Abstract

To investigate the effect of space tightness on inerting of liquid CO2. Pottery jar liquor warehouse was selected as the research subject, numerical simulation was utilized to study the spatial inerting and CO2 migration and distribution under different space tightness degrees and injection flow rates. The results revealed that after injection into the space, CO2 distributed like an “umbrella”, the CO2 protective layer undergoes a dynamic process of concentration increase and thickness enhancement, achieving upward accumulation and migration of the inert medium protective layer. The space was divided into direct inerting zone, CO2 accumulation zone and accumulation zone, with an effective inerting diameter of approximately 2 m for the direct inerting zone. When the fire extinguishing system is activated in the fire source space for 60 s, the O2 concentration at Z = 0.3 m decreases to less than 10%, and the CO2 inerting rate exceeds 98%. The space inerting effect increased with the injection flow and space tightness, whereas the effective inerting rate decreased with the space height and injection time. After 60 s of injection, the leakage reached the maximum, about 1.0 ~ 1.2 kg/s. It could improve liquid CO2 utilization by reducing the injection flow rate or enhancing space tightness. Based on this, a design concept of liquid CO2 intelligent control fire extinguishing system is proposed.

Similar content being viewed by others

Introduction

In 2023, Chinese Baijiu production reached 5.586 million tons, generating profits of 232.8 billion RMB. It is projected that by 2025, the industry’s production will increase to 8 million tons. The alcohol content of Chinese Baijiu is defined by the ethanol volume fraction, typically ranging from 30 to 65%1. Research indicates that alcoholic beverages with an ethanol percentage of 20% or higher can create a significant fire load2. Given that most liquor have a higher alcohol content, their fire risk is evident. When the ethanol volume fraction in liquor exceeds 34.8vol%, the fire hazard level is classified as the highest, Grade I3. As a liquor centralized storage place, the liquor warehouses have the characteristics of large storage capacity and frequent operation in and out of liquor, and its fire risk cannot be underestimated. Studies by Song4 show that 90% of the combustible materials causing fires in liquor warehouses are liquor. Once a fire occurs in a liquor warehouse, it can result in substantial losses. In April 2023, a fire at a liquor company in Luzhou, Sichuan Province, resulted in 4 fatalities. The Sichuan Fire Rescue Corps mobilized 22 vehicles and 102 personnel to handle the incident, which took 4 h to extinguish fire. In July 2024, a fire at a liquor tank of a Moutai liquor company in Guizhou led to 4 injuries.

CO2 has excellent suffocation effects, strong coverage capabilities, and high fire extinguishing efficiency5, making it widely used in power plants, ships, computer rooms, and other locations. Li6 et al. established fire models for jar liquor warehouses under different fire suppression systems. The results indicate that liquid CO2 fire suppression systems exhibit the highest efficiency in extinguishing fires, spatial cooling effects and oxygen isolation. A comprehensive assessment was conducted based on efficient fire suppression performance, cleanliness of fire extinguishing, and cost considerations, confirming the feasibility of clean and efficient fire suppression using liquid CO2 in pottery jar liquor warehouse. Liquid CO2, compared to gaseous CO2, has dual fire suppression characteristics of inerting and cooling. At 0 °C, the liquid-to-gas expansion ratio of liquid CO2 reaches 1:5577, generating a large amount of low-temperature inert gas. This allows for high-flow, low-temperature CO2 injection into the fire area, ultimately achieving rapid inerting, cooling, and explosion suppression effects, making it a highly promising clean and efficient fire extinguishing agent. Currently, liquid CO2 has shown good results in preventing coal spontaneous combustion and mine thermal hazards8,9,10,11. Nevertheless, its application research in liquor warehouses is less, resulting in the underdevelopment of liquid CO2 clean and efficient fire suppression systems in pottery jar liquor warehouses projects.

The key of liquid CO2 fire extinguishing system is whether it can give full play to its fire extinguishing mechanism in the fire field. That is, by injecting CO2 into the space, the oxygen concentration can be diluted, and the percentage of oxygen by volume can be reduced to a level that cannot meet the minimum oxygen consumption requirements for ignition or maintenance of combustion. Inert gas is generally suitable for non-open spaces, and closed environments can effectively reduce the leakage of inert fire extinguishing medium, ensuring that the fire extinguishing agent can fully cover the fire site and play its best fire extinguishing effect. However, it is almost impossible to achieve complete airtight in a real working building, such as pottery jar liquor warehouses, storerooms, and other industrial buildings, which have fixed and normally open ventilation shutters. Such as liquor warehouses, warehouses, storerooms and other industrial buildings are generally exist with fixed often-open ventilation shutters.

The gas extinguishing agent may leak from the non-confined space, affecting its fire extinguishing effect. According to Dundas’ statistical data12, the fire extinguishing failure rate of fully submerged halon or CO2 systems can reach 37% when fire extinguishing agents leak from vents. The leakage of fire extinguishing agent is mainly caused by the difference of hydrostatic pressure between inside and outside the space. The leaking inert gas will be replaced by outside air, reducing the effective inerting in the space and affecting the fire extinguishing effect. The leakage area is an important factor affecting the leakage rate of fire extinguishing agent13,14. Larger leakage areas result in greater leakage rates, reducing the space’s effective inerting and fire extinguishing performance of gas extinguishing agents. Therefore, the efficiency of an inert gas fire extinguishing system largely depends on the space sealing15. Hu et al.16 studied the effect of inert gas on closet fires with cracked rooms, showing that the location of fractures influences oxygen content in the space. If the leak is on the upper level, less inert gas is forced out, and the gas extinguishing system can successfully extinguish deep closet fires. The natural ventilation shutters and other fixed vents in liquor warehouses are located higher up, with a much larger opening leakage area than general wall cracks and gaps. CO2 can inhibit O/OH/H and other free radicals to some extent in fire reaction process. CO2 extinguishes ethanol (alcohol) fires with a CO2 concentration of about 25.3%17. The natural ventilation shutters can lead to CO2 leakage, which cannot achieve effective fire extinguishing concentration. Studies on the effect of space tightness on the fire extinguishing performance of liquid CO2 in liquor storage are limited, so it is necessary to study the effect of space tightness on the fire extinguishing effect of liquid CO2 in liquor warehouse. This paper firstly studied the distribution and migration laws of CO2 by conducting liquid CO2 injection in a limited space without a fire source, and further investigated the inerting characteristics of a liquid CO2 fire extinguishing system under different space tightness and injection flow rate. Based on this, an application concept for a liquid CO2 intelligent control fire extinguishing system was proposed. This technology can effectively reduce the risk of liquid CO2 pipe plugging and fire extinguishing agent leakage, and improve the fire extinguishing efficiency and safety of the liquid CO2 system. The research results can provide an idea for the design of liquid CO2 clean and efficient fire extinguishing technology for pottery jar liquor warehouses, thus improving the fire prevention and control level of liquor warehouses.

