Abstract

Jining is one of the important coal production bases in eastern China. Due to the widespread occurrence of thick unconsolidated layers in this area, the surface movement and deformation characteristics caused by coal mining have special features. This paper collected the measured boundary angles, movement angles, and probability integral method parameters of surface subsidence under longwall caving mining in this area. Through data analysis of relevant parameters, the characteristics of mining under thick unconsolidated layer in this area were clarified, and a regression equation with reference value was established. On this basis, used the method of establishing numerical models, the influence laws of unconsolidated layer thickness, bedrock thickness, and working face mining width on the surface subsidence characteristics under thick unconsolidated layer were simulated and analyzed. The research results have important reference values for the selection of mining parameters and the protection of buildings in future working face mining in this area.

Similar content being viewed by others

Introduction

Coal is an important industrial raw material and plays a key role in the world’s economic and social development. According to the "Statistical Review of World Energy (2024)" released by the British Energy Research Institute, in 2023, global coal production reached a record high level (about 179EJ), and global coal consumption exceeded 164EJ1. Among them, China’s coal production and consumption account for more than half of the world’s total, and it is the world’s largest coal output and consumption country. In most areas of eastern China such as Shandong, Henan, Anhui, Jiangsu, and other provinces, there are often thicker unconsolidated layers above the rock strata, resulting in large differences in the surface subsidence law caused by mining and thin unconsolidated layers. The main manifestations are as follows: (1) The surface subsidence coefficient is too large, and in some areas, it is even greater than 1.0; (2) The range of surface subsidence is obviously expanded, and the tangent of boundary angle and main influence angle is small. (3) The active period of surface movement is severely deformed, and the recession period lasts for a long time. (4) The convergence of the surface movement basin edge area is slow.

Liu took the mining under the thick unconsolidated layer in Lunan mining area as the prototype, and used numerical simulation to analyze the influence of the h/hb (the ratio of unconsolidated layer thickness to bedrock thickness) on the parameters such as the subsidence coefficient, the main influence angle tangent, and the horizontal movement coefficient, which characterize the surface movement and deformation characteristics, and obtained very useful conclusions2. Taking a coal mine in Jining as the background, Xia used the method of similar material simulation test to analyze the movement and deformation law of overlying strata and surface under the thick unconsolidated layer. The simulation results show that the movement and deformation of the unconsolidated layer are caused by the superposition of bedrock subsidence and unconsolidated layer compression, and the subsidence basin of the thick unconsolidated layer mining area is more gentle and the influence range is larger, and the slow compression of the thick unconsolidated layer causes the residual subsidence time to be longer3. Dai obtained through numerical simulation that with the increase of the thickness of the unconsolidated layer, the scope of the surface subsidence basin has an obvious expansion trend, and the surface deformation is alleviated, which is conducive to the protection of buildings4. Sun studied the surface subsidence of filling mining under thick unconsolidated layers, and the influence degree of surface movement and deformation was filling rate > key layer thickness > filling body strength > unconsolidated layer thickness5. Zhao analyzed that the maximum surface subsidence value increased with the increase of the thickness of the unconsolidated layer6. Wu studied the mining under the thick unconsolidated layer and thin bedrock, and concluded that the thickness of the unconsolidated layer was positively correlated with the subsidence coefficient and the horizontal movement value, and with the increase of the thickness of the unconsolidated layer, the surface disturbance was more obvious7. According to the field-measured data, Jiang pointed out that when mining under thick unconsolidated layer, the subsidence at the edge of the surface subsidence basin changes gently and the convergence speed is slow8. Based on GNSS subsidence monitoring data, Zheng calculated that the active period subsidence accounted for about 91% of the total during thick unconsolidated layer mining9. Wang pointed out that the surface subsidence coefficient, horizontal movement coefficient and subsidence range of Henghe Coal Mine in Jining are relatively large, the analysis shows that the thick unconsolidated layer of the surface has the characteristics of integral subsidence and rheology10.

In view of the above special subsidence law, through the analysis and research on its deformation mechanism, Zhang11, Guo12, Bai13, Zhu4, Shi15, Zhou16,17, and other scholars believe that when mining under thick unconsolidated layer, with the stress and deformation transfer in the mining process, the unconsolidated layer soil will be compressed and consolidated, which is the main reason for the large surface subsidence. According to the 'slip-crack-shear’ failure stage of thick unconsolidated layers in the deformation process, Zuo18,19,20 proposed the internal and external analogous hyperbola failure mode of rock and soil. Yan21,22 and Yan23 believed that the strata play a controlling role in the movement and deformation of the unconsolidated layer. Dong24, Wang25,26,27, Tan28 and others think that although the unconsolidated layer is loose, but it will form an arch structure under certain mining conditions, thus supporting the upper part of the arch.

