Abstract

Aiming at the problems of complex stress and large deformations in the surrounding rocks of the roadway driven under the goafs of small collieries and heading for adjacent advancing coal face, by numerical modeling and field practice, the failure characteristics of the overlying coal and rocks were investigated, and the stopping and resuming times of the roadway excavation were identified. A zoning-based reinforcement technique was put forward and applied in engineering practice. The results showed that (1) The roadway roof was divided into four zones: “Rolid coal zone”, “Residual pillar zone”, “Roof caved zone”, and “Roof un-caved zone”. (2) It was determined that the roadway excavation was stopped when the unmined distance between the return airway face and the 32,101 working face was 70 m. After the 32,101 working face passed the return airway face by 90 m, the roadway driving was restarted. (3) I.e. cable reinforcement for the “residual pillar zone” and bolt-wire mesh-cable-shotcreting-grouting reinforcement for the “roof failure zone” (“Roof caved zone” + “Roof un-caved zone”). The field observation results indicated that the maximum amount of the roof-to-floor convergence and the wall-to-wall convergence was 97 mm and 69 mm, respectively, which ensured the safety of roadway excavating.

Similar content being viewed by others

Introduction

As mining equipment continuously upgrades, the mining rate increases as well, resulting in undesirable succession of mining and excavation in some mines1. Roadway heading for adjacent advancing face has become one of the effective ways to tackle the problem of the tight succession of mining and excavation2. Different from a traditional retreating roadway, the roadway tunneling towards adjacent mining face is influenced by the superposition action of the front abutment pressure and side abutment pressure hence the surrounding rocks are fragile and the support becomes more difficult3,4. Moreover, the stress environment of the surrounding rocks is more complex during the extraction of a remaining coal seam5. Scholars have conducted a great amount of research on the stability control of the roadway under a mined-out space or the roadway heading for adjacent retreating face.

(1) Some scholars pay attention to the dynamical stress behaviors and the stability control of the roadway that is driven towards adjacent mining face. By means of theoretical analysis, physical simulation and numerical calculation, Gao6, Han7 and Liu8 revealed that the roadway deformation and failure is dependent on the stress concentration coefficient and the failure zone width in the surrounding rocks under the influence of dynamic pressures. Guo9, Yu10 and Kang11 explored the evolution characteristics of the front abutment stress and side abutment stress, defined the influence range of the adjacent working face on roadway dynamic pressures, and determined reasonable occasions for driving the roadway and the mining face. Yang12 inspected the deformation features of the roadway under different pillar widths and proposed an asymmetric support technique through rock blots and cables. Wang13 constructed a stress model of the overlying strata and coal pillars in the mine-out area and put forward a combined support technique, i.e. “deep-hole-blast roof cutting coupled with grouting-cable reinforcement”. Bai14 and Qiao15 built a dynamic mechanical model of the roof structure of the roadway that was driven towards adjacent mining face, and devolved a combined support technique of “deep and shallow borehole grouting + bolting with wire meshes and cables” based on the use of zoning. Wang16 and Cao17 examined the relationship between pressure and crack formation and expansion, and incorporated the maximum tensile stress criterion and the Mohr-Coulomb criterion into the extended non-ordinary state-based peridynamics (NOSB-PD) to simulate the initiation, propagation and coalescence of the pre-existing flaws in rocks subjected to compressive loads. Wang18 proposed a new layout pattern about the gob-side entry under dynamic pressure, which mainly uses the roof cutting and pressure relief technology to maintain the stability of the roadway. (2) Other scholars focus on the stress distribution and the support technology of the roadway under a failure zone. Suchowerska19, Wojtecki20 and Lv21 clarified that the design of the roadway under the mined-out space should avoid the stressed area of residual pillars and the roadway should be away from the upper residual pillar as far as possible. Bi22 concluded that the failures of shallow and deep surrounding rocks of the roadway under the mined-out space are determined by vertical stress and horizontal stress, respectively. Liu23 and Ru24 disclosed that roadway asymmetry deformation is caused by the non-uniform stress in the coal pillar of the upper coal seam. Chen25 explained the main reasons for great difficulty in supporting the roadway under a mined-out area, that is, the caved waste is not connected with the unsupported roof and the stress distribution in the surrounding rocks is complex owing to stress superimposition for many times. Wu26 unraveled that the roof and pillar ribs under a goaf are the determinant parts for surrounding rock control. Shan27 examined the stress distribution in the surrounding rocks of the roadway under a goaf and presented a combined support technique with concrete-filled steel tubes, rock bolts and cables. Based on the deformation characteristics of the roadway under the residual pillar of the upper coal seam, Tian28 developed a critical bolting technique by means of directional pre-split blasting and using anchor cables with constant resistance to large deformations. Cao29 further investigated the diffusion law of grouting slurry in crack under different rheological index and different consistency index. Wang30, Cao31 and Wang32 studied the peak strength and failure characteristics of fractured rocks under loading were studied, and clarified the morphology and permeability characteristics of sandstone fracture surfaces with different particle sizes. Yang33 put forward the time-effect collaborative control countermeasures of the roof and rib in gob-side roadway of “hole collapse anchor cable of solid coal rib lag construction and waits for pressure relief and rapid excavation-support cycle in the heading face.“. Han34 proposed a collaborative control technology using pressure relief and anchoring, and the differentiated control method is formed for the three zones. Jia35 Put forward The “umbrella arch” overlying strata structure of isolated island working face mining, and formed the asymmetric pressure relief control strategy of roadway surrounding rock in isolated island working face mining.Hanzui coal mine is formed by integrating multiple small coal mines. After the layered mining of the No. 2 coal seam, multiple old goafs have been formed. Currently, the mining area is a single wing mining area. To avoid tight mining succession, the excavation face of the mining roadway is pushed towards the mining area. Due to the impact of small coal mine mining, there are many goaf damage areas and residual coal pillars on the roof of the mining roadway, and the range of plastic damage areas in the surrounding rock of the roadway increases. Under the influence of complex surrounding rock stress, the difficulty of roadway support increases. Therefore, it is urgent to carry out relevant research on the control of surrounding rock in the small kiln damage area when mining enters the roadway.

