Abstract

In-situ stress is a significant factor in the occurrence of dynamic disasters in coal mines. Measured data from 22 measuring points in the Luxin mining area was analyzed to investigate the distribution of in-situ stress and regional structure action. The results reveal that in-situ stress in the Luxin mining area is predominantly a structure stress, it is mainly manifested in the medium and low stress levels. The maximum horizontal principal stress, minimum horizontal principal stress, and vertical principal stress are 5.47–18.8 MPa, 3-10.15 MPa, and 4.8–12.5 MPa, respectively, all of them are positively correlated with the burial depth. As the burial depth increases, the discreteness of the maximum and minimum horizontal principal stresses first increases and then decreases. The lateral pressure ratio varies from 0.6 to 2.1, gradually approaching 1 with increasing depth, and the discreteness gradually decreases with the increase of depth and its discreteness gradually decreases. The differences between maximum and minimum horizontal principal stress range from 2.47 to 9.6 MPa. The predominant direction of the maximum horizontal principal stress in the Luxin mining area is NW. The influence of the F1 and F2 reverse faults alters this direction, with seven measuring points indicating a maximum horizontal principal stress direction of N (21.4°-78.6°) E. From the axis of the Xishan anticline to the bottom of the flanks, the maximum horizontal principal stress generally increases. The F1 and F2 reverse faults cause stress redistribution, leading to fluctuations in the maximum horizontal principal stress in the hanging wall region of these faults. The distribution of in-situ stress in Luxin Mining Area is the result of the combined action of the Xishan anticline, faults and torsional stress in the north-south direction. The distribution of in-situ stress in Luxin Mining Area is the consequence of the combined effect of the Xishan anticline, faults, and torsional stress in the north-south direction. Based on the measured in-situ stress data from Shadunzi coal mine, a roadway support scheme for the S4103 working face was developed, which improved roadway stability.

Similar content being viewed by others

Introduction

In China, the geological conditions of coal mines exhibit significant complexity, influenced by various geological structures such as faults, folds, and joints. This complexity leads to a complicated distribution of in-situ stress, which is crucial for understanding the dynamics of coal mine operations. In-situ stress is a significant factor in the occurrence of dynamic disasters in coal mines. These phenomena are primarily driven by the in-situ stress, which can cause deformation and failure of surrounding rock in roadways. An examination of in-situ stress distribution and the influence of regional geological structures is crucial for mitigating such hazards and ensuring the safety of coal mining operations1,2.

Many academics have executed in-situ stress measurements employing techniques including stress relief3, hydraulic fracturing4, stress recovery5, acoustic emission6, and rheological stress recovery7. By calculating the in-situ stress values and azimuth angles, they have delineated the distribution patterns of the in-situ stress. Academics have executed in-situ stress assessments and systematically analyzed attributes such as the magnitude, direction, and type of in-situ stress across various mining regions, including the Xishan mining area8, Yima mining area9, Jincheng mining area10, Yangquan mining area11, and Luan mining area12. Gao et al. employing conventional hydraulic fracturing combined with primary fracture reopening tests in inclined boreholes, optimized the shear stress hypothesis on primary fracture surfaces and combine it with borehole cross-sectional stress to accomplish triaxial stress tensor inversion13. Drawing upon in-situ stress data from the Shoushan No.1 coal mine, Guo et al. utilized approaches from structural physics, rock mechanics, and numerical simulations to model the in-situ stress distribution characteristics14. Kang et al. established a comprehensive database of in-situ stress pertinent to Chinese coal mines and conducted a thorough exploration of the influences and characteristics dictating the in-situ stress. Based on this data, they crafted a series of simulation platforms and support tests for mine roadways, reveal its mechanical response characteristics and failure mechanisms15,16,17. Additionally, the outcomes from this research have been extensively applied to control dynamic mining catastrophes such as rock bursts, coal and gas outbursts, deformations around mine roadways in roadways, thereby ensuring the coal mines’ operational safety and efficiency18,19,20.

The aforementioned investigations predominantly focus on the analysis of in-situ stress measurements, the inversion of in-situ stress, and the assessment of influencing factors across numerous mining area within China. Nevertheless, analyses concerning the distribution of in-situ stress and the contributions of regional geological structures have been comparatively limited within the Luxin mining area. In this paper, in-situ stress test was conducted by using the hydraulic fracturing method at 22 measuring points in 3 pairs of mines in the Luxin Mining Area. The exploration delineates the distribution of in-situ stress patterns within this region and assesses the impact of geological structures alongside various determinants on in-situ stress. The implications ofthis research are critical for the prophylaxis of geological disasters in the Luxin mining area.

Geological overview of the Luxin mining area

The Luxin mining area, situated in Sandaoling town, Yizhou District, Hami City, within the Xinjiang Uygur Autonomous Region, located at the southern periphery of the Tianshan Mountains. This area extends 43.2 km from east to west and 24.3 km from north to south. A schematic representation of the Luxin mining area is illustrated in Fig. 1.

