Abstract

This study investigates the bearing characteristics and damage evolution of regenerative rock masses formed under varying geological conditions through uniaxial loading tests, numerical simulations, and theoretical derivations. Regenerative rock mass samples with different water-cement ratios and cementing materials were prepared, and the mechanical behavior during the loading process was analyzed. The results indicate that the secondary damage process can be divided into three stages: pre-peak, weakening, and friction. As the mechanical properties of the cementing matrix improve, the bearing capacity increases, and the failure mode transitions from ductile to brittle. A damage constitutive model incorporating the Weibull distribution and a damage correction coefficient is proposed to predict the mechanical strength of regenerative rock masses. Numerical simulations using Particle Flow Code 3D (PFC3D) reveal that enhanced mechanical properties of the cementing material lead to a shift from tensile to shear failure. This study provides theoretical and practical guidance for the stability control of regenerative rock mass engineering, offering new insights into the design of support systems for mining operations. The findings have significant implications for the recovery of shallow residual coal resources and the stability control of mining roadways.

Similar content being viewed by others

Introduction

China is the globe’s largest coal manufacturer and consumer, with its energy structure being primarily coal-dependent, and this situation is unlikely to change in the short term1,2. Due to limitations in mining technology and equipment, the average recovery ratio of coal remains low, leaving a significant amount of quality coal resources are left in the range of 0–800 m buried depth2,3. When recovering this portion of coal resources, the mining face is often positioned within the influence zone of the original goaf, facing the challenge of regenerated rock mass stability4,5. The regenerated rock mass is an intact rock mass with a certain bearing capacity, formed by the secondary consolidation of collapsed coal and rock in the goaf after longwall mining has ended. This consolidation occurs within a confined space over a long geological period, involving the compaction effect of ground stress and hydration reactions between internal clay minerals and accumulated water in the goaf. Although this type of rock possesses a certain bearing capacity, it is prone to loosening and fracturing under the influence of mining activities due to the relatively short geological consolidation time and weak internal bonding6,7. Therefore, studying the mechanical characteristics and secondary damage failure rules of the regenerative rock mass is of great significance for the recovery of shallow residual coal resources and the design of engineering support for regenerative rock mass.

Bearing characteristics are key parameters that must be understood in rock mass engineering design, especially for weak rock masses. Many scholars have conducted in-depth research on the bearing characteristics of weak rock masses. In 1994, Japanese scholars Takashi Kobayashi and Ryunosuke Yoshinaka researched the connection between stress and strain in soft rock mixed with gravel and found that its deformation characteristics are controlled by the matrix component8. In 2004, H.B. Li and others investigated the mechanical characteristics of soft rock under dynamic uniaxial compression conditions and found that its compressive strength and Young’s modulus increased with strain rate more significantly than those of hard rock9. In addition, recent studies have also focused on the strength retrogression and physical properties evolution of soft rocks under different environmental factors10,11. However, research on the bearing characteristics and damage failure rules of regenerative rock masses formed through the secondary diagenesis of fractured coal rocks remains limited.

In the area of strengthening the mechanical characteristics and stability control of broken surrounding rocks, many experts and scholars have conducted research12,13,14,15,16. Among them, Ma, Wenqiang, and Tongxu Wang, based on the regenerated roof model, modified the natural equilibrious arch theory and guided its practical engineering application17. Through the compaction experiment of fractured rock mass, he further revealed the relationship between rock particle size distribution, compression ratio, and shear strength characteristics of different compacted regenerative rock masses18. WANG, Ping, et al. established the 'Parabolic-semi hyperbolic’ mechanical model for weakly cemented regenerated roofs and proposed the basic principles of "protecting the bottom, reinforcing the sides, and controlling the roof" for the stability control of weak regenerated roof surrounding rocks4. Hu et al. analyzed the structural evolution characteristics and porosity distribution laws of the regenerated roof during the mining of bifurcation coal seams and proposed ground pre-grouting reinforcement measures19,20,21. Li et al. developed a thin plate model for elastic rectangular cantilevers for regenerated roofs and examined the crucial circumstances that lead to the bending and breaking of regenerated roofs in mining operations5. Chi, Xiaolou, Ke Yang, and Qiang Fu analyzed the fracturing patterns of steeply inclined regenerated roofs and proposed control strategies for support instability22. Despite significant progress in the engineering stability control of regenerative rock mass, research on the bearing characteristics and damage failure rules of regenerative rock mass is still relatively scarce. Furthermore, many experts have studied the secondary diagenesis and mechanical characteristics of fractured coal rocks. For example, through gravel compression tests, Li et al. analyzed the evolution laws of grain size, porosity, compaction ratio, expansion coefficient, and permeability during the secondary diagenesis of fractured coal rock mass and discussed the effects of particle strength, particle size, and stress on the particle fragmentation of coal rock mass23,24,25. Zhang et al. revealed the diagenetic mechanism and grain size evolution laws of fractured coal rock mass during the secondary diagenesis process through numerical simulation and experimental research and proposed a three-dimensional modeling method for fractured coal rock mass26,27,28. However, existing compaction experiments have not fully considered the bonding reaction and hydration reaction occurring during the diagenesis process of fractured coal rock mass, and research on the mechanical properties of regenerative rock mass formed through secondary diagenesis remains insufficient. Underground mining activities inevitably cause unloading damage to the surrounding rocks. Consequently, numerous experts have studied the damage failure rules of rocks. For example, Homand-Etienne, F., Dashnor Hoxha, and Jian-Fu Shao proposed the continuous damage failure rules of brittle rocks29, Burdine studied the damage failure rules of rocks under dynamic loading conditions30, and Wang, Chunlai et al. investigated the damage evolution rules of hard rocks31. However, research on the damage failure rules of regenerative rock mass formed through the secondary consolidation of fractured coal rock mass is still limited.

