Abstract

The migration of overlying rock layers caused by underground coal seam mining is the root cause of all mining pressure manifestations in the mining area. In order to visually record the changes in the overlying rock structure during coal seam mining, this paper proposes a borehole image monitoring method suitable for monitoring the changes in the overlying rock structure during coal seam mining. Firstly, based on the characteristics of rock structure borehole images collected in actual borehole environments, a preprocessing method for rock structure borehole images that can weaken the brightness and darkness features caused by lighting intensity is constructed to improve the recognition ability of borehole images. Subsequently, in response to the complexity and uncertainty of changes in the overlying rock mass structure, a method for locating the characteristic areas of rock mass structure is proposed to achieve the localization of structural characteristic areas at different times. Finally, a three state expression method is constructed to achieve dynamic tracking of the evolution process of rock mass structure. At the same time, combined with practical case analysis, the feasibility and correctness of the method proposed in this paper have been verified. This study not only contributions to to deepen the understanding of the evolution process and laws of the overlying rock mass structure, improve the ability of coal mine disaster prevention and control, but also provides useful references and guidance for the further development and application of coal mine video surveillance technology.

Similar content being viewed by others

Introduction

Over the past half century, with the rapid development of the world economy, especially in the fields of infrastructure and applications, global coal consumption has grown rapidly1,2. With the continuous exploitation and utilization of coal resources, the evolution process of overlying rock structure during coal seam mining has become a hot research topic3,4. Underground coal mining often causes deformation, detachment, fracture, and collapse of the overlying strata of coal seams, accompanied by rock movement leading to the manifestation of mining pressure5,6,7. The stability and safety of the overlying rock mass are crucial for the safe production of the mine during coal mining. In addition, due to the wide scope, multiple field effects, significant superposition effects of influencing factors, strong concealment, poor monitoring conditions, high dynamic response requirements, and long monitoring cycles of mining engineering, it poses great challenges to the monitoring and early warning of various disasters, accidents, and mining engineering problems. The existing monitoring methods are difficult to accurately and in real-time detect the impact of deformation of the overlying rock mass on local deformation of tunnels and ground subsidence during coal seam mining. Therefore, a deep understanding of the evolution process of the overlying rock mass structure is of great theoretical and practical significance for preventing and controlling coal mine disasters and improving mine production efficiency.

The traditional research methods for the evolution process of overlying rock structures mainly rely on physical and numerical simulations. Although these methods can reflect the evolution laws of rock structures to a certain extent, they are limited by factors such as model size and parameter settings, making it difficult to comprehensively and accurately reflect the complex situations in actual engineering. In addition, these methods typically only provide static and discrete data results, making it difficult to capture dynamic changes and real-time information during the evolution of rock mass structures8. In recent years, with the continuous development of video surveillance technology, its application in the field of coal mine safety monitoring has become increasingly widespread. Video surveillance technology can monitor various situations during coal mining in real-time and continuously, providing strong technical support for coal mine safety production. Especially in the monitoring of the evolution process of overlying rock structures, video monitoring technology has unique advantages. Through video images, it is possible to visually observe the deformation, failure, and collapse processes of rock mass structures, thereby more accurately grasping their evolution patterns9,10. However, there are still some problems in using video image monitoring methods to study the evolution process of overlying rock structures. The movement of overlying strata caused by underground coal seam mining is the root cause of all mining pressure manifestations in the mining area. The differences in characteristics such as lithology, thickness, stratigraphic relationships, and physical and mechanical properties of the overlying strata also determine the differences in the migration patterns of the roof.

In order to visually record the process of structural changes in the overlying rock mass during coal seam mining and provide basic research data for the movement of the overlying rock mass during underground coal seam mining, this project intends to record the changes in rock mass structure during the mining process through borehole images11,12. A borehole image monitoring method suitable for monitoring the structural changes of overlying rock mass during coal seam mining has been proposed. The overall idea of this article is to set up geological boreholes directly above the study area, penetrate the geological structure to be studied, and then observe the changes in borehole images at different mining positions multiple times. To achieve monitoring of changes in rock mass structure through image processing and data analysis. Provide more accurate and reliable technical support for coal mine safety production. This study not only helps to deeply understand the evolution mechanism and laws of overlying rock mass structure, improve the ability of coal mine disaster prevention and control, but also provides useful reference and guidance for the further development and application of coal mine video monitoring technology13,14. Meanwhile, the results of this study can also be extended to other similar engineering fields, providing new ideas and methods for solving similar problems. It has achieved precise monitoring of rock movement changes in mining engineering from macro to micro, from static to dynamic, which can provide first-hand monitoring data for ensuring safe mining and disaster prevention and reduction of mining subsidence.

