Abstract

To mitigate the effects of motor load torque variations on the control performance of a 126 kV high voltage vacuum circuit breaker equipped with a motor driven operating mechanism, this paper presents the derivation of dynamic equations for the motor load torque. These equations, formulated using the Euler-Lagrange equation, Lagrange multipliers, and geometric constraints, are expressed in terms of a single independent variable: the angular displacement of the motor. Utilizing these equations, the load torque can be calculated in real-time using the motor position sensor feedback, and the motor control strategy is optimized through a feedforward method designed to actively compensate for load disturbances. Subsequently, an angular displacement trajectory has been designed to serve as a positional reference for the motor control, with the aim of enhancing the operational reliability of the operating mechanism. Furthermore, comparative control experiments have been conducted in the motor-breaker integrated experimental platform to assess the reduction in the motor’s position tracking error, contact bouncing duration, and mechanical collision duration under the optimized motor control strategy. The obtained experimental results reveal the efficacy of the load torque dynamic equations established and their contribution to enhancing control accuracy and improving the operational reliability of the operating mechanism.

Similar content being viewed by others

Introduction

Vacuum circuit breakers are being sought as an important means of progressing towards higher voltage levels and replacing SF\(_6\) circuit breakers, to mitigate the environmental issues associated with their greenhouse effect. Actively promoting the improvement of the reliability of high voltage vacuum circuit breakers (HVCBs) is significant for ensuring the safe and reliable operation of the power grid1,2,3.

The operating mechanism, as a crucial component of HVCBs, is the primary cause of circuit breaker failures due to its complex structure and numerous moving parts4. The motor driven operating mechanism (MDOM) simplifies the transmission structure by utilizing a direct drive method with the motor5. Meanwhile, the excellent servo performance of the motor enables the movement stroke and speed of the MDOM to be flexibly adjusted, allowing its application in higher voltage circuit breakers and optimizing the switching characteristics to improve working reliability6,7,8. However, unlike the control of motors operating in a continuous rotation state, the motion characteristics of the MDOM must meet the mechanical requirements of the vacuum interrupter (VI), which necessitates the motor to operate in a short-term, limited angular range. Therefore, many control strategies have been proposed to enhance the control performance of the motor under these specific working conditions.

The initial research on the MDOM focused on the structural design and performance optimization of the motor. The adopted control strategy was open-loop control, which regulated the motor’s motion speed by adjusting the power supply voltage to meet the mechanical requirements of VI. However, under open-loop control, the motor’s speed cannot be dynamically adjusted, making it difficult to optimize the motion of the MDOM9,10,11. The process by which the MDOM controls the circuit breaker to opening and closing operations is essentially a process of position control of the motor. Accordingly, scholars in12,13 applied the traditional servo control strategy to perform position control on the motor. However, they did not optimize the control strategy in accordance with the motor’s working conditions. The fixed control parameters in traditional methods cannot quickly make targeted adjustments in response to load disturbances within a short time, thereby affecting its control accuracy. In contrast, Kejian et al.14 adopt intelligent control strategy, aiming to dynamically adjust control parameters in rapid response to load variations through the reasonable setting of intelligent rules. However, the calculation of these parameters is complex and time-consuming, making it difficult to adopt these strategies in practical applications. To enhance the response speed of the motor while avoiding complex calculations, scholars in15,16,17 do not adopt a strategy of tracking a fixed position reference. Instead, they have designed a segmented control strategy that divides the motor’s motion into several stages and presets the control parameters in each stage according to the motor’s load characteristics and the motion requirements of the operating mechanism18,19. However, the insufficient flexibility of this control strategy is not conducive to the further development of intelligent operation of circuit breakers.

In summary, existing studies have made considerable efforts to optimize control performance for the MDOM, but none have accurately obtained the dynamic characteristics of the motor load torque. This results in the control inputs for the motor being adjusted passively in response to load changes, rather than through active compensation, which impacts the potential for further enhancing the control accuracy of the MDOM. For motors in continuous rotation, the problem of active compensation for uncertain loads is addressed by a load observer, but the convergence speed limits practical application in the MDOM control20. In contrast, the MDOM features a fixed transmission structure, and the motor has a limited rotation angle. The motor’s load torque should be primarily determined by the motor’s motion state and the dynamic parameters of the MDOM21. Thus, the main contributions of this paper could be highlighted as follows:

-

1.

Based on the kinematic and dynamic analysis results of the operating mechanism for the 126 kV HVCB, the Euler-Lagrange equation, Lagrange multipliers, and geometric constraints are combined to construct the dynamic model of the operating mechanism, using the drive motor’s angular displacement as the single independent variable. This model accurately establishes the relationship between the dynamic variations in the motor load and the angular displacement of the motor during the operating process.

-

2.

The motor control strategy utilizes the dynamic model to enhance control performance through a feedforward approach within the speed control loop. It actively compensates for load disturbances by utilizing feedback from the motor position sensor, achieving more precise control performance of the operating mechanism.

-

3.

The angular displacement reference in the motor drive control has been optimized. The implementation of the proposed feedforward optimized control strategy reduces contact bouncing and shortens the mechanical collision duration in the operating mechanism, improving the operational reliability of the circuit breaker.