In summary, current research on regenerative rock mass engineering primarily focuses on the variation of physical parameters during the compaction and diagenesis process of coal rock mass and the engineering instability mechanisms and stability control of regenerative rock mass. Research on the damage failure mechanisms of regenerative rock mass remains limited. Most studies on rock damage failure have taken intact rocks as the research object, with relatively few focusing on regenerative rock mass. Moreover, the geological conditions required for the secondary diagenesis of fractured coal rock mass include in-situ stress, mineral composition of coal and rock, block size, geological action time, and water, among other factors. This leads to significant differences in the bearing characteristics of regenerative rock masses formed under varying geological conditions. Therefore, understanding the bearing characteristics and damage failure rules of regenerative rock mass not only complements research on the mechanical properties of rock mass but also has major consequences for the stability control of regenerative rock mass engineering.

Therefore, this paper conducted uniaxial loading tests on prepared regenerated rock mass specimens to study their bearing characteristics. Considering that regenerated rock masses retain a certain bearing capacity after the peak, a damage correction coefficient α was introduced into Lemaitre’s strain equivalence principle to establish a damage constitutive model accounting for post-peak characteristics. Finally, the Particle Flow Code (PFC3D) was used to further analyze the mesoscopic damage and failure mechanisms of regenerated rock masses. The research findings of this paper will provide a reference for the stability control of regenerated rock mass engineering projects.

Experiment method

Preparation of specimens from regenerated rock mass

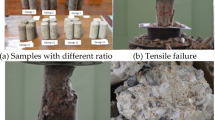

According to the field investigation results, as shown in Fig. 1, the regenerated rock mass contains significant residual large-particle aggregates, and distinct cementation damage marks are observed on the surface of the fractured rock mass after secondary destruction. Based on the investigation of the mining data, it was found that 34 years have passed since the initial mining of this working face was completed. Therefore, it can be inferred that a large proportion of the original aggregates were retained during the secondary diagenesis process of the broken coal-rock mass in the original goaf, and the fractures between the aggregates were filled with various forms of cementing materials, resulting in the regenerated rock mass exhibiting good overall integrity.

According to field conditions and considering that regenerated rock masses tend to loosen and fracture easily under mining disturbances, obtaining intact regenerated rock mass samples on-site becomes extremely difficult. Therefore, this study employs rock-like material testing methods to simulate regenerated rock masses under different geological conditions for experimentation. There are significant differences in factors such as ground stress environments, hydrogeological conditions, and compaction times of goafs during the formation of regenerated rock masses. The mechanical properties of regenerated rock masses vary greatly across different times and regions. Therefore, in designing the experiments, we selected representative raw materials—gypsum, M32.5 Portland cement, and K600 superfine cement—that are commonly used in rock-like material fabrication and have significantly different mechanical properties to prepare the cementing matrix of the regenerated rock masses. Based on the research of Ping Wang et al.32, we consolidated the crushed rocks using mixtures of K600 superfine cement, M32.5 Portland cement, and gypsum with water–cement ratios of 0.5, 0.6, and 0.7, respectively, to obtain regenerated rock masses with different bearing capacities. Previous studies have found that aggregates themselves have a significant influence on the bearing characteristics of rock-like materials33,34,35. To eliminate the influence of particle size on the bearing characteristics of rock masses, this study uses coal gangue with a particle size range of 5–10 mm as the aggregate for the regenerated rock mass.

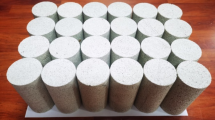

Three steps were involved in the preparation of the samples of regenerated rock mass. First, take 5 kg of coal gangue with a particle size of 5 ~ 10 mm and place it into a mold with dimensions of 150 mm * 150 mm * 150 mm. Second, different types of cement were mixed according to the specified water-cement ratios, and the slurry mixture was poured into the mold until it was level with the top of the mold. Third, after the regenerated rock mass solidified, it was demolded and placed in a constant temperature and humidity chamber, with a humidity of 90% and a temperature of 20 ± 2 °C.

In summary, nine experimental groups were designed according to different types of cement and water-cement ratios. To ensure reliability, four samples were prepared for each test group, resulting in a total of 36 samples. The materials and processes used for sample preparation are shown in Fig. 2.

Testing system

We used the RMT-150C rock mechanics loading machine from the University of Science and Technology of Hunan to load the regenerated rock mass samples. The experiment utilized a uniaxial loading method, with a displacement-controlled loading rate of 0.05 mm/s. The testing system is shown in Fig. 3.

Analysis of the mechanical properties with regenerated rock mass

Characteristic analysis of the stress–strain curves of regenerated rock mass

The uniaxial compression test results are presented in Table 1, with the stress–strain curves illustrated in Fig. 4. Based on the characteristic points (peak point), convergence tendency, and data volume of the stress–strain curves, we divided the analysis of the mechanical properties of regenerated rocks into three stages: pre-peak, weakening, and friction.