Located at the eastern periphery of the Northern Tianshan Mountains, the Sandaoling Basin, the site of the Luxin mining area, was formed through the convergence of the Bogda Late Paleozoic rift system and the Kalamaili suture zone. The northeastern segment of the basin intersects with the Kalamaili-Moqinwula gold-tin belt, while the northwestern segment is intersected by the Bostan copper belt. The central sector of the basin comprises the western extension of the Harlik copper metallogenic belt. In structural terms, the Sandaoling Basin is classified as part of the Late Paleozoic island arc characteristic of the Dananhu region. In terms of geological configuration, the fold structures within the Sandaoling Basin are comparatively straightforward; however, fractures are more developed.

The geological structure of the Luxin Mining Area is influenced by the Yanshan Movement and the Himalayan Movement, presenting a complex configuration of both folds and faults. The fold has been significantly shaped by the Xishan plunging anticline, and the faults include F1, F2, F3 and F4.The F1 reverse fault is distributed in a “bow” shape along the southern edge of the mining area. The western part lies north of the Shadunzi Mining Area, the middle part is delineates the southern border of the Sandaoling Mining Area, and the eastern part stretches along the southern edge of the Shazaoquan Mine Field. The thrust plane has a dip angle ranging from 45° to 80° and a vertical displacement of 50–500 m, constituting a large-scale north-south thrust-nappe structure across the entire area. The F2 reverse fault in the Sandaoling Mining Area extends over ten kilometers and intersects with the F1 fault. Its dip angle displacement ranges from 28° to 64°, with a throw of 14–40 m and a fault displacement exceeding 3000 m. The F3 normal fault, located in the eastern periphery outside the Sandaoling Mining Area, extends approximately east-west through the Xishan Area, with a length of about 20 km within the area. The fault plane dips northward at 27–79°, with a throw of 50–250 m, causing damage to the coalfield and deeper burial of coal-bearing strata in some parts. The F4 thrust fault on the northern side of the Sandaoling Mining Area is a strike-slip fault cutting across the plunging end of the Xishan plunging anticline in an east-west axial direction. Its eastern end intersects with the F1 fault and is complementary to the F1 reverse thrust fault. In essence, with the major F1 reverse thrust fault as the core, secondary structures are associated and combined, generating multiple secondary thrust planes that are steep above and gentle below, as well as multiple geological slices.

The Luxin mining area operates as a subsidiary of Jineng Holdings Lu’an Xinjiang Coal Chemical Group Co., Ltd. This complex comprises several constituents, including No.1 coal mine, Luxin No.2 coal mine, Shadunzi coal mine, and an open-pit coal mine. The Luxin No. 1 coal mine is located in the core of Sandaoling mining area, which is defined by coal-bearing strata that exhibit a southward trend in a monocline, toward NE-SW, tend to ES. The prominent structural orientation within this area trends EW, marked by notable folds and faults, particularly the F1 and F2 faults. Luxin No.2 coal mine, positioned in the eastern sector of the district, is predominantly dictated by the Xishan anticline structure, paralleled by several smaller folds trending NE, each extending approximately 10 km. This area’s geological faults, namely F1, F2, and F4, are significant features. Shadunzi coal mine, located in the western portion of the Houyao Well area of the district, resides on the southern side of a complex anticline, typified by a monocline interspersed with numerous faults and locally pronounced folds, exhibiting dip angles ranging from 6 to 12 degrees. Faults in this region predominantly display a NE-SW orientation, with the eastern faults being more intricate and the western ones deeper and simpler. The geological complexity of the Shadunzi coal mine area is categorized as class II medium.

In-situ stress testing of the Luxin mining area

Methods for in-situ stress testing

4 − 1 coal seam within the Luxin mining area is subjected to subsurface stress analysis through hydraulic fracturing. Under the imposition of high pressure, the rock formations fissure, thus disclosing the orientation of the maximal horizontal stress. To guarantee precision and representativeness in the findings, test points are meticulously positioned to circumvent concentrations of tunnels and to deliberately encompass structural zones. The diameters of boreholes designated for these in-situ stress measurements vary from 50 to 75 mm, and are drilled perpendicular to the ceiling of the roadways, with depths extending up to 30 m.

In the designated areas, vertical boreholes are meticulously executed, and isolators are employed to demarcate the sections under examination. At both ends of each isolator, pressure sensors and flowmeters are positioned to continuously track variations in pressure and the dynamics of the fracturing procedure. A fluid medium, such as water, is introduced into the isolated sections of the borehole, progressively augmenting the pressure until rock fracturing occurs. Record the data such as the peak pressure required for rock fracture, as well as the orientation, length and shape of the fracture cracks. Employing parameters such as fracturing pressure, volume of fluid injected, and back pressure after closing the pump, a designated formula (referenced as Formula 1) facilitates the computation of both the stress magnitudes and the direction of the rocks at specific measurement points. These measurement points are stratified among three distinct coal mines: Luxin No.1 coal mine, Luxin No.2 coal mine, and Shadunzi coal mine, aggregating twenty-two points in total. Among them, there are 5 locations in Luxin No.1 Coal Mine, 9 locations in Luxin No.2 Coal Mine, and 8 locations in Shadunzi Coal Mine21.

In the formula, Ps, Pr respectively represent the confining pressure and closure pressure, MPa; γw is the density of water, MN/m3; H is the depth of the measurement point, m.

