Abstract

In order to solve the tough problem of safety and reasonable exploration of coal resources under the reservoir, through developing GIS reservoir area model and the surface mining subsidence visualization system by probability integral method, it is expected to achieve the precise calculation of the working face underwater mining area, it is also proposed that optimal criterion of coordinating mining for the selection of minimum reservoir water covering area of the working face under the reservoir, the safety and reasonable working order of working face is determined. Taking the 11 working face mining area of Northern First and Southern Second mining areas under Daping coal reservoir, it can be figured out by the movement and distribution of performing dynamic simulation reservoir water: The optimal working face sequence is S2S9\(\rightarrow\)S2S8\(\rightarrow\)S2N7\(\rightarrow\)S2N6\(\rightarrow\)S2N5\(\rightarrow\)S2N3\(\rightarrow\)N1S5\(\rightarrow\)S2N4\(\rightarrow\)N1S3\(\rightarrow\)S2N2\(\rightarrow\)N1S4, the total area of underwater mining is 1028236.18 \(m^{2}\), which is 224762.29 \(m^{2}\) less than current mining plan. The research results showed that through the movement and regulations of distribution of dynamic simulation of reservoir water, making the reasonable connection of working face under the reservoir achieved, reducing the danger degree of the recovery process of underwater working face obviously, lowering the cost of mine control water, which can provide theoretical value and guiding significance for the safe recovery of working face under the reservoir in other mining areas.

Similar content being viewed by others

Introduction

The exploitation of coal resources under the reservoir destroyed the state of the existing mechanical equilibrium of the interior of the rocks1, which leads to different degrees of movement, deformation and destruction of the overlying strata in the goaf2. When internal tensile stress in rock exceeds the tensile strength limit of rock stratum, the overlying strata in the goaf will appear rupture, breakage, successive caving, even spread to the surface and form subsidence basin, it can also cause water level elevation in the overlying reservoir and water redistribution in the area3, the amount of the underwater mining area and the number of working face are changing, which would make significant increase in the risk of exploiting the working face underwater4. In recent years, scholars in Russia, Poland, the United Kingdom and the United Stated have conducted a large number of experiments and researches on the coal mining in river surface, lakes and aquifer. In the UK5, the subsea coal mining regulations have been promulgated. The minimum thickness of overlying strata is 105 m, of which there must be a 61 m thickness and shale bearing coal bearing strata. The maximum thickness of the coal seam is 1.7 m, and the depth ratio is 62:1. In the case of the existence of the aquifers in the former Soviet Union6, the height of the waterproof coal pillar is 20\(\sim\)40 times higher, or 20\(\sim\)60 times the thickness of the rock strata in the overlying rock, according to the proportion of the rock strata of different properties in the overburden. The United States provides a safe deep ratio of 60:1 for large water bodies under the surface7. According to the rules for mining under the sea of Japan8, 100 m permanent waterproof coal pillars are generally reserved along the coal seam from the seabed, it is proposed that the use of filling method can safely exploit the coal resources under the water body. But they determined the safety mining depth and mining plan only from the water flowing fractured zone height caused by mining effect, rather than through the water level changes and underwater mining area caused by earth surface subsidence and through the movement role of reservoir water, then decreased underwater mining area, calculated the underwater mining area accurately9, and determined the optimal mining plan, and recovered the coal resources underwater safely to the utmost extend10. There are 1332 million tons of coal under reservoir in Daping coal mine, which accounted for 49.5% of the industrial reserves in the field, and the urgent problem needed to be solved is that formulating an reasonable underwater mining plan and recovered the coal resources safely and efficiently11,12.

