Abstract

With global ecological problems and uncertainties in the international economy, the resilience of the wood supply chain is becoming important for the sustainable development of the wood industry. Heilongjiang Province is a key region for wood production and consumption in China. However, it faces many internal and external challenges in its wood supply chain. This paper uses a system dynamics method to build a wood supply chain model for Heilongjiang Province with Anylogic. It includes resilience factors from infrastructure, economic, and ecological perspectives. The goal is to find the system’s dynamics and how different factors influence and interact with each other. The results show that relying on overseas raw materials makes supply chain management more difficult. Logistics information platforms are essential for better coordination. The manufacturing sector does not respond well, so improving manufacturing efficiency is necessary to increase the system’s efficiency. The sales sector is affected by changes in market demand. Balancing the consumption of domestic and international customer groups can help stabilize production and sales. This study explains the current situation of the wood supply chain in Heilongjiang Province. It provides a theoretical basis for regional wood supply chain management and offers useful insights for improving supply chain resilience in other similar regions.

Similar content being viewed by others

Introduction

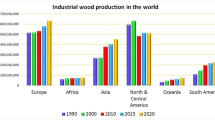

Wood is a sustainable resource that plays an important role in construction, furniture production, and recreation. Heilongjiang Province is a major center for wood production and processing in China. Its wood furniture industry is significant both domestically and internationally. However, the wood supply chain in this region faces many challenges. These include fluctuations in raw material supply, production inefficiencies, uncertainties in domestic and global market demand, and policy changes. These issues weaken the stability and resilience of the wood supply chain1. The increasing complexity of global supply chains and the growing competition in international markets have created new demands for improving the resilience of Heilongjiang’s wood supply chain. Research on this topic is important for maintaining stability, achieving sustainable development, and helping policymakers, businesses, and stakeholders prepare for future challenges. Enhancing resilience can improve resource allocation, strengthen risk management, and support the long-term growth of the wood industry.

Resilience in the wood supply chain means the ability of providers to meet customer needs under very difficult and unstable conditions. In recent years, many scholars have focused on wood supply chain resilience2,3. Several researchers have investigated how costs at various stages of the supply chain impact resilience. For example, Hayek et al.4 examined the influence of logistics costs on supply chain resilience. Susanty et al.5 explored information sharing and connectivity between wood waste producers and buyers to reduce operational costs in the furniture supply chain. Longo et al.6 addressed costs arising from supply chain disruptions and proposed strategies to manage crises such as COVID-19.

Other researchers have focused on risks within the wood supply chain and their effects on resilience. Auer et al.7 highlighted the lack of analysis on risk mitigation strategies across the entire value chain of wood products. Habibi et al.8 introduced six indicators to measure resilience in absorbing, adapting to, and recovering from disruptions. They used simulations to test the recovery capabilities of supply chain networks. Ioannidou et al.9 developed a framework to study the risks of wood supply shortages in different regions and their impact on construction materials.

As research progressed, some scholars found that improving resilience relies on collaboration among supply chain stakeholders. Suong10 noted the low level of collaboration in the furniture supply chain and investigated key factors influencing cooperation. Azadegan et al.11 demonstrated that managing long-term risks through collaboration enhances the adaptability and resilience of supply chains. Shahriari et al.12 created a framework to improve supply chain competitiveness, covering areas such as business, marketing, collaboration, and quality. Liu et al.13 developed digital twin technology for industrial networks and established a user-centered framework for supply chain collaboration.

Advances in technology have also introduced new methods for studying resilience. Some researchers employed optimization algorithms. Gao et al.14 combined demand forecasting with particle swarm optimization to address issues such as poor communication and supply-demand imbalances. Gholian-Jouybari et al.15 utilized an improved Keshtel algorithm to tackle uncertainties in production and demand within agri-food supply chains. Ivanov16 explained how digital twins support supply chain resilience.

These studies have made significant contributions to identifying key resilience indicators and uncovering causal relationships within wood supply chain systems. However, they have not evaluated the long-term dynamics of wood supply chain systems from a holistic perspective, focusing instead on specific segments.

Based on the above analysis, this study aims to construct a resilience factor model for the wood supply chain in Heilongjiang Province using system dynamics. Indicators are selected from three dimensions: infrastructure resilience, economic resilience, and ecological resilience. Through simulation and analysis, the study will identify the key resilience factors affecting the coordination of the wood supply chain in Heilongjiang Province and propose strategies to improve the system’s robustness. The research aims to provide a theoretical foundation for managing regional wood supply chains and offer insights for similar studies in other regions.

Literature review

Wood supply chain resilience

Numerous researchers have conducted extensive studies on supply chain resilience, indicating that the resilience of the wood supply chain is influenced by multiple interrelated factors. These factors include stakeholder behavior, the application of information technology, logistics and transportation capabilities, policies and regulations, environmental and social factors, and risk management strategies. For instance, Hoeben et al.17 investigated the diverse perspectives and recommendations of stakeholders regarding the European wood supply chain. Stopfer et al.18 demonstrated that blockchain technology can enhance the management of wood supply chains, supporting sustainability and biodiversity. Xu et al.19 examined the significant impact of uncertainties and delays in logistics, such as port congestion, on supply chain performance, and proposed models to mitigate the effects of adverse logistics events, thereby enhancing responsiveness and resilience. Zhou et al.20 emphasized the critical moderating role of government technological support and policies in supply chain coordination, which significantly strengthens supply chain resilience. Hisjam et al.21 employed multi-objective planning to study the wooden furniture supply chain in Indonesia, revealing that focusing on social and environmental objectives improves outcomes. Brusset et al.22 considered risks such as price fluctuations, delivery delays, infections, and supplier exposure, and proposed strategies to mitigate the cascading effects of these risks.

By reviewing the aforementioned literature, key factors influencing the resilience of supply chain systems can be summarized, providing a theoretical foundation for the model construction in this study. However, current research on supply chain system simulations primarily focuses on short-term scenarios, lacking exploration of long-term trends. Additionally, most studies concentrate on a single segment of the supply chain, failing to comprehensively summarize the resilience factors of the wood supply chain from a macro perspective. This study aims to address these gaps by integrating a systemic and dynamic approach to analyze the resilience factors of the wood supply chain over extended periods.

