Abstract

The increasing adoption of renewable solar energy sources offers significant opportunities for sustainable energy applications due to their economic benefits and the conservation of natural resources with eco-friendly and reduced drying time. Solar dryers play an important role in drying agricultural products; however, it found the challenges of heat loss, instability in varying weather conditions, and limited efficiency during periods of insufficient solar radiation. This study aims to enhance the thermal performance of solar dryers that incorporate paraffin phase change material (PCM) into a fin collector absorber for drying agricultural products, specifically banana and potato slices cut to 2 mm thickness. The investigation was carried out using three different setups: a conventional solar collector (Case 1), a solar collector featuring PCM (Case 2), and a solar collector with both fin and PCM configurations (Case 3). The experimental results reveal that in Case 3, the fin collector with the PCM-configured absorber exhibited the best drying performance among the three setups. It reached an optimal temperature of 60.8 °C, achieving improved moisture ratios of 0.51 for bananas and 0.54 for potatoes. The drying rates recorded for Case 3 were 0.89 kg/h for banana slices and 0.85 kg/h for potato slices. Furthermore, the collector efficiency increased to 75.3% for bananas and 78.7% for potatoes, reflecting improvements of 77% and 43%, respectively, compared to the efficiency of Case 1 (plain absorber).

Similar content being viewed by others

Introduction

Solar thermal energy is preserved from natural resources, which were used for various engineering applications, including heat exchangers, solar air heaters, and solar-based air conditioning systems1. However, it has found variations in thermal performance due to climatic change2 and overcome by the adaptation of phase change materials3. While the solar thermal collector system featured with nanofluid found uniform heat transfer behaviour with enhanced thermal performance than water fluid operated solar thermal system4. Recently, solar thermal dryers have gained significance in commercial applications and are utilized for drying agricultural products5. Selvam et al.6 experimentally studied the thermal behaviour of flat plate solar collectors featuring hybrid nanofluid (alumina/nickel/water) under varied flow rates. With the excellence of hybrid nanofluid, the heat absorption and thermal efficiency behaviour of flat plate solar collector was progressively enhanced and pressure drop influenced to limits the enhancement of thermal efficiency. Besides, the contribution of PCM inside the solar (flat) collector was found to have better thermal efficiency and improved dryer performance compared to conventional systems7.

The functional behaviour of the solar air dryer was enhanced by the collector featured with copper tube, and operated with paraffin PCM and engine oil filler. The copper tube and combinations of PCM/engine oil influenced superior air dryer performance, with its drying time reduced by 78.12% related to sunlight drying performance time8. The effectiveness of dryers was improved by using paraffin phase change materials (PCMs) and by dehydrating products after sunset9. Experimental studies have been conducted on waste beverage cans configured with solar air heaters. These investigations demonstrated that, based on thermodynamic analysis, the system achieved maximum energy and exergy efficiencies of 21% and 1.8%, respectively10. In the context of drying chilli products, the latent heat properties of solar air dryers were enhanced through the use of PCM materials. Solar air dryers that incorporate PCM exhibit superior moisture removal capabilities and improved moisture ratios compared to systems without PCM. This was because PCM effectively stores thermal energy, which significantly enhances the drying performance for chilli applications11. Saxena et al.12 experimentally studied the performance of solar air heaters in space heating technology. They analyzed three different configurations: conventional solar heaters, air heaters modified with PCM (coconut oil), and paraffin. The results showed that the solar air heater featuring paraffin provided better heat transfer (372.81 W/m2 K), improved thermal efficiency (75.9%), and higher air heating temperatures (44.07 °C). Additionally, the functional properties of the solar air heater were enhanced by integrating PCM with a helical tube absorber setup, resulting in improved thermal efficiency and an exhaust air temperature of 52.5 °C, which was greater than that of conventional solar air heaters13. Recently, the thermal characteristics of solar dryers have been investigated under conduction mode for drying agricultural products, achieving a maximum output air temperature and an optimum drying efficiency of 50.09%14.