Besides, in recent years, in order to solve the safety issues of underground mining in reservoirs13, Yang et al. have conducted research on the development height of the water-conducting fracture zone under the conditions of coal mining and top coal caving in water bodies, by means of physical simulation, numerical simulation and theoretical analysis, etc. This is to increase the coal recovery rate and protect the resources of reservoirs14.Liu et al. established a fluid-solid coupling calculation model for the deformation evolution of the underground reservoir coal pillar dam body using FLAC3D numerical simulation software. It was found that the development range of the plastic zone, the maximum vertical stress, and the maximum vertical deformation all increased with the increase of the working face inclination length and mining height. The increase of the coal pillar width would lead to a decrease in the maximum vertical stress. The increase of water pressure would result in a reduction of the maximum vertical deformation15.A novel method for fluid-solid coupling simulation has been proposed by Yin et al. to analyze the weakening situation of coal bodies under various factors, and the stability of residual coal pillars (RCPs) in underground reservoirs during longwall mining has been studied16.Zhang et al. conducted a study on the stability of residual coal pillars in underground reservoirs during longwall mining and water storage by combining numerical simulation with on-site measurements.The results show that during the mining process in adjacent areas, the stress and plastic zone development of RCPs will increase, and the potential unstable factors will affect the stability of the reservoir17.Wang et al. combined the characteristics of the coal pillars (CP) in underground reservoirs and conducted indoor experiments to explore the cumulative damage laws of the samples under cyclic loading and unloading (CLU) and different soaking times. Based on the indoor experiments, the progressive damage characteristics of the underground reservoir CP during the mining and water storage processes were studied. Under the same CLU time, it was observed that the strength of the coal samples gradually decreased with different soaking periods. Compared with the three CLU times of 7 days and 14 days of soaking, the load fluctuations and strain expansion in the peak post region reached the maximum when the coal samples were soaked for 21 days. The CP exhibited the “damage - seepage - cumulative damage” effect under the water-soaking-stress coupling environment18.From the perspectives of water conservation mining and ecological environment protection in ecologically fragile areas, Chang et al. have conducted on-site measurements and numerical simulations to study the development height and morphological characteristics of the water-conducting fracture zone (WCFZ) beneath the reservoir, revealing its four-stage evolution process. They also discovered that the “bridging phenomenon” of the overlying weak rock strata can effectively inhibit the development of WCFZ19.Water-saving coal mining technology has promoted water resource protection and high-quality coal development by safeguarding the structure of aquifers and the stability of ecosystems. Currently, a complete technical system and monitoring system have been formed. Fan et al. conducted research and analysis on the technical principles, applicable conditions, and engineering application effects of eight representative projects of water-saving coal mining technology, and established the fundamental research framework of the water-saving coal mining technology system20.

In this paper, through developing GIS reservoir area model and the surface mining subsidence visualization system by probability integral method21,22(S1. Support Information. System login interface), establishing a high accurate initial topography and a 3D digital elevation model of subsidence basin, the dynamic correction of the geographic database in reservoir area and the real-time reconstruction of 3D terrain in the reservoir area can be realized by adopting the seamless embedding technology of the subsidence basin23, the movement and distribution of the dynamic simulation reservoir water, then calculated the mining area of each working side precisely, put forward the optimal criterion of coordinating mining, of which mines the minimum water cover-area of the working face under reservoir and chooses the sequential working face, the safe and reasonable mining sequence under reservoir water is determined, and the degree of the threat of reservoir water from pre-mining work is reduced.

GIS reservoir area model

The GIS reservoir area model24,25 is based on component technology and Arc Engine component object of ArcGIS, which provides efficient spatial information processing capabilities and strong decision support services, it can also offer spatial data management, implement 3D display of the reservoir terrain, spatial query and spatial analysis, predict the movement rule of water body caused by surface deformation26, all of the above are through establishing 3D digital model in the surface of mining field27.

Development plan

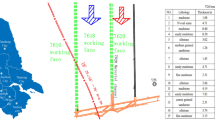

The GIS reservoir area model is a basic development platform which is based on tee professional geographic information system ArcGIS 9.0, is a programming tools which is an object-oriented Microsoft Visual C++ 2005 advanced programming language, it build application development by using the component objects offered by second development package Arc Engine and powerful spatial data management and analysis functions, then it can improve the development efficiency of application system and realize the flexible application of GIS and extend the functionality. The application development process is shown in Fig. 1.

The establishment of 3D surface model of reservoir area

The 3D surface model of reservoir area is the important basis of GIS reservoir area model, which was established by DEM28,29. The DEM surface of the reservoir area is generated by means of TIN. TIN is a high precision approach for generating DEM surface, which can use all the irregular distributed discrete sampling points in the research area, in accordance with the principle of optimum combination, and link these discrete points together to successive triangle surface network, in addition, the shape and size of the triangle surface depend on the density and position of these discrete points. Each triangular face represents partial plane, so it approaches the surface of the terrain. Any point in the area is located on the vertex of the triangular, edge of the triangular or within the triangular, and if any point is not on the node, the elevation value of this point can be obtained by the method of linear interpolation30,31,32, of which the elevation of the point on the edge is calculated by the use of the elevation of two vertices of this side, while the elevation of the points within the triangular can be obtained by elevation of three vertices.

TIN model is a kind of typical vector topological structure, through the relationship between side and node, and the relationship between triangular surface and edge, it can represent the topological relationship between terrain feature points and represent the fluctuation changes of space accurately.

