Abstract

In this paper, an explicit and implicit hybrid topology optimization method is proposed for the design of multiple materials structure. The explicit topology optimization employs the moving morphable component (MMC) method to determine where the solid material is present within the design domain. The implicit topology optimization employs the solid isotropic material with penalization (SIMP) method to identify material type within the solid material region. The explicit and implicit topology optimization methods are combined through a surrogate material model, resulting in a new hybrid topology optimization framework known as the MMC–SIMP hybrid topology optimization method. The proposed method retains the advantages of both individual optimization methods, allowing for explicit boundary representation and high design freedom in material selection. The element density function and sensitivity analysis are conducted based on two-phase materials topology optimization. Finally, some numerical examples demonstrate the effectiveness of the proposed method.

Similar content being viewed by others

Introduction

Lightweight structure is a critical requirement in fields such as aerospace and automotive engineering1,2,3. It is primarily achieved through the use of high-strength lightweight materials and structural optimization design, in which the structural optimization design can fundamentally address the lightweight issue. And if high-strength lightweight materials are used on the basis of structural optimization, even better lightweight effects can be achieved. However, the application of single high-strength lightweight material is often limited by factors such as overall performance, processing technology, and cost. Consequently, multiple materials structure incorporating locally high-strength lightweight materials is gaining increasing attention. Compared to single material structure, multiple materials structure can make more rational use of materials with different properties, collaboratively bearing structural loads to meet diverse design requirements4,5,6. In order to make more effective use of multiple materials structure, it is highly desirable to develop efficient multiple materials structural optimization design methods, which can not only further enhance the level of lightweight structure, but also improve structural performance while balancing both overall and local performance indicators.

Among structural optimization design, topology optimization, with more design freedom and the ability to obtain larger design space, is the most creative design method. Since the pioneering work of Bendsøe and Kikuchi7, topology optimization has developed rapidly over the past few decades. It has gradually formed two main categories, including implicit topology optimization methods, such as the solid isotropic material with penalization (SIMP) method8, evolutionary structural optimization (ESO) method9, and level set method (LSM)10,11,12, and explicit topology optimization methods, such as the moving morphable component (MMC) method13,14, moving morphable void (MMV) method15, feature-driven method16,17, and geometric projection (PG) method18. The basic idea of the implicit topology optimization methods is to establish the optimization model using the implicit function during the topology optimization process. The boundaries of the obtained optimization results may not be clear, making it impossible to directly and clearly describe the structural topology. However, due to their early introduction and simple models, implicit topology optimization methods are widely used, and have been successfully applied to commercial software. The core idea of the explicit topology optimization methods is to use geometric parameters of components or members as design variables, enabling easily control the shape of structural boundaries and obtaining geometric parameter information of the boundary, thus facilitating the direct establishment of the relationship between topology optimization results and computer-aided design (CAD) system. Moreover, explicit topology optimization methods can avoid the possible numerical problems that may arise with implicit topology optimization methods and generally involve a small number of design variables, which can accelerate the optimization efficiency of calculation.

Unlike single material topology optimization, which only requires determining the presence or absence of material within the prescribed design domain, multiple materials topology optimization not only necessitates determining the presence or absence of material but also need to decide which type of material to use. Consequently, the design variables in multiple materials topology optimization are often more numerous, and the optimization process is generally more complex. Thomsen19 pioneered the research on multiple materials topology optimization (MMTO), proposing a solution for the design of structure composed of two-phase isotropic materials. Subsequently, various topology optimization methods have been gradually applied to the optimization design of multiple materials structure. Generally, single material topology optimization methods can be applied to multiple materials structure optimization, such as homogenization method20, density-based method21,22, level set method23,24, and MMC method25,26. Multiple materials topology optimization theories have also been widely applied in the infill structures optimization27,28,29, surface reinforcement rib optimization30,31,32, and fiber-reinforced composites multi-scale optimization33,34,35,36.

Li et al.37 presented an approach for designing hybrid material structures, which extends the recursively defined power-law type multiple materials interpolation model by incorporating additional gradient material phases. Unlike conventional models, the new extended model considers the secondary “solid” material phase as a type of lattice, enabling adjustment of lattice geometry and mechanical behavior with gradient control variables such as density or size. Wang and Sigmund38 employed a multi -material topology optimization scheme to optimize the buckling capacity of active structures made of structural and actuating materials and prestressed structures containing prestressed components. Later, they39 developed a general topology optimization approach to design novel multiple materials active structural systems to reduce environmental impact. The approach is based on the density-based scheme, and passive and active materials are considered in the optimization process. Additionally, with the development of additive manufacturing technology40,41,42, the manufacturability of multiple materials topology optimization results has been greatly improved. Like single material topology optimization methods, multiple materials topology optimization methods can also be categorized into implicit and explicit topology optimization methods. However, considering the different material selection strategies for multiple materials, for ease of analysis and understanding, multiple materials topology optimization methods can be divided into density-based and boundary-based topology optimization. In density-based multiple materials topology optimization, the optimization strategy of selecting multiple materials locates on the elements, such as the homogenization method and SIMP method. In boundary-based multiple materials topology optimization, the optimization strategy of selecting multiple materials locates on the level set functions, such as the level set method and MMC method.