Although much effort has been put in the stability control of the roadway under a failure zone or the roadway advancing towards adjacent mining face, little consideration has been given to the surrounding rock control of the roadway which is driven under a mined-out area and also heading for adjacent working face. In this paper, the No. 32,103 return airway at Hanzui coal mine was taken as the research object. The evolution characteristics of the front abutment stress and the lateral stress in the surrounding rocks were analyzed. The stabilization time of the overburden movement was obtained. Reasonable stopping and resuming times of the roadway excavation were decided. Suitable reinforcement scheme was also proposed and employed in field practice to ensure the safe and efficient excavation. The research results can provide guidance on the stability control of roadways with similar conditions.

General situation and roof failure characteristics of the 32,103 return airway

Geological conditions and primary support schemes

Geological and mining conditions

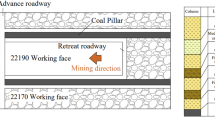

The main minable seam was the 2# coal seam with a thickness of 5.8 m and a dip angle of 7° on average. The roof and floor of the 32,103 return airway were siltstone and mudstone, respectively. The roadway had a strike length of 1264 m and a rectangular cross-Sect. (5.0 m × 3.3 m). The excavation of the 32,103 return airway and the mining of the 32,101 panel were performed simultaneously. The 32,103 return airway had progressed 610 m in the direction opposite to the retreating direction of the 32,101 panel which had advanced 551 m. The distance between the 32,103 return airway face and the 32,101 retreating face was 110 m. The layout of the roadways and panels is shown in Fig. 1.

Primary support schemes

-

(1)

Primary support scheme for the roadway under the residual pillar.

The primary support of the roadway under the residual pillar utilized rock bolts, wire meshes and cables. The support parameters are shown in Fig. 2. Specified support scheme was that ① The roof and walls were supported by rebar bolts with a specification of Φ 22 × 2400 mm and Φ 20 × 2000 mm, respectively, and the spacing was 900 × 800 mm; and ② Pre-stressed anchor cables of Φ 17.8 mm × 8300 mm and Φ 17.8 mm × 4300 mm were used to support the roof and the side walls, respectively, and the spacing was 2000 × 1600 mm.

-

(2)

Primary support scheme for the roadway under the roof failure zone.

Steel shed support was adopted to support the roadway under the roof failure zone. Meanwhile, rock bolts and anchor cables were applied to reinforce the walls. The support parameters are given in Fig. 3. Specified design was that ① Mine-used 11# I-shaped steel was arranged to build the shed for roof support. The steel beam distance was 800 mm. ② The walls were reinforced by rebar bolts with a specification of Φ 20 × 2000 mm and a spacing of 1000 × 1600 mm, as well as by highly pre-stressed cables having a specification of Φ 17.8 × 4300 mm and a spacing of 2000 × 1600 mm. ③ Timber laggings of 1000 × 200 × 50 mm were also installed at an interval distance of 900 mm.