Measurement results of in-situ stress

The minimum burial depth for stress measurement points within the Luxin mining area is established at 192 m, whereas the maximal depth reaches 500 m. Based on the prescribed formula, the obtained data concerning the in-situ stress within the Luxin area are presented in Table 1. Within this table, ‘H’ denotes the burial depth of the measurement points, ‘σH’ signifies the maximum horizontal principal stress, ‘σh’ represents the minimum horizontal principal stress, and ‘σv’ denotes the vertical principal stress.

Distribution of the in-situ stress in the Luxin mining area

Types of in-situ stress

Based on the in-situ stress test outcomes in the Luxin mining area, the types of in-situ stress is depicted in Fig. 2. Among the 22 measurement points in Luxin Mining Area, 3 measurement positions, situated entirely within Luxin No.2 coal mine and accounting for 13.64% of the study sample, exhibited characteristics of a gravitational stress field (σv > σH > σh). These positions are located at respective depths of 267 m in the station of the W4203 track roadway, 278 m at the 100 m downstream of the 4 th horizontal crosscut track dip roadway, and 359 m at the end of the track dip roadway, all located in Luxin No.2 coal mine. Additionally, 19 measurement points exhibited a structure stress field; 16 of these points reflected a structure stress configuration (σH > σv > σh) that constitutes 72.72% of the findings, and 3 measurement points displayed a configuration (σH > σh > σv) representing 13.64% of the study sample. These 3 measurement points with the minimal burial depths are precisely at 192 m in the N4303 transport roadway in the eastward expansion, 193 m in the E4303 lower roadway, and 233 m in the return dip airway in the eastward expansion, all located in Luxin No.2 coal mine.

Magnitude of in-situ stress

Derived from the in-situ stress test results within the Luxin mining area, the distribution of maximum horizontal principal stress varies across distinct measurement points. Analysis revealed that 6 measurement points registered stress levels ranging between 0 and 10 MPa, comprising 27.27% of the study sample. Additionally, 15 measurement points recorded stress levels ranging between 10 and 18 MPa, representing 68.18% of the study sample, and a singular point noted a stress range of 18 to 30 MPa, constituting 4.55% of the study sample. The lowest recorded value of the maximum horizontal principal stress was 5.47 MPa, observed at the 4 th horizontal crosscut track dip roadway within Luxin No.2 coal mine, situated 100 m below the surface. Conversely, the highest recorded level of this stress parameter was 18.8 MPa, identified at the centralized return airway of the N41 mining area within Shadunzi coal mine.

Based on established evaluation parameters17, the range of the maximum horizontal principal stress within the mining area can be classified into 4 distinct levels: 0 to 10 MPa as a low stress zone, 10 to 18 MPa as a medium stress zone, 18 to 30 MPa as a high stress zone, and above 30 MPa as an ultra-high stress zone. Within Luxin No.1 coal mine, of the 5 measurement points, one is classified within the low stress zone and four within the medium stress zone. Conversely, within the Luxin No.2 coal mine, out of 9 measurement points, five are in the low stress zone and four in the medium stress zone. Furthermore, among 8 measurement points in Shadunzi coal mine, seven belong to the medium stress zone, while one is classified within the high stress zone. Consequently, the Luxin mining area is predominantly categorized as a medium-low stress region, with localized sectors categorized as high stress zones. The magnitude of in-situ stress in the Luxin mining area is shown in Fig. 3.

Direction of the maximum horizontal principal stress

Figure 4 illustrates the vector diagram representing the direction of maximum horizontal principal stress within the Luxin mining area. Within the confines of Luxin No.1 coal mine, the direction of the maximum horizontal principal stress at 5 measurement points are predominantly ranged between N19.8°W and N78.6°E. In contrast, at Luxin No.2 coal mine, the direction for the maximum horizontal principal stress at 9 measurement points are observed predominantly between N64.6°W and N70.4°E. Furthermore, at Shadunzi coal mine, the maximum horizontal principal stress direction at 8 measurement points are primarily concentrated from N17.6°W to N42°W. The in-situ stress demonstrates a conspicuously pronounced directionality.

Variation of in-situ stress with burial depth

As depicted in Fig. 5, the range of the maximum horizontal principal stress within the Luxin mining area extends from 5.47 to 18.8 MPa. The peak value of this stress is observed in the return airway of the N4 l district, situated at a depth of 440 m, while the minimal value is identified 100 meters downstream of the 4 th horizontal crosscut track dip roadway in Luxin No.2coal mine, located at a depth of 278 m. Similarly, the minimum horizontal principal stress spans from 3 to 10.15 MPa. The highest measurement of this stress is detected in the S4103 belt roadway in Shadunzi coal mine, reaching a depth of490 meters, with the lowest measurement located 100 m downstream of the 4 th horizontal crosscut track dip roadway in Luxin No.2 coal mine, at a depth of 278 m. As the burial depth increases, the magnitudes of both the maximum and minimum horizontal principal stresses exhibit an upward tendency. In the Luxin Mining Area, the in-situ stress magnitude varies with burial depth and its data discreteness shows certain characteristics. As burial depth rises, the data dispersion of the maximum and mininum horizontal principal stresses first widens and then narrows, peaking at 300–400 m. The vertical stress has a basically linear increasing relation with burial depth.

