Abstract

In view of the poor adaptability of the clamping device to different ball diameters and the damage of the pulling device to the bottom of leaf ball in the mechanized harvesting of Chinese cabbage. In order to achieve low-loss and high-efficiency harvesting of Chinese cabbage, a self-propelled Chinese cabbage harvester consisting of clamping conveyor, cutting device and inclined conveyor was designed. Based on the dynamic analysis, the flexible clamping mechanism (maximum clamping force of 152.82 N) and the double disc knife cutting system (rotation speed of 200–400 r min−1) were adopted, combined with the inclined conveyor, to achieve the whole process of clamping-root cutting-conveying integrated operation. Through orthogonal experiments, multi-objective optimization was carried out on key parameters to obtain the better combination of a harvester travel speed of 0.30 m s−1, a clamping and conveying speed of 131 r min−1, and a cutting speed of 339 r min−1. The field validation experiment results showed that the accurate root cutting rate was 94.72% and the damage rate was 5.06%, which satisfied the design and operational performance requirements. The research provides core equipment support for the intensive production of Chinese cabbage, and provides a reference for the mechanized harvesting of knotweed vegetables.

Similar content being viewed by others

Introduction

Chinese cabbage has long been the most consumed vegetable and cultivated area in China, and is the world’s largest producer of Chinese cabbage1. However, in the whole process of Chinese cabbage production, the operation of its harvesting accounts for more than 40% of the total production2. At present, the mechanization level of Chinese cabbage harvesting is low, mainly relying on manual root cutting, picking, bagging, handling, loading and other work, which is time-consuming and labor-intensive, and the harvesting efficiency is low. It is difficult to meet the needs of large-scale production of Chinese cabbage. At the same time, high labor costs seriously restrict the benefits of large-scale cultivation of Chinese cabbage, therefore, mechanized harvesting is the way to solve this problem. Existing Chinese cabbage harvester has different ball diameter adaptability is poor, pulling device damage to the bottom of the leaf ball and other problems, it is difficult to scale up applications3,4.

Numerous studies have been conducted both domestically and internationally on the theory, design, and experimentation of Chinese cabbage harvesters. Kanamitsu et al.5 developed a hand-held Chinese cabbage harvester that uses a method of first pulling and then cutting the roots, resulting in a high damage rate during harvesting. To address this, they developed another suspended harvester with an additional pulling device, but the pulling effect of the screw lifting mechanism is greatly affected by soil conditions, and the Chinese cabbage bulb is susceptible to slant cutting6,7. Kim et al.8 developed a self-propelled Chinese cabbage harvester, which reduces the difficulty of Chinese cabbage pulling by a pulling device, but the bottom of the Chinese cabbage is prone to breakage. After removing the pulling device, Wu et al.9 conducted bench tests on key components such as the cutting device and clamping conveyor of a self-propelled fully hydraulic Chinese cabbage harvester. Miao obtained a belt feed speed of 1.04 m s−1 and a cutting speed of 353 r min−1 through a Chinese cabbage harvester cutting table test10. Zhao designed a two-row Chinese cabbage harvester with contoured ground wheels with an operating efficiency of 1.2 s/plant11. For cutting devices, Han et al. realized the cutting of Chinese cabbage roots through the rotary closing motion of petal-like blades, and the cutting efficiency is 59.8 plants min−1 12. Didamony et al. investigated the effect of cutter shape, angle, and rotational speed on the power and cost of Chinese cabbage harvester13. Cao et al.14 explored the influence of cutter shape, rotational speed, and feed rate on the quality of root cutting of Chinese cabbage. Zhang et al.15 designed a two-row cabbage harvester, and the results of field tests showed that the accurate root cutting rate is 95%. In terms of electric harvesters, Hu et al. designed a small electric tracked type vegetable harvester with a harvesting efficiency of 0.09 hm2/h16. Miao et al.17 established an automatic alignment control system for vegetable harvesters through PID and fuzzy control to realize automatic alignment of leafy vegetables.

Chinese cabbage harvesting is mainly used first plucking and then cutting the root, but it is easy to cause the internal rupture of Chinese cabbage. Therefore, the pulling device is added to reduce the damage of Chinese cabbage during the clamping and pulling process. However, the bottom end of Chinese cabbage extruded by the spiral extraction mechanism is very easy to be damaged, and resulting in oblique cutting of the cutting device, which affects the subsequent storage and sales of Chinese cabbage. In summary, in order to achieve low-loss and high-efficiency harvesting of Chinese cabbage, a self-propelled single row Chinese cabbage harvester is designed. Adopting flexible clamping mechanism and double disc knife cutting system for synergistic harvesting, combined with inclined conveyor, to achieve the whole process of clamping-root cutting-conveying integrated operation. Combining response surface methodology and field validation, optimized the better operating parameters and cracked the efficiency-damage rate trade-off problem. The research provides core equipment support for the intensive production of Chinese cabbage, and provides a reference for the mechanized harvesting of knotweed vegetables.