In TIN model, it can generated 3D digital elevation model by using Delaunay triangular subdivision, whose process is to utilize the horizontal coordinate of the known initial point set P and to generate Delaunay triangular mesh, providing elevation value for the nodes in Delaunay triangular. The insertion generation algorithm of Delaunay triangulation network is as follows:

(1)First of all, extracting the smallest external rectangle in the entire data area and being regarded as the simplest convex closure.

(2)The rectangle of the data area is divided grisly according to certain rules, to achieve the desired comprehensive efficiency, the average number of data points per grid unit can be limited.

(3)Establishing a linear list of block indexes according to data point(x, y) coordinates.

(4)Two super triangles are formed by the region’s convex closure, and all the data points must be within these two triangles.

(5)According to the sequence of the linear data list established in (3), find the triangular containing data points in the triangular in (4), and insert the data points and connect the data to the three vertices of the triangular, and three new triangular will be cut out.

(6)According to the empty circle characteristics of Delaunay triangle, adjust three new triangles generated and their adjacent triangles respectively. Test every two adjacent triangles for two times, if one of the outer circles of one of the triangle contains another triangle that has the third vertex except for the common vertex, and then exchange the common side.

(7)Repeat (5)(6) until all the data points are inserted into the triangular mesh.

The Daping mine reservoir area surface triangular mesh generated by the above algorithm was shown in Fig. 2.

Surface mining subsidence prediction system in reservoir area

The surface mining subsidence prediction system33,34 is based on mining subsidence theory, computer graphics and computer software development technology, using the object-oriented Microsoft Visual C++ 2005, and it is able to realize the visualization integrated management platform for surface movement deformation caused by mining. It also can predict model and algorithm by probabilistic integration35,36, in addition, it can calculate the maximum movement and deformation value of the surface, determine movement and deformation distribution of the direction or inclination of the main section, and predict the movement and deformation value of any point in the basin, in this way, it provides important technical support for the calculation of the water transport of the multi-working surface mining.

Surface movement deformation prediction model

The surface movement deformation prediction model uses the probabilistic integration method, regards the rock mass in mines as a loose discontinuous medium, and the rock and surface movement caused by mining are similar to the movement process of loose medium, the movement process is a stochastic process which obeys statistical rules and can uses probability theory to reveal the regularity of random distribution of rock and surface movement.

It regards the subsidence of the upper strata caused by the unit mining as a random ever, and describes the settlement probability and settling volume of the rock mass according to the probability of the occurrence of a sedimentation event. From the viewpoint of statistics, divide the whole mining area into infinitely many infinitesimal ‘unit mining’, and form ‘unit basin’ above the surface of the ‘unit mining’, the subsidence curve of the ‘unit basin’ is the probability density curve of normal distribution. The effect of the whole mining area on the rock and the earth’s surface is equal to the sum of the effects of an infinite number of “mining units” on the strata and the earth’s surface; the superposition of an infinite number of “cell basins” on the surface constitutes the total surface movement basin.

The mining scope of the working face is \({\varvec{o}}_1{\varvec{C}}D{\varvec{E}}\). Among them,\(o_{1} C\) is strike length \(D_{3}\) of working face,CD is tendency length \(D_{1}\) of working face. The ground coordinate system is xoy, X-axis parallels strike main cross section. Y-axis parallels tendency main cross section. Origin O is located in the bottom left-hand corner of working face. It is shown in Fig. 3.

For the earth’s surface arbitrary point A(x, y), X-axis forward direction anticlockwise appointment direction’s angle value is \(\varvec{\varphi }\). So estimated formula of A point along \(\varvec{\varphi }\)’s movement and deformation value is:

Subsidence value W(x, y):

\({\varvec{W}}_0\) is the maximum subsidence value of the trend and tendency when fully mined and explicated.\({\varvec{W}}^0(x)\) is inclination plenary exploitation. Subsidence main cross section’s coordinate is subsidence value of x’s the earth’s surface arbitrary point A(x, y) when strike limited mining;\({\varvec{W}}^0(y)\) is strike plenary exploitation. Inclination main cross section’s coordinate is subsidence value of x’s the earth’s surface arbitrary point A(x, y) when inclination limited mining;

Incline value \(i(x,y,\varphi )\):

\(i^0(x)\) is inclination plenary exploitation. Strike main cross section’s coordinate is inclination value of x’s the earth’s surface arbitrary point A(x, y) when strike limited mining; \(i^0(y)\) is strike plenary exploitation. Inclination main cross section’s coordinate is inclination value of x’s the earth’s surface arbitrary point A(x, y) when inclination limited mining.