System dynamics model

System dynamics emphasizes that the interactions between systems are primarily governed by internal mechanisms23,24, which effectively capture the dynamic relationships within and outside the system. Based on feedback loops, it aids in modeling systems with insufficient data, insensitivity to parameters, or inadequate parameter estimates. Computer simulations serve as a supplementary tool to explore the system’s trends. By adjusting parameters, one can simulate and compute the system’s behavior under various conditions. This allows for the examination of how changes in parameters affect system behavior and state. Unlike traditional quantitative analysis, system dynamics integrates both qualitative and quantitative methods for comprehensive thinking, analysis, and reasoning. During the modeling process, it draws on various data, information, experience, and knowledge to form conclusions.

Because it is particularly suitable for describing causal relationships and feedback mechanisms in complex systems, it has been widely applied in fields such as business, agriculture, military, logistics, economics, industry, scientific research, ecology, and urban planning. For instance, Taheri et al.25 applied system dynamics to develop a sustainable bioethanol supply chain model, illustrating the complex relationship between bioethanol production and food security in Australia, while emphasizing the balance within a sustainable bioethanol supply chain. Hamed et al.26 used system dynamics to study the global development of rare earth resource supply chains and proposed policies to reduce dependence on single countries. Jahani et al.27 employed system dynamics to assess biomass energy supply chain investment plans, identifying and evaluating investment risks associated with the development of renewable supply chains.

Despite the limited research on wood supply chain resilience analysis using system dynamics, the aforementioned studies demonstrate the utility of system dynamics models in analyzing different product supply chains. This provides a solid foundation for the present study, highlighting the potential of system dynamics in wood supply chain research. Accordingly, this paper investigates the complex feedback relationships among subsystems of the wood supply chain in Heilongjiang Province, using these models to evaluate the impact of strategies from key stakeholders such as governments and enterprises on the wood supply chain.

Methodology

Selection of resilience indicators

The resilience of supply chains, including the wood furniture supply chain, has been widely studied28. This research reviews existing literature to identify key resilience factors that impact the long-term stability of the supply chain. Based on the three-tier structure of the wood furniture supply chain, the study analyzes each stage to identify factors that disrupt resilience and those that strengthen risk resistance. These factors are categorized as resilience indicators and will help assess the overall status of the wood supply chain in Heilongjiang Province from a global perspective29,30. The resilience indicators are grouped into three categories: infrastructure resilience, economic resilience, and ecological resilience31.

Infrastructure resilience

Disruptions in infrastructure and equipment can lead to significant social, economic, and financial losses. Infrastructure resilience focuses on the transportation network, transport efficiency, and the safety and modernization of storage facilities32. Key factors include the coverage and density of rail, road, and air networks, transportation times, costs, and on-time delivery rates. These factors influence logistics efficiency for raw materials and finished goods. The stability of the power supply, the automation and intelligence of production equipment33, and the efficiency of communication networks are critical for maintaining production stability34. Similarly, the performance of the logistics and distribution network ensures timely delivery to consumers.

Economic resilience

Economic resilience is the ability to maintain functionality and reduce economic losses during disruptions. It focuses on raw material supply stability, price control, and the coordination of the industrial chain35. The stability of forest resources and wood prices is crucial for reliable raw material supplies. In production, factors such as cost control, the skill level of workers36, and the international competitiveness of sales enterprises impact efficiency37. Market performance is also influenced by market diversification, the involvement of foreign businesses, and the integration of online and offline sales channels.

Ecological resilience

Ecological resilience addresses how the wood furniture supply chain adapts to environmental challenges. It emphasizes sustainable forest management38, eco-friendly production technologies, and pollution control. For raw materials, balancing forest harvesting with afforestation and following environmental regulations are key factors39. In production, using renewable energy, eco-friendly technologies, and managing waste emissions are essential for reducing environmental impact. Promoting a circular economy, certifying green products, and establishing recycling and reuse systems contribute to sustainable resource use.

To evaluate the resilience of the wood supply chain in Heilongjiang Province, a system dynamics model is built using these indicators and the actual conditions of the supply chain. The model conducts long-term simulations to analyze the system’s evolution and assess the effects of various resilience factors. By identifying key variables and their interactions, the model provides theoretical support for improving production and marketing coordination in the wood supply chain. The main resilience factors are shown in Figure 1 below.

Model boundary

The operation of the wood supply chain in Heilongjiang Province is influenced by dynamic interactions and feedback loops, as described in system dynamics. The system’s behavior depends on the interaction of its internal elements, assuming that changes in the external environment do not significantly alter its performance. Since the wood supply chain involves multiple stakeholders and influencing factors, it is a large and complex system.

The model is built on the three-level structure of the wood supply chain in Heilongjiang province. Shadow variables are used to divide the system into three subsystems: the wood import supply subsystem, the wood processing and manufacturing subsystem, and the sales and recycling subsystem for wooden furniture. The three subsystems work together but have distinct boundaries. These boundaries represent the various capacities, resources, and limitations within each subsystem. The key factors for each subsystem are as follows:

In the wood import supply subsystem, it includes import capacity, port service capacity, and logistics/transportation capacity. The performance of this subsystem depends on the efficiency of ports, transportation systems, and logistics infrastructure. Any issues in these areas could cause delays in supply and affect the entire chain, such as bottlenecks in port services or insufficient warehousing capacity.

In the wood processing and manufacturing subsystem, it involves production capacity, the ability to innovate, and overcoming production obstacles. The wood processing industry must stay efficient and innovative to keep up with market demands. Challenges in production capacity or technological limitations can hinder growth and impact the availability of processed wood products for furniture manufacturing.

In the wooden furniture sales and recycling subsystem, it focuses on logistics efficiency and consumption capacity, especially targeting customers in foreign markets. The number of foreign enterprises involved and any sales barriers can significantly impact how the furniture is distributed and sold. Efficient logistics and an understanding of customer needs are crucial for success in this subsystem.