Numerical model setups

Model verification

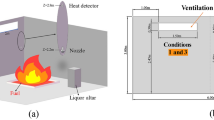

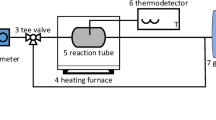

In order to guarantee the accuracy and reliability of the numerical simulation study, we used the small-size experimental platform of liquid CO2 to put out the oil pool fire built earlier, and established a 1:1 fire model to compare the experimental data of the two. The small-size test bench is mainly composed of a 5 m long, 2.4 m wide and 2.9 m high container and a liquid CO2 system pipeline. In the fire model, the location of the fire source, the layout of the nozzle and the setting of the gas concentration measurement point are in agreement with the experiment site.

Figure 1 shows the comparison between experimental and numerical simulation results. It is found that in the initial start-up of the fire extinguishing system, the variation trend of CO2 concentration in space under experimental and numerical simulation conditions is the same. The distribution characteristics of CO2 at different heights in the space show obvious sedimentation characteristics, that is, the concentration of CO2 at the bottom of the space is higher. However, compared with the change of CO2 concentration growth, the growth rate of CO2 concentration under numerical simulation is slightly higher than the experimental result. This is mainly because there are holes for data acquisition and fire extinguishing system pipelines near the measuring point of the sensor on the small experimental bench, and CO2 leakage will occur during the fire extinguishing process. With the passage of time, the cumulative leakage of CO2 increases, and its concentration changes gradually decrease. However, the spatial tightness under the numerical simulation conditions is better than that in the experiment site, and CO2 deposition forms a more significant accumulation layer over time, resulting in a slight upward tendency of CO2 concentration at the bottom of the space. The comparison error of CO2 concentration between numerical simulation and experimental results is given in Table 1. Within 600s, the maximum error of both is preserved within 7%, and the average error of CO2 concentration is within 5%.

In summary, the change trend of numerical simulation is placed on the brink of that of experimental results. The airtight of walls and fire doors of on-site liquor warehouse are preferable to those of containers. The FDS numerical simulation method can better predict the distribution characteristics of CO2 inert gas under the action of liquid CO2 fire extinguishing system in on-site liquor warehouse.

Model building

In this study, the fire protection zone of a liquor warehouse in Renhuai, Guizhou serves as the basis for the development of a numerical simulation model. Figure 2 presents a schematic diagram of the fire model, which measures 6.5 m (X direction) × 6 m (Y direction) × 3 m (Z direction). Based on the previous grid sensitivity analysis, the 0.1 m×0.12 m×0.1 m grid size with relatively high precision and short solving time was selected as the basis for numerical simulation research. Table 2 shows the numerical Settings, which are consistent with literature6.

As the fire-rated doors of the liquor warehouses is typically closed, provide better tightness. Consequently, the effect of doors, door cracks, or other small openings on inert gas leakage and fire extinguishing effect is disregarded in model construction. Since the liquor warehouse needs a natural ventilation environment, there are shutters mainly used for natural ventilation, which hold the characteristics of normal opening and fixed. It is the main factor that may cause CO2 leakage when the fire is started. Therefore, only the leakage effect of shutters is considered. The shutters on both sides of the model are simplified into long vents, the shutters on both sides of the model are simplified into long vents, each measuring 1.5 m × 0.3 m (total area of 1.8 m2) and 2 m × 0.4 m (total area of 3.2 m2). The vents are positioned at a constraint of 2.4 m and 2.45 m from the floor, respectively. In the simulation process, the liquid CO2 fire extinguishing system adopts a fully submerged application mode. The pressure of the sprinkler head is set to 1.4 MPa, located at (x, y, z) = (3.5 m, 3 m, 2.2 m). The start mode is delayed for 20 s when the temperature detector, positioned directly above the sprinkler head at Z = 2.8 m, reaches 65 ℃. Gas detectors are set at different levels above the fire source (x, y) = (2 m, 4.5 m) to monitor gas concentration changes. The unbroken liquor jar will occupy part of the volume in the space, and there are two simplified 0.5 m × 0.5 m × 1 m liquor pottery jar models in the model. A gas mass flow section is set on the right wall of the space to monitor in-and outflow, which can be used to determine CO2 leakage from the space.

The design dosage of fire extinguishing agent in the CO2 fire extinguishing system specification document17 is a dynamic variable related to the protection space and the size of the opening area. With the increase of the opening area, the injection amount of inert medium is an important parameter that directly determines the effect of inerting and cooling. Li6 shows that when the injection flow rate of liquid CO2 increases with the increase of the opening area (red circular mark in Fig. 3), the fire extinguishing effect of liquid CO2 is less affected by the natural ventilation opening. However, Li did not clarify the influence of different liquid CO2 flow rates injected into the same space with the same air tightness on the fire extinguishing effect. Therefore, in this paper, in addition to setting different opening areas as research variables. Different liquid CO2 injection flow rates in the same space are set by controlling injection flow rates variables. To further discuss the effect of tightness and liquid CO2 injection flow rates on fire extinguishing effect. The design dosage of liquid CO2 in this study is calculated by reference to the gas CO2 fire extinguishing system specifications, which can be approximated by the formula y = 134.78 + 7.211x6 (x is the open area, m2) under this model, as shown in the red line in Fig. 3. According to the three opening areas (0, 1.8 m2 and 3.2 m2), the injection flow rates of liquid CO2 is calculated to be 134.78 L/min, 147.76 L/min and 157.86 L/min. In addition, this study also added an experimental study under the condition of no fire source to understand the distribution characteristics of CO2 after injection. Table 3 shows the simulated working conditions of this study. A total of eighteen model conditions are shown in Fig. 3 according to the relationship between injection flow rates and opening area. Among them, N1 ~ N8 are no fire source models, and F1 ~ F8 are with 2 m2 fire source model. For example, under condition N 1, liquid CO2 is injected into a non-fire source space with a total opening area of 0 m2 at an injection flow rate of 134.78 L/min; under working condition F4, the fire source area is 2 m2 and the total ventilation opening area is 1.8 m2. The injection flow rate is set to 134.78 L/min.