Materials and methods

Planting agronomy and physical characteristics of Chinese cabbage

Chinese cabbage is a leaf vegetable of the Brassica genus, with many varieties and diverse planting agronomy. Yihe is one of the main varieties of Chinese cabbage in Shandong Province of China, and is selected as the research object in this paper. The planting agronomy is single row ridge farming, which is easy to realize mechanized harvest. As shown in Fig. 1, the row spacing L1 is 600 mm, the width of the ridge surface L2 is 300–350 mm, and the height of the ridge H1 is 150–200 mm.

The leaf bulbs of mature Chinese cabbage are long oval, crisp and easy to damage, and their volume and shape differ greatly. According to the design requirements of the Chinese cabbage harvester, the parameters of the Chinese cabbage such as the total height Lh, the leaf expansion Ld, the longitudinal diameter of leaf bulb Qh, the transverse diameter of leaf bulb Qd, the root diameter at the cutting Sd, and the mass after root cutting m are measured. The geometric model is shown in Fig. 2.

The sampling site is located in Hanting District, Weifang City, Shandong Province. 100 Chinese cabbage with normal growth at maturity are randomly selected for determination, and the results are shown in Table 1.

Structure and working principle of Chinese cabbage harvester

The structure of the self-propelled Chinese cabbage harvester is shown in Fig. 3, which mainly consists of header, inclined conveyor, crawler power chassis, and hydraulic system, etc. All devices and chassis are driven by hydraulic system. The header consists of clamping conveyor and double disc knife cutting device, etc. The header is located at the left front of the crawler power chassis and is connected to the chassis through a four-bar mechanism, hydraulic cylinder, etc. The hydraulic cylinder contraction drives the four-bar mechanism to lift and lower the height of the header relative to the ground is adjustable. The inclined conveyor is located directly behind the header. The installation position and operation parameters of clamping conveyor, cutting device and inclined conveyor can be adjusted mechanically or hydraulically to adapt to different planting modes of Chinese cabbage.

Before the operation of the Chinese cabbage harvester, align the center of the clamping conveyor and cutting device with the center of the Chinese cabbage, and keep the disc knife close to the ridge surface (not into the soil). During operation, the Chinese cabbage is fed through the bell mouth at the front end of the clamping conveyor belt, and its root is cut off by the double disc knife of the cutting device at the moment of being clamped. The Chinese cabbage after root cutting is continued to be clamped by the clamping conveyor and conveyed backward to the inclined conveyor. Finally, the Chinese cabbage is conveyed to the collection box by the inclined conveyor to complete the mechanized harvesting. The main technical parameters of the harvester are shown in Table 2.

Design and analysis of key components

Design and analysis of clamping conveyor

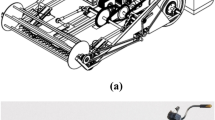

The main function of the clamping conveyor is to assist the cutting device to cut the root accurately and to clamp and convey the Chinese cabbage. Considering that the stems and leaves of Chinese cabbage are relatively crisp and tender, sponge belt is used for clamping. The clamping conveyor consists of synchronous sponge belt, guide tensioning mechanism, clamping spacing adjustment mechanism, frame, hydraulic motor and so on, as shown in Fig. 4. During operation, the hydraulic motor drives the sponge belt to rotate in the opposite direction at the same speed. The guide tensioning mechanism is located at the feeding inlet of the clamping conveyor belt to form a bell mouth at the front end of the clamping conveyor belt, and the opening size is automatically controlled by the torsion spring in order to improve the adaptability to the rows of Chinese cabbage. The clamping spacing adjustment mechanism is parallel and symmetrically distributed with the conveyor belt, and each side contains two groups, each group being 2 front and 2 rear, and each located inside the conveyor belt near the middle of the side. When different corms of Chinese cabbage through the clamping conveyor, and the pressure on both sides of the sponge belt is different. The spacing adjustment mechanism automatically adjusts the spacing of the conveyor through springs according to the pressure, to achieve the clamping of Chinese cabbage in a certain range of corms. When different bulbs of Chinese cabbage pass through the clamping and conveying device, the pressure on the sponge belts on both sides is different.

