Abstract

The search for sustainable construction materials has initiated the investigation of alternative binders to partially substitute cement in sandcrete brick manufacturing. This research examines how Saw Dust Ash (SDA) and Banana Leaf Ash (BLA) can partially replace cement in sandcrete brick manufacturing to produce sustainable building materials. Environmental pollution arises from improper management of agro-industrial wastes. Construction use of these materials leads to improved sustainability practices while simultaneously decreasing the carbon footprint associated with traditional cement-based materials. The study integrated Saw Dust Ash and Banana Leaf Ash into sandcrete bricks through different replacement levels from 0 to 25%. The mix design adhered to standard guidelines which maintained correct amounts of cement, SDA, BLA, sand, and water to reach optimal workability and strength. After casting and curing the bricks under controlled conditions, they underwent mechanical and durability testing. With a compressive strength value of 4.281 MPa, Bricks incorporating 8% SDA-BLA replacement demonstrated improved compressive strength development throughout the testing period because of the pozzolanic activity exhibited by the ashes. Durability tests showed that SDA-BLA-modified bricks matched the performance of conventional sandcrete bricks in water absorption tests, with a water absorption value of 9.119%. SDA-BLA bricks achieved the required structural performance standards according to flexural strength test results. Although SDA-BLA bricks demonstrated reduced early-age strength levels, they achieved superior long-term strength through secondary hydration reactions. Economic evaluations showed that manufacturing SDA-BLA sandcrete bricks costs about as much as producing conventional bricks which positions them as a financially feasible sustainable substitute within the construction industry. This research establishes that SDA and BLA function effectively as partial cement substitutes in sandcrete brick manufacturing which supports eco-friendly building practices alongside waste management and sustainable development.

Similar content being viewed by others

Introduction

Bricks are widely used as essential building materials in most construction projects due to their high strength, durability, and cost-effectiveness1,2,3. Their significance in construction dates back thousands of years, with historical evidence of their use in ancient Egypt, Rome, and Mesopotamia4. Over time, the introduction of cement as a binder led to the development of cement bricks, reducing the energy-intensive processes associated with traditional clay brick production. Today, both clay and cement bricks remain fundamental in modern construction.

However, the construction industry faces increasing challenges in achieving sustainability, prompting researchers to explore alternative materials that can minimize environmental impact while meeting structural and functional requirements5,6. Sustainability in construction involves collaborative efforts across disciplines to address housing demands and improve the built environment7,8. Conventional bricks consume significant natural resources such as limestone, clay, sand, and gravel, alongside high energy usage9. To address this issue, researchers are investigating sustainable alternatives to reduce the carbon footprint of brick manufacturing.

In recent years, agricultural and industrial waste materials have gained attention as viable substitutes for conventional raw materials in brick production. Some of these alternative materials include sawdust ash (SDA)10, banana leaf ash (BLA)11, rice husk ash12, wastewater sludge13, tannery sludge14, and dust waste15. These waste-based materials not only promote sustainable construction practices but also contribute to waste management and resource efficiency. Countries with strong agricultural and forestry-based economies, such as Uganda, generate large volumes of waste, making it crucial to implement effective reuse strategies to mitigate environmental pollution and enhance material sustainability16,17. Particularly, the identified wastes are sawdust ash (SDA) and banana leaf ash (BLA), which can be repurposed as aggregate and cement replacements, respectively, to manufacture sustainable bricks in matching with the global efforts in improving existing waste management.

The construction and demolition sector is responsible for approximately 40% of global energy consumption and contributes to nearly one-third of greenhouse gas emissions18,19. Reports indicate that as demand for construction materials rises, so does the extraction and consumption of natural resources, leading to increased energy use in processing, transportation, and material production20,21. Currently, global solid waste generation stands at around 2.01 billion tons per year, with projections estimating an increase to approximately 3.40 billion tons annually by 205022. A promising strategy to mitigate these environmental impacts involves repurposing industrial solid waste as alternative stabilizers in construction, offering economic, social, and ecological benefits23,24. One of the major contributors to solid waste accumulation is rapid urbanization, particularly in developing nations, where irregular landfill disposal and open dumping are prevalent25,26. A viable solution to the waste disposal challenge is incorporating recycled waste materials into construction products, thereby reducing their environmental footprint27. Among various construction materials, bricks remain one of the most versatile due to their mechanical and physical properties, as well as their adaptability to alternative waste-based compositions28. However, traditional brick production is highly resource- and energy-intensive, contributing significantly to carbon emissions29,30,31. Recent studies emphasize the need to reduce energy consumption in construction processes32. Growing demand for sustainable and environmentally friendly materials has driven research into alternative production methods and eco-friendly construction materials6,33. The construction industry alone consumes nearly 24% of the world’s natural resources, underscoring the urgency of selecting sustainable materials34.

One approach to achieving sustainability is the development of soil–cement bricks, which eliminate the need for burning, reduce cement usage, and allow for waste material incorporation. Additionally, cement bricks can lower construction costs by up to 40% compared to conventional masonry, particularly for low-cost housing35. This makes cement bricks a more sustainable choice than traditional bricks9. The increasing depletion of natural resources and the growing challenge of solid waste management are pressing global concerns36,37,38. As a result, sustainable construction practices have become essential, not only to improve building efficiency but also to promote environmental balance39,40. With technological advancements shaping the construction industry, there is a rising interest in alternative building materials, particularly earth-based options41,42,43.

One of the key benefits of stabilized soil bricks is their low thermal conductivity, which enhances a building’s energy efficiency. These bricks also contribute to better acoustic and thermal insulation, making them a practical choice for sustainable housing44. When it comes to engineering performance, abrasion resistance in materials like Sawdust Ash (SDA) and Banana Leaf Ash (BLA) depends on their composition and processing methods, influencing their effectiveness in construction17,45,46. Both SDA and BLA contain fine particles that enhance pozzolanic activity, leading to improved strength and durability in concrete. Additionally, their porous nature allows for better bonding within the cement matrix without compromising the overall structural integrity46. Research on incorporating SDA and BLA in concrete mixtures has shown remarkable improvements in compressive strength, durability, and chemical resistance, positioning them as a sustainable alternative to conventional cement-based materials. By integrating these eco-friendly substitutes, construction projects can reduce environmental impact while maintaining the necessary load-bearing capacity.

With the high demand for cement bricks in the construction industry and Uganda’s increasing industrial waste, it is crucial to develop efficient waste management strategies. This research explores the potential of sustainable sandcrete bricks by partially replacing cement with locally sourced sawdust ash and banana leaf ash. To assess the mechanical properties of these bricks, we conducted compressive strength, flexural strength, and water absorption tests. Additionally, a cost analysis was performed to compare production expenses against conventional bricks, helping determine their economic viability. The findings of this study aim to encourage sustainable construction practices and promote the use of locally available waste materials in the building industry.

Experimental investigation

This research on the feasibility of utilizing local waste materials in sandcrete brick production was conducted in three distinct phases. Phase 1 focused on mix design identification, Phase 2 involved characterization of material properties, and Phase 3 was dedicated to code compliance, morphological analysis, and cost evaluation.

Materials

The primary materials explored in this research were Sawdust Ash (SDA) and Banana Leaf Ash (BLA), which were used as partial cement replacements to develop a lightweight, solid mix for brick production. Other key materials included Portland cement, fine aggregates (river sand), and clean tap water which are all essential components in standard sandcrete brick formulation.

Sawdust ash (SDA)

Sawdust was sourced from commercial sawmills in Ishaka, Bushenyi District, Uganda. The material was first dried and subsequently burned in a muffle furnace at temperatures between 600 and 800 °C to produce SDA. To ensure consistency and enhance pozzolanic activity, the resulting ash was sieved using a 45 μm mesh in accordance with ASTM C618 standards to remove large particles and promote uniformity47.

