Abstract

In this work, the synthesis of smart hosting materials from modified gelatin with different fatty acids (myristic acid, palmitic acid, and stearic acid) has been observed and characterized. Coconut oil was used as a natural phase change material (PCM) and octadecanol was used as an organic phase change material. Different concentrations of Phase change materials were impregnated in modified gelatin and applied to cotton and/or dyed cotton fabric with reactive dye. The treatment process was done using two methods, first method, the fabric was pre-treated with PCM composite and then dyed with reactive dye solution, and second method, the fabric was dyed with reactive dye solution and then treated with PCM composite. Smart PCM composite based on modified gelatin produced thermo-regulating properties which are responsible for controlling body temperature. The gelatin/PCM composite and treated cotton fabric were characterized using DSC, FT-IR, and SEM. The results confirmed the synthesis of modified gelatin and also confirmed its reaction with the cotton surface. DSC results showed that the treated cotton fabric with coconut oil composite has the best thermo-regulating properties.

Similar content being viewed by others

Introduction

Smart fabrics have grown in popularity during the previous decade. New materials have been produced to attain high performance characteristics. Phase change materials (PCMs) are novel substances that are incorporated into textile structures to obtain a thermoregulated fabrics. PCMs are thermal energy storage (TES) materials that can store and release large amounts of latent heat during phase change. There are many kinds of PCMs have been synthesized, including organic and inorganic1 and investigated for a variety of applications such as buildings2, thermal protection3, textiles4,5,6, etc.7,8,9.

The most common problems with PCM materials during use are melting and leaking. Therefore, a hosting material has been developed for their benefit in order to retain the PCMs within its network. There are many different types of hosting materials, some of them have very long side chains that keep PCMs between them and enabling them to perform their functions without leaking. These hosting materials can be chemically or physically attached to the surface. Thus, chemically bonded hosting materials are more preferable since they make the surface permanently treated10,11.

PCMs used in textiles are typically microencapsulated into a polymer to avoid material leakage in a liquid condition12. Microencapsulation might take place through physical coating methods or chemical methods. Although urea formaldehyde, styrene, polyurethane, melamine formaldehyde, methacrylate, and its copolymers are commonly employed as shell materials in PCM microencapsulation, they could lead to health and environmental issues13,14. To tackle this problem, many studies have investigated natural polymers as alternative shell to retain the PCMs within their network.

One of the important natural polymers is gelatin. Gelatin is a polypeptide with a high molecular weight which is non-toxic and biodegradable15,16. Gelatin is a soluble protein compound formed when collagen is partially hydrolyzed17. Gelatin is made up of eighteen different amino acids, the three most prevalent amino acids in gelatin are proline, hydroxyproline, and glycine. These amino acids form polypeptide chains when they combine. There are more than a thousand amino acids in these polypeptide chains (Fig. 1)18,19.

Linear long chain hydrocarbon paraffin waxes, polyethylene glycols, fatty acids, and their mixtures are PCMs that can be used in textiles12,20,21,22. Coconut oil has a high latent heat capacity for TES and it has received little attention in the studies, particularly for textile applications. Coconut oil is a natural source that is derived commercially from copra, which is the flesh of a coconut. From coconut milk, virgin coconut oil is extracted. Coconut oil contains a significant concentration of low molecular weight saturated fatty acids, mostly from lauric oil. Virgin coconut oil includes 46–48% lauric acid and the rest is made up of myristic acid, stearic acid, caproic acid, capric acid, linoleic acid, and caprylic acid23. These fatty acids that was found in coconut oil have some merits, such as congruent melting, high latent heat storage capacity, suitable phase change temperature range, favorable thermal and chemical stability, non-toxic and non-flammability1.

The goal of this study was to investigate the usage of organic coconut oil as a natural PCM for textile applications as a low-cost, sustainable alternative to presently utilized PCMs like paraffin waxes by contrasting them with those of recognized PCMs (octadecanol) and the usage of gelatin as a bio-hosting material to keep the PCMs inside its chains. Then, further application onto cotton fabric to have thermo-regulated fabric.

Experimental

Materials

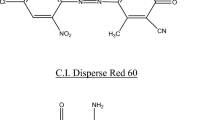

Cotton fabric (100%, 265 gm/m2) supplied by Al-Qasas Company. stearic palmitic, and myristic acid was provided from Alpha Chemika. coconut oil purchased from Qus natural oil. octadecanol provided from Sigma Aldrich Co., C.I. Reactive blue 19 as a reactive dye were kindly supplied by Dystar Co., Egypt (chemical structure of dye was illustrated in Fig. 2). Gelatin, sodium chloride, tween 80 and sodium hydroxide were purchased from El Nasr pharmaceutical chemicals Co. Citric acid, sodium hypophosphite (SHP) was provided from Fluka. All the reagents and chemicals were used without any purification.

Methods

Synthesis of gelatin/fatty acid ester

Gelatin/fatty acid ester was prepared according to the modified method reported before by Hassabo et al.10,24,25 In brief, 10 g gelatin was dissolved in 100 ml of distilled water at 70 °C. Then fatty acids was added to gelatin solution under continuous stirring for 60 min at 160 °C. after that, the mixture was left to cool at room temperature. The final product was dialyzed in deionized water for 1 day and finally lyophilized for 2 days. To adjust the best condition of synthesizing, different fatty acids (stearic, myristic and palmitic acid) was used and added to gelatin with different molar ratios.