Structure diagram of clamping conveyor: 1. Slave clamping synchronous belt wheel; 2. Guide tensioning mechanism; 3. Tensioning screw; 4. Frame; 5. Side support roller; 6. Hydraulic motor; 7. Hydraulic motor bracket; 8. Movable hydraulic bracket block; 9. Active clamping synchronous belt wheel; 10. Clamping conveyor sponge belt; 11. Clamping spacing adjustment mechanism; 12. Telescopic belt wheel bracket.

The physical object of the clamping conveyor is shown in Fig. 5.

-

(1)

Force analysis of clamping and conveying process

The Chinese cabbage after root cutting is clamped by sponge belt and continues to be conveyed backward. In this process, the clamping force of the clamping conveyor is very important for the lossless harvest and stable transportation of Chinese cabbage. Excessive clamping force will damage the interior of Chinese cabbage leaf ball, on the contrary, it will cause the conveying posture of Chinese cabbage to be uncontrollable or even fall. In the clamping and conveying stage, the Chinese cabbage is completely off the ground, which is mainly affected by the clamping force of the clamping conveyor belt and its own gravity. The clamping position is located in the middle of Chinese cabbage according to its shape characteristics. Neglecting the slight deformation of the Chinese cabbage itself and the relative sliding between the Chinese cabbage and the conveyor belt during the clamping and conveying process, the force analysis of the Chinese cabbage clamping and conveying process is carried out, as shown in Fig. 6.

From the force analysis, it can be concluded that:

where Ff—Lifting force of Chinese cabbage by clamping conveyor, N; α1—Angle between clamping conveyor and horizontal plane, (°); Ga—Gravity of Chinese cabbage after root cutting, N; FC—Pushing force of harvester forward on Chinese cabbage, N; f1—Friction coefficient between Chinese cabbage and clamping conveyor belt; F1—Clamping force provided by clamping conveyor belt, N.

According to the physical parameters measured in Table 1, the maximum mass of Chinese cabbage after root cutting is 4.32 kg, which is taken as 6 kg for clamping a larger weight. The friction coefficient f1 between the conveyor belt and Chinese cabbage is 0.81 from the inclined friction test18. The angle between the clamping conveyor and the horizontal plane is 20°. Therefore, the lifting force Ff is 171.92 N and the clamping force F1 is 212.25 N from Eq. (1). In the preliminary stage, we conducted a compression test on the Chinese cabbage leaf ball (loading speed 20 mm min−1), and obtained the critical pressure for leaf ball breakage as 727.51 N. The clamping force F1 obtained from Eq. (1) is much smaller than this critical threshold, so there will not be the case of internal rupture of the leaf ball due to excessive clamping force.

The clamping force of the clamping conveyor on Chinese cabbage mainly depends on the spring in the clamping spacing adjustment mechanism. When Chinese cabbage is clamped and conveyed, the bracket is subject to the thrust of the conveyor belt and the tension of the spring. The force analysis is shown in Fig. 7.

According to the principle of moment balance and force and reaction force:

where F3—Thrust of the conveyor belt on the adjusting wheel, N; FN3—Thrust of the adjusting wheel on the conveyor belt, N; F5—Tension of the spring, N; L3—Vertical distance between the rotation center line of the adjusting wheel and the rotation center line of the frame, mm; L4—Vertical distance between the rotation center of the frame and the spring, mm.

The clamping force of Chinese cabbage is generated by the clamping spacing adjustment mechanism squeezing the conveyor belt, that is F1 = FN3cosα, so the spring force can be obtained as follows:

where α—Angle between FN3 and vertical direction, (°).

Where L3 is 100 mm, L4 is 60 mm, 0° ≤ α ≤ 45°, and 353.75 N ≤ F5 ≤ 673.40 N by calculation. The diameter of the leaf bulb of this variety of Chinese cabbage is generally 163–193 mm. The maximum unilateral shrinkage of the spacing adjustment mechanism and the sponge conveyor belt when squeezed by Chinese cabbage is 50 mm. In order to adapt to Chinese cabbage with different bulbs, the spacing of the conveyor belt is set at 120 mm, and the conveyor belt is adjustable from left to right, with an adjustment margin of ± 30 mm.

-

(2)

Analysis of the speed of clamping conveyor belt

The clamping and conveying speed will affect the conveying efficiency and damage rate of Chinese cabbage. Too fast speed in clamping and conveying will lead to missed cutting, less cutting and skew incision, otherwise it will cause blockage of Chinese cabbage. The vector diagram of velocity analysis is established to analyze the relationship between the speed of clamping and conveying and the speed of travel, as shown in Fig. 8.