Pre-peak stage (OA): In this stage, the stress–strain curves of the regenerated rock mass exhibits characteristics of elastic–plastic deformation. As the cementation properties decrease, plastic deformation in the regenerated rock mass increases, while elastic deformation diminishes. Since the external force of the broken cement is significantly lower than that of the coal gangue, the bearing characteristics of the regenerated rock mass in the pre-peak stage are similar to those of the cementing material.

Weakening stage (AB): Unlike the brittle stress drop behavior exhibited by typical rock materials after the peak, regenerated rock masses retain a certain level of bearing capacity post-peak, which is beneficial for the stability control of surrounding rock in roadways. Since the external force required for the secondary failure of coal gangue particles within the regenerated rock mass is much greater than that needed for the failure of the cementing material, the coal gangue can be considered an elastic body during the post-peak stage. Essentially, the failure of the regenerated rock mass is the secondary failure of the cementing matrix. When the load applied to the regenerated rock mass exceeds its ultimate bearing capacity, the main cracks penetrate through the mass. However, there remains some residual cementing matrix within the fractured regenerated rock mass. At this point, the bearing capacity of the regenerated rock mass is composed of the residual cohesion provided by the remaining cementing matrix and the frictional resistance between fracture interfaces. As loading continues, internal cracks within the regenerated rock mass keep opening, leading to a continuous decrease in residual bonding strength within the fractured mass. Meanwhile, the frictional resistance between fracture interfaces continuously increases. Therefore, the post-peak weakening stage of the regenerated rock mass is a process of bonding weakening and frictional resistance strengthening. For stronger cementations such as K600 superfine cement, the strong cementation properties make secondary compression failure of the broken blocks difficult. Consequently, the bearing characteristics decrease rapidly, and the behavior is dominated by interface shear strength and interface friction; For weaker cementations such as gypsum, the weak cementation properties make secondary compression failure of the broken blocks easy. Consequently, the bearing characteristics decrease slowly, and the behavior is dominated by cohesion and interface friction; For medium-strength cementations, such as M32.5 Portland cement, the moderate cementation properties result in moderate secondary compression failure of the broken blocks. Consequently, the bearing characteristics decrease at a moderate rate, and the behavior is influenced by cohesion, shear strength, and interface friction, shows as Fig. 4.

Friction stage (after point b): In this stage, internal cracks have fully developed, and the bearing characteristics are primarily attributed to the interface friction between the broken blocks. Based on the data size and variation trend of the strain–stress curve, it exhibits both frictional-slip and frictional-weakening characteristics, as shown in Fig. 4d. For different cementation materials, we can observe frictional weakening, which is exhibited by a reduction in data size and a diminishing gradient on the strain–stress curve. Additionally, the frictional-slip characteristics are only exhibited in the strain–stress curves of M32.5 Portland cement. For stronger cementations, such as K600 superfine cement, the bulged areas at the interface with the broken blocks are sheared off during the weakening stage. The friction coefficient of the broken blocks can then be considered constant, causing the strain–stress curve to form a straight line during the friction stage. The strain–stress curve for weaker cementations (e.g., gypsum) during the friction stage is similar to that of stronger cementations. However, the regenerated rock mass with weaker cementations becomes more fragmented because its cementation is more easily broken than stronger materials. The weaker cementation is completely destroyed during the weakening stage of the regenerated rock mass. The bearing characteristics of the regenerated rock mass are determined by a group effect, which is the friction-slip of crushed bulk rock.

Change in the uniaxial compressive strength of regenerated rock mass

Based on the results shown in Table 1, a bar chart of the uniaxial compressive strength of the regenerated rock mass was plotted, as illustrated in Fig. 5. The chart demonstrates that the uniaxial compressive strength decreased as the water-cement ratio increased, as indicated by the green arrow in Fig. 5. Taking regenerated rock mass using ultrafine cement as an example, as the water-cement ratio increases, the uniaxial compressive strength decreases by 14.62% and 54.88%, respectively. The concentration of the cementitious solution is determined by the water-cement ratio. As the water-cement ratio increases, the concentration of the cementitious solution decreases. A higher water-cement ratio leads to a higher porosity in the formed regenerated rock mass, weaker bonding between coal gangue blocks, and a more fragile cementation bond, making it more prone to damage. Consequently, the macroscopic bearing capacity of the regenerated rock mass is significantly reduced. The chart demonstrates that the uniaxial compressive strength increased as the cementation character of cement increased, as indicated by the brown arrow in Fig. 5. Taking the regenerated rock mass with a water-cement ratio of 0.5 as an example, as the bonding performance of the cementitious material weakens (from K600 ultrafine cement to M32.5 Portland cement to gypsum), the uniaxial compressive strength is 14.64 MPa, 11.16 MPa, and 6.74 MPa, respectively, with decreases of 23.77% and 53.96%. This indicates that the cementitious material significantly influences the bearing characteristics of the regenerated rock mass. When the water-cement ratio is constant, the porosity of the regenerated rock mass remains relatively consistent, and the bonding performance of the cementitious material determines the strength of the bonds between coal gangue blocks. As the bonding performance of the cementitious material improves, the bonds between coal gangue blocks become more resistant to damage, thus enhancing the macroscopic bearing capacity of the regenerated rock mass.