Simulation results and analysis

Gas migration law of liquid CO2 injected into finite space

The airtightness of the space is an important factor affecting the gas migration law of CO2. Clarifying the transport and distribution law of the inert medium (CO2) in the space is the basis for studying the inerting characteristics and fire extinguishing effect of liquid CO218. Firstly, liquid CO2 is injected into a confined space without ignition to understand the gas migration law in this space. Under working condition N1 (confined space - injection flow rate is 134.78 L/min), Origin software was used to draw the slice cloud image at Y = 3 m at 5 s, 10 s and 20 s when the liquid CO2 fire extinguishing system is started is shown in Fig. 3.

As can be observed in Fig. 4, the CO2 concentration at the nozzle site is the highest when the fire extinguishing system is activated for 5 s. With the continuous injection of fire extinguishing agent to 10s and 20 s, the highest CO2 concentration remains in the nozzle, and the volume fraction can reach 50-70%. The CO2 released by the sprinkler shows an “umbrella” distribution, and part of the CO2 gas expands and diffuses upward, so that a “cap” with a CO2 concentration of 20–30% appears above the sprinkler. The height of the “cap” can reach 0.5 m at 5 s when the fire extinguishing system is started, and 0.3 m at 10 s and 20 s. To ensure that CO2 at the “peak cap” of the sprinkler head is retained in the space as much as possible, the sprinkler head should not be placed under the smoke outlet, skylight, pressure relief port, or any other form of vent of the smoke exhaust pipe to reduce CO2 leakage.

Figure 5 reveals that an entrainment vortex forms below the nozzle and that the vortex strength decreases with injection time. This occurs because the downward-directed CO2 jet caused by the spray angle causes the flow to diverge directly below the nozzle, reducing the pressure there. As a result, the converging airflow from the surroundings moves toward the center below the nozzle, and the migration of CO2 is influenced by a biasing force that causes it to deflect inward (directly below the nozzle) and form a jet entrainment. Figure 6 shows the pressure variation curve at Z = 1.5 m directly below the nozzle, indicating a negative pressure state at 20 ~ 35 s. Under the influence of the entrainment vortex, a large amount of CO2 gas accumulates below the nozzle, with a volumetric content reaching 30-40%. As the pressure below the nozzle gradually rises to positive, the pressure difference decreases, the entrainment intensity diminishes, and the migration speed of CO2 decreases. The initial pressure drops (due to cooling) followed by a pressure rise within the space, that aligns with the general pattern of pressure fluctuation changes observed in literature19,20 for total flooding gas fire suppression systems discharged into enclosed spaces.

The CO2 jet reaches the space bottom firstly, and exhibits a horizontal diffusion trend. Upon encountering the wall, it spreads upward, forming an entrainment vortex that converges to create an inert gas protective layer. Throughout both the jetting process and accumulation at the bottom, the CO2 protective layer diffuses upward and in all directions due to concentration differences. As shown in Fig. 5, diffused CO2 gas increases the coverage area of the inert gas protective layer. Continuous CO2 flow reaching the bottom of the space enhances the concentration of both the initial and thickened CO2 protective layers. Therefore, the CO2 protective layer undergoes a dynamic process of concentration increase, thickening, further concentration increase, and further thickening, thereby achieving thickening of the inert medium protective layer and its gradual migration and accumulation toward the upper part of the space, ultimately realizing a total flooding inerting of the space.

The migration patterns and distribution properties of CO2 remain largely consistent when spatial compactness or injection rates are varied, and are therefore not repeated here. The main differences are: when the compactness is reduced, some CO2 gas may leak out at the opening, reducing the strength of the entrainment at the wall and consequently the growth rate of the CO2 concentration building-up layer at the bottom of the space; when the injection flow rate is increased, the rate of CO2 concentration increases directly below the nozzle accelerates, reducing the intensity of the entrainment vortex below the nozzle, and allowing more CO2 gas to diffuse at the bottom of the space, thereby increasing concentration and growth rate of the CO2 protective layer at the bottom.

Study on inerting characteristics of liquid CO2

Given the migration patterns and distribution characteristics of CO2, it is particularly important to further clarify the inerting effect of the CO2 fire suppression system in assessing fire suppression effectiveness. Using a CO2 concentration design of 43%17 as the threshold for effective inerting. The post-processing software “Tecplot” is used to draw the slice contour of CO2 concentration, and the effective inerting protection area can be calculated at Z = 0.3 m (the center of the oil pool flame) 60 s after the fire extinguishing system is started. Utilizing Eq. (1), the proportion of the effective inerting area within the entire fire compartment can be quantified, further characterizing the inerting effect. The Fig. 8 shown and Figs. 4, 5, 11 and 13 in this article is created by used the software “Origin 2020”.

Where, \(\eta\) is the space inerting rate, %; S1 is the effective inerting area, m2; S2 is the area of fire protection zone, m2, the value of this model is 34.88 (excluding part of the wall and simulated liquor jar).

Figure 7 shows the spatial inerting rate at Z = 0.3 m (flame center position of pool fire) under different space tightness and injection flow rates conditions without fire source. It is found that both the spatial tightness and the inertia rate increase for the same injection flow rate.

Under the same opening area, the injection flow rate is increased, and the inerting rate is increased. When the minimum design flow required in the design code of CO2 fire extinguishing system is injected into a limited space without fire source, the inerting rate decreases with the decrease of space tightness. For example, when the total opening area increases from 0 m2 to 1.8 m2 and 3.2 m2, the inerting rate decrease from 98.57 to 70.81% and 67.23%. This shows that when the design flow rate in the specification document is injected into the enclosed space without fire source, it can better realize the full submerged inerting at the bottom of the space. However, when there is a normal opening, the design calculation of the open compensation flow (Mx)17 in the design flow rate cannot meet the requirements of maintaining the inerting at the bottom of the space. Therefore, according to the designed flow rate in GB 50193-93, when the liquid CO2 fire extinguishing system is used to conduct the inerting efficiency test or “fire prevention” work in the limited space with no fire source and normal opening, the inerting effect may be unsatisfactory or even unable to achieve effective inerting. Space tightness and injection flow rate are two important factors to ensure the fire extinguishing effect of space inerting. When the other variable is unchanged, the smaller the opening area or the larger the design flow rate, the more beneficial to improve the inerting effect of fire protection zone.

Figure 8 shows the slice diagram of CO2 concentration at different spatial heights at 60 s when N1 liquid CO2 was injected. From the center of the space (where the nozzle is located) to the surrounding walls, the distribution of CO2 presents a high-low-high distribution, and the O2 content presents an opposite trend. According to the distribution law of CO2, the space can be divided into three regions from the inside out.

Zone I is the CO2 direct inerting zone. The zone is surrounded by CO2 air flow with the nozzle spray angle. Under the nozzle, the CO2 airflow enrolls inward to form a CO2 cloud. In this zone, the CO2 growth rate is the fastest, the accumulation amount is the most, and the inerting effect is the best.