The rest of this paper is organized as follows. In “Structure and principle” section, the structure, control system composition, and working principle of the MDOM are elaborated. In “Dynamic modeling” section, the dynamic equation of the operating mechanism is derived by analyzing the kinetic and potential energy and utilizing the Euler-Lagrange equation. In “Dynamic equation reduction” section, the dynamic equation for the motor load torque is derived by utilizing the geometric constraint relationships to achieve model reduction. In “Verification” section, the verification of the dynamic model is completed. In “Control strategy and experimental results” section, the motor control strategy is optimized, and an experimental platform integrating the MDOM and 126 kV HVCB is set up to conduct comparative control experiments. Finally, conclusions are drawn in “Conclusion” section.

Structure and principle

Structure

The connection structure between the 126 kV HVCB and the MDOM is shown in Figure 1. By means of a linkage system comprising a crank, connecting rod, and insulating rod, the motor converts the rotary motion into linear motion for the moving contact. It can control the circuit breaker for single-pole operations and achieve three-pole operations via the main shaft. A finite-angle permanent magnet synchronous motor is utilized as the drive motor for the operating mechanism22, enabling single-pole operation of the circuit breaker. During the closing process, the drive motor is the sole provider of power, making the impact of load disturbances on its control performance more pronounced. In this paper, discussions are conducted with a focus on the closing operation.

The overall structure of the control system of the MDOM is shown in Fig. 2. The motor is powered by an energy buffer unit consisting of a capacitor bank, which minimizes power consumption from the AC power supply. The energy buffer is charged by a charging unit. The microprocessor-based control unit is the heart of the control system, responsible for collecting sensor feedback and sending control signals to the inverter through the drive unit, thereby controlling the speed of the MDOM.

Principle

The geometric illustration of the MDOM for the 126 kV HVCB is shown in Figure 3, where OA, AB, BC, CD, and DE represent the crank, connecting rod, insulating rod, contact spring, and moving contact. The mechanical requirements are listed in Table 1, which include a clearance of 60 mm and an overtravel of 24 mm. To meet these requirements, the crank is designed to be 109.2 mm in length, and the connecting rod is designed to be 139.9 mm in length. With this design, the MDOM is in the movement stage (MS) when the motor driven crank rotates between \(0^\circ\) and \(34^\circ\) and in the overtravel stage (OS) when it rotates between \(34^\circ\) and \(64^\circ\). The closing process involves the motor angular displacement of \(64^\circ\), with the linear displacement of the operating mechanism being 84 mm, as shown in Fig. 4.

The variation in the motor’s static torque during the operation is also shown in Fig. 4. The torque on the motor in the MS fluctuates minimally, and the correspondence between angular displacement and linear displacement is approximately linear, which is very conducive to achieving precise control of the MDOM. When the motor is positioned at \(34^\circ\), the torque experiences a sudden increase. This phenomenon is attributed to the sudden application of the preload from the contact spring. As the motor continues to rotate, the torque gradually decreases, reaching zero at \(64^\circ\). At this point, the crank aligns with the connecting rod, making the linkage system reach the dead-center position. So, the motor does not require additional torque to maintain the breaker closed state, which allows the MDOM to remove the closing holding device. Moreover, to prevent the motor from exceeding the necessary angular limits, a set of mechanical limit devices has been incorporated, as shown in Fig. 3. This ensures that the motor operates within the designated angular range of \(0^\circ\)–\(64^\circ\).

Dynamic modeling

Dynamic equation in the MS

From the geometric relationship shown in Fig. 3, it is observed that the configuration of the MDOM in the MS can be determined by two angles: the angle \(q_1\) between OA and the X-axis (i.e., the angular displacement of the motor), and the angle \(q_2\) between OA and AB. Therefore, we select \(\varvec{q}_{\textrm{I}}=\begin{bmatrix} q_1&q_2\end{bmatrix} ^T\) as the vector of generalized coordinates.

Refer to Fig. 3, the lengths of components AD, AB, BC, CD, DE are denoted as \(l_1\), \(l_2\), \(l_3\), \(l_4\), \(l_5\), and their masses are denoted as \(m_1\), \(m_2\), \(m_3\), \(m_4\), \(m_5\). We denote the moment of inertia of OA about its centroid as \(I_1\), and the moment of inertia of AB about its centroid as \(I_2\). Assuming that the mass of each component is uniformly distributed, with the centroid located at the geometric center of each part. Their kinetic energies in the MS are as follows:

where \(x_1=\frac{1}{2}l_1\cos q_1\), \(y_1=\frac{1}{2}l_1\sin q_1\), \(x_2=l_1\cos q_1+\frac{1}{2}l_2\cos \left( q_1+q_2 \right), y_2=l_1\sin q_1 +\frac{1}{2}l_2\sin\left( q_1+q_2 \right),\) \(x_3=l_1, y_3=l_1\sin q_1+l_2\sin \left( q_1+q_2 \right) +\frac{1}{2}l_3\), \(x_4=l_1, y_4=l_1\sin q_1+l_2\sin \left( q_1+q_2 \right) +l_3+\frac{1}{2}l_4\), \(x_5=l_1, y_5=l_1\sin q_1+l_2\sin \left( q_1+q_2 \right) +l_3+l_4+\frac{1}{2}l_5\).

