysis ability, the wavelet basis function should have symmetry and compact support. In view of the large amount of acoustic emission data of rock samples, in order to speed up the analysis, discrete wavelet transform is adopted, and the selected wavelet basis function should be suitable for discrete wavelet transform analysis.

Based on the above analysis, Daubechies (db) wavelet has compact support, orthogonality and strong localization ability. Daubechies (db) wavelets are highly suitable for analyzing acoustic emission data and are beneficial for obtaining internal information of acoustic emission data33. Therefore, db wavelet basis function is selected to carry out discrete wavelet transform of acoustic emission signal. The signal frequency collected in this experiment is 10 MHz. According to the Nyquist theory, the vanishing moment of the wavelet basis function is 6, and the scale of the wavelet decomposition is 5, that is, db6 wavelet is used to decompose the acoustic emission signal in 5 layers.

Acoustic emission signal noise processing

During the test, affected by environmental factors such as cylinder piston movement, static electricity, servo valve vibration and other difficult to eliminate, the collected acoustic emission signal often contains a certain amount of noise. In acoustic emission signals, specific noise characteristics may include random noise, background noise, instrument noise, etc. These noises are usually mixed with useful signals, affecting the quality of the signal and subsequent analysis. Wavelet analysis, as an effective signal processing technique, can perform multi-scale decomposition on signals with different frequency components, enabling precise analysis and processing of signals in the time-frequency plane. This characteristic makes wavelet analysis particularly suitable for identifying and removing noise features in acoustic emission signals.Compared with other denoising techniques, wavelet analysis shows higher efficiency in processing non-stationary signals. For example, although traditional Fourier transform is very effective in analyzing stationary signals, it has limitations in dealing with time-varying and non-stationary signals because it lacks local information about time. In contrast, wavelet transform provides the ability for time-frequency localization analysis, allowing for simultaneous analysis and processing of signals in both time and frequency. That is, the signal is decomposed by wavelet, and the decomposed high frequency coefficient is denoised to a certain threshold, and then the signal is reconstructed.

Acoustic emission ringing count rate and energy rate can better describe the damage and rupture of rock samples in the test process, and ringing count and energy rate are strongly correlated, so the ringing count rate is selected for analysis here. Matlab software was used to write the corresponding program for 5-layer decomposition of the raw law body signal using db6 wavelet basis function33, and then the appropriate soft threshold was used to denoise the decomposed wavelet coefficients of each layer, as shown in Fig. 6.

By comparing the signals before and after denoising, it can be found that after wavelet decomposition and soft threshold denoising, the noise contained in the acoustic emission signal is effectively removed and the acoustic emission information that can effectively reflect the damage and fracture process of rock sample is retained. Therefore, the acoustic emission signal noise processing is carried out by using the wavelet analysis method. More real and reliable acoustic emission information can be obtained.

Discrete wavelet decomposition of AE time series

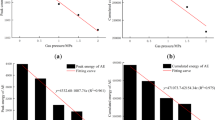

As AE energy represents the strength of AE events and reflects the intensity of rock fissure occurrence and fracture, it is of more guiding significance for the study of rock failure prediction. In this paper, AE energy is selected for analysis and research. The main steps: Matlab general inspection and processing of data series; Call Matlab wavelet analysis toolbox; Parameter analysis; Show the dispersion coefficient. Figure 7 shows the wavelet coefficients extracted from acoustic emission energy signals at different scales by using Matlab wavelet toolbox.

As can be seen from the figure, the damage and rupture points inside the rock correspond to the maximum value of discrete wavelet coefficients at each scale. Therefore, the mutation of wavelet coefficients at each scale can reflect the law of damage and rupture of rock samples. It can be seen from Fig. 7 that the change of discrete wavelet coefficients of acoustic emission signals is correlated with the damage and rupture of rock samples, and the sudden change of discrete coefficients can be used to predict the rupture of rock samples.

Acoustic emission prediction of rock fracture based on discrete wavelet coefficients

From the previous analysis, it can be seen that the wavelet dispersion coefficient of acoustic emission signal will mutate near the rock sample rupture, and the mutation part or singularity in the signal often contains important characteristic information. The singularity in the acoustic emission signal of rock sample is detected here, so as to obtain the internal information of rock sample damage and rupture.