Lateral pressure coefficient with burial depth

The lateral pressure coefficient (σH/σv) serves as an indicator of the in-situ stress state at measurement points. Figure 6 delineates the distribution of lateral pressure coefficients recorded at 22 designated measurement points within the Luxin mining area. Within this region, the range of the lateral pressure coefficient spans from 0.6 to 2.1. At these monitoring locations, the highest recorded lateral pressure coefficient is 2.08, encountered at the minimal depth of 192 m. Conversely, the lowest lateral pressure coefficient, measuring 0.67, is recorded at a deeper location, 359 m. With increasing depth, the lateral pressure coefficient tends to converge toward a value of 1. Significantly, at depths exceeding 400 m, there is a notable decrease in the lateral pressure coefficient.

Figure 7 shows that the lateral pressure ratio of in-situ stress in the Luxin Mining Area has varying discreteness at different burial depths. For the ranges of 100–200 m, 200–300 m, 300–400 m, and 400–500 m, the absolute value ranges of its differences from 1 are 1.07–1.08, 0.03–0.91, 0.03–0.82, and 0.11–0.65 respectively, and the differences between the maximum and minimum lateral pressure ratios are 0.01, 1.12, 1.14, and 0.53 in turn. When the burial depth is below 400 m, the discreteness of the ratio is quite significant and the points with a ratio less than 1 all have burial depths under 400 m. When it exceeds 400 m, the discreteness is relatively small. This indicates that as the burial depth increases, the original rock stress state in the area is gradually changing from the tectonic stress field to the self-weight stress field.

As depicted in Fig. 8, the majority of measurement points exhibit lateral pressure coefficients within the range of 1 to 2. Specifically, three locations, representing 13.6% of the study sample, possess coefficients below 1, at depths varying from 267 m to 359 m. Conversely, 17 points, accounting for 77.27% of the total, register coefficients between 1 and 2, spanning depths from 233 m to 369 m. Additionally, two points, comprising 9.09% of the total, display coefficients exceeding 2, with depths situated between 192 m and 193 m. Notably, both the domains where coefficients fall below 1 and those exceeding 2 are exclusively found within the Luxin No.2 coal mine.

Difference of principal stress with burial depth

The difference between the maximum and minimum horizontal principal stress exerts a significant impact on the geological structure. This differential contributes to the formation of joints and fissures within the rock strata, ultimately precipitating the failure of the coal-rock mass. Figure 9 illustrates that the horizontal principal stress difference in the Luxin mining area varies from 2.47 to 9.6 MPa. Notably, at depths beyond 400 m, all recorded values of the horizontal principal stress difference exceed 5 MPa. The minimal stress difference, recorded at 2.47 MPa, corresponds to the position at 100 m downstream of the 4 th horizontal crosscut track dip roadway in Luxin No.2 coal mine, at a depth of 278 m. In contrast, the peak value of this stress difference, 9.6 MPa, is observed in the centralized return airway of the N41 mining area within Shadunzi coal mine, at a depth of 440 m. It is observed that as the depth increases, not only does the horizontal principal stress difference elevate, but also the intensity of shear stress within the geological strata progressively augments.

The principal stress difference ratio is the ratio derived from dividing the differential between the maximum and minimum horizontal principal stress by the maximum horizontal principal stress11. Illustrated in Fig. 10, this ratio attains a maximum of 0.52 and a minimum of 0.37 in the Luxin mining area. The data display a mean value closely aligned with 0.45. According to the previous data, the uniaxial compressive strength of the 4 − 1 coal seam in Shadunzi is within the range of 8.9 to 12.18 MPa. The difference in horizontal principal stress in the Luxin Mining Area is from 5.85 to 9.6 MPa, and the difference in some horizontal principal stresses is close to the uniaxial compressive strength of the coal mass, which means a small portion of the coal mass is subjected to relatively large shear stress, possessing relatively poor integrity and being liable to fragmentation. In contrast, the remaining part of the coal mass can maintain a relatively favorable integrity.

Ratio of coefficient of horizontal pressure with burial depth

As inferred from the collected data in the Luxin mining area, Fig. 11 illustrates a scatter plot delineating the fluctuation of the ratio between the average horizontal principal stress and vertical principal stress (σH + σh/2σv) as a function of burial depth. The data manifest considerable variations, suggesting a broad dispersion of stress fields in the shallow regions of mining areas. In the near-surface strata, it is common for the horizontal principal stress to surpass the vertical principal stress. With increasing burial depth, the average ratio between horizontal principal stress and vertical principal stress is gradually close to 1, demonstrating a progression from a dominantly structure stress field to a gravitational stress field.

A linear fit is performed on the variation of the ratio of average horizontal principal stress to vertical principal stress with burial depth for 22 measurement points in the Luxin mining area, where the results are used to analyze the stress field transformation.

Meanwhile, the following formula is also present.

Where (a) and (b) are undetermined constants, we have the following formula:

The test data, when fitted with linear regression, yields: a = 137.55, b = 0.6504, resulting in the following expression:

Influence of regional structural on in-situ stress in the Luxin mining area

The in-situ stress distribution characteristics in the Luxin mining area, as presented above, offer a comprehensive understanding of the stress state within the region. These characteristics, such as the magnitude, direction, and variation trends of the principal stresses, provide valuable insights into the mechanical behavior of the rock masses in the mines. However, to gain a deeper understanding of the factors governing this in-situ stress distribution, it is essential to explore the role of geological structures.