Classification of the failure zone of overlying coal and rock masses

The upper part of the 2# coal seam had been excavated by early small collieries. There were a large number of irregular goafs, which greatly affected the safety of the 32,103 return airway. Advanced drilling and borehole peeping methods were used to probe the coal and rock masses above the roadway so as to understand the damage characteristics. Based on the detection results and the width of the top coal, in terms of damage characteristics of the top coal and the overlying strata, the roof of the excavated roadway was divided into 4 zones: ① “Solid coal zone (Intact top coal)” (0 ~ 200 m away from the entrance of the roadway), ② “Residual pillar zone (Cracks existing in the top coal)” (320 ~ 330 m, 340 ~ 350 m, 450 ~ 515 m and 575 ~ 605 m away from the entrance of the roadway), ③ “Roof caved zone (Overlying rocks caved in the previously mined-out space)” (200 ~ 320 m, 350 ~ 450 m and 515 ~ 575 m away from the entrance of the roadway), ④ “Roof un-caved zone (Void space existing in the roof)” (330 ~ 340 m away from the entrance of the roadway). Figures 4 and 5 show the specific roof characteristics of the 32,103 return airway.

Stopping and resuming times of roadway excavation

Temporal and spatial evolution characteristics of mining excavation stress field

Numerical modeling

In order to define the influence ranges of the stress in front of and behind the working face, numerical simulation was performed to analyze the distributions of the front abutment stress and the side abutment stress during the face advancing process, to simulate the mining influence on the 32,103 return airway, and to clarify the influence range of the 32,101 panel so that the stopping and restarting times of the roadway excavation can be determined.

-

(1)

Model establishment.

According to the geological conditions of the 32,103 return airway, a numerical model with dimensions of 320 m ×600 m ×100 m (length × width × height) was established, as shown in Fig. 6. The roadway dimensions were 5 × 3.3 m (length × height). A 40 m wide chain pillar was set between the 32,103 return airway and the 32,101 panel, and 20-m-wide boundary pillars were set around the model. The simulated dip length of the 32,101 panel was 180 m. A vertical stress of 3.83 MPa was applied on the top of the model, which was used to replace the overburden loads. Displacement constraints were set at the bottom and other four boundaries. Spatial relations between the panels and the roadways in the model are illustrated in Fig. 7.

-

(2)

Constitutive model and parameters.

-

(1)

The parameters required for the Mohr-Coulomb model were obtained by combining the results of laboratory mechanical tests and previous studies, and the specific parameters are listed in Table 1.

-

(2)

Parameter calibration of strain softening model.

-

(1)

To improve the accuracy of modeling results, a strain softening model was used to simulate the residual pillar in the upper goaf (Fig. 8). According to theoretical calculation of pillar strength through an empirical formula (Eq. 1), the parameters of the strain softening model can be calibrated.

where σp is the strength of the coal pillar (MPa), σc is the strength of the intact coal (MPa), h is the height of the residual pillar (m), H is the burial depth of the coal seam (m), and w is the width of the residual pillar (m).

Figure 9 shows the relation between the numerical simulation results and the calculation results. It can be seen that there was a positive linear correlation between the two sets of data. The fitting degree was 0.984. When the width-height ratio of the residual pillar was 4.5, difference in the peak strength of the residual pillar was the largest and the difference value was 8.84%. The average peak strength obtained by numerical modeling and by theoretical calculation was 9.715 MPa and 9.419 MPa, respectively, where the difference value was 3.14%. These indicate that the numerical parameters are highly reliable and can be used for subsequent simulation. The parameters of the strain softening model are given in Table 2.

-

(3)

Modeling schemes and layout of surveying lines.

For a better understanding of the digging opportunities at different roof conditions, the distributions of the mining-excavation stress field under the residual pillar and under the solid coal were simulated, respectively. Figure 10 presents the modeling schemes and the layout of surveying lines. In Scheme 1, solid coal was in front of the roadway while in Scheme 2, a residual pillar was in front of the roadway. A surveying line (AA in Scheme 1, or BB in Scheme 2) was arranged along the direction perpendicular to the roadway axis (chain pillar) to obtain the vertical stress in the chain pillar.

Evolution characteristics of the lateral stress at the working face

-

(1)

Influence of dynamic pressure under the solid coal.

The distributions of the stress field in front of and behind the working face under the solid coal are illustrated in Figs. 11 and 12, respectively. It can be found that the area with obvious mining disturbance was located in the range of 60 m ahead of or behind the working face. With the shortening distance between the surveying line and the working face, corresponding vertical stress in the chain pillar increased in the range of 60 m ahead of the working face but decreased in the range of 60 m behind the working face. Before the mining face reaching the surveying line, the stress peak in the chain pillar (14.83 MPa) occurred when the relative distance was 10 m, and the stress peak was located at 3 m in front of the 32,101 panel. After the mining face passed the surveying line, the stress peck in the chain pillar (33.66 MPa) occurred when the relative distance was 60 m, and the stress peak position was 4 m away from the panel goaf. In the range of 25 m ahead of the surveying line and 30 m behind the surveying line, the vertical stresses in the chain pillar were all greater than the in-situ stress, indicating that these areas were mostly affected by the mining activities.