The test results showed that the uniaxial compressive strength of the regenerated rock mass ranged from 4.05 to 14.64 MPa. This reflects the bearing characteristics of the regenerated rock mass under varying geological conditions and different periods of geological activity. Under the condition of strong matrix cementation (when the cementation materials is K600 superfine cement), the bearing characteristics of the regenerated rock mass are significantly enhanced. The weakening characteristics after the stress peak are similar to those of typical rock. In the medium matrix cementation state (when the cementation materials is M32.5 Portland cement), the regenerated rock mass exhibits a definite bearing capacity. The post-peak phase shows clear characteristics of ductile failure, which is beneficial for supporting roadway roofs. In the weak matrix cementation state (when the cementation materials is gypsum), the regenerated rock mass exhibits clear characteristics of ductile failure, but its bearing capacity is too low. This makes supporting the surrounding rock more challenging. By comparing the uniaxial compressive strength and post-peak variation trends of regenerated rock masses, we can determine the optimal conditions for recovering residual coal resources under a medium cementing matrix state. At this time, the regenerated rock mass possesses strong bearing capacity and exhibits certain ductility after the peak, providing an opportunity for reinforcement support in regenerated rock mass engineering.

Analysis of damage and failure characteristics in regenerated rock mass

Damage constitutive model for regenerated rock mass

The regenerated rock mass retains definite bearing characteristics after the peak stress, making it more favorable for controlling the surrounding rock in roadways. Numerous scholars have studied the Damage36,37,38,39,40,41 Constitutive Model for rock materials. The regenerated rock mass does not exhibit a brittle drop after peak stress, indicating that its damage factor at peak stress is not equal to 1.0. Based on Lemaitre’s strain equivalence principle, a damage correction factor, α, was introduced to develop a revised damage constitutive model42,43,44. The revised model is presented in Eq. (1).

where σ is stress, E is elastic modulus, ε is strain and α is the damage correction factor.

It is assumed that the microelement destruction of the regenerated rock mass follows a Weibull distribution, then the expression of damage factor, D, as shown as Eq. (2).

where λ is scale parameter of Weibull distribution and κ is shape parameter of Weibull distribution. Simultaneous Eqs. (1) and (2), we can get the damage constitutive equation as shown as Eq. (3).

The boundary conditions of the uniaxial compression test as shown as Eqs. (4)–(7).

where σp is peak stress and εp is peak stress. Substituting Eq. (5) into Eq. (3).

Take the logarithm of both sides of Eq. (8)

Differentiate both sides of Eq. (3).

Substituting Eq. (6) into Eq. (10).

Substituting Eq. (8) into Eq. (11).

Simultaneous Eqs. (9) and (12)

By substituting the results from Table 1 into Eqs. (13) and (14), we can obtain the values of κ and λ. Then, substituting these values into the equations allows us to determine the damage factor, D. Finally, by substituting the values of κ, λ, and D into Eq. (3) and introducing the modification factor α, we derive the corresponding damage constitutive equation. Using Matlab software, the constitutive equation diagram was plotted, as shown in Fig. 6. Table 2 lists the constitutive equation of the regenerated rock mass when the modification factor α is equal to 0.97.

The measured stress–strain curve and theoretical stress–strain curves for different damage factors, α, are shown in Fig. 6. It can be observed from Fig. 6 that the measured stress–strain curve closely matches the theoretical curves during the pre-peak stage and the weakening phase. However, in the friction stage, the measured stress–strain curve exhibits significant friction-sliding and friction-weakening characteristics, while the theoretical stress–strain curves display pronounced friction-hardening behavior. This is because, in practical engineering and experiments, when the rock or rock mass enters the friction stage, it tends to move toward a free face and lose stability. As a result, the measured stress–strain curve exhibits significant friction-sliding and friction-weakening characteristics during this stage. However, for the theoretical stress–strain curves, when the damage factor D equals 1, the minimum residual stress value appears, followed by friction-hardening behavior. So this damage constitutive model only could explain the pre-peak stage and weakening stage of regenerated rock mass.

In the pre-peak stage, the theoretical stress–strain curves with different substituted damage factors, D, remain consistent. However, deviations appear in the post-peak stage, where both the rate of decline and the minimum residual stress values show significant differences. This demonstrates that the damage factor D has a substantial impact on the post-peak mechanical characteristics of regenerated rock mass. Figure 5 shows that the damage correction factor, ααα, for regenerated rock mass should be lower for shorter periods of geological activity and higher for longer periods. Therefore, for different engineering applications involving regenerated rock mass, the value of α should be adjusted accordingly. Figure 7 illustrates the destruction characteristics of regenerated rock mass with M32.5 Portland cement and a water-cement ratio of 0.6 under different stress values. It can be seen from Fig. 7 that the regenerated rock mass does not break at peak stress, and no surface cracks are visible.

Particle flow code numerical simulation

Particle Flow Code 3D (PFC3D) software is a widely used tool for researching the deformation and internal cracking of rock, as it enables the visualization of deformation, crack propagation, mesoscopic energy change, and other related processes within the rock. Since the surface cracks of the regenerated rock mass cannot fully represent the internal damage and failure conditions, the Particle Flow Code software (PFC3D) can simulate the development of micro-cracks and the evolution of mesoscopic energy during the loading process of the rock mass. Due to space limitations, only the regenerated rock mass with a water-cement ratio of 0.6 is illustrated as an example.