Banana leaf ash (BLA)

Banana leaves were collected from Ishaka, Bushenyi District, Uganda, and underwent drying and incineration in a muffle furnace at temperatures between 600–750 °C to produce BLA. The obtained ash was sieved using a 75 μm mesh, allowing for finer particles with a higher surface area, which enhances mix dispersion and interaction within the brick matrix48.

Cement

Portland cement was employed for the production of conventional sandcrete bricks, serving as the control specimen for comparison with SDA-BLA-modified bricks. The cement used conformed to BS 12 (1978) specifications.

Fine aggregate

The fine aggregate used in the experiment was river sand, which plays a crucial role in filling voids between cement particles, thereby improving workability, cohesion, and strength of the solid mix. The sand was sourced from a construction site at Kampala International University, Western Campus, Uganda, and had a maximum particle size of 3.18 mm. The aggregates were verified to be free of organic matter, clay, silt, and other contaminants, in compliance with BS EN 12620:2013 standards49.

Water

Clean tap water, free from impurities, was used in the sandcrete brick production process. The water met the BS EN 1008:2002 standard for mixing water in concrete production. The water-cement binder ratio was adjusted within the range of 0.5–0.7, depending on the desired workability and mix consistency50.

Methods

The production of sandcrete bricks incorporating industrial and agricultural waste followed a structured approach, ensuring precision at every stage—from material collection to final testing. The necessary raw materials, including Sawdust Ash (SDA), Banana Leaf Ash (BLA), cement, fine aggregates, and water, were carefully measured and thoroughly mixed to achieve a uniform and workable consistency. Once the mixture was prepared, it was manually compacted into block molds to ensure proper shape and density. The curing process played a crucial role in strength development, with the bricks undergoing water curing for 7–28 days under controlled conditions. Throughout the process, adjustments in mix proportions and curing duration were examined to optimize mechanical performance. After curing, the hardened bricks were subjected to quality assessments, including compressive strength, flexural strength, and water absorption tests, to evaluate their structural suitability. This systematic methodology underscores the potential of agro-industrial waste utilization in sustainable construction while emphasizing the importance of precise material processing techniques for achieving high-quality sandcrete bricks51.

Mix design

The mix design for producing sandcrete bricks was developed in accordance with BS 3148, BS 4550, and NIS 87:2007, which outline the optimal cement content and water-cement ratio necessary for ensuring the required performance of both fresh and hardened bricks. The key steps in the mix design process included determining the ideal combination of cement, river sand, and water to create a homogeneous and workable mixture, manually compacting the blended materials into standard molds to achieve the required brick dimensions, curing the molded bricks for 7–28 days, primarily using water curing, to enhance compressive strength and durability.

The cement-sand ratio, water-cement ratio, and curing conditions were carefully optimized, as these factors play a significant role in determining workability, strength, and long-term durability. The specific mix proportions and curing conditions, detailed in Tables 1 and 2, ensure the production of high-quality, sustainable bricks that comply with industry standards.

By fine-tuning these parameters and validating them through laboratory testing, this study highlights the feasibility of producing eco-friendly, durable sandcrete bricks, aligning with sustainability objectives in modern construction.

Compressive strength test

The compressive strength test measures the sandcrete brick’s resistance to axial loads, ensuring it can withstand structural forces without failure. This test is vital for assessing quality, durability, and load-bearing capacity in construction applications. For this test, the sandcrete mix is thoroughly blended and molded into standard brick dimensions of 100 mm × 100 mm × 100 mm.

The bricks are compacted to remove air voids and cured for 7–28 days under controlled conditions to develop the required strength46. Before testing, the brick surfaces are leveled and smoothed to ensure accurate results. The hardened bricks are tested using a Universal Testing Machine (UTM), which applies a gradual and uniform load until failure occurs. The compressive strength is calculated by dividing the maximum load sustained at failure by the brick’s cross-sectional area52.

This test guarantees that sandcrete bricks meet the minimum strength standards outlined in BS EN 772-1 and NIS 87:2007 for structural applications.

Flexural strength test

The flexural strength test assesses a sandcrete brick’s ability to resist bending forces, which is crucial for ensuring structural integrity under flexural loads. The brick specimens measuring 215 × 102.5 × 65 mm are used for the test. To guarantee consistent uniformity, the sandcrete mix is carefully prepared and mixed. The mixture is molded into brick forms and compacted to eliminate air voids, which could weaken the strength and durability. Curing is performed under controlled conditions, allowing for proper hydration and strength development.

Once the bricks have cured, they are placed on a support span and subjected to a gradually increasing load at the center until failure. A Universal Testing Machine (UTM) equipped with a flexural loading fixture is used to apply a constant-rate load to accurately measure flexural strength53,54.

Chemical and morphological characterization

A detailed examination of chemical composition and physical structure provides valuable insights into the material properties and potential applications of sandcrete bricks. Chemical Analysis identifies elemental composition and compound presence, offering an understanding of chemical properties and reactions. Morphological Analysis evaluates particle size, shape, and distribution, which directly affect mechanical properties and structural performance55.

X-ray fluorescence (XRF) analysis

X-ray Fluorescence (XRF) is an advanced analytical technique used to determine the elemental composition of sandcrete bricks. High-energy X-rays irradiate the sample, causing it to emit fluorescent X-rays, the emitted X-rays are analyzed to identify and quantify elements within the material56. The analysis includes sample preparation, instrument calibration, data acquisition, and interpretation. XRF is a fast, non-destructive method widely applied in materials analysis and quality control across industries57,58.

Thermogravimetric analysis (TGA)

Thermogravimetric Analysis (TGA) is used to evaluate the thermal stability and decomposition behavior of sandcrete bricks by measuring mass loss over time at controlled temperatures. The sample is heated under a controlled atmosphere to prevent oxidation or unwanted chemical reactions, as the temperature increases, various thermal events occur, leading to mass changes in the sample59. These events might include dehydration (removal of moisture), dehydroxylation (loss of hydroxyl groups), and decomposition of organic additives. By analyzing TGA curves, the temperature ranges for different thermal processes are identified, providing insights into the material’s thermal behavior and kinetics.

This analysis is crucial for optimizing the composition and performance of sandcrete bricks, ensuring their stability under varying environmental conditions60,61,62,63.

Results discussion and analysis

This section presents the findings of the study on the mechanical properties of sandcrete bricks incorporating sawdust ash (SDA) and banana leaf ash (BLA) as partial replacements for cement. The analysis includes evaluating the influence of SDA and BLA on the compressive strength, flexural strength, and durability of the produced sandcrete bricks. Additionally, the optimal mix proportions are identified and compared with conventional sandcrete bricks to assess their structural performance and sustainability potential. It further explores key factors affecting the strength and durability of the sandcrete bricks, including hydration, curing conditions, and material composition. Experimental results are critically examined to validate the efficacy of SDA and BLA as supplementary materials, providing insights into their practical application in sustainable construction64, emphasizing the need for continued exploration of alternative cementitious materials to enhance sandcrete brick performance and environmental sustainability.

Materials characterization

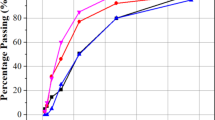

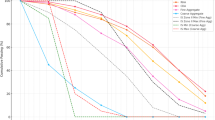

Characterizing materials is essential for advancing technology and fostering innovation in various fields. A series of laboratory tests was conducted to assess the suitability of individual components for use in civil engineering construction. These tests included sieve analysis on aggregate and admixtures to evaluate their particle size distribution and gradation65,66. Figure 1 illustrates the sieve analysis results, showing the variation in particle sizes along with a cumulative frequency distribution curve. The analysis indicated that the fine aggregates passed sieve sizes ranging from 2 mm to 75 µm, with passing rates from 92.45 to 4.16%. For the SDA and BLA samples, passing rates ranged from 99.74 to 46.32% and 99.74 to 60.12%, respectively, for sieve sizes from 2 mm to 75 µm. These findings comply with the BS EN 933-1:2012 standards, confirming the presence of well-graded sand particles that enhance the durability of bricks67. The particle size distribution in the aggregates and ash samples meets the criteria necessary for producing durable, high-quality construction. This ensures that construction materials conform to industry standards, ultimately improving the performance and lifespan of civil engineering structures68.

