Abstract

In order to isolate energy dissipators from hydraulic engineering projects and address the issues of vibration damage caused by the discharge structures. This study develops a novel vertical jet-type energy dissipator by placing fragmentation needles at the vertical jet pipe nozzle, which mainly uses the fragmentation needles to fragment the high-energy jet into multiple smaller jets. Along with the mixing of air into the water flow, the mechanical energy of the flow is converted into internal energy and dissipated in the air. The structural parameters of the vertical jet-type energy dissipator include the size, shape, and number of fragmentation needles. The study employs numerical simulations primarily, with physical model experiments for validation, to investigate the nappe characteristics, energy dissipation rate, and energy dissipation mechanisms of the vertical jet energy dissipator under various structural parameters. The results show that within the scope of this study, the energy dissipation rate of the vertical jet increases with the Reynolds number, the number of fragmentation needles, and the size of the fragmentation needles. Compared to the case without fragmentation needles, the energy dissipation rate increases by 1.04–4.89 times. Under the same Reynolds number, the total height of the jet and the height of the potential core decrease as the number and size of the fragmentation needles increase. The height and diameter of the nappe crown increase, and the diameter and thickness of the vortex ring decrease as the number and size of the fragmentation needles increase. The jet under the influence of rectangular fragmentation needles is more dispersed compared to the jet under the influence of cylindrical fragmentation needles. The total height and potential core height of the jet are smaller with rectangular fragmentation needles, while the height and diameter of the nappe crown are larger. The air concentration in the nappe under rectangular fragmentation needles is higher than that under cylindrical fragmentation needles, and the energy dissipation rate of the vertical jet is also higher under rectangular fragmentation needles than under cylindrical fragmentation needles. The vertical jet-type energy dissipator proposed in this study addresses key engineering challenges, such as terrain constraints and the need for flexible design solutions. Its ability to efficiently dissipate energy while maintaining adaptability makes it a valuable tool for hydraulic engineers designing energy dissipation systems. The conclusions of this study provide a reference for the application of vertical jet-type energy dissipators.

Similar content being viewed by others

Introduction

The energy dissipation of hydraulic structures is crucial to the overall safety and stability of hydraulic engineering projects1. The energy dissipators in existing hydraulic engineering projects are often arranged on the surfaces of hydraulic structures within the project2. However, they typically dissipate energy by intensifying the aeration of the flow to dissipate energy3, which can sometimes lead to problems such as cavitation and erosion in drainage structures4, and even induce vibration damage to discharge structures5.