Method and principle

Overall principle framework of the method

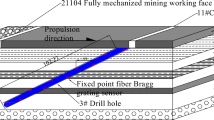

The movement of overlying strata caused by underground coal seam mining is the root cause of all mining pressure manifestations in the mining area. The differences in lithology, thickness, stratigraphic relationships, physical and mechanical properties of the overlying strata also determine the differences in the migration patterns of the roof15,16. In order to visually record the process of structural changes in the overlying rock mass during coal seam mining and provide basic research data for the movement of overlying rock layers during underground coal seam mining, this project intends to record the changes in rock mass structure during the mining process through borehole images. The overall idea of this article is to set up geological boreholes directly above the study area, penetrate the geological structure to be studied, and then observe the changes in borehole images at different mining positions multiple times. To achieve monitoring of changes in rock mass structure through image processing and data analysis. The schematic diagram of the overall principle framework is shown in Fig. 1.

Obtain borehole image information of the core observation area DD position through borehole optical imaging technology. When the coal seam excavation process reaches position AA, that is, the mining process has not entered the position directly below the core observation area borehole hole. Obtain a panoramic image PA of the borehole wall at position DD of the core observation area using borehole optical imaging equipment. When the coal seam excavation process is at position BB, that is, the mining process has just entered the position directly below the borehole hole in the core observation area. Obtain a panoramic image PB of the borehole wall at position DD of the core observation area using borehole optical imaging equipment. When the coal seam excavation process is at position CC, that is, the mining process passes directly below the borehole hole in the core observation area. Obtain panoramic images PC of the borehole wall at position DD of the core observation area using borehole optical imaging equipment. After obtaining borehole images at different time states, the processing of rock mass structural feature data is achieved through image preprocessing, feature parameter calculation, and feature region localization. Subsequently, by comprehensively analyzing the evolution process at different times, dynamic tracking of the rock mass structure evolution process in key areas during the mining process is achieved, thereby providing research basic data for the migration of overlying rock layers during underground coal seam mining.

Rock mass structure borehole image collection

The acquisition methods of borehole images are diverse, including but not limited to optical, acoustic, and electrical methods. Among them, optical imaging has shown significant advantages in presenting the characteristics of rock wall pore structure due to its intuitiveness and accuracy. Therefore, the research focus of this article is mainly on optical borehole images to better reveal and analyze the structural characteristics and variation processes of rock masses. At present, borehole camera technology plays an important role in capturing high-precision optical borehole images. This technology utilizes optical principles to continuously take photos or videos of the borehole walls by delving deep into the interior of the borehole, thereby visually displaying the structural information of the rock mass. This technology not only improves the efficiency and accuracy of image acquisition, but also helps researchers or on-site operators to have a more comprehensive understanding of the internal conditions of rock masses. The borehole image data analyzed subsequently in this paper comes from the digital panoramic borehole camera system developed by Institute of Rock and Soil Mechanics, Chinese Academy of Sciences. This system is a comprehensive equipment that integrates advanced optical, mechanical, and electronic technologies. It mainly consists of panoramic probes, cables, depth encoders, and control boxes. The schematic diagram of its structure is shown in Fig. 2 (a). Figure 2 (a) shows the connection relationships and overall layout between the various components of the system.

The digital panoramic borehole camera system has the characteristic of high resolution when collecting images. Its maximum horizontal resolution can reach 0.05 mm, and its maximum vertical resolution can reach 0.1 mm, which ensures the high clarity and accuracy of the captured images. Through the borehole images collected by the system, researchers or on-site operators can observe and analyze the pore structure, texture characteristics, and crack distribution of rock masses in more detail, which can provide important basis for subsequent research on rock mechanics properties and engineering applications. In summary, the digital panoramic borehole camera system, as an efficient and accurate optical borehole image acquisition tool, has important application value in the research of academic papers. By conducting in-depth analysis of the borehole images collected, we can gain a deeper understanding of the internal structure and properties of the rock mass,, which can provide strong support for scientific research and technological applications in related fields.

The digital panoramic borehole camera technology, as an advanced in-situ testing method, provides us with a way to deeply understand the geological structure inside the borehole with its precise optical detection principle17,18,19. This technology directly captures geological information on the borehole wall through undisturbed in-situ camera recording, thus avoiding the potential disturbance effects that may occur during traditional borehole and core extraction processes. Compared to core sampling, digital panoramic borehole camera technology can more accurately reflect the geological structure inside the borehole, and the results obtained are more reliable and intuitive. In the process of panoramic image acquisition technology, high-definition cameras play a crucial role. It achieves real-time acquisition of 360° all-round image data of the borehole wall by capturing the optical images reflected by the truncated conical mirror, as shown in Fig. 2 (b). These panoramic image data not only contain complete annular borehole wall images, but also integrate depth and orientation information, providing us with a comprehensive and detailed geological structure view. Digital image unfolding technology involves multiple complex processing steps, including continuous frame narrowband image acquisition, feature detection and data matching, narrowband image stitching and fusion, as well as image optimization and information annotation. Through the exquisite application of digital image processing technology, the panoramic image is transformed into a more intuitive panoramic image, as shown in Fig. 2 (c). These panoramic images usually come in two forms of presentation: borehole wall flat unfolding images and virtual core images. Among them, the flat plan is based on the true north direction, with the horizontal length corresponding to the circumference of the borehole, and the vertical length representing the depth of the borehole. This presentation format enables us to more conveniently analyze and interpret geological information inside the borehole.