In view of the particularity of mining under thick unconsolidated layers, some scholars have studied the surface subsidence and its characteristic parameters. Based on the measured surface subsidence characteristic angle parameters, Wang29 established a robust model for parameter estimation. Jiang30 proposed a settlement expectation model based on Cauchy distribution, which can better realize the accurate prediction of the edge area of subsidence basin in thick unconsolidated layer mining. Chi31 established an MPGAIB parameter calculation model based on the Boltzmann function (IB) and multi-population genetic algorithm (MPGA), which has a good ability to resist random errors. Hou32 integrated Kelvin viscoelastic rheological model and probability integral method model to establish a superposition model of mining subsidence prediction under thick unconsolidated layers. Based on the Winker foundation beam model and random medium theory, Cao33 established a two-layer medium prediction model and achieved good prediction results. Zhou34 established a combined prediction model of surface subsidence based on the mechanism of soil-rock synergy in the process of mining subsidence under thick unconsolidated layer, which has been applied in Huainan mining area.

The above research results on mining under thick unconsolidated layer have very important reference value for subsequent research and engineering. However, for different regions, due to the large differences in geological structure and stratigraphic lithology, there are often some differences in mining under the same thick unconsolidated layer. For example, Huainan mining area often has a subsidence coefficient greater than 1.0, but for Jining mining area, although the subsidence coefficient is also large, it is rarely greater than 1.0, and it is more manifested as a larger subsidence range. Given the regional differences, this paper takes Jining mining area as the research object, by collecting the relevant surface subsidence monitoring data, the surface subsidence characteristics of Jining mining area under thick unconsolidated layer are analyzed and studied by statistical analysis and numerical simulation.

Date collection

Jining is located in Shandong Province in eastern China. It is recorded that the region had coal mining cases in the Song Dynasty. It is now one of the important coal-producing areas in eastern China, with an annual production of raw coal exceeding 52 million tons.

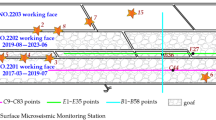

Influenced by factors such as the erosion and deposition of the Yellow River and other rivers in history, the whole area of Jining is covered by thick unconsolidated layer. In order to fully study and analyze the particularity of the surface movement and deformation law of mining under thick unconsolidated layers in Jining area, and to explain the internal relationship between the surface movement and deformation characteristic parameters of mining under thick unconsolidated layer and geological and mining factors in this area, the surface movement observation station data of 33 long-wall working faces (roof management by caving method) in 11 coal mines in Jining area were collected and sorted out. It includes the geological and mining conditions (mining thickness ‘M’, dip angle ‘α’, average mining depth ‘H’, working face width ‘D’, and unconsolidated layer thickness ‘h’), the boundary angles β0, γ0, δ0 and movement angles β, γ, δ in the angular parameters of surface movement and deformation, and the predicted parameters of probability integral method (subsidence coefficient ‘q’, horizontal movement coefficient ‘b’ and main influence angle tangent ‘tanβ’), as shown in Table 1. The schematic diagram of the angular parameter is shown in Fig. 1.

It can be seen from the data in the Table 1 that there is basically no correlation between the geological and mining elements of the 33 working faces collected. The mining thickness of each working face is quite different, ranging from 0.96 m to 8.79 m, with an average value of 5.0 m, which is distributed from thin coal seam to thick coal seam. The dip angle of coal seam is between 2.5° and 11°, with an average value of 5.6°, and most of the dip angles of working face are below 8°, which belongs to near horizontal and gently inclined coal seam mining. The mining depth is between 264 m and 794.2 m, with an average of 460 m, and the mining width is between 55 and 544 m, with an average of 200 m. According to the empirical relationship between the width-depth ratio and the mining degree, except for Yangcun 316 and Baodian 5304-m working face, the remaining working faces have not reached full mining in the tendency. The thickness of the unconsolidated layer is between 41 and 245 m, with an average of 180 m. Except for the 1664 working face of Tangcun, the thickness of the overlying unconsolidated layer on the other working faces is greater than or equal to 100 m, which belongs to the typical mining under the condition of thick unconsolidated layer.

In order to analyze the difference in surface movement and deformation parameters between mining under thick unconsolidated layer and mining under thin unconsolidated layer, the surface movement and deformation parameters of a total of 8 sets of observation stations in Feicheng mining area and Xinwen mining area in northern Jining were collected, as shown in Table 2. The Feicheng mining area and the Xinwen mining area are the same as the Jining mining area to mine the Carboniferous Permian coal seam. However, due to the proximity to Mount Taishan, the thickness of the unconsolidated layer is thin, which can be compared with the mining under the thick unconsolidated layer in Jining area.