Furthermore, the properties of solar thermal dryers were enhanced through advanced PCM techniques combined with a thermal energy storage system, leading to better energy performance in drying agricultural products15. The impact of PCM and nano PCM on the functional behaviour of solar photovoltaic (PV) cell systems has also been studied, showing that nano PCM provides better cooling and reduces overheating in solar PV cells16. PCM-based materials enhance latent heat and increase heat transfer rates due to their large surface area17. The forced convection technique was employed to improve the performance of solar dryers, resulting in an efficiency increase of 51.7%18. A parabolic trough collector-based thermoelectric generator has been used to boost the thermal efficiency of solar drying systems19. The application of hybrid phase change materials in solar dryers has led to significant improvements in collector thermal efficiency, drying rates, and overall dryer effectiveness. Notably, the integration of PCMs in forced convection systems consistently outperforms traditional setups, regardless of whether convection is natural or forced20. Moreover, Cakmak et al.21 conducted experiments using a PCM-integrated solar dryer for drying seeded grapes, achieving faster drying with lower moisture content. Another study noted an estimated thermal efficiency of 52% when using paraffin wax for drying potato chips22. Rezaei et al.23 studied the solar dryer performance of an air heater featured with paraffin PCM. The solar air heater designed with forced convection flow with PCM exposed better dryer efficiency behaviour, which was superior to conventional solar air heaters without PCM. Suherman et al.24 investigated the dryer performance and moisture behaviour of solar air dryers featuring liquefied natural gas heaters. It found enhanced dryer performance with optimum moisture ratio behaviour. Cisni et al.25 experimentally studied the dryer performance of a solar air dryer configured with an electrical heater setup. Hybrid solar electrical systems found better dryer performance and found variation in overall efficiency due to heat loss. Agriculture products like fruits and vegetables were dried via a thermoelectric heat pump and found to have better dryer performance with enhanced dryer efficiency of 22.5%26. Similarly, the banana slice was dried via a heat pump dryer and found to have a better dryer efficiency of 30%, but it was costlier than solar-assisted air dryer behaviour27. However, paraffin-based PCM materials were influenced to better thermal stability and degradation behaviour and exposed better latent heat of fusion28,29. The PCM system is mapped with a photovoltaic module to provide better cooling and enhanced solar cell performance than a monolithic PV setup without PCM30. Karthikeyan et al.31 studied the PV module performance. They found that the system featured with paraffin PCM provided better thermal degradation and absorbed the excessive heat from the PV cell result enhanced PV solar cell performance. Rekha et al.32 evaluated the effect of PCM on thermal energy capabilities and operational stability of heat batteries with 1000 thermal cycles on solar cooking applications. It results showed that the PCM-configured system has an optimum solar efficiency of 22.8%. Likewise, Satish et al.33 studied the solar air heater performance using hybrid nanofluid and paraffin PCM for solar cooking applications. The box-type solar thermal cooking system configured with WMCNT/SiO2 hybrid nanofluid and PCM showed enhanced solar thermal and exergy efficiency behaviour. However, modification of the solar thermal system featured a hybrid design module found better solar thermal performance34,35.

The present investigation of solar dryers configured with fin absorbers and PCM closely interrelated previous literatures are studied and its details are elaborated above. The solar air-heater system featured nanofluid or PCM material along with a modified absorber design that was exposed to better thermal performance compared to conventional systems. Besides, the helical type absorber was found to be complex in design. The efficiency of heat exchange depends on the thermal conductivity of the PCM, which is often lower than desired, leading to slower response times and requiring larger space constraints. The novelty of the present solar air-dryer system’s functional properties is enhanced by a modified fin absorber and configured with paraffin phase change material (PCM). The solar dryer system functioned by a conventional solar collector (case 1), PCM featured (case 2), and a fin & PCM-configured setup (case 3) for drying the banana and potato slice with a thickness of 2 mm. Influences of case 1, case, and case 3 on functional properties like outlet temperature, drying rate, moisture ratio, and collector efficiency were investigated and compared.

Materials and methods

Material details

Current investigation, the flat plate solar collector is used, and its specification is presented in Table 1.

Paraffin phase change material (PCM) is utilized for thermal energy storage systems to enhance the thermal performance of conventional solar dryer systems, and it is collected from M/S. Saveetha university (department of research and development), Chennai, Tamilnadu, India. The paraffin PCM has high latent heat fusion (250 kJ/kg), a wide range of melting points, better chemical stability, non-toxic, low cost, and non-corrosive12. Table 2 presents the properties of paraffin PCM.