The potential energies of OA, AB, BC, CD, and DE are as follows:

where g is the gravitational acceleration and k is the stiffness coefficient of the contact spring. \(x_0\) is the initial compression of the contact spring, providing the necessary preload for the operating mechanism.

Thus, the Lagrangian function \(L_\textrm{I}\) in the MS is defined as the total kinetic energy \(T_{\textrm{I}}=\sum \nolimits _{i=1}^5{T_{\textrm{I}.i}}\) minus the total potential energy \(V_{\textrm{I}}=\sum \nolimits _{i=1}^5{V_{\textrm{I}.i}}\) as:

In the MS, the torque from the motor and the self-closing force in the VI are applied to the operating mechanism. The virtual works \(\delta W_{\textrm{I}.\textrm{A}}\), done by the applied torque \(\tau\) on the crank with the virtual angle \(\delta q_1\), and by the self-closing force \(f_c\) on the moving contact with the virtual displacement \(\delta s\), can be expressed in terms of the generalized coordinate \(\varvec{q}_{\textrm{I}}\) and the generalized force \(\varvec{Q}_{\textrm{I}.\textrm{A}}\):

where

The virtual work \(\delta W_{\textrm{I}.\textrm{C}}\) done by the generalized constraint force \(\varvec{Q}_{\textrm{I}.\textrm{C}}\) can be expressed as:

Applying the Euler-Lagrange equation23, we have:

From (6), the dynamic equation of the operating mechanism in the MS can be derived in matrix form as:

where

in which the parameters \(p_1-p_5\) consist of the dynamic parameters of the operating mechanism:

Dynamic equation in the OS

In the OS, the moving contact remains stationary while the contact spring is continuously compressed, which causes its length to vary continuously. We denote this variable length as \(l_4'\). The configuration of the MDOM is caused not only by the variations in \(q_1\) and \(q_2\) but also by the parameter \(l_4'\). Thus, the vector of generalized coordinates is updated to include \(l_4'\), resulting in the new vector \(\varvec{q}_{\textrm{II}}=\begin{bmatrix} q_1 & q_2 & l_4'\\ \end{bmatrix} ^T\).

The process of calculating the kinetic and potential energy of the MDOM in the OS is similar to that in the MS. However, the total kinetic energy should exclude the kinetic energy contribution of the moving contact. The elastic potential energy of the contact spring in the total potential energy should be modified to \(\frac{1}{2}k\left( l_4-l_4'+x_0 \right) ^2\). The Lagrangian function \(L_\textrm{II}\) in the OS is expressed as:

In the OS, only the applied torque \(\tau\) does virtual work on the operating mechanism. The virtual work \(\delta W_{\textrm{II}.\textrm{A}}\) can be expressed in terms of the generalized coordinate \(\varvec{q}_\textrm{II}\) and the generalized force \(\varvec{Q}_{\textrm{II}.\textrm{A}}\), as:

where \(\varvec{Q}_{\textrm{II}.\textrm{A}}=\begin{bmatrix}\tau & 0 & 0\\ \end{bmatrix} ^T\).

The virtual work \(\delta W_{\textrm{II}.\textrm{C}}\) done by the generalized constraint force \(\varvec{Q}_{\textrm{II}.\textrm{C}}\) can be expressed as:

Applying Euler–Lagrange equation, the dynamic equation in matrix form of the operating mechanism in the OS is:

where

in which the dynamic parameters \(p_1-p_9\) are:

Dynamic equation reduction

Dynamic equation reduction of MS

According to the geometric relationship in Fig. 3, in the MS, the moving contact is restricted to the vertical direction, the projections of the operating mechanism on the X-axis remain constant. The following constraint equation can be established:

In (12), \(\varvec{q}_{\textrm{I}}=\begin{bmatrix} q_1 & q_2\\ \end{bmatrix} ^T\) is the vector of generalized coordinates. It is seen that two variables are used to describe the system and it contains one constraint equation, thus the system has one degree of freedom. We select \(q_1\), which represents the angular displacement of the motor, as the variable describing the constrained motion and \(q_2\) as the redundant variable. Form the constraint equation (12), \(q_2\) can be expressed as:

The generalized velocities and generalized accelerations can be expressed as:

where \(\varvec{L}_{\textrm{I}}\left( q_1 \right) =\begin{bmatrix} 1 & \frac{\partial \sigma _1\left( q_1 \right) }{\partial q_1}\\ \end{bmatrix} ^T\).

By substituting (13)–(15) into (7), we obtain the dynamic equation for the operating mechanism in the MS, which only includes the variable \(q_1\):

where \(\varvec{D}_{\textrm{I}.1}\left( q_1 \right) =\varvec{D}_{\textrm{I}}\left( q_1 \right) \varvec{L}_{\textrm{I}}\left( q_1 \right)\), \(\varvec{C}_{\textrm{I}.1}\left( q_1,\dot{q}_1 \right) =\varvec{D}_{\textrm{I}}\left( q_1 \right) \dot{\varvec{L}}_{\textrm{I}}\left( q_1 \right) +\varvec{C}_{\textrm{I}}\left( q_1,\dot{q}_1 \right) \varvec{L}_{\textrm{I}}\left( q_1 \right)\), \(\varvec{G}_{\textrm{I}.1}\left( q_1 \right) =\varvec{G}_{\textrm{I}}\left( q_1 \right) -\varvec{Q}_{\textrm{I}.\textrm{A}}^{2}\left( q_1 \right)\).