In general, there are two kinds of signal singularity. One is that the amplitude of the signal changes at a certain time, resulting in the discontinuity of the signal, which is the first kind of discontinuity point; Second, there is no obvious mutation in the appearance of the signal and it is continuous and smooth, but it is found that there is discontinuity in the first-order differentiation of the signal, which is the second kind of discontinuity point. If there is a kind of discontinuity point or the second kind of discontinuity point of a certain derivative at a certain position, it is considered that the function has singularity here, so the singularity of the function can be used to judge the law of the function, and the local change of the function can be measured by Lipschitz index α (Lipschitz index). The above analysis method is also applicable to the detection of the singularity of acoustic emission signal. Therefore, the Lipschitz index value α of the signal can be obtained to judge the singularity of the signal. Lipschitz index α can be used to measure the singularity of the signal as follows34:

Let 0 ≤ α ≤ 1 at the point, if there is a constant K > 0, the neighborhood of the pair makes the following formula true.

Then the value of the function f(x) at point x0 is said to be the Lipschitz index number α; When α = 1, it indicates that the function f(x) is differentiable at x0, and the function f(x) has no singularity at this point; When α = 0, it indicates that the function f(x) is discontinuous at x0, and the larger the α value, the closer the singular function f(x) is to the rule; The smaller the α value, the more the singular function f(x0) mutates at x.

In addition, when 0 < α < 1, the degree of mutation of the function at that point is between the step function and the polyline function; When α = 0, the function has a step mutation at this point; When − 1 < α < 0, the degree of mutation of the function at this point is between the step function and the delta function.

Wavelet coefficients play an important role in the study of rock sample damage and fracture. Through wavelet analysis, researchers can more effectively interpret energy changes related to rock failure processes. According to the principle of energy, Lipschitz values are calculated through wavelet packet decomposition and reconstruction. The time point in the time series corresponding to the minimum alpha value is considered as the time of rock fracture, thus effectively extracting the time information of rock fracture.

Before calculating the Lipschitz index, the acoustic emission signal was denoised to ensure the accuracy of the results. Using the signal singularity detection method mentioned above, Matlab software is used to write the corresponding calculation program to detect the singularity of discrete wavelet coefficients of acoustic emission signals at each layer of coal and rock under triaxial unloading confining pressure, and the regularity that the maximum value of the system modulus changes with the scale is adopted. The first negative α value of the acoustic emission ringing count rate of each layer of discrete wavelet coefficients under different scales and its occurrence time are calculated, as shown in Table 1.

The α value of the acoustic emission signal will change obviously when the rock sample is about to crack. The time when the acoustic emission signal appears negative α value is selected as the prediction time of the rock sample crack. Because the time when the discrete wavelet coefficient appears negative α value is different in different scales, the prediction time of the rock sample crack cannot only depend on the sudden change of the discrete wavelet coefficient on one scale. The calculation results of different scales need to be compared and analyzed, so the first negative α value of Lipschitz index of D1, D2, D3, D4 and D5 discrete wavelet coefficients is selected as the forecast time.

As can be seen from Table 1, the difference between the earliest negative α value of many coal samples and the fracture time of rock samples is large, that is, the earliest negative α value of time is much larger than the fracture time of rock samples. The reasons include the non-uniformity of the internal structure of coal samples, the presence of joints and cracks, and the noise that cannot be effectively removed, etc. If only the earliest negative α value of time is used to forecast the fracture of rock samples, It may reduce the accuracy of the prediction results. Therefore, when predicting the fracture of rock samples, on the one hand, the time of the earliest negative α value is taken as the prediction index, and on the other hand, the Lipschitz index value (α value) should be referred to. By comparing the data in Table 1, it can be seen that when there is a large difference between the occurrence time of negative α value and the fracture time of rock sample, the Lipschitz index value of rock sample ranges from − 0.15 to −0.31, indicating that the abrupt change of acoustic emission signal of rock sample is not obvious here. It can be seen that, when selecting the prediction time, the mutation point corresponding to the Lipschitz index value between − 0.15 and − 0.31 should be excluded. According to this criterion, the actual prediction time of coal sample rupture can be obtained as shown in Table 2, and the absolute range of the difference between the prediction time and the actual rupture time is [5.2s, 17.1s]. In addition, coal samples with absolute time difference of [5.2s, 10.0s] account for 63.6% of the total.