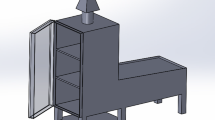

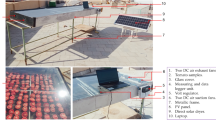

Figure 1 shows the actual experimental setup along with the schematic layout of the present investigational solar dryer unit. The experiments were conducted by conventional solar collector (case 1), paraffin PCM configured system (case 2), and fin and PCM featured solar system. This setup is located at Saveetha University, Chennai, with a longitude and latitude of about 80.5° E and 13.1° N. On February 2 week, the experiment was conducted with the environmental conditions like day average mean ambient temperature is 25.7 °C, relative humidity is 68.3% and the direction of wind & its velocity is 8.1 mph SE with a range of solar radiance is 340–780 W/m2.

The specification of the dryer container is 0.5 m × 0.4 m × 0.08 m in length, width, and height. Similarly, the PCM container with absorber unit is prepared by mild steel material with and without copper fin setup (Total fin is 9). Each fin has a specification of 0.3 m × 0.05 m in length and width. Potatoes and bananas (slices) are taken as dried products in the investigation due to the reasons for high moisture content, nutritional contents like carbohydrates (potatoes) and potassium, natural sugar, & vitamins (bananas), used in processed foods for optimized quality, and demand for consumer preference. Through this, various food products are processed like chips and snacks. Figure 2a,b indicates the before and after drying of Bananas and potato slices.

During the experimentation, the SKU-made FST200-1000 model anemometer was used to measure the wind velocity, which features a direct sensor with 4–20 ma output at 0.5 to 50 m/s range. The KIPP & ZONEN SMP 10 model pyrometer is used to monitor the solar radiation configured with Spectrally Flat Class A and its range − 200 to 2000 w/m2. The J-type thermocouple is used to measure the temperature, and its range is 0–400 °C. A BOSCH-made GBL model air blower is used, which is featured with a dust collector setup.

Drying process details

With the support of the blower, the air was circulated to the dryer chamber, which passes through the collector and absorber setup. During the experiment, the airflow rate was maintained by 0.1 m3/s. The sliced bananas and potatoes are kept in dryer trays, which are highlighted in Fig. 2b. The schematic layout for the drying process is presented in Fig. 1b. The air is passed through the collector absorber unit, and the initial stage is operated without PCM and fin configuration. A J-type thermocouple setup measures the inlet and outlet temperature of the air. Similarly, the weight of sliced bananas and potatoes is weighted by a digital balancing machine before and after the drying process to calculate the moisture ratio. A similar procedure was repeated for all three cases (cases 1, 2, and 3).

The thermal performance of solar collectors is calculated by using the following equations: collector efficiency (Eq. 1), drying efficiency (Eq. 2)23 and drying performance like moisture ratio & drying rate were calculated by using Eqs. (4) and (5)24.

where ma is mass flow in kg/s, Cpa is specific heat capacity in j/kgK, Tcl,o and Tcl, i is outlet & inlet temperature of air in °C, Is is solar radiation in W/m2, and Acl is Collector area in m2.

where mwt is the mass of water vapour in kg, L and H are the length and height of the dryer unit and Ei, dry is the heat input for the dryer unit in W.

where ms,i and ms,d is the initial and final mass of drying products in kg.

where dMC is the change in moisture content, and dt is the change in the time interval.

Uncertainty analysis

Based on the measuring instrument configuration, the uncertainties were detailed, and the total uncertainties of each instrument system are expressed in Table 3.

The mathematical expression for the uncertainty of the system is represented in Eq. (5).

Results and discussions

According to the investigation experimentation results of the present study are elaborated in Table 4.

The experiment was conducted on February 2 week (5 days) from 9.00 am to 6.00 pm, and its average value of five days is presented in Table 4. During the experiments, the maximum solar performance is found at 1.00 pm and stored thermal energy is utilized after the experiment hours. During the experiment, the average solar radiation and PCM temperature is found to be 750 W/m2 and 51 °C.