The constraint force \(\varvec{Q}_{\textrm{I}.\textrm{C}}\) in (16) can be expressed using the vector of Lagrange multipliers \(\varvec{\lambda }_{\textrm{I}}\)24 as:

where \(\varvec{J}_{\phi \textrm{I}}\left( \varvec{q}_{\textrm{I}} \right) =\partial \varvec{\phi }_{\textrm{I}}\left( \varvec{q}_{\textrm{I}} \right) /\partial \varvec{q}_{\textrm{I}}\) is the Jacobian matrix of the constraint equation.

By differentiating the constraint equation (12), we obtain:

Using the property of (18) and left-multiplying (16) by \(\varvec{L}_{\textrm{I}}^{T}\left( q_1 \right)\), we can derive the dynamic equation that relates the torque \(\tau\) only to the angular displacement \(q_1\) of the motor, as follows:

where \(T_{\textrm{I}}\left( q_1,\dot{q}_1,\ddot{q}_1 \right) =\varvec{L}_{\textrm{I}}^{T}\left( q_1 \right) \left[ \varvec{D}_{\textrm{I}.1}\left( q_1 \right) \ddot{q}_1+\varvec{C}_{\textrm{I}.1}\left( q_1,\dot{q}_1 \right) \dot{q}_1+\varvec{G}_{\textrm{I}.1}\left( q_1 \right) \right]\).

The torque \(\tau\) in (19) represents the torque that needs to be applied to the operating mechanism to meet specific motion trajectories. For the motor, this torque is the load torque it experiences during the operation, which is what we need.

Dynamic equation reduction of OS

In the OS, the breaker is closed. Similarly, from the geometry of Figure 3, the projections of the operating mechanism on the X-axis remain constant, which is the same as in the MS. Meanwhile, the projection on the Y-axis also remains constant. Thus, there exist two constraint equations as follows:

where d is the vertical distance from the fixed contact to the X-axis.

In (20), \(\varvec{q}_{\textrm{II}}=\begin{bmatrix} q_1&q_2&l_4'\end{bmatrix} ^T\) is the vector of generalized coordinates. It is seen that three variables are used to describe the system, which contains two constraint equations, and the system still has one degree of freedom. By selecting \(q_1\) as the variable describing the constrained motion, and \(q_2\) and \(l_4'\) as the redundant variables, we can express \(q_2\) and \(l_4'\) in terms of \(q_1\) from (20) as follows:

Thus, the generalized velocities and generalized accelerations are:

where \(\varvec{L}_{\textrm{II}}\left( q_1 \right) =\begin{bmatrix} 1& \frac{\partial \sigma _1\left( q_1 \right) }{\partial q_1}& \frac{\partial \sigma _2\left( q_1 \right) }{\partial q_1}\\ \end{bmatrix} ^T\).

By substituting (21)–(24) into (11), we obtain:

where \(\varvec{D}_{\textrm{II}.1}\left( q_1 \right) =\varvec{D}_{\textrm{II}}\left( q_1 \right) \varvec{L}_{\textrm{II}}\left( q_1 \right)\), \(\varvec{C}_{\textrm{II}.1}\left( q_1,\dot{q}_1 \right) =\varvec{D}_{\textrm{II}}\left( q_1 \right) \dot{\varvec{L}}_{\textrm{II}}\left( q_1 \right) +\varvec{C}_{\textrm{II}}\left( q_1,\dot{q}_1 \right) \varvec{L}_{\textrm{II}}\left( q_1 \right)\), \(\varvec{G}_{\textrm{II}.1}\left( q_1 \right) =\varvec{G}_{\textrm{II}}\left( q_1 \right)\), \(\varvec{J}_{\phi \textrm{II}}\left( q_1 \right) =\partial \varvec{\phi }_{\textrm{II}}\left( \varvec{q}_{\textrm{II}} \right) /\partial \varvec{q}_{\textrm{II}}\).

Similarly, by utilizing the property of (18) and left-multiplying (25) by \(\varvec{L}_{\textrm{II}}^{T}\left( q_1 \right)\), the dynamic equation for the motor load torque in the OS can be obtained as follows:

where \(T_{\textrm{II}}\left( q_1,\dot{q}_1,\ddot{q}_1 \right) =\varvec{L}_{\textrm{II}}^{T}\left( q_1 \right) \left[ \varvec{D}_{\textrm{II}.1}\left( q_1 \right) \ddot{q}_1+\varvec{C}_{\textrm{II}.1}\left( q_1,\dot{q}_1 \right) \dot{q}_1+\varvec{G}_{\textrm{II}.1}\left( q_1 \right) \right]\).