Geological structures play a significant role in shaping the in-situ stress field. In the context of the Luxin mining area, various geological structures, including folds and faults, have been identified. These structures have not only influenced the formation of the mining area but also have a profound impact on the distribution of in-situ stress. Therefore, in the following sections, we delve into the influence of regional geological structures on the in-situ stress in the Luxin mining area, aiming to uncover the underlying mechanisms and relationships.

Since the Permian period, the Turpan Basin has undergone numerous geological structure phenomena. These phenomena have triggered alternating phases of extension and compression, coupled with repeated cycles of subsidence and uplift within the basin. From the early Permian period, the formation of the Rotagh Mountains occurred, whereas the Bogda-Harli region has yet to undergo orogenic reversal. The basin, situated in an extensional structure setting, has experienced pronounced structure activities.

Following sediment in the early Permian, a swift uplift ensued in the Bogda-Harli region due to the novel tectonic activity of the Turpan Basin, effectuating a separation between the Turpan and Junggar Basins. Subsequently, beginning in the late Permian, the basin transitioned into a continental lake basin phase. During this transformation, the rift-type basin progressively morphed into a depression basin, accompanied by a reduction in the erosion height of the Bogda Mountains.

Influenced by the Yanshan orogeny in the Jurassic period, the basin witnessed the formation of numerous faults, which precipitated an overall uplift and extensive denudation, creating incongruent contacts between the Cretaceous and the underlying strata. In the late Tertiary, the Bogda Mountains underwent extensive surface uplift, and throughout the Quaternary period, drying up and disappearance of the lake basin occurred, leading to the gradual transformation of the depression basin into a compressed basin. This series of events culminated in the formation of the present Turpan Basin, depicted in Fig. 12.

In subsequent developments within the Turpan Basin, movements were observed in faults associated with the Indosinian, Yanshan, and Himalayan structure stages. The basin, during the Indosinian orogeny, was predominantly influenced by compressive forces oriented from the northeast to the southwest. The underlying crustal architecture from the northwest and northeast exerted control and influenced the southern region, eliciting distinct geological responses. The central segment of the basin is predominantly delineated by a sequence of anticlines extending in a northeast direction, with the anticlines in the Aiding Lake slope area being particularly prominent and well-developed.

In the western region of Turpan, during the Yanshan period, local stress fields altered, generating compressive forces-oriented northwest-southeast, which resulted in the formation of several northeast-trending reverse faults on the northern side of the basin, noted predominantly in the northern subsidence area. During the Himalayan period, the principal stress field transitioned to an NNE-SSW orientation. The formation of the northern subsidence area is intricately linked to the progressive southward thrust of reverse faults, which also exhibit fault characteristics trending north-south. This complexity has shaped the intricate structure of the contemporary Turpan Basin22.

Geological structure of Tuha basin23.

In consequence of the north-south compressive stress impinging upon the TianShan latitudinal chain substantial east-west foreland fold-thrust belts and subsidence zones within the Tian Shan and Turpan regions have manifested. Within this geographical setting, alterations to the orientations of the Xishan anticlines have occurred, precipitated by the lateral structure forces from the Tian Shan. This region was subsequently reshaped during the late Paleogene period due to the Himalayan orogeny culminating in the development of secondary fold structures oriented from southwest to northeast Simultaneously influenced by these folds and southwestern torsional stress, the Luxin mining area observed deviations in the maximum horizontal principal stress direction. Consequently, in this locality, flanking the Xishan anticlines, predominantly northwest-oriented maximum horizontal principal stress directions have been noted in three coal mines.

Additionally, fault structures have exerted a pronounced impact on stress orientation, with vertical principal stress surpassing horizontal stress, the predominant failure mode of the stratigraphy is tensional, leading to the formation of F3 normal faults. In contrast, when horizontal stress overpower vertical principal stress, the stratigraphy predominantly encounters horizontal compression, facilitating the concentration of stress at structural weaknesses and resulting in the genesis of fault slip surfaces, such as Fl, F2, and F4 reverse faults. Specifically, Luxin No.l coalmines and Luxin No.2 coal mines are positioned over Fl and F2 reverse faults.

In regions characterized by faults, the direction of maximum horizontal principal stress typically aligns perpendicular to the fault’s direction of stretch24,25. However, this orientation can alter due to changing structural profiles, influenced by steep zones, tilting end, saddles, or nose structures of’ the Xishan anticlines. Near fault lines, three measurement points at Luxin No.l coal mine indicated a maximum horizontal principal stress direction ranging from N 22.5° to 78.6° E, whereas four point sat Luxin No.2 coal mines displayed readings ranging from N 21 0.4° to 70.8° E. Profiles A-A, B-B, and C-C, illustrated in Figure l, portray the geological structures of Luxin No.l coal mines, Luxin No.2 coal mines, and Shadunzi coal mine, as delineated in Fig. 13.