Air outlet temperature performance

Figure 3 presents the air outlet temperature of the solar dryer system configured with a conventional system, PCM, and fin & PCM (cases 1, 2, and 3) with a permissible error is 4%. It is noted from Fig. 3 that the outlet temperature air is progressively enhanced with improved time duration, and the optimum temperature is spotted at 1.00 pm due to higher solar radiance of 750 W/m2 and combined actions of copper fin and PCM. It provides improved absorption with uniform distribution temperature. As earlier, Selvam et al.6 reported that solar radiance influences better thermal performance and increases the solar collector temperature, resulting in better outlet fluid temperature.

Here, the air outlet performance of case 1 (without PCM and fin configuration) shows the progressive enhancement in air outlet temperature and maximum temperature of 48 and 46 °C noted by DB and DP products. It is lower than the case 2 and case 3 air outlet temperatures. After 1.00 pm, the temperature of the system was marginally decreased due to reduced solar radiance of 470 W/m2. Besides, the air outlet temperature of case 2 (system configured with PCM) is exposed performance and attained significant enhancement from 34–56 °C and 33–53 °C for bananas and potatoes drying. The presence of PCM influences better thermal conductivity and enhanced latent heat capacity, resulting in superior thermal performance12. Moreover, the excessive heat is absorbed and stored in PCM, balancing the thermal performance.

Likewise, the solar radiance increased from 400 to 750 W/m2. The air outlet temperature for case 3 (PCM and fin configuration) recorded superior performance compared to others and reached maximum temperatures of 60 and 59 °C for DB and DP products. However, the contribution of PCM and fin material influences improved surface conduct, resulting in better heat transfer rate with increased temperature outlet related to others. Besides, the air outlet temperature is gradually decreased after 1.00 pm due to the reduction of solar radiation. With the advantages of PCM material, the stored energy is utilized for climate variation and sunset timings.

Moisture ratio

The average moisture ratio of solar dryers featured with a conventional system (case 1), PCM (case 2), and PCM & fin material (case 3) is shown in Fig. 4 with a test significance of 4% error bar. Generally, the moisture ratio is decreased with increasing the dryer temperature8. The case 3 solar dryer system functioned with PCM and fin recorded better moisture ratio behaviour compared to other systems due to combinations of PCM and fin leading to increased contact surface and PCM storing the waste heat.

During the drying of DB products in cases 1, 2, and 3, the moisture ratio is significantly decreased from 0.78 to 0.51. In case 1, the moisture ratio of DB is spotted by 0.78, which is higher than other values due to reduced air outlet temperature (48 °C-average value). While the system configured with PCM, it shows a better moisture ratio of 0.64 under the air outlet temperature of 56 °C. The PCM exposed a better heat transfer rate with increased dryer temperature12. Besides, the system configured with PCM and fin offers a superior moisture ratio of DB products due to the PCM provides better thermal energy, and the fin leads to an increase in the contact surface. It results in enhanced drying performance the moisture of DB is limited by 0.51, which is 53% better than case 1.

Similarly, the moisture ratio performance of DP under case 1, case 2, and case 3 is illustrated in Fig. 4. Case 3 of the solar system featured PCM and fin design, enhancing the drying behaviour with a better moisture ratio of 0.54. The modified absorber copper fin system leads to an increase in the conducting surface and transfers the heat effectively15. However, the contribution of the copper fin with PCM setup exposed superior thermal conductivity with better energy storage, resulting in better dryer behaviour and reduced moisture ratio. The drying of DP product by case 54 is 51% better than case 1 performance.

Drying rate

Figure 5 illustrates the average drying ratio of a solar dryer system functioned by three cases and its DB & DP product drying details. The drying rate of the drying product is directly influenced by the dryer temperature18. Here the drying rate of DB and DP found better performance on case 2 and case 3 related to case 1.

For case 1, the drying rate for DB and DP products is noted by 0.61 and 0.57 kg/h, while the system evaluated by PCM is found to have better drying rate performance. Because the PCM absorbs the maximum thermal energy from solar radiation and transfers the heat to the air, resulting in enhancement of dryer chamber temperature, and copper fin leads to better thermal conductivity with enhanced heat transfer efficiency leads to better temperature distribution to PCM and absorbs the excessive temperature. This system influenced improved dryer performance and drying time to be minimized. The drying rate of case 2 indicates 0.81 and 0.78 kg/h for DB and DP products. However, the drying rate of case 3 is offered maximum value and is higher than the others. The drying rate of DB and DP noted by case 3 is 0.89 and 0.85 kg/h. Enhancement of the drying rate of the system by reason of a modified fin-designed setup along with PCM provides a better conductive surface resulting in superior thermal transformation and exposed better drying rate. However, the case 3 drying rate of DB and DP is 46% and 49% better than the drying rate of DB and DP in case 1 studies.