Verification

The circuit breaker tested in this study is a 126 kV single-break HVCB with the model number ZW\(\Box\)-126/2000-40. The critical dynamic parameters of each component in the operating mechanism are provided in Table 2. To verify the accuracy of the motor load torque dynamic equations (19) and (26) for the MS and OS derived in the previous section, angular displacement data during motor operation is additionally required. For this purpose, an optimized motor angular displacement trajectory, shown in Fig. 5, was designed to provide the essential data required for calculating the load torque.

In Figure 5, the motor angular displacement trajectory is divided into three segments by four keyframes based on the speed measurement interval specified by the VI. To ensure continuity in position, velocity, and acceleration at the keyframes, a quintic polynomial trajectory is used for each segment25, with the expression given as:

where \(a_{ij}\) is the \(j^{th}\)-order polynomial coefficient of the \(i^{th}\)-segment of the trajectory.

The time allocation scheme is designed as follows: \(t_0=0\) ms, \(t_1 = 61.2\) ms, \(t_2=75\) ms, and \(t_3=150\) ms. Under this scheme, the closing time of the operating mechanism is 75 ms, the motion time within the speed measurement interval is 13.8 ms, and the corresponding average closing speed is 1.3 m/s. These values are precisely at the median of the mechanical requirements for the VI listed in Table 1. This ensures that the operating characteristics of the mechanism are satisfied while maximizing its tolerance to potential disturbances during the control process.

Based on this, we optimized the angular displacement trajectory in Fig. 5 as follows:

-

Minimizing the snap (i.e., \(\min \int _{t_0}^{t_3}{|q_{1}^{\left( 4 \right) }\left( t \right) |^2dt}\)).

-

Setting derivatives (including angular velocity and angular acceleration) at the start and end keyframes to zero.

These optimizations aim to achieve adequate smoothness of the entire trajectory, suppress mechanical vibrations during motor control26, and minimize the mechanical collision between the operating mechanism and the mechanical limit device at the end of the movement, improving the operational reliability of the circuit breaker. The angular velocity and angular acceleration trajectories corresponding to Fig. 5 are shown in Fig. 6.

To complete the verification of Eqs. (19) and (26), we utilized these optimization results to calculate the load torque of the motor in Matlab and Adams, and the comparison results are shown in Fig. 7. It can be observed that there is a high degree of agreement between the results from them, confirming the accuracy of the dynamic equations.

Control strategy and experimental results

Control strategy

The control of the operating mechanism is based on the position control of the motor. In this paper, a three-loop (current, speed, and position) control strategy for the motor is adopted as the core framework, with the optimized angular displacement trajectory that is shown in Fig. 5 serving as the position reference. Within this framework, by utilizing the load dynamic equations (19) and (26) derived in the previous section, active feedforward compensation for load disturbances can be integrated into the motor speed control loop, thereby enhancing the control performance. However, as demonstrated by the torque calculation results in Fig. 7, the load torque undergoes an abrupt change during the transition of the operating mechanism from MS to OS, which may potentially compromise system stability. To mitigate the abrupt change and enhance system stability, a smooth transition mechanism is implemented using Eq. (28), which incorporates a sigmoid function27. The resulting smoothed load torque transition is shown in Fig. 8.

In Eq. (28), \(f\left( t \right) =\frac{1}{1+e^{-\lambda t}}\) is the sigmoid function, where the parameter \(\lambda\) is a transition coefficient used to adjust the sharpness of the transition interval. \(q_{1c}\) is the closing angle of breaker, which is \(34^\circ\) in this paper. The term \(\varepsilon\) represents the angular deviation predefined to adjust the size of the transition interval. In this paper, we set the transition interval to \(4^\circ\), i.e., \(\varepsilon =\frac{4}{2}=2^\circ\). The torques \(T_{\textrm{I}}\left| _{q_1=q_{1c}-\varepsilon } \right.\) and \(T_{\textrm{II}}\left| _{q_1=q_{1c}+\varepsilon } \right.\) are calculated using Eqs. (19) and (26) when the motor rotates to the beginning and ending angles of the transition interval, respectively. For the calculation of \(T_{\textrm{II}}\left| _{q_1=q_{1c}+\varepsilon } \right.\), it is necessary to predict the values of angular velocity and acceleration at the angle \(q_{1c}+\varepsilon\). This prediction is based on the initial values at the beginning of the transition interval and is expressed as:

where \(\Delta \omega\) and \(\Delta \alpha\) are the prediction parameters that need to be adjusted.

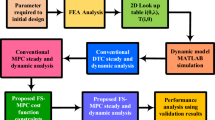

In addition, for the position control loop of the motor, the addition of speed feedforward compensation is a simple and effective method to enhance the motor’s position response, enabling it to better meet the high-speed motion requirements of the operating mechanism. Finally, the optimized motor control strategy, which integrates the load dynamic equations (19), (26), and (28) for load feedforward compensation in the speed loop and incorporates speed feedforward compensation in the position loop, is shown in Fig. 9.