Jet flow can be classified into confined space jet flow and unconfined space jet flow based on the proximity to boundaries6,7. According to the classification of jet media, it can be divided into submerged jets and non-submerged jets8. If the Reynolds number of the jet is sufficiently large, it is considered a turbulent jet9. Zhang et al.10found that the dynamic water pressure distribution along the flow direction, generated by submerged jets acting on the bottom plate at different incident angles, exhibits similar distribution characteristics. Guo et al.11conducted a large eddy simulation to study the turbulent flow field of submerged jets, analyzing the intrinsic relationship between the evolution process of the jet flow field and its hydraulic characteristics. They concluded that as the jet moves downward, it is accompanied by phenomena such as deformation, splitting, and merging. Violato et al.12conducted an extensive physical experimental study on submerged jets using 3D-3C PIV, performing proper orthogonal decomposition on the obtained samples to analyze the motion behavior of the potential core and the spatial modes of jet flow. Based on this, they analyzed the evolution of turbulent statistical moments.Li et al.13used numerical simulations and experimental verification methods to study the flow field characteristics of a finite-space annular jets. They concluded that, due to convective effects, the jet induces the formation of recirculating vortex structures in the regions adjacent to the jet.Panda et al.14used proper orthogonal decomposition to study the evolution phenomena such as flow structure generation, precession, and fragmentation of annular jets. They observed the pairing phenomenon of vortex ring structures formed by the jet.Li et al.15used the dynamic subgrid stress large eddy simulation method to study the jet of a jet-type centrifugal pump. They observed the phenomenon where a twisted vortex ring propagates downstream and absorbs the kinetic enegy of the fluid with high velocity. Sader et al.16conducted a study on the large-amplitude flapping of a flow impinging flag using a combination of mathematical theory, scaling analysis, and measurement. The results showed that this vortex-induced vibration occurs by synchronisation of the vortex shedding frequency with the natural resonant frequency of the cylinder (in fluid). Yan17used a combination of experimental research and theoretical analysis to study the vortex structure characteristics of twin-screw propeller jets in confined waterways.They analyzed the evolution characteristics of the vortex structures and explored the mutual interaction between large-scale coherent structures and vortex structures. Hao et al.18used large eddy simulation to study the periodic vortex motion process of synthetic jets. They obtained the generation and evolution mechanism of the vortex interaction between the synthetic jet and the cross flow are studied under different driving parameters. Gui et al.19used Rortex to assess and visualize the rotational motion and structure of the vortex in swirling jets in comparison with other kinds of vortex criteria. They analyzed the vector triangles formed by the Rortex, the non-rotational shear, and the vorticity, and gave mechanical explanations of the effect of the non-rotational shear on the rotation of fluids. Xu et al.20used large eddy simulation to study the inflow forcing effects on the predicted flow and noise results. The results showed that both the vortex-ring forcing and the multi-mode liner instability forcing methods are efficient to damage the azimuthal stability of the large scale ring vortices appeared near nozzle exit. This leads to an accelerated flow transition to turbulent shear-layer, which is the exact state of the flow in realistic nozzles. Kim et al.21used an open-loop wind tunnel composed of an array of 10 × 10 computer fans to study the dynamics of an inverted flag. The results showed that reversing the sheet’s orientation,with the flow impinging on its free-edge, dramatically alters its dynamics.The flapping of the sheet, accompanied by periodic vortex shedding, synchronizes at the deflection maxima. Research on the impact of jet flow on fixed-edge is relatively limited. Marusic et al.22used two-dimensional particle image velocimetry experiments to study high Reynolds number turbulent boundary layers. It is found that the turbulent/non-turbulent interfaces exists across a broader range of wall-normal distance in presence of an adverse pressure gradient, as compared to the zero-pressure gradient case. Joksimović et al.23 used the Improved Instability-Sensitive Reynolds Stress Model (IIS-RSM) method to study the statistical and dynamic flow characteristics in open channels with emerging jet configurations, and obtained the corresponding isocontours of the first and second order turbulence statistics on the central vertical plane.

High-speed water flow can be classified into two types based on the aeration process: self-aeration and forced aeration24,25. J. Exposito et al.26studied the shock velocity using the intensity formula of the radiative shocks. The research results show that continua are not available in the high-speed jet shock region. Assuming that the shape of the continuum remains constant would result in a slight overestimation of the jet velocity due to the underestimation of the flux at higher energies. Peng et al.27 used the Lattice Boltzmann method to simulate the impact of the jet and two jets in the flood discharge process, and the moving interface of the aerated jet and the spatial distribution of the nappe wind are obtained. Xu et al.28,29 tackled the challenge of measuring the shape of the air jet. They proposed using a two-dimensional Gaussian function to represent the inflow distribution after impact of the jet according to the characteristics of air flow collision. Lian et al.30,31 present a numerical method for plane-facade nappe collision modes, considering the characteristics of atomized sources and atomized rainfall fields to predict the characteristics of atomized jet nappes in high dam flood release caused by complicated aerial nappe collisions.

According to the types of energy dissipators32, the research on flow energy dissipation can be divided into traditional underflow energy dissipation, surface flow energy dissipation, ski-jump energy dissipation, bucket energy dissipation, emerging pier energy dissipation( flaring gate pier, T-shaped pier ), surface energy dissipation of the overflow dam33, etc. And, depending on the type of dam, the height conditions of the dam can use a variety of combined energy dissipators34. Ma et al.35,36 conducted a study on stepped spillways using model experiments, analyzing the variation patterns of conventional hydraulic parameters such as flow velocity, Froude number, and energy dissipation rate, as well as three relative hydraulic parameters along the spillway. Jet energy dissipation refers to the process in which, within a certain range, the water flow mixes with the medium, undergoes sudden expansions and contractions, and generates strong turbulence, effectively dissipating energy37,38. Nasrabadi et al.39 used the Flow3D model to study the air entrainment and energy dissipation process on stepped spillway surfaces, discussing the initial air entrainment point, the division of air-entrainment zones, and scale effects related to air entrainment. Zhang et al.40conducted a comprehensive study of the Xiangjiaba Hydroelectric Plant using the 1:100 hydraulic model tests. They demonstrated that using multiple layers of horizontal submerged jets for energy dissipation in the flood discharge process is feasible,and the relevant parameters can meet the design requirements. Liu et al.41presents a kind of jet-swirl cascade internal energy dissipator to solve the energy dissipation problem in the reconstruction of discharge tunnels with diversion tunnels and perform numerical simulation research on its feasibility and effectiveness, and the results showed that this energy dissipator has a good energy dissipation effect. Li et al.42studied two propagation models of pulsating pressure, namely the transient flow model and the seepage model, to investigate the pressure propagation mechanism in the gap. The research results indicate that energy-dissipating water flow can impact downstream hydraulic structures and induce strong vibrations. It is urgent to explore energy dissipation patterns that can isolate energy dissipation structures from hydraulic engineering projects.