Preprocessing of rock structure borehole images

Due to the smaller probe size used for collecting rock mass structures on the borehole wall, especially as the borehole depth increases, probes placed by flexible cables are often prone to eccentricity during the data collection process. Due to the eccentricity of the probe, there may be differences in the distance between the light source on the probe and the borehole wall, resulting in differences in the intensity of light shining on the borehole wall. The formed borehole unfolding image is prone to bright and dark features. Therefore, in order to eliminate this image phenomenon and highlight the structural characteristics of the rock mass, it is necessary to preprocess the borehole image before recognizing the rock mass structure in borehole image, in order to weaken the brightness characteristics of the borehole image caused by the intensity of lighting.

As shown in Fig. 3 (a), assuming the diameter of the borehole is D, the corresponding center position of the borehole wall is point O. The diameter of the panoramic probe is d, corresponding to the center position of the probe at point O’. In a Cartesian coordinate system with the center position o of the borehole wall as the origin, the distance between the center of the borehole wall and the center of the probe is |OO’|. The angle between the line connecting the center of the hole wall and the center of the probe and the x-axis is θ0. The distance between any point M on the panoramic probe and the borehole wall is | MM ‘|. | MM ‘| is the extension line connecting point O’ and point M. So, the expression for the distance between any point M on the panoramic probe and the borehole wall is:

Among them, θ is the angle between OM and the x-axis, that is, the angle between any point M on the panoramic probe corresponding to the illumination point on the borehole wall and the center of the borehole. Assuming a borehole diameter of 98 mm and a panoramic probe diameter of 72 mm. The distance between the center of the borehole wall and the center of the probe is 13 mm. According to Eq. (1), calculate the values corresponding to pi/8 and pi for θ, as shown in Fig. 3 (b). From Eq. (1) and Fig. 3 (b), it can be seen that in the case of probe eccentricity, the light intensity of the probe light source shining on the borehole wall varies as a cosine function. In order to weaken the impact of differences in lighting intensity on imaging quality, it is necessary to perform differentiated intensity enhancement processing on different positions around the aperture, that is, there are differences in the degree of enhancement of pixels in different directions.

The core of this article’s preprocessing is to find the azimuth corresponding to the strongest illumination point, where the distance between the light source and the borehole wall is the shortest. The RGB color space is one of the most widely used color systems, which obtains various colors by changing the red (R), green (G), and blue (B) color channels and overlaying them with each other. The HSV color space is mainly represented by three components: hue (H), saturation (S), and brightness (V). Among them, the V component represents the brightness of the color, with a value range of [0,1]. It can reflect the maximum value of the R, G, and B components of each pixel in the RGB color space of the image. The expression for brightness level V is:

Among them, R, G, and B correspond to the grayscale values of the red, green, and blue channels in the image. If the brightness value of the i-th image with the j-th pixel before preprocessing is \({V_{i,j}}\), then combined with the eccentric image acquisition model, a cosine enhancement function is established to form the preprocessed image. The expression \({\bar {V}_{i,j}}\) for the brightness value of the i-th image with the j-th pixel after preprocessing is:

Among them, \(\lambda\) is the enhancement coefficient, which can be adjusted according to the actual situation. Normally, the enhancement system selects 0.5. If the enhancement system takes 0.5 to form a light and dark image with unclear effects, the enhancement system will gradually increase until a satisfactory enhancement effect is obtained. If the enhancement system distorts the brightness and darkness image formed by taking 0.5, the enhancement system gradually decreases until a satisfactory enhancement effect is obtained.\({J_{i,\hbox{max} }}\) represents the position of the horizontal pixel corresponding to Vi and max. N represents the total number of horizontal pixels in the image. After processing the original image with brightness values, the HSV color space image is then converted into an RGB color space image, completing the preprocessing process of the rock structure borehole image.

Calculation of structural characteristic parameters of drilled rock mass

Assuming the structural plane is a plane, then the structural plane intersects with the cylindrical borehole wall, forming an ellipse. The ellipse forms a trigonometric function curve through coordinate transformation. It is usually assumed that the structural plane curve in the borehole image is a sine curve in the flat unfolded diagram, as shown in Fig. 4, and its corresponding descriptive expression is:

In the above equation, \(\omega ={\text{2/}}D\), and D is the borehole diameter. y0 represents the position of the curve. A is the amplitude, and θ is the original phase.

Assuming P1, P2, and P3 are any three points where the rock mass structural plane intersects with the borehole wall, corresponding to P1’, P2’, and P3’ points in the borehole image, respectively. The rock mass structural plane is presented in the form of a sine curve in the borehole unfolding image, and the amplitude A of the curve depends on the borehole diameter D and the inclination angle β of the rock mass structural plane. The corresponding relationship between them is:

By deforming Eq. (5), the inclination angle value \(\beta\) of the rock mass structural plane can be obtained, which is expressed as:

From this, two directional vectors \(\overrightarrow {{V_{\text{1}}}} =\overrightarrow {{P_1}{P_2}}\) and \(\overrightarrow {{V_{\text{2}}}} =\overrightarrow {{P_1}{P_3}}\) in the plane composed of P1, P2, and P3 points can be calculated. The normal vector \(\overrightarrow V\) of the plane can be obtained:

If the vector \(\overrightarrow {{V_{\text{0}}}}\)(X0, Y0) is the projection of the normal vector \(\overrightarrow V\) on the XOY plane of the cartesian coordinate system, then the inclination direction of the structural plane α is:

Localization of rock mass structural characteristics regions

In the borehole images recorded at different times, due to the complexity of structural changes in the overlying rock mass, phenomena such as the addition, closure, expansion, upward and downward movement, and displacement of structural planes may occur in the same area. The structural plane at a certain depth may not be the same as the structural plane at a different time point. Therefore, in order to grasp the changing characteristics of structural features, it is necessary to analyze the structural image information of the previous moment, and achieve regional localization of the previous structural feature in the subsequent moment based on the structural information, which can provide a basis for tracking the evolution process of rock mass structure.

As shown in Fig. 5, assuming that structural plane A originally existed in the target image, there are structural planes B, C, and D near the same position in the search image. It is necessary to compare the characteristic parameters of structural plane B, structural plane C, and structural plane D based on the characteristic parameters of structural plane A, to determine which group of structural plane characteristic parameters are closest to those of structural plane A. Consider the structural plane with the closest feature parameters to structural plane A as the corresponding structural plane.

In the previous text, the amplitude A, inclination direction α, and inclination angle \(\beta\) of the rock mass structural plane in the borehole image have been defined, which can reflect the characteristics of the rock mass structure. In addition, there are differences in the thickness of different structural planes. Therefore, W is defined as the thickness of the structural plane, and the vertical distance between the upper and lower edges of the structural plane is taken. The amplitude A, inclination direction α, inclination angle \(\beta\), and thickness W can only reflect the macroscopic distribution characteristics of rock mass structural planes. In Fig. 5, AA, \({\alpha _A}\), \({\beta _A}\), WA, and DFA represent the amplitude, inclination direction, inclination angle, thickness and fractal dimension corresponding to structural plane (A) AB, \({\alpha _B}\), \({\beta _B}\), WB, and DFB respectively represent the amplitude, inclination direction, inclination angle, thickness and fractal dimension corresponding to structural plane (B) AC, \({\alpha _C}\), \({\beta _C}\), WC, and DFC respectively represent the amplitude, inclination direction, inclination angle, thickness and fractal dimension corresponding to structural plane (C) AD, \({\alpha _D}\), \({\beta _D}\), WD, and DFD respectively represent the amplitude, inclination direction, inclination angle, thickness and fractal dimension corresponding to structural plane (D) For the characteristics of contour morphology, fractal dimension needs to be used to describe them. Fractal geometry focuses on the large number of non smooth and irregular geometric shapes that appear in nature and nonlinear systems, aiming to quantitatively describe complex shapes that are not suitable for classical Euclidean geometry. The structural planes of rock masses have a certain degree of self similarity and fine structure, with fractal characteristics. Fractal dimension is one of the most important concepts in fractal geometry, which usually includes capacity dimension, information dimension, and correlation dimension. The more widely used is capacity dimension, which can be applied to plane, line, and spatial point sets. Its definition is: if the bounded point set on the plane is F, a rectangle can always be found in it, including F. Firstly, divide the plane to be calculated into multiple small squares with a side length of n, so that the bounded point set F occupies N(n) small squares. Then, define DF as the capacity dimension of the bounded point set F, which is expressed as:

In the localization of rock mass structural feature areas, the amplitude characteristics, inclination direction characteristics, inclination angle characteristics, thickness characteristics, and fractal characteristics of the target structural surface within a certain depth range are combined, and similarity matching algorithms are used to achieve the localization search of rock mass structural feature areas between different time periods and within the same area. The amplitude, inclination direction, inclination angle, and thickness corresponding to structural plane A in the target image are amplitude AA, inclination direction \({\alpha _A}\), inclination angle \({\beta _A}\), and thickness WA, respectively. The amplitude, inclination direction, inclination angle, and thickness corresponding to structural plane B in the search image are amplitude AB, inclination direction \({\alpha _B}\), inclination angle \({\beta _B}\), and thickness WB, respectively. The amplitude, inclination direction, inclination angle, and thickness corresponding to structural plane C in the search image are amplitude AC, inclination direction \({\alpha _C}\), inclination angle \({\beta _C}\), and thickness WC, respectively. The amplitude, inclination direction, inclination angle, and thickness corresponding to the structural plane D in the search image are amplitude AD, inclination direction \({\alpha _D}\), inclination angle \({\beta _D}\), and thickness WD, respectively. The degree of deviation between regional positioning is represented by XS, and its corresponding expression is:

Among them, λ1, λ2, λ3, λ4 and λ5 are the weighted values of the amplitude characteristics, inclination direction characteristics, inclination angle characteristics, thickness characteristics, and fractal characteristics of the structural plane, respectively. So, the degree of deviation between structural plane A and structural plane B is represented by XS(A, B). The degree of deviation between structural plane A and structural plane C is represented by XS(A, C). The degree of deviation between structural plane A and structural plane D is represented by XS(A, D). After calculating the deviation XS between the target area structural plane and the search area structural plane, the two structural planes with the smallest deviation are considered as corresponding structural planes.