As shown by Table l and Figure l, a significant distinction in stress levels exists between the crustal uplift and subsidence zones of the Xishan anticline-stress is remarkably high in the uplift zone while remaining subdued in the subsidence area. Within this context, the vertical principal stress at the axial position of the anticlinal structure supersedes the horizontal stress. At this axis, the maximum horizontal principal stress commences at a low level, elevating progressively towards both flanks. Additionally, proximity to the Fl, F2, and F4 reverse faults within the Luxin mining area precipitates a reduction in stress on the fault planes prior to slippage. Energy dissipation and stress redistribution, triggered by fault activity, foster stress agglomeration at fault intersections, branches, and inflection points, thereby engendering pronounced variations in stress distribution along the faults as illustrated in Fig. 14.

Specifically, at Luxin No.1 coal mines, two axial points exhibit maximum horizontal principal stress of 9.18 MPa and 10.17 MPa, respectively. This contrasts with measurements from three points located toward the base of the anticline’s flanks, where stress range from 15.17 to 16.53 MPa. In a similar vein, at Luxin No.2 coal mines, the axial zone shows stress between 5.47 and 6.49 MPa, rising to 7.38 MPa transitioning toward the flanks and peaking at 9.5 ~ 11.12 MPa at the base. At Shadunzi coal mine, stress in the axial zone range from 13.15 to 13.69 MPa and climb steadily to 14.7 MPa before reaching 16.07 ~ 18.8 MPa at the flanks’ bases. Conclusively, there is an ascending trend in maximum horizontal principal stress from the axial zone towards the bases of the anticline’s flanks in the Luxin mining area. This trend is notably influenced by the proximity to the F1 and F2 reverse faults, leading to stress variations within the transitional zones of the Xishan anticline’s flanks. The in-situ stress distribution within the Luxin Mining Area is attributed to the integrated influence of the Xishan anticline, faults, as well as the torsional stress in the north-south orientation.

Engineering applications

The S4103 working face of Shadunzi Coal Mine is situated in the southern region of the Shadunzi Coal Mine area, boasting a burial depth ranging from 466 to 552 m. The principal coal seam being mined is the 4 − 1 coal seam, with a thickness spanning from 16.11 to 20.14 m, which falls into the category of a thick coal seam. Its uniaxial compressive strength measures 10.57 MPa. The immediate roof of the working face consists of sandstone with a thickness of 0.3 m, and the uniaxial compressive strength of this sandstone is 42.35 MPa.

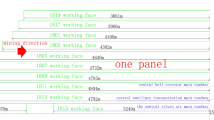

Upon conducting a comprehensive stress assessment on the S4103 working face of Shadunzi Coal Mine, it has been determined that the maximum horizontal principal stress of the S4103 working face fluctuates between 13.4 and 17.8 MPa. The minimum horizontal principal stress lies within the range of 10.33 to 12.5 MPa, and the difference between the maximum and minimum horizontal principal stresses is 5.47 to 9.6 MPa. The direction of the maximum horizontal principal stress is from N23°W to N36.2°W, forming a relatively large angle with the strike of the S4103 roadway. Notably, both the values of the maximum horizontal principal stress and the lateral pressure coefficient exhibit a steadily decreasing tendency from the western part to the eastern part.The maximum horizontal principal stress and lateral pressure coefficient in S4103 is shown in Fig. 15.

Fault structures like the Xishan Anticline, F1, and F2 present in the S4103 working face render the stress distribution in the vicinity of the working face highly intricate. These geological structures not only alter the in - situ stress state of the rock mass but also have the potential to inflict damage on the coal seam, thereby escalating the safety risks during the mining process. Taking into account the aforesaid geological conditions, the mining operation of the S4103 working face confronts numerous challenges. The substantial horizontal stress, the issue of the angle between the stress direction and the roadway strike, and other factors all exert an adverse influence on the stability of the roadway. Consequently, it is of utmost necessity to reinforce the roadway support.

The analysis of the contour map displaying maximum principal stress and lateral pressure ratio at the S4103 working face reveals distinct high stress at greater depths. Considering the varied geological strata along the east-west axis of the S4103 working face, a return airway and belt roadway support plan has been carefully devised.

As depicted in Fig. 16(a), the return airway possesses a rectangular cross-section, measuring 4.9 m in width and 3.7 m in height. Anchor bolts for both the ceiling and sidewalls implement left-hand thread steel with a diameter of Φ22 mm and an un-reinforced length of 2400 mm. The installation pattern for these bolts is set at 850 × 800 mm for the ceiling, installing six bolts per row, and 1000 × 800 mm for the sidewalls, accommodating eight bolts per row. Robust arch-type saddles with dimensions of 150 × 150 × 10 mm strengthen the structural integrity of both top and side anchor bolts, supplemented by a grid network of 10# iron wire. Anchoring cables, utilized on both the top and side, comprise Φ21.8 × 8300 mm steel strands, spaced 1600 mm apart. Support is further enhanced by steel beam saddles constructed from Φ12 mm round steel, measuring 3400 × 80 mm. U-shaped supports, fabricated from U29 steel, are spaced at 900 mm intervals.