Zone II is the CO2 accumulation zone. In the Zone II, the CO2 concentration decreases, and the O2 concentration increases. This zone is due to the horizontal migration and diffusion of CO2 air arriving at the bottom of the space to form an inert medium protective layer. Based on Fick’s diffusion law, CO2 gas will continue to diffuse under the action of concentration difference, so that the protection range of the inert gas protective layer will gradually increase, and the diffused CO2 will rapidly mix with the air, resulting in a distribution law of less CO2 concentration and higher O2 concentration in the region. At that time, the continuous injection of the extinguishing agent increases the concentration of the “newly thick” inert gas protective layer to the design concentration, thus achieving effective inerting in space. The dynamic change process of the CO2 protective layer in Zone II shows obvious gradual accumulation during the gradual increase of concentration and thickness. Therefore, the inerting characteristics of Zone II differ significantly at different heights, and the locations that do not reach the design inerting concentration of 43% often occur in this zone.

Zone III is the CO2 aggregation zone. The outer layer near the wall is the CO2 aggregation zone. CO2 reaching the bottom and spreading horizontally encounters the wall, moving upward along it, causing the phenomenon of enrolling vortex along the wall. Slow airflow in corners causes CO2 to aggregate, exhibiting a retention characteristic, forming a stable concentration distribution, creating the CO2 aggregation zone. The wall vortex, moving inward towards Zone II, involves CO2 diffusion and carries a small amount of oxygen, resulting in higher CO2 near the wall than Zone II.

Comparing CO2 inerting effects at different heights, it was found that the CO2 inerting rate decreases with height. For example, when the height increases to Z = 1.5 m, the CO2 inerting rate is 85.51% (with no liquor pottery jar model at Z = 1.5 m, hence S2 is 35.38), which is a decrease of 13.06% compared to the inerting rate at Z = 0.3 m. This is mainly due to the different inerting characteristics of different zones at different heights. The CO2 inert medium protective layer in Zones II and III are in a dynamic state of CO2 diffusion and replenishment; CO2 levels only rise when the replenishment exceeds the diffusion. However, the process of liquid CO2 injection for fire extinguishing medium inerting concentration replenishment primarily occurs from the bottom up. Therefore, the replenishment of CO2 to 43% at higher elevations in zones II and III exhibits a delay, and these zones demonstrate a clear phenomenon where the CO2 inerting rate decreases with increasing height. Zone I, where the initial injection of liquid CO2 forms a CO2 cloud with the highest concentration, can quickly replenish its CO2 content through entrainment, resulting in a lesser height-dependent effect on CO2 inertization in this zone.

Consequently, the diameter of the direct inertization zone formed at nozzle heights of 0 ~ 2 m is approximately 2 m. When designing a CO2 fire suppression system, the nozzle should be installed at the top of flammable areas or priority protection zones to ensure these areas are within zone I during firefighting. This allows liquid CO2 to rapidly inert the protected areas, achieving efficient firefighting or inerting.

Study on fire extinguishing characteristics of liquid CO2 under fire source conditions

Variation of O2 concentration in space

Indoor oxygen concentration is an important factor affecting flame extinguishing behavior21,22. Fire development in an enclosed environment is mainly controlled by the space oxygen concentration. As shown in fire-extinguishing time data in literature6, in a closed environment, the fire source will be extinguished naturally after the limited oxygen in the space is exhausted. The space tightness is reduced, and the opening enrolls fresh air from the outside world, which will lead to prolonged fire extinguishing time or fire extinguishing failure. This is because the extinguishing behavior of the flame is directly related to the oxygen concentration in the confined space23. Therefore, under different spatial tightness conditions, the inerting effect of liquid CO2 on the fire site space will be different, which will affect the fire extinguishing effect.

As shown in Table 4, fire extinguishing time and gas concentration changes under different opening area conditions with the same injection flow rate (157.86 L/min) are shown. When the opening area increases from 0 m2 to 1.8 m2 and 3.2 m2, the fire extinguishing time is 13.8 s, 12.2 s and 10.8 s respectively (t = fire source extinguishing time - fire extinguishing system starting time). With the increase of the opening area, the extinguishing time of the fire source is shortened. This is mainly because the large area vents in the initial stage of the fire source will discharge more high-temperature flue gas, which delays the response of the fire extinguishing system, that is, the time delay of inert gas extinguishing agent to inhibit the fire source from entering the “ventilation-controlled combustion” stage, so the fire source extinguishing time is delayed. As the opening area increases, more fresh air is sucked into the vent. When the fire extinguishing system is started, the oxygen concentration at Z = 0.3 m above the fire source increases from 17.29 to 18.31% and 18.60%, and when the fire source is extinguished, the oxygen concentration increases from 13.67 to 14.21% and 14.47%, respectively. When the fire extinguishing system starts to the fire source is extinguished, ∆φ (O2) are 3.63%, 4.1% and 4.13% respectively. After the fire extinguishing system is started, the fire source can be quickly extinguished under the coupling action of oxygen replacement by fire extinguishing agent and oxygen consumption. If there is no leakage of fire extinguishing agents (assuming that CO2 inerting results in the same decrease in oxygen concentration), it means that the opening area increases, the burning oxygen content of the fire source increases, and the role of oxygen consumption in the extinguishing process of the fire source increases, thus shortening the extinguishing time. But from the point of view of fire source development hazards, this is obviously unfavorable. The increase in the opening area will not only suck up more fresh air, increase the fire hazard, but also cause the fire extinguishing agent to leak and reduce the inerting effect. When the fire source is extinguished, the CO2 content is about 23.6–26.2%, which is basically consistent with the theoretical CO2 extinguishing concentration of 25.3%17 in alcohol (ethanol) fires, and the corresponding O2 concentration is between 12.6 and 14.5%.

Figure 9a shows the concentration change curve of gas at space center Z = 0.3 m under different CO2 injection flow rates. The fire extinguishing times for F4- F6 are 12.6 s, 12.6 s, and 11.4 s respectively. With increasing injection flow rate, the extinguishing time shorten. In the fire’s early stage, oxygen consumption did not decrease obviously. As the fire grow, the oxygen consumption rate increase. Upon starting the liquid CO2 system, the concentration curve shows a significant inflection point. Under the action of CO2 replacement, the volume fraction of O2 decrease rapidly. With increasing injection flow rate, the oxygen drop is faster, and the higher the CO2 concentration at the space bottom, the better the oxygen isolation. The volume fraction of O2 is less than 10% when the fire extinguishing system start.