Collector efficiency

The collector efficiency of the solar dryer with case 1, case 2, and case 3 is represented in Fig. 6. The average collector efficiency shows the uptrend on the system configuring with PCM and PCM & fin design. Case 3 exposed maximum collector efficiency performance compared to others.

For case 1, the collector efficiency of DB and DP products is shown at 42.5 and 55.1% due to the climate variations influencing changes in solar radiance on conventional solar dryer systems. Limiting the issues that a system configured with paraffin PCM absorbs the high thermal energy during the higher solar radiation and balances the climate variation8,12. It results in better thermal performance and increasing in overall collector performance. The collector efficiency of DB and DP for case 2 is 62.1 and 64.1%. However, the collector efficiency of DB and DP for case 3 recorded optimum values of 75.3 and 78.7%, respectively. The contribution of PCM is to store the high thermal energy, and the fin surface transfers the thermal energy to the dryer system owing to better thermal performance and increased drying rate. Moreover, the collector efficiency of DB and DP of case 3 is 77 and 43% better than the performance of the DB and DP product of case 1.

Thermal conductivity and heat transfer efficiency

Figure 7 presents the thermal conductivity and heat transfer efficiency behaviour of solar collectors featured with conventional aluminium and copper fin material. It is found that the thermal conductivity of copper fin is higher than the aluminium fin due to enhanced heat absorption behaviour14. The thermal conductivity of aluminium and copper fin collectors is found to be 195 W/mK and 228 W/mK, respectively.

Likewise, the copper fin has the potential for improved heat transfer efficiency behaviour, which is higher than the aluminium fin materials due to lower thermal resistance behaviour and higher energy utilization34. The heat transfer efficiency of aluminium and copper fin-featured solar collectors is 68 and 78%, respectively, with respect to improved heat transfer behaviour with higher thermal conductivity, which was incorporated with a PCM-based system to enhance the optimum dryer performance. However, the copper fin is costlier than the aluminium fin, but the copper fin provided higher heat transfer efficiency behaviour than aluminium alloy and improved dryer performance.

Moreover, the novel of the present investigation is highlighted by the comparison of previously reported values, as shown in Table 5

The solar dryer system configured with PCM & fin is found to have better dryer performance for banana and potato product drying and 78% better than the drying performance of tomato slices7. Similarly, the efficiency of solar dryers with PCM & fin configuration is exposed maximum value of 75.3 and 78.7% for DB and DP product drying. It is 32% better than the performance of timber seasoning13. Moreover, the drying performance of the solar collector with absorber featured with paraffin PCM and fin design was found to be 60%, 104%, and 53%, and better than the Solar featured electrical dryer25, thermoelectric heat pump26 and heat pump dryer27 for drying the fishery, agriculture products and banana slice. In addition, incorporating phase change materials (PCM) and a copper fin structure enhances both material and manufacturing costs. This may hinder the widespread adoption of the technology, particularly in low-income agricultural sectors. Furthermore, repeated phase change cycles can cause thermal degradation, diminishing the long-term effectiveness of the PCM and necessitating periodic maintenance/replacement.

Conclusion

The performance of the solar dryer system is evaluated under conventional solar dryer setup (case 1), PCM-configured solar system (case 2), and PCM and fin-configured solar system. The influence of PCM and PCM & fin configuration on air outlet temperature, moisture ratio, drying rate and collector efficiency of the solar dryer is investigated, and its outcomes are compared with conventional solar dryer systems. The significance of PCM and fin-configured solar dryer systems own optimum drying properties related to other cases. The important findings from the experiment are summarized below key points.

-

Among the various configurations, case 3 (PCM and fin featured solar dryer system) of DB and DP found better dryer performance. It shows the better air outlet temperature behaviour of DB and DP, which are 25 and 28% better than the air outlet temperature of DB and DP for case 1.

-

The moisture ratio of DB and DP for case 3 is recorded as 54 and 51% better than the moisture ratio of DB and DP products for case 1.