Similarly, the belt roadway, as illustrated in Fig. 16(b), features a rectangular cross-section with dimensions of 5.6 m by 3.7 m. Anchor bolts here also utilize left-hand thread steel, boasting identical diameter and lengths as those in the return airway, yet with slightly adjusted spacing configurations: 950 × 800 mm for the ceiling and 1000 × 800 mm for the sidewalls. Like in the return airway, high-strength arch-type saddles and a supportive grid of No.10 iron wire are employed. Anchoring cables and steel beam saddles maintain the same specifications as those used in the return airway, while U-shaped steel supports are set at 1000 mm intervals.

During mining operations within the S4100 working face, significant convergences—measured at 287 mm and 305 mm for the roof and walls of the return airway, and 312 mm and 334 mm for the belt roadway—indicate deformation. The surrounding rock shows minor deformation, a validation of the efficacy of the implemented support systems in maintaining the structural integrity of the roadway.

Conclusion

(1) Through hydraulic fracturing, in-situ stress testing was conducted at 22 survey points in the Luxin mining area. Overall, the Luxin Mining Area is characterized by a medium to low stress field, with some localized high-stress areas. Both the maximum horizontal principal stress and the minimum horizontal principal stress, as well as the vertical stress, show a positive correlative relationship with the depth. The maximum horizontal principal stress ranges from 5.47 to 18.8 MPa, the minimum horizontal principal stress ranges from 3 to 10.15 MPa, and the vertical principal stress ranges from4.8 to 12.5 MPa. With the increase in burial depth, the discreteness of the maximum and minimum horizontal principal stresses first increases and then decreases.

(2) The stress ratio of lateral pressure to vertical pressure in the Luxin mining area ranges from0.6 to 2.1. As depth increases, the lateral pressure ratio gradually decreases and approaches a value of 1. The difference between the maximum and minimum horizontal stress in the Luxin mining area ranges from 2.47 to 9.6 Pa. For measurement points with depths greater than 400 m, the difference in principal stress exceeds 5 MPa. The ratio of average horizontal principal stress to vertical principal stress gradually approaches l as depth increases. The discreteness of the lateral pressure ratio gradually decreases as the burial depth increases.

(3)In the Luxin mining area, the direction of the maximum principal stress is predominantly NW. Due to the influence of the F1 and F2 reverse faults, which have rotated the stress direction, the maximum horizontal principal stress at seven measurement points in Luxin No. 1 Mine and Luxin No. 2 Mine is oriented N (21.4°~78.6°) E. The maximum horizontal principal stress in the axial part of the Xishan Anticline, the transition zone, and the two wing bases are 5.47 ~ 13.15 MPa, 7.38 ~ 14.7 MPa, and 9.5 ~ 18.8 MPa, respectively. The maximum horizontal principal stress shows an increasing trend from the axial part to the base. The fluctuations in the maximum horizontal principal stress in this area are due to energy dissipation and stress redistribution caused by the fracturing of rock masses along the F1 and F2 reverse faults. The in-situ stress distribution within the Luxin Mining Area is attributed to the integrated influence of the Xishan anticline, faults, as well as the torsional stress in the north-south orientation. According to the in-situ stress data from the Sandunzi coal mine, a support plan for the S4103 working face roadway was designed to ensure the safety of the roadway.

Data availability

Data will be made available on request by contacting Dr Feng Wang (wangfeng@sdust.edu.cn).

References

Xie, H. P. et al. Preliminary research and scheme design of deep underground in situ geo-information detection experiment for geology in time. Int. J. Min. Sci. Technol. 34 (1), 1–13. https://doi.org/10.1016/j.ijmst.2023.12.004 (2024).

Li, P. et al. Current stress field and its relationship to tectonism in a coal mining district, central China, for underground coal energy exploration. Energy Rep. 8, 5313–5328. https://doi.org/10.1016/j.egyr.2022.04.008 (2022).

Lyu Feng, L. J. C. et al. 3D in-situ stress prediction for shale reservoirs based on the CapsNet-BiLSTM hybrid model. Int. J. Rock Mech. Min. Sci. 183, 105937. https://doi.org/10.1016/j.ijrmms.2024.105937 (2024).

Zhou, Z. L. et al. Experimental study of hydraulic fracturing for deep shale reservoir. Eng. Fract. Mech. 307, 110529. https://doi.org/10.1016/j.engfracmech.2024.110259 (2024).

Jiang, J. D. et al. Analytical investigation for stress measurement with the rheological stress recovery method in deep soft rock. International Journal of Mining Science and Technology. 26(6), 1003–1009. (2016). https://doi.org/10.1016/j.ijmst.2016.09.007Get rights and content.

Li Xb, Chen, J. Z. et al. A novel in-situ stress measurement method incorporating non-oriented core ground re-orientation and acoustic emission: A case study of a deep borehole, International Journal of Rock Mechanics and Mining Sciences. 152, 105079. (2022). https://doi.org/10.1016/j.ijrmms.2022.105079Get rights and content.

Zhou, H. W. et al. Numerical analysis on mechanical difference of sandstone under in-situ stress, pore pressure preserved environment at depth. Int. J. Min. Sci. Technol. 33 (11), 1339–1350. https://doi.org/10.1016/j.ijmst.2023.07.005 (2023).

Zhang, J. et al. Distribution law of underin-situ in-situ stress in Xishan coal mine field in Shanxi Province. J. China Coal Soc. 45 (12), 4006–40160. https://doi.org/10.13225/j.cnki.jccs.2020.1605 (2020).