Among them, “→” represents that the structural plane I in the target image matches the structural plane J in the search image.

Tracking of the evolution process of rock mass structure

This article divides the evolution process of rock mass structure into three categories based on the macroscopic geometric conditions of rock mass structure, namely: closure, translational, and opening stages. Closure includes the disappearance and narrowing of structural planes. Translation includes the upward, downward, and rotational movements of the structural plane. Opening includes the addition and widening of structural planes. The disappearance of rock mass structural planes refers to the thickness of the structural planes approaching zero. Narrowing of the rock mass structural plane refers to a decrease in the thickness of the structural plane. The addition of structural planes in rock mass refers to the number of new structural planes added to the corresponding area. The upward movement of the rock mass structural plane refers to the upward movement of the curve position of the corresponding regional structural plane. The downward movement of the rock mass structural plane refers to the downward movement of the curve position of the corresponding regional structural plane. The rotation of rock mass structural planes refers to the change in phase of the corresponding regional structural planes. The widening of the rock mass structural plane refers to an increase in the thickness of the structural plane. The comparison table between structural evolution and geometric parameter changes is shown in Table 1.

The evolution process of rock mass structure may include several stages of closure, translation, and opening at the same time. In order to present their corresponding differences, the evolution process of overlying rock mass structure during coal seam mining is displayed. Constructing a three state expression method to track the evolution process of rock mass structure. Due to the several stages of rock mass structure evolution, which mainly take the form of structural plane thickness transformation, structural plane position movement, and structural plane angle deviation, different symbols can be used to achieve the presentation of these three states, which can quickly reflect the structural change information produced by the rock mass structure at different times. The three state expression form is T1 → T2 (S1, S2, S3), and its specific form is as follows:

Among them, “S1” represents the change state of structural surface thickness transformation. “↑” indicates an increase in the thickness of the structural plane or an addition of new structural planes. “↓” indicates a decrease in the thickness of the structural plane or a disappearance of the structural plane. “-” indicates that the thickness of the structural plane remains unchanged. “S2” represents the changing state of the position movement of the structural plane. “↑” indicates that the structure is moving upwards. “↓” indicates that the structure is moving downwards. “-” indicates that the structural plane has not moved up or down. “S3” represents the change state of structural plane angle deviation. “\(\cap\)” indicates clockwise deflection of the structural plane. The “\(\cup\)” indicates that the structural plane has undergone counterclockwise deflection. “-” indicates that the structural plane has not deviated. Assuming that from time T1 to time T2, the thickness of the rock mass structural plane increases, the structural plane moves downward, and clockwise deflection occurs, the result expressed using the three state expression method is: T1 → T2 (↑, ↓, \(\cap\)).

Case analysis

This article takes the borehole images of the front, middle, and back mining processes of a certain coal mine as an example for method analysis. The burial depth of the mine is 507.32–996.66 m, with an average of 661.79 m. The thickness of the mined coal seam ranges from 0.81 to 8.15 m, with an average of 5.38 m. The inclination angle of the coal seam is 0 °~11 °, with an overall average dip angle of 4 °. The coal seam has a Brinell hardness of f = 3–4. The inclined length of the working face is about 252 m, and the strike length is about 1623 m. The coal seam is a fully concealed coal field of the North China type Carboniferous Permian system, consisting of the Quaternary, Upper Jurassic, Upper Permian Shihezi Formation, and Lower Permian Shanxi Formation from top to bottom. Among them, the thickness of the Quaternary system ranges from 79.15 to 141.18 m, with an average of 121.98 m, mainly composed of clay and sandy soil. The thickness of the Jurassic system ranges from 393.27 to 735.20 m, with an average of 500.56 m. It is divided into two sections: the upper section is mainly composed of interbedded gray green sandstone and fine sandstone, with an average of 175.31 m. The lower section is mainly composed of purple red medium sandstone, fine sandstone, and siltstone, with an average of 338.52 m. The Upper Permian Shihezi Formation, with an average depth of 27.18 m, is mainly composed of a set of purple red, gray green flower like variegated mudstone. The Shanxi Formation in the lower part of the Permian system, with an average depth of 77.26 m, is the main coal bearing formation.

The depth of the observation borehole is 480 m. The borehole diameter is 98 mm, and the diameter of the panoramic probe is 72 mm. The time of the first measurement, expressed as T1 time. The borehole image collected at time T1 corresponds to the position directly below the core observation area where the mining process does not enter. The time of the second measurement, expressed as T2 time. The borehole image collected at time T2 corresponds to the position directly below the borehole in the core observation area during the mining process. The time of the third measurement, expressed as T3 time. The borehole image collected at time T3 corresponds to the position directly below the borehole that passes through the core observation area during the mining process. This article first analyzes the borehole images at depths of 229.3–229.7 m as an example. The original panoramic image of the borehole in the depth range of 229.3–229.7 m is shown in Fig. 6.