Synthesis of PCM composite based on gelatin/fatty acid ester

PCM composites were prepared by mixing gelatin fatty acid ester with different PCM materials (coconut oil or octadecanol) in different molar ratios (10, 20 and 30% (w/w) PCM material: polymer) at 90 °C for 2 h, then PCM composite was employed for further investigation and application.

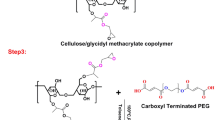

Treatment of cotton fabric with PCM composite

The treatment solution was prepared with different concentrations (30, 50, and 100 gm/l) of PCM composites and was dispersed in water in the presence of tween 80 (2 g/L) as a surfactant. The solution was homogenized for 10 min at 20,000 rpm using homogenizer. After that the cotton fabric was treated with the PCM solution using the pad-dry-cure method by immersing in the treatment bath at 80 °C for 15 min and then being squeezed with 100% wet pickup. The materials were then dried in an air oven at 100 °C for 5 min. Figure 3 suggested mechanism for the preparation and application of PCM composite.

Dyeing of cotton fabric with reactive dye

The dyeing process was done using two methods. a) first method, the fabric was pre-treated with PCM composite and then dyed with reactive dye solution, and b) second method, the fabric was dyed with reactive dye solution and then treated the with PCM composite.

The dyeing procedure was carried out using (3%) reactive dye, 10 g/L NaCl, 5 g/L NaOH at 70 °C for 75 min. then the fabric was dried in oven at 100 °C for 3 min. Finally, the fabric is immersed for 15 min at 50 °C in a soaping bath containing non-ionic detergent.

Characterization

Fourier transform infrared (FT-IR)

FT-IR spectra were recorded on a JASCO FT-IR spectrometer (ATR) was used to analyses the spectrum of the untreated and treated samples. The tester collected transmittance of the infrared in the film between 400 and 4000 cm−1 are examined.

Scanning electron microscopy (SEM)

Scanning Electron Microscopy HITASHI S-3000 microscope S, at 15-kV acceleration voltage was used to study the fabric surface morphology.

Differential scanning calorimetric (DSC)

DSC measurements were carried out on Netzsch DSC 204. 7 mg weighted samples were closed in aluminum pans, and an empty aluminum pan was used as reference. Heating, cooling and heating steps were applied to the pans through the program. Temperature ranged from 0 to 70 °C, with 10 °C/min. The melting temperature and enthalpy ΔH of the peaks recorded during the second heating. Each measurements was repeated 3 time and take the average.

Duration index (DI) and total resistance to dry heat transfer

Duration index (DI) (J/cm3/K), is a parameter characterizing the material and the temperature at which itis aimed at functioning. Its measure to know that, at a constant temperature during the phase change, how long a PCM will remain26.

where ΔH is the enthalpy of PCM change of state, ρ is the PCM density and ΔT is the temperature difference between measurable temperature and the temperature of interest (ambient, or body temperature).

The total resistance to dry heat transfer (R) is the insulation value of the clothing systems, and it is related to the textile material on which PCM is applied.

where; A: Area of material, ΔT is the temperature difference between material’s two sides, ΔT = TF−TR (Material’s Front and Rear), and Heat Flow (H). The unit for clothing insulation adopted from studies of hygienic comfort is “clo” (m2 °C/W), where 1 clo = 0.155 m2 °C/W (zero (0) clo corresponds to a person in a typical business suit and one (1) clo corresponds to a person wearing a naked body)27,28,29.

Q-max (warm/cool sensation) and thermal conductivity measurements

Rior to determining the fast dry’s thermal characteristic, each fabric were prepared in compliance with ASTM D177630.

The capacity of heat transport through fabric is referred to as thermal conductivity. Thermal conductivity in this investigation was measured using the KES-F7 standard. The following formula may be used to determine fabric’s thermal conductivity31:

where A is the heat plate’s size (25 cm2), k is the thermal conductivity (W/cm °C), W is heat flow (W), D is the average thickness of the samples, and ∆T is the temperature differential (heat plate temperature (30 °C)—the cooling base temperature (20 °C) equals 10 °C. The SI unit (W/m-k) may be converted as follows: KSI (W/m-k) = k × 102.

Q-max measurement (feeling hot or cold).

The index that measures how much warmth or coolness a piece of skin feels when it touches cloth is called Q-max. The amount of heat that is lost from the skin to the cloth determines it.

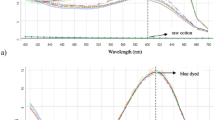

Measurement of color strength

A Data color (Data color International 500 reflectance spectrophotometer) was used to determine the color of the textile materials. The Kubelka–Munk equation was used to calculate the color strength (K/S)32,33,34,35,36,37,38:

where R denotes reflectance, K denotes absorption coefficient, and S denotes scattering coefficient.

Color fastness properties

The washing fastness properties of colored samples were assessed using the standard ISO 105-C01:2006 test technique39. Launderings were done in the Launder-O-Meter (Atlas Electric Co., USA) at 30 °C with soap. The washed specimens were graded on a visual grey scale.

Fatness to rubbing is intended to determine the quantity of color transferred by rubbing from the surface of a colored textile material to another surface. The test is performed using the AATCC crock meter following AATCC Test Method 8-201640. Wet and dry rubbing fastness tests were performed. The test specimens were evaluated using a visual grey scale, and the rubbing fastness rating is graded on a five-point scale41. Acidic and alkaline perspiration was carried out according to the test method of AATCC 15-2013 and ISO 105-EO4 (2013)42,43. The five fastness ratings could be described as follows: 5 = excellent; 4 = good; 3 = fair; 2 = bad and 1 = extremely poor.