Wu, Y. Z. et al. Study on geostress distribution law of deep mine in Yima mining area. Coal Sci. Technol. 46 (10), 16–21. https://doi.org/10.13199/j.cnki.cst.2018.10.003.( (2018).

Kang, H. P. et al. Research on in-situ stress in Jincheng mining area and its application. Chin. J. Rock Mechan. Eng. 28 (1), 1–8 (2009).

He, J. et al. Field measurement research on in-situ stress distribution law of main coal seams in Yangquan mining area. J. Min. Strata Control Eng. 40 (6), 1191–1200. https://doi.org/10.13545/j.cnki.jmse.2022.0327 (2023).

Kang, H. P. & Gao, F. Q. Evolution of Mining - induced stress in coal mines and surrounding rock control. Chin. J. Rock Mechan. Eng. 43 (01), 1–40. https://doi.org/10.13722/j.cnki.jrme.2023.1055 (2023).

Gao, G. Y., Wang, C. H. & Gao, K. Stress tensor determination by modified hydraulic tests on pre-existing fractures: method and stress constraints. J. Rock Mech. Geotech. Eng. 16 (5), 1674–1648. https://doi.org/10.1016/j.jrmge.2023.11.029 (2024).

Guo Dy, Chuai, X. S. et al. Distribution pattern and influencing factors of in-situ stress for deep levels in Shoushan 1 coal mine. J. China Coal Soc. 49 (5), 2360–2375. https://doi.org/10.13225/j.cnki.jccs.2023.1646 (2024).

Kang, H. P., Gao, F. Q. & Xu, G. Mechanical behaviors of coal measures and ground control technologies for China’s deep coal mines – A review. J. Rock Mech. Geotech. Eng. 15 (1), 37–65. https://doi.org/10.1016/j.jrmge.2022.11.004 (2023).

Kang, H. P. et al. Database and characteristics of underground in-situ stress distribution in Chinese coal mines. J. China Coal Soc. 44 (1), 23–33. https://doi.org/10.13225/j.cnki.jccs.2018.5032 (2019).

Kang, H. P. In-situ Geomechanics Measurements for Coal and Rock Masses and Their Application on Strata Control.(ed,Feng XT.) 16–30(Science Press, (2013).

Wang, F. et al. Surface collapse control under Thick unconsolidated layers by back-filling strip mining in coal mines. Int. J. Rock Mech. Min. Sci. 113, 268–277. https://doi.org/10.1016/j.ijrmms.2018.11.006 (2019).

Wang, F. et al. Effects of arch structure in unconsolidated layers on fracture and failure of overlying strata. Int. J. Rock Mech. Min. Sci. 114, 141–152. https://doi.org/10.1016/j.ijrmms.2018.12.016 (2019).

Chen, S. J. et al. Law and mechanism of surface movement and deformation above shallow Longwall abandoned gob under Building load. J. China Coal Soc. 47 (12), 4403–4416. https://doi.org/10.13225/j.cnki.jccs.w022.0775 (2022).

Tan, G. Q. Study on the distribution characteristics of ground stress field in Luxin mining area. Coal Min. 18 (03), 75–77. https://doi.org/10.13532/j.cnki.cn11-3677/td.2013.03.017 (2013).

Guo, R. Study on jurassic hydrocarbon accumulation law in Piedmont zone of Northern Tuha basin. DaQing: Northeast Petroleum Univ. 7-8. https://doi.org/10.26995/d.cnki.gdqsc.2023.001019 (2023).

Wang, S. X. Geological characteristics of structure evolution and coal-forming law in the Southern margin of Turpan-Hami basin, Xinjiang. Changchun: JiLin Univ. 22-33 https://doi.org/10.13545/j.cnki.jmse.2022.0327 (2013).

Zhang, J. G. et al. Changes in pore pressure and temperature during coal and gas outburst stimulated by mining-induced stress. J. China Coal Soc. 49 (11), 4486–4494. https://doi.org/10.13225/j.cnki.jccs.2023.1377 (2024).

Wang, J. et al. In-situ stress distribution characteristics and its relationship with geological structure in Xingcun mine. J. Min. Saf. Eng. 36 (06), 1240–1246. https://doi.org/10.13545/j.cnki.jmse.2019.06.022 (2019).

Acknowledgements

The authors acknowledge the support from the National Natural Science Foundation of China (Grant No. 52274129), Taishan Scholars Project Special Fund (grant No. tsqn202312195), Youth Innovation Team Development Plan of Colleges and Universities of Shandong Province (grant No. 2022 KJ320), Science and Technology Plan Project of Guizhou Province (grant No. Qiankehezhicheng [2023] Generally 247)

Author information

Authors and Affiliations

Contributions

LL was primarily responsible for drafting the manuscript text, with WF overseeing the manuscript, MJ providing the analyzed data, and MJQ, CBH, and ZPP handling the fieldwork.All authors critically revised and approved the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Lu, L., Wang, F., Mu, J. et al. Distribution of in-situ stress and regional structural influence in the Luxin mining area and engineering applications. Sci Rep 15, 16945 (2025). https://doi.org/10.1038/s41598-025-01533-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-01533-x