For the multiple materials topology optimization using SIMP method or MMC method only, the SIMP method directly assigns materials to the elements, and the evolution of the overall structure and the selection of element materials are carried out simultaneously, providing a high degree of freedom in material selection. The multiple materials topology optimization theoretical model based SIMP method is simple, has good convergence, and is suitable for any complex geometric shapes. However, it involves a large number of design variables and has unclear optimization boundaries. The MMC method assigns materials to the components and then assigns the materials to the elements mapped by the components. Multiple groups of components, which one group of component has the same material, evolve simultaneously to obtain the optimized structure and corresponding materials layout. The MMC method provides clearer geometric boundaries in multiple materials topology optimization and facilitates size control. However, since materials are preset on the components, the flexibility in material selection is limited. And as the increase of the number of materials, the difficulty of arranging different types of components also increases. That is because the MMC method needs to determine the initial layout of the components (including the number and structure of the components), and the structural topology is evolved based on the changes of the components, so the number of components has a greater impact on the final topology. Since materials are defined on the component in MMC method, in the multiple materials topology optimization, in order to ensure the overall optimization, each material generally needs to set the same initial layout (for example, material 1 is set to 16 components, and material 2 is generally set to 16 components even if it is used as a reinforcement material). At this time, local reinforcement materials also require overall layout optimization, which adds to the computational complexity. Additionally, the MMC method involves the issue of component overlap, so some strategies need to be set to select material in the overlapping region.

In order to address the aforementioned issues, an explicit and implicit hybrid topology optimization method is proposed to fully leverage their respective advantages while avoiding the drawbacks of the single method. The hybrid topology optimization method has already garnered the attention of some scholars. To seek the optimal material distribution, Deng43 proposed a two-step topology optimization method. Initially, a rough material configuration is obtained based on the traditional density method. Subsequently, an inverse optimization problem is solved to fit the geometric components to the solution obtained in the first step, achieving a favorable optimization response. Coniglio44 presented a generalized geometric projection theoretical framework aimed at unifying three explicit topology optimization frameworks (the geometric projection method, the MMC method using surrogate material models, and the moving node method) into a single formulation. Hederberg and Thore45 combined the density-based topology optimization method with the MMC method to perform fault-tolerant optimization design. Li et al.46 developed an integrated optimization strategy that includes two different topology optimization methods, where the MMC method is used for the initial topology prediction, and the SIMP method is employed for subsequent topology refinement to optimize the microchannel layout in multi-channel heat exchangers. Qiu et al.47 proposed a method coupling moving morphable voids and components for the topology optimization of hydrogel structures involving recoverable large deformations. In this method, the geometric parameters of the moving morphable voids and components are set as design variables to describe the contours and material distribution of the hydrogel structure. Sun et al.48 proposed a method for simultaneous topology and size optimization using the MMC method. The main idea is to connect certain design variables and modify their sensitivities during the optimization iterations to make them identical. Liu et al.49 introduced a hybrid MMC-MMV method for the optimization design of shell-graded infill structures. In this method, morphable voids are used to represent the shell’s boundaries, while morphable components are employed to depict the distribution of infill material. Guo et al.50 proposed a hybrid explicit and implicit topology optimization method for the design of shell-infilled composite structures, utilizing the MMC method for shell optimization and the SIMP method for the optimization of the internal infill structure. Compared to the single topology optimization method, the hybrid topology optimization method has demonstrated significant advantages to achieve better optimization results.

In this paper, an explicit and implicit hybrid topology optimization method based on MMC method and SIMP method is proposed to meet the following design requirements. (1) Minimize the number of design variables to achieve an overall structure optimization of multiple materials. (2) Allow more freedom and flexibility for multiple materials selection. (3) Avoid overlapping between different materials. (4) Explicitly express the boundary of the optimized structure. The remaining sections of the paper are organized as follows: The single MMC and SIMP method for multiple materials structure are introduced in Section “MMC and SIMP method for multiple materials structure”. The implementation process of the MMC–SIMP hybrid optimization method is illustrated in Section “Problem formulation for minimum structural compliance”. The mathematical formulation of the optimization problem and numerical application are described in Section “Explicit and implicit hybrid optimization method”. The effectiveness of the proposed method is verified in Section “Numerical application” through several numerical examples. Section “Numerical examples” provides some concluding remarks on the proposed method and its potential for future research.

MMC and SIMP method for multiple materials structure

The hybrid topology optimization method proposed in this paper combines MMC method and SIMP method, so it is necessary to understand how these two methods achieve topology optimization of multiple materials structure. The key of topology optimization, to a certain extent, can be considered as how to define the element density function, that is establishing the relationship between the element’s ‘Young’s modulus, design variables, and the actual material’s Young’s modulus. Then solve the element’s Young’s modulus through the element density function, and obtain the element’s equivalent stiffness matrix. After that, the overall structural response can be analyzed via the finite element method. In the proposed MMC–SIMP hybrid topology optimization method, the element density function is determined by the combination of two topology optimization methods. The presence or absence of the element material is determined by the MMC method, while the type of element material is determined by the SIMP method. The two methods are combined to realize the multiple materials structure design. In this section, the principles of SIMP method and the MMC method for multiple materials structure are introduced firstly, and then followed by a detailed explanation of the MMC–SIMP hybrid topology optimization method.