Existing engineering studies such as underflow, pick flow, as well as new stepped overflow, flexible overflow ,etc. are often fixed on the surface of the discharge building and rigidly connected with the discharge building. The energy dissipation method can sometimes bring cavitation and erosion to the discharge building and even have the potential to induce vibration damage to the discharge building. Isolating the energy dissipator from the discharge structure is a feasible way to solve the above hazards, especially to solve the vibration damage of the discharge structure. This study develops a novel vertical jet-type energy dissipator by involves adding special boundary conditions (fragmentation needles) at the jet nozzle to disrupt the flow. The fragmentation needles undergo forced vibrations under the effect of the jet43, intensifying the aeration and converting mechanical energy into internal energy, thus dissipating part of the mechanical energy of the flow in the air. Compared to traditional jet energy dissipators, this method offers the advantage of directing upstream water through an energy dissipation pipeline into the vertical jet-type dissipation system, allowing flexible energy dissipator layout without being constrained by the terrain and geological conditions of the project area. This energy dissipation method, as a novel means of isolating energy dissipators from hydraulic engineering projects, serves to supplement and improve existing jet energy dissipation methods. The objective of this study is to investigate the energy dissipation characteristics of this novel vertical jet-type energy dissipator. Numerical simulations of vertical jets under various structural parameters using the RNG k-\(\epsilon\) turbulence model, to provide a theoretical basis for its application. This analysis aimed to compare how the Reynolds number of flows with and without fragmentation needles affects the nappe characteristics of the vertical jet energy dissipator within the flow field. In addition, physical model experiments were conducted to validate the numerical simulation results. Furthermore, the energy dissipation characteristics of the vertical jet energy dissipator under various structural parameters and Reynolds number were analyzed using the vortex motion theory method.

Research methods

Design of structural form and parameters

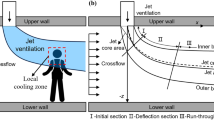

The vertical jet-type energy dissipator is a kind of downstream energy dissipator (Fig. 1), with fragmentation needles installed in the nozzle of the vertical jet pipe (Fig. 2). As a special boundary condition, the structure of the fragmentation needles, including their number, size, and shape, greatly influences the energy dissipation characteristics of the vertical jet energy dissipators. The fragmentation needles’ shapes studied in this paper are cylindrical and rectangular. The ratio of the diameter L of the cylindrical fragmentation needle to the radius R of the vertical jet pipe nozzle, as well as the ratio of the width L of the rectangular fragmentation needle to the radius R of the vertical jet pipe nozzle, are both represented by a unified size parameter m for the fragmentation needles. The number of fragmentation needles is represented by parameter n, the blocking ratio is represented by the parameter O, and the shape of the fragmentation needle is represented by s = A for the cylindrical shape and s = B for the rectangular shape. The relationship between the number, size, and blocking ratio is shown in Table 1.

In Figs. 1 and 2: 1. inlet tower 2. dam 3. energy dissipation pipeline 4. energy dissipation pool 5. bypass pipe 6. vertical jet-type energy dissipation component 7. end of the cylinder diffuser 8. fragmentation needles 9. vertical jet pipe 10.streamlined boundary layer

Physical model experiments

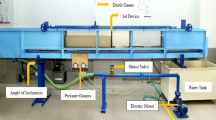

To ensure the precision of the simulation results for the vertical jet energy dissipators, physical model experiments are required for verification. The entire experimental system consists of a water intake tank, centrifugal pump, control valve, electromagnetic flowmeter, vertical jet-type energy dissipation component, fragmentation needle, pressure sensors, energy dissipation pool, open channel, fixings, and fixed inclined supports (Fig. 3). During the experiment, the flow rate is adjusted and measured using the control valve and the electromagnetic flowmeter. The centrifugal pump is used to draw water from the intake tank through the energy dissipation pipeline. The intake tank is equipped with