Curvature value \(K(x,y,\varphi )\):

\(K^0(x)\) is inclination plenary exploitation. Strike main cross section’s coordinate is curvature value of x’s the earth’s surface arbitrary point A(x, y) when strike limited mining;\(K^0(y)\) is strike plenary exploitation. Inclination main cross section’s coordinate is curvature value of x’s the earth’s surface arbitrary point A(x, y) when inclination limited mining.

Level movement value \(U(x,y,\varphi )\):

\(U^0(x)\) is inclination plenary exploitation. Strike main cross section’s coordinate is level movement value of x’s the earth’s surface arbitrary point A(x, y) when strike limited mining; \(U^0(y)\) is strike plenary exploitation. Inclination main cross section’s coordinate is level movement value of x’s the earth’s surface arbitrary point A(x, y) when inclination limited mining.

Level deformation value \(\varepsilon (x,y,\varphi )\):

\(\varepsilon ^0(x)\) is inclination plenary exploitation. Strike main cross section’s coordinate is level deformation value of x’s the earth’s surface arbitrary point A(x, y) when strike limited mining;\(\varepsilon ^0(y)\) is strike plenary exploitation. Inclination main cross section’s coordinate is level deformation value of x’s the earth’s surface arbitrary point A(x, y) when inclination limited mining.

The surface movement deformation prediction model is shown in Fig. 4.

The calculation of the working face area under water

The prediction of the working face mining

Select any points of the moving and tending in the ground moving basin and deformation computing subsystem, input the parameters of the working face set in the software and the prediction of extraction rock, import the calculation parameters of the recovery working face, select deformity value of point movement in the calculation area, then the software sets the calculation step length and the calculation range on itself, the calculated estimated data is stored in the format of the text file. The calculation interface of the movement deformation of any point in the surface of the basin is shown in Fig. 5(S2. Support Information. GIS reservoir area model embedded in 11 working face SUBSIDENCE BASINS).

By sousing the expected result data files, the main section direction, tendency main section and subsidence contour of the movement basin can be drew, and the expected results data can be allowed to import to EXCEL, SURFER software for the corresponding processing and operation.

The embedded model in GIS reservoir area of subsidence basin

After mining working face, in the process of embedding formed subsidence basin into the model in reservoir area, it uses average subsidence value to correct original coordinate value, which in order that subsidence basin has the same volume, then realize the correction to the original coordinates37.

The specific approach is that finding out the volume of the subsidence basin on ArcGIS, divided by the rectangular area which influence the contoured range, then getting the average subsidence value, h, of the rectangular basin.\(h{=}V/S.\).

The embedding process of the equivalent subsidence basin is to import the subsidence basin from prediction software to drawing software SUFER, determine the influence range of the subsidence basin (rectangular equivalent basin) and calculate the average deflection of the equivalent basin. In EXCEL software, delineated the original coordinates in reservoir area in the scope of the equivalent basin, then use the ordinate minus the average deflection, after this, embed the corrected coordinate point data into the model data in the reservoir area, forming new model database in reservoir area, finally, import the new model data into ArcGIS, reservoir model and contour map will be produced.

The calculation of the working face and underwater mining area

On the contour line of the new reservoir model, find the corresponding contour line and water level elevation according to the reservoir water yield, insert its elevation contour line into mine excavation plan (Auto CAD), the closed area formed by the water line and the boundary line of the working face is the working face in mining area underwater, and mining area underwater can be calculated out by the function of Auto CAD.

The optimal principle of coordinating mining under the reservoir

Predict the subsidence basin caused by the working face mining by using anticipated developed software, calculate the cover area in reservoir of the working face to be mined on the mining engineering map, choose the smallest working face of the cover area in the reservoir water which needs to be mined as the next excessive working face, and then insert the surface subsidence basin of this working face into established reservoir model, analyze the movement rules of the reservoir water caused by mining. In accordance with the above principles, select each working face which is unmined, until all the working faces in the research range are selected completely, forming the most optimal coordinating mining plan to be formulated. The optimization process is shown in Fig. 6.

Optimization effect test

To verify the effectiveness of the coordinating exploitation plan, according to the current exploitation plan of Daping Coal Mine, the stopping sequence of the working face, and analyze each working face in accordance with the above process, calculate the area of underwater mining and the total area of underwater mining. Comparing and analyzing with the total area of the underwater mining which was calculated by coordinating exploitation plan, verify the advantages of the coordinating exploitation plan.