-

The drying rate properties of DB and DP of case 3 are offered 46% and 49% better than the value of case 1 DB and DP products.

-

The collector efficiency for case 3 DB and DP products is 77 and 43% better than case 1 collector efficiency of DB and DP products.

-

Moreover, the copper fin-featured solar collector was found to improve thermal conductivity and heat transfer efficiency, which are 17% and 15% better than the aluminium fin-featured solar collector system.

-

The optimum behaviour of case 3 solar dryer recommended for agriculture product drying application and future the system will investigated with nanofluid configured PCM solar dryer system.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

Abbreviations

- \(\dot{{m}_{a}}\) :

-

Air flow rate (kg/s)

- \({A}_{cl}\) :

-

Collector area (m2)

- \({C}_{pa}\) :

-

Specific heat

- \({E}_{i, dry}\) :

-

Heat input for dryer (W)

- \({I}_{s}\) :

-

Solar radiation (W/m2)

- \({Q}_{cl,i}\) :

-

Heat input (W)

- \({Q}_{cl,o}\) :

-

Heat absorption by collector (W)

- \({T}_{a}\) :

-

Ambient temperature (°C)

- \({T}_{cl, i}\) :

-

Inlet temperature of air (°C)

- \({T}_{cl, o}\) :

-

Outlet temperature of air (°C)

- \({m}_{s, d}\) :

-

Drying product final mass (kg)

- \({m}_{s, i}\) :

-

Drying product initial mass (kg)

- \({m}_{wt}\) :

-

Mass of water vapour (kg)

- SE :

-

Energy supplied (kWh/kg)

- SR :

-

Specific moisture extraction rate (kg/kWh)

- g1, g2 … gn:

-

Independent variables

- u1, u2 … un:

-

Measured uncertainty

- U Z :

-

Overall uncertainty (%)

- \(LH\) :

-

Latent heat for vaporization of water (J/kg)

- η cl :

-

Collector efficiency (%)

- η dry :

-

Dryer efficiency (%)

- DB:

-

Drying of banana

- DP:

-

Drying of potato

- DR:

-

Drying rate

- MC:

-

Moisture content

- MR:

-

Moisture ratio

- PCM:

-

Phase change material

- TES:

-

Thermal energy storage

References

Kumar, C. M. S. et al. Solar energy: A promising renewable source for meeting energy demand in Indian agriculture applications. Sustain. Energy Technol. Assess. https://doi.org/10.1016/j.seta.2022.102905 (2023).

Logesh, K. et al. Performance investigation of silicon nitride (SiNx) layer doped with twin thin films of gallium and zinc oxide for solar cell. Opt. Quant. Electron. 56, 1160. https://doi.org/10.1007/s11082-024-07100-4 (2024).

Tyagi, V. V. et al. Phase change material based advance solar thermal energy storage systems for building heating and cooling applications: A prospective research approach. Sustain. Energy Technol. Assess. 47, 318. https://doi.org/10.1016/j.seta.2021.101318 (2021).

Wole-osho, I., Okonkwo, E. C., Abbasoglu, S. & Kavaz, D. Nanofluids in solar thermal collectors: Review and limitations. Int. J. Thermophys. https://doi.org/10.1007/s10765-020-02737-1 (2020).

Madhankumar, S., Viswanathan, K., Taipabu, M. I. & Wu, W. A review on the latest developments in solar dryer technologies for food drying process. Sustain. Energy Technol. Assess. 58, 298. https://doi.org/10.1016/j.seta.2023.103298 (2023).

Selvam, L. et al. Impact of hybrid nanofluid on thermal behavior of flat-plate solar collector: Performance study. J. Therm. Anal. Calorim. 1, 1–11. https://doi.org/10.1007/s10973-024-12994-z (2024).

Ebrahimi, H., Samimi Akhijahani, H. & Salami, P. Improving the thermal efficiency of a solar dryer using phase change materials at different position in the collector. Sol. Energy 220, 535–551. https://doi.org/10.1016/j.solener.2021.03.054 (2021).

Bhardwaj, A. K., Kumar, R., Chauhan, R. & Kumar, S. Experimental investigation and performance evaluation of a novel solar dryer integrated with a combination of SHS and PCM for drying chilli in the Himalayan region. Therm. Sci. Eng. Prog. 20, 713. https://doi.org/10.1016/j.tsep.2020.100713 (2020).