SIMP topology optimization method for multiple materials structure

The SIMP method belongs to the global optimization. The fundamental idea involves introducing a hypothetical material with a relative density variable between 0 and 1. The artificial density is used as the design variable, and penalization power is employed to make the design variable approach 0 or 1. Taking two-phase materials (two solid materials) and three-phase materials (two solid materials and void) as examples, a commonly used hybrid interpolation method will be illustrated, which the interpolation between different materials is performed using a power function21.

For the two-phase materials design, the Young’s modulus of the element can be described as

where ρ is the artificial density of material, p is a penalization power (generally p ≥ 3), E1 and E2 are the Young’s modulus of material 1 and 2, respectively.

For the three-phase materials design, it is convenient to interpolate between two nonzero phases and then between this material and void. The Young’s modulus of the element can be described as

where ρ1 is the density of the mixture of two materials with stiffness, and ρ2 is the density of material 1 in this mixture. In this element density function, the topology optimization issue is extended to three-phase materials by introducing two design variables into each element. One variable determines whether there is material in the element, and the other variable determines the type of material in the element.

The essence of the above element density function is a multiple materials mixed model, and m−1 density functions can be used to represent m-phase materials.

MMC topology optimization method for multiple materials structure

The MMC method belongs to a discrete component optimization method, which optimization strategy is to set a certain number of basic structural components in the design domain, and take the geometric parameters of components, such as the center position, thickness and rotation angle of each component, as the design variables. The changes of the structural topology are realized through the movement, deformation and rotation of the components. For more information on the current research status of the MMC method, the review article51 and references therein are referred to.

In MMC method, the setting of components is particularly important. Taking the component description of hyperelliptic equation as an example, the component description function can be expressed as

with

where \(\phi (x,y)\) represents the topological function values of the coordinates corresponding to the whole design domain, and the parameter p is a relatively large positive even number (generally p=6). L is the half length of the component, \(\left( {x^{\prime},y^{\prime}} \right)\) and (x, y) represent the coordinates of any point in the local coordinate system and the global coordinate system respectively, θ is the rotation angle of the component (from the global coordinate system to the local coordinate system), \(f(x^{\prime})\) is a function describing the shape of the component. In this paper, a quadratically varying thickness component is adopted, as shown in Fig. 1, with component variables are [x0, y0, t1, t2, t3, L]. The \(f(x^{\prime})\) is specifically expressed as

After determining the component description equation and the number of components, according to the all boundaries of components, the whole design domain can be divided into the following areas.

where D is the overall design domain, \(\Omega^{S}\) is the area occupied by solid materials in the design domain, \(\partial \Omega^{S}\) represents the boundary and \(D\backslash \left( {\Omega^{S} \cup \partial \Omega^{S} } \right)\) is the void area. \(\phi^{S} (x)\) is the topological description function of all components, which can be expressed as

where \(\phi_{i}^{e}\) is the area occupied by i-th component, which can be described as

For the application of MMC method in multiple materials structure design, Zhang et al.25 proposed a multiple materials description method. When the optimization problem involves multiple types of materials, under the guidance of the basic idea of MMC method, multiple groups of components are introduced, and all components in the same group have the same material properties (Young’s modulus, Poisson’s ratio, etc.), then the area occupied by the i-th material (i-th group of components) can be expressed as

Then the topological description function of the i-th group of component can be expressed as

where ni represents the total number of components included in the i-th group.

Through the above method, the structure area of each group of components can be determined. However, different groups of components may overlap each other during the optimization process, so how to choose the material in the overlap area is important to implement MMC method for multiple materials topology optimization. The strategy of material selection can be defined that when the topological description functions of various groups of components at the same node are all positive, the material with the largest Young’s modulus is selected as the material of the node. For instance, assuming that two materials overlap and there is Ei < Ej, then E = Ej is specified. It should be noted that the proposed strategy focuses on the volume constraint problem. If there is a constraint problem such as quality or cost, the strategy needs to be modified. Based on this strategy, the area occupied by the i-th material should be revised as

Then the area occupied by all different materials in the overall design domain can be expressed as

where K is total number of multiple materials.

Based on the surrogate material model, taking four nodes bilinear element as an example, the element density is represented as

where H = H(x) is the Heaviside function and \(\phi_{i}^{e}\), i = 1,…,4 are the values of the topological function of the whole structure (i.e., ϕs(x)) at four nodes of element e. q is the penalization power. For numerical implementation purpose, as a common practice in the literature, H(x) is often replaced by its regularized version \(H_{\tau } (x)\). In the present work, the form of \(H_{\tau } (x)\) is taken as:

where \(\tau\) and \(\alpha\) are two small positive numbers used for controlling the length of the transition zone and avoiding the singularity of the global stiffness matrix, respectively.

For single material, the Young’s modulus of the element can be described as

For multiple materials, the Young’s modulus of the elements mapped by the components can be determined through surrogate material model and overlapping component selection strategy.