Data analysis

Descriptive statistical analysis

Descriptive statistical analysis is the primary collation and analysis of data through charts or mathematical methods. The commonly used statistical indicators are mean, median, mode, quartile, variance and standard deviation. In general, descriptive statistical analysis is often the first step in data processing, it can understand, analyze and summarize data in a simple and intuitive way to prepare for further analysis, so it’s widely used in statistical analysis in various fields35. In this part, the angular parameters and probability integral prediction parameters of the surface movement and deformation characteristics collected in Jining mining area are statistically analyzed, and compared with the surface deformation characteristic parameters of the mining face under the thin unconsolidated layer in the adjacent Feicheng mining area and Xinwen mining area.

Descriptive statistical analysis of surface movement deformation angle parameters

According to the boundary angle and movement angle data obtained by the observation stations of each working face in Jining mining area listed in Table 1, the corresponding box plot is drawn, as shown in Fig. 2. It can be seen that under the condition of collecting and sorting out the observation station data as the sample, the average winze boundary angle \(\overline{{\beta }_{0}}\) under the condition of thick unconsolidated layer in Jining area is 53.7°, the average raise boundary angle \(\overline{{\gamma }_{0}}\) is 55.1°, and the average strike boundary angle \(\overline{{\delta }_{0}}\) is 58.1°. The average boundary angle of the three directions is winze < raise < strike; the average winze movement angle \(\overline{\beta }\) is 71.1°, the average raise movement angle \(\overline{\gamma }\) is 70.8°, and the average strike movement angle \(\overline{\delta }\) is 71.1°. The average difference of the movement angle in the three directions is small.

According to the boundary angle and movement angle data obtained by the observation stations of each working face in Feicheng mining area and Xinwen mining area listed in Table 2, the corresponding box plot is drawn, as shown in Fig. 3. It can be seen that under the condition of the collected observation station data as the sample, the average winze boundary angle \(\overline{{\beta }_{0}}\) under the condition of thin unconsolidated layer is 60.9°, the average raise boundary angle \(\overline{{\gamma }_{0}}\) is 67.0°, and the average strike boundary angle \(\overline{{\delta }_{0}}\) is 65.9°. The average boundary angle of the three directions is winze < strike < raise. The average winze movement angle \(\overline{\beta }\) is 68.9°, the average raise movement angle \(\overline{\gamma }\) is 74.7°, and the average strike movement angle \(\overline{\delta }\) is 73.1°. The winze movement angle is significantly smaller than the raise movement angle and the strike movement angle.

From the sample mean values of the surface movement and deformation parameters of the thick unconsolidated layer conditions and the adjacent thin unconsolidated layer conditions in Jining area shown in Table 3, it can be seen that compared with the mining under the thin unconsolidated layer in Feicheng and Xinwen mining area, the mean value of the boundary angle of the mining under the thick unconsolidated layer in Jining mining area is obviously smaller. The mean value of the winze boundary angle is 7.2° smaller, the mean value of the raise boundary is 11.9° smaller, and the mean value of the strike boundary angle is 7.8° smaller, indicating that compared with the thin unconsolidated layer mining area, the surface subsidence range of the mining under the thick unconsolidated layer will be significantly expanded. Compared with the mining under the thin unconsolidated layer in Feicheng and Xinwen mining area, the average value of the movement angle of the mining under the thick unconsolidated layer in Jining mining area is slightly smaller except the winze direction. The average value of the moving angle in the raise direction is 3.9° smaller, and the movement angle in the strike direction is 2.0° smaller, indicating that compared with the thin unconsolidated layer mining area, the deformation and failure range of the surface subsidence under the thick unconsolidated layer mining has a certain degree of expansion.

Probability integral method to predict parameters descriptive statistics

According to the probability integral method predicted parameters calculated from the monitoring data of each working face observation station in Jining mining area listed in Table 1, the corresponding box line diagram is drawn, as shown in Fig. 4. It can be seen from the diagram that under the condition of insufficient mining in Jining mining area in the sample, the subsidence coefficient q is mainly concentrated between 0.60 and 0.85, with an average of 0.76; the horizontal coefficient b is mainly concentrated between 0.27 and 0.33, with an average of 0.29. The main influence angle tangent tanβ is mainly concentrated between 1.65 and 2.20, with an average of 1.97.