Zachariah, R., Maatallah, T. & Modi, A. Environmental and economic analysis of a photovoltaic assisted mixed mode solar dryer with thermal energy storage and exhaust air recirculation. Int. J. Energy Res. 45(2), 1879–1891. https://doi.org/10.1002/er.5868 (2021).

Cuce, P. M. et al. Thermodynamic performance analysis of a low-cost, recycled and energy-efficient solar air heater with waste beverage cans: An experimental research. J. Therm. Sci. 32(4), 1657–1670. https://doi.org/10.1007/s11630-023-1807-x (2023).

Pankaew, P. et al. Performance of a large-scale greenhouse solar dryer integrated with phase change material thermal storage system for drying of chili. Int. J. Green Energy 17(11), 632–643. https://doi.org/10.1080/15435075.2020.1779074 (2020).

Saxena, A. et al. Experimental studies of latent heat storage based solar air heater for space heating: A comparative analysis. J. Build. Eng. 69, 282. https://doi.org/10.1016/j.jobe.2023.106282 (2023).

Saxena, A., Agarwal, N. & Cuce, E. Thermal performance evaluation of a solar air heater integrated with helical tubes carrying phase change material. J. Energy Storage 30, 406. https://doi.org/10.1016/j.est.2020.101406 (2020).

Jain, R., Paul, A. S., Sharma, D. & Panwar, N. L. Enhancement in thermal performance of solar dryer through conduction mode for drying of agricultural produces. Energy Nexus 9, 182. https://doi.org/10.1016/j.nexus.2023.100182 (2023).

Kumar, P. & Singh, D. Advanced technologies and performance investigations of solar dryers: A review. Renew. Energy Focus 35, 148–158. https://doi.org/10.1016/j.ref.2020.10.003 (2020).

Sheik, M. A. et al. A comprehensive review on recent advancements in cooling of solar photovoltaic systems using phase change materials. Int. J. Low-Carbon Technol. https://doi.org/10.1093/ijlct/ctac053 (2022).

Tian, Y. et al. A novel latent heat storage unit by introducing jet breakup of phase change material. J. Energy Storage 49, 7. https://doi.org/10.1016/j.est.2022.104070 (2022).

Huddar, V. B. et al. Thermal performance study of solar air dryers for cashew kernel: A comparative analysis and modelling using response surface methodology (RSM) and artificial neural network (ANN). Int. J. Photoenergy 1, 1. https://doi.org/10.1155/2022/4598921 (2022).

Cuce, P. M., Guclu, T. & Cuce, E. Design, modelling, environmental, economic and performance analysis of parabolic trough solar collector (PTC) based cogeneration systems assisted by thermoelectric generators (TEGs). Sustain. Energy Technol. Assess. 64, 745. https://doi.org/10.1016/j.seta.2024.103745 (2024).

Mandala, S. et al. Design and development of phase change material (PCM) based hybrid solar dryer for herbs and spices. Indian J. Agric. Sci. 90(11), 2217–2224. https://doi.org/10.56093/ijas.v90i11.108599 (2020).

Akmak, G. & Yildiz, C. The drying kinetics of seeded grape in solar dryer with PCM-based solar integrated collector. Food Bioprod. Process. 89(2), 103–108. https://doi.org/10.1016/j.fbp.2010.04.001 (2011).

Senthil, R., Vijayan, G., Phadtare, G. & Gupta, B. Performance enhancements of solar dryers using integrated thermal energy storage: A review. In Lecture Notes in Mechanical Engineering 355–362. https://doi.org/10.1007/978-981-15-9678-0_31 (Springer, 2021).

Rezaei, M. et al. Investigating performance of a new design of forced convection solar dryer. Sustain. Energy Technol. Assess. 50, 863. https://doi.org/10.1016/j.seta.2021.101863 (2022).

Suherman, S., Hadiyanto, H., Susanto, E. E., Utami, I. A. P. & Ningrum, T. Hybrid solar dryer for sugar-palm vermicelli drying. J. Food Process Eng 43(9), 471. https://doi.org/10.1111/jfpe.13471 (2020).