Chemical properties results

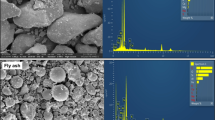

The chemical properties of the studied admixtures were assessed using X-ray fluorescence (XRF) analysis, as detailed in Table 3. The results showed that sawdust ash (SDA) contains 2.26% Fe2O3, 5.12% Al2O3, and 66.95% SiO2, accounting for a total of 74.33% of its composition. This composition indicates good pozzolanic properties, aligning with the standards set by BS EN 450-169. Banana-leaf ash (BLA), on the other hand, is composed of 29.09% CaO, 5.75% MgO, 24.07% K2O, 27.56% SiO2, and 8.19% Al2O3. This combination forms a strong ternary mixture when used in an SDA-BLA sandcrete blend. The high level of CaO enhances the sandcrete brick’s performance by interacting with pozzolanic substances (such as SiO2 and Al2O3) to produce additional calcium silicate hydrates, which contribute to strength development and improve the setting process by providing an active lime source, potentially boosting early-age strength. The Ordinary Portland Cement (OPC) in this study was found to contain 53.6% CaO, 29.49% SiO2, and 4.54% Al2O3, indicating good binding properties and the potential to form hydration products that enhance mechanical performance. The XRF analysis offers significant insights into the chemical compositions of the admixtures and OPC, suggesting their potential use in sandcrete bricks70. The presence of pozzolanic and binding components in the samples points to promising results for creating high-performance mixtures, which is crucial for optimizing material formulations and improving the mechanical properties of sandcrete in civil engineering projects71,72.

Sandcrete experimental test responses

Laboratory testing of sandcrete bricks includes evaluating various mechanical, morphological, and chemical properties in both fresh and hardened states. These tests encompass compressive strength, flexural strength, water absorption, and microstructural analysis. Such assessments provide important information about sandcrete bricks’ performance and suitability for construction applications73. The results from these tests help optimize mix designs and support the long-term structural durability of the sandcrete.

Compressive strength result

The compressive strength of sandcrete brick is a critical parameter that determines its suitability for structural applications74,75. The experimental results highlight the critical factors influencing the compressive strength of sandcrete brick, with a particular focus on the cement-aggregate ratio and the SDA and BLA ratio, as shown in Figs. 2 and 3. The results reveal that substituting 8% of cement with SDA and BLA at a cement-to-aggregate ratio of 1:5.5 and a water-binder ratio of 0.6 considerably improves the compressive strength of sandcrete bricks, achieving a peak value of 4.281 MPa, compared to a minimum of 3.344 MPa at a replacement level of cement with 25% of SDA and BLA with a cement-to-aggregate ratio of 1:3 and a w/c ratio of 0.5. The increase in strength can be attributed to an ideal balance of pozzolanic reactivity at lower replacement levels (8%), the reactive silica (SiO₂) and alumina (Al₂O₃) in SDA and BLA effectively react with the calcium hydroxide (Ca(OH)₂) released during cement hydration hence producing additional calcium silicate hydrate (C–S–H), which enhances the strength and durability of the matrix. Additionally, the cement-aggregate ratio of 1:5.5 ensures better binding of aggregate particles due to a more cohesive mix, and the water-binder ratio of 0.6 promotes sufficient hydration, ensuring proper pozzolanic activity and hydration reactions, unlike the mix with a 0.5 water-binder ratio, where insufficient water may limit hydration and reactivity. The findings aligns with studies by Okonkwo et al.76 and Akinyemi et al.77, who reported that moderate levels of agricultural ash replacement optimize mechanical properties, while excessive replacement adversely affects strength due to reduced cementitious content and matrix bonding.

Flexural strength result

The flexural strength of sandcrete bricks indicates their capacity to withstand bending or flexural stress, which is crucial for applications where tensile strength and crack resistance are important78. This strength is assessed through a three-point bending test, where beam specimens are subjected to loading until failure. The experimental results, as shown in Figs. 4 and 5, underscore the critical role of cement replacement levels, curing duration, and mix ratios in optimizing the strength of sandcrete bricks. The findings reveal that low cement replacement levels with SDA and BLA yielded superior strength outcomes. Specifically, a 0.25% replacement of cement, combined with a 0.5 w/c ratio and a cement-to-aggregate ratio of 1:4, achieved a maximum strength of 1.798 MPa. This was significantly higher than the 0.78 MPa strength recorded at a 25% replacement level, with a cement-to-aggregate ratio of 1:3 and a w/c ratio of 0.5. The enhanced strength at 0.25% replacement can be attributed to an optimal balance of pozzolanic reactivity, efficient hydration, and well-designed mix proportions, which collectively improved the matrix’s strength and durability. Conversely, the reduced strength at 25% replacement is linked to lower cement content and insufficient hydration, which compromised the integrity of the matrix. These findings align with previous studies, such as those by Olutoge et al.79 and Adeyemi et al.80, which emphasize the importance of achieving the right balance in cement replacement levels to maximize the pozzolanic benefits without compromising structural performance. Longer curing periods also contributed to improved mechanical properties by allowing for more complete polymerization and stabilization of the sandcrete. The aggregate-to-binder ratio and w/c ratio are key factors in determining the final strength, as they balance reactive components and structural materials needed for a dense and cohesive matrix that maximizes strength81.

The divergence between the flexural strength peak at 0.25% replacement and the 8% optimum for compressive strength can be attributed to the distinct mechanisms governing these two strength characteristics. Flexural strength is more sensitive to the surface integrity, micro-crack resistance, and tensile bonding within the matrix. At low replacement levels, the incorporation of SDA-BLA introduces fine pozzolanic particles that act as micro-fillers, improving matrix compactness and bridging micro-cracks, thus enhancing tensile resistance without significantly disrupting the original cementitious matrix82,83. This results in an early gain in flexural strength, often observed in the early stages of hydration. Conversely, compressive strength is more influenced by the overall microstructural development and the accumulation of secondary hydration products over time. At higher replacement levels of cement with SCMs like SDA and BLA, the pozzolanic reactions from these SCMs contribute more substantially to the formation of additional calcium silicate hydrates (C–S–H), which densify the matrix and improve resistance under compressive loads84,85,86. Thus, the compressive strength increases as more cementitious material is produced, resulting in a more robust and compact structure ideal for compressive applications.

Statistical analysis of experimental results

A statistical regression analysis was carried out to confirm the experimental results regarding the compressive and flexural strength of sandcrete bricks that contained Sawdust Ash (SDA) and Banana Leaf Ash (BLA). A second-degree polynomial regression model fitted to the data is displayed in Figs. 6 and 7, which illustrates the correlation between compressive strength (MPa) and SDA-BLA replacement levels (in percentage), same as the flexural strength (MPa) and SDA-BLA replacement levels (in percentage). For clarification, the graph showed the derived trend line equation together with the coefficient of determination (R2).

The regression model is defined as:

where \(x\) is the percentage replacement of cement with SDA-BLA.

From the regression analysis, the R2 value of the compressive strength was found to be 0.8036, indicating that approximately 80.36% of the variation in compressive strength can be explained by the polynomial model. This degree of correlation, which shows a significant statistical link between the SDA-BLA concentration and the bricks’ mechanical performance, is deemed acceptable in materials research. Compressive strength first rises with SDA-BLA replacement, reaching a peak of around 8%, before gradually declining with greater replacement levels, according to the polynomial curve’s non-linear tendency. This observation validates the experimental results and shows that the ideal replacement range for compressive strength optimization is between 5 and 10%.