Numerical modeling

The numerical model was set by regenerated rock mass with M32.5 Portland cement and a water-cement ratio of 0.6, and there are two parts, one is coal coal gangues, the other is cementation materials. To ensure the accuracy of the numerical model, four representative types of broken coal gangue, classified based on their morphology and size ratios, were selected: strip-like (see Fig. 8a), disc-like (see Fig. 8b), tooth-like (see Fig. 8c), and triangular prism-shaped (see Fig. 8d). Spherical particles were used to represent the cemented matrix within the regenerated rock mass, as shown in Fig. 9. According to research on rock-like materials using Particle Flow Code 3D (PFC3D), the linear parallel bond model is an effective contact model for such materials45. Since the conversion between macro-mechanical parameters and meso-bonding parameters is not provided in the PFC3D manual, a trial-and-error method was employed in the testing. Based on prior experience, when the stress–strain curve obtained from the numerical simulation closely matches that from laboratory tests—especially in terms of elastic modulus and peak stress—the meso-bonding parameters can be considered reasonable46,47,48. Table 3 presents the meso-bonding parameters, while Fig. 10 compares the stress–strain curves from numerical modeling, laboratory tests, and theoretical derivation.

Analysis of mesoscopic energy

Particle Flow Code 3D (PFC3D) can monitor the mesoscopic energy throughout the entire uniaxial loading test process. According to the law of conservation of energy, the work done by the RMT-150C rock mechanics testing system on the regenerated rock mass is converted into various forms of energy. The external force applied changes the shape and motion state of the object. In this test, the work done by the RMT-150C on the regenerated rock mass was considered as the sum of kinetic energy, strain energy, bonding energy, and friction energy. Energy change of the entire uniaxial loading test process was exhibited in Fig. 11. As shown in Fig. 11, during the pre-peak stress stage, most of the work from external forces is converted into strain energy and bonding energy. These forms of energy lead to the deformation of the regenerated rock mass and are stored in the bonds between different materials. In the post-peak stress stage, strain energy and bonding energy gradually decrease, while kinetic energy and friction energy increase rapidly. For batter analyze the energy changes throughout the uniaxial loading process, the stress–strain curve was divided into four stages based on characteristic stresses: the elastic deformation stage, plastic deformation stage, weakening stage, and friction stage, as shown in Fig. 11. In this figure, σy represents the yield stress,σc represents the peak stress, and σf represents the residual stress.

In the elastic deformation stage (where σ ≤ σy), the curves for cumulative strain energy and cumulative bonding energy exhibit a parabolic ascent, while cumulative kinetic energy and cumulative friction energy remain tend to zero. This is because, during this stage, the external work is entirely converted into strain and bonding energy. The cumulative kinetic and friction energies remain negligible due to minimal breakage of the linear parallel bonds. Any breakage that does occur leads to relative motion between particles or coal gangue, resulting in some friction loss and kinetic energy conversion.

In the plastic deformation stage (σy < σ ≤ σc), the regenerated rock mass experiences volumetric dilation, and numerous fissures begin to open. According to Fig. 7, no significant cracking is observed on the surface of the regenerated rock mass. As continuous axial loading causes these open fissures to close, the relative motion between coal gangue or particles generates an increase in cumulative friction energy and cumulative kinetic energy. Since the uniaxial loading test is a quasi-static process, the cumulative kinetic energy remains close to zero, while the friction energy shows a noticeable rise, as illustrated in Fig. 11.

In the weakening stage (σc < σ < σr), fissures in the regenerated rock mass rapidly propagate, leading to a decrease in its load-bearing capacity. Due to the ability of broken fragments to transfer forces to adjacent sections, continued axial loading causes secondary breakage within the cemented fragments, further reducing the integrity of the regenerated rock mass. Consequently, during this stage, the strain and bonding energies decrease, while the friction energy increases.

In the friction stage (σ > σr), the friction energy surpasses the strain and bonding energies as fissures completely propagate through the rock mass. The residual cohesion of the regenerated rock mass approaches zero, making the frictional resistance of the fragmented bulk the primary contributor to its load-bearing capacity. Continuous loading induces relative motion among these broken fragments, causing shear failure at the interfaces. This results in a slip phenomenon in the stress–strain curve. When shear failure occurs at the interface between broken bulk, the friction coefficient decreases, leading to a reduction in the load-bearing capacity until the rock mass eventually loses its stability.

By analyzing the energy changes throughout the uniaxial loading process, it is evident that the primary contributor to the load-bearing capacity changes significantly in the post-peak stage. This transformation is crucial for understanding and controlling the stability of surrounding rock in roadways, especially for broken surrounding rock in high-stress roadways. Furthermore, this analysis reveals the post-peak bearing characteristics of weakened bond resistance and enhanced frictional resistance.

Analysis of crack expansion

Particle Flow Code 3D (PFC3D) can monitor micro-crack development throughout the entire uniaxial loading test process and distinguish between tensile and shear cracks. The micro-cracks of three types of regenerated rock mass with a water-cement ratio of 0.6 are presented statistically in Fig. 12. According to the rate of micro-crack development, the fastest crack propagation occurs between the yield stress and residual stress, with the maximum rate observed at the peak stress point. It is worth noting that micro-cracks continue to develop in the friction weakening stage until the load-bearing capacity reaches zero. Based on the proportion of tensile and shear cracks, it is evident that the regenerated rock mass cemented by M32.5 Portland cement and K600 mesh superfine cement primarily exhibits shear cracks. In contrast, when cemented with gypsum, tensile cracks dominate. In other words, regenerated rock mass formed under short-term geological processes primarily undergoes tensile failure, while that formed under long-term geological processes predominantly experiences shear failure. Based on the micro-crack data at typical stress points, the micro-crack increment in each stage, and the corresponding micro-crack increment ratio can be calculated. For the regenerated rock mass cemented with M32.5 Portland cement and a water-cement ratio of 0.6, the micro-crack increments in the elastic deformation stage, plastic deformation stage, weakening stage, and friction stage account for 9.74%, 27.08%, 53.68%, and 9.50%, respectively.