These subsystems are not isolated; they interact and influence each other. If the wood import supply subsystem faces delays, the wood processing and manufacturing subsystem might not have enough raw materials, causing production delays. This in turn would affect the sales subsystem, where inventory shortages could lead to lost sales or missed opportunities in the market. Conversely, changes in the sales subsystem, such as a sudden increase in demand, may put pressure on the wood processing and import supply subsystems to increase output and capacity.

By modeling this system using system dynamics, we can simulate different scenarios to understand how these feedback loops work. The dynamic and interconnected nature of this system emphasizes the importance of managing each subsystem efficiently and recognizing how changes in one part of the system can cascade throughout the entire supply chain. The detailed dynamic interactions are shown in the following causality diagram.

Causality diagram

The main feedback loops of the model are shown in Fig. 2, where the wood import supply subsystem is represented in blue, the wood processing and manufacturing subsystem in red, and the sales and recycling subsystem in green. In this model, the GDP of Heilongjiang Province is considered as one of the key variables influencing the upstream and downstream of the supply chain40. On one hand, GDP can capture changes in the wood industry at the macroeconomic level, effectively reflecting the overall health of the regional economy. Strong economic growth may enhance the risk resilience of the entire wood industry, while an economic recession may weaken the resilience of the supply chain. On the other hand, fluctuations in economic output are strongly correlated with supply chain resilience, directly affecting various links in the supply chain. This helps to understand the supporting role of the wood industry in the economy of Heilongjiang Province, as well as the performance of the wood supply chain at different economic levels.

Additionally, considering data availability and reliability, compared to more industry-specific or hard-to-quantify variables, GDP, as a macroeconomic indicator, can comprehensively reflect the performance of various industries, making it easier to provide a stable and traceable core variable for the model. Table 1 shows the causal chains of the main causal loops and exogenous variables. Among them, positive loop as R, negative loop as B, and exogenous causal linkage as E.

For the wood import supply subsystem, the primary source of wood raw materials in Heilongjiang Province comes from imports, and logistics is a critical link in ensuring the supply of imported wood. The level of logistics directly affects the efficiency and effectiveness of the wood import supply subsystem. Taking Heilongjiang Province’s GDP as an indicator, this subsystem considers the dual impact of logistics capacity and wood import trade, analyzing the factors influencing both. The main feedback loops are as follows:

R1: GDP of Heilongjiang Province → (+) Volume of Wood Imports → (+)Wood Supply Growth→ (+) Production Value of the Wooden Furniture → (+) GDP of Heilongjiang Province;

R2: GDP of Heilongjiang Province → (+) Investment in Transportation Networks/Warehousing→ (+) Logistics Hard Power Factors → (+) Wood Supply Volume → (+) Production Value of the Wooden Furniture → (+) GDP of Heilongjiang Province;

R3: GDP of Heilongjiang Province → (+) Logistics Information Networks Index/ Logistics Talent Efficiency Index→ (+) Logistics Soft Power Factors→ (+) Logistics Supply Volume → (+) Production Value of the Wooden Furniture → (+) GDP of Heilongjiang Province;

R4: GDP of Heilongjiang Province → (+) Wood Supply Volume→ (+) Production Value of the Wooden Furniture → (+) GDP of Heilongjiang Province;

B1: Volume of Wood Imports → (-)Wood Supply Volume→ (+)Furniture Freight Conversion Volume →(+) Production Value of the Wooden Furniture → (+) GDP of Heilongjiang Province;

E1: Port Service Capacity Factors→ (+) Volume of Wood Imports → (-)Wood Supply Volume →(+) Production Value of the Wooden Furniture → (+) GDP of Heilongjiang Province;

E2: Import Barriers→ (-) Volume of Wood Imports → (-)Wood Supply Volume →(+) Production Value of the Wooden Furniture → (+) GDP of Heilongjiang Province.

For the wood processing and manufacturing subsystem, it focuses on the impact of Heilongjiang Province’s GDP on the furniture manufacturing industry. Fixed asset investments in the furniture manufacturing industry increase R&D spending, while supportive policies stimulate industry growth. Automation, power stability, and renewable energy utilization effectively enhance manufacturing efficiency. The main feedback loops are as follows:

R5: GDP of Heilongjiang Province → ( +)Furniture Industry Investment Coefficient → ( +) Production Value of the Wooden Furniture → ( +) GDP of Heilongjiang Province ;

R6: GDP of Heilongjiang Province → ( +)Furniture Manufacturing Conversion Efficiency ( +) Production Value of the Wooden Furniture → ( +) GDP of Heilongjiang Province ;

B2: Production Value of the Wooden Furniture → (-)Production Sales Discrepancy (-) GDP of Heilongjiang Province ;

E3: Production Barriers → (-) Production Value of the Wooden Furniture → ( +)Production Sales Discrepancy → ( +) GDP of Heilongjiang Province.

For the wooden furniture sales and recycling subsystem, it uses Heilongjiang Province’s GDP as an indicator to analyze its impact on the furniture sales industry. As a downstream sector of the real estate industry and an essential product, furniture demand increases with the growth of the target customer base driven by GDP growth in Heilongjiang Province, ultimately boosting corporate revenue. Simultaneously, the improved purchasing power of target customers further stimulates furniture demand. The main feedback loops are as follows:

R7: GDP of Heilongjiang Province → ( +) Growth of Furniture Enterprises → ( +) Sales Value of the Wooden Furniture → ( +) GDP of Heilongjiang Province.

R8: GDP of Heilongjiang Province → ( +) Target Customer Consumption Growth → ( +) Sales Value of the Wooden Furniture → ( +) GDP of Heilongjiang Province.

E4: Sales Barriers → (-) Sales Value of the Wooden Furniture → ( +)Production Sales Discrepancy → ( +) GDP of Heilongjiang Province;

E5: Volume of Target Customer → ( +) Target Customer Consumption Growth → ( +)Sales Value of the Wooden Furniture → ( +) GDP of Heilongjiang Province.

Additionally, external variables are introduced to account for negative impacts on the system.