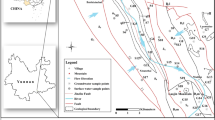

Daping Coal Mine has already recovered several working faces, only Northern First and Southern Second mining areas were remained, because each working face of north wing of Northern First mining area is outside of the scope of reservoir covering area, therefore, determine the scope of research to the south wing of the Northern First mining area, which contains three recovery working faces and eight recovery working faces in Southern Second mining area.

According to the observational data of the surface subsidence and rock strata movement provided by Daping Coal Mine, the prediction of surface movement and deformation are estimated: subsidence factor \(q{=}0.76\), trend of the horizontal movement coefficient \(b{=}0.36\), tendency to upper boundary horizontal movement coefficient \(b{=}0.3\), tendency to bottom boundary horizontal movement coefficient \(b{=}0.36\), mining propagation influence angle \(\theta _0=90^0-0.7\alpha\)(\(\alpha\) is the dip angle of coal seam), the greatest subsidence angle is \(\theta =90^0-0.7\alpha\), tangent of the main tendency influence angle is \(\tan \beta =2.0\), tangent of the main tendency to upper boundary influence angle is \(\tan \beta =2.0\), tangent of the main tendency to bottom boundary angle is \(\tan \beta =2.2\), the offset of tendency and inclination inflection point is \(s=0.05H\)(H is the mining depth of coal seams ), the current water level elevation is 81.24cm. The mining parameters of each mining face are shown in Table 1(S3. Support Information. The characteristic parameter table of each working face subsidence basin when implementing the current mining plan) .

The current exploitation plan

According to the current exploitation plan in research range, the mining sequence of the 11 working face is S2S9\(\rightarrow\)N1S3\(\rightarrow\)S2N7\(\rightarrow\)N1S4\(\rightarrow\)S2N2\(\rightarrow\)S2N6\(\rightarrow\)N1S5\(\rightarrow\)S2S8\(\rightarrow\)S2N5\(\rightarrow\)S2N4\(\rightarrow\)S2N3. by using mining subsidence prediction software system, ArcGIS geographic information system, SURFER mapping software, EXCEL calculation software, analyze and study the 11 working face in research range which caused surface subsidence basin, changes in the water level of the reservoir and movement of the reservoir water, the total mining area underwater and the total area after the implementation of the current mining plan can be calculated(S4. Support Information. Relative location map of water level in the reservoir area after mining in accordance with the current mining plan for 11 working surfaces). As shown in Table 2.

As can be seen in Table 2, after the implementation of the current mining plan, the water level falls to +80.25 m, and the total mining area underwater is 1252998.47 \(m^{2}\).

Coordinating mining plan

Since the generated basin and equivalent basin after implementation the coordinating mining each working face are same with the current mining plan, the difference is that the insertion sequence is different, and the water movement and water level are different, therefore, insert the equivalent basin of each working face into the reservoir model directly, according to the analysis process of the coordinating mining plan, the optimal coordinating mining plan can be formed in accordance with the minimum determination criterion of the reservoir cover are, determining the successive working face at the same time.

It is can be figured out from Table 2 that after mining S2S9 working face, the mining area underwater of S2S8 working face is 0, therefore, making S2S9 working face as the successive working face of S2S8. According to the results of the water cover area after mining S2S8 working face, the next successive working face is S2N7 by the principle of minimum reservoir water cover area. Such optimization process of repetitive successive working face, the optimal mining plan will be formed, the mining sequence is S2S9\(\rightarrow\)S2S8\(\rightarrow\)S2N7\(\rightarrow\)S2N6\(\rightarrow\)S2N5\(\rightarrow\)S2N3\(\rightarrow\)N1S5\(\rightarrow\)S2N4\(\rightarrow\)N1S3\(\rightarrow\)S2N2\(\rightarrow\)N1S4. After the implementation of optimization mining of the above 11 stopping working faces, the water level elevation and the mining area underwater are shown in Table 3(S5. Support Information. The relative location of the water level line in the reservoir after coordinating mining plan).

As can be seen from Table 3, after the mining plan put into effect, the water line falls to +80.13 m, the total mining area underwater is 1028236.18 \(m^{2}\).