Polynomial regression analysis was also used to validate the flexural strength data. An even higher correlation was found in the model fit, with an R2 value of 0.9903. The polynomial regression model offers a good match for the flexural strength data, precisely reflecting the performance peak seen at 0.25% SDA-BLA substitution, as seen by this remarkably high R2 value. Additionally, this confirms the accuracy and consistency of the flexural strength trends seen in the experimental tests.

Water absorption test result

Figure 8 shows the water absorption results of sandcrete bricks with varying levels of SDA and BLA replacement ranging from 0 to 20% at 28 days. The water absorption values range from 9.12% to 16.0%. The minimum water absorption is observed at 8% SDA and BLA replacement with a value of 9.12%, while the maximum is recorded at 20% SDA and BLA replacement with a value of 16.0%. According to BS EN 771-1:201187, the standard water absorption for masonry units should generally not exceed 12% for bricks exposed to weathering and freeze–thaw conditions, depending on the type and application. Bricks with water absorption below 10% are generally considered to have good durability and reduced susceptibility to moisture ingress88.

At 0% SDA and BLA replacement, the water absorption value was 9.425%, which meets the standard requirements. Water absorption initially increases slightly with increasing ash content (10.751% at 2% replacement and 12.682% at 4%) but decreases at 8% replacement (9.12%). This indicates an optimal mix at 8%, where the pozzolanic reaction enhances the brick’s density and reduces porosity. Beyond 8% replacement, water absorption consistently increases, with values exceeding the standard limit of 12%. At 20% replacement, the absorption reaches 16.0%, suggesting that excessive ash content negatively impacts the brick’s pore structure, increasing its permeability. Bricks with SDA and BLA replacements up to 8% meet the standard requirements for water absorption and are suitable for use in construction. However, beyond this level, the increased porosity due to higher ash content compromises durability. These results highlight the importance of optimizing SDA and BLA proportions to balance sustainability with performance in sandcrete bricks.

Strength development of SDA-BLA Sandcrete Brick

Using laboratory data collected for evaluating the mechanical properties of sandcrete bricks with varying proportions of cement replaced by SDA and BLA, compressive and flexural strength tests were conducted over hydration periods ranging from 3 to 56 days. These tests assessed the effect of pozzolanic reactions on strength development. The highest and lowest strength values were recorded at 8% and 20% cement replacement, respectively, with compressive strength results of 1.83–1.49, 1.97–1.70, 4.28–3.52, and 4.49–3.84 MPa for 3, 14, 28, and 56 days, and flexural strength results of 1.22–0.93, 1.41–1.02, 1.72–1.05, and 1.96–1.59 MPa for the same time intervals. These findings comply with the masonry unit requirements for both non-loadbearing and load-bearing structural applications, as outlined in BS EN 771-1:2011: Part 187.

Figures 9 and 10 illustrate the graphical representation of compressive and flexural strength responses across different hydration periods. The data reveal that strength decreases beyond an 8% replacement level of cement by SDA and BLA, with the lowest strength observed at a 20% replacement level. During the initial hydration stages (3 and 14 days), strength gain was slower. At the 28-day mark, a critical benchmark for strength evaluation (as more than 90% strength is typically developed by this stage), the results showed a noticeable increase in strength for various replacement levels, though the lowest compressive strength still occurred at 20% replacement. By the 56-day hydration period, the rate of compressive strength increase for SDA and BLA replacements exceeded that of the control mix (0% replacement) from 6 to 12% replacement. While the control mix exhibited high mechanical strength, the mixes with SDA and BLA replacements showed improved performance at later hydration stages. This enhancement is attributed to pozzolanic reactions, where alumina-silicates in SDA and BLA interact with hydrated lime released during cement hydration. The results at 56 days demonstrate further strength improvement in mixes containing SDA and BLA, confirming that extended curing allows continued hydration and strength development in the cementitious matrix.

Morphological and mineralogical characterization of the sandcrete brick

Morphological and mineralogical analysis of sandcrete bricks entails thoroughly examining their physical structure and the identification of the minerals within the material. This type of analysis is crucial for assessing the properties, performance, and durability of sandcrete bricks89,90. By employing these techniques, researchers and engineers can refine the composition and processing methods of sandcrete bricks to achieve targeted properties and performance levels. Gaining insights into the microstructure and mineral content is vital for predicting the material’s long-term behavior, such as its mechanical strength and ability to withstand environmental conditions91.

Fourier transform infrared spectroscopy (FTIR) results

The results of Fourier Transform Infrared Spectroscopy (FTIR) provide important insights into the chemical composition and bonding characteristics of bricks blended with sawdust ash (SDA) and banana leaf ash (BLA). This analysis identifies functional groups and chemical interactions that influence the bricks’ performance and durability. The test is carried out on SDA-BLA blended sandcrete brick of selected levels at 0%, 8%, 15%, and 25% in respect to the obtained strength as shown in Fig. 11a–d. For the brick sample with 0% SDA-BLA shown in Fig. 11a, the FTIR spectrum reflects the typical chemical composition of bricks without ash additives. Broad absorption peaks in the range of 3550–3870 cm−1 indicate the presence of hydroxyl groups associated with water molecules or hydroxylated minerals, suggesting retained moisture or bound water in the brick matrix. A strong peak at 1,407 cm−1 corresponds to carbonate (C–O) vibrations, pointing to carbonate compounds naturally present in the brick or formed during carbonation in drying or curing. Peaks at 965 cm−1 and in the range of 470–530 cm−1 are associated with silica (Si–O) bonds, forming the structural framework of the brick. Additional peaks near 712 cm−1 indicate aluminosilicate compounds, while a feature at 2,175 cm−1 suggests minor organic or carbonaceous residues. Vibrations in the 400–500 cm−1 range indicate the presence of metal–oxygen bonds, such as those from iron oxides, which contribute to the material’s physical and chemical properties. The absence of peaks related to pozzolanic materials, such as calcium silicates, indicates no chemical modification from ash-derived components, limiting the potential for enhanced strength and durability. For brick sample with 8% SDA-BLA, shown in Fig. 11b, a significant spectral changes was observed, reflecting the addition of ash components. A broad peak around 3853–3958 cm−1 corresponds to hydroxyl groups, indicating moisture content and surface interaction between pozzolanic compounds and water. A sharp peak at 2986 cm−1 suggests the presence of organic carbonates or residues introduced by the ashes. The band at 1409 cm−1, attributed to carbonate (C–O) vibrations, appears with increased intensity, indicating a higher carbonate content from the ash. Notable peaks at 965 cm−1, 873 cm−1, and 712 cm−1 correspond to silica (Si–O) and aluminosilicate (Al–O–Si) bonds, confirming enhanced silica and alumina content due to the ash addition. These changes suggest improved pozzolanic activity, which may enhance the mechanical strength and durability of the bricks. Furthermore, for the brick sample with 15% SDA-BLA as seen in Fig. 11c, broad bands around 3838–3877 cm−1 correspond to hydroxyl (-OH) stretching vibrations, indicating water molecules and hydrogen-bonded silanols, although with reduced intensity compared to samples with lower ash content. This reduction reflects decreased surface hydration and bonding activity. Peaks at 2188–1991 cm−1 suggest organometallic or carbonate compounds, but their lower intensity points to weakened mineral interactions at higher ash replacement levels. Vibrations at 1407 cm−1 and 1007 cm−1 represent carbonate (C–O) and silicate (Si–O) groups, but diminished silicate peaks indicate reduced silica reactivity due to ash dilution. Bands at 873 cm−1, 774 cm−1, and 712 cm−1 correspond to aluminosilicate and crystalline silica, with reduced intensities reflecting a decline in polymerization or pozzolanic reactions. The metal oxide vibrations in the 400–500 cm−1 range are also weaker, suggesting less contribution from metallic bonds. These spectral changes correlate with slightly reduced mechanical strength due to excessive ash content disrupting the bonding matrix. Additionally, in the 25% SDA-BLA sample shown in Fig. 11d, a broad absorption band between 3550 and 3360 cm−1 corresponds to O–H stretching vibrations, indicating hydroxyl groups linked to adsorbed water or hydration products like calcium silicate hydrates (C–S–H). This retained water contributes to reduced mechanical strength by limiting crystallinity and incomplete geopolymerization. A peak at 2194 cm−1 is associated with CO₂ vibrations, likely due to residual carbonation from unreacted materials. The region between 1005 and 433 cm−1 features peaks related to silicate (Si–O) and aluminate (Al–O) groups, integral to the geopolymeric matrix. However, the Si–O stretching band at 1005 cm−1 reflects partially polymerized silicate phases, suggesting incomplete bonding and structural weaknesses. Peaks at 872 cm−1 and 712 cm−1 indicate carbonate compounds, which can hinder proper bond formation and strength development. Minor peaks at 467 cm−1 and below correspond to metal oxide groups like Fe–O or Al-O, which contribute to secondary phases with limited reactivity.