According to the predicted parameters of the probability integral method calculated by the monitoring data of each working face observation station in Feicheng and Xinwen mining area listed in Table 2, the corresponding box plot is drawn, as shown in Fig. 5. It can be seen from the figure that the sinking coefficient q in the sample is mainly concentrated between 0.52 and 0.72, with an average of 0.61. The horizontal coefficient b was between 0.30 and 0.32, with an average of 0.31. The main influence angle tangent tanβ is mainly between 1.60 and 2.20, with an average of 1.86.

From the sample mean values of the predicted parameters of the probability integral method in Jining mining area and Feicheng and Xinwen mining areas shown in Table 4, it can be seen that compared with the mining under the thin unconsolidated layer in Feicheng and Xinwen mining area, the subsidence coefficient of mining under thick unconsolidated layer in Jining mining area is approximately 0.15 higher, while the differences in the horizontal movement coefficient and the tangent of the main influence angle are relatively small.

Grey correlation analysis of characteristic parameters of surface movement and deformation

Grey correlation analysis is a multi-factor statistical analysis method based on grey system theory. Its core idea is to measure the degree of correlation between factors according to the similarity or dissimilarity of the changing trend between factors. The obtained grey correlation degree is between 0 and 1. It is generally believed that when it is greater than 0.5, there is a correlation between the two, and the closer to 1, the stronger the correlation between the two.

In this part, the collected data from 33 groups of observation stations are used as sample data, and the grey correlation analysis function module of SPSS is used to analyze the grey correlation between the characteristic parameters of surface movement and deformation and the six single factors of geological mining factors, such as mining thickness ‘M’, dip angle ‘α’, mining depth ‘H’, mining width ‘D’, unconsolidated layer thickness ‘h’and bedrock thickness ‘hb’, as well as the three combined factors, such as ‘D/H’, ‘h/hb’and ‘h/H’. As shown in Table 5, the grey correlation degree between the characteristic parameters of surface movement and geological mining factors is analyzed by grey correlation analysis.

According to the above grey correlation analysis results, it can be seen that :

-

(1)

For the subsidence boundary angle, in the single factor, the highest correlation with the boundary angle in the three directions is ‘h’, followed by ‘D’ or ‘H’, indicating that the subsidence boundary angle has the strongest correlation with the thickness of the unconsolidated layer, and there is also a strong correlation between the mining width and the mining depth.

-

(2)

For the subsidence movement angle, ‘h’ is highly correlated with the movement angle in the single factor; among the three combined factors, the highest grey correlation degree is ‘h/H’, followed by ‘D/H’, indicating that the thickness of the unconsolidated layer and its proportion in the mining depth have a strong correlation with the movement angle, and the mining degree also has an important influence on the change of the movement angle.

-

(3)

For the subsidence prediction parameters, the highest correlation with the subsidence coefficient is ‘h’, and the highest correlation with the subsidence coefficient in the three combination factors is ‘h/H’, indicating that the subsidence coefficient has a strong correlation with ‘h’ and ‘h/H’. The highest correlation with the horizontal movement coefficient is ‘h’, among the combined influencing factors, the highest correlation with the horizontal movement coefficient is ‘h/H’, indicating that the thickness of the unconsolidated layer and its proportion in the mining depth have a strong correlation with the horizontal movement coefficient. The thickness of the unconsolidated layer has the highest correlation with ‘tanβ’, among the combined influencing factors, the highest correlation is ‘h/H’, indicating that there is a strong correlation between the thickness of the unconsolidated layer, the mining thickness, and the tangent of the main influence angle.

In the single factor, except for the highest correlation between ‘γ’ and the ‘H’, the other parameters have the highest correlation with ‘h’, followed by ‘D’ or ‘H’. Among the three combined factors, except that ‘β’ has the highest correlation with ‘D/H’, the other parameters have the highest correlation with ‘h/H’. The results of the grey correlation analysis show that the thickness of unconsolidated layer and its proportion in mining depth have a strong correlation with the characteristic parameters of surface movement and deformation, and have a strong correlation with the mining degree.

Regression analysis of surface movement and deformation characteristic parameters

Through the grey correlation analysis of surface movement deformation characteristic parameters and geological mining factors, the correlation degree between different factors is determined. Based om the correlation degree obtained from the analysis, combined with the relevant research of other scholars, this part attempts to carry out regression analysis of surface movement parameters and geological mining factors and obtain the fitting relationship. The regression relationship is tested by means of joint hypothesis test, in order to obtain the change relationship between surface movement deformation characteristic parameters and geological mining conditions with reference value.