The injected CO2 extinguishing agent preferentially gather at the space bottom, and the CO2 concentration of different heights varied by accumulate upward. Taking condition F5 as an example (Fig. 9b), the Z = 0.3 ~ 2 m concentration variation trend is similar, decreasing with increasing horizontal height. This is the same as Section "Gas migration law of liquid CO2 injected into finite space", where the CO2 inerting effect in the accumulation area increases with height, while the efficiency decreases. The CO2 accumulation growth rate is slowest at the ceiling Z = 2.8 m. At t = 60 s, the O2 concentration is 14.3%, and the inerting effect is poor. At t = 300 s, the concentration only reaches 40%, due to continuous leakage above nozzles, making it difficult to reach the designed 43% above leaks. After 60 s of starting the fire extinguishing system, the O2 content in space Z = 0.3 m decreased from 18.1 to 8.72%, and its decline rate reached 0.16%/s. At t = 300 s (3 min after the fire extinguishing system started), the volume fraction of O2 decreased to about 5%, consistent with literature24 research results that the oxygen concentration can be as low as 5% or less after continuous liquid CO2 injection into a completely sealed or relatively sealed continuous positive pressure space, provided sufficient liquid CO2 is stored.

Variation of CO2 concentration in space

There are CO2 produced by alcohol combustion and CO2 sprayed by the fire extinguishing system under the condition of fire source. As shown from Fig. 9, The CO2 produced by combustion within 0–120 s is about 2% at the bottom of the space. Before the fire extinguishing system is started, CO2 will migrate to the ceiling along with the flue gas. After the fire extinguishing system is started, the fire enters the attenuation stage, and the amount of CO2 generated will gradually decrease. The CO2 sprayed by the fire extinguishing system is mainly concentrated at the bottom of the space, which plays the role of isolating the oxygen at the bottom of the space. The CO2 generated by combustion is mainly reflected in increasing the content of CO2 in the space, which theoretically increases the inerting effect of the space. CO2 sprayed by fire extinguishing system is the main fire extinguishing agent.

The CO2 concentration trends within the 0.3 ~ 2 m height range are similar. Thus, we analyzed the relationship of CO2 extinguishing agent concentration change over time, using the change and growth rate of CO2 concentration at Z = 0.3 m (condition F5). As shown in Fig. 10, within the first 10 s after activation, CO2 is in a rapid-growth phase, reaching a concentration of 21.46% within 10 s, with a growth rate of 2.15%/s. During the period from 10 s to 60 s, the CO2 concentration increased by 29.62%, with an average growth rate of 0.59%/s, indicating a reduced but still steady-growth phase. From 60 s to 180 s after activation, the CO2 concentration increased by 16.91%, with an average growth rate of approximately 0.14%/s, showing a slower growth rate. The growth rate of CO2 at the bottom of the space gradually decreases with the extension of injection time, because the CO2 gas accumulated at the bottom of the space, based on Fick’s law, based on Fick’s law, the accumulated CO2 gas at the bottom tends to migrate and diffuse from the bottom to the upper part, and leak out of the space through the ventilation openings. Therefore, the growth rate of CO2 concentration at the bottom is slow.

The fire source extinguished at t = 13.2 s when the fire extinguishing system activated. At this moment, the O2 concentration at Z = 0.3 m above the fire source is 13.67%, and the CO2 concentration is 23.63%, which is close to the extinguishing concentration of 25.3% for CO2 gas extinguishing ethanol (alcohol)17. The amount of CO2 used for extinguishing is approximately 32 kg. Under the continuous action of the fire suppression system, at t = 37 s, the CO2 concentration at Z = 0.3 m above the fire source reaches the designed concentration of 43%, while the O2 concentration was 10.2%. At t = 60 s, the CO2 concentration reaches 51.08%, and the O2 concentration is 8.7%. In Zone II, away from the fire source at coordinates (x, y, z) = (3.5 m, 1 m, 0.3 m), the O2 concentration is higher than above the fire source at the moment of extinguishment, at 13.9%, and the CO2 concentration is slightly lower, at 22.58%. The time for CO2 to reach the designed concentration of 43% at this location is essentially the same as above the fire source, with the O2 concentration at 10.3%, similar to that above the fire source. The flame extinguishes when the O2 concentration in the air drops below 12%25,26. When the O2 concentration above the fire source decreases to 12%, the CO2 concentration is 33.02%. At the location away from the fire source, when the oxygen concentration reaches 12%, the CO2 concentration is 33.95%. This matches the theoretical value that the CO2 concentration can reach 30–35% when the O2 concentration is below 12% by injecting CO2 into the extinguishing space.

Figure 11 presents the CO2 volume fraction slice under different conditions. Comparing Fig. 11 with Fig. 8, it is evident that the distribution characteristics of CO2 in the fire space are similar to those in the confined space without a fire source where liquid CO2 is injected. By contrasting Fig. 11a and b, it is observed that as the height of Zone II (CO2 accumulation zone) and Zone III (CO2 aggregation zone) increases, the inerting effect decreases. For instance, under condition F1, when the height increases from Z = 0.3 m to 1.5 m, the space inerting rate drops from 98.68 to 98.56%, but it is still 13.05% higher than the inerting rate at Z = 1.5 m in the space without a fire source (N1). Figure 11b–d depict the CO2 distribution at Z = 1.5 m with the same liquid CO2 flow rate (134.76 L/min) under different space tightness degrees, revealing that the inerting effect in the direct inerting zone is less affected by the space tightness. Under fire source conditions, the diameter of Zone I (direct inerting zone) remains approximately 2 m.

As shown in Table 5, the inerting efficiency of liquid CO2 at Z = 0.3 m under fire conditions (Conditions F1 to F9) consistently exceeds 98% across different space tightness conditions and injection flow rates. The inerting efficiency at Z = 0.3 m in all fire source conditions is higher than that under non-fire source conditions. This is because, according to Eq. (2) of CO2 volume fraction, the oxygen consumed by combustion reduces V0, thus increasing φ (CO2) and the space inerting rate under the fire source conditions. Under the same injection flow rate, an increase in the total opening area also leads to an increase in the inerting efficiency of CO2. This is because the increased opening area prolongs the time for the fire to extinguish, consuming more oxygen during this period, which reduces V0 and increases φ (CO2), expanding the area where the concentration reaches 43%. When the injection flow increases, VCO2 increases, leading to an increase in φ (CO2) and thus enhancing the inerting efficiency.

Where, φ (CO2) represents the volume fraction of the fire extinguishing agent CO2, in %; VCO2 is the volume of the injected fire extinguishing agent CO2; V0 is the total volume of air.