Problem formulation for minimum structural compliance

In this paper, the minimum compliance of the structure is taken as the objective function, and the total volume of the structure and the volume ratio of each material relative to the basic material are taken as constraints. The problem formulation can be described as

where D is the design variable, including component geometric design variables DMMC and material selection density variables DSIMP. C = UTKU is the structural compliance, ue and k0 are the element displacement and the element stiffness matrix without Young’s modulus respectively, Ee(ρe) is the element density function. F = KU is the governing equation of finite element analysis. V(D) is the total volume of the structure, \(\overline{V}\) is the volume constraint. Vi is the i-th material volume with \(\sum\limits_{i = 1}^{m} {V_{i} } = V(D),{\kern 1pt} {\kern 1pt} {\kern 1pt} m = 1,2,3 \ldots\). V1 is the volume of base material, and fi is the volume ratio of the i-th material to the base material. Taking two-phase materials as an example, the volume constraint should also meet \(V_{1} + V_{2} = V(D)\) and \(V_{2} = V_{1} * f\). In the implementation algorithm, the volume constraint of two-phase materials can be realized by constraining V1.

Explicit and implicit hybrid optimization method

Implementation principle

The schematic of MMC–SIMP hybrid topology optimization method is shown in Fig. 2. Two topology optimization methods are implemented in parallel, with MMC method determining the structural boundary and SIMP method implementing material selection for component mapping elements, and the multiple materials structural topology is ultimately formed.

The element materials in the MMC–SIMP hybrid topology optimization method are jointly determined by the surrogate material model in the MMC method and the artificial density in the SIMP method, as illustrated in Fig. 3. In the MMC method, elements are classified into void elements, boundary elements, and solid elements, and the materials present only in boundary elements and solid elements. The SIMP method is used to determine the material of the elements by the material density variables. Unlike the single MMC method for multiple materials optimization, in the proposed hybrid method, the selection of materials is not focused on the components but on the elements. The MMC method is only used to determine whether an element contained material, obtaining the force transmission path and forming the structural topology.

Taking two-phase materials as an example, using four nodes bilinear element, the element density function of MMC–SIMP hybrid topology optimization method can be described as

where \(\rho_{e}^{M}\) and \(\rho_{e}\) are used to determine whether the element has material and the material type of the element respectively, and \(\rho_{e}^{M}\) are calculated by surrogate material model based on MMC method.

Implementation points

-

(1)

Element material information input.

The proposed hybrid topology optimization method is mainly based on the MMC method, and the SIMP method is used to update the element material properties. The Young’s modulus of the element is separated from the element stiffness matrix, and the element density is formed based on the element material selection model and the element surrogate material model, which achieve the element material information input. The number of design variables in the SIMP method is (N−1) times of the number of meshed divided, where N is the number of materials.

-

(2)

Multiple materials volume constraint setting.

Multiple materials structure topology optimization involves volume constraints of different materials. In the present work, one material is selected as the base material, and the ratio of i-th material relative to the base material is used as the volume constraint of the i-th material. At the same time, the sum of all materials volumes is used as the structural volume constraint.

-

(3)

Design variable update.

Generally speaking, the design variables of topology optimization can be divided into one-dimensional (including one type of parameter characterizing one material) design variables and multi-dimensional (including one type of parameter characterizing many materials, many types of parameters characterizing one material and many types of parameters characterizing many materials) design variables. For example, in single material topology optimization, there is usually only one type of design variables (artificial densities) in density-based method, while MMC method involves many types of design variables such as coordinate, component size and rotation angle. The optimization solvers used for different types of design variables are different.

The commonly used solvers for topology optimization include the optimization criteria (OC) method and the moving asymptotes (MMA) method. The OC method establishes the Lagrange equation through objective function and constraint condition, and combines constraint equation with objective function to become unconstrained problem. Then, Kuhn-Tucker criterion is used to solve the extreme point of Lagrange function, and iterative formula is constructed through corresponding optimization criteria. The OC method can deal with large-scale problems with high optimization efficiency, but for multi-dimensional design variables, which usually involve complex problems with multiple constraints, the OC method requires the introduction of different Lagrange multipliers, and they are often difficult to construct, so the OC method is mostly used for the design variables with the same meaning, such as pseudo density variable used by SIMP method for single material optimization problem. The MMA method transforms the implicit optimization problem into a series of explicit, separable, and strictly convex sub-optimization problems by introducing moving asymptotes. The objective function and constraint condition in the mathematical model are approximated as convex linearization sub-problems by Taylor expansion. In each iteration process, the moving asymptote is constructed by solving the gradient value of the sub-problem function to update the design variables, and constantly approaching the extreme point of the original function. This is unlike the OC method, which directly obtains new design variables through an explicit heuristic iterative format. For complex topology optimization problems, the complex function can always be expanded into an explicit linear function by Taylor expand and the optimization value can be obtained through iteration calculation. Therefore, the MMA method is more suitable for dealing with topology optimization problems with complex objective functions and multiple constraints. For the topology optimization of multiple materials, no matter which topology method is adopted, it usually needs to increase the variables indicating material properties, so MMA method should be preferred.

In this paper, based on the expression of element density function (18), OC method and MMA method can be simultaneously used to update the design variables in order to simplify the optimization process and reduce the computation cost.