According to the above analysis results, using the relevant data collected in Table 1, the regression analysis of surface movement and deformation characteristic parameters and geological and mining factors is carried out respectively, and the joint hypothesis test of the regression relationship is carried out (confidence level is 95%). Table 6 shows the regression analysis and hypothesis test results of each parameter, the fitting diagrams are shown in Fig. 6.

According to the above analysis results, it can be seen that among the characteristic parameters characterizing the surface movement law of mining under thick unconsolidated layers, the regression relationships between ‘β0’, ‘γ0’, ‘δ0’, ‘β’, ‘q’ and ‘tanβ’ and the corresponding geological and mining parameters have passed the hypothesis test. The relevant results can provide a reference for the prediction of the corresponding parameters of future working face mining in Jining area. For the parameters ‘γ’, ‘δ’ and ‘b’ that fail to establish a better regression model, they should be selected according to the working face parameters under similar conditions in the future.

Numerical simulation analysis

Establishment of numerical model

According to the aforementioned statistical analysis based on the measured data, there are certain particularities in mining under the thick loose layer in Jining area. However, due to the complexity of geological conditions, although some correlation equations between surface movement parameters and geological conditions have been established, further qualitative analysis of their influence is still needed. Numerical simulation method is widely used in the research of mining subsidence because of its simple use and reliable results, which is very advantageous in analyzing the influence of specific factors on the results36,37,38.

Therefore, in order to further qualitatively analyze the influence of various factors of mining under thick loose layer on the surface settlement characteristics, FLAC3D numerical simulation software is used to establish a numerical model for further analysis. In the process of numerical simulation, the 5316 working face of Jining No.3 Coal Mine is taken as the prototype. By simulating the changes in factors such as the thickness of the unconsolidated layer, the thickness of bedrock, and the mining width when going for longwall mining, and then qualitatively analyzing the influence of each factor on the surface movement during mining under thick unconsolidated layer.

Because the average dip angle of the 5316 working face is only 5°, it is near-horizontal coal seam mining, so it is simplified to horizontal coal seam mining for modeling during simulation. The model coordinate system is constructed by using the ‘right hand’ space rectangular coordinate system, that is, the coal seam strike is the x-axis, the tendency is the y-axis, the xoy plane is the horizontal plane, the vertical xoy plane is the z-axis, the gravity direction is set to the negative direction of the z-axis, and the gravity acceleration is set to 9.8 m/s2. In order to eliminate the influence of the boundary effect of the numerical model, large-size coal pillars are left around the model. Finally, the model size is determined to be 2600 m*2000 m, and the simulated excavation size is 800 m in strike and 240 m in inclination. Mohr–Coulomb failure criterion is adopted for rock and soil mass, and the excavation area in coal seam is simulated by the Null model.

The lithology of the model strata is determined based on the drilling data by merging and simplifying adjacent strata. According to the results of simplified pre-merger formation lithology and core mechanical strength test, the rock parameters of this numerical simulation are obtained by means of thick-weighted average, as shown in Table 7.

The boundary conditions of the model are constrained by displacement and velocity, which are set as follows: the displacement and velocity in the normal direction of the bottom boundary of the model are set to zero; the displacement and velocity in the normal direction of the front-back and left–right boundary of the model are set to zero; the top boundary of the model is set to free boundary. The final FLAC3D model diagram is shown in Fig. 7.

Numerical simulation results analysis

Analysis of the influence of unconsolidated layer thickness on surface movement and deformation

In order to analyze the influence of the variation of unconsolidated layer thickness on surface movement and deformation, a simulation analysis was conducted on the movement and deformation patterns of the surface under the condition where the thickness of bedrock is the same but the thickness of unconsolidated layer varies. That is, on the aforementioned three-dimensional model, the thickness of bedrock was fixed at 200 m, and eight schemes were designed respectively with the thickness of unconsolidated layer being 50 m, 100 m, 150 m, 200 m, 250 m, 300 m, 350 m and 400 m. A total of 8 schemes were designed.

By conducting simulations on each of the above-mentioned design schemes, the data of subsidence and horizontal movement on the main section of the surface trend were extracted based on the numerical simulation results. After sorting and analysis, the maximum subsidence value ‘Wmax’ and the maximum horizontal movement value ‘Umax’ under different thicknesses of unconsolidated layer were obtained, and the boundary angle ‘δ0’and the movement angle ‘δ’ of the surface subsidence basin were calculated, as shown in Fig. 8.