Variation of CO2 leakage in space

Figure 12 illustrates the variability of the gas flow at the vent on the right side of the fire source model for different conditions. Since external ambient winds were not considered, gas flowing inward is denoted as negative, indicating entrainment of fresh air from outside, while outward flow is positive, indicating CO2 leakage. Figure 12 a shows that after activation of the liquid CO2 system, during the first 60 s, there is less CO2 leakage and higher VCO2 values under fire conditions, indicating superior inerting effects of liquid CO2 in a fire-involved confined space compared to a non-fire confined space. Initially, in the inerting process of a non-fire confined space, the cold CO2 flow temporarily reduces internal pressure, causing slight entrainment of fresh air through the vents. As internal pressure increases with rising CO2 concentration, CO2 leakage occurs at the vents, with a maximum leakage rate of 0.5 kg/s. Under fire conditions, combustion consumes oxygen, creating negative pressure below the neutral plane. And the injected cold CO2 flow temporarily exacerbates pressure changes, enhancing entrainment at the vents compared to a non-fire confined space. As the injection of inert gas agent increases in the air, the oxygen content entrained by the flame decreases, achieving rapid suffocation of the flame. The injection of CO2 agent replenishes the oxygen consumed by combustion, the internal pressure gradually shifts to positive pressure, reducing external air entrainment and increasing leakage of the CO2 extinguishing agent. After 40 s of injection, the leakage rate is similar to non-fire conditions.

Figure 12b shows the variation curves of CO2 leakage under different injection flow rates and enclosure conditions in the fire source space. After 60 s of fire extinguishing system activation, it’s found that increasing the total opening area and the injection flow rates both lead to greater CO2 leakage. When comparing F5 and F8, as well as F6 and F9, it’s noted that under the same injection flow rate, poorer space enclosure results in greater CO2 leakage, with maximum CO2 leakage of 0.6 kg/s under F9. Comparing F5 with F6, as well as F8 with F9, it’s observed that, with the same enclosure condition, larger injection flow results in greater CO2 leakage. This is because the leakage area and pressure difference between regions are crucial factors affecting the leakage rate of the fire extinguishing agent. Typically, the mass density of the inert fire extinguishing agent (CO2) mixed with air inside the space is greater than the density of the outside air. As the injection flow of CO2 increases, it enhances the interior-to-exterior pressure differential of the space. These pressure differences drive convection of the CO2-air mixture to flux out from lower leakage points and fresh air to flux in through higher leakage points, achieving volumetrically balanced conditions27.

The magnitude of the pressure difference driving CO2 leakage depends on the accumulation position of the extinguishing agent throughout the inertization holding time28. Therefore, neglecting minor openings such as bottom door gaps, the height of ventilation openings like shutters is an important factor affecting leakage time of the fire extinguishing medium. The higher the position of the ventilation opening, the later the CO2 leakage occurs, leading to better fire suppression effectiveness. Given that the lowest points of the ventilation openings in this study differed by only 0.05 m, the differences in onset of leakage were not significant. Increasing the injection flow rate leads to a greater pressure (concentration) difference between the space inside and outside the vents, thereby increasing the rate of CO2 leakage per unit time. An increase in the area of the space vents results in an increased leakage volume. As previously mentioned, after the fire extinguishing system has been injected for 60 s, the growth rate of CO2 in the area below Z = 2 m within the space significantly decreases, and the amount of CO2 leakage increases. Therefore, it is recommended that in the field application of the liquid CO2 fire extinguishing system, the injection flow rate could be reduced or the space sealing could be improved after 60 s of system injection to minimize CO2 leakage and enhance the efficient utilization of liquid CO2 resources. After extinguishment, CO2 accumulates from the space bottom to the space top, exhibiting a high concentration distribution characteristic below vents. Due to its high density, CO2 exhibits a settling property and is not easily expelled from vents after extinguishment, which may cause suffocation or other adverse effects on personnel the protection zone. Therefore, dedicated CO2 special exhaust fans should be installed at the bottom of the space on-site.

Variation of space temperature

Temperature is also one of the essential factors of combustion, liquid CO2 has a certain cooling effect on the space and fire source during the fire extinguishing process. The Fig. 13 indicates the changes of space temperature field under different closed conditions when the injection flow rate is 157.86 L/min. When the fire extinguishing system is initiated, the injected liquid CO2 will phase change and absorb heat in the space to form low temperature CO2 gas, and carry out heat exchange with the surrounding air. The cooling characteristics of CO2 on the space are related to its migration path, and the cooling effect of CO2 on the space Z = 2 m is better than that on the ceiling. When the opening area is 0m2, the flue gas can not effectively exclude the space, and the average temperature of the space is the highest, which is 252.4 ℃. After 10 s of fire extinguishing system, the average space temperature decreased to 101.4 ℃, and the average space temperature reduced to 151 ℃. The average space temperature of F6 under the working condition decreased from 232.8 ℃ to 59.6 ℃, which decreased by 173.2 ℃. The average space temperature of F9 under the working condition decreased from 248.2 ℃ to 69.7 ℃, which decreased by 178.5 ℃. With the increase of the opening area, the removal of high temperature flue gas is more favorable, and the cooling effect of space average temperature is increased.

Potential application of liquid CO2 intelligent control fire extinguishing system

The fire situation within a pottery liquor warehouse facility is complex, as broken pottery jars can easily “hide” small localized fire sources, increasing the inaccuracy of fire image detectors in recognizing flames. When it is not clear from space whether the flames within the fire scene have been extinguished, inert gas agents are continuously injected into the enclosed protection area to ensure the reliability of the total flooding inert gas fire extinguishing system and to prevent rekindling. The injection of a large amount of high-pressure gas quickly increases the pressure within the protected area. When the pressure exceeds the building’s sustainable pressure (typically 2.4 KPa for liquor warehouses), the protective area’s maintenance structure can be damaged, leading to cracks or even breakage in the weak points of the facility (such as windows and doors), which can result in agent loss and fire suppression failure18. Therefore, when the pressure within the protected area becomes too high, timely pressure relief is necessary. If exhaust ports are only opened for pressure relief after the wall reaches the maximum allowable peak pressure P0, the slow rate of pressure release would not allow sufficient time for the pressure to dissipate, leading to a higher peak pressure and increasing the risk of damage to the protective area’s maintenance structure. Thus, even when injecting a large amount of inert gas into a closed space with pressure relief vents, it is particularly important to monitor and appropriately release the space pressure.