-

(2)

Influence characteristics of dynamic pressure under the residual coal pillarA.

The distributions of the stress field in front of and behind the working face under the residual pillar are presented in Figs. 13 and 14, respectively. As can be seen from Fig. 13, when the working face was still 50 m heading for the surveying line, the stress in the chain pillar began to increase in different amplitude. Meanwhile, the stress peak in the chain pillar reached its maximum value (19.01 MPa) when the relative unmined distance between the 32,101 panel and the surveying line was 10 m. With the working face approaching the surveying line, there was no obvious change in the peak stress position in the chain pillar, and the area having the stress increased inside the chain pillar gradually expanded. Meanwhile, within 30 m distance to the 32,101 panel, the stress in the chain pillar was relatively large. From Fig. 14, it can be seen that when the distance between the working face and the surveying line was less than 60 m, the peak stress value largely increased with the increase of the relative distance. The peak stress value in the chain pillar increased from 19.01 MPa (where the working face was 10 m away from the surveying line) to 37.24 MPa (where the working face was 60 m away from the surveying line), and the corresponding stress concentration coefficients were 4.47 and 5.39, respectively. The peak stress positions were 3.2 m and 4.98 m away from the 32,101 panel, respectively.

In sum, due to the influence of the damage zone in the top coal, the transmission of the front abutment stress at the 32,101 panel was obstructed, resulting in a smaller influence range (50 m) when the working face advanced through the region under the residual pillar compared with that under the solid coal (60 m). The occurrence characteristics of the top coal behind the surveying line were the same. Hence, the influence ranges of the mining stress in the two schemes were the same (60 m) after the working face passed the surveying line.

Evolution characteristics of side abutment stress during the whole process

The changes of the side abutment stress under different roof conditions are displayed in Fig. 15, where “-” implies the distance between the 32,101 working face and the surveying line before the face reaching the surveying line, and “+” denotes the distance between the 32,101 working face and the surveying line after the face passed the surveying line. It can be noted that in the range of -60 m to -50 m, the side abutment stress in the chain pillar under the solid coal had a larger increase than that under the residual pillar. Within the range of -50 m to 60 m, the peak stress in the chain pillar no matter under the solid coal or under the residual pillar increased continuously with the panel advancement and the corresponding value was 35.36 MPa or 37.25 MPa, respectively. When the distance exceeded 60 m, with the progressing of the working face, the peak lateral stress tended to be stable in both cases.

Position distributions of peak lateral stress under different roof conditions are exhibited in Fig. 16. It can be observed that within the influence range of the abutment stress, the position of peak lateral stress quickly moved into the chain pillar. In the range of -70 m to -60 m, the peak lateral stress was located at the shallow part of the chain pillar. In Scheme 2, within the range of -60 m to 60 m, the distance between the peak stress position and the coal wall increased from 2.2 m to 4.98 m, while in Scheme 1, within the range of -70 m to 80 m, the distance between the peak stress position and the coal wall increased from 1.2 m to 4.12 m. The distance between the peak stress position and the coal wall had a small variation beyond the influence range of the dynamic pressures.

Stabilization time of overburden movement

45 monitoring points (A13-A57) were arranged at the ground surface corresponding to the dip center of the 32,101 panel. The 5 intermediate points (A30-A34) were selected for analysis. Figure 17 depicts the displacement changes of the surface monitoring points. During the period from August 27 to September 26, 2020, the surface subsidence at the monitoring points A30-A34 increased rapidly. Among them, the maximum subsidence of points A30 and A31 reached 2889 mm and 4209 mm, respectively. During the period from September 26 to November 16, there was no significant change in the surface subsidence. It can be inferred that the active time of the overburden movement at the 32,101 panel was about one month.

Determination of the stopping and resuming times of the roadway excavation

The numerical results showed that no matter under the solid coal or under the residual pillar and whether the 32,101 working face passed the roadway face or not, the stress influence range was 60 m. The measurement results of ground surface deformation showed that the overlying strata had regained an equilibrium state about 1 month later since the start of extracting the 32,101 panel. Since the mining rate was 2.4 m per day, the overburden movement became stable when the working face advanced 72 m away from the roadway face. Based on the failure characteristics of the roadway roof, it was finally determined that the excavation of the 32,103 return airway was stopped when the unmined distance between the roadway face and the 32,101 working face was 70 m and was restarted after the 32,101 working face passed the roadway face by 90 m.

Zone based roadway reinforcement technique

Roadway deformation characteristics under primary support schemes

Through the deformation observation at the measuring stations placed at 320 m and 450 m away from the entrance of the 32,103 return airway, deformation amount of the surrounding rocks under the primary support schemes was obtained (Fig. 18).

