Abstract

Measurement error (ME) is a critical factor that affects the accuracy and reliability of statistical process control (SPC) methods, often leading to delayed fault detection and compromised process monitoring. This study proposes an improved adaptive cumulative sum (IACUSUM) control chart that effectively mitigates the adverse effects of ME by integrating a linear covariate model and a multiple measurement procedure. The performance of the proposed chart is evaluated using average run length (ARL) and standard deviation of run length (SDRL) through rigorous Monte Carlo simulations and real-data applications. The findings demonstrate that ME significantly impacts the detection capability of control charts, underscoring the need for effective error management strategies. The IACUSUM control chart, when implemented with a multiple measurement approach, exhibits superior sensitivity, enhanced shift detection, and greater robustness compared to conventional methods. The results confirm that the proposed methodology significantly improves process monitoring efficiency, making it a highly reliable tool for industrial applications where measurement variability is prevalent. This study provides a practical and scalable solution for enhancing SPC performance and sets the foundation for further advancements in adaptive control charts for real-world quality assurance systems.

Similar content being viewed by others

Introduction

Statistical Process Control (SPC) is a quality management method focused on monitoring and controlling processes using statistical techniques to identify variations. It helps with cutting down defects, boosting productivity, and maintaining product quality. Some of the most important tools of SPC include control charts to monitor performance; process capability analysis; and cause-and-effect analysis for looking into potential causes of variation. The variations in SPC are labeled as common cause (natural) or special cause (unexpected). For instance, consider a cement factory in Bangladesh where SPC can identify unusual variations in concrete strength enabling pre-emptive adjustments. SPC helps drive continuous quality improvement across industries by reducing waste and improving process stability. Shewhart control charts, proposed by1, utilize only the current sample data to monitor the variations in a process. Unlike the Shewhart chart, which only addresses the most recent observation, memory-based charts such as the cumulative sum (CUSUM) chart by Page2 and the exponentially weighted moving average (EWMA) chart by Roberts3 use both the current and past sample information, making them better at narrowing down shifts in process parameters. Due to that, CUSUM and EWMA charts are more enhanced and powerful compared to Shewhart charts. Control charts have been widely studied, primarily to improve their ability to detect small shifts in process parameters that are critical for maintaining production quality. Haq and Munir4 introduced CUSUM and Shewhart-CUSUM charts for monitoring process means using the best linear unbiased estimator based on ordered double-ranked set sampling. Monte Carlo simulations show that the proposed CUSUM charts outperform existing methods in detecting various process shifts, with a real dataset demonstrating their application. Wang and Huang5 proposed an adaptive multivariate CUSUM chart that dynamically updates the reference value using an EWMA-based mean shift estimate, enhancing the detection of a range of location shifts. Comparisons with existing methods show improved detection efficiency, particularly when the shift magnitude is unknown but within an expected range. Arslan et al.6 introduced the EWMA-DCC (EDCC) and AIB-based EWMA-DC (EDC) charts to improve mean shift detection across a range of shift sizes. Monte Carlo simulations and comparisons show that the proposed charts outperform existing methods, with a real-life application demonstrating their effectiveness. Rabia and Haq7 proposed a weighted Double CUSUM (DCUSUM) control chart aimed at enhancing the detection of mean shifts in normally distributed processes. The effectiveness of the proposed chart was rigorously assessed through Monte Carlo simulations, utilizing three key performance metrics: ARL, Expected ARL (EARL), and Expected Weighted Run Length (EWRL). The results demonstrated that the proposed method significantly outperforms traditional control charts, especially in detecting small to moderate shifts. Furthermore, its applicability was validated using a real-world dataset, confirming its practical value in efficient process monitoring and quality control. Kotchaporn and Yupaporn8 designed with symmetrical control limits, excels in detecting small process shifts. It outperforms traditional EWMA and extended EWMA charts in terms of detection accuracy, computational efficiency, and performance metrics like ARL, SDRL, AEQL, and PCI, as validated through theoretical analysis and real-life data. Zaman and Khan9 introduced an adaptive CUSUM control chart enhanced with support vector regression (SVR) to dynamically adjust parameters based on process shifts. Simulation results and real manufacturing data confirm its superior performance and efficiency compared to traditional control charts. Hu et al.10 proposed combined RZ monitoring schemes to enhance sensitivity to various shift sizes in quality control, outperforming existing Shewhart-RZ, CUSUM-RZ, and EWMA-RZ charts. Monte Carlo simulations and a food industry case study confirm their superior performance and practical applicability.