The color fastness measurements to light were determined according to the AATCC Test Method 16-201444.

Mechanical properties

According to ASTM Test Method D5035-2011, tensile strength and elongation at a break were measured using a tensile strength apparatus type FMCW 500 (Veb Thuringer Industrie Werk Rauenstein 11/2612 Germany) at 25 °C and 65% relative humidity45. The AATCC Test Method 66-2014 was followed in measuring the dry crease recovery angle (CRA)46. Using ASTM Test Method D 7127-13, the Surface Roughness measuring equipment SE 1700 was used to test the roughness of the fabric47. The cantilever equipment was used to test for stiffness in accordance with ASTM test method D 1388-14e148. The ATSM was used to test air permeability (AP) (D 737-18)49. WVP (water vapour permeability) was measured using the ATSM (E96/E96M-16) method50.

Results and discussion

Optimization and Characterization of synthesized bio-PCM composite

Effect of fatty acid concentration

During this research the effect of palmitic acid concentration was investigated whether the mixture of fatty acid (palmitic) with gelatine may reach an eutectic (palmitic acid (melting Temp.: 66.9 °C, ΔH: 244.2 J/g)51. Octadecanol (melting Temp.: 51.2 °C, ΔH: 188.3 J/g) and coconut oil (melting Temp.: 33.6 °C, ΔH:30.8 J/g). Gelatine were used as 10% in four different ratios (gelatine to palmitic), calculated to the corresponding polymer (gelatine). 2.5, 5, 7.5 and 10 g of palmitic acid to 30 g gelatine (10%). The DSC results from second heating for PCMs are shown in Table 1, Figs. 4 and 5.

Comparison of DSC recorded data for the palmitic acid at different concentration. (A) melting Temperature, (B) enthalpy, (C) duration index, and (D) relation between temperature and enthalpy. Duration Index (DI): based on ΔT from melt point to body temperature (37 °C) and average density of 0.8 g/cm3.

The first observe from the second heating run that, for PCM-polymer composites prepared from gelatine and palmitic using octadecanol or coconut oil provide increasing in the enthalpy upon increasing the palmitic acid in the host materials. In addition, increasing the palmitic acid concentration up to 10 g results in increasing in the heat storage, so it’s provided good heat storage without further increasing in the palmitic acid concentration in the hosting materials.

In Fig. 5, the PCM-polymer composites are ordered according to the Duration Index. The estimates are based on insulation at 37 °C, which is the temperature of the body. The values of the Duration Index of the hosting materials including both octadecanol and coconut oil are 16.7 J/cm3/K and 27.8 J/cm3/K palmitic acid for coconut oil and octadecanol, respectively. These materials provide the best material (having the highest Duration Index).

FT-IR analysis

Utilizing FT-IR, gelatin palmitate was characterized. Figure 6 shows the IR spectra of gelatin, palmitic acid, coconut oil and produced PCM composites.

The results of FT-IR depicted in Fig. 6 showed that the absorption peaks observed at 3270 cm−1 for gelatin and 3182 cm−1 for the new gelatin derivatives correspond to the intermolecular hydrogen-bonded –OH stretching and –NH stretching in secondary amides (gelatin amide A).

The FTIR spectrum of the Gelatin provide band at 1328 cm−1, which is attributed predominantly to the so-called wagging vibration of proline side chains. The 1328 cm−1 band in gelatin does not simply represent the carboxyl group, but it is one of a number of bands in the range of 1400–1260 cm−1 which are attributed to the presence of type-I gelatin.

gelatin FT-IR spectra exhibit peaks at 2932 cm−1, which are associated with –CH stretching peaks. Additionally, another peak was identified as a CH2 peak at 1357 cm−1. Additionally, Fig. 6 supported the addition of a palmitic acid to gelatin for chemical modification. Following are some examples of how FT-IR spectra reveal chemical alteration for gelatin: O–H: 3270 cm−1, C–H: 2932 cm−1, C=O: 1747 cm−1 (methyl ester), C=O: 1694 cm−1 (fatty acid ester), COO: 1618 cm−1 and COO: 1433 cm−1, and C–O: 1204 and 1147 cm−1.

Among edible fats and oils, coconut oil has unique IR spectrum. Figure 6 revealed FTIR spectra of coconut oil confirm that there is no peak at region near 3008 and 1645 cm−1. Peaks at these regions correspond to unsaturated double bond (=CH; cis) and –C=C–(cis), respectively. These peaks can be used as an indicative for the unsaturation degree of triglyceride. Coconut oil contained high level of lauric acid (about 50%) and very low level of unsaturated FA of oleic and linoleic acids, therefore, it is not surprising if coconut oil has no peak at region near 3008 and 1645 cm−1. In addition, at region ranges of 1120–1090 cm−1, due to C–O ester linkage vibration, coconut oil has one peak52.