On the basis of unfolding the original image through panoramic borehole, the method proposed in this article is used for image processing and data analysis. The result of processing Fig. 6 is shown in Fig. 7. The structural characteristic parameters and evolution process tracking results of the borehole rock mass are shown in Table 2. From Table 2, it can be seen that during the mining process, there is a T1 → T2 (↓, ↓,) change in the structural plane at 229.3–229.7 m from the position directly below the borehole that never entered the core observation area to the position directly below the borehole that entered the core observation area. That is, the thickness of the structural plane decreased, the structural plane moved downwards, and at the same time, the structural plane shifted clockwise. During the mining process, there is a T2 → T3 (↑, ↑, -) change in the structural plane at 229.3–229.7 m from the position directly below the borehole entering the core observation area to the position directly below the borehole passing through the core observation area, that is, the thickness of the structural plane increases, the structural plane moves upward, and the structural plane does not deflect. Through the analysis in this article, it is possible to use borehole images to monitor the structural changes of the overlying rock mass during coal mining.

In the analysis and processing of borehole images at depths of 229.3–229.7 m, the number of structural planes does not change, indicating an ideal process of rock mass structural change. But in some areas, structural planes may disappear or increase. For this purpose, further analysis will be conducted using borehole images at depths of 277.2–278.2 m as an example. As shown in Fig. 8 (a) shows the original image at time T1 of the borehole image. Figure 8 (b) shows the original image at time T2 of the borehole image. Due to the long depth of the image, in order to visually present the structural features of the image, the image is horizontally deployed, with the horizontal direction being the depth increasing direction and the vertical direction being the N-E-S-W-N orientation from top to bottom.

The results of borehole image processed at depths of 277.2–278.2 m are shown in Fig. 9. Figure 9 (a) shows the processed image of the borehole image T1. Figure 9 (b) shows the processed image of the borehole image at time T2. From the Figs. 8 and 9, it can be seen that Fig. 9 has clearer image quality and more prominent detail information. In addition, the image quality at time T2 at depths of 277.2–278.2 m is slightly inferior to that at time T1, mainly due to the collapse of the borehole on site, which is later repaired by the drill pipe and collected without washing the borehole. Comparing images at different times can also reflect some intuitive differences in changes. In terms of quantitative analysis, due to the presence of multiple structural planes at depths of 277.2–278.2 m at both TI and T2 moments, there are certain differences in depth and morphology. If we use common sense or estimation directly, it is easy to give incorrect descriptions of changes in structural planes. Therefore, in analyzing the evolution characteristics of the structural plane change process at depths of 277.2–278.2 m and the analysis at depths of 229.3–229.7 m, it is necessary to combine the above-mentioned rock mass structural feature area positioning method in this article to achieve matching and searching of different structural planes.

By identifying the structural planes and extracting parameters from the image in Fig. 9, and labeling the structural planes with different colors, the results are shown in Fig. 10. From Fig. 10 (a), it can be seen that there are 6 obvious structural planes at depths of 277.2–278.2 m in the borehole image at time T1, namely structural plane ①, structural plane ②, structural plane ③, structural plane ④, structural plane ⑤, and structural plane ⑥. From Fig. 10 (b), it can be seen that there are three distinct structural planes at depths of 277.2–278.2 m in the borehole image at time T2, namely structural plane ⑦, structural plane ⑧, and structural plane ⑨.

Using the method described in this article, the structural planes at 277.2–278.2 m are represented in three states from time T1 to time T2, as shown in Fig. 11. From Fig. 11, it can be seen that the deviation between structural plane ① and structural plane ⑦ is the smallest, that is, the structural plane ① at time T1 corresponds to the structural plane ⑦ at time T2, resulting in a narrowing of the thickness of the structural plane and a downward shift and phase deviation. The deviation between structural plane ② and structural plane ⑧ is minimal, that is, the structural plane ② at T1 corresponds to the structural plane ⑧ at T2, resulting in a narrowing of the thickness of the structural plane and a downward shift and phase deviation. The deviation between structural plane ④ and structural plane ⑨ is the smallest, that is, the structural plane ④ at T1 corresponds to the structural plane ⑨ at T2, resulting in a widening of the thickness of the structural plane and a downward shift and phase deviation. The corresponding structural planes ③, ⑤, and ⑥ in the borehole image at time T1 are not found in the borehole image at time T2. This article demonstrates that the method can achieve structural correspondence search and state description at different times.

In addition, a comparison is made between the traditional processing method without considering eccentricity and the borehole image preprocessing method in this paper on the borehole images at T2 time points 277.2–278.2 m. The results are shown in Fig. 12. Figure 12 (a) shows the original borehole images from 277.2 to 278.2 m at time T2. Figure 12 (b) shows the borehole images at T2 time 277.2–278.2 m without considering the traditional eccentricity processing method. Figure 12 (c) shows the borehole images obtained from the preprocessing method of the borehole images in this paper at time T2, ranging from 277.2 to 278.2 m. From Fig. 12, it can be seen that the borehole images obtained by sampling the preprocessing method of the borehole images in this paper are clearer. In order to comprehensively analyze the image enhancement effect and clarity of the borehole image preprocessing algorithm in this article, information entropy, standard deviation, and average gradient algorithms are used to objectively evaluate the preprocessing effects of the traditional processing method without considering eccentricity and the borehole image preprocessing method in this article. The results are shown in Fig. 13. Figure 13 (a) shows a comparison of the evaluation results for region a. Figure 13 (b) shows a comparison of the evaluation results for region b. Figure 13 (c) shows a comparison of the evaluation results for region c. Figure 13 (d) shows a comparison of the evaluation results for region d. Figure 13 (e) shows a comparison of the evaluation results for region e. Figure 13 (f) shows a comparison of the overall evaluation results of the region.