It can be seen from Fig. 18 that under the original support schemes, the mining disturbance to the roadway was obvious. Phenomena such as steel beam deformation, floor heave, and timber lagging breakage were observed. At 320 m away from the roadway entrance, the deformation amount of the roof, floor and two side-walls reached 400 mm, 95 mm and 420 mm, respectively, the steel ladder beam sagged seriously. Besides, the legs and roof beam of the shed encountered lateral bending. At 450 m away from the roadway entrance, the deformation amount of the roof, floor and walls was up to 100 mm, 358 mm and 138 mm, respectively, and the fissure in the floor was noticeable and had a long extension. It can be said that even though the roadway had been supported by adopting the primary support schemes, it was still seriously influenced by the dynamic mining pressures.

Zone based roadway reinforcement strategy

Based on the roof failure characteristics of the 32,103 return airway, an additional control strategy was proposed i.e. “surrounding rock reinforcement for the section of roadway under the residual pillar, surrounding rock modification for the section of roadway under the roof failure zone, and support process optimization”:

-

(1)

Surrounding rock reinforcement. Supplemental anchor cables are capable to improve the strength of support, alter the stress environment of the surrounding rocks, and increase the rock strength. In view of large separation layers and fracture zones existing in the roof, the length of supplemental anchor cables should be increased to make sure that the anchoring ends are located in a stable rock formation.

-

(2)

Surrounding rock modification. According to the field measurement results, the cracks in the surrounding rocks at the study site were well developed. Therefore, under the condition of having a fractured roof, it is necessary to reinforce the surrounding rocks by means of grouting for the sake of rock strength and integrity.

-

(3)

Support process optimization. In some region of the roadway, there was a large distribution of broken rocks and longitudinal cracks within 2.6 m range of the roof. To prevent that rock bolts cannot be anchored, rock bolts lose function or other unfavorable issues might occur, it is recommended that grouting should be carried out before the installation of rock bolts. After the grouting process is completed, the bolts are installed in the surrounding rocks as required.

Zone based roadway reinforcement technique

Cable reinforcement scheme for the section of roadway under the residual pillar

Since goafs sat nearby the two sides of the upper residual pillar, the roadway bore a large amount of overburden load due to stress concentration. To improve the self-supporting ability of the surrounding rocks and ensure the performance of the roadway, on the basis of the primary support scheme in this area, an extra anchor cable with a specification of Φ17.8 mm×8300 mm was installed in the roof and the right wall, respectively. The interval distance between the newly installed roof/wall cables was 1600 mm. The specific scheme is shown in Fig. 19.

Reinforcement scheme for anchor mesh cable spraying for the section of roadway under the roof failure zone

The “roof caved zone” and the “roof un-caved zone” previously divided in Sect. 2.2 are collectively called as the “roof failure zone”. Since in the roof failure zone, the surrounding rocks of the roadway are fragmented and there may be void spaces in the roof, it needs to improve the performance of bolt-cable support and optimize the grouting process aiming to finally form a combined “bolt-wire mesh-cable-shotcreting-grouting” support at this area.

-

(1)

Grouting reinforcement technique.

Shallow- and deep-hole grouting methods were introduced to fill the void spaces in the roof, to enhance the stress environment of the surrounding rocks, and to upgrade the strength and the bearing capacity of the surrounding rocks. Shallow-hole grouting was adopted for strengthening the residual top coal. Afterwards, deep-hole grouting was applied to reinforcing the caved rocks or filling the void spaces in the roof so as to effectively improve the bearing capacity of the roadway.

-

(1)

Low-pressure shallow-hole grouting.

The borehole was 63 m in diameter and 2000 m in length. A row of four grouting holes were drilled in the roof. A row of two grouting holes were arranged in each side-wall. There was a row of grouting holes every two sheds. The spacing of the grouting holes in the roof was 1300 mm×1600 mm. The distance between the side-wall and its nearest grouting hole in the roof was 300 mm. The grouting holes in the side-wall were 1200 mm and 2500 mm away from the roof edge. The grouting pressure was 1.5 ~ 2 MPa. The detailed parameters of the boreholes are offered in Fig. 20; Table 3.

-

(2)

High-pressure deep-hole grouting.

As shown in Fig. 21, subsequent high-pressure deep-hole grouting was conducted through the same grouting holes for primary low-pressure shallow-hole grouting. A pneumatic drilling machine was utilized to extend the grouting holes to 8000 mm. The diameter of the extended borehole was 30 mm. Note that the borehole angles and positions were not changed.

The grouting material was single liquid cement slurry, mainly including ordinary Portland cement of grade 42.5. The water-cement ratio was 0.5 ~ 0.6. High-efficiency water reducing agent was added. The grouting pressure was 3 ~ 5 MPa. Before grouting, a layer of concrete about 160 mm thick was sprayed on the roof and on the two sides of the roadway to prevent slurry overflow.

-

(2)

Combined bolt-cable reinforcement technique.