Effect of fatty acid type

The DSC results for naturally synthesized composite materials made from gelatine and different fatty acid (myristic, palmitic and stearic acid) in presence and absence of Octadecanol and coconut oil as PCM materials are shown in Table 2 and Figs. 7 and 8. Table 2 clearly shows that the latent heat of the hosting materials increases when the fatty acid backbone increases in the completed composite form. When the biopolymer interacted with fatty acid, the melting point likewise decreased, and it was increased again once Octadecanol was introduced to PCM composite. Phase compliance with the final melting temperature. The best result was obtained by using stearic acid because it has the largest number of carbon atoms in its backbone which caused highly melting point and highly heat storage ability. The results conclude that, the best result was stearic acid because it is the biggest in the number of carbon atoms or not.

The DI values of the composite made from both octadecanol and coconut oil suggest that it may be structured to shield the body from the environment’s changing temperature, according to the data in Table 2.

Effect of coconut and octadecanol concentration

The DSC results for naturally synthesized composite materials made from gelatine and stearic acid in presence and absence of Octadecanol and coconut oil as PCM materials with different concentration (10, 20 and 30%) are shown in Table 3, Figs. 9 and 10. Table 3 clearly shows that the latent heat of the hosting materials increases when the concentration of PCM material increased in the completed composite form. Figure 9 shows the DSC curve for hosting materials utilising stearic acid at various PCM (coconut and octadecanol) concentrations from the second heating.

The DI values of the composite made from both octadecanol and coconut oil increased with increasing the PCM concentration inside the hosting material suggest that it may be structured to shield the body from the environment’s changing temperature, according to the data in Table 3.

Characterization of treated fabrics

Differential scanning calorimetric (DSC)

Heat is lost to the environment via convection, radiation, and skin evaporation. Table 4 and Fig. 11 displays the DSC findings of cotton fabric treated with gelatine/stearic acid and octadecane or coconut oil. It has been noticed that covered cotton fabric using these composites imparts the thermo-regulating capabilities in contrast to uncovered fabric (Blank). In terms of thermal protection, textiles’ most important job is to maintain a microclimate next to the skin in order to meet any surface’s need for thermoregulatory behaviour53. The existing insulating characteristic of the structure can give an increased warm thermal capacity while preserving comfortability when textile apparel is paired with PCM material.

With order to increase the thermal insulator qualities and minimise temperature fluctuations, the cotton fabric was wrapped in PCM composite material. Using PCM materials is an efficient way to store and release heat while modifying the ambient temperature10,54,55,56.

Gelatine/Stearic with coconut oil gives more latent heat than coated fabric with Gelatine/Stearic with octadecanol and uncoated fabric. According to estimates of the total resistance to dry heat transfer, cotton fabric coated with Gelatine/Stearic acid/Octadecane or coconut oil composite are more pleasant than those that are untreated. Finally, it can be said that PCM composites may be used to cover cotton fabric, and that the covered fabric outperforms their uncovered counterparts in terms of performance.

Dyeing performance

Effect of treatment on the dyeing performance and the vice versa was investigated during this research. Treated cotton fabric using gelatine/stearic/ octadecanol or coconut oil was dyed and investigated for their thermal storage performance and thermal conductivity. In addition, cotton fabric was dyed at optimum condition then treated using gelatine/stearic/octadecanol or coconut oil and investigated for their thermal storage performance and thermal conductivity.

Table 5 and Fig. 12 shows thermal storage performance and thermal conductivity for treated fabric (T), treated then dyed fabric (TD) and dyed then treated fabric (DT). It is clear from the data in Table 5 that, dyed fabric then treated using each PCM materials (octadecanol or coconut oil) provide better thermal storage performance and thermal conductivity than treated then dyed fabric. it is may be attributed to that, after dyeing all the functional group on the surface of cotton fabric was reacted with dye molecules, then upon treatment, PCM composite material make a thin film on the surface of dyed cotton fabric which allow the PCM materials to react and produce the effect of thermoregulation properties. From the other point of view, dyeing treated fabric allow the dye molecules to react with hosting materials (gelatine / stearic acid) and free functional group on the surface of cotton fabric and as the dyeing process occurred at 70 °C which convert the PCM from solid phase to liquid phase and make them laying out from the surface led to decreasing the thermoregulated performance10,57.

From Table 6, it can be noticed that the dyeing of the treated fabric provides higher color strength properties than dyeing then treated fabric which could be attributed to the formation of the thin film from the PCM composites which activate the surface with functional groups helps the fabrics to absorb more dyes molecules. While dyeing then treated provides almost similar color strength to the blank dyed fabric. In addition, the slightly increasing in the color strength of the fabric dyed then treated could be attributed to the PCM composite which compact the fabric thickness and causing slightly increasing in the color strength.

Thermal conductivity measurement

The thermal conductivity of variably cotton fabrics is shown in Table 5. Both treated fabrics (T) with octadecanol or coconut oil has a substantially greater thermal conductivity than treated then dyed (TD) and dyed then treated (DT). The highest thermal conductivity for T is 0.062 and 0.06 for treated fabrics (T) with octadecanol or coconut oil. The thickness of the fabric affects its ability to transfer heat. That influence is clear from the data in Table 5. It was previously reported that heat conductivity decreases with increasing textile thickness58,59,60. As a result of its greater thermal insulation, the thicker fabric has a lower heat conductivity.

The greater the thermal conductivity rating, the better the fabric’s ability to conduct heat. Treated fabric only (T) had the highest thermal conductivity, whilst treated then dyed fabrics (TD) had the lowest.