The combined velocity is obtained from Fig. 8:

where \(\overrightarrow {{V_{p} }}\)—Absolute velocity of Chinese cabbage during harvesting, m s−1; \(\overrightarrow {{V_{m} }}\)—Forward speed of the Chinese cabbage harvester, m s−1;\(\overrightarrow {{V_{b} }}\)—Speed of the clamping conveyor belt, m s−1.

According to the sine theorem:

where β2—Angle between the direction of the combined velocity and the horizontal plane, (°).

When m < 1, the backward clamping and conveying speed of Chinese cabbage is too slow leading to its accumulation and blockage at the feeding inlet. At the same time, the angle β2 between the direction of the absolute velocity Vp and the horizontal plane is obtuse, and the Chinese cabbage will tilt forward during the clamping and conveying process, so that the bottom end of the Chinese cabbage is cut by the disc knife and damaged. Therefore, in order to avoid blockage and reduce the damage rate of Chinese cabbage bottom, Vb > Vm and β2 < 90°. Based on the above analyses and referring to the relevant literature19,20, in order to ensure the conveying efficiency and reduce the damage rate, the traveling speed of the harvester is set to be 0.3–0.5 m s−1, and the value of m is taken to be 2.6, so that the conveying speed of the clamping conveyor belt is 0.78–1.3 m s−1.

Design and analysis of cutting device

The cutting device and the clamping conveyor cooperate with each other to cut the root of Chinese cabbage, and the effect of root cutting affects the harvest quality. Considering the force balance, space layout, cutter speed and other factors during cutting, the double disc knife root cutting device is selected, which is composed of disc knife, transmission shaft, gear box, knife carrier, universal joint coupling, etc., as shown in Fig. 9. The cutting device is fixed at the front end of the header through the carrier frame and its symmetry center is consistent with the symmetry center of the clamping conveyor belt, and its mounting position can be adjusted forward and backward, up and down through the fixing holes. During operation, the hydraulic motor is connected with the transmission shaft through the coupling to drive the double disc knife to rotate at the same speed in the opposite direction.

Selection of double disc knifes with bright edge, material 65Mn, diameter 300 mm. They are overlapped up and down with an overlap of 20 mm, which can balance the cutting force and avoid missing cutting, less cutting, etc., thus improving the stability of cutting and the quality of root cutting. The coordinate system is established with the center of the disc knife as the origin, the positive direction of the X axis is the traveling direction of the harvester, and the motion diagram of the contact point at the root cutting position is shown in Fig. 10.

The time from position B1 to B2 is t0, then the motion equation of the contact point is:

where Rd—Radius of disc knife, mm; β0—Angle between the contact point at B1 and the X axis, (°); t0—Time from position B1 to B2, s; ω—Angular velocity of disc knife, rad s−1.

The motion trajectory equation of the disc knife at point B1 is as follows, and the combined velocity at point B1 at any time is synthesized by the motion components Vx, Vy and Vz in the X, Y and Z directions.

If the cutting speed is too fast, the disc knife cutting cabbage instantly will produce greater collision impact and vibration, which will affect the quality of root cutting and waste energy in re-cutting. If the cutting speed is too slow, incomplete root cutting or missed cutting are likely to occur. Taking into account the experimental results of the shear mechanical properties of Chinese cabbage roots and the requirements of root cutting21,22, the rotating speed range of the disc knife is 200–400 r min−1.

Design and analysis of inclined conveyor

The structure of the inclined conveyor is shown in Fig. 11, which is mainly composed of an inclined conveying frame, conveyor belt with baffle, side plate, screw tensioning mechanism, roller, etc. The hydraulic motor drives the driving drum to rotate, thus driving the conveyor belt to rotate. The Chinese cabbage is thrown onto the conveyor belt of the inclined conveyor from the rear end of the clamping conveyor, and then conveyed to the collection box at the rear. According to the measurement results of the physical characteristic parameters of Chinese cabbage in Table 1, the width of the conveyor belt is 300 mm, the length of the baffle is 260 mm, the height of the baffle is 200 mm, and the spacing between adjacent baffles is 500 mm. The front end of the inclined conveyor belt is located at the rear lower end of the clamping conveyor, which is staggered up and down.

Schematic diagram of the inclined conveyor: 1. Follower drum; 2. Inclined conveyor frame; 3. Side plate; 4. Front support rod; 5. Rear support rod; 6. Bracket; 7. Hydraulic motor; 8. Screw tensioning mechanism; 9. Conveyor belt with baffle; 10. Coupling; 11. Active drum; 12. Bearing seat; 13 Hydraulic motor fixing frame.