Contrastive analysis

The working face sequence S2S9\(\rightarrow\)N1S3\(\rightarrow\)S2N7\(\rightarrow\)N1S4\(\rightarrow\)S2N2\(\rightarrow\)S2N6\(\rightarrow\)N1S5\(\rightarrow\)S2S8\(\rightarrow\)S2N5\(\rightarrow\)S2N4\(\rightarrow\)S2N3 is determined by the current mining plan, then mining, the water level elevation in reservoir are falls from initial +81.24 m to +80.25 m, the total mining area underwater is 1252998.47 \(m^{2}\).

The optimal coordinated mining sequence is obtained according to coordination optimization criterion: S2S9\(\rightarrow\)S2S8\(\rightarrow\)S2N7

\(\rightarrow\)S2N6\(\rightarrow\)S2N5\(\rightarrow\)S2N3\(\rightarrow\)N1S5\(\rightarrow\)S2N4\(\rightarrow\)N1S3\(\rightarrow\)S2N2\(\rightarrow\)N1S4, the water level elevation in reservoir area falls from initial +81.24 m to +80.13 m, the water head is 1.11 m, the total mining area underwater is 1028236.18 \(m^{2}\).

Through the comparison and analysis with the current mining plan, the total mining area underwater of the two mining area corresponding with the most optimal coordinating mining plan decreased by 224762.29 \(m^{2}\). compared with the current mining plan, which is 17.94% of the total mining area of two mining area of the current mining plan, therefore, it can minimize the mining range underwater to the biggest extent, reducing the risk of the mining coal resources in the reservoir.

Conclusion

Through the establishment of 3D digital model in underground mine field surface, it can predict the movement rule of water caused by deformation of surface, calculate the reservoir volume below the water level accurately, and then determine the distribution range of the reservoir water and boundary of water.

By means of probability integral method, the deformation value and the movement of any points in the surface subsidence basin can be predicted, which also provide the theoretical support for the water level line mapping and the calculation of cover area underwater after the multi-working face mining under the reservoir.

Predict the subsidence basin caused by mining each working face by using prediction software, calculate the cover area of the needed mining working face, then select the next successive working face with the principle of minimum surface area of working face in the reservoir, finally compile the optimal coordination mining sequence.In actual operation, implementing the proposed mining sequence may encounter some challenges. For instance, the surface movement and deformation caused by mining is a dynamic process that varies with the expansion of mining space and the continuation of time. Further research is needed to develop dynamic prediction methods that can accurately calculate the surface subsidence values at any given moment. Real-time simulation of the dynamic migration patterns of reservoir water during the mining process is also necessary to further enhance the practicality of the research results.

According to the mining area underwater in the current mining plan and coordination mining plan of the eleven working face in the Northern First mining area and Southern Second mining area in Daping Coal Mine, the mining area underwater after the implementation of coordination mining plan decreased by 224762.29 \(m^{2}\), which occupied 17.94% of the total area. Reduce the mining scope underwater from the largest extent, lower the cost of the mine control water programs and the danger degree of mining coal resources under reservoir, ensuring the safety of mine resources and efficient recovery under the reservoir.

Data availability

All data generated or analysed during this study are included in this published article [and its supplementary information files].

Abbreviations

- GIS:

-

Geographic information system

- 3D:

-

Three-dimensional

- DEM:

-

Digital elevation model

- TIN:

-

Triangulated irregular network

- CAD:

-

Computer aided drafting

- \({\varvec{o}}_1{\varvec{C}}D{\varvec{E}}\) :

-

The mining scope of the working face

- \(o_{1} C\) :

-

Strike length

- CD :

-

Tendency length

- \(D_{3}\),\(D_{1}\) :

-

Working face

- A(x, y):

-

The earth’s surface arbitrary point

- \(\varvec{\varphi }\) :

-

X-axis forward direction anticlockwise appointment direction’s angle value

- W(x, y):

-

Subsidence value

- \({\varvec{W}}_0\) :

-

The maximum subsidence value of the trend and tendency when fully mined and explicated

- \({\varvec{W}}^0(x)\) :

-

Inclination plenary exploitation

- \({\varvec{W}}^0(y)\) :

-

Strike plenary exploitation

- \(i(x,y,\varphi )\) :

-

Incline value

- \(K(x,y,\varphi )\) :

-

Curvature value

- \(U(x,y,\varphi )\) :

-

Level movement value

- \(\varepsilon (x,y,\varphi )\) :

-

Level deformation value

References

Čebašek, V., Rupar, V., Đenadić, S. & Miletić, F. Cutting resistance laboratory testing methodology for underwater coal mining. Minerals 11, 564 (2021).