A higher Q-max value (warmth or coldness) denotes a colder first contact experience. The Q-max values for the examined samples (T, TD and DT) are 0.136, 0.136, and 0.136, for treated fabric with octadecanol respectively, while it was 0.119, 0.106 and 0.135 for treated fabric with coconut oil respectively. As can be seen, treated fabric using coconut oil had lowest Q-max values than treated fabric using octadecanol in all cases.

Additionally, the fabric thickness after treatment with prepared PCM are reduced because the treatment has made a thin layer on the fabric’s surface, lowering the fabric’s thickness. However, all treated fabrics now have higher thermal insulation qualities since prepared materials can retain temperature.

The initial touch feeling provided by Q-max is essential since it causes a cooling sensation when in contact with human skin. In this investigation, it was noticed that treated cotton fabrics had a cooler touch feel and are thus superior than untreated ones for apparel.

Durability measurement

Table 7 and Fig. 13 show the DSC chart for dyed and treated fabric using different PCM-based composite using (coconut and octadecanol) after different washing cycles (5 and 10 washing cycles). It is clear that the overall characteristics of dyed treated fabric (thermal insulation and color intensity) slightly decreased upon 5 washing cycle and the decreasing was increased upon increasing the washing cycle to 10 cycles. Although this decreasing in fabric characteristics upon different washing cycle, the fabric still has the ability to store the heat and the changing in the color strength still in acceptable value and more than the blank fabric without treatment.

Evaluation of comfortability

Textiles are a material that is frequently used in daily life. On the other hand, surface treatment or multilayer methods are needed for direct outdoor usage of textiles, including natural ones like cotton, for weather protection and waterproofing61,62. Due to their innate hydrophilicity and structural instability when exposed to water, these materials are particularly desirable for weathering63.

The air permeability of various cotton fabrics has a significant impact on how well they operate. The cloth’s air permeability is significantly influenced by its weight and structure (thickness and porosity).

The void volume in woven textile fabrics is what makes them permeable to air. The air permeability of a textile is determined by the rate at which air moves through a material when there is a pressure differential between the two surfaces of the fabric64.

Figure 14 shows the air and water vapour permeabilities of treated and untreated textiles, and the data sources show that both of the tested parameters slightly dropped after treatment but remained within acceptable ranges. This demonstrates that both treatment and dyeing had no impact on the comfortability of the cloth.

Morphological behavior

The morphological behaviour of cotton textiles was examined after being treated with PCM composite material before dyeing (see Fig. 15). It is clear from that treatment using both composites (using coconut and octadecanol) provide the presence of homogeneous thin film on the surface of the cotton fibers. This thin film causing homogeneity in the filling the gabs in the surface of cotton fiber which responsible for the enhancement of thermal properties as well as the heat storage property.

Mechanical and physical performance

The tensile strength, elongation at break, roughness, and crease recovery angle of cotton textiles in the warp and weft directions were examined before and after being treated with PCM composite material before and after dyeing. The Young’s Modulus is an inherent characteristic of all materials, which remains constant but can be influenced by temperature and pressure. It represents the stiffness of a material, indicating how easily it can be bent or stretched. It is defined as the ratio of tensile stress (force per unit area) to tensile strain (elongation at a break). The increase in Young’s Modulus observed after treating the fabric with PCM composite coating resulted in reduced rigidity of the fabric.

Table 8 displays the results, and it shows how differences in process of treated and dyeing fabric lead to changes in the physicomechanical properties of cotton fabric. While only slightly improving in the crease recovery angle and fabric roughness, the treatment dramatically increased the tensile strength and elongation at the break. This shows that the gelatin/stearic polymer material used as the hosting was extensively absorbed into the textile fabrics’ microstructure, resulting in a thin coating layer on the fabric’s surface that was responsible for the observed alterations65,66,67,68.

The covalent chemical connection, which also led to the creation of an intensive network with a high degree of cross-linking, was most likely the root cause of the significant increase in the crease recovery angle.

Conclusion

Smart fabrics have gained popularity in recent years, with phase change materials (PCMs) being incorporated into textile structures to create thermoregulated fabrics. PCMs are thermal energy storage materials that can store and release large amounts of latent heat during phase change. To address melting and leaking issues, hosting materials have been developed to retain PCMs within their network. Chemically bonded hosting materials are preferred as they make the surface permanently treated. PCMs used in textiles are typically microencapsulated into a polymer to avoid material leakage. To address this issue, natural polymers like gelatin have been investigated as an alternative shell. Gelatin is a non-toxic and biodegradable polypeptide with a high molecular weight, making it a promising alternative to traditional PCMs. This study aims to investigate the use of organic coconut oil as a natural PCM for textile applications as a low-cost, sustainable alternative to current PCMs, comparing it with recognized PCMs like octadecanol.

This research investigates the mechanical and physical performance of cotton fabrics treated with gelatine/stearic acid, octadecane or coconut oil. The results show that covered cotton fabric using these composites imparts thermo-regulating capabilities in contrast to uncovered fabric. Textile apparel is crucial for maintaining a microclimate next to the skin, and the insulating characteristics of the structure can provide increased warm thermal capacity while preserving comfortability when paired with PCM material.

To increase thermal insulator qualities and minimize temperature fluctuations, cotton fabric was wrapped in PCM composite material. Gelatine/Stearic with coconut oil gives more latent heat than coated fabric with Gelatine/Stearic with octadecanol and uncoated fabric. Cotton fabric coated with Gelatine/Stearic acid/Octadecane or coconut oil composite are more pleasant than those that are untreated.