Experimental scheme and results

The experimental setup for evaluating the performance using the proposed motor control strategy is shown in Figure 10. It consists of ZW\(\Box\)-126/2000-40 single-break HVCB equipped with a specially designed FAPMSM, which capable of delivering a maximum output torque of 1257 N.m. The control system of the MDOM is powered by a capacitor bank comprising six capacitors, each with a capacitance of 0.022 F and a rated voltage of 450 V, while the core of its microprocessor-based control system is a digital signal processor (DSP), model TMS320F28379D, which sends control signals to a three-phase full-bridge inverter circuit utilizing IGBTs for motor control.

To verify the superiority of the optimized control strategy and the optimized trajectory in enhancing motor control performance and improving the operational reliability of the operating mechanism, three comparative experimental schemes were designed. In all experiments, the capacitor voltage is charged to 400 V. The specific control strategies used for the motor are as follows:

-

Scheme 1: open-loop control.

-

Scheme 2: traditional three-loop control without speed/torque feedforward compensation.

-

Scheme 3: three-loop control with speed feedforward compensation.

-

Scheme 4: proposed optimized control strategy (see Figure 9).

The experimental results are shown in Fig. 11. In each experiment, the actual angular displacement results of the motor are recorded and represented by the blue curve. And the position tracking error results are recorded and represented by the red curve. Simultaneously, various key information during the motor control is recorded in the form of indicator signals. Among these signals, the blue curve represents the start trigger signal sent by the controller. The red curve indicates the signal at the starting time when the operating mechanism reaches the closing speed measurement interval. The green curve represents the closing signal sent by the closing detection circuit. The orange curve signifies the end signal of the closing process.

It can be observed in Fig. 11 that the closing times for the four experimental schemes are 40 ms, 82 ms, 78 ms, and 76 ms. The durations within the speed measurement interval are 9.3 ms, 14.0 ms, 13.9 ms, and 13.8 ms. The corresponding average closing speeds are 1.9 m/s, 1.3 m/s, 1.3 m/s, and 1.3 m/s (for the latter three schemes, after rounding). It is evident that after the implementation of the closed-loop control scheme on the motor, the operating time and speed of the MDOM meet the mechanical specifications of VI listed in Table 1. This reflects the good servo performance of the motor.

In Fig. 11a , the open-loop control strategy cannot dynamically adjust the control signals on the IGBTs in response to load characteristics, resulting in the motor always being in the full voltage starting state. In the MS, the excessively high control voltage accelerates the movement speed of the moving contact, resulting in a contact bouncing duration of 4 ms. In the OS, the excessive control voltage makes the motor unable to adapt to the decreasing load torque at this stage, which causes a notable upward trend in the angular displacement curve, indicating that the operating mechanism is continually accelerating. This results in a mechanical collision duration of 6.7 ms between the operating mechanism and the mechanical limit device at the end of the closing process.

In Fig. 11b , the three-loop control strategy improves the motion characteristics of the motor. However, the lack of speed and torque feedforward results in slower position and torque responses, causing a certain degree of tracking error between the actual angular displacement and the position reference. In the MS, the maximum tracking error reached \(6^\circ\) prior to closing. At the instant of closing, the sudden increase in load torque caused a fluctuation in the angular displacement, and then the tracking error reached a maximum of \(12^\circ\), leading to a contact bouncing duration of 3.3 ms. When the motor overcomes the load torque at the closing position and enters the OS, the slower torque response does not adapt well to the decreasing load torque, resulting in an overshoot of \(2^\circ\) and a mechanical collision duration of 2.9 ms.

In Fig. 11c , the motor’s tracking performance has significantly improved compared to Scheme 2 in the MS. This improvement is attributed to the consistently low and minimally fluctuating motor load. The incorporation of speed feedforward compensation effectively accelerates the motor’s position response speed and enhances position tracking accuracy, reducing the maximum tracking error to \(2^\circ\) before closing. However, this compensation strategy cannot effectively predict and compensate for load variations of the motor. At the instant of closing, noticeable fluctuations still occur in the angular displacement curve. Although these fluctuations are somewhat reduced compared to those in Scheme 2, the maximum position tracking error after closing still reaches \(9^\circ\), and the closing bouncing duration has not been effectively improved. In the OS, the motor output is also unable to adapt well to the decreasing load characteristics of this stage. The overly rapid response speed leads to increased overshoot, with a maximum of \(3^\circ\), resulting in more intense mechanical collisions and a prolonged mechanical collision duration of 4.2 ms at the end of the closing process.

In Fig. 11d , the motor under the optimized control strategy has the smallest position tracking error, both in the MS and the OS. And at the instant of closing, there is no significant fluctuation in the motor’s angular displacement curve, the maximum position tracking error of the motor does not exceed \(2^\circ\). The experimental results effectively verify the contribution of the feedforward compensation control strategy for load torque, based on dynamic equations, to the effective control of motor torque and the enhancement of control accuracy. Meanwhile, the improved torque regulation capability of the motor results in shorter contact bouncing and mechanical collision durations, which are 1.5 ms and 2.9 ms, respectively.