Malela-Majika and Rapoo11 proposed distribution free mixed CUSUM-EWMA and EWMA-CUSUM control charts that were based on the Wilcoxon rank-sum test for detecting a significant shift in process mean without assuming any distribution. We evaluate the performance with several metrics and demonstrate that our methods outperform the existing charts under both normal and non-normal distributions. A numerical example demonstrates their applicability and success in monitoring processes. Anwer et al.12 proposed a new HWMA statistic based on auxiliary information to improve the conventional CUSUM control chart. Monte Carlo simulations are conducted to validate its advantage in terms of ARL, PDARL, and FRT metrics. An application in the real-life context serves as an additional validation of its efficacy in process monitoring. Saengsura et al.13 proposed the Tukey cumulative sum-moving average (MCM-TCC) control chart for identifying the process mean for both symmetric and asymmetric distributions. An extensive Monte Carlo simulation with ARL and MRL reveals that it outperforms a number of the existing charts, especially for exponential distributions. Practical usage shows that its detection for mean shifts is better than other control charts. Abid et al.14 proposed a new CUSUM chart incorporating the homogeneously weighted moving average statistic. Monte Carlo simulations and run length profile comparisons demonstrate its superior performance over existing charts. A real-life manufacturing dataset application further validates its effectiveness. In SPC, the assumption of a flawless measurement system is often unrealistic due to various influencing factors. Environmental conditions, human errors, and system limitations introduce measurement errors, affecting the accuracy of recorded observations Maleki et al.15 and Bennett16. Measurement error, the difference between recorded and true values, is inevitable across various fields. Examples include inaccuracies in liquid volume measurement on production lines, peak area estimation in mass spectrometry, and readings from analog blood pressure machines (Riaz17). Linna and Woodall18 examined its impact on \({\overline{\text{X}}}\) and S2 charts and explored conditions where multiple measurements improve detection power. A cost model is proposed for optimal sampling, considering ME variance as a function of the process mean. Munir et al.19 examined the impact of MEs on four combined control charts for monitoring normally distributed process means. Monte Carlo simulations reveal that MEs reduce chart effectiveness, mitigated by a multiple measurements scheme. Among the charts, Shewhart-Crosier’s CUSUM performed best, while Shewhart-EWMA was the least effective, with findings illustrated using a simulated dataset. Wang et al.20 examined the impact of measurement error on the TEWMA control chart, evaluating its performance using ARL through Monte Carlo simulations. A comparison with the EWMA chart highlights its efficiency and a real dataset application demonstrates its practical utility.

In quality control, accurate process monitoring is a challenge; however, ME is an unaddressed, non-resolved problem in control chart methodologies. While there has been significant progress made in classical and Bayesian approaches, these existing solutions do not lead to generalizable or flexible policies for optimal ME mitigation. This forms a risk in high-precision industries, as the mistakes lead to compromised decision-making, reduced reliability of the process, and diminished ability to identify real changes in process parameters. In response, this paper proposes a novel framework that integrates ME correction techniques with IACCUSUM control chart, which results in unparalleled flexibility and sensitivity for detecting deviations in the process. In particular, our approach combines two ME-handling methods: (1) a covariate model and (2) multiple measurement modes, making our solution resilient against measurement inaccuracies.

Using Monte Carlo simulation with rigor, we evaluate performance using ARL and SDRL and establish the superiority of our framework confines to the current methods. And finally, as a premier methodological contribution, this study fills a methodological gap in statistical process control by providing a novel solution to overcome practical limitations and allow control charts to be more robust, accurate, and versatile. These findings have important ramifications and establish a new standard for accuracy in quality monitoring across a variety of fields.