Overall, the FTIR results reveal that excess ash content leads to residual hydration, and carbonate interference, causing lower mechanical strength.

Thermogravimetric analysis (TGA) results

TGA offers insights into the thermal stability, dehydration, and decomposition behavior of the sandcrete brick. It also provides insights into the reaction mechanisms during heating. The test is carried out on SDA-BLA blended sandcrete brick samples with replacement levels of 0%, 8%, 15%, and 25% as shown in Fig. 12a–d. The brick sample shown in Fig. 12a with 0% SDA-BLA demonstrates a major weight loss event between approximately 300 °C and 500 °C, which corresponds to a mass loss of volatile components and organic matter decomposition. Beyond 500 °C, the weight stabilizes, indicating that most decomposition reactions have been completed. The negligible weight change beyond this temperature suggests the material’s stability in higher thermal regimes. These results suggest that the brick sample undergoes significant chemical transformations during heating, primarily driven by the release of organic matter and dehydration of mineral phases. The high-temperature stability makes the material potentially suitable for applications requiring thermal resistance. For the brick sample shown in Fig. 12b with 8% SDA-BLA, the TGA curve shows an initial weight loss below 200 °C, attributed to the evaporation of free and physically adsorbed water. This stage is typical of most brick materials and indicates minimal moisture retention due to the low substitution levels of SDA and BLA. Between 200 and 400 °C, the weight loss is more pronounced and corresponds to the decomposition of organic matter and the loss of water from hydrated phases present in the ash content. The use of 8% SDA and BLA contributes to moderate thermal stability compared to lower ash content, as evidenced by a steady weight-loss profile. The TGA curve for the brick sample shown in Fig. 12c with 15% SDA-BLA shows a primary weight loss occurring between approximately 400 °C and 500 °C, likely corresponding to the decomposition of organic matter and carbonates within the sample. Beyond this range, the curve flattens, indicating thermal stability with minimal weight change, suggesting that the residue is predominantly made up of thermally stable inorganic materials like silica and other oxides. The final weight loss stabilizes at about 20%, indicating a relatively high residual material content, which could contribute to the structural integrity of the brick under thermal exposure conditions. The result suggests that the incorporation of SDA and BLA at 15% replacement, while beneficial for sustainability, may slightly reduce the mechanical strength of the bricks due to the residual ash content, which can act as micro-voids within the structure. Figure 12d shows distinct weight loss stages and thermal behavior trends for the 25% SDA-BLA brick sample. The TGA curve reveals a major weight loss occurring between approximately 400 °C and 500 °C, representing the thermal decomposition of organic materials and volatile compounds within the ash additives. The final weight stabilizes around 20% of the original mass, indicating a high percentage of residual inorganic matter, such as silica and other mineral oxides, which remain stable at higher temperatures. This weight loss profile suggests that the sample primarily loses organic and volatile fractions, leaving behind thermally stable components. The result of the TGA for a brick sample of 25% SDA-BLA suggests the presence of a higher residual ash content compared to the other samples, which can increase porosity and reduce the density of the brick, hence, negatively impacting its compressive strength.

Cost analysis

A preliminary cost estimation was carried out to compare the unit production cost of the proposed agro-industrial sandcrete bricks incorporating SDA and BLA with that of conventional Ordinary Portland Cement (OPC) sandcrete bricks. The estimated cost for producing a single sandcrete brick incorporating 8% Sawdust Ash (SDA) + 8% Banana Leaf Ash (BLA) was calculated and compared to that of a traditional cement brick, as shown in Table 4. The dimensions of each brick used in the cost analysis were height of 65 ± 1.875 mm, width of 102.5 ± 1.875 mm, and length of 215 ± 3 mm. Cost components considered include cement, sand, water, and labor. The unit prices were based on local market rates in a Sub-Saharan African context, where:

-

The price of cement was taken as $200/ton, translating to approximately $0.01 per brick for conventional bricks and $0.002 per brick for the SDA-BLA bricks due to the reduced cement usage.

-

Sand and water costs were assumed to be constant across both types due to equal volume use.

-

Labor cost was estimated at $6/day, with the assumption that one mason can produce approximately 100 bricks/day, resulting in a labor cost of $0.06 per brick.

-

Transportation of raw materials within a 10–15 km radius was included in the material costs, assuming locally sourced agricultural waste (SDA/BLA) incurs minimal transportation charges.

For OPC bricks and the suggested SDA/BLA bricks, the total projected cost per brick was $0.073 and $0.065 respectively. This illustrates the economic feasibility of using agro-industrial by-products, since it represents a 10.96% decrease in material cost. While maintaining a comparable level of physical performance, the suggested bricks also provide environmental advantages, including reduced carbon emissions and resource conservation, in addition to the economic advantage. Because of these advantages, SDA-BLA bricks are an appealing option for economical and environmentally friendly building, particularly in areas with a surplus of agricultural waste.

Conclusion

This study successfully investigated sawdust ash (SDA) and banana-leaf ash (BLA) as partial replacements for conventional cement in sandcrete bricks to optimize their strength properties. Integrating these agricultural and industrial by-products aimed to enhance the sustainability of construction materials while maintaining or improving mechanical performance.

-

I.

The sandcrete mix design incorporated varying proportions of SDA and BLA with an optimal mix ratio determined to achieve desired mechanical properties. The results from the compressive strength test revealed that with a compressive strength value of 4.281 MPa, the optimum proportion of replacing cement with blended SDA-BLA can be achieved at 8% when combined with a cement-to-aggregate ratio of 1:5.5 and a w/c ratio of 0.6. Similarly, the flexural strength test result indicated the highest value of 1.798 MPa achieved at 0.25% replacement of cement with SDA and BLA when combined with a w/c ratio of 0.5 and a cement-to-aggregate ratio of 1:4. Higher replacement levels at 25% resulted in a significantly lower flexural strength of 0.781 MPa due to reduced cementitious content and compromised matrix integrity. The optimal strengths were achieved through a balance of pozzolanic reactivity, efficient hydration, and well-proportioned mix designs.

-

II.

The study’s conclusion that a reasonable amount of SDA-BLA improves mechanical characteristics while an excessive amount impairs performance by diluting the cementitious matrix and increasing porosity is supported by the statistical analysis

-

III.

Durability assessment through water absorption tests showed that bricks with up to 8% SDA-BLA content remained within the BS EN 771-1:2011 limit of 12%, with the lowest absorption rate of 9.119% observed at this optimal point. However, at 20% replacement, water absorption increased to 16.021%, exceeding acceptable thresholds and indicating compromised pore structure and moisture resistance at higher ash levels.

-

IV.