To avoid blockage and fully utilize the blocking and separating conveying function of the baffle, the speed of the inclined conveyor should match the traveling speed and clamping conveying speed. If the speed of the inclined conveyor belt is too low, it will cause 2 or more Chinese cabbage to be stored in adjacent baffles. If it is too large, there will be empty travel and the Chinese cabbage will be greatly impacted and damaged when it falls into the collection box. Therefore, the following formula needs to be satisfied:

where tm—Time for adjacent Chinese cabbage to fall into the inclined conveyor, s; Lm—Plant spacing between adjacent Chinese cabbage plants, mm; Vd—Speed of the inclined conveyor belt, m s−1; nc—Number of inclined conveyor belt baffles moving at the same position within tm time, unit; Hc—Spacing between adjacent baffles, mm.

According to measurements, the plant spacing of Chinese cabbage is 600 mm, and the traversing speed of the harvester is 0.3 m s−1 ≤ Vm ≤ 0.5 m s−1, so the minimum tm is 1.2 s. Taking nc to be 2, the speed of the inclined conveyor belt is 0.5–0.83 m s−1. To reduce the impact and collision damage of Chinese cabbage entering the collection box and ensure smooth conveying, the speed of the inclined conveyor belt is taken as the middle value and rounded to 0.65 m s−1.

Field performance experiment

Experimental conditions

The prototype of the developed self-propelled Chinese cabbage harvester (Fig. 12) is experimented in the Chinese cabbage experimental site (Fig. 13) in Hanting District, Shandong Province on 30th November 2022. Yihe Chinese cabbage is taken as the experimental object, and the planting mode is single row planting on the ridge. 40 m (60–70 Chinese cabbage) are harvested in each experiment. The dead and immature Chinese cabbage in the experimental area is removed before the experiment. There is a 10 m blank area in front of the experimental area as the acceleration area of the harvester, so that the harvester can reach the specified traveling speed when it reaches the experimental area.

Experimental method

-

(1)

Evaluation indexes

At present, there are no relevant standards and regulations for mechanized harvesting of Chinese cabbage. Therefore, according to other relevant standards and combines with the planting agronomy and other practical situations23,24. The accurate root cutting rate and the damage rate of Chinese cabbage are taken as the experimental indexes to carry out the field harvest experiment of Chinese cabbage harvester.

Accurate root cutting means that the position of root cutting is within the range of 2–15 mm from the bottom of Chinese cabbage stem. The root is completely cut off, without missing cutting, re-cutting, less cutting, etc., and the leaf ball of Chinese cabbage is not damaged25.

The accurate root cutting rate Y1 is as follows25:

where Wn—Number of Chinese cabbage that does not meet the root-cutting requirements, PCs; W0—Total number of Chinese cabbage harvested, PCs.

Chinese cabbage is considered damaged if it is broken, missing, torn or even falling apart after harvest, which affects its appearance, storage and sales25. The damage rate Y2 of Chinese cabbage is as follows:

where Ws—Number of damaged Chinese cabbage after harvested, PCs.

-

(2)

Experimental design

Through the pre-experimentation, the preferred range of experimental factors is determined, that is, the traveling speed of the harvester is 0.3–0.5 m s−1, the clamping and conveying speed is 120–170 r min−1, and the cutting speed is 200–400 r min−1. The traveling speed of the harvester, clamping and conveying speed and cutting speed are taken as the experimental factors, and the accurate root cutting rate and damage rate of Chinese cabbage are taken as the evaluation indexes. The coding of experimental factors level is shown in Table 3.

Before the operation of the harvester, the clamping and conveying speed and cutting speed are adjusted to set value in advance. The harvester’s traveling speed was controlled by the operator’s console, and the traveling speed was adjusted by adjusting the speed control knob. The clamping and conveying speed and cutting speed were controlled by flow valves and measured by a tachometer (DElIXI, DLX-ZSY2301, 2.5–9999 rpm). The speed of the inclined conveyor belt is 0.65 m s−1. Each group of parameter combination is repeated three times to get the average value, and a separate row is selected for harvesting in each experiment. After harvest, all the Chinese cabbage in the experimental area are collected, and classify and count the Chinese cabbage according to the requirements of accurate root cutting rate and damage rate, respectively.

Results and discussion

The experimental scheme and results are shown in Table 4. X1, X2, X3 are the coded values of the factors.