Measurement error

The methodological, experimental, or observational constraints of measuring instruments; human error; and environmental variability introduce measurement errors that severely compromise the accuracy of data reporting: Through biased estimates and distorted relationships, or flawed statistical inferences. These inaccuracies taint finding validity, limit decision-making, and weaken research reliance thereby making ME amelioration an emergent need within statistical process control. This is an important study as it addresses this field of ME by implementing a covariate model and multiple measurement methods, which improves precision as it systematically averages repeated observations used to estimate true values. The linearly increasing variance approach is also investigated as a robust correction mechanism for cases where ME variance rises linearly with the process mean. By combining these advanced ME-handling strategies, our approach significantly enhances data integrity, fortifies research credibility, and ensures more reliable statistical outcomes, setting a new standard for precision in quality control and analytical methodologies.

Covariate model

Bennett16 introduced a foundational model to quantify the impact of ME on Shewhart control charts, formulated as Y = X + ε. In this model, X represents the process variable, assumed to follow a normal distribution with mean θ and variance σ2, characterizing an in-control process. The term ε encapsulates stochastic error, arising from measurement inaccuracies, thereby distorting the observed data. Expanding on Bennett’s work, Linna and Woodall18 refined this concept by introducing the covariate model, expressed as:

The model consists of constants A and B, as well as a normally distributed variable with zero mean and a specified variance \(\sigma_{m}^{2}\). All model parameters are assumed to be known, with the variables X and e considered independent. i.e., \(Cov\left( {X,\varepsilon } \right) = 0\), the variable under consideration Y is also distributed normally having mean \(A + B\theta\) and variance \(B^{2} \sigma^{2} + \sigma_{m}^{2}\).

Where A and B are fixed constants, and e follows a normal distribution with zero mean and variance \(\sigma_{m}^{2}\). This model assumes that all parameters are known, with X and e being independent, i.e., \(Cov\left( {X,\varepsilon } \right) = 0\), ensuring that Y remains normally distributed with mean \(A + B\theta\) and variance \(B^{2} \sigma^{2} + \sigma_{m}^{2}\). By incorporating ME dynamics into statistical process control, these models provide a crucial framework for understanding and mitigating measurement-induced distortions, paving the way for more robust and reliable quality monitoring methodologies.

Multiple measurements method

Walden21 introduced a strategic approach to counteract the detrimental effects of ME by replacing single-point observations with multiple measurements per sampling unit. This method significantly reduces ME-induced variability, as the variance of the ME component diminishes toward zero with an increasing number of measurements, thereby enhancing data reliability and control chart precision. Crucially, in the absence of ME, employing multiple measurements does not affect control chart performance, ensuring its robust applicability across different process conditions. When utilizing multiple measurements with a sample size of m, the variance of the overall mean is expressed as:

This framework reinforces process stability and enhances statistical efficiency, making it an essential technique for minimizing distortions and improving the accuracy of quality control monitoring systems.

Proposed improved adaptive CUSUM (IACUSUM) control chart under measurement error

We introduce an Improved Adaptive CUSUM (IACUSUM) control chart to assess process monitoring using ME correction techniques. The use of a covariate model and multiple measurement approaches in this proposed chart reduces the influence of ME on the process while providing reliable sensitivity to process shifts. Incorporating an adaptive update mechanism, the IACUSUM chart dynamically adjusts itself to process variations, thus allowing for greater detection capability than a traditional CUSUM chart. So, the IACUSUM one using the covariate method is based on the following IACUSUM statistic:

and

where \(\tilde{\delta }_{t}^{*} = \max \left( {\delta_{\min } ,\left| {\tilde{\delta }_{t} } \right|} \right)\), \(\tilde{\delta }_{t} = \frac{{\tilde{\delta }_{t} - \left( {1 - \lambda } \right)^{t} \delta_{\min } }}{{1 - \left( {1 - \lambda } \right)^{t} }}\) and \(S_{t}^{*} = 0\). The IACUSUM chart applies a linear weight \(\tilde{\delta }_{t}^{*}\) to \(\overline{Y}_{t}\). The two-sided IACUSUM chart operates with a single CUSUM statistic \(S_{t}^{*}\), using decision thresholds h and –h over time t. This control chart signals an out-of-control condition whenever c exceeds h or falls below –h, indicating an upward or downward shift in the in-control process mean. Similarly, the one-sided IACUSUM chart employs \(S_{t}^{*}\) with either h or –h to detect only increases or decreases in the in-control process mean, respectively. The value of h remains consistent with that of the IACUSUM chart and determines the in-control ARL of the IACUSUM chart. Since the CCUSUM chart is uniformly, but slightly, more sensitive than the CUSUM chart, it is expected that the IACUSUM chart will outperform the ACUSUM chart. The following section examines the detection capabilities of both the proposed and existing control charts. In the similar lines we also express it for multiple measurements method.