Microstructural analyses further supported the performance trends. FTIR results revealed a shift in chemical bonding and the presence of residual carbonates at higher ash contents, correlating with reduced strength. TGA analysis confirmed the presence of key decomposition phases and enhanced thermal stability in the optimally mixed bricks.

In summary, the study affirms that SDA and BLA, at controlled replacement levels, can serve as effective supplementary cementitious materials in sandcrete brick production. Their use supports sustainable construction practices by reducing reliance on Portland cement and promoting the beneficial reuse of agricultural waste, thus aligning with broader goals of circular economy and low-carbon development in the construction sector.

Recommendation for future studies

Building on the findings of this research on developing sustainable sandcrete bricks using industrial and agricultural waste, the following recommendations are suggested for future studies:

Long-term durability assessment: Future research should examine how these bricks perform over time under different environmental conditions, such as moisture exposure, freeze–thaw cycles, and sulfate attacks. This will help determine their durability and suitability for various climates.

Life cycle assessment (LCA) and environmental impact: Conducting a Life Cycle Assessment (LCA) would provide valuable insights into the carbon footprint, energy consumption, and overall sustainability of sandcrete bricks made with industrial and agricultural waste compared to traditional bricks.

Field performance and real-world applications: Testing these bricks in actual construction projects would help assess their practicality, workability, and durability in real-life scenarios. Comparing them to conventional sandcrete blocks in terms of handling and performance can provide critical insights for adoption in the industry.

Incorporating self-healing and smart materials: Exploring the use of self-healing agents, such as bacteria-based additives, or smart materials could further enhance the lifespan and durability of sustainable sandcrete bricks.

These recommendations aim to push the boundaries of research in eco-friendly, high-performance sandcrete bricks, supporting more sustainable construction practices and environmental conservation efforts.

Data availability

The datasets used and/or analyses during the current study are available from the corresponding author on reasonable request.

References

Herbert, T. Brick: A world history. Choice Rev. Online 41, 3863 (2004).

Zhang, L. Production of bricks from waste materials: A review. Constr. Build. Mater. 47, 643–655 (2013).

Makul, N. et al. Capacity to develop recycled aggregate concrete in South East Asia. Buildings 11, 234 (2021).

Sebastián, E. & Cultrone, G. Technology of rammed-earth constructions (“Tapial”) in Andalusia (Spain): Their restoration and conservation. In Materials, Technologies and Practice in Historic Heritage Structures (eds Dan, M. B. et al.) 11–28 (2010).

Balaguera, A., Carvajal, G. I., Albertí, J. & Fullana-i-Palmer, P. Life cycle assessment of road construction alternative materials: A literature review. Resour. Conserv. Recycl. 132, 37–48 (2018).

Imoh Christopher Attah, George Uwadiegwu Alaneme, Olaolu George Fadugba, Bamidele Charles Olaiya. 12: Sustainability measurement of developed concrete by incorporating solid waste. in Woodhead Publishing Series in Civil and Structural Engineering, Recent Developments and Innovations in the Sustainable Production of Concrete 333–347 (Woodhead Publishing, 2025). https://doi.org/10.1016/B978-0-443-23895-6.00012-1.

Ukpata, J. O. et al. Effects of aggregate sizes on the performance of laterized concrete. Sci. Rep. 14, 448. https://doi.org/10.1038/s41598-023-50998-1 (2024).

Iro, U. I. et al. Optimization of cassava peel ash concrete using central composite design method. Sci. Rep. 14, 7901. https://doi.org/10.1038/s41598-024-58555-0 (2024).

Murmu, A. L. & Patel, A. Towards sustainable bricks production: An overview. Constr. Build. Mater. 165, 112–125 (2018).

Olaiya, B. C., Lawan, M. M. & Olonade, K. A. Utilization of sawdust composites in construction: A review. SN Appl. Sci. 5, 140. https://doi.org/10.1007/s42452-023-05361-4 (2023).

Dhage, B., Rathi, V. & Kolase, P. Experimental study on partial replacement of cement by banana leaves ash. Int. J. Anal. Exp. Mod. Anal. 12(9), 1869 (2020).

Chiang, K. Y., Chou, P. H., Hua, C. R., Chien, K. L. & Cheeseman, C. Lightweight bricks manufactured from water treatment sludge and rice husks. J. Hazard. Mater. 171, 76–82 (2009).

Juel, M. A. I., Mizan, A. & Ahmed, T. Sustainable use of tannery sludge in brick manufacturing in Bangladesh. Waste Manag. 60, 259–269 (2017).

Kinuthia, J. M. & Nidzam, R. M. Towards zero industrial waste: Utilisation of brick dust waste in sustainable construction. Waste Manag. 31, 1867–1878 (2011).

Ng, W. P. Q., Lam, H. L., Ng, F. Y., Kamal, M. & Lim, J. H. E. Waste-to-wealth: Green potential from palm biomass in Malaysia. J. Clean. Prod. 34, 57–65 (2012).

Muñoz, V. P., Morales, O. M. P., Letelier, G. V. & Mendívil, G. M. A. Fired clay bricks made by adding wastes: Assessment of the impact on physical, mechanical and thermal properties. Constr. Build. Mater. 125, 241–252 (2016).

Olaiya, B. C. et al. Sustainable building practices for modern clinical laboratories. Discov. Civ. Eng. 2, 74. https://doi.org/10.1007/s44290-025-00232-w (2025).

Charles Olaiya, B., George Fadugba, O. & Muhammad Lawan, M. Building information modeling (BIM) implementation and practices in construction Industry: A review. IntechOpen https://doi.org/10.5772/intechopen.1006363 (2024).

Asensio, E., Medina, C., Frías, M. & de Rojas, M. I. S. Characterization of ceramic-based construction and demolition waste: Use as pozzolan in cements. J. Am. Ceram. Soc. 99, 4121–4127 (2016).

Aguome, N. M., Alaneme, G. U., Olaiya, B. C. & Lawan, M. M. Evaluation of lean construction practices for improving construction project delivery. Case Study Bushenyi District. Uganda Cogent Eng. 11(1), 210 (2024).

De Lassio, J., França, J., Espirito Santo, K. & Haddad, A. Case study: LCA methodology applied to materials management in a Brazilian residential construction site. J. Eng. 2016, 8513293 (2016).

Kaza, S., Yao, L. C., Bhada-Tata, P. & Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050 (World Bank Publications, 2018).

Arrigoni, A. et al. Reduction of rammed earth’s hygroscopic performance under stabilisation: An experimental investigation. Build. Environ. 115, 358–367 (2017).

Sekhar, D. C. & Nayak, S. Utilization of granulated blast furnace slag and cement to manufacture compressed stabilized earth blocks. Constr. Build. Mater. 166, 531–536 (2018).

Da Cardoso, A. C. F., Galatto, S. L. & Guadagnin, M. R. Estimativa de geração de resíduos da construção civil e estudo de viabilidade de usina de triagem e reciclagem. Rev. Bras. Ciênc. Ambient. 31, 1–10 (2014).

Rodseth, C., Notten, P. & von Blottnitz, H. A revised approach for estimating informally disposed domestic waste in rural versus urban South Africa and implications for waste management. S. Afr. J. Sci. 116, 1–6 (2020).

Jong, L. Y. & Teo, D. C. L. Concrete containing palm oil fuel ash (POFA) and oil palm shell (OPS) subjected to elevated temperatures. J. Civ. Eng. Sci. Technol. 5, 13–17 (2014).

Kadir, A. A. & Mohajerani, A. Bricks: An excellent building material for recycling wastes—A review. in Proceedings of the IASTED International Conference on Environmental Management and Engineering (EME 2011) 108–115 (2011).

Al-Fakih, A. et al. Characteristic compressive strength correlation of rubberized concrete interlocking masonry wall. Structures 26, 169–184 (2020).