The dyeing performance of treated cotton fabric was investigated for thermal storage performance and thermal conductivity. The results showed that treated fabric then treated using each PCM materials (octadecanol or coconut oil) provided better thermal storage performance and thermal conductivity than treated then dyed fabric. The treated fabric also provided higher color strength properties than the untreated fabric.

The thermal conductivity of variably cotton fabrics showed that both treated fabrics with octadecanol or coconut oil had substantially greater thermal conductivity than treated then dyed and dyed then treated fabrics. The treated fabric only had the highest thermal conductivity, while treated then dyed fabrics had the lowest.

Durability measurements showed that the overall characteristics of dyed treated fabric slightly decreased upon 5 washing cycles and increased upon increasing the washing cycle to 10 cycles. However, the fabric still has the ability to store heat and the changing in color strength remains acceptable value.

Morphological behavior of cotton textiles after being treated with PCM composite material before dyeing revealed that treatment using both composites (using coconut and octadecanol) provides the presence of a homogeneous thin film on the surface of the cotton fibers, which enhances thermal properties and heat storage.

Data availability

The datasets generated and/or analysed during the current study are available in the the manuscript.

References

Lin, Y., Zhu, C., Alva, G. & Fang, G. Microencapsulation and thermal properties of myristic acid with ethyl cellulose shell for thermal energy storage. Appl. Energy 231, 494–501 (2018).

Zhang, Y., Zhou, G., Lin, K., Zhang, Q. & Di, H. Application of latent heat thermal energy storage in buildings: State-of-the-art and outlook. Build. Environ. 42(6), 2197–2209 (2007).

Zalba, B., Marın, J. M., Cabeza, L. F. & Mehling, H. Review on thermal energy storage with phase change: Materials, heat transfer analysis and applications. Appl. Therm. Eng. 23(3), 251–283 (2003).

Chaudhari, V. N., Rathod, M. K. & Chaudhari, K. A. Stearic acid as phase change material: Thermal reliability test and compatibility with some construction materials. Seeds 4, 5 (2013).

Zhu, F., Feng, Q., Liu, R., Yu, B. & Zhou, Y. Enhancing the thermal protective performance of firefighters’ protective fabrics by incorporating phase change materials. Fibres Text. East. Eur. 2(110), 68–73 (2015).

Koo, K., Park, Y., Choe, J. & Kim, E. The application of microencapsulated phase-change materials to nylon fabric using direct dual coating method. J. Appl. Polym. Sci. 108(4), 2337–2344 (2008).

Hassabo, A. G. et al. Smart wearable fabric using electronic textiles – A review. J. Text. Color. Polym. Sci. 20(1), 29–39 (2023).

Hassabo, A. G., Eid, M. M., Mahmoud, E. R. & Asser, N. A. H. A. Innovation of smart knitted fabrics for functional performance of sportswear upon treatment using phase change material. Egy. J. Chem. 66(3), 133–156 (2023).

Hassabo, A. G., Zayed, M., Bakr, M. & Othman, H. A. Chromic dyes for smart textile: A review. Lett. Appl. NanoBioSci. 12(4), 161 (2023).

Hassabo, A. G. & Mohamed, A. L. Enhancement the thermo-regulating property of cellulosic fabric using encapsulated paraffins in modified pectin. Carbohyd. Polym. 165, 421–428 (2017).

Bayés-García, L. et al. Phase change materials (pcm) microcapsules with different shell compositions: Preparation, characterization and thermal stability. Sol. Energy Mater. Sol. Cells 94(7), 1235–1240 (2010).

Hassabo, A. G. New approaches to improving thermal regulating property of cellulosic fabric. Carbohyd. Polym. 101, 912–919 (2014).

Saraç, E. G., Öner, E. & Kahraman, M. V. Microencapsulated organic coconut oil as a natural phase change material for thermo-regulating cellulosic fabrics. Cellulose 26, 8939–8950 (2019).

Wang, J.-P., Zhao, X.-P., Guo, H.-L. & Zheng, Q. Preparation of microcapsules containing two-phase core materials. Langmuir 20(25), 10845–10850 (2004).

Derkach, S. R., Kuchina, Y. A., Baryshnikov, A. V., Kolotova, D. S. & Voron’ko, N. G. Tailoring cod gelatin structure and physical properties with acid and alkaline extraction. Polymers 11(10), 1724 (2019).

Lin, K. et al. Advanced collagen-based biomaterials for regenerative biomedicine. Adv. Funct. Mater. 29(3), 1804943 (2019).

Zhang, T. et al. Gelatins as emulsifiers for oil-in-water emulsions: Extraction, chemical composition, molecular structure, and molecular modification. Trends Food Sci. Technol. 106, 113–131 (2020).

Deshmukh, K. et al. Biopolymer composites with high dielectric performance: Interface engineering. In Biopolymer Composites in Electronics 27–128 (Elsevier, 2017). https://doi.org/10.1016/B978-0-12-809261-3.00003-6.

Hassabo, A. G., Zayed, M. T., Bakr, M. & Othman, H. A. The utilisation of gelatin biopolymer in textile wet processing. J. Text. Color. Polym. Sci. 19(2), 125–136 (2022).

Ali, M. A., Hassabo, A. G., Seddik, K. M., Yahia, S. & Mohamed, N. Characterization of the thermal and physico-mechanical properties of cotton and polyester yarns treated with phase change materials composites. Egy. J. Chem. 65(13), 21–37 (2022).