Implementation process

The MMC–SIMP hybrid topology optimization process is shown in Fig. 4. Firstly, it is necessary to confirm the design variables, including component geometric variables in MMC method and material selection density variables in SIMP method. Then construct the element density function based on surrogate material model and material selection model. After that, set the objective function and the constraint conditions. Then build the global stiffness matrix of the multiple materials structure and carry out the finite element analysis to solve the structural response. To update the design variables, analyse sensitivity of MMC variables and SIMP variables respectively. Finally, update the design variables through the selected solver and check the convergence.

Characteristics of the proposed method

It can be seen from the implementation that the proposed explicit and implicit hybrid topology optimization method has the following advantages:

-

(1)

The structural topology is expressed explicitly with explicit boundary geometry information.

-

(2)

Material selection is based on SIMP method, and the freedom of material selection is high.

-

(3)

The surrogate material model can transform non-component regions into weak materials, which is convenient for the assembly of overall stiffness matrix, so the proposed method can improve the efficiency of finite element analysis

-

(4)

Although the proposed method still has hybrid elements, it avoids the element cutting problem in MMC method when selecting material, and the material continuity is improved

-

(5)

The proposed method is a parallel optimization algorithm. Compared with the sequential optimization algorithm, the reliability of the optimization results is improved.

-

(6)

The proposed method is easy to implement. For two-phase materials, the OC method and MMA method can be used to update the design variables of SIMP method and MMC method respectively, and the calculation efficiency can be further improved.

Moreover, if the design variable reduction strategy22,52,53,54 can be used, the superiority of the proposed method can be further improved.

Numerical application

Two-phase materials are taken as an example in this paper, and they are taken as the research object in the following finite element analysis, sensitivity analysis and numerical examples.

Finite element analysis

The key of finite element analysis is to calculate the global stiffness matrix. Based on the topological optimization method proposed in this paper, taking two-phase materials as an example, the element stiffness matrix can be expressed as

The global stiffness matrix is

where NE is the total number of elements.

Sensitivity analysis

-

(1)

Sensitivity analysis of MMC variables.

The sensitivity of MMC variables can be solved by finite difference method, because the topological description adopts the max function and the max function is non-differentiable. And the specific method can be found in reference14.

-

(2)

Sensitivity analysis of SIMP variables.

Sensitivity of objective function can be expressed as

According to the constraint conditions, the volume of the material 1 (the ratio of the volume occupied by the material 1 to the design domain volume) is

where DW and DH are the length and width of the design domain respectively, EW and EH are the length and width of the element respectively.

The total volume of structure can be expressed as

where f = V2/V1.

Sensitivity of constraint condition can be expressed as

It should be noted that volume constraint includes two aspects. One is the total volume of multiple materials should be equal to the total volume of the structure determined by MMC method, and the other is the volume constraint between multiple materials. Table 1 shows the relationship between the volume of each material and the total volume of the structure under different volume ratios.

-

(3)

Sensitivity filtering of SIMP method.

Sensitivity filtering is mainly used in density-based topology optimization method to avoid checkerboard phenomenon and reduce the mesh dependence. In this paper, the sensitivity filtering technology proposed by Sigmund55,56 is adopted. The weighted average value of the sensitivity of each element within the filtering radius is used to replace the sensitivity value of the central element. The modified sensitivity of the objective function to the design variables is

where \(\widehat{H}_{i}\) is the convolution operator (weight factor), which can be expressed as

where dist(e, i) is the distance between the centers of element e and i, rmin is the filtering radius, and NE is the total number of elements.

Numerical examples

In this part, the short beam problem and MBB beam problem are analyzed to verify the feasibility of the proposed method. Both numerical examples take the minimum compliance as the objective function and the total volume and volume ratio of two-phase materials as the constraint conditions. In order to simplify the analysis, it is assumed that all the related quantities in the research problem are dimensionless, and the thickness of the design domain is set to a unit value. Young’s modulus of two materials are set to E1 = 1 and E2 = 2, Poisson’s ratio is chosen as vs = 0.3, total volume constraint is chosen as V(D) = 0.4, volume ratios of two materials are set to f = V2/V1 = [0.2, 0.5, 0.8, 1, 1.5, 2]. Penalization powers are chosen as p = 3 and q = 2, respectively.

Short beam example

The short beam problem is shown in Fig. 5. The design domain size is set to 2 × 1, and is discretized by a 80 × 40 FEM mesh. The load is set to F = 1.

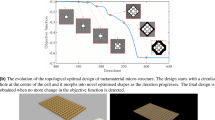

The short beam optimization results of two-phase materials with different volume ratios f using the MMC–SIMP hybrid topology optimization method are shown in Fig. 6. The final optimization structure consists of two parts, including the MMC boundary and the SIMP material layout. The MMC method obtains a smooth and explicit topological structure boundary, while the SIMP method determines the layout of materials within the boundary. In the final optimization structure, the black area within the boundary represents material E1, and the white area within the boundary represents material E2. The optimization results also show that the compliance of the multiple materials structure gradually decreases with the increase of the volume fraction of material E2. The iterative histories of the optimization process are shown in Fig. 7, which can form a relatively stable topology structure and the objective function values are also relatively stable.