Lesovik, V., Volodchenko, A., Fediuk, R., Mugahed Amran, Y. H. & Timokhin, R. Enhancing performances of clay masonry materials based on nanosize mine waste. Constr. Build. Mater. 269, 121333 (2021).

Al-Fakih, A., Mohammed, B. S., Wahab, M. M. A., Liew, M. S. & Mugahed Amran, Y. H. Flexural behavior of rubberized concrete interlocking masonry walls under out-of-plane load. Constr. Build. Mater. 263, 120661 (2020).

Buyle, M., Braet, J. & Audenaert, A. Life cycle assessment in the construction sector: A review. Renew. Sustain. Energy Rev. 26, 379–388 (2013).

Smol, M., Kulczycka, J., Henclik, A., Gorazda, K. & Wzorek, Z. The possible use of sewage sludge ash (SSA) in the construction industry as a way towards a circular economy. J. Clean. Prod. 95, 45–54 (2015).

Raut, A. N. & Gomez, C. P. Development of thermally efficient fibre-based eco-friendly brick reusing locally available waste materials. Constr. Build. Mater. 133, 275–284 (2017).

Mohd Hasan, M. R., Chew, J. W., Jamshidi, A., Yang, X. & Hamzah, M. O. Review of sustainability, pretreatment, and engineering considerations of asphalt modifiers from the industrial solid wastes. J. Traffic Transp. Eng. 6, 209–244 (2019).

Amran, M. et al. Rice husk ash-based concrete composites: A critical review of their properties and applications. Crystals 11, 168 (2021).

Lee, Y. H. et al. Thermal behavior and energy efficiency of modified concretes in the tropical climate: A systematic review. Sustainability 13, 11957 (2021).

Tolstoy, A. et al. Production of greener high-strength concrete using russian quartz sandstone mine waste aggregates. Materials 13, 5575 (2020).

Da Silva, T. R. et al. Application of plastic wastes in construction materials: A review using the concept of life-cycle assessment in the context of recent research for future perspectives. Materials 14, 3549 (2021).

Avudaiappan, S. et al. Experimental investigation and image processing to predict the properties of concrete with the addition of nano silica and rice husk ash. Crystals 11, 1230 (2021).

Krishna, R. S. et al. Industrial solid waste management through sustainable green technology: Case study insights from steel and mining industry in Keonjhar, India. Mater. Today Proc. 33, 5243–5249 (2020).

Lesovik, V., Volodchenko, A., Fediuk, R. & Mugahed Amran, Y. H. Improving the hardened properties of nonautoclaved silicate materials using nanodispersed mine waste. J. Mater. Civ. Eng. 33, 04021214 (2021).

Petropavlovskii, K. et al. Faience waste for the production of wall products. Materials 14, 6677 (2021).

Yuan, X. et al. Environmental and economic impacts assessment of concrete pavement brick and permeable brick production process: A case study in China. J. Clean. Prod. 171, 198–208 (2018).

De Carvalho Araújo, C. K. et al. Circular economy practices on wood panels: A bibliographic analysis. Sustainability 11, 1057 (2019).

Ashour, T., Korjenic, A., Korjenic, S. & Wu, W. Thermal conductivity of unfired earth bricks reinforced by agricultural wastes with cement and gypsum. Energy Build. 104, 139–146 (2015).

Raheem, A. A., Olasunkanmi, B. & Folorunso, C. Saw dust ash as partial replacement for cement in concrete. Organizat. Technol. Manag. Construct: Int. J. https://doi.org/10.5592/otmcj.2012.2.3 (2012).

Pawar, J. R. & Aman, S. K. Experimental investigation on properties of concrete by partial replacement of cement with banana leaves ash. in International Journal for Research in Engineering Application & Management (IJREAM) Special Issue-ICRTET-2018.

Pereira, A. et al. Mechanical and durability properties of alkali-activated mortar based on sugarcane bagasse ash and blast furnaceslag. Ceram Int. 41, 13012–13022 (2015).

Ikpa, C. C. et al. Evaluation of water quality impact on the compressive strength of concrete. J. Kejuruter. 33(3), 527–538. https://doi.org/10.17576/jkukm-2021-33(3)-15 (2021).

Ramya, M., Mercy Shanthi, R. & Suji, D. Strength evaluation of sustainable concrete with partial replacement of cement by combination of banana leaf powder and cattle bone powder. Int. J. Innovat. Technol. Explor. Eng. 8(4), 884–886 (2019).

Alaneme George, U. & Mbadike Elvis, M. Modelling of the mechanical properties of concrete with cement ratio partially replaced by aluminium waste and sawdust ash using artificial neural network. SN Appl. Sci. 1(11), 1514. https://doi.org/10.1007/s42452-019-1504-2 (2019).

Li, Y., Liu, Y., Lin, H. & Jin, C. Study of flexural strength of concrete containing mineral admixtures based on machine learning. Sci. Rep. 13(1), 18061. https://doi.org/10.1038/s41598-023-45522-4 (2023).

Namdar, A. et al. An experimental study on flexural strength enhancement of concrete by means of small steel fibers. Fract. Struct. Integrit. 7(26), 22–30. https://doi.org/10.3221/IGF-ESIS.26.03 (2013).

Jalal, M., Mansouri, E., Sharifpour, M. & Pouladkhan, A. R. Mechanical, rheological, durability and microstructural properties of high performance self—Compacting concrete containing SiO2 micro and nanoparticles. Mater. Des. 34, 389–400 (2012).

Oyedotun, T. D. T. X-ray fluorescence (XRF) in the investigation of the composition of earth materials: A review and an overview. Geol. Ecol. Landsc. 2, 1–7. https://doi.org/10.1080/24749508.2018.1452459 (2018).

Shilar, F. A., Ganachari, S. V., Patil, V. B., Khan, T. Y. & Khadar, S. D. Molarity activity effect on mechanical and microstructureproperties of geopolymer concrete: A review. Case Stud. Constr. Mater. 16, e01014. https://doi.org/10.1016/j.cscm.2022.e01 (2022).

Chindaprasirt, P., Kroehong, W., Damrongwiriyanupap, N., Suriyo, W. & Jaturapitakkul, C. Mechanical properties, chlorideresistance and microstructure of Portland fly ash cement concrete containing high volume bagasse ash. J. Build. Eng. https://doi.org/10.1016/j.jobe.2020.101415 (2020).

Memon, J. R. et al. Characterization of banana peel by scanning electron microscopy and FT-IR spectroscopy and its use forcadmium removal. J. Colloid Interface Sci. 66, 260–265. https://doi.org/10.1016/j.colsurfb.2008.07.001 (2008).

Oyebisi, S., Ede, A., Olutoge, F. & Omole, D. Geopolymer concrete incorporating agro-industrial wastes: Effects on mechanical properties, microstructural behavior and mineralogical phases. Constr. Build. Mater. 256, 119390 (2020).

Zhou, W. et al. Chip-based MEMS platform for thermogravimetric/differential thermal analysis (TG/DTA) joint characterization of materials. Micro Mach. 13(3), 445. https://doi.org/10.3390/mi13030445 (2022).

Srivastava, T., Katari, N. K., Ravuri, B. R., Govindrajan, K. V. & Krishna, M. S. Investigation of high-temperature stability andthermal endurance of silicone potting compound by thermo-gravimetric analysis. SILICON 13, 4147–4154. https://doi.org/10.1007/s12633-020-00725-6 (2020).

BurduhosNergis, D. D., Vizureanu, P., Sandu, A. V., BurduhosNergis, D. P. & Bejinariu, C. XRD and TG-DTA study of newphosphate-based geopolymers with coal ash or metakaolin as aluminosilicate source and mine tailings addition. Materials 15(1), 202. https://doi.org/10.3390/ma15010202 (2021).