Using the time correspondence method and typical stress points on the stress–strain curve, the actual micro-crack distribution and development at characteristic stress values are obtained, as shown in Fig. 13. It was observed that micro-cracks first appeared at the boundaries where cementation was weakest. This explains why the elastic deformation stage accounts for 9.74% of the total micro-crack development. When the stress equal to peak-stress, The shear failure bond is initially formed inside the regenerated rock mass, as shown in Fig. 13 PS0.6 σ = σc. According to the purple arrow in Fig. 13, it is not difficult to find that the cracks in the regenerated rock mass develop along the periphery to the center, and extend along the weak cementation.

Microstructural analysis of fracture interfaces of regenerated rock masses

The failure of regenerated rock masses is closely related to the cementing matrix. A Hitachi SU3500 tungsten filament scanning electron microscope was used to magnify the fracture interfaces of regenerated rock masses with different cementing matrices by 500 times; the scanning results are shown in Fig. 14. Overall, the scanned interfaces of the regenerated rock masses show no traces of coal gangue damage, indicating that their failure is essentially due to the breakdown of the cementing matrix. Therefore, the bearing characteristics and damage mechanisms of regenerated rock masses are closely related to the properties of the cementing matrix and cementing materials.

For weak cementing matrices (e.g., gypsum), as shown in Fig. 14a, the scanned surface appears flocculent with large pores and extremely poor cementation. Additionally, the fracture interface shows no obvious exposed coal gangue particles or signs of shear failure of fine particles, indicating that the failure of this type is caused by tensile failure of the cementing matrix. The failure mode is illustrated in Fig. 15a.

For medium cementing matrices (e.g., M32.5 Portland slag cement), as shown in Fig. 14b, the scanned surface is locally rough with visible pores and coal gangue particles, exhibiting obvious shear failure characteristics. Clear fissures are also present at the interface, showing tensile failure features. This indicates that the failure of this type is caused by tensile-shear action between weakly and well-cemented regions. The failure mode is illustrated in Fig. 15b.

For strong cementing matrices (e.g., K600 superfine cement), as shown in Fig. 14c, the scanned surface is relatively homogeneous, and the fracture interface exhibits obvious shear slip traces and residual fragments of the sheared cementing matrix. This indicates that the failure of this type is caused by shear failure of the cementing matrix. The failure mode is illustrated in Fig. 15c.

Analysis of the scanned surfaces of different regenerated rock masses reveals that their failure is essentially due to the breakdown of the cementing matrix. Their mechanical properties and failure modes are closely related to the properties of the cementing matrix. With the improvement of the mechanical properties of the cementing matrix, the failure mode of regenerated rock masses shows a clear transition from tensile to tensile-shear to shear failure.

Discussion

Figure 16 illustrates the deformation and failure of a regenerated rock mass roadway at a re-mining face in Yunnan, China. Under the influence of mining activities, the regenerated rock mass roadway becomes loose and fractured, extruding into the roadway space. The loose rock mass exerts loads on the support frames, causing severe deformation. The individual hydraulic supports become inclined, and in severe cases, the hydraulic supports may bend and deform. Therefore, the key to controlling the stability of the surrounding rock in regenerated rock mass roadways is to resist the pressure exerted by the loose rock mass on the support structures. In the support design, attention should be paid to the following three points:

-

1.

The support design should provide overall constraint for the regenerated rock mass roadway to prevent widespread failure caused by local damage;

-

2.

In selecting support frames, priority should be given to Ω-shaped supports. This type of support can reduce the bending moment of the top beam, provide support for the side beams, is easy to fabricate, highly adaptable, and is well-suited for engineering conditions where loose rock mass extrudes into free space;

-

3.

After providing overall constraint to the roadway surface, apply secondary support to the surrounding rock using grouted anchor bolts. Grouting can enhance the integrity of the surrounding rock and provide a stable anchorage for the bolts, allowing them to suspend the shallow fractured rock mass.

Conclusion

This study simulates regenerated rock masses formed under varying geological conditions by combining coal gangue particles with sizes ranging from 5 to 10 mm and cementing matrices of different strengths. Uniaxial loading tests, particle flow numerical simulations, and theoretical derivations were conducted to analyze the bearing characteristics and secondary damage evolution patterns of regenerated rock masses. The main findings are as follows:

(1) The secondary damage process of regenerated rock masses can be divided into three stages: pre-peak, weakening, and friction. The cementing matrix exerts different influences during each stage. As the mechanical properties of the cementing matrix improve, the bearing capacity of the regenerated rock mass increases, with the failure mode transitioning from ductile to brittle failure. This transition is accompanied by more pronounced frictional deformation characteristics in the residual stage.

(2) A damage constitutive model and bearing strength prediction method for regenerated rock masses were established. The appropriate damage factors were identified, and a constitutive damage equation was developed for evaluating the mechanical strength of regenerated rock masses formed by cementing matrices of varying strengths.

(3) Through particle flow numerical simulations and a statistical analysis of micro-energy and microcrack development during uniaxial loading, it was found that the improvement in the mechanical properties of the cementing material (which corresponds to an extended geological action time) induces a failure mode transition from tensile to shear failure. This study further reveals the bearing weakening mechanism of regenerated rock masses, characterized by post-peak cementation resistance weakening and frictional resistance strengthening.

Data availability

The data is for internal reference only; if needed, please request it via email at [zengts1997@163.com].