Based on this, we propose the design concept of a liquid CO2 intelligent regulation fire extinguishing system, which includes a liquid CO2 intelligent perfusion system, an intelligent fire monitoring system, and an intelligent regulation system (Fig. 14). Upon receiving a fire alarm signal, the fire monitoring system first issues an audible and visual alarm. However, to ensure the safe evacuation of personnel within the liquor warehouses, the system delayed the release of the extinguishing agent by 20 s. During this delay period, the intelligent regulation system controls the opening of the gas phase valve of the liquid CO2 tanker to pressurize the liquid CO2 pipeline. Subsequently, the liquid phase valve and the main valve are opened to transport liquid CO2 into the pipeline, enabling rapid large-flow CO2 injection. The entire process of extinguishing agent transportation is monitored by temperature and pressure transmitters for the pipeline’s temperature and pressure, and the information is input into the regulation system. If the information predicts insufficient pressure in the pipeline, the intelligent regulation system activates the booster pump to increase the pipeline pressure, further reducing the risk of dry ice clogging the pipeline. When beginning to inject the inert agent into the space, the integrated control system closes ventilation shutters and other fixed vents via the programmable logic controller (PLC) control cabinet to enhance the space tightness. During the extinguishing process, pre-deployed sensors (gas concentration, temperature, and pressure sensors) and image fire detectors transmit real-time information on gas concentrations (CO2, O2, C2H5OH, etc.), space temperature (℃), space pressure (T), and fire detection images to the PLC control cabinet, achieving real-time visualization of multi-dimensional indicators. Based on comprehensive information from multiple sources, the system determines whether the fire has been extinguished, providing a basis for autonomous implementation of safe and efficient fire-fighting measures.

In practical scenarios, there are three situations to consider: (1) If the liquid CO2 fire suppression system is activated and the flame is extinguished within 1 min, i.e., the detector identifies no flame, the oxygen concentration at Z = 0.3 m (the least favorable point) is below 10%, and the space temperature is continuously decreasing, then the injection flow rate should be reduced and the fire suppression system should be shut off 60 s after activation; (2) If the flame persists after 60 s of system activation, maintain the flow rate and continue injecting the fire suppressant until the fire is extinguished (space pressure P is less than 0.8P0); (3) If the flame persists after 60 s of system activation, continue the injection. When the monitored space pressure reaches 0.8P0, open some vents ports away from the fire source to ensure that the space pressure does not damage the building enclosure while minimizing the impact of CO2 depressurization on the fire suppression effect in the fire area. After the fire is extinguished, open the ventilation shutters and CO2-specific fans to expel the accumulated CO2 gas from the space. When the space’s air returns to a normal atmospheric environment and poses no harm to personnel, staff may enter the liquor warehouse area to proceed with further safety measures.

The intelligent control system for liquid CO2 fire extinguishing can automatically implement safe and efficient measures to suppress fires with liquid CO2. This includes achieving rapid large-scale injection of liquid CO2 while reducing the risk of pipe clogging, reducing the likelihood of fire rekindling, ensuring the preservation of structural integrity of the building, and ensuring the safety of on-site personnel. This system provides an innovative to the application of intelligent and efficient fire prevention and extinguishing technologies using liquid CO2 in pottery jar liquor warehouses.

Conclusions

This study conducted numerical simulations to investigate migration and distribution patterns of CO2, as well as its inerting effects, under different spatial tightness degrees and injection flow rates in a liquid CO2 fire suppression system. Potential applications of the system are also proposed. Findings provide a foundational basis for field application of a clean and efficient liquid CO2 fire suppression system in pottery jar liquor warehouses. Main conclusions are as follows:

-

1.

1. According to the distribution characteristics of CO2, the space can be divided into direct inerting zone, accumulation zone and aggregation zone. The inerting effect of the direct inerting zone is less affected by the space tightness and height, and the effective inerting diameter is 2 m. Nozzle heads should be preferentially placed above flammable or priority protection areas, and should not be placed under openings of any kind.

-

2.

2. The liquid CO2 fire extinguishing system operates through the accumulation area and aggregation zone of CO2 from the bottom up to form a specific concentration of inert gas protective layer to achieve space total flooding inerting. Under the conditions in this paper, vents with boundary condition Z = 2.4 m have little influence on fire extinguishing effect. The higher the height of the vent in the liquor warehouse, the more conducive to CO2 fire suppression. However, it will increase the difficulty of CO2 emission, which is not conducive to on-site emergency disposal measures after the disaster. Special CO2 exhaust fans should be added at the low place.

-

3.

3. As space tightness degrees and injection flow rates increase, the inerting effect of the space enhances. With enlarged opening area and injection flow, CO2 leakage increases, peaking at approximately 1.0–1.2 kg/s after 60 s of system injection. Reducing injection flow or improving space tightness after 60 s effectively enhances efficient fire extinguishing agent utilization.

-

4.

4. At bottom of space Z = 0.3 m, when CO2 concentration reaches design 43%, O2 concentration is about 10.2%. After 60 s of injection, O2 concentration drops to 8.7%, and continuous injection for 180 s can further reduce O2 concentration to 5%. Inerting effect of liquid CO2 fire extinguishing systems decreases with increasing height of space, but can meet rapid inerting needs of bottom area. Inerting effect of CO2 is poor above vents, with O2 concentration 14.3% at Z = 2.8 m after 60 s of injection. Practical CO2 fire extinguishing application should consider positional relationship between injection location and fire source/leakage points.

-

5.

5. A new concept for liquid CO2 intelligent control fire extinguishing system is proposed, which can intelligently regulate pressure and injection flow within liquid CO2 transport pipes, effectively reducing pipe blockage and leakage risk, and enhancing fire extinguishing efficiency and safety of the liquid CO2 system.

Data availability

All data generated or analysed during this study are included in this published article.

References

Han, Q., Shi, J., Zhu, J., Lv, H. & Du, S. Enzymes extracted from apple peels have activity in reducing higher alcohols in Chinese liquors. J. Agric. Food Chem. 62, 9529–9538. https://doi.org/10.1021/jf5018862 (2014).

Hakkarainen, T., Korhonen, T. & Vaari, J. Heat release characteristics of ethanol-water mixtures: small-scale experiments. Fire Saf. J. 91, 174–181. https://doi.org/10.1016/j.firesaf.2017.03.071 (2017).

Chen, Q., Wang, X., Zhou, T., Ding, C. & Wang, J. Investigation on the fire hazard characteristics of ethanol–water mixture and Chinese liquor by a cone calorimeter. J. Therm. Anal. Calorim. 135, 2297–2308. https://doi.org/10.1007/s10973-018-7323-7 (2019).

Song, X. A Discussion on the fire and Explosion Protection Design of Liquor Factories [Master] (Chongqing University, 2005).