It is usually easier to obtain reliable structural topology by using a single material and a single topology optimization method. When only a single material (E1 = 1) is used, the optimization structures of MMC method and SIMP method are shown in Fig. 8, and the iteration histories are shown in Fig. 9. It can be seen that the overall optimized structure obtained by the proposed method is similar to that obtained by the single method, and is better than that obtained by the MMC method at the current mesh resolution. The iterative convergence speed is also similar. Moreover, after adopting the multiple materials structure, the structural stiffness is further improved.

Figure 10 shows partial optimization results obtained from other literature on the short beam multiple materials problem. It can be seen that the proposed method also yields the clear multiple materials structure and has a relatively stable topology with flexible material selection.

MBB beam example

The MBB beam problem is shown in Fig. 11. Considering the symmetry of the structure, the design domain size is set to 3 × 1, and is discretized by a 120 × 40 FEM mesh. The load is set to F = 1.

The MBB beam optimization results of two-phase materials with different volume ratios f using the MMC–SIMP hybrid topology optimization method are shown in Fig. 12. The proposed method can also be used to obtain multiple materials topology optimization structures with explicit topological structure boundary and the clear layout of materials within the boundary, and the overall compliance of the multiple materials structure decreases with the increase of material E2. When f = 0.5, the optimization result is poor, indicating that certain volume ratios may have a certain impact on the optimization result, but it can be improved by adjusting the mesh resolution. The iterative histories of the optimization process are shown in Fig. 13, which can also form a relatively stable topology structure, and the objective function values are also relatively stable.

Similarly, when only a single material (E1 = 1) is used, the optimized structures of MMC method and SIMP method are shown in Fig. 14, and the iteration histories are shown in Fig. 15. It can be seen that at the current mesh resolution, the overall optimized structure obtained by the proposed method is better than that obtained by any single method, and the iterative convergence speed is similar, but the stiffness of the multiple materials structure is further improved.

Conclusion

An explicit and implicit hybrid topology optimization method based on MMC method and SIMP method is proposed in this paper, which is used to achieve multiple materials structure design. Within this framework, the problem formulation of the optimization problem is established with the minimum compliance as the objective function and the total volume and relative volume of multiple materials as constraints. The stiffness matrix of the element and the sensitivity information of the corresponding design variables are calculated using two-phase materials as the design objects. The OC optimization criterion is used to update the SIMP method design variables, and the MMA optimization criterion is used to update the MMC method design variables. The proposed hybrid topology optimization method not only has an explicit expression of the optimization structure, but also fully expresses the design details, and significantly reduces the number of design variables compared to using the SIMP method alone. Through the examples analysis of hybrid topology optimization method under different volume ratios, it is demonstrated that the proposed method can obtain feasible topology optimization of the overall structure, and the structure boundaries and internal material layout are clear, confirming the feasibility of the proposed method.

Although the proposed hybrid topology optimization method can effectively avoid the shortcomings of the single optimization method, there is still room for further improvement in terms of the applicability. In the present work, only the structure of two-phase materials is analyzed. In SIMP method, only one design variable is needed to represent two-phase materials of the element, so the design variables can be updated by the optimization criterion method. However, for three-phase or more materials, the MMA method will be the preferred solver. So the MMC method variables and SIMP method variables will be updated by MMA method together, and the control and integration of the related parameters need further analysis. Another important problem is the connection of multiple materials, mainly including the connection mode between different materials, the feasibility of manufacturing about multiple materials structures, and the reliability of overall structural performance.

Data availability

The datasets used and analysed during the current study available from the corresponding author on reasonable request.

References

Sun, G., Chen, D., Zhu, G. & Li, Q. Lightweight hybrid materials and structures for energy absorption: A state-of-the-art review and outlook. Thin-Walled Struct. 172, 108760 (2022).

Zhang, W. & Xu, J. Advanced lightweight materials for Automobiles: A review. Mater. Des. 221, 110994 (2022).

Li, S., Zhou, D. & Pan, A. Integrated lightweight optimization design of wall thickness, material, and performance of automobile body side structure. Struct. Multidiscip. Optim. https://doi.org/10.1007/s00158-024-03810-1 (2024).

Bohrer, R. Z. G. & Kim, I. Y. Multi material topology and stacking sequence optimization of composite laminated plates. Struct. Multidiscip. Optim. https://doi.org/10.1007/s00158-022-03363-1 (2022).

Noda, M., Matsushima, K. & Yamada, T. Orientation optimization via topological derivatives in combination with multi-material topology optimization based on extended level set method. Comput. Methods Appl. Mech. Eng. 418, 116585 (2024).

Zhang, C. et al. Multi-material topology optimization for spatial-varying porous structures. CMES-Comput. Model. Eng. Sci. 138, 369–390 (2024).

Bendsøe, M. P. & Kikuchi, N. Generating optimal topologies in structural design using a homogenization method. Comput. Methods Appl. Mech. Eng. 71, 197–224 (1988).

Bendsøe, M. P. Optimal shape design as a material distribution problem. Struct. Optim. 1, 193–202 (1989).

Xie, Y. M. & Steven, G. P. A simple evolutionary procedure for structural optimization. Comput. Struct. 49, 885–896 (1993).