-

(1)

Rock bolt reinforcement.

The rock bolt reinforcement in the roof is illustrated in Fig. 22. It can be seen from Fig. 22a that within 2.6 m range of the roof, rock breakages and longitudinal cracks were widely distributed. In order to avoid that the bolts cannot be anchored or the bolts lose their function, rock bolts shall be installed after the grouting process is completed. This is to guarantee a normal stress environment in the anchoring area and to enhance the supporting effect of the rock bolts. The roadway roof was reinforced by rebar bolts with a specification of Φ20 mm×2800 mm. There were 5 bolts in each row and the row spacing was 900 × 2600 mm (Fig. 22b).

-

(2)

Cable reinforcement.

The detection results of the boreholes in the roof indicated that there was a large amount of layer separation and severe rock damage within 8 m range of the roof and there were fewer cracks in the borehole wall within 8 ~ 8.67 m range of the roof (see Fig. 23). With regard to a large-scale fractured roof, it requires to increase the cable length to make sure that the cable ends are anchored in a stable rock formation. The supplemental anchor cables for supporting the roof of the 32,103 return airway were pre-stressed cables having a diameter of 17.8 mm and a length of 10,000 mm. Rows of four anchor cables were arranged in the roof. The distance between the two middle cables was 1000 mm, the distance between the side cable and the middle cable was 1300 mm, and the row spacing was 1600 mm.

Engineering application

Observation scheme of surrounding rock deformation

In order to assess the control effects of the reinforcement techniques under the residual pillar zone and under the roof failure zone, two measuring stations were set at 345 m (Station 1#) and 395 m (Station 2#) away from the entrance of the 32,103 return airway to inspect the surrounding rock deformation. The roof-to-floor-convergence and the wall-to-wall convergence were observed once a day through cross-shaped stationing points.

Deformation characteristics of roadway surrounding rocks

According to the measurement data, the variation curves of surrounding rock deformation can be drawn, as shown in Figs. 24 and 25. (The sign “+” in the figures indicates the distance between the working face and the measuring station after the working face passed the measuring station, while the sign “-” represents the distance between the working face and the measuring station before the working face reaching the measuring station.)

As can be seen from Figs. 24 and 25, with the decrease of the relative distance between the working face and the measuring station, the amount and rate of the roadway deformation at the stations 1# and 2# gradually increased. When the retreating face passed the measuring station by 10 ~ 40 m, the deformation amount and rate at station 1# were both larger than those at station 2#. The maximum rate of the roof-to-floor convergence and the wall-to-wall convergence at station 1# was 6 mm/d and 5 mm/d, respectively. When the mining face was + 60 m away from the measuring station, the roadway deformation tended to be stable. The accumulative amount of the roof-to-floor convergence and the wall-to-wall convergence was only 97 mm, 69 mm at Station 1# and 57 mm and 43 mm at Station 2#, respectively. In sum, there was a slight deformation in the surrounding rocks of the 32,103 return airway, suggesting that the control effect was satisfying.

Figure 26 exhibits the overall support effect after adopting the zoning-based reinforcement technique. It can be found that slight deformations occurred in the roof and sidewalls, so the deformation of the roadway was effectively controlled.

Conclusions

Aiming at the problems of complex stress and large deformations in the surrounding rocks of the roadway driven under the mined-out area and heading for adjacent advancing coal face, the distribution characteristics of the failure zone in the top coal were defined, the stopping and resuming times of the roadway excavation were decided, a zoning-based reinforcement scheme was designed and validated in engineering practice. The main conclusions are as follows:

-

(1)

The distribution characteristics of the roof failure zone of the 32103 return airway were clarified. Through roof drilling and borehole detecting methods, the roadway roof was divided into 4 zones: ①“Solid coal zone” (Intact coal roof), ② “Residual pillar zone” (Cracks existing in the top coal), ③ “Roof caved zone (Overlying rocks caved in the previously mined-out space)”, and ④ “Roof un-caved zone” (Void space existing in the roof).

-

(2)

The stopping and resuming times for excavating the 32,103 return airway were obtained. According to the numerical simulation and field measurement results, the influence range of the abutment stress was about 60 m before the working face meeting the roadway face, and was about 72 m after the working face passed the roadway face. Combined with the geological conditions of the roof, it was finally determined that the roadway stopped tunneling when it was still 70 m towards the panel face, and restarted digging when the mining face passed the roadway face by 90 m.