Fathallah, A. I. et al. Intelligent PCM composite for enhancing the thermoregulated properties of different cotton/polyester fabric constructions. J. Text. Color. Polym. Sci. 20(1), 113–123 (2023).

Mohamed, H. A., Gaafar, Z. S., Roshdy, Y.A.E.-M., El-Shamy, M. N. & Hassabo, A. G. Microencapsulation and its application in textile industry. J. Text. Color. Polym. Sci. 22(1), 81–87 (2025).

Marina, A., Che Man, Y., Nazimah, S. & Amin, I. Chemical properties of virgin coconut oil. J. Am. Oil Chem. Soc. 86, 301–307 (2009).

Hassabo, A., Mohamed, A. I. Enhancement of thermo-regulating textile materials using phase change material (PCM). (2019).

Hassabo, A. G. & Ragab, M. Ultarvielote protection of cellulosic fabric. J. Text. Color. Polym. Sci. 19(1), 51–61 (2022).

Mottinger, B. Space Hardware Design Final Project, ASEN 4512 (University of Colorad, 1999).

Shim, H., McCullough, E. & Jones, B. Using phase change materials in clothing. Text. Res. J. 71(6), 495–502 (2001).

Doerr, D. F. Heat Stress Assessment and A Countermeasure 2 (Biomedical Laboratory Kennedy Space Center, 1997).

McCullough, E. A. & Jones, B. W. A Comprehensive Data Base for Estimating Clothing Insulation 161 (The American Society of Heating Refrigerating and Air-Conditioning Engineers Inc., 1984).

ASTM Standard Test Method (D 1776/D1776M − 20). Standard practice for conditioning and testing textiles. (2020).

Fathallah, A. I. et al. Alginic/stearic/octadecane as phase change material (PCM) for enhancing the thermal comfort-ability of different polyester fabrics constructions. Egy. J. Chem. 66(4), 167–177 (2023).

Kubelka, P. & Munk, F. Ein beitrag zur optik der farbanstriche. Z. Tech. Phys. 12, 593 (1931).

Mehta, K. T., Bhavsar, M. C., Vora, P. M. & Shah, H. S. Estimation of the kubelka–munk scattering coefficient from single particle scattering parameters. Dyes Pigm. 5(5), 329–340 (1984).

Waly, A., Marie, M. M., Abou-Zeid, N. Y., El-Sheikh, M. A., Mohamed, A. L. Process of single – bath dyeing, finishing and flam – retarding of cellulosic textiles in presence of reactive tertiary amines. In 3rd International Conference of Textile Research Division, NRC; Textile Processing: State of the Art & Future Developments, Cairo, Egypt 529–543 (2006).

Waly, A., Marie, M. M., Abou-Zeid, N. Y., El-Sheikh, M. A. & Mohamed, A. L. Flame retarding, easy care finishing and dyeing of cellulosic textiles in one bath. Egy. J. Text. Polym. Sci. Technol. 12(2), 101–131 (2008).

Hassabo, A. G. Synthesis and Deposition of Functional Nano-materials on Natural Fibres 154 (RWTH Aachen University, Germany, 2011).

Mohamed, A. L. & Hassabo, A. G. Cellulosic fabric treated with hyperbranched polyethyleneimine derivatives for improving antibacterial, dyeing, pH and thermo-responsive performance. Int. J. Biol. Macromol. 170, 479–489 (2021).

Hassabo, A. G. Preparation, Characterisation and Utilization of Some Textile Auxiliaries (El-Azhar University, 2005).

ISO 105-C01:2006. Textiles—Tests for Colour Fastness—Part c01: Colour Fastness to Washing: Test 1. (Deutsches Institut fur Normung E.V. (DIN), 2006).

AATCC Test Method (8-2016). Colorfastness to Crocking, Crockmeter Method. 17–19 (Technical Manual Method American Association of Textile Chemists and Colorists, 2018).

Wei, W., Zhou, Y.-H., Chang, H.-J. & Yeh, J.-T. Antibacterial and miscibility properties of chitosan/collagen blends. J. Macromol. Sci. Part B 54(2), 143–158 (2015).

ISO 105-E04:2013. Textiles — Tests for Colour Fastness — Part e04: Colour Fastness to Perspiration. (Deutsches Institut fur Normung E.V. (DIN), 2014).

AATCC Test Method (15–2013). Colour Fastness to Perspiration. 30–32 (Technical Manual Method American Association of Textile Chemists and Colorists, 2017).

AATCC Test Method (16.1–2014). Colour fastness to light: Outdoor. 33–48 (Technical Manual Method American Association of Textile Chemists and Colorists, 2015).

ASTM Standard Test Method (D5035–11 (Reapproved 2019)). Standard test Method for Breaking Force and Elongation of Textile Fabrics (Strip Method). (ASTM International, 2019).

AATCC Test Method (66–2014). Wrinkle Recovery of Fabric: Recovery Angle Method. 113–116 (Technical Manual Method American Association of Textile Chemists and Colorists, 2017).

ASTM Standard Test Method (D7127 − 13). Standard Test Method for Measurement of Surface Roughness of Abrasive Blast Cleaned Metal Surfaces Using a Portable Stylus Instrument1. (ASTM International, West Conshohocken, 2016).