The harvest effect of Chinese cabbage is shown in Fig. 14. The experimental results showed that the overall performance of the harvester is stable, and each device worked normally, which basically met the requirements of mechanized harvesting of single-row Chinese cabbage. Chinese cabbage entering the clamping conveyor after root cutting did not fall and the leaf ball breakage. In the inclined conveying process, the Chinese cabbage has no falling and uneven distribution, and the conveying is stable. The average of accurate root cutting rate is 93.74%, which verifies the effectiveness of the root cutting device, and there is no missing cutting, less cutting and so on. The root cutting of individual Chinese cabbage is unqualified, mainly because the cutting device lacked the function of grounding profiling, and the root cutting height is not adjusted in time when the field ground is uneven. The average of damage rate is 7.45%, which is mainly due to the lack of automatic row alignment function of the harvester. The harvester needs to be constantly adjusted to align the rows during the harvesting process, resulting in untimely cutting, which leads to a high damage rate.

Accurate root cutting rate

The results of the variance analysis for the accurate root cutting rate are shown in Table 5, and the experimental model is extremely significant (p < 0.01). X1, X2, X3, X2X3, \(X_{2}^{2}\) all have very significant effects on the accurate root cutting rate (p < 0.01). X1X2, \(X_{3}^{2}\) have a significant effect on the accurate root cutting rate (p < 0.05). The rest of the items are not significant. The order of the influence of each factor on the accurate root cutting rate is clamping and conveying speed, traveling speed, cutting speed.

It can be seen from Table 5 that the lack of fit of the model is not significant (p > 0.05), and the regression model is established. The insignificant items are removed, and the regression equation of each factor on the accurate root cutting rate is obtained as shown in formula (11).

Response surface analysis of the interactions was performed using Design-Expert 10 software. When the cutting speed is 300 r min−1 (zero level), there is an interaction between the traveling speed and the clamping and conveying speed, as shown in Fig. 15a. When the traveling speed is constant, the accurate root cutting rate first increases and then decreases with the increase of clamping and conveying speed, and the increase is less than the decrease. The reason may be that the accurate root cutting rate reached the peak when the clamping and conveying speed and the traveling speed are highly coordinated. With the continuous increase of the clamping and conveying speed, the conveying speed of the clamping conveyor belt to the back of the Chinese cabbage increased, and the Chinese cabbage root cutting is not timely and the incision is inclined. When the clamping and conveying speed is constant, the accurate root cutting rate decreases with the increase of traveling speed. The reason may be that the greater the traveling speed, the greater the impact of the disc knife on the root of Chinese cabbage, and the blockage at the feeding inlet makes it impossible to cut the root.

When the traveling speed is 0.4 m s−1 (zero level), there is an interaction between the clamping and conveying speed and the cutting speed, as shown in Fig. 15b. At a certain clamping and conveying speed, the accurate root cutting rate increases slightly with the increase of cutting speed. The reason may be that the higher the cutting speed, the more thorough the root cutting, but it is easy to re-cutting. At a certain cutting speed, the accurate root cutting rate increases first and then decreases with the increase of clamping and conveying speed. The reason may be that with the gradual increase of the clamping and conveying speed, when the matching degree with the cutting speed is high, the accurate root cutting rate reaches the peak. As the clamping and conveying speed continues to increase, the conveying speed of the clamping conveyor belt to the back of the Chinese cabbage increased, and the Chinese cabbage root cutting is not timely and the incision is inclined.

Damage rate

The results of the variance analysis for the damage rate are shown in Table 6, and the experimental model is extremely significant (p < 0.01). X1, X1X2, \(X_{2}^{2}\) all have very significant effects on the damage rate (p < 0.01). X2, \(X_{1}^{2}\) have a significant effect on the damage rate (p < 0.05). The rest of the items are not significant. The order of the influence of each factor on the damage rate is traveling speed, clamping and conveying speed, cutting speed.

It can be seen from Table 6 that the lack of fit of the model is not significant (p > 0.05), and the regression model is established. The insignificant items are removed, and the regression equation of each factor on the damage rate is obtained as shown in formula (12).

When the cutting speed is 300 r min−1 (zero level), there is an interaction between the traveling speed and the clamping and conveying speed, as shown in Fig. 15c. When the traveling speed is constant, the damage rate of Chinese cabbage first decreased and then increased with the increase of clamping and conveying speed. The reason may be that with the increase of clamping and conveying speed, the damage rate of Chinese cabbage reaches the lowest when the degree of coordination with the traveling speed is high. With the continuous increase of the clamping and conveying speed, the conveying speed of the clamping conveyor belt to the back of the Chinese cabbage increases, and the untimely root cutting causes the abnormal collision between the Chinese cabbage and the disc knife, so that the attitude of the Chinese cabbage tilts and is damaged. When the clamping and conveying speed is constant, the damage rate of Chinese cabbage decreased first and then increased with the increase of traveling speed. The reason may be that with the increase of traveling speed, the damage rate of Chinese cabbage is the lowest when the degree of coordination with the clamping and conveying speed is the best. As the traveling speed continues to increase, the matching degree of the two gradually decreases, and the Chinese cabbage is congested at the entrance of the clamping conveyor belt, resulting in its inability to feed or tilted attitude after feeding and thus damage.