Stock and flow diagram

Based on a thorough analysis of the factors influencing the three subsystems and their interactions, a unified dynamic system is constructed. This system integrates the feedback mechanisms of the subsystems, forming a total stock-flow model for the wood supply chain in Heilongjiang Province. The goal is to comprehensively reflect the operational dynamics and internal workings of the wood supply chain in the province, as shown in Fig. 3. Data was collected from sources such as the Heilongjiang Provincial Statistical Yearbook, the China Logistics Statistical Yearbook, and the China Forestry Statistical Yearbook. Using literature research, regression analysis, and statistical prediction methods, the nonlinear relationships between variables were analyzed. The optimal parameter configuration was determined by setting initial model parameters and applying an experimental optimization search method.

The model simulates the period from 2012 to 2035 and includes seven key stock variables: wood import capacity, number of furniture enterprises, GDP, total target customer base, volume of the wood supply, volume of the furniture production, and volume of the furniture sales. It also incorporates thirteen flow variables, which represent factors such as economic growth, improvement in logistics, wood import consumption, furniture production growth, and sales growth, as well as changes in the target customer base and the number of enterprises. Additionally, the model includes a range of auxiliary variables.

The state equations describing the system behavior in the model are represented using following difference equations:

where \(X(t)\) represents the value of the state variable at time \(t\), \(F[x(t),p]\) is the rate variable at time \(t\), and \(dt\) is the simulation time step.

The detailed variable formulas used in the model are provided in Supplementary Table S1.

Model validity check

Historical check

To ensure the reliability of the system dynamics model for the wood supply chain in Heilongjiang Province, this study compares the historical data for total GDP, wood supply capacity, and the total target customer base in the province from 2012 to 2021 with the model’s output41,42. A reliability test is conducted by calculating the deviation rate between the historical values and the model results. The analysis shows that the relative error of the model output is within an acceptable range, indicating that the simulation model accurately reflects the actual operation of the system. The stock error rates are presented in Table 2.

Stability check

To verify the reliability of the system dynamics model for the wood supply chain in Heilongjiang Province, we conducted extreme condition tests43. The initial value of logistics supply capacity was set to 0 to simulate a scenario where logistics transportation is completely stalled at the initial stage. The simulation results (Fig. 4) show that the model remains stable under extreme conditions, demonstrating its robustness and accuracy.

Case Study

Background of Heilongjiang Province

This study focuses on Heilongjiang Province, a critical hub for wood production and processing in China. The province’s wood furniture industry holds a prominent position in both domestic and international markets. However, the resilience of its wood supply chain is increasingly affected by factors such as raw material fluctuations, environmental regulations, market uncertainties, and changes in global trade. Identifying these influencing factors is essential for improving the adaptability and sustainability of the region’s wood supply chain.

Analysis of resilience factors in the wood supply chain system

In the wood supply chain system, infrastructural resilience, economic resilience, and ecological resilience factors play critical roles within each subsystem. This section explores key resilience factors in each subsystem and their impact on the overall resilience of the wood supply chain. The analysis identifies critical factors by comparing the basic operations of each subsystem and the extent to which these factors contribute to the growth of system stocks.

Sensitivity analysis in the wood import supply subsystems

The experimental results result (Fig. 5) show that the resilience factors related to infrastructure have a significant impact, especially the construction of digital information networks. There has a well-established physical infrastructure for transportation, warehousing, and ports, and the import of wood raw materials is supported by tax reduction policies. However, the digital capability remains weak. The development of an informatized network has the potential to provide significant support for the growth of Heilongjiang’s wood supply chain. The logistics information network connects the upstream and downstream of the supply chain, enabling real-time tracking of wood transportation, inventory, and demand. It reduces delays and errors, optimizing procurement, transportation, and inventory management. Imported wood faces challenges such as international shipping, customs clearance, and regional policies, which the network can help manage through transparent data.

The transportation network is essential for moving wood from import ports to processing plants and distribution centers, especially in vast areas like Heilongjiang. Most wood enters via Cross-border port, such as Suifenhe and Manzhouli. The transportation network integrates railways, highways, and waterways for efficient transport. Heilongjiang’s harsh winter climate requires network optimization to ensure year-round transportation. An efficient network aids regional industrial coordination, facilitating the swift movement of wood and supporting the growth of the wood processing industry.

Warehousing facilities are crucial for storing, sorting, and distributing wood. Investment in these facilities enhances supply chain resilience and flexibility. Fluctuations in market prices, transportation, and policies can cause supply instability, but adequate warehouses buffer these fluctuations. Modern facilities, such as temperature-controlled warehouses, protect wood from weather-related damage. Regional warehousing centers reduce response times and improve distribution efficiency.

In summary, logistics networks, transportation, and warehousing form the backbone of the import subsystem, boosting the supply chain’s ability to handle emergencies. An efficient import system supports Heilongjiang’s wood processing and furniture industries, driving economic growth. Information networks reduce resource waste, while optimized transport and warehousing cut carbon emissions, promoting sustainable supply chain development.

Sensitivity analysis in the wood processing and manufacturing subsystems

The experimental results (Fig. 6) show that in the processing and manufacturing subsystem of Heilongjiang’s wood supply chain, both manufacturing conversion efficiency and logistics conversion efficiency are crucial to the overall success of the supply chain. In contrast, the impact of furniture R&D investment policies and hindering factors, such as malicious competition, is relatively small. Manufacturing efficiency involves several key factors, such as stable electricity supply, automation levels, and clean energy use efficiency. These factors collectively determine the production capacity, cost, and environmental impact of the manufacturing process. A stable electricity supply reduces energy consumption and equipment wear, thereby lowering maintenance and operational costs. High levels of automation can significantly improve production efficiency, reducing reliance on a large workforce, especially in Heilongjiang, where labor costs are rising each year. At the same time, it helps address complex production demands and adapt to changes in both domestic and international markets. As an ecologically sensitive area, Heilongjiang’s use of clean energy aligns with both international and domestic policy directions, helping companies gain policy support and tax incentives, while enhancing their corporate image.