It can be seen from the figure that with the increase of the thickness of the unconsolidated layer, the maximum subsidence and maximum horizontal movement of the surface show a slight increase and then gradually decrease. This is because the bedrock can play a certain supporting role in the overlying unconsolidated layer during limited mining. The increase in the thickness of the unconsolidated layer leads to an increase in the additional stress on the bedrock, which increases the subsidence. When the thickness of the unconsolidated layer increases to a certain extent, the increase in the thickness of the unconsolidated layer leads to a significant decrease in the degree of mining, so that the increase in subsidence is not enough to offset the decrease in the degree of mining, resulting in a decrease in the maximum value of surface movement.

When the bedrock thickness is constant, with the increase of the thickness of the unconsolidated layer, the boundary angle and the movement angle show a decreasing trend, which is consistent with the statistical results of the measured data. The decrease in the boundary angle reflects that with the increase of the thickness of the unconsolidated layer, the range of surface subsidence caused by mining will increase. The decrease in the movement angle reflects that with the increase of the thickness of the unconsolidated layer, the damage range of the surface buildings caused by mining will increase.

Analysis of the influence of bedrock thickness on surface movement and deformation

For the same coal mine, the thickness of the unconsolidated layer generally does not change much, and the change in mining depth is mainly caused by the change in bedrock thickness. Therefore, the thickness of the fixed unconsolidated layer is simulated by the change in the thickness of the bedrock instead of the change of the mining depth. The thickness of the unconsolidated layer is fixed at 200 m, and the thickness of the bedrock is 50, 100, 150, 200, 250, 300, 350, and 400 m respectively.

Through the simulation of the above design schemes, the subsidence and horizontal movement data on the main section of the surface strike are extracted according to the numerical simulation results. The maximum subsidence value ‘Wmax’ and the maximum horizontal movement value ‘Umax’ under different bedrock thicknesses are obtained through collation and analysis. The boundary angle ‘δ0’and the movement angle ‘δ’ of the surface subsidence basin are calculated, as shown in Fig. 9.

According to the numerical simulation results, under the condition that the thickness of the unconsolidated layer is constant, it can be seen that:

(1) The maximum subsidence and the maximum horizontal movement value gradually decrease with the increase of the thickness of the bedrock, and suddenly decrease when the thickness of the bedrock is 250 m-350 m, indicating that the movement and deformation of the bedrock has a significant control effect on the movement and deformation of the surface. When the thickness of the bedrock is thin, the control effect of the bedrock is weak, as its thickness increases, the control effect of the bedrock gradually increases.

(2) With the increase of bedrock thickness, the boundary angle ‘δ0’ increases first and then decreases. The increase in boundary angle reflects the enhancement of the control effect of bedrock on surface deformation in the process of bedrock thickness from thin to thick. However, due to the synchronous increase of mining depth, the boundary angle shows a slight decrease trend when the bedrock thickness is greater than 150 m.

(3) With the increase of bedrock thickness, the movement angle ‘δ’ increases gradually, which indicates that because the rock layer controls the movement of the loose layer, the damage scope of the surface buildings is smaller, which is conducive to the protection of the buildings.

Analysis of the influence of mining width on surface movement and deformation

Under the same mining depth, the width-depth ratio (D/H) of the working face increases with the increase of mining width, and D/H reflects the change in mining degree. In this part, the factors such as mining depth and advancing length of fixed working face are unchanged, and the surface movement change law of different working face mining width is simulated and analyzed. A total of 13 numerical models with simulated mining width of 100, 150, 200, 250, 300, 350, 400, 450, 500, 550, 600, 650, and 700 m are designed. For each model, the thickness of the unconsolidated layer was fixed at 200 m, the thickness of the bedrock was 300 m, the advancement length was 800 m, the mining height was 5 m, and the model size was 2600 m*2600 m.

By conducting simulations on each of the above schemes, and based on the simulation results, the changes of surface subsidence coefficient ‘q′’, surface subsidence basin boundary angle ‘δ0’ and movement angle ‘δ’ with respect to D/H were analyzed and summarized, as shown in Fig. 10.

According to the numerical simulation results under different mining width conditions, it can be seen that:

-

(1)

When mining under thick unconsolidated layers, with the increase of working face mining width, the surface mining degree gradually changes from extremely insufficient mining to insufficient mining and then to full mining. At the same time, the surface subsidence rate increases with the increase of D/H, which shows a change process from slow increase to rapid increase and then to slow increase and gradually stabilize.

-

(2)

When D/H is less than 0.5, the boundary angle decreases rapidly with the increase of the width of the working face. When D/H is greater than 0.5, the boundary angle gradually tends to be stable. The change of the boundary angle with D/H is basically consistent with the statistical analysis results of the measured data. With the increase of the width of the working face, the movement angle does not show a simple decrease or increase, but a fluctuating decrease trend.