Information entropy, as a measure of image information content, the larger its value, the richer the information contained in the image, and the better the display details of the image. The standard deviation reflects the degree of dispersion between image pixel values and mean values, and the larger the value, the better the image quality. The average gradient represents the rate of change of grayscale values on both sides of the image edge, and its value mainly measures the fine detail of the image. The larger the value, the clearer the image. From Fig. 13, it can be seen that the information entropy, standard deviation, and average gradient of the preprocessing method proposed in this paper are higher than those of traditional image preprocessing methods without considering eccentricity in regions a, b, c, d, e, and overall. The preprocessing effect of the method described in this article is relatively obvious, the image details are also clear, and the colors are more realistic and natural, with less obvious distortion. It has a better improvement effect on the borehole image of the overlying rock mass in coal seams. This is mainly due to the fact that the preprocessing method in this article considers the need for differences in the degree of pixel enhancement in different orientations. In order to weaken the impact of differences in lighting intensity on imaging quality, differential intensity enhancement is applied to different positions around the aperture, thereby improving the overall contrast of the image. Through the research in this article, more accurate and reliable technical support can be provided for coal mine safety production. This study not only helps to deeply understand the evolution mechanism and laws of overlying rock mass structure, improve the ability of coal mine disaster prevention and control, but also provides useful reference and guidance for the further development and application of coal mine video monitoring technology. Meanwhile, the results of this study can also be extended to other similar engineering fields, providing new ideas and methods for solving similar problems. We have achieved precise monitoring of mining engineering from macro to micro, from point to surface to body, and from static to dynamic, providing first-hand analysis and evaluation information for ensuring safe mining and disaster prevention and reduction of mining subsidence.

Due to the fact that the method proposed in this article mainly relies on optical borehole images, if the test borehole section is a mud medium, it will be difficult to obtain effective image information using the optical imaging method proposed in this article. Therefore, it is necessary to use acoustic wall imaging or resistivity imaging to obtain texture information of the borehole wall surface. Although the borehole image information obtained by other means is not as detailed as optical images, the method proposed in this article can still be used to analyze the evolution characteristics of rock structure. In practical engineering, it is also common to encounter situations where boreholes are blocked. If the borehole wall image data collected again after cleaning can be guaranteed to be the original drilling position information, then the method proposed in this article can be applied. If the borehole position tilts and changes after cleaning, there will be errors in the results of this method, mainly because it relies heavily on the orientation and depth information of the rock structure. In addition, as the method proposed in this article mainly relies on comparative analysis of data from different stages of single drilling, it only focuses on the three types of evolution: closure, translation, and opening. The actual evolution process is more complex, such as shear and sliding evolution, and it is difficult to effectively control it using the method proposed in this article alone. In the future, it is necessary to combine multiple boreholes or other technical means for comprehensive analysis to ensure accurate control of complex evolution stages.

Conclusion

The movement of overlying strata caused by underground coal seam mining is the root cause of all mining pressure manifestations in the mining area. The differences in characteristics such as lithology, thickness, stratigraphic relationships, and physical and mechanical properties of the overlying strata also determine the differences in the migration patterns of the roof. In order to visually record the process of structural changes in the overlying rock mass during coal seam mining and provide basic research data for the movement of the overlying rock mass during underground coal seam mining, this article records the changes in rock mass structure during the mining process through borehole images. A borehole image monitoring method suitable for monitoring the structural changes of overlying rock mass during coal seam mining has been proposed. By arranging geological boreholes directly above the study area, the boreholes penetrate the geological structure to be studied, and then observe the changes in borehole images at different mining positions multiple times. To achieve monitoring of changes in rock mass structure through image processing and data analysis. Provide more accurate and reliable technical support for coal mine safety production. We have achieved precise monitoring of mining engineering from macro to micro, from point to surface to body, and from static to dynamic, providing first-hand analysis and evaluation information for ensuring safe mining and disaster prevention and reduction of mining subsidence.

Data availability

All data generated or analysed during this study are included in this published article.

References

Verma, N. et al. Reservoir characterisation using hybrid optimisation of genetic algorithm and pattern search to estimate porosity and impedance volume from post-stack seismic data: A case study. J. Earth Syst. Sci. 133 (2). https://doi.org/10.1007/s12040-024-02299-y (2024).