Cisni, F. M., Neethu, K. C., Murali, S., Delfiya, D. S. A. & Ninan, G. Design and development of solar-electrical hybrid dryer and its performance evaluation using shrimps. Biomass Convers. Bioref. https://doi.org/10.1007/s13399-023-04651-6 (2023).

Tikhomirov, D., Khimenko, A., Kuzmichev, K., Budnikov, D. & Bolshev, V. Raising the drying unit for fruits and vegetables energy efficiency by application of thermoelectric heat pump. Agriculture 14, 922. https://doi.org/10.3390/agriculture14060922 (2024).

Murugesan, G. K., Murugesan, C. & Tamilkolundu, S. Assessment of performance and sustainability of waste heat dryer coupled with air conditioner unit during drying of banana slices. Case Stud. Therm. Eng. 59, 104506. https://doi.org/10.1016/j.csite.2024.104506 (2024).

Karthikeyan, V., Sirisamphanwong, C. & Sukchai, S. Thermal investigation of paraffin wax for low-temperature application. J. Adv. Res. Dyn. Control Syst. 11, 1437–1443 (2019).

Homlakorn, S., Velmurugan, K., Suksri, A. & Wongwuttanasatian, T. Comparative study for photovoltaic cooling using metal mesh inserted eutectic phase change material enclosure. Case Stud. Therm. Eng. 45, 24. https://doi.org/10.1016/j.csite.2023.103024 (2023).

Velmurugan, K., Karthikeyan, V., Kumarasamy, S., Wongwuttanasatian, T. & Sa-ngiamsak, C. Thermal mapping of photovoltaic module cooling via radiation-based phase change material matrix: A case study of a large-scale solar farm in Thailand. J. Energy Storage 55, 805. https://doi.org/10.1016/j.est.2022.105805 (2022).

Karthikeyan, V., Sirisamphanwong, C. & Sukchai, S. Investigation on thermal absorptivity of PCM matrix material for photovoltaic module temperature reduction. Key Eng. Mater. 777, 97–101. https://doi.org/10.4028/www.scientific.net/KEM.777.97 (2018).

Rekha, S. M. S. et al. Efficient heat batteries for performance boosting in solar thermal cooking module. J. Clean. Prod. 324, 223. https://doi.org/10.1016/j.jclepro.2021.129223 (2021).

Sathish, T., Giri, J., Saravanan, R., Said, Z. & Al-Iehaibi, M. MWCNT/SiO2 hybrid nano-PCM for ultrafast solar cookers: An experimental study. Eng. Rep. 7(1), e13102. https://doi.org/10.1002/eng2.13102 (2024).

Bhore, C. V. et al. Experimental investigation on minimizing degradation of solar energy generation for photovoltaic module by modified damping systems. Sol. Energy 250, 194–208. https://doi.org/10.1016/j.solener.2022.12.015 (2023).

Sathish, T. Sustainable hydrogen production by integrating solar PV electrolyzer and solar evacuated tube collector with hybrid nanoparticles enhanced PCM. Appl. Therm. Eng. 257, 124317. https://doi.org/10.1016/j.applthermaleng.2024.124317 (2024).

Acknowledgements

The authors extend their appreciation to the Researchers Supporting Project at King Saud University, Riyadh, Saudi Arabia, for funding this research work through the project number RSP2025R278.

Author information

Authors and Affiliations

Contributions

All the authors contributed to the study’s conception and design. Material preparation, data collection, and analysis were carried out by R. Venkatesh, Prashant Sharma, Ch. China Subbarao, Vinayagam Mohanavel, Kajuluri Veerababu, Abhilasha Jadhav, M. Ravichandran, Manzoore Elahi M. Soudagar, Majed A. Alotaibi and Rajkumar Sivanraju. The first manuscript draft was prepared by [Rajkumar Sivanraju], and subsequently, all the authors contributed to the finalization of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical approval

This is an observational study. Enhancement solar energy conversion and functional behaviour study of paraffin PCM/copper fin featured solar dryer; Research Ethics Committee has confirmed that no ethical approval is required.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Venkatesh, R., Sharma, P., Subbarao, C.C. et al. Enhancement solar dryer performance and collector efficiency of paraffin PCM/copper fin featured solar dryer. Sci Rep 15, 31746 (2025). https://doi.org/10.1038/s41598-025-01555-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-01555-5