Here’s the simulation steps that are used to find the results of ARL profile for IACUSUM control chart paper.

Setting up the threshold value

-

1.

Determine the in-control ARL0 set to 370 and select the control limit h.

-

2.

Draw a sample of size n from a normal distribution with mean μ and variance \(\sigma_{y}^{2} + \sigma_{m}^{2}\) using the covariate model. Estimate the smoothing constant k based on the mean magnitude of the process shift.

-

3.

Calculate the IACUSUM statistic using the equations defined at the start of this section.

-

4.

Apply the control chart decision rule. If the process is declared out-of-control, record the number of subgroups as the in-control run length.

-

5.

Repeat steps (1) to (4) 50,000 times to compute the in-control ARL and SDRL. Adjust the value of h if necessary to achieve the desired ARL0.

Evaluating the out-of-control ARL

-

1.

Generate a random sample from a shifted process and compute the IACUSUM statistic using the same equations as in the in-control scenario.

-

2.

Follow the control chart procedure. If an out-of-control signal is detected, record the subgroup number as the run length.

-

3.

Repeat the entire procedure 50,000 times to calculate the ARL and SDRL for different process shifts.

The run length profiles presented in Tables 1, 2, 3 and 4 is extensively generated using this simulation approach to evaluate the performance of the proposed IACUSUM control chart.

Discussion and main findings

The results of the IACUSUM control chart are summarized in Tables 1 and 2, applied to the scenarios with and without ME. In this analysis, we evaluate the effect of ME and its relevance for process monitoring. The covariate method is used as an adjustment method to reduce ME’s distortions to produce more accurate and reliable statistical inferences. The ARL values given in these tables emphasize that the proposed control chart can detect and control ME properly and has better performance than the conventional one. Tables 3 and 4 presents a more sophisticated evaluation by multiplying a series with different multiple measurements of those sampled values. Estimation is applied as a technique to address and reduce the variability caused by ME to enhance the sensitivity and precision of the control chart. Using statistical analysis of multifaceted observations, this study highlights the need to adopt sophisticated. In this section, we present a thorough evaluation of the tabulated results, which reveal the potential advantages of the IACUSUM control chart for real-world applications. These results highlight the need for the incorporation of ME correction methods to preserve control chart performance quality. Additionally, the high level of adaptability of the proposed approach permits its implementation in a range of different industrial contexts, demonstrating its robustness and reliability. This study is part of the continued evolution toward more accurate and efficient monitoring approaches, filling important holes in the literature on statistical process control. Tables 1, 2, 3 and 4 suggest an unequivocal trend: as the shift strength increases across the range of 0.10 to 0.20, and up to 3, ARL and SDRL both exhibit systematic downward trends. This reduction indicates that even minor, moderate, and substantial variations in process parameters are detected with increasing efficiency. Since lower ARL values are seen for higher shift magnitudes, the proposed control chart responds very quickly to deviations in the process, as established by the fact that ARLs coming very close to unity through a shift magnitude of 3 indicates almost instantaneous detection. Notably, this trend holds in all scenarios, irrespective of ME absence or addition at different concentrations (0.1, 0.2, 0.5, or 1). With this, it can be inferred that the IACUSUM control chart with its robustness and sensitivity outperforms the traditional ARL to detect process shifts precisely. Overall, the reliable results obtained under diverse error conditions consolidate its practical use as an effective tool for process monitoring and quality in real industrial problem applications. In Table 1, the ability of the IACUSUM control chart to detect process shifts, even in the presence of ME, is clearly shown by the high sensitivity and robustness of the process control chart. Specifically, for λ = 0.10, n = 5, \(\delta_{\min }\) = 0.50, and a shift magnitude of δ = 0.3, with \(\frac{{\sigma_{m}^{2} }}{{\sigma^{2} }}\) = 0.0, 0.5, and 1.0, the IACUSUM chart achieves ARL and SDRL values of 52.8 (47.71), 67.49 (61.89), and 79.98 (72.68), respectively, for \(\delta_{\max }\) = 1, the chart preserves its performance, resilient ARL and SDRL values of 85.22 (81.73), 102.03 (97.09), and 113.52 (110.11), respectively. These results confirm the chart’s adaptability in different ME conditions while confirming precise monitoring. Table 2, similarly, examines the effects of B values on the performance of the suggested chart at \(\delta_{\min }\) = 0.50. For B = 1, 3, we get the results as (52.8 (47.71), 176.99 (154.05) for the ARL (SDRL), respectively. For \(\delta_{\max }\) = 1, these values increase to 85.22 (81.73) and 192.29 (190.84), respectively, demonstrating the control chart’s robustness and performance under varying measurement conditions.