Cao, Z. Z. et al. Diffusion Evolution Rules of Grouting Slurry in Mining-induced Cracks in Overlying Strata (Rock Mechanics and Rock Engineering, 2025). https://doi.org/10.1007/s00603-025-04445-4

Fu, J. H. et al. Study on the shear movement law of overlying strata by slice mining. ENERGY Sci. Eng. 8 (7), 2335–2351. https://doi.org/10.1002/ese3.668 (2020).

Jirankova, E. & Konicek, P. Ground surface uplift during hardcoal Longwall mining. Int. J. Rock Mech. Min. Sci. 153, 105099. https://doi.org/10.1016/j.ijrmms.2022.105099 (2022).

Lv, W. Y. et al. Evolution Characteristics of Overlying Strata Fractures in Paste Composite Filling Stope. MINERALS, 12 (5): 654. (2022). https://doi.org/10.3390/min12050654

Wang, C. L., Sun, L. H. & Shen, H. R. An aftermath analysis of caving characteristics and movement of overlying strata in fully mechanized Longwall gob. Sci. Rep., 14 (1): 28095. https://doi.org/10.1038/s41598-024-79968-x(2024).

Wang, B. et al. Characteristics of coal pore structure and its impact on gas extraction. Min. Technol. 23 (5), 163–170. https://doi.org/10.3969/j.issn.1671-2900.2023.05.034 (2023).

Huang, B. X. et al. Theory of rheological and structural instability and large deformation of surrounding rock in deep mining tunnels. J. Coal Sci. 45 (3), 16. https://doi.org/10.13225/j.cnki.jccs.SJ19.1451 (2020).

Xu, Z., Li, J., Zhang, M. A. & Surveillance Video Real-Time analysis system based on Edge-Cloud and FL-YOLO Cooperation in coal mine. IEEE Access. 9, 68482–68497. https://doi.org/10.1109/ACCESS.2021.3077499 (2021).

Wang, Q. C., Han, G. Q. & Wei, D. W. Comparative study of AI video monitoring system and inspection robot for coal mine belt conveyor. Coal Mine Mach. 46 (3), 98–100. https://doi.org/10.13436/j.mkjx.202503027 (2025).

Wang, J. C. et al. Research on 3D visualization of geological borehole based on photoacoustic combination measurement. J. Rock. Mech. Eng. 42 (3), 649–660. https://doi.org/10.13722/j.cnki.jrme.2022.0528( (2023).

Wang, J. C. et al. Research on quantification method of pore structure in low illumination images inside holes based on pixel space information. J. Rock. Mech. Eng. 43 (S1), 3175–3186. https://doi.org/10.13722/j.cnki.jrme.2023.0887( (2024).

Sun, J. P. & Peng, M. Research and formulation of coal mine information comprehensive carrier network standards. Industrial Min. Autom. 50 (4), 1–8. https://doi.org/10.13272/j.issn.1671-251x.18185 (2024).

Tian, F., Gao, L. & Zhang, J. An image dehazing algorithm for underground coal mines based on gUNet. Sensors 24 (11), 24. https://doi.org/10.3390/s24113422 (2024).

Zhang, X. B., Wang, P. & Wang, H. Research on gas migration law in Goaf under the influence of small faults. Coal Sci. Technol. 52 (4), 214–230. https://doi.org/10.12438/cst.2023-0672 (2024).

Yang, Y. G. et al. Particle discrete element study on rock movement and crack development in Coal aluminum Co mining. J. Min. Saf. Eng. 41 (1), 58–66. https://doi.org/10.13545/j.cnki.jmse.2023.0472( (2024).

Mishra, R. K. et al. Detection and delineation of coal mine fire in Jharia coal field, India using geophysical approach: A case study. J. Earth Syst. Sci., 127(8). https://doi.org/10.1007/s12040-018-1010-8(2018).

Wang, J. C., Xu, H. H. & Chen, W. Evaluation method of rock mass structure integrity based on borehole multivariate data. Int. J. Geomech., 22(1): 04021248. https://doi.org/10.1061/(ASCE)GM.1943-5622.0002232(2022).

Wang, J. C., Xu, H. H. & Zou, J. P. Fine detection technology of rock mass structure based on borehole acousto-optic combined measurement. Measurement 187, 110259. https://doi.org/10.1016/j.measurement.2021.110259 (2022).

Acknowledgements

All the images and data are from our actual tests and permitted by the owners. We are compliant with ethical standards, and all authors declare that this paper has no conflict of interest. Finally, we are grateful for the many helpful and constructive comments from many anonymous reviewers.

Funding

This work is supported by Open Fund of State Key Laboratory of Water Resource Protection and Utilization in Coal Mining (Grant No. GJNY-20-113-07), and the Key R&D Plan Project in Hubei Province (Grant No. 2023BAB099), and the National Natural Science Foundation of China (No.52404109), and the Open Foundation of Science and Technology Innovation Center of Hubei Institute of Urban Geological Engineering(No. KCJJ202401).

Author information

Authors and Affiliations

Contributions

Wang Jinchao wrote the main manuscript text. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Jinchao, W., Junpeng, Z., Chao, W. et al. Monitoring method for borehole images of changes in overlying rock structure during coal mining. Sci Rep 15, 15495 (2025). https://doi.org/10.1038/s41598-025-00513-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-00513-5