Conclusion

(1) The discrete data sequence of rock compression and fracture acoustic emission parameters over time is a typical unstable signal, and it is difficult to effectively analyze the internal information of the acoustic emission signal using conventional data analysis methods. Therefore, the discrete wavelet method can be used to process the acoustic emission signal and analyze the intrinsic information of the coal sample failure process;

(2) On the basis of denoising the acoustic emission signal, a corresponding calculation program was written using Matlab software to detect the singularity of the discrete wavelet coefficients of the acoustic emission signal of coal samples under triaxial unloading confining pressure, and the Lipschitz exponent analysis of acoustic emission energy at different scales was calculated. The results showed that the time when the Lipschitz exponent value first appeared as a negative alpha value was used as the prediction time, but the time when the Lipschitz exponent value was between − 0.15 and − 0.31 should be excluded;

(3) The absolute value range of the difference between the predicted time and the actual time of coal sample fracture is [5.2s, 17.1s], and 63.6% of the coal samples have an absolute time difference within [5.2s, 10.0s]. Therefore, discrete wavelet processing of coal sample acoustic emission data and the use of Lipschitz index for coal sample fracture prediction have good application value.

Data availability

The data used to support the findings of this study are available from the corresponding author upon request.

References

Wang, S. G. et al. Experimental study on failure process of arch dam based on acoustic emission technique. Eng. Fail. Anal. 97, 128–144 (2019).

Ma, D. P. et al. Creep behavior and acoustic emission characteristics of coal samples with different moisture content. Acta Geodyn. Geomater. 4 (192), 405–412 (2018).

Fan, X. Q. et al. Acoustic emission properties of concrete on dynamic tensile test. Constr. Build. Mater. 114, 66–75 (2016).

Zhang, Z. B. et al. Nonlinear characteristics of acoustic emission during the heating process of coal and rock.Fractals-Complex Geometry Patterns And Scaling In. Nat. Soc. 26(4) (2018).

Wang, G. et al. Shear behaviour and acoustic emission characteristics of bolted rock joints with different roughnesses. Rock Mech. Rock Eng. 51 (6), 1885–1906 (2018).

Codeglia, D. et al. Analysis of acoustic emission patterns for monitoring of rock slope deformation mechanisms. Eng. Geol. 219, 21–31 (2017).

Liu, J. P. et al. Analysis of rock mass stability according to power-law attenuation characteristics of acoustic emission and microseismic activities. Tunn. Undergr. Space Technol. 83, 303–312 (2019).

Lei, H. et al. Characteristics of the microseismicity resulting from the construction of a deeply-buried shaft. Tunn. Undergr. Space Technol. 85, 114–127 (2019).

Ma, T. H. et al. Rockburst mechanism and prediction based on microseismic monitoring. Int. J. Rock Mech. Min. Sci. 110, 177–188 (2018).

Cheng, J. L. et al. Research developments and prospects on microseismic source. location mines Eng. 4 (5), 653–660 (2018).

Likhodeev, D. V. et al. Studying the deep structure of elbrus volcano by microseismic sounding. J. Volcanol. Seismolog. 11 (6), 413–418 (2017).

Wu, X. Z. et al. Estimating the support effect of the energy-absorbing rock bolt based on the mechanical work trasfer ability. Int. J. Rock. Mech. Min. Sci. 103, 168–178 (2018).

Wang, P. et al. Stratabehaviors and rock-burst-inducing mechanism under the coupling effect of a hard thick stratum and a normal fault. Int. J. Geomech. 18 (2), 04017135 (2018).

Cao, W. et al. Numerical modelling of microseismicity associated with longwall coal mining(Article). Int. J. Coal Geol. 193, 30–45 (2018).

Vassiliadis, D. V. et al. Low-dimensional chaos in magnetospheric activity from AE time series. Geophys. Res. Lett. 17 (11), 1841–1844 (1990).

Polito, F. et al. Analysis of Metal Cutting Acoustic Emissions by. Time SeriesModels Stat. 48 (9–12), 897–903 (2013).