Zhang, G. et al. Influence of injection method on the fire extinguishing efficiency of liquid nitrogen in urban underground utility tunnel. Case Stud. Therm. Eng. 28, 101427. https://doi.org/10.1016/j.csite.2021.101427 (2021).

Li, X. et al. Feasibility assessment of a clean and efficient fire extinguishing system for pottery jar liquor warehouses. Sci. Rep. 14 https://doi.org/10.1038/s41598-024-64168-4 (2024).

Xu, J., Zhai, C., Liu, S., Qin, L. & Sun, Y. Feasibility investigation of cryogenic effect from liquid carbon dioxide multi cycle fracturing technology in coalbed methane recovery. Fuel 206, 371–380. https://doi.org/10.1016/j.fuel.2017.05.096 (2017).

Song, D. et al. Liquid carbon dioxide phase-change refrigeration and cooling technology of high temperature mine. Coal Sci. Technol. 45, 82–87 (2017).

Song, D. et al. Experimental study on cooling by phase transitionof liquid CO2. China Saf. Sci. J. 27, 120–125 (2017).

Yao, H. et al. Study on inhibition of spontaneous combustion of coal by liquid CO2. Solid Fuel Chemistry 57, 513–518, (2023). https://doi.org/10.3103/S0361521923080086

Yuan, K., Liu, Y., Ling, Y., Wei, J. & Liu, Z. Thermal performance analysis on shell-and-tube heat exchangers by utilizing liquid carbon dioxide for mine cooling. Int. J. Green Energy. 21, 1043–1059. https://doi.org/10.1080/15435075.2023.2228906 (2024).

Dundas, R. E. Experience with external fires in gas turbine installations and implications for fire protection, ASME 1990 International Gas Turbine and Aeroengine Congress and Exposition. (1990).

Kubica, P., Czarnecki, L., Boroń, S. & Węgrzyński, W. Maximizing the retention time of inert gases used in fixed gaseous extinguishing systems. Fire Saf. J. 80, 1–8. https://doi.org/10.1016/j.firesaf.2015.11.008 (2016).

DiNenno, P. J. & Forssell, E. W. Evaluation of the door fan pressurization leakage test method applied to halon 1301 total flooding systems. J. Fire. Prot. Eng. 1, 131–140. https://doi.org/10.1177/104239158900100403 (1989).

Yuan, S. et al. A review of fire-extinguishing agent on suppressing lithium-ion batteries fire. J. Energy Chem. 62, 262–280. https://doi.org/10.1016/j.jechem.2021.03.031 (2021).

Hu, X. & Kraaijeveld, A. Experimental and numerical investigation of extinguishing effectiveness of inert-gas agents in a leaky enclosure. Energies 15 https://doi.org/10.3390/en15124323 (2022).

Code of design for. Carbon dioxide fire extinguishing systems. GB 50193-93 (China Planning, Beijing, (2010).

Jiang, Y. et al. The transport and diffusion characteristics of superheated fire extinguish agent released via different nozzles in a confined space. Saf. Sci. 129, 104787. https://doi.org/10.1016/j.ssci.2020.104787 (2020).

Genge, C. Preventing excessive enclosure pressures during clean agent discharges. Halon Options Technical Working Conference, 15th Proceed-ings, pp. 1–16 (Albuquerque,2005).

Harry, L. & Robin, J. M. M. Development of room pressure in the discharge of FM-200 compared to the strength of various structural components. Halon Options Technical Working Conference, 7th Proceedings, pp. 1–12Albuquerque, (1997).

He, Q., Li, C., Lu, S., Wang, C. & Zhang, J. Pool fires in a corner ceiling vented cabin: ghosting flame and corresponding fire parameters. Fire Technol. 51, 537–552. https://doi.org/10.1007/s10694-015-0467-0 (2015).

Prétrel, H. & Suard, S. Investigation of the fire mass loss rate in confined and mechanically ventilated enclosures on the basis of a large-scale under-ventilated fire test. Fire Saf. J. 141, 103962. https://doi.org/10.1016/j.firesaf.2023.103962 (2023).

Cai, G., Zheng, X., Gao, W. & Guo, J. Self-extinction characteristics of fire extinguishing induced by nitrogen injection rescue in an enclosed urban utility tunnel. Case Stud. Therm. Eng. 59, 104478. https://doi.org/10.1016/j.csite.2024.104478 (2024).

Ge, L. et al. Experimental research on inerting characteristics of carbon dioxide used for fire extinguishment in a large sealed space. Process Saf. Environ. Prot. 142, 174–190. https://doi.org/10.1016/j.psep.2020.06.005 (2020).

Hu, X., Kraaijeveld, A. & Log, T. Numerical investigation of the required quantity of inert gas agents in fire suppression systems. Energies 13, 2536. https://doi.org/10.3390/en13102536 (2020).

Rosa, M. & Litton, D. Effectiveness of various concentrations of an inert gas mixture for preventing and suppressing mining equipment cab fires: development of a dual cab fire inerting system. Fire Technol. 43, 29–44. https://doi.org/10.1007/s10694-006-0002-4 (2007).

Hetrick, T. M. Analysis of hold time models for total flooding clean extinguishing agents. Fire Technol. 44, 239–261. https://doi.org/10.1007/s10694-008-0047-7 (2008).

Hetrick, T. M. & Rangwala, A. S. A modified hold time model for total flooding fire suppression. Fire Saf. J. 45, 12–20. https://doi.org/10.1016/j.firesaf.2009.08.006 (2010).

Acknowledgements

This work was financially supported by Scientific Research Fund of Liaoning Provincial Education Department (LJKQZ20222338), the National Natural Science Foundation of China (No.52104195, 52274204), China Association for Science and Technology ‘Young Talent Promotion Project’ (2022QNRC001), Research project on fire characteristics and inert gas (carbon dioxide) fire extinguishing technology and equipment of liquor pottery warehouses(MTGF2023008). These supports are gratefully acknowledged. The authors are grateful to the reviewers for discerning comments on this paper.

Author information

Authors and Affiliations

Contributions

Xueming Li: Conceptualization, Methodology, Writing-original draft. Wei Wan: Investigation, Writing-original draft. Gang Bai: Conceptualization, Methodology. Youkai Zhao: Resources. Xunxian Shi: Resources. Jinsong Zhu: Investigation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Li, X., Wan, W., Bai, G. et al. Study on the effect of space tightness on the inerting effect of liquid CO2 in pottery jar liquor warehouses. Sci Rep 15, 470 (2025). https://doi.org/10.1038/s41598-024-84180-y

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-84180-y