Conclusion

When mining under thick unconsolidated layer, the characteristics of surface movement and deformation are often different from those in thin unconsolidated layer. In this paper, the characteristics of surface movement and deformation under thick unconsolidated layers in Jining area are studied by investigating and collecting relevant mining data and carrying out relevant analysis. The main results are as follows:

-

(1)

By comparing the surface movement and deformation parameters of thin unconsolidated layer in Feicheng mining area and Xinwen mining area, it is found that the boundary angle of Jining mining area is obviously smaller, the movement angle of raise and strike direction is slightly smaller, and the subsidence coefficient is slightly larger. The horizontal movement coefficient and the main influence angle tangent are not much different.

-

(2)

According to the results of grey correlation analysis, the thickness of unconsolidated layer and its proportion in mining depth have a strong correlation with the characteristic parameters of surface movement and deformation, and have a strong correlation with the mining degree of working face. On this basis, the characteristic parameters of surface movement and deformation and geological mining factors are established, which can provide a reference for the determination of relevant parameters of future mining in Jining mining area.

-

(3)

Taking Jining No.3 coal mine as the geological prototype, the FLAC3D numerical model is established. The influence of unconsolidated layer thickness, bedrock thickness and mining width on surface movement and deformation is studied and analyzed respectively. The relationship between the maximum surface subsidence, maximum horizontal movement, boundary angle and movement angle and the thickness of unconsolidated layer, bedrock thickness and mining width is revealed.

Data availability

All data generated or analysed during this study are included in this published article.

References

The energy institute. statistical review of world energy. London. (2024). https://www.energyinst.org/statistical-review

Liu, H. et al. Surface deformation law of mining under thick loose layer and thin bedrock: taking the southern Shandong Mining Area as an example. Coal Sci. Technol. 51(9), 11–23 (2023).

Xia X. et al. Experimental study on overlying strata and surface movement and deformation law of mining under thick loose layer 23(32), 14053-14059 (2023)

Dai, H. et al. Numerical simulation of surface movement laws under different unconsolidated layers thickness. Trans. Nonferrous Met. Soc. China 21, 599–603 (2011).

Sun, D. et al. Sensitivity analysis and numerical simulation study on main controlling factors of surface movement and deformation in strip filling mining under thick unconsolidated layers. Geofluids 2021, 1–10 (2021).

Zhao, G. et al. Mechanical properties of mega-thick Alluvium and their influence on the surface subsidence. Geotech. Geol. Eng. 38(1), 137–149 (2020).

Wu, S. et al. Effect of alluvial thickness on the surface subsidence characteristics at deeply buried mining area with thin bedrock: A case study. J. Mt. Sci. 22, 1–17 (2025).

Jiang, Q. et al. Investigation of coordinated development of coal mining and pipeline protection under boundary effect of thick unconsolidated layer. Bull. Eng. Geol. Env. 81(136), 1–12 (2022).

Zheng, Z. et al. Study on the impact of coal mining under thick loose layers on ground vibrations and subsidence processes based on GNSS monitoring data. China Mining Magazine 33(S2), 318–324 (2024).

Wang, Y. et al. Subsidence prediction under thick alluvium based on probability integration method. Appl. Mech. Mater. 448–453, 3808–3813 (2013).

Zhang, H. et al. Mechanism and prediction research of the surface mining subsidence of thick loose in mining area. Appl. Mech. Mater. 204–208, 3488–3493 (2012).

Guo, W. et al. Effect of overburden bending deformation and alluvium mechanical parameters on surface subsidence due to longwall mining. Bull. Eng. Geol. Env. 80, 2751–2764 (2021).

Bai G. et al. Research on the characteristic of surface movement and its formation mechanism under thick unconsolidated layer in Kailuan mine area. Proceedings of the Beijing International Symposium Land Reclamation and Ecological Restoration, 127-130 (2015).

Zhu, X. et al. Simulation analysis of influencing factors of subsidence based on mining under loose strata: a case study of Heze mining area. China. Geofluids 2020, 1–17 (2020).

Shi, W. et al. Analysis on subsidence law of bedrock and ultrathick loose layer caused by coal mining. Geofluids 2021, 1–12 (2021).

Zhou, D. et al. A new methodology for studying the spreading process of mining subsidence in rock mass and alluvial soil: an example from the Huainan coal mine, China. Bull. Eng. Geol. Env. 75(3), 1067–1087 (2016).

Zhou, D. et al. Mechanism of mining subsidence in coal mining area with thick alluvium soil in China. Arab. J. Geosci. 8(4), 1855–1867 (2015).

Zuo, J. et al. Movement mechanism and analogous hyperbola model of overlying strata with thick alluvium. J. China Coal Soc. 42(6), 1372–1379 (2017).