Optimization of parameters

To obtain the best operating performance of the Chinese cabbage harvester, based on the multi-factor experiment, the operating parameters of the Chinese cabbage harvester are optimized using a multi-objective optimization algorithm.

The objective functions are as follows:

The constraints are as follows:

Optimization results: the traveling speed of the harvester is 0.30 m s−1, the clamping and conveying speed is 131 r min−1, and the cutting speed is 339 r min−1. At this time, the accurate root cutting rate is 94.44%, and the damage rate is 4.86%, which meets the operation requirements of the accurate root cutting rate greater than 90% and the damage rate less than 10%.

In order to verify the correctness of the optimized combination of parameters, the above optimization results are used as the parameters for the validation experiment, and the experiment is repeated 5 times to take the average value. The experimental results are shown in Table 7. The average accurate root cutting rate is 94.72%, and the average damage rate is 5.06%. The maximum error with the parameter optimization results is less than 5%, and the results of parameter optimization are accurate.

Limitations and future prospects of research

Limitations

-

(1)

Limitations of sample diversity. The experiment was only conducted on the main cultivar “Yihe” in Shandong, and its physical characteristics may not be fully representative of other varieties.

-

(2)

Insufficient terrain adaptability. The current cutting device does not integrate a grounded profiling mechanism, which may increase the cutting height error when working on sloping land or uneven ridges.

-

(3)

Automation level to be upgraded. Relies on manual adjustment of rows, and does not realize automatic navigation based on vision/LIDAR.

Future prospects

-

(1)

Multi-species adaptability optimization. Establish a database of Chinese cabbage mechanical properties (e.g. root shear modulus, leaf bulb compression strength), and improve the adaptability to other Chinese cabbage varieties through modularized design (e.g. replaceable clamping belt).

-

(2)

Intelligent control system development. Explore target detection algorithms based on deep learning (YOLOv8), and integrate LiDAR to realize Chinese cabbage imitation cutting and automatic row alignment.

-

(3)

Energy consumption and sustainability optimization. Research on solar-assisted power systems to reduce diesel engine carbon emissions.

Conclusions

-

(1)

The sponge belt clamping conveyor device was designed. Through dynamic analysis, the maximum clamping force of the clamping conveyor belt was obtained to be 152.82 N, and the conveying speed was 0.78–1.3 m s−1. It achieved fully adaptive flexible clamping of Chinese cabbage bulbs within the range of 163–193 mm.

-

(2)

The cutting device with double disc knife stacked vertically and reverse equal speed rotation was designed. Based on the disc knife kinematics analysis, efficient root cutting of Chinese cabbage can be achieved when the cutting speed is 200–400 r min−1.

-

(3)

The matching model of baffle spacing-speed was established based on dynamic analysis of Chinese cabbage, and the optimal speed of inclined conveyor belt of 0.65 m s−1 was determined to realize the orderly conveying of Chinese cabbage, which lays the foundation for the subsequent automation of box loading.

-

(4)

Based on the multi-objective optimization, the better parameter combinations of the harvester were the harvester traveling speed of 0.30 m s−1, the clamping and conveying speed of 131 r min−1 and the cutting speed of 339 r min−1. Through verification experiments, the accurate root cutting rate was 94.72%, and the damage rate was 5.06%, which meets the design and operational performance requirements. Provided equipment support for the intensive production of Chinese cabbage.

Data availability

The data supporting this study’s findings are available from the corresponding author upon reasonable request.

References

Yang, Y. T. et al. Present situation of Chinese cabbage mechanization production and development suggestions. Chin. Veg. 11, 9–16 (2020).

Wang, M. S. Design and Experimental Research on Root Cutting Device of Chinese Cabbage Harvester (Central South University of Forestry & Technology, 2023).

Yang, J. H. et al. Research status and direction of headed vegetable harvesting machinery. J. Agric. Mech. Res. 45(11), 10–17 (2023).

Swe, K. M. et al. Physical and strength properties of radish and Chinese cabbage. Precis. Agric. 4(2), 98–108 (2022).