References

Hao, Y., Zhang, Z.-Y., Liao, H. & Wei, Y.-M. China’s farewell to coal: A forecast of coal consumption through 2020. Energy Policy 86, 444–455 (2015).

Huang, W.-G., Zhang, S.-W., Lu, X., Wu, S.-L. & Huang, J. Residual coal distribution in China and adaptability evaluation of its resource conditions to underground coal gasification. Sustain. Energy Technol. Assess. 49, 101654 (2022).

Zhang, Y. et al. Residual coal exploitation and its impact on sustainable development of the coal industry in China. Energy Policy 96, 534–541 (2016).

Wang, P., Feng, T., Jiang, Y., Liu, H., Li, L., Yu, W., Zhu, Y., & Lu, Y. Control principle and technology and instability mechanism of surrounding rock in weak regenerated roof. J. China Coal Soc. (10) (2019).

Li, X., Chen, S., Zhang, Q., Gao, X. & Feng, F. Research on theory, simulation and measurement of stress behavior under regenerated roof condition. Geomech. Eng. 26(1), 49–61 (2021).

Kang, H. Support technologies for deep and complex roadways in underground coal mines: A review. Int. J. Coal Sci. Technol. 1, 261–277 (2014).

Zhao, C., Li, Y., Liu, G. & Meng, X. Mechanism analysis and control technology of surrounding rock failure in deep soft rock roadway. Eng. Fail. Anal. 115, 104611 (2020).

Kobayashi, T. & Yoshinaka, R. Mechanical properties of gravelly soft rocks. Doboku Gakkai Ronbunshu 1994(487), 31–40 (1994).

Li, H. B., Li, J. R., Zhou, Q. C., Liu, Y. Q. & Xia, X. Study on the mechanical properties of soft rock under dynamic uniaxial compression. Key Eng. Mater. 261, 277–282 (2004).

Aydan, Ö., Sato, A. & Yagi, M. The inference of geo-mechanical properties of soft rocks and their degradation from needle penetration tests. Rock Mech. Rock Eng. 47, 1867–1890 (2014).

Cui, G., Zhou, C., Liu, Z., Xia, C. & Zhang, L. The synthesis of soft rocks based on physical and mechanical properties of red mudstone. Int. J. Rock Mech. Min. Sci. 151, 105037 (2022).

Hao, J., Li, X., Song, Y., Zhang, P. & Liu, H. Analysis of mining roadway with large deformation of broken soft coal and research on supporting technology: A case study in Xin’an coal mine. China. Eng. Fail. Anal. 130, 105761 (2021).

Zhao, G., Liu, C., Kao, S., Zhang, X. & Cheng, X. Stress and load-bearing structure analysis of the surrounding rock in a soft broken roadway. Arab. J. Geosci. 13, 1–16 (2020).

Wang, X., Li, R., Liu, Z., Jiang, D. & Ji, Z. Comprehensive evaluation of the reinforcement effect of grouting in broken surrounding rock in deep roadways. Geotech. Geol. Eng. 40(5), 2443–2454 (2022).

Sun, G., Wang, P., Feng, T., Yu, W., Yin, Z., Jiang, Y., Liu, H., & Li, L. Deformation mechanism and control technology of surrounding rock in soft and broken roof roadway. Coal Sci. Technol. 48(5) (2020).

Yuan, C., Cao, L., Wang, W., Fan, L. & Huang, C. Case study on rock support technology for roadways based on characteristics of plastic area. KSCE J. Civ. Eng. 25(2), 705–723 (2021).

Ma, W. & Wang, T. Instability mechanism and control countermeasure of a cataclastic roadway regenerated roof in the extraction of the remaining mineral resources: A case study. Rock Mech. Rock Eng. 52, 2437–2457 (2019).

Ma, W. & Wang, T. Experimental study of shear strength features of regenerated rock mass compacted and consolidated by broken soft rocks. KSCE J. Civ. Eng. 23, 1839–1848 (2019).

Hu, R., Wu, J., Shi, W., Zhai, X. & Huang, K. Study on evolution characteristics of regenerated roof structure in downward mining of bifurcated coal seam. Adv. Mater. Sci. Eng. 2021(1), 8226616 (2021).

Hu, R., Wu, J., Zhai, X., Shi, W. & Huang, K. Structural characteristics of regenerated roof and distribution law of overburden porosity in downward mining of a bifurcated coal seam. Geofluids 2022(1), 6914746 (2022).

Zhai, X. et al. Study on surface pre-grouting reinforcement layer of stratified regenerated roof under bifurcated coal seam. Coal Sci. Technol. 50(11), 30–39 (2022).

Chi, X., Yang, K. & Fu, Q. Analysis of regenerated roof and instability support control countermeasures in a steeply dipping working face. Energy Explor. Exploit. 38(4), 1082–1098 (2020).

Li, B., Liang, Y., Zhang, L. & Zou, Q. Experimental investigation on compaction characteristics and permeability evolution of broken coal. Int. J. Rock Mech. Min. Sci. 118, 63–76 (2019).

Li, B., Liang, Y., Zhang, L. & Zou, Q. Breakage law and fractal characteristics of broken coal and rock masses with different mixing ratios during compaction. Energy Sci. Eng. 7(3), 1000–1015 (2019).

Li, B. et al. Experimental research on the influence of different factors on the behaviour of broken coal and rock particles during compaction. Constr. Build. Mater. 367, 130127 (2023).