-

(3)

A zoning-based reinforcement technique was proposed. Based on the roof failure conditions and stress characteristics, a combined zoning-based reinforcement technique was put forward, that is, cable reinforcement for the section of roadway under the residual pillar zone and bolt-wire mesh-cable-shotcreting-grouting reinforcement for the section of roadway under the roof failure zone. The field observation results showed that the maximum value of the roof-to-floor convergence and the wall-to-wall convergence was only 97 mm and 69 mm, respectively. Thus, it can be inferred that the zoning-based reinforcement technique had a good effect on the surrounding rock control.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

Abbreviations

- σ p :

-

The strength of the coal pillar

- σ c :

-

The strength of the intact coal

- h :

-

The height of the residual pillar

- H :

-

The burial depth of the coal seam

- w :

-

The width of the residual pillar

References

Yin, S. et al. Non-uniform failure and differential pressure relief technology of roadway under irregular goafs in deep close-distance coal seams. Sci. Rep. 13(1), 18527. https://doi.org/10.1038/s41598-023-45857-y (2023).

Rong, H. et al. Research on main influencing factors and complete support technology for dynamic pressure and large deformation roadway. Sci. Rep. 13(1), 4136. https://doi.org/10.1038/s41598-023-31170-1 (2023).

Fan, K. et al. Non-harmonious deformation controlling of gob-side entry in thin coal seam under dynamic pressure. J. Rock Mech. Geotech. Eng. 6(3), 269–274. https://doi.org/10.1016/j.jrmge.2014.05.001 (2014).

Yavuz, H. & Fowell, R. J. A physical and numerical modelling investigation of the roadway stability in longwall mining, with and without narrow pillar protection. Trans. Inst. Min. Metall. Sect. A-Min. Technol. 113(1), A59–A72. https://doi.org/10.1179/03718404225004300 (2004).

Zhao, T. & Liu, C. Roof instability characteristics and pre-grouting of the roof caving zone in residual coal mining. J. Geophys. Eng. 14(6), 1463–1474. https://doi.org/10.1088/1742-2140/aa8eb6 (2017).

Gao, F., Stead, D. & Kang, H. Numerical simulation of squeezing failure in a coal mine roadway due to mining-induced stresses. Rock Mech. Rock Eng. 48(4), 1635–1645. https://doi.org/10.1007/s00603-014-0653-2 (2015).

Han, C. et al. Superposed disturbance mechanism of sequential overlying strata collapse for gob-side entry retaining and corresponding control strategies. J. Cent. South Univ. 25(9), 2258–2271. https://doi.org/10.1007/s11771-018-3911-8 (2018).

Liu, H., Liu, C. & Dong, Y. Theoretical study on the mechanism of asymmetrical large deformation of heading roadway facing mining. Sustainability 14(22), 15065. https://doi.org/10.3390/su142215065 (2022).

Guo, Z. Surrounding rock control for gob-side entry driving toward mining disturbance in extra-thick coal seam. Coal Eng. 52(11), 42–46. https://doi.org/10.11799/ce202011009 (2020) (in Chinese).

Yu, Y. et al. Study on spatiotemporal effect and control technology of roadway driving face to mining. Coal Technol. 37(4), 18–21. https://doi.org/10.13301/j.cnki.ct.2018.04.008 (2018) (in Chinese).

Kang, J. et al. Study on surrounding rock deformation rule and sectional control technology of roadway with strong dynamic pressure. Min. Saf. Environ. Prot. 44(02), 74–78. https://doi.org/10.3969/j.issn.1008-4495.2017.02.017 (2017) (in Chinese).

Yang, J., Cao, S. & Li, X. Failure laws of narrow pillar and asymmetric control technique of gob-side entry driving in island coal face. Int. J. Min. Sci. Technol. 23(2), 271–276. https://doi.org/10.1016/j.ijmst.2013.04.008 (2013).

Wang, M. et al. Stability control of overburden and coal pillars in the gob-side entry under dynamic pressure. Int. J. Rock Mech. Min. Sci. 170, 105490. https://doi.org/10.1016/j.ijrmms.2023.105490 (2023).

Bai, J. et al. Roof deformation, failure characteristics, and preventive techniques of gob-side entry driving heading adjacent to the advancing working face. Rock Mech. Rock Eng. 48(6), 2447–2458. https://doi.org/10.1007/s00603-015-0713-2 (2015).

Qiao, Z. et al. Deformation mechanism and the control technology of roadway under mining influence in top coal failure area. Coal Eng. 54(6), 95–100. https://doi.org/10.11799/ce202206019 (2022) (In Chinese).

Wang, M. et al. Numerical simulation of propagation and coalescence of flaws in rock materials under compressive loads using the extended non-ordinary state-based peridynamics. Bull. Eng. Geol. Environ. 79(6), 3121–3144. https://doi.org/10.1007/s10064-020-01759-1 (2020).

Cao, Z. et al. Fracture propagation and pore pressure evolution characteristics induced by hydraulic and pneumatic fracturing of coal. Sci. Rep. 14(1), 9992. https://doi.org/10.1038/s41598-024-60873-2 (2024).