Xiong, W. U., Jian, Y. & Wei, D. Q. Impact of coal mining on safety of reservoir. J. Hydraulic Eng. 35, 100–104 (2004).

Zhai, X., Zhai, Y., Tu, X., Li, R. & Huang, G. Numerical study of the influence of coal seam mining under reservoir on deep oversize fault deformation. Therm. Sci. 23, 2315–2322 (2019).

Li, H.-J. et al. A study of coal resources mining under the zhanghe reservoir. Hydrogeol. Eng. Geol. 36, 16–20 (2009).

Bukowski, P. Determining of safety pillars in the vicinity of water reservoirs in mine workings within abandoned mines in the upper silesian coal basin (uscb). J. Min. Sci. 46, 298–310. https://doi.org/10.1007/s10913-010-0037-2 (2010).

Serzhan, S. Determining the rational immersion depth of a mining complex capsule for underwater mining of ferromanganese nodules. Proc. Eng. 150, 1. https://doi.org/10.1016/j.proeng.2016.07.063 (2016).

Gandhe, A., Venkateswarlu, V. & Gupta, R. N. Extraction of coal under a surface water body-a strata control investigation. Rock Mech. Eng. 38, 399–410. https://doi.org/10.1007/s00603-005-0051-x (2005).

Majdi, A., Hassani, F. P. & Nasiri, M. Y. An estimation of the height of fracture zone in longwall coal mining. J. Am. Chem. Soc. 107, 4343–4345 (2012).

Trabelsi, F. et al. Gis-based subsurface databases and 3-d geological modeling as a tool for the set up of hydrogeological framework: Nabeul-hammamet coastal aquifer case study (northeast tunisia). Environ. Earth Sci. 70, 2087–2105. https://doi.org/10.1007/s12665-011-1416-y (2013).

Wu, X. et al. Exploitation of coal resources under surface water body. Chin. J. Rock Mech. Eng. 25, 1029–1036 (2006).

Cools, J. et al. Large-scale gis-based hydrogeological modeling of flanders: a tool for groundwater management. Environ. Geol. 50, 1201–1209. https://doi.org/10.1007/s00254-006-0292-3 (2006).

Zhang, C., Luo, B., Xu, Z., Sun, Y. & Feng, L. Research on the capacity of underground reservoirs in coal mines to protect the groundwater resources: A case of zhangshuanglou coal mine in xuzhou, china. Water 15, 1. https://doi.org/10.3390/W15081468 (2023).

Mingbo, C. et al. Water supply and regulation of underground reservoir in coal mine considering coal-water occurrence relationship. Geofluids https://doi.org/10.1155/2022/2892964 (2022).

Yang, T. et al. Simulated prediction of roof water breakout for high-intensity mining under reservoirs in mining areas in western china. Appl. Sci. 13, 1. https://doi.org/10.3390/APP13179902 (2023).

Liu, X., Song, S., Wu, B., Li, X. & Yang, K. Study on deformation and fracture evolution of underground reservoir coal pillar dam under different mining conditions. Geofluids 2022, https://doi.org/10.1155/2022/2186698 (2022).

Yin, D. et al. Mechanical properties and damage characteristics of coal samples under water immersion pressure. Lithosphere (2022).

Cun, Z., Xiaojie, W., Penghua, H., Qingsheng, B. & Jianhang, C. Failure analysis of residual coal pillar under the coupling of mining stress and water immersion in the goaf underground water reservoir. Environ. Earth Sci. 82. https://doi.org/10.1007/S12665-023-10978-0 (2023).

Fangtian, W., Xueqian, W., Dongliang, S. & Cun, Z. The progressive failure mechanism for coal pillars under the coupling of mining stress and water immersion in underground reservoirs. Bull. Eng. Geol. Environ. 82, 1. https://doi.org/10.1007/S10064-023-03151-1 (2023).

Chang, X., Wang, M., Zhu, W., Fan, J. & Liu, M. Study on height development characteristics of water-conducting fracture zone in fully mechanized mining of shallow thick coal seam under water. Sustainability 15, 1. https://doi.org/10.3390/SU15097370 (2023).

Limin, F. et al. Technological system of water-conserving coal mining. Coal Geol. Explor. 51, 196–204 (2023).

Wang, Z. et al. Refined subsidence monitoring and dynamic prediction in narrow and long mining areas based on insar and probabilistic integral method. Sci. Rep. 14, 28009 (2024).

Li, T., Zhang, H., Fan, H., Zheng, C. & Liu, J. Position inversion of goafs in deep coal seams based on ds-insar data and the probability integral methods. Remote Sens. 13, 2898 (2021).