Zuo, J. et al. Mining rock fracture mechanics and internal and external hyperbolic overall movement model. China Acad. J. Electron. Publ. House 36(01), 128–136 (2022).

Zuo, J. et al. Theoretical model and verification of “analogous hyperbola (hyperboloid)” for the overall movement of mining rock strata: From two-dimensional “analogous hyperbola” to three-dimensional “analogous hyperboloid” models. J. China Coal Soc. 49(4), 1731–1751 (2024).

Yan, Y. et al. The prediction model of super Large subsidence in high water table coal mining areas covered with thick unconsolidated layer. Geofludis 2021, 1–15 (2021).

Yan, Y. et al. Distribution characteristics and formation mechanism of surface crack induced by extrathick near horizontal seam mining: an example from the Datong coal field. China. Adv. Civil Eng. 2021, 1–10 (2021).

Yan, W. et al. Severe damage law on the ground surface induced by high-strength mining: a case study from the Shendong coal field in China. Front. Earth Sci. 10, 1–10 (2022).

Dong, G. The roof Broken mechanism of fully mechanized coal face with super thick and loose layer. Adv. Mater. Res. 690, 3068–3075 (2013).

Wang, F. et al. Effect of arch structure in unconsolidated layers on failure of the overlying strata. J. China Univ. Min. Technol. 48(5), 975–983 (2019).

Wang, F. et al. Research on ground control based on arch structure in unconsolidated layers theory. Coal Sci. Technol. 48(9), 130–138 (2020).

Wang, F. et al. Load bearing capacity of arch structure in unconsolidated layers. Sci. Rep. 13(1), 1–11 (2023).

Tan, Y. et al. Structural evolution of a “bulk arch structure” within a thick loose layer and overburden transportation law. J. Henan Poly. Univ. (Nat. Sci.) 2024, 1–14 (2024).

Wang, L. et al. Robust estimation of angular parameters of the surface moving basin boundary induced by coal mining: a case of Huainan mining area. KSCE J. Civ. Eng. 24(1), 266–277 (2020).

Jiang, Y. et al. A new prediction model of surface subsidence with cauchy distribution in the coal mine of thick topsoil condition. Arch. Min. Sci. 65(1), 147–158 (2020).

Chi, S. et al. Research on prediction model of mining subsidence in thick unconsolidated layer mining area. IEEE Access 9, 23996–24010 (2021).

Hou, D. et al. Superposition model for analyzing the dynamic ground subsidence in mining area of thick loose layer. Int. J. Min. Sci. Technol. 28(4), 663–668 (2018).

Cao, J. et al. Subsidence prediction of overburden strata and ground surface in shallow coal seam mining. Sci. Rep. 11(1), 1–12 (2021).

Zhou, D. et al. Combined prediction model for mining subsidence in coal mining areas covered with thick alluvial soil layer. Bull. Eng. Geol. Env. 77(1), 283–304 (2018).

Gabrijela D. et al. Descriptive Statistical Analysis in the Process of Educational Data Mining. 2019 14th International Conference on Advanced Technologies, systems and services in Telecommunications, 388–391 (2019).

Huang, C. et al. Development rule of ground fissure and mine ground pressure in shallow burial and thin bedrock mining area. Sci. Rep. 15, 10065 (2025).

Zhang, C. et al. Study on the simulation of bridge deformation in a mining subsidence area. Sci. Rep. 15, 529 (2025).

Yang, W. Law of overburden and surface deformation in roof cutting and backfilling mining under thin bedrock in shallow buried coal seam. Q. J. Eng. Geol. Hydrogeol. 58(1), qjegh2024–qjegh2039 (2025).

Acknowledgements

This work was funded by the National Natural Science Foundation of China (Grant No. U21A20109), the China General Technology Group Science and Technology Major Project (Grant No. GTZD-2023-019), and the “Haiyou Plan” Industrial Leading Talent Support Project of Jinan City (Grant No. CYLJ20241901474).

Author information

Authors and Affiliations

Contributions

Leixiang Peng, Xiang Hua and Weihua Sun collected and analyzed the measured data. Qian Jiang and Huaizhan Li carried out numerical simulation analysis work. Xiangsheng Yang and Guangli Guo made and modified the chart of the paper. All authors reviewed the manuscript

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Peng, L., Jiang, Q., Hua, X. et al. Investigation on the characteristics of surface movement and deformation in mining under thick unconsolidated layer in Jining area, China. Sci Rep 15, 17315 (2025). https://doi.org/10.1038/s41598-025-02697-2

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-02697-2