Wang, M. Y., Wang, X. & Guo, D. A level set method for structural topology optimization. Comput. Methods Appl. Mech. Eng. 192, 227–246 (2004).

Mei, Y. & Wang, X. A level set method for structural topology optimization and its applications. Adv. Eng. Softw. 35, 415–441 (2004).

Grégoire, A., Franois, J. & Anca, M. T. Structural optimization using sensitivity analysis and a level-set method. J. Comput. Phys. 194, 363–393 (2004).

Guo, X., Zhang, W. & Zhong, W. Doing topology optimization explicitly and geometrically-a new moving morphable components based framework. J. Appl. Mech.-Trans. Asme. 81, 081009 (2014).

Zhang, W., Yuan, J., Zhang, J. & Guo, X. A new topology optimization approach based on moving morphable components (MMC) and the ersatz material model. Struct. Multidiscip. Optim. 53, 1243–1260 (2016).

Zhang, W., Yang, W., Zhou, J., Li, D. & Guo, X. Structural topology optimization through explicit boundary evolution. J. Appl. Mech. https://doi.org/10.1115/1.4034972 (2017).

Zhang, W., Zhao, L., Gao, T. & Cai, S. Topology optimization with closed B-splines and Boolean operations. Comput. Methods Appl. Mech. Eng. 315, 652–670 (2017).

Jiu, L., Zhang, W., Meng, L., Zhou, Y. & Chen, L. A CAD-oriented structural topology optimization method. Comput. Struct. 239, 106324 (2020).

Norato, J. A., Bell, B. K. & Tortorelli, D. A. A geometry projection method for continuum-based topology optimization with discrete elements. Comput. Methods Appl. Mech. Eng. 293, 306–327 (2015).

Thomsen, J. Topology optimization of structures composed of one or two materials. Struct. Multidiscip. Optim. 5, 108–115 (1992).

Gibiansky, L. V. Multiphase composites with extremal bulk modulus. J. Mech. Phys. Solids 48, 461–498 (1998).

Bendsøe, M. P. & Sigmund, O. Material interpolation schemes in topology optimization. Arch. Appl. Mech. 69, 635–654 (1999).

Wan, C., Jiao, H., Lv, L. & Lu, C. Multi-material topology optimization based on multiple simp of variable density method. J. Mech. Sci. Technol. 38, 749–759 (2024).

Wang, Y., Luo, Z., Kang, Z. & Zhang, N. A multi-material level set-based topology and shape optimization method. Comput. Methods Appl. Mech. Eng. 283, 1570–1586 (2015).

Xu, Y. et al. Concurrent optimization of topological configuration and continuous fiber path for composite structures—A unified level set approach. Comput. Methods Appl. Mech. Eng. 399, 115350. https://doi.org/10.1016/j.cma.2022.115350 (2022).

Zhang, W. et al. Topology optimization with multiple materials via moving morphable component (MMC) method. Int. J. Numer. Meth. Eng. 113, 1653–1675 (2018).

Sun, Z., Song, Z., Song, J., Li, H. & Guo, X. Structural optimization of fiber-reinforced material based on moving morphable components (MMCs). Acta Mech. Solida Sin. 35, 632–646 (2022).

Li, H., Gao, L., Li, H. & Tong, H. Spatial-varying multi-phase infill design using density-based topology optimization. Comput. Methods Appl. Mech. Eng. 372, 113354 (2020).

Xie, W., Feng, J., Xia, Q., Kim, J. & Li, Y. Design of the shell-infill structures using a phase field-based topology optimization method. Comput. Methods Appl. Mech. Eng. 429, 117138 (2024).

Bai, J. & Zuo, W. Multi-material topology optimization of coated structures using level set method. Compos. Struct. 300, 116074. https://doi.org/10.1016/j.compstruct.2022.116074 (2022).

Wang, Y., Zhang, H., Du, Z., Zhang, W. & Guo, X. Design of a stiffened space membrane structure using explicit topology optimization. J. Mech. Des. https://doi.org/10.1115/1.4055375 (2022).

Jiang, X. et al. Explicit topology optimization design of stiffened plate structures based on themoving morphable component (MMC) method. CMES-Comput. Model. Eng. Sci. 135, 809–838 (2023).

Bakker, C., Zhang, L., Higginson, K. & van Keulen, F. Simultaneous optimization of topology and layout of modular stiffeners on shells and plates. Struct. Multidiscip. Optim. 64, 3147–3161 (2021).

Stegmann, J. & Lund, E. Discrete material optimization of general composite shell structures. Int. J. Numer. Meth. Eng. 62, 2009–2027 (2005).

Lund, E. & Stegmann, J. On structural optimization of composite shell structures using a discrete constitutive parametrization. Wind Energy 8(1), 109–124. https://doi.org/10.1002/we.132 (2005).

Smith, H. & Norato, J. A. Topology optimization with discrete geometric components made of composite materials. Comput. Methods Appl. Mech. Eng. 376, 113582. https://doi.org/10.1016/j.cma.2020.113582 (2021).

Bohrer, R. Z. G. & Kim, I. Y. Concurrent topology and stacking sequence optimization of composite laminate plates using lamination parameters. Compos. Struct. 276, 114556 (2021).