Zhao, B. et al. Prediction method for surface subsidence of coal seam mining in loess donga based on the probability integration model. Energies 15, 2282 (2022).

Shikunova, E., Pavlovsky, A., Zemlyanov, I. et al. Optimization of computer-based technology of creating large reservoir’s digital elevation models. Egu General Assembly (2010). http://adsabs.harvard.edu/abs/2010eguga..12..582s.

Lai, L. F. & Zhang, Y. F. Study on the utilization of digital elevation model for calculation method of reservoir capacity. Adv. Mater. Res. 472–475, 1627–1631. https://doi.org/10.4028/www.scientific.net/AMR.472-475.1627 (2013).

Vušović, N., Vlahović, M. & Kržanović, D. Stochastic method for prediction of subsidence due to the underground coal mining integrated with gis, a case study in serbia. Environ. Earth Sci. 80, 67 (2021).

Krassakis, P. et al. Gis-based subsurface analysis and 3d geological modeling as a tool for combined conventional mining and in-situ coal conversion: the case of kardia lignite mine, western greece. Mining 2, 297–314 (2022).

Tucker, G. E. et al. An object-oriented framework for distributed hydrologic and geomorphic modeling using triangulated irregular networks. Comput. Geosci. 27, 959–973. https://doi.org/10.1016/S0098-3004(00)00134-5 (2001).

Vivoni, E. R. et al. On the effects of triangulated terrain resolution on distributed hydrologic model response. Hydrol. Process. 19, 1. https://doi.org/10.1002/hyp.5671 (2010).

Muzik, J. et al. Creation of 3d geological models using interpolation methods for numerical modelling. Proc. Earth Planet. Sci. 15, 25–30. https://doi.org/10.1016/j.proeps.2015.08.007 (2015).

Wasilewska-Błaszczyk, M. et al. 3d lithological model using by interpolation and simulation methods. Biuletyn - Panstwowego Instytutu Geologicznego https://doi.org/10.5604/01.3001.0010.0115 (2017).

Tomeckasuchoń, S. & Marcak, H. Interpretation of ground penetrating radar attributes in identifying the risk of mining subsidence. Arch. Min. Sci. 60, 645–656. https://doi.org/10.1515/amsc-2015-0042 (2015).

Wu, X. et al. The influences of mining subsidence on the ecological environment and public infrastructure: a case study at the haolaigou iron ore mine in baotou, china. Environ. Earth Sci. 59, 803–810. https://doi.org/10.1007/s12665-009-0076-7 (2009).

Marschalko, M. et al. Unique documentation, analysis of origin and development of an undrained depression in a subsidence basin caused by underground coal mining (kozinec, czech republic). Environ. Earth Sci. 72, 11–20. https://doi.org/10.1007/s12665-013-2930-x (2014).

Diao, X. et al. Combining differential sar interferometry and the probability integral method for three-dimensional deformation monitoring of mining areas. Int. J. Remote Sens. 37, 5196–5212. https://doi.org/10.1080/01431161.2016.1230284 (2016).

Li, L., Wu, K. & Zhou, D. W. Extraction algorithm of mining subsidence information on water area based on support vector machine. Environ. Earth Sci. 72, 3991–4000. https://doi.org/10.1007/s12665-014-3288-4 (2014).

Xue, S. et al. Bias estimation and correction for triangle-based surface area calculations. Int. J. Geogr. Inf. Sci. 30, 2155–2170. https://doi.org/10.1080/13658816.2016.1162795 (2016).

Acknowledgements

We thank the staff of the Daping Coal Mine for our work relating to the help. We appreciate Sun Chenliang and Yang yanguo’s support and help in compiling software work.

Funding

This work was funded by National Natural Science Foundation of China (Grant No. 52274120), the Natural Science Foundation of Hebei Province (E2024508006), Supported by Fundamental Research Program of Shanxi Province (20210302122389).

Author information

Authors and Affiliations

Contributions

F.Z. designed and performed the analysis, wrote the paper. Y.L. is responsible for software development. S.B.H and Z.Y.T. are responsible for coordinating the design of optimization guidelines and the determination of mining solutions. J.X.Z and H.D.W. are responsible for field data collection and calculation, who contributed to the design of the analysis. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, F., Li, Y., Hu, S. et al. Coordinated mining technology based on GIS reservoir area model and probability integral method under reservoirs. Sci Rep 15, 15749 (2025). https://doi.org/10.1038/s41598-025-00639-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-00639-6