ASTM Standard Test Method (D1388 − 14e1). Standard Test Methods for Stiffness of Fabrics. (ASTM International, West Conshohocken, PA, 2016).

ASTM Standard Test Method (D 737 - 18). Standard Test Method for Air Permeability of Textile Fabrics. (ASTM International, West Conshohocken, 2018).

ASTM Standard Test Method (E 96/96M - 16). Standard Test Methods for Water Vapor Transmission of Materials. (2016).

Al-Ahmed, A. et al. Thermal energy storage and thermal conductivity properties of octadecanol-mwcnt composite pcms as promising organic heat storage materials. Sci. Rep. 10(1), 9168. https://doi.org/10.1038/s41598-020-64149-3 (2020).

Rohman, A. Infrared spectroscopy for quantitative analysis and oil parameters of olive oil and virgin coconut oil: A review. Int. J. Food Prop. 20(7), 1447–1456 (2016).

Sarier, N. & Onder, E. Organic phase change materials and their textile applications: An overview. Thermochim. Acta 540, 7–60 (2012).

Hassabo, A. G. A. A. Synthesis and deposition of functional nano-materials on natural fibres. (2011).

Hassabo, A. G., Mohamed, A. L., Wang, H., Popescu, C. & Moller, M. Metal salts rented in silica microcapsules as inorganic phase change materials for textile usage. Inorgan. Chem. Indian J. 10(2), 59–65 (2015).

Mondal, S. Phase change materials for smart textiles–an overview. Appl. Therm. Eng. 28(11–12), 1536–1550 (2008).

Hassabo, A. G., Ebrahim, S., Othman, H. A., Mosaad, M. M. Using pectin to enhance the dyeability performance and antimicrobial activity using different dyes on modified proteinic and synthetic fabrics. Biointerf. Res. Appl. Chem. 13(5), (2023).

Milenkovic, L., Skundric, P., Sokolovic, R. & Nikolic, T. Comfort properties of defence protective clothing. Sci. J. Facta Universitatis 1(4), 101–106 (1999).

Kan, C. W., Ko, C. M. C., Ariyakuare, K., Changmuong, W. & Mongkholrattanasit, Rattanaphol. Study on air permeability and warmth retention ability of polyurethane foam plying with fabrics. Appl. Mech. Mater. 866, 233–239. https://doi.org/10.4028/www.scientific.net/AMM.866.233 (2017).

Kan, C. W., Tam, H. T. & Mongkholrattanasit, R. A study of thermal properties of commercially available innerwear. Appl. Mech. Mater. 848, 178–181. https://doi.org/10.4028/www.scientific.net/AMM.848.178 (2016).

Xue, C.-H., Bai, X. & Jia, S.-T. Robust, self-healing superhydrophobic fabrics prepared by one-step coating of pdms and octadecylamine. Sci. Rep. 6(1), 1–11 (2016).

Wang, H. et al. Durable, self-healing superhydrophobic and superoleophobic surfaces from fluorinated-decyl polyhedral oligomeric silsesquioxane and hydrolyzed fluorinated alkyl silane. Angew. Chem. 123(48), 11635–11638 (2011).

Szostak-Kotowa, J. Biodeterioration of textiles. Int. Biodeterior. Biodegrad. 53(3), 165–170 (2004).

Oberle, B. et al. Dissecting the effects of diameter on wood decay emphasizes the importance of cross-stem conductivity in fraxinus americana. Ecosystems 21(1), 85–97 (2018).

Hebeish, A., Shaarawy, S., Hassabo, A. G. & El-Shafei, A. Eco-friendly multifinishing of cotton through inclusion of motmorillonite/chitosan hybrid nanocomposite. Der Phar. Chem. 8(20), 259–271 (2016).

El-Naggar, M. E., Hassabo, A. G., Mohamed, A. L. & Shaheen, T. I. Surface modification of SiO2 coated ZnO nanoparticles for multifunctional cotton fabrics. J. Coll. Interface Sci. 498, 413–422 (2017).

Mohamed, A. L., Hassabo, A. G., Nada, A. A. & Abou-Zeid, N. Y. Properties of cellulosic fabrics treated by water-repellent emulsions. Indian J. Fibre Text. Res. 42(June), 223–229 (2017).

Mohamed Salama, A. G., Hassabo, A. A., El-Sayed, T. S. & Popescu, C. Reinforcement of polypropylene composites based on recycled wool or cotton powders. J. Nat. Fibers 14(6), 823–836. https://doi.org/10.1080/15440478.2017.1279582 (2017).

Acknowledgements

The authors are gratefully grateful to acknowledge the Faculty of Applied Arts, Benha University. Furthermore, the authors are gratefully grateful to acknowledge the Central Labs Services (CLS) and Centre of Excellence for Innovative Textiles Technology (CEITT) in Textile Research and Technology Institute (TRTI), National Research Centre (NRC) for the facilities provided.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

AGA own the idea and make the methodology plan, analysing the data, writing the first draft and finalising the last article form HAO makes the methodology plan, analysing the data, MZ make the methodology work, analysing the data, writing the first draft an HG and EA make the methodology plan, analysing the data.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical approval

There is no human and/ or animal studies during this work.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zayed, M., Ghazal, H., Othman, H.A. et al. Functionalization of cotton fabric using bio-organic heat storage materials for human protection and thermal comfortability. Sci Rep 15, 17792 (2025). https://doi.org/10.1038/s41598-025-01328-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-01328-0