Logistics conversion efficiency refers to the logistics support capacity in transforming raw wood materials into finished products, including the efficiency of raw material delivery, semi-finished product flow, and finished product distribution. It acts as a bridge in the processing and manufacturing subsystem, ensuring the timely supply of materials and preventing production disruptions. It also helps shorten production cycles and reduce quality losses during the flow of materials. Additionally, efficient logistics optimizes inventory management, reduces inventory backlog, and lowers inventory holding costs. By improving the flow rate of semi-finished and finished products, it also reduces carbon emissions during transportation. At the same time, high logistics efficiency ensures that wood processing enterprises can quickly respond to market demand and achieve flexible manufacturing with small batches and multiple varieties.

Due to the long investment return cycle and low level of industry chain integration in the wood processing and manufacturing sector, the policy support for research and development investments in furniture has a limited impact on the wood supply chain.

Sensitivity analysis in the wooden furniture sales and recycling subsystems

The experiment result (Fig. 7) shows that in the sales and recycling subsystem of Heilongjiang’s wood supply chain, the coordination of residential consumption and the scale of the trading market are key to the supply chain’s success. Residential consumption coordination refers to the alignment between consumer demand (domestic and international) and market supply. This includes balancing consumption capacity, preferences, and supply-demand dynamics. Proper coordination impacts downstream demand and influences upstream production and resource allocation. It helps Heilongjiang’s wood industry move toward high-value products, driving improvements in production technology and product structure. Demand is highly influenced by fluctuations in real estate, furniture manufacturing, and exports. Consumer coordination can reduce market volatility by diversifying demand, such as interior materials and custom furniture. By analyzing consumption trends, companies can better predict demand, preventing product overstock and material waste. It also helps expand Heilongjiang’s wood industry into high-end markets, attracting more consumers and boosting regional brand development.

The trading market scale affects transaction efficiency, cost optimization, and coordination across the supply chain. In Heilongjiang, a large-scale market is vital for resource flow and industry expansion. It serves as a key trade corridor for wood between China and Russia. A large market attracts international buyers, raising China’s position in the global wood market. From logging to processing and downstream markets, an efficient market is essential. Larger markets bring together more buyers and sellers, improving efficiency. They also overcome the fragmentation of small markets, enabling bulk transactions and reducing costs. Transparent pricing benefits small and medium enterprises by providing reasonable access to resources. Heilongjiang can use its resource advantages to build an integrated market, uniting the entire industry chain. A large-scale market can quickly adjust supply and demand in case of disruptions, reducing reliance on external markets and improving resilience.

Scenario analysis

To evaluate the impact of resilience factors in the subsystems on the wood supply chain in Heilongjiang Province, this section uses the initial simulation results as a baseline. Multi-factor simulation experiments are conducted using localized Monte Carlo simulations to identify the key resilience factors influencing system operation. Sensitivity analysis is then carried out by adjusting the values of specific factors while keeping others constant. The results before and after these adjustments are compared to determine how these changes affect the system’s overall behavior and state. This method provides a clearer understanding of the role and influence of each resilience factor in the wood supply chain system.

Impact of changes in information network

In the wood supply chain, overseas raw material supply has a dual impact on the resilience of the wood supply chain in Heilongjiang Province. On one hand, it enhances price competitiveness and introduces advanced technology and management practices by diversifying supply sources. On the other hand, it increases the complexity and management challenges of the supply chain, along with political and economic risks such as trade conflicts, exchange rate fluctuations, and customs clearance inefficiencies. Local Monte Carlo experiments indicate that the logistics information network significantly affects the wood supply chain within the wood import supply subsystem. To analyze its influence on various segments of the wood supply chain and the production-to-sales ratio, a simulation was conducted by adjusting the logistics information network index by ±10%. The results, shown in Fig. 8a–d, reveal that the red line (original) represents the baseline, while the blue and green lines indicate increases and decreases of 10%, respectively. The findings show that enhancing the logistics information network has a notable impact across all segments, particularly in improving production efficiency and the production-to-market ratio.

These results highlight the need to strengthen upstream and downstream coordination within the wood supply chain in Heilongjiang Province. Due to delays in information transmission and goods flow, supply chain members at different levels struggle to access accurate demand information in real-time. This results in demand distortion during transmission, which reduces the overall efficiency of the supply chain. For the wood processing industry, which is primarily composed of small and medium-sized enterprises, improving the logistics information network and adopting modern information technology are critical steps. These measures can enhance responsiveness to market changes, reduce inventory backlogs, and improve transportation quality.

In conclusion, enhancing supply chain coordination and improving the efficiency of information flow are key priorities for optimizing wood supply chain management in Heilongjiang Province in the future.

Impact of changes in manufacturing efficiency

The wood processing and furniture manufacturing stage is critical in the supply chain, connecting upstream and downstream activities. Effective management and risk planning at this stage are essential for leveraging the advantages of overseas raw material supply and addressing potential risks in downstream sales. This stage also enhances the overall resilience of the supply chain. Collaboration with overseas suppliers introduces new business models and innovative ideas, promoting upgrades in supply chain management and operations. By adopting advanced wood processing technologies and management practices from overseas partners, local companies can improve both production efficiency and product quality. Local Monte Carlo experiments reveal that Manufacturing Efficiency significantly affect the wood processing and manufacturing subsystem, directly impacting the efficiency of wood resource conversion. To analyze this, Manufacturing Conversion Efficiency were adjusted by ±10% in the simulation. The results, shown in Fig. 9a–d, compare three scenarios: the baseline (red line), a 10% increase (blue line), and a 10% decrease (green line). The findings show that higher Manufacturing Conversion Efficiency greatly enhance the production chain and improve the production-to-sales ratio. Increased Manufacturing Efficiency strengthens the system’s feedback mechanisms, creating larger positive effects and boosting overall system performance.

However, the impact of production-related factors in the wood processing subsystem on upstream and downstream activities is relatively weak. This indicates that the wood supply chain in Heilongjiang requires stronger coordination between its upstream and downstream components. To achieve this, an information-sharing platform must be established across the entire supply chain. Such a platform would improve transparency and ensure efficient communication at every stage. Therefore, optimizing the wood supply chain’s overall performance requires collaboration among all participants to create an effective synergy mechanism.