These results unambiguously demonstrate the major impact that ME has on control chart performance and highlight the importance of effective ME mitigation strategies. We demonstrate that the IACUSUM control chart is more effective, sensitive, and versatile than its alternatives, providing better detection of a shift under conditions where measurement uncertainty is high. Its robust performance under diversified conditions suggests that it could have plenty of applications in real life such as process monitoring and quality control. Table 3 presents the run-length performance of the proposed IACUSUM control chart under varying conditions based on the multiple measurement method. The chart’s effectiveness is evaluated using λ = 0.10, n = 5, \(\delta_{\min }\) = 0.50, and a shift magnitude of δ = 0.2, considering \(\frac{{\sigma_{m}^{2} }}{{\sigma^{2} }}\) = 0.0, 0.5, and 1.0. The resulting ARL and SDRL values for the IACUSUM chart are 100.46 (97.76), 106.38 (104.67), and 111.03 (105.18), respectively. When \(\delta_{\max }\) = 1, the corresponding ARL and SDRL values are 154.31 (151.54), 160.17 (155.95), and 164.17 (160.46), respectively, reinforcing the chart’s robustness and reliability in detecting process shifts in the presence of ME. Its unique sensitivity and power, especially when used with multiple measurement techniques, it is confirmed by these results for the IACUSUM chart. The high values of ARL validate its efficiency which can promote its application in the actual industrial quality control. The flexibility of the chart allows rapid identification of small to moderate shifts in the process, which helps identify defects and increases efficiency. The study also shows that as ME increases, chart performance deteriorates, indicating the importance of effective ME mitigation strategies. The accompanying simulation study serves as a crucial alert for system designers to minimize ME as much as possible to achieve optimal outcomes. Despite the challenges posed by ME, the IACUSUM control chart remains a promising and highly efficient tool for process monitoring and quality assurance, provided that preventive measures are implemented to manage ME effectively. The following are the main findings of the study:

-

Tables 1, 2, 3 and 4 provide compelling evidence that ME significantly impacts ARL and SDRL in both in-control and out-of-control settings, highlighting ME as a critical determinant in the effectiveness of process monitoring systems. Variations in ME magnitude induce notable fluctuations in ARL and SDRL, yet the proposed approach demonstrates enhanced reliability in fault detection and probability consistency, even under modified conditions. These findings underscore the urgent need for effective ME management strategies to optimize monitoring accuracy and ensure robust performance. Controlling ME is essential to maintaining the integrity of process monitoring, minimizing false alarms, and maximizing the detection of true process shifts, ultimately leading to more precise and reliable quality control outcomes.

-

With a fixed δ, an increase in \(\frac{{\sigma_{m}^{2} }}{{\sigma^{2} }}\) leads to a corresponding rise in the ARL. For example, as shown in Table 3 for multiple measurements, when δ = 0.20 and \(\frac{{\sigma_{m}^{2} }}{{\sigma^{2} }}\) = 0.5, the ARL is 100.46, which increases to 106.38 when \(\frac{{\sigma_{m}^{2} }}{{\sigma^{2} }}\) = 1. This pattern demonstrates the substantial impact of σ on ARL values, indicating a direct and consistent relationship between these parameters. The observed trend across multiple tables reinforces the importance of accounting for variations in \(\frac{{\sigma_{m}^{2} }}{{\sigma^{2} }}\) to ensure accurate process monitoring and maintain control chart effectiveness.