Codeglia, D. et al. Analysis of acoustic emission patterns for monitoringof rock slope deformation mechanisms. Eng. Geol. 219:21–31

Jiang, C. et al. Estimation algorithm of minimum dwell time in precision cylindrical plunge grinding using acoustic emission signal. Int. J. Precis. Eng. Manuf. 15 (4), 601–607 (2014).

Jing, G., Zhao, Y., Gao, Y., Marin Montanari, P. & Lacidogna, G. Noise Reduction Based on Improved Variational Mode Decomposition for Acoustic Emission Signal of Coal Failure. Appl. Sci. 13 (16), 9140 (2023).

Jing, G. et al. Study of Coal and Magnetite Collapse Process and Precursor Based on Acoustic Emission Flicker Noise Spectroscopy. Rock. Mech. Rock. Eng. https://doi.org/10.1007/s00603-024-03989-1 (2024).

Lockner, D. The role of acoustic emission in the study of rock fracture. Int. J. Rock. Mech. Min. Sci. Geomech. Abstracts. 30 (Issue 7), 883–899 (1993).

Landis, E. N. & Shah, S. P. Frequency-dependent stress wave attenuation in cement-based materials. J. Eng. Mech. ASCE. 121, 737–743 (1995).

Lacidogna, G., Piana, G. & Carpinteri, A. Acoustic emission and modal frequency variation in concrete specimens under four-point bending. Appl. Sci. 7, 339 (2017).

Aggelis, D. G., Mpalaskas, A. C., Ntalakas, D. & Matikas, T. E. Effect of wave distortion on acoustic emission characterization of cementitious materials. Constr. Build. Mater. 35, 183–190 (2012).

Tandon, S., Faber, K. T. & Bažant, Z. P. Crack stability in the fracture of cementitious materials. Mater. Res. Soc. Symp. Proc. 370, 387–396 (1995).

Niccolini, G., Potirakis, S. M., Lacidogna, G. & Borla, O. Criticality Hidden in Acoustic Emissions and in Changing Electrical Resistance during Fracture of Rocks and Cement-Based Materials. Materials 13, 5608 (2020).

SERRANO E P, FABIO, M. A. Application of the wavelet transformto acoustic emission signals processing. lEEE Trans. Signals Process. 44 (5), 1270–1275 (1996).

LI, Y. W. et al. Evaluation method of rock brittle-ness based on statistical constitutive relations for rock damage. J. Petroleum Sci. Eng. 2017, 153(5): 123–132 .

ZHANG Bing. Study on geological evaluation and key technologies for shale reservoir in the northern Songliao Basin. Special Oil& Gas Reservoirs. 29 (5), 72–79 (2022).

Yuwei, L. I. & Shuai, Y. A. N. G. Experimental of hydraulic fracture propagation using fixed-point multistage fracturing in a vertical well in tight sandstone reservoir. J. Petroleum Sci. andEngineering 2018, 171:704–713 .

Cong, H. E. et al. Application of SP logging wave-let transform in single well sequence divisionJ. Special Oil &Gas Reservoirs,2015,22(6):14–18 .

Yuwei, L. I. et al. A hydraulic fracture height mathematical model considering the influence of plastic region at fracture tip. Pet. Explor. Dev. 47 (1), 184–195 (2020).

Yunan, G. U. A. N., Chao, W. A. N. G. & Boyang, S. O. N. G. Processing and Analysis of Acoustic Emission Signals from Wind Turbine Blades Using Wavelet Analysis, Journal of Xi’an Jiaotong University, https://link.cnki.net/urlid/61.1069.T.20241021.1407.004

Qing, L. I. & Wan-qing, S. O. N. G. Tool Wear State Monitoring Using Lipschitz Exponent (Machinery Design &Manufacture, 2014).

Author information

Authors and Affiliations

Contributions

Shaojie Ma is responsible for writing, revising and processing data, Yan Zhou is responsible for designing and processing data, and Depeng Ma is responsible for rock mechanics testing, data processing and image processing. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ma, S., Zhou, Y. & Ma, D. Research on acoustic emission precursor characteristics of coal sample unloading failure based on discrete wavelet analysis. Sci Rep 14, 31854 (2024). https://doi.org/10.1038/s41598-024-83153-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-83153-5