Wang, M. et al. Study on the new layout pattern about the gob-side entry under dynamic pressure and its surrounding rock stability control. Energy Sci. Eng. 12(4), 1389–1410. https://doi.org/10.1002/ese3.1667 (2024).

Suchowerska, A. M., Carter, J. P. & Merifield, R. S. Horizontal stress under supercritical longwall panels. Int. J. Rock Mech. Min. Sci. 70, 240–251. https://doi.org/10.1016/j.ijrmms.2014.03.009 (2014).

Wojtecki, L., Golda, I. & Mendecki, M. J. The influence of distant coal seam edges on seismic hazard during longwall mining. J. Seismol. 25(1), 283–299. https://doi.org/10.1007/s10950-020-09959-8 (2021).

Lv, K. et al. Field and simulation study of the rational retracement channel position and control strategy in close-distance coal seams. Energy Sci. Eng. 10(7), 2317–2332. https://doi.org/10.1002/ese3.1140 (2022).

Bi, Y. et al. Surrounding rock stability in unsupported roof area and rapid heading technique for deep arch coal roadways under Goaf. Minerals 12(10), 1329. https://doi.org/10.3390/min12101329 (2022).

Liu, H. et al. Asymmetric deformation mechanism and control technology of roadway under room-pillar group in Huasheng coal mine. J. Cent. South Univ. 30(7), 2284–2301. https://doi.org/10.1007/s11771-023-5364-y (2023).

Ru, W. et al. Study on the rheological failure mechanism of weakly cemented soft rock roadway during the mining of close-distance coal seams: A case study. Adv. Civ. Eng. 2020, 8885849. https://doi.org/10.1155/2020/8885849 (2020).

Chen, D. et al. Combined support technology for main roadway passing through goaf: A case study. Energy Sci. Eng. 8(11), 3925–3941. https://doi.org/10.1002/ese3.787 (2020).

Wu, X. et al. Failure mechanism and stability control of surrounding rock of docking roadway under multiple dynamic pressures in extrathick coal seam. Geofluids. 2020, 8871925. https://doi.org/10.1155/2020/8871925 (2020).

Shan, R. et al. Research on the evolution of the deviatoric stress and control of a gas extraction roadway under mining influence. Environ. Earth Sci. 82(18), 425. https://doi.org/10.1007/s12665-023-11114-8 (2023).

Tian, X. et al. Research and application of Gob-Side entry retaining with roof presplitting under residual coal pillar of upper coal seam. Energy Explor. Exploit. 40(5), 1494–1521. https://doi.org/10.1177/01445987221095116 (2022).

Cao, Z. et al. Research on slurry diffusion and seepage law in mining overburden fractures based on CFD numerical method. Sci. Rep. 13(1), 21302. https://doi.org/10.1038/s41598-023-48828-5 (2023).

Wang, M. et al. Experimental and numerical study on peak strength, coalescence and failure of rock-like materials with two folded preexisting fissures. Theor. Appl. Fract. Mech. 125, 103830. https://doi.org/10.1016/j.tafmec.2023.103830 (2023).

Cao, Z. et al. Experimental study on the fracture surface morphological characteristics and permeability characteristics of sandstones with different particle sizes. Energy Sci. Eng. 12(7), 2798–2809. https://doi.org/10.1002/ese3.1768 (2024).

Wang, M. et al. Peak strength, coalescence and failure processes of rock-like materials containing preexisting joints and circular holes under uniaxial compression: Experimental and numerical study. Theor. Appl. Fract. Mech. 125, 103898. https://doi.org/10.1016/j.tafmec.2023.103898 (2023).

Yang, H. et al. Efficient excavation and support cooperation technology for surrounding rock of deep buried long-distance and large section gob-side roadway: A case study. Geofluids. 2022, 6895887. https://doi.org/10.1155/2022/6895887 (2022).

Han, C. et al. Zoning control technology of gob-side roadway driving with small coal pillar facing mining in a special isolated island working face: A case study. Appl. Sci.-Basel. 11(22), 10744. https://doi.org/10.3390/app112210744 (2021).

Jia, C. et al. Mining pressure distribution law and disaster prevention of isolated island working face under the condition of hard “umbrella arch”. Rock Mech. Rock Eng. 57(10), 8323–8341. https://doi.org/10.1007/s00603-024-03961-z (2024).

Acknowledgements

This work is funded by the Shanxi Provincial Key Research and Development Project (Grant No. 20201101009).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Data collection and analysis were performed by Z.N., X.W., C.W., Z.F., C.S. All authors read and approved the fnal manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Niu, Z., Wang, X., Wang, C. et al. Surrounding rock control for the roadway driven under the goafs of small collieries and heading for adjacent advancing face. Sci Rep 15, 968 (2025). https://doi.org/10.1038/s41598-024-83842-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-83842-1