-

As shown previously, using several measurements also mitigates the effects of ME, as reflected in the ARL values shown in Tables 3 and 4. The reason for the substantial improvements can be seen from these results as multiple measurements can appreciably alleviate the detrimental impacts of ME while improving the precision and credibility of the new control charts.

Real life data applications

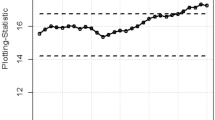

In this section, we analyze a real dataset to demonstrate the usability of the proposed control charts. Montgomery22 considered a case in which the quality characteristic of interest is the volume, per 500 mL milk bottle, in a 500 mL milk bottle production process. According to Phase I estimation, the process parameters were established μ = 500.02 and σ = 0.9616. The first 20 subgroups were classified as in-control, while the subsequent 20 subgroups were considered out-of-control to evaluate process deviations. For this analysis, a covariate model is assumed with parameters A = 0, B = 1, and an error ratio of 0, 0.1, and 0.2. Figures 1, 2 and 3 illustrate the monitoring outcomes derived from control charts, considering a sample size of n = 5 and an in-control ARL0 = 370. This case study provides valuable insights into the performance of the offered methodology in real-world quality control applications.

Figure 1 presents the IACUSUM control chart in the absence of ME, where the first out-of-control signal appears at the 29th point. In contrast, Fig. 2, which incorporates an \(\frac{{\sigma_{m}^{2} }}{{\sigma^{2} }}\) = 0.1, detects the first out-of-control signal at the 35th point, while Fig. 3, with an \(\frac{{\sigma_{m}^{2} }}{{\sigma^{2} }}\) = 0.2, identifies the out-of-control condition at the 37th point. These outcomes explicitly indicate that ME affects shift detection, increase in the ME is associated with a decrease in chart sensitivity, which results in a lag in detecting these aberrations in process. This highlights the importance of appropriate ME mitigation strategies, as these ensure that control charts in process monitoring remain accurate and reliable.

Conclusion

This study thoroughly examines the influence of ME on the functioning of the IACUSUM control chart and suggests efficient measures to minimize the effect of ME. Based on the thorough evaluation of ARL and SDRL, our results reveal that ME would significantly hinder the capability of control charts for detecting shifts in the process, resulting in a prolonged period for detecting process shifts. Nonetheless, the addition of covariate modeling and multiple measurement strategies significantly improves the accuracy, sensitivity, and robustness of the IACUSUM control chart, thus leading to more reliable process monitoring. These results confirm that a multiple measurements approach is successful in eliminating ME-induced distortions while providing insight into relatively extreme conditions. This highlights the importance of incorporating ME management techniques to improve fault detection, process stability, and quality assurance through statistical process control. The high adaptability and precision of the IACUSUM control chart make it a powerful and useful tool for industrial applications of ME. Future studies could investigate further applications of the proposed methodology in diverse industrial contexts and fine-tuning ME correction techniques to further improve control chart performance. With careful consideration of these challenges, this study lays the groundwork for more effective, efficient, and data-driven process monitoring solutions, enhancing decision-making and quality control in numerous fields.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

Change history

06 October 2025

A Correction to this paper has been published: https://doi.org/10.1038/s41598-025-19774-1

References

Shewhart, W. A. The application of statistics as an aid in maintaining the quality of a manufactured product. J. Am. Stat. Assoc. 20(152), 546–548 (1925).

Roberts, S. W. Control chart tests based on geometric moving averages. Technometrics 1(3), 239–250 (1959).

Page, E. S. Continuous inspection schemes. Biometrika 41(1/2), 100–115 (1954).

Haq, A. & Munir, W. New CUSUM and Shewhart-CUSUM charts for monitoring the process mean. Qual. Reliab. Eng. Int. 37(8), 3512–3528 (2021).

Wang, T. & Huang, S. An adaptive multivariate CUSUM control chart for signaling a range of location shifts. Commun. Stat. Theory Methods 45(16), 4673–4691 (2016).