Impact of changes in consumption coordination

The sales of wooden furniture are heavily influenced by the consumption levels of target customer groups and the market adaptability of wood enterprises. Heilongjiang Province’s favorable geographic location enables it to export finished furniture to Russia and other European countries. The diverse needs of these markets require studying how overseas markets affect sales risk diversification and identifying ways to improve market adaptability. Local Monte Carlo experiments show that the degree of consumption coordination significantly impacts the wood supply chain. In the simulation, the consumption coordination degree was adjusted by ±10%, with results shown in Fig. 10a–d. The red line represents the baseline, while the blue and green lines indicate a 10% increase and decrease, respectively.

The results reveal that increasing consumption coordination among target customer groups leads to a significant rise in sales. This suggests that better regional consumption coordination enhances the purchasing power of target customers and creates a more favorable sales environment. The impact on furniture spending and the production-to-sales ratio is moderate and stable. However, a sharp increase in consumption may create a surge in demand, while the production chain may lag in responding to this growth. This imbalance could make it harder to meet market demand, negatively affecting the production-to-sales ratio. Therefore, improving consumption coordination must be paired with strengthening the production chain’s backup capacity to ensure a balance between production and sales.

In addition, effective demand forecasting and management are essential. It is important to monitor fluctuations in market demand across different regions and assess their impact on supply chain stability. Trade policies and environmental regulations in export markets must also be considered. Strategies for growth include strengthening brand development, expanding market reach, and improving the international competitiveness of wooden furniture from Heilongjiang Province in both domestic and global markets.

The interactions among resilience factors

The interaction between infrastructure resilience and economic resilience

In the wood supply chain of Heilongjiang Province, a strong interactive relationship exists between infrastructure resilience and economic resilience. A robust and efficient network of transportation, warehousing, and information systems ensures the smooth flow of wood raw materials and finished products within and beyond the region, playing a critical role in maintaining the continuity and stability of cross-border supply chains. This in turn enhances the capacity to withstand and recover from disruptions. At the same time, the long-term economic foundation and industrial agglomeration of Heilongjiang’s wood sector provide sufficient resources to support continuous investment in and modernization of infrastructure. Through the coordinated operation of logistics and information flows, along with implicit coupling mechanisms such as policy guidance and industrial collaboration, these two dimensions jointly establish a risk response and adjustment system characterized by systemic resilience. This synergy ultimately promotes the development of a more resilient wood supply chain at a higher level.

The interaction between economic resilience and ecological resilience

Under the guidance of the carbon neutrality strategy, the wood import–oriented supply chain structure in Heilongjiang Province places higher demands on the coordination between regional economic resilience and ecological resilience. On the one hand, reliance on imported wood helps alleviate the pressure of overexploitation on local forest resources, creating favorable conditions for forest ecosystem restoration and sustainable management. This, in turn, enhances ecological resilience and provides critical ecological support for realizing forest carbon sink functions. On the other hand, the heavy dependence on overseas wood supply exposes vulnerabilities within the supply chain. Geopolitical tensions, trade barriers, and disruptions in transportation can lead to unstable raw material supply, threatening the continuity of industrial operations and the robustness of the regional economy. In this context, economic resilience contributes to ecological resilience by ensuring sustained investment in green infrastructure, carbon emissions management, and ecological compensation mechanisms. Conversely, ecological resilience lays a natural foundation for the long-term sustainability of the supply chain. Through their co-evolution, these two dimensions jointly support the development of forestry economy.

The integrated impact of infrastructure, economic, and environmental resilience

In the context of the development of Heilongjiang’s wood industry, there is a strong interconnection and coupling among infrastructure resilience, economic resilience, and environmental resilience. On one hand, the stable operation of infrastructure systems is essential for ensuring the efficient functioning of the wood supply chain and the smooth flow of cross-border trade. This stability enhances the industry’s ability to respond to external shocks and improves resource allocation efficiency, thereby strengthening the pressure resistance and recovery capacity of the economic system. On the other hand, enhanced economic resilience is reflected not only in the flexibility and adaptability of the industrial chain but also in its ability to provide sustained financial and technological support for infrastructure investment and green upgrades. Meanwhile, as the "carbon peaking and carbon neutrality" strategy progresses, rising demands for ecological protection is driving the wood industry to prioritize environmental resilience alongside economic gains, through measures such as green manufacturing and sustainable forest management. These three dimensions interact through a cyclical mechanism of resource security, economic feedback, and environmental constraints, forming a dynamic adjustment system.

Discussions and limitations

The wood supply chain is a complex and dynamic system influenced by multiple interacting factors, making long-term trend prediction inherently challenging. Based on the specific context of Heilongjiang Province, this study develops a system dynamics model to simulate the long-term impact of key resilience factors and assess how changes in these factors affect the coordination between production and sales through multiple policy scenarios. This study further underscores the systemic nature of supply chain resilience, particularly highlighting the importance of feedback mechanisms and cross-sectoral coordination, which is consistent with existing literature. However, unlike previous studies that often focus on a single dimension such as logistics or policy, this research develops a holistic system dynamics model tailored to the specific regional context. In doing so, it responds to the growing academic call for place-based and integrated approaches to resilience assessment in resource-dependent industries, thereby enriching the research in this field.

From a theoretical perspective, this study examines the wood supply chain through three key dimensions, aiming to reveal the feedback relationships among infrastructure, economic and ecological resilience. Sensitivity analysis identifies critical variables affecting coordination performance and informs strategies for resilience improvement. From a practical standpoint, the model, grounded in real-world data, supports policymaking by enabling dynamic evaluation of policy effects and long-term development trends. The simulation results highlight potential coordination risks, such as reliance on imported raw materials, low digitalization, outdated production technologies, and production-consumption imbalances, which should be prioritized in resilience planning.