Li, Y., Qiu, W., Liu, Z., Liu, Y. & Xia, L. A multi-material topology optimization approach to hybrid material structures with gradient lattices. Comput. Methods Appl. Mech. Eng. 425, 116969 (2024).

Wang, Y. & Sigmund, O. Multi-material topology optimization for maximizing structural stability under thermo-mechanical loading. Comput. Methods Appl. Mech. Eng. 407, 115938 (2023).

Wang, Y. & Sigmund, O. Topology optimization of multi-material active structures to reduce energy consumption and carbon footprint. Struct. Multidiscip. Optim. https://doi.org/10.1007/s00158-023-03698-3 (2024).

Ichihara, N. & Ueda, M. 3D-printed high-toughness composite structures by anisotropic topology optimization. Compos. Part B-Eng. 253, 110572 (2023).

Wang, S. et al. A modified equally-spaced method (MEQS) for fibre placement in additive manufacturing of topology-optimised continuous carbon fibre-reinforced polymer composite structures. Compos. Struct. 335, 117998 (2024).

Wu, T., Liu, P. & Liu, J. Geometric complexity control in topology optimization of 3D-printed fiber composites for performance enhancement. Materials 17, 2005 (2024).

Deng, H. A Heaviside function-based density representation algorithm for truss-like buckling-induced mechanism design. Int. J. Numer. Meth. Eng. 119, 1069–1097 (2019).

Coniglio, S., Morlier, J., Gogu, C. & Amargier, R. generalized geometry projection: A unified approach for geometric feature based topology optimization. Arch. Comput. Methods Eng. 27, 1573–1610 (2020).

Hederberg, H. & Thore, C.-J. Topology optimization for fail-safe designs using moving morphable components as a representation of damage. Struct. Multidiscip. Optim. 64, 2307–2321 (2021).

Li, B. T. et al. Multidisciplinary optimization of liquid cooled heat sinks with compound jet/channel structures arranged in a multipass configuration. Appl. Therm. Eng. 195, 117159 (2021).

Qiu, Y. et al. Coupling moving morphable voids and components based topology optimization of hydrogel structures involving large deformation. J. Appl. Mech. https://doi.org/10.1115/1.4052431 (2022).

Sun, J., Tian, Q., Hu, H. & Pedersen, N. L. Simultaneous topology and size optimization of a 3D variable-length structure described by the ALE-ANCF. Mech. Mach. Theory 129, 80–105 (2018).

Liu, C. et al. Optimal design of shell-graded-infill structures by a hybrid MMC-MMV approach. Comput. Methods Appl. Mech. Eng. 369, 113187 (2020).

Guo, Y., Liu, C. & Guo, X. Shell-infill composite structure design based on a hybrid explicit- implicit topology optimization method. Compos. Struct. 337, 118029 (2024).

Li, Z., Xu, H. & Zhang, S. A comprehensive review of explicit topology optimization based on moving morphable components (MMC) method. Arch. Comput. Methods Eng. 31(5), 2507–2536 (2024).

Yin, L. & Ananthasuresh, G. K. Topology optimization of compliant mechanisms with multiple materials using a peak function material interpolation scheme. Struct. Multidiscip. Optim. 23, 49–62 (2001).

Zuo, W. & Saitou, K. Multi-material topology optimization using ordered SIMP interpolation. Struct. Multidiscip. Optim. 55, 477–491 (2016).

Seong, H. K., Kim, C. W., Yoo, J. & Lee, J. Multiphase topology optimization with a single variable using the phase-field design method. Int. J. Numer. Methods Eng. 119(5), 334–360 (2019).

Sigmund, O. & Maute, K. Sensitivity filtering from a continuum mechanics perspective. Struct. Multidiscip. Optim. 46, 471–475 (2012).

Sigmund, O. A 99 line topology optimization code written in Matlab. Struct. Multidiscip. Optim. 21, 120–127 (2001).

Yi, B. et al. A unified material interpolation for topology optimization of multi-materials. Comput. Struct. 282, 107041 (2023).

Tavakoli, R. & Mohseni, S. M. Alternating active-phase algorithm for multimaterial topology optimization problems: A 115-line MATLAB implementation. Struct. Multidiscip. Optim. 49, 621–642 (2014).

Acknowledgements

The authors acknowledge the support of the Science and Technology Research Project of Henan Province (242102241055), the Industry-University-Research Collaborative Innovation Base on Automobile Lightweight of “Science and Technology Innovation in Central Plains” (2024KCZY315), and the Opening Fund of State Key Laboratory of Structural Analysis, Optimization and CAE Software for Industrial Equipment (GZ2024A03-ZZU).

Author information

Authors and Affiliations

Contributions

LZ: Manuscript writing, method conceptualization, software analysis, data processing, result analysis. XHY: Method conception, result analysis. ZS: Method conception, software analysis. CJT: Software analysis, data processing. LXF: Image Processing. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Li, Z., Xu, H., Zhang, S. et al. Design of multiple materials structure based on an explicit and implicit hybrid topology optimization method. Sci Rep 15, 19591 (2025). https://doi.org/10.1038/s41598-025-02850-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-02850-x