The power consumption of the MDOM under the four control schemes can be reflected by the voltage dynamics of the supply capacitor, which are shown in Fig. 12. When the operating mechanism is in the MS, the load torque on the drive motor is relatively small, resulting in minimal differences in power consumption among the schemes. The remaining capacitor voltages at the end of the MS are 394 V, 395 V, 396 V, and 396 V, respectively. After entering the OS, the rapid increase in the torque demand of the motor leads to a significant drop in the capacitor voltage under all schemes. However, the motor in Schemes 2 to 4, which employ a closed-loop control strategy, retain the ability to continue tracking the position reference even after experiencing load fluctuations. Following the initial steep drop, the capacitor voltage gradually stabilizes as the motor speed decreases and the load diminishes during this stage. This reduction in power consumption results in a more gradual decline in the capacitor voltage. The remaining capacitor voltages at the end of the closing operation for each control scheme are 365 V, 378 V, 379 V, and 387 V, with corresponding power consumption values of 1767 J, 1130 J, 1080 J, and 675 J. It is evident that the optimized control strategy in Scheme 4 achieves the smallest and smoothest variation in capacitor voltage. Compared to the other control schemes, the power consumption is reduced by 61.8\(\%\), 40.3\(\%\), and 37.5\(\%\), respectively.

Based on the experimental results of Figs. 11 and 12, it is evident that the motor, operating under the optimized control strategy proposed in this paper, meets the mechanical requirements of the VI while enabling more accurate tracking of the optimized angular displacement trajectory. This results in shorter contact bouncing and mechanical collision duration for the circuit breaker and demonstrates superior energy efficiency performance. This demonstrates the effectiveness of the proposed control strategy and confirms the accuracy of the dynamic model established in this paper. To further validate the stability and environmental adaptability of the optimized control strategy, we conducted five repeated trials at ambient temperatures of \(0^\circ\)C, \(5^\circ\)C, and \(10^\circ\)C, respectively. The tracking error, collision duration, and power consumption performance were statistically analyzed, and the results are shown in Fig. 13. It can be seen that the control repetition trials of the motor at the same temperature exhibit good consistency, with a small standard deviation. As the temperature rises from \(0^\circ\)C to \(10^\circ\)C, the tracking error is decreases by \(0.56^\circ\), the collision time is shortened by 0.45 ms, and the power consumption is reduced by 90 J. The control performance improves with the rise in temperature, but the overall variation range remains small, ensuring good environmental consistency.

Conclusion

This paper derives the dynamic equations for the load torque of the drive motor in the MDOM of the 126 kV HVCB. It establishes a relationship between the dynamic variations in the motor load torque and the angular displacement during the operating process. The motor control strategy is optimized using a feedforward method to actively compensate for load disturbances, improving the control precision of the operating mechanism. The main conclusions drawn from this paper are as follows:

-

1.

Under the proposed optimized control strategy, the drive motor can more accurately track the position reference, resulting in a maximum position tracking error that does not exceed \(2^\circ\). By using the optimized angular displacement trajectory, the contact bouncing duration of the operating mechanism is reduced to 1.5 ms, and the mechanical collision duration between the operating mechanism and the mechanical limit device at the end of the closing process is reduced to 2.9 ms.

-

2.

Compared with the traditional three-loop control strategy, the optimized motor control strategy reduces the maximum position tracking error by \(10^\circ\) and shortens the contact bouncing duration of the operating mechanism by 1.8 ms. These improvements demonstrate the effectiveness of the proposed control strategy, based on the load torque dynamic model, in enhancing the motion control capability and reliability of the operating mechanism.

-

3.

The limitation of this study is that the established dynamic model of the operating mechanism does not consider the electromagnetic force in the VI during the loaded operation of the circuit breaker. Further improvements are necessary to refine the model and conduct experiments under load conditions to further validate the control performance of the motor and facilitate the intelligent operation process of the circuit breaker.

Data availability

Data is provided within the manuscript.

References

Tan, Y., Hu, E., Liu, Y., Li, J. & Chen, W. Review of digital vibration signal analysis techniques for fault diagnosis of high-voltage circuit breakers. IEEE Trans. Dielectr. Electr. Insul. 31, 404–418 (2024).

Hadizadeh, M. H., Hu, Y., Xu, F. & Wang, W. Mechanism insights and experimental feasibility of using boron nitride nanocones for rapid adsorption and degradation of sf6 decomposition compounds. Sci. Rep. 14, 27317 (2024).

Lin, X. et al. Dynamic dielectric strength of C3F7CN/CO2 and C3F7CN/N2 gas mixtures in high voltage circuit breakers. IEEE Trans. Power Deliv. 37, 4032–4041 (2022).

Song, Q. et al. Fault diagnosis of HVCB via the subtraction average based optimizer algorithm optimized multi channel CNN-SABO-SVM network. Sci. Rep. 14, 29507 (2024).

Bosma, A. & Thureson, P.-O. A new reliable operating mechanism for HVAC circuit-breakers. In 2001 IEEE/PES Transmission and Distribution Conference and Exposition. Developing New Perspectives (Cat. No. 01CH37294). Vol. 1. 573–577 (IEEE, 2001).

Jiang, J., Lin, H. & Fang, S. Optimization design of a permanent magnet actuator for 126-kV vacuum circuit breaker. IEEE Trans. Appl. Superconduct. 28, 1–5 (2017).