Arslan, M. et al. Novel mixed EWMA dual-crosier CUSUM mean charts without and with auxiliary information. Math. Probl. Eng. 2022(1), 1362193 (2022).

Rabia, M. & Haq, A. A weighted dual cumulative sum chart for monitoring the process mean. Qual. Reliab. Eng. Int. 4, 361–376 (2025).

Karoon, K. & Areepong, Y. The efficiency of the new extended EWMA control chart for detecting changes under an autoregressive model and its application. Symmetry 17(1), 20738994 (2025).

Zaman, B. & Khan, N. Adaptive CUSUM control chart utilizing supervised learning for monitoring the process location parameter: A case study application. Qual. Reliab. Eng. Int. 22, 45 (2025).

Hu, X., Zhao, Y., Zhang, J. & Zhong, J. Combined Shewhart-EWMA and Shewhart-CUSUM schemes for monitoring the ratio of two normal variables. J. Stat. Comput. Simul. 95(2), 258–304 (2025).

Malela-Majika, J. C. & Rapoo, E. Distribution-free mixed cumulative sum-exponentially weighted moving average control charts for detecting mean shifts. Qual. Reliab. Eng. Int. 33(8), 1983–2002 (2017).

Anwer, F., Sanaullah, A., Ahmad, A. & Asghar, A. An improved mixed-homogeneously weighted moving average-CUSUM control chart for efficient monitoring of a process mean. J. Stat. Comput. Simul. 93(10), 1644–1666 (2023).

Saengsura, N., Areepong, Y. & Sukparungsee, S. Distribution-free mixed CUSUM-MA control chart to detect mean shifts. Lobachevskii J. Math. 45(9), 4348–4360 (2024).

Abid, M., Mei, S., Nazir, H. Z., Riaz, M. & Hussain, S. A mixed HWMA-CUSUM mean chart with an application to manufacturing process. Qual. Reliab. Eng. Int. 37(2), 618–631 (2021).

Maleki, M. R., Amiri, A. & Castagliola, P. Measurement errors in statistical process monitoring: A literature review. Comput. Ind. Eng. 103, 316–329 (2017).

Bennett, C. A. Effect of measurement error on chemical process control. Ind. Qual. Control 10(4), 17–20 (1954).

Riaz, M. Monitoring of process parameters under measurement errors. J. Test. Eval. 42(4), 980–988 (2014).

Munir, T. et al. Novel combined Shewhart-CUmulative EWMA-SUM mean charts without-and with measurement error. Meas. Control 57(10), 1480–1498 (2024).

Munir, T., Hu, X., Kauppila, O. & Bergquist, B. Effect of measurement uncertainty on combined quality control charts. Comput. Ind. Eng. 175, 108900 (2023).

Wang, J., Arslan, M., Riaz, A., Lone, S. A. & Gunaime, N. M. Triple exponentially weighted moving average control chart with measurement error. Sci. Rep. 13(1), 14760 (2023).

Walden, C.T. An analysis of variables control charts in the presence of measurement errors. Master’s Thesis, Mississippi State University, Starkville, MI, USA (1991).

Montgomery, D. C. Introduction to Statistical Quality Control (Wiley, 2009).

Acknowledgements

The authors extend their appreciation to Northern Border University, Saudi Arabia, for supporting this work through project number (NBU-CRP-2025-2461).

Author information

Authors and Affiliations

Contributions

A.A.H.A., I.K., and S.S.A.A., contributed to drafting the original manuscript, performing mathematical analyses, and conducting numerical simulations. R.A., H.A., and B.A., conceptualized the core research problem and executed the data analysis. I.K., and R.A., rigorously validated all results, restructured the manuscript, and oversaw funding acquisition. R.A., H.A., and A.A.H.A., enhanced the manuscript’s language and contributed further to the numerical simulations. All authors reviewed and approved the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this Article was revised: In the original version of this Article: Hadeel AlQadi was omitted from the Author Contributions Section.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ahmadini, A.A.H., Khan, I., Alshqaq, S.S.A. et al. Improved adaptive CUSUM control chart for industrial process monitoring under measurement error. Sci Rep 15, 16616 (2025). https://doi.org/10.1038/s41598-025-01734-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-01734-4