Alaneme, G. U. et al. Mechanical properties optimization and simulation of soil-saw dust ash blend using extreme vertex design (EVD) method. Int. J. Pavement Res. Technol. 17, 827–853. https://doi.org/10.1007/s42947-023-00272-4 (2024).

Sasha, A. A., Diaz-Carrillo, A. J., Florez-Lopez, E. & Tovar, D. G. Recovery of banana wastes: Loss from production and processing—a contribution to a circular economy. MDPI J. Mol. 26(17), 5282 (2021).

Khalel, H. H. Z. & Khan, M. Modelling Fibre-reinforced concrete for predicting optimal mechanical properties. Materials 16(10), 3700. https://doi.org/10.3390/ma16103700 (2023).

British Standards Institution (BSI). Tests for geometrical properties of aggregates—Part 1: Determination of particle size distribution—Sieving method (2012). (BS EN 933–1:2012)

Baiden, B. K. & Asante, C. K. O. Effects of orientation and compaction methods of manufacture on strength properties of sandcrete blocks Constr. Build. Mater. 18, 717–725. https://doi.org/10.1016/j.conbuildmat.2004.04.032 (2004).

British Standards Institution. BS EN 450–1:2012: Fly ash for concrete: Definition, specifications and conformity criteria (BSI, 2012).

Farrant, W. E., Babafemi, A. J., Kolawole, J. T. & Panda, B. Infuence of sugarcane bagasse ash and silica fume on the mechanicaland durability properties of concrete. Materials 15, 3018. https://doi.org/10.3390/ma15093018 (2022).

Hannesson, G., Kuder, K., Shogren, R. & Lehman, D. The influence of high volume of fly ash and slag on the compressive strength of self-consolidating concrete. Constr. Build. Material 30, 161–168. https://doi.org/10.1016/j.conbuildmat.2011.11.046 (2012).

Bediako, M. Pozzolanic potentials and hydration behavior of ground waste clay brick obtained from clamp-firing technology. Case Stud. Constr. Mater. 8, 1–7. https://doi.org/10.1016/j.cscm.2017.11.003 (2018).

Cai, Y., Hou, P., Zhou, Z. & Cheng, X. Effects of nano-CaCO3 on the properties of cement paste: Hardening process and shrinkage at different humidity levels. in Proceedings of the 5th International Conference on Durability of Concrete Structures, China 207-10 (2016). https://doi.org/10.5703/1288284316132

Zhang, X. & Biswas, W. K. Development of eco-efficient bricks: A life cycle assessment approach. J. Build. Eng. 42, 102429. https://doi.org/10.1016/j.jobe.2021.102429 (2021).

Uwadiegwu, A. G. & Michael, M. E. Characterization of Bambara nut shell ash (BNSA) in concrete production. J. Kejuruter. 33(3), 621–634. https://doi.org/10.17576/jkukm-2021-33(3)-21 (2021).

Okonkwo, O. O., Olutoge, F. A. & Afolayan, J. Performance of blended cement composites with agricultural waste ashes. J. Construct. Build. Mater. 25(2), 112–120 (2020).

Akinyemi, B. A., Adesanya, D. A. & Raheem, A. A. Effects of agricultural waste ashes on the strength and durability of concrete blocks. J. Civil Eng. Res. 10(4), 201–209 (2018).

Jayakumari, B. Y., Swaminathan, E. N. & Partheeban, P. A review on characteristics studies on carbon nanotubes-based cement concrete. Construct. Build. Mater. 367, 130344. https://doi.org/10.1016/j.conbuildmat.2023.130344 (2023).

Olutoge, F. A., Adedeji, O. O. & Alade, O. A. Pozzolanic properties of agricultural waste ash in cementitious materials. J. Sustain. Build. Mater. 17(3), 120–132 (2019).

Adeyemi, B. A. & Raheem, A. A. Effects of partial cement replacement with ash on the strength properties of concrete and bricks. Int. J. Eng. Res. 12(4), 234–243 (2021).

Ibe Iro, U. et al. Optimization and simulation of saw dust ash concrete using extreme vertex design method. Adv. Mater. Sci. Eng. 1, 5082139. https://doi.org/10.1155/2022/5082139(2022) (2022).

Shubbar, A. A., Jafer, H., Dulaimi, A., Hashim, K. & Atherton, W. The development of a low carbon binder produced from the ternary blending of cement, ground granulated blast furnace slag and high calcium fly ash. Constr. Build. Mater. 187, 1151–1160. https://doi.org/10.1016/j.conbuildmat.2018.08.011 (2018).

Neville, A. M. Properties of Concrete 5th edn. (Pearson Education Limited, 2011).

Umar, M. A., Shafiq, N., Nuruddin, M. F. & Ayub, T. A review on pozzolanic utilization of banana waste in sustainable construction materials. Mater. Today: Proc. 46, 2148–2153. https://doi.org/10.1016/j.matpr.2020.10.336 (2020).

Singh, M., Siddique, R. & Choudhary, S. Strength and micro-structural properties of controlled low-strength material made using fly ash and rice husk ash. Constr. Build. Mater. 94, 274–284. https://doi.org/10.1016/j.conbuildmat.2015.07.042 (2015).

Olaiya, B. C. et al. An overview of the use and process for enhancing the pozzolanic performance of industrial and agricultural wastes in concrete. Discov. Appl. Sci. 7, 164. https://doi.org/10.1007/s42452-025-06586-1 (2025).

British Standards Institution. BS EN 771–1:2011: Specification for masonry units—Part 1: Clay masonry units (BSI, 2011).

Fadele, O. A. & Ata, O. Water absorption properties of sawdust lignin stabilised compressed laterite bricks. Case Stud. Constr. Mater. https://doi.org/10.1016/J.CSCM.2018.E00187 (2018).

Nath, S. K., Maitra, S., Mukherjee, S. & Kumar, S. Microstructural and morphological evolution of fly ash based geopolymers. Constr. Build. Mater. 111(758–765), 127 (2016).

Islam, M. N., Noaman, M. A., Islam, K. S. & Hanif, M. A. Mechanical properties and microstructure of brick aggregate concrete with raw fly ash as a partial replacement of cement. Heliyon 10(7), e28904. https://doi.org/10.1016/j.heliyon.2024.e28904 (2024).

Schackow, A., Correia, S. L. & Effting, C. Influência das propriedades microestruturais e morfológicas de argilas in natura na reatividade de resíduos de tijolos em uma matriz cimentícia. Cerâmica 66, 154–163 (2020).

Funding

There was no funding received for this work.

Author information

Authors and Affiliations

Contributions

BCO: Conceptualization; Formal analysis; Investigation; Methodology; Software; Data curation; Validation; Writing—original draft. MML: Conceptualization, Methodology, Investigation, Validation, Visualization; Writing—Original draft KAO: Methodology, Investigation, Formal analysis, Validation; Visualization; Writing—Original draft SAA: Investigation, Formal analysis, Validation; Visualization; Writing—Original draft.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Olaiya, B.C., Lawan, M.M., Olonade, K.A. et al. Development of sustainable sandcrete bricks using industrial and agricultural waste. Sci Rep 15, 17202 (2025). https://doi.org/10.1038/s41598-025-02308-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-02308-0

Keywords

This article is cited by

-

Effect of nano-silica and sisal fibre on the mechanical and durability properties of concrete

Scientific Reports (2026)

-

Experimental investigation and optimization of mechanical and tribological performances of bio-based sustainable hybrid composites incorporating Nano-SiO₂ fillers

Scientific Reports (2026)

-

Sustainable and cost-efficient machining of ZE41 magnesium alloy through optimization with Intuitionistic Fuzzy TOPSIS

Scientific Reports (2025)

-

The impact of adding dual and triple combinations of quicklime and plastic wastes and palm fibers on the California bearing ratio of fine sand

Scientific Reports (2025)

-

Municipal solid waste incineration bottom ash in concrete : A systematic review and meta-analysis

Scientific Reports (2025)