It is important to note that the model represents a methodological choice that emphasizes measurable variables commonly used in system dynamics. Although this approach simplifies certain socio-technical complexities, it offers a clear and structured framework for examining key interactions within the system. As an exploratory study, it does not seek to produce precise forecasts. Future research may integrate qualitative stakeholder data to better capture behavioral and institutional dynamics, thereby enhancing the depth and robustness of the model.

Conclusions

The findings highlight the critical role of resilience factors in the transnational wood supply chain, especially in Heilongjiang Province. This study develops a system dynamics model to analyze interactions among key components, including wood import supply, processing, manufacturing, and furniture sales. The simulation results underscore the dual impact of overseas raw material supply, emphasizing both its benefits in terms of advanced technology and management practices, as well as the challenges it introduces, such as increased complexity and logistical dependencies. This suggests globalization offers advantages but requires strong risk management to mitigate disruptions.

A key insight is the importance of logistics and information flow in enhancing resilience. Monte Carlo experiments reveal delays in information and cargo flow distort demand data, reducing efficiency. This aligns with literature emphasizing digital technologies like blockchain and IoT for improving transparency and responsiveness. For Heilongjiang, which relies heavily on transnational logistics, investing in advanced logistics platforms and modern technologies is crucial. Governments can promote regional collaboration by establishing wood circulation platforms to optimize resource allocation and coordination.

The study also highlights the critical role of manufacturing efficiency in wood processing. While improvements enhance resource conversion and system performance, the limited impact on upstream and downstream links indicates a need for better supply chain coordination. Enhancing resilience requires internal optimization and stronger collaboration with overseas suppliers and downstream partners. Such collaboration can introduce innovative business models and advanced technologies, improving product quality and market responsiveness. Wood producers should also cooperate with research institutions to stay informed about policy changes and technological advancements, driving innovation and optimizing production. Flexible manufacturing systems and modular equipment can help production lines adapt quickly to market changes, enabling flexible switching of furniture types and specifications.

In the furniture sales stage, sensitivity to market fluctuations highlights the importance of demand forecasting and management. Simulation results show improving consumption coordination among target customer groups strengthens resilience and increases the production-to-sales ratio. However, Heilongjiang’s furniture trade deficit underscores the need to boost export capacity and attract foreign investment. Strengthening production backup capacity and considering trade policies and environmental regulations in export markets are essential for maintaining production-sales balance. Wholesalers and retailers should develop localized marketing strategies to meet consumer needs. For example, participating in international trade exhibitions can help expand overseas markets and build partnership.

Data availability

The datasets used and analyzed during the current study available from the corresponding author on reasonable request.

References

Han, Y., Ma, C., Li, C. & Shao, X. Research on sustainable supply chain optimization of wood processing enterprises in Heilongjiang. Forest Eng. 5, 137–144 (2021).

Hosseini, S., Ivanov, D. & Dolgui, A. Review of quantitative methods for supply chain resilience analysis. Transport. Res. E-log. 125, 285–307 (2019).

Cheng, Y., Elsayed, E. A. & Huang, Z. Systems resilience assessments: a review, framework and metrics. Int. J. Prod. Res. 60, 595–622 (2022).

Hayek, M., Mahringer, G., Segner, R., Landschützer, C. & Sihn, W. Development of a Physical Internet container for an optimized wood supply chain. Transp. Res. Proc. 72, 1950–1957 (2023).

Susanty, A., Sari, D. P. & Budiawan, W. Improving green supply chain management in furniture industry through internet based geographical information system for connecting the producer of wood waste with Buyer. Proc. Comput. Sci. 83, 734–741 (2016).

Longo, F., Mirabelli, G. & Solina, V. A simulation-based framework for manufacturing design and resilience assessment: A case study in the wood sector. Appl. Sci. 12, 7614 (2022).

Auer, V. & Rauch, P. Wood supply chain risks and risk mitigation strategies: A systematic review focusing on the Northern hemisphere. Biomass Bioenergy 148, 106001 (2021).

Habibi, F., Chakrabortty, R. K. & Abbasi, A. Evaluating supply chain network resilience considering disruption propagation. Comput. Ind. Eng. 183, 109531 (2023).

Ioannidou, D., Pommier, R. & Habert, G. Evaluating the risks in the construction wood product system through a criticality assessment framework. Resour. Conserv. Recy. 146, 68–76 (2019).

Suong, H. T. T. Factors impacting on the supply chain collaboration of the furniture industry in Vietnam. J. Asian. Finan. Econ. 4, 67–77 (2017).

Azadegan, A. & Dooley, K. A typology of supply network resilience strategies: complex collaborations in a complex world. J. Supply Chain Manag. 57, 17–26 (2021).

Shahriari, K., Hessami, A. G. & Jadidi, A. An approach toward a conceptual collaborative framework based on a case study in a wood supply chain. IEEE Syst. J. 9, 1163–1172 (2015).

Liu, Z., Hansen, D. W. & Chen, Z. Leveraging digital twins to support industrial symbiosis networks: A case study in the Norwegian wood supply chain collaboration. Sustainability 15, 2647 (2023).

Gao, Q., Xu, H. & Li, A. The analysis of commodity demand predication in supply chain network based on particle swarm optimization algorithm. JCoAM 400, 113760 (2022).

Gholian-Jouybari, F., Hashemi-Amiri, O. & Mosallanezhad, B. Metaheuristic algorithms for a sustainable agri-food supply chain considering marketing practices under uncertainty. Expert Syst. Appl. 213, 118880 (2023).

Ivanov, D. Intelligent digital twin (iDT) for supply chain stress-testing, resilience, and viability. Int. J. Product. Econ. 263, 108938 (2023).

Hoeben, A. D. et al. Stakeholder views of adaptation measures to improve climate resilience: Case study evidence from European wood value chains. Forest Policy Econ. 170, 103379 (2025).

Stopfer, L., Kaulen, A. & Purfürst, T. Potential of blockchain technology in wood supply chains. Comput. Electron. Agric. 216, 108496 (2024).

Xu, B. et al. Resilience measurement and dynamic optimization of container logistics supply chain under adverse events. Comput. Ind. Eng. 180, 109202 (2023).