Kanamitsu, M. et al. Development of a Chinese cabbage harvester, (Part l) Fundamental research and development of harvesting mechanism. J. Jpn. Soc. Agric. Mach. 55(5), 133–140 (1993).

Kanamitsu, M. et al. Development of a Chinese cabbage harvester, (Part 2) Tractor-attached type experimental harvester. J. Jpn. Soc. Agric. Mach. 55(6), 121–128 (1993).

Kanamitsu, M. et al. Development of a Chinese cabbage harvester, (Part 3) Development of height controller and field test of harvester. J. Jpn. Soc. Agric. Mach. 56(2), 127–133 (1994).

Kim, H. J. & Choi, Y. S. Pulling performance of a self-propelled Chinese cabbage harvester and design of a preprocessing unit. J. Agric. Life Sci. 54(1), 99–108 (2022).

Wu, X. W. et al. Study on self propelled Chinese cabbage harvester. CHN South. Agric. Mach. 49(24), 23–24 (2018).

Miao, S. T. Optimization Analysis and Experimental Research on Key Components of Cabbage Harvester (Heilongjiang University, 2022).

Zhao, T. S. Study on the Design and Key Technology of Cabbage Harvester (Heilongjiang University, 2020).

Han, F. P. et al. Design and experiment of a fully closed cutting type cabbage harvester. J. Agric. Mech. Res. 45(6), 64–71 (2023).

Didamony, M. I. E. I. & Shal, A. M. E. I. Fabrication and evaluation of a cabbage harvester prototype. Agriculture 10, 631 (2020).

Cao, L. W., Miao, S. T. & Gu, L. Z. Design and cutting test analysis of Chinese cabbage harvester. J. Phys. Conf. Ser. 2185, 012005 (2022).

Zhang, J. F. et al. Design and experiment of cutting table of cabbage harvest machine. J. Agric. Mech. 41(11), 39–44 (2020).

Hu, K. T. et al. Design of small electric caterpillar type Brassica campestris ssp. chinensis var. rosularis harvester. J. Agric. Mech. 43(8), 7–14 (2022).

Miao, P. et al. Research on automatic alignment control system of electric leaf vegetable harvester. J. Agric. Mech. Res. 44(3), 84–89 (2022).

Zhang, J. et al. Design and experiment of crawler self-propelled single-row harvester for Chinese cabbage. Trans. Chin. Soc. Agric. Mach. 53(12), 134–214 (2022).

Wang, M. S. et al. Research status and development trend of Chinese cabbage mechanized harvesting technology. J. Agric. Mech. Res. 46(3), 252–258 (2024).

Kumar, M. et al. Force and power requirement for development of cumin harvester: A dynamic approach. Sci. Rep. 14, 13666 (2024).

Zhang, G. Z. et al. Design and experiment of a combined peeling machine for water chestnut. Sci. Rep. 13, 2393 (2023).

Zhu, H. B. et al. Design and experimental study on pruning machine of Yunnan edible rose. Sci. Rep. 13, 4118 (2023).

NY/T 1412–2007, Operating Quality for Beet Harvester. (2007).

GB/T 8097–2008, Equipment for Harvesting-Combine Harvesters-Test Procedure. (2008).

Sun, Z. X. Design and Experimental Research on the Root Cutting Device of Cabbage Harvester (Heilongjiang Bayi Agricultural University, 2023).

Funding

The work was supported financially by the Shandong Province Key R&D Program (2022CXGC010612), the Start-up Foundation for Doctoral Research of Weifang University (N0.2022BS30), and the Shandong Province Higher Education Institutions Young Innovation Team Talent Introduction Program.

Author information

Authors and Affiliations

Contributions

Conceptualization, Y.Y. and J.Q.; methodology, Y.Y.; software, F.X.; validation, Y.Y., F.X. and J.S.; formal analysis, Y.Y.; investigation, J.S. and Y.B.; resources, J.Q.; data curation, Y.L.; writing—original draft preparation, Y.Y.; writing—review and editing, Y.Y.; visualization, F.X.; supervision, J.S.; project administration, Y.L. and J.Q.; funding acquisition, J.Q. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yu, Y., Qi, J., Li, Y. et al. Design and experiment of key components for self-propelled harvester for Chinese cabbage. Sci Rep 15, 17007 (2025). https://doi.org/10.1038/s41598-025-02222-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-02222-5

Keywords

This article is cited by

-

Parameter optimization of key components in seed-metering device for pre-cut seed stems of Pennisetum hydridum

Scientific Reports (2025)

-

A Comparative Review of Mechanization Status and Cultivation Pattern of Chinese Cabbage in the USA and South Korea

Journal of Biosystems Engineering (2025)