Indragandhi, V., Kumar, L. A. & Vishnumoorthy, K. Methods of operating mechanisms of high voltage circuit breakers—An overview. In 2017 International Conference on High Voltage Engineering and Power Systems (ICHVEPS). 57–63 (IEEE, 2017).

Wang, Z., Sun, L., He, S., Geng, Y. & Liu, Z. A permanent magnetic actuator for 126 kV vacuum circuit breakers. IEEE Trans. Magnet. 50, 129–135 (2013).

Xin, L., Yong-xiang, L., Chuan, Y., Jian-yuan, X. & Ai-Min, L. Design and dynamic simulation of permanent magnet motor actuator on high voltage circuit breaker. In 2009 IEEE International Conference on Automation and Logistics. 181–185 (IEEE, 2009).

Aimin, L., Jinhua, Z., Jiachuan, L. & Yujie, B. Design and analysis of salient pole rotor coil excitation brushless dc motor using in high voltage circuit breaker operating mechanism. In 2015 3rd International Conference on Electric Power Equipment–Switching Technology (ICEPE-ST). 177–181 (IEEE, 2015).

Zeng, G. et al. Analysis, design and dynamic simulation of novel limited swing angle torque permanent magnet motor for high voltage circuit breaker application. Energies 11, 2652 (2018).

Huang, Y. et al. A motor-drive-based operating mechanism for high-voltage circuit breaker. IEEE Trans. Power Deliv. 28, 2602–2609 (2013).

Wang, X. et al. Research on direct drive operation mechanism of 126 kV high-voltage vacuum circuit breaker. In 2019 22nd International Conference on Electrical Machines and Systems (ICEMS). 1–5 (IEEE, 2019).

Kejian, S. et al. Research on the RBF-PID control method for the motor actuator used in a UHV GIS disconnector. J. Eng. 2019, 2013–2017 (2019).

Feng, Y., Wan, H., Wu, J., Lan, J. & Deng, Y. Research on segmented control of motor operating mechanism for high-voltage circuit breaker. J. Eng. 2019, 794–797 (2019).

Lou, J., Liu, A. & Yu, S. A reliable and controllable motor actuator without permanent magnetic for 40.5 kV vacuum circuit breakers. IEEE Transactions on Industry Applications 56, 1218–1225 (2019).

Liu, A., Wu, Z., Wang, Y. & Ma, S. A novel control strategy of phase-controlled switching technology for vacuum circuit breaker. IEEE Access 10, 43571–43582 (2022).

Yu, L., Geng, Y., Li, Q., Wang, J. & Liu, Z. An approach for minimum percussion welding in closing operation of a 126-kV vacuum circuit breaker. IEEE Trans. Compon. Packag. Manuf. Technol. 4, 840–847 (2014).

Zhang, B. et al. A relationship between minimum arcing interrupting capability and opening velocity of vacuum interrupters in short-circuit current interruption. IEEE Trans. Power Deliv. 33, 2822–2828 (2018).

Lian, C., Xiao, F., Gao, S. & Liu, J. Load torque and moment of inertia identification for permanent magnet synchronous motor drives based on sliding mode observer. IEEE Trans. Power Electron. 34, 5675–5683 (2019).

Kang, B. & Mills, J. K. Dynamic modeling of structurally-flexible planar parallel manipulator. Robotica 20, 329–339 (2002).

Wang, Y., Lin, X., Xu, J. & Li, W. Research on motor drive technology for an operating device of 126 kV vacuum circuit breaker. IEEJ Trans. Electr. Electron. Eng. 18, 970–979 (2023).

Beckers, J., Verstraten, T., Verrelst, B., Contino, F. & Van Mierlo, J. Analysis of the dynamics of a slider-crank mechanism locally actuated with an act-and-wait controller. Mech. Mach. Theory 159, 104253 (2021).

Ha, J.-L., Fung, R.-F., Chen, K.-Y. & Hsien, S.-C. Dynamic modeling and identification of a slider-crank mechanism. J. Sound Vib. 289, 1019–1044 (2006).

Spong, M. W. & Vidyasagar, M. Robot dynamics and control (John Wiley & Sons, 2008).

Mellinger, D. & Kumar, V. Minimum snap trajectory generation and control for quadrotors. In 2011 IEEE International Conference on Robotics and Automation. 2520–2525 (IEEE, 2011).

Suid, M. H. & Ahmad, M. A. Optimal tuning of sigmoid PID controller using nonlinear sine cosine algorithm for the automatic voltage regulator system. ISA Trans. 128, 265–286 (2022).

Acknowledgements

This work was supported by the National Natural Science Foundation of China under Grant 51777130.

Author information

Authors and Affiliations

Contributions

Y.W. and J.X. conceived and designed the study. Y.W. conducted the modelling and the simulation. J.X. and W.L. provided the experimental platform. Y.W., J.X. and W.L. designed the experiments. Y.W. and J.L. performed all the experiments. Y.W. and J.X. wrote the manuscript. All authors discussed the results and commented on the paper, and approved its final version.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, Y., Xu, J., Li, W. et al. Research on dynamic modeling and control strategy of motor driven operating mechanism for 126 kV high voltage vacuum circuit breaker. Sci Rep 15, 17039 (2025). https://doi.org/10.1038/s41598-025-01859-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-01859-6