Zhang, C., Liu, J., Zhao, Y., Han, P. & Zhang, L. Numerical simulation of broken coal strength influence on compaction characteristics in goaf. Nat. Resour. Res. 29, 2495–2511 (2020).

Zhang, C., Chen, Y., Ren, Z., & Wang, F. Compaction and seepage characteristics of broken coal and rock masses in coal mining: A review in laboratory tests. Rock Mech. Bull. 100102 (2024).

Zhang, C., Zhao, Y. & Bai, Q. 3D DEM method for compaction and breakage characteristics simulation of broken rock mass in goaf. Acta Geotech. 17(7), 2765–2781 (2022).

Homand-Etienne, F., Hoxha, D. & Shao, J.-F. A continuum damage constitutive law for brittle rocks. Comput. Geotech. 22(2), 135–151 (1998).

Burdine, N. Rock failure under dynamic loading conditions. Soc. Petrol. Eng. J. 3(01), 1–8 (1963).

Wang, C., He, B., Hou, X., Li, J. & Liu, L. Stress–energy mechanism for rock failure evolution based on damage mechanics in hard rock. Rock Mech. Rock Eng. 53, 1021–1037 (2020).

Wang, P. et al. Mechanical property testing and damage assessment of the regenerated rock mass with very weakly bonded cement. Front. Built Environ. 10, 1207832 (2024).

Yin, S., Guo, Z., Wang, Q., Zhao, Y. & Li, Y. Effects of particle size on compressive deformation characteristics of broken rock mass in gangue rib of automatically formed gob-side entry retaining. Powder Technol. 430, 118987 (2023).

Shu, B., Liang, M., Zhang, S. & Dick, J. Numerical modeling of the relationship between mechanical properties of granite and microparameters of the flat-joint model considering particle size distribution. Math. Geosci. 51(3), 319–336 (2019).

Wu, J., Yin, Q., Gao, Y., Meng, B. & Jing, H. Particle size distribution of aggregates effects on mesoscopic structural evolution of cemented waste rock backfill. Environ. Sci. Pollut. Res. 28, 16589–16601 (2021).

Brünig, M., Gerke, S. & Schmidt, M. Damage and failure at negative stress triaxialities: Experiments, modeling and numerical simulations. Int. J. Plastic. 102, 70–82 (2018).

Bian, K. et al. Mechanical behavior and damage constitutive model of rock subjected to water-weakening effect and uniaxial loading. Rock Mech. Rock Eng. 52, 97–106 (2019).

Xu, X.-L., Karakus, M., Gao, F. & Zhang, Z.-Z. Thermal damage constitutive model for rock considering damage threshold and residual strength. J. Central South Univ. 25(10), 2523–2536 (2018).

Zhu, Z. et al. Statistical thermal damage constitutive model of rocks based on Weibull distribution. Arab. J. Geosci. 14, 1–14 (2021).

Xu, X., Yue, C. & Xu, L. Thermal damage constitutive model and brittleness index based on energy dissipation for deep rock. Mathematics 10(3), 410 (2022).

Wang, Z., Feng, C., Wang, J., Song, W. & Wang, H. An improved statistical damage constitutive model for rock considering the temperature effect. Int. J. Geomech. 22(11), 04022203 (2022).

Lee, U., Lesieutre, G. A. & Fang, L. Anisotropic damage mechanics based on strain energy equivalence and equivalent elliptical microcracks. Int. J. Solids Struct. 34(33–34), 4377–4397 (1997).

Lemaitre, J. A course on damage mechanics (Springer, 2012).

Lemaitre, J. Damage modelling for prediction of plastic and creep fatique failure in structures (1979).

Castro-Filgueira, U., Alejano, L. R. & Ivars, D. M. Particle flow code simulation of intact and fissured granitic rock samples. J. Rock Mech. Geotech. Eng. 12(5), 960–974 (2020).

Shi, C., Yang, W., Yang, J. & Chen, X. Calibration of micro-scaled mechanical parameters of granite based on a bonded-particle model with 2D particle flow code. Granul. Matter 21(2), 38 (2019).

Asadi, M. S., Rasouli, V. & Barla, G. A bonded particle model simulation of shear strength and asperity degradation for rough rock fractures. Rock Mech. Rock Eng. 45, 649–675 (2012).

Poisel, R., & Preh, A. 3D landslide run out modelling using the particle flow code PFC3D. In Landslides and Engineered Slopes. From the Past to the Future, Two Volumes+ CD-ROM; pp 895–902 (CRC Press, 2008).

Acknowledgements

The collection of the original data used in this study was supported by the National Natural Science Foundation of China (Grant No. 52174110), the Hunan Province Science and Technology Talent Support Program (2022TJ-N06), the Key Laboratory of Safe and Efficient Mining of Coal Mines Co-built by the Ministry and Province (JYBSYS2021203), and the Hunan Province Graduate Student Innovation Project Fund (CX20221048).

Author information

Authors and Affiliations

Contributions

Ping Wang: methodology, resources, funding acquisition. Zilong Zeng: Conceptualization, Methodology, Validation, Investigation, Formal analysis, Writing—original draft, Funding acquisition. Yingming Li: investigation, funding acquisition. Hongbo Liao: investigation. Jianhua Lv: investigation. Haijun Guo: investigation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, P., Zeng, Z., Li, Y. et al. Bearing characteristics and damage rules of regenerated rock mass. Sci Rep 15, 2076 (2025). https://doi.org/10.1038/s41598-024-84377-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-024-84377-1