Zhou, L., Tang, C. & Cao, Y. Innovative human capital, government support for science and technology policy, and supply chain resilience. Financ. Res. Lett. 74, 106741 (2025).

Hisjam, M., Guritno, A. D. & Supriyatno, N. A sustainable partnership model among supply chain players in wooden furniture industry using goal programming. Agric. Agric. Sci. Procedia. 3, 154–158 (2015).

Brusset, X., Ivanov, D. & Jebali, A. A dynamic approach to supply chain reconfiguration and ripple effect analysis in an epidemic. Int. J. Product. Econ. 263, 108935 (2023).

Li, H., Dong, L. & Liu, Z. Prediction of sustainable development level of maoershan forest farm based on system dynamics. Forest Eng. 0(1), 11–20 (2023).

Guzzo, D., Pigosso, D. C. A. & Videira, N. A system dynamics-based framework for examining Circular Economy transitions. J. Clean. Prod. 333, 129933 (2022).

Taheri, N., Jahani, H. & Pishvaee, M. S. Modeling sustainable bioethanol supply chain in Australia: A system dynamics approach. Renew. Energy 22, 120481 (2024).

Hamed, M. M., Turan, H. H. & Elsawah, S. Balancing supply diversification and environmental impacts: A system dynamics approach to de-risk rare earths supply chain. Resour. Policy 92, 105038 (2024).

Jahani, H., Gholizadeh, H., Hayati, Z. & Fazlollahtabar, H. Investment risk assessment of the biomass-to-energy supply chain using system dynamics. Renew. Energy 203, 554–567 (2023).

Ivanov, D. Revealing interfaces of supply chain resilience and sustainability: a simulation study. Int. J. Prod. Res. 56, 3507–3523 (2018).

Agarwal, N., Seth, N. & Agarwal, A. Evaluation of supply chain resilience index: a graph-theory based approach. Benchmarking. 29, 735–766 (2022).

Izadikhah, M., Azadi, M. & Toloo, M. Sustainably resilient supply chains evaluation in public transport: A fuzzy chance—constrained two-stage DEA approach. Appl. Sof. Comput. 113, 107879 (2021).

Lou, G. et al. Resilience assessment of the electric vehicle lithium-ion battery supply chain under supply shortages of upstream mineral enterprises. Resour. Conserv. Recycl. 215, 108161 (2025).

Alizadeh-Meghrazi, M., Tosarkani, B. M. & Amin, S. H. Design and optimization of a sustainable and resilient mask supply chain during the COVID-19 pandemic: A multi-objective approach. Environ. Dev. Sustain. 2022, 1–46 (2022).

Kline, K. L., Dale, V. H. & Rose, E. Resilience lessons from the southeast united states woody pellet supply chain response to the COVID-19 pandemic. Front. For. Glob. Chang. 4, 674138 (2021).

Emmanuel-Yusuf, D., Morse, S. & Leach, M. Resilience and livelihoods in supply chains (RELISC): An analytical framework for the development and resilience of the UK wood fuel sector. Sustainability 9, 660 (2017).

Asada, R., Hurmekoski, E. & Hoeben, A. D. Resilient forest-based value chains? Econometric analysis of roundwood prices in five European countries in the era of natural disturbances. Forest. Policy. Econ. 153, 102975 (2023).

Belhadi, A., Kamble, S. & Jabbour, C. J. C. Manufacturing and service supply chain resilience to the COVID-19 outbreak: Lessons learned from the automobile and airline industries. Technol. Forecast. Soc. 163, 120447 (2021).

Larsson, M., Stendahl, M. & Roos, A. Supply chain management in the Swedish wood products industry—A need analysis. Scand. J. Forest. Res. 8, 777–787 (2016).

Dubey, R., Bryde, D. J. & Dwivedi, Y. K. Dynamic digital capabilities and supply chain resilience: The role of government effectiveness. Internat. J. Prod. Econ. 258, 108790 (2023).

Ayyildiz, E. Interval valued intuitionistic fuzzy analytic hierarchy process–based green supply chain resilience evaluation methodology in post COVID-19 era. Environ. Sci. Pollut. R. 30, 42476–42494 (2023).

Tao, M., Zhao, Y., Jiang, Q., Wang, Z. & Wu, Y. Study on the nonlinear transition relationship between water resources consumption and economic development in Heilongjiang province based on system dynamics. J. Hydrol. Reg. Stud. 57, 102193 (2025).

Feng, Y., Liu, B. & Yan, Q. Forecasting research on urban green development based on system dynamics—A case study of Hefei in China. Systems 12, 109 (2024).

Hu, W. et al. Using system dynamics to analyze the development of urban freight transportation system based on rail transit: A case study of Beijing. Sustain. Cities Soc. 53, 101923 (2020).

Arasteh, M. A. & Farjami, Y. New hydro–economic system dynamics and agent–based modeling for sustainable urban groundwater management: A case study of Dehno, Yazd Province. Iran. Sustain. Cities Soc. 72, 103078 (2021).

Acknowledgements

We are grateful to the Special Funds for the Basic Research Operating Costs of the Central Universities, the Natural Science Foundation of Heilongjiang Province, and the National Natural Science Foundation of China for the financial support of the project.

Funding

Funded by the Heilongjiang Provincial Natural Science Fund (LH2023G002); Funded by the Special Funds for Basic Research Operating Costs of Central Universities (2572022BL02).

Author information

Authors and Affiliations

Contributions

Wood Supply Chain and Model Conceptualization, C.M. and L.Z.; System Dynamics Modeling, C.M. and L.Z.; Software, L.Z.; Validation, X.G. and L.Z.; Model Analysis, L.Z.; Surveys, L.Z. and C.L.; Data Collation, X.G. Writing-Original Draft Preparation, C.M. and L.Z.; Writing-Review and Editing, C.M. and L.Z; Visualization, L.Z.; Supervision, C.L.; Project Management, C.M.; Funding Acquisition, C.M.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ma, C., Zhang, L., Gao, X. et al. Modelling and evaluating wood supply chain resilience factors based on system dynamics. Sci Rep 15, 16207 (2025). https://doi.org/10.1038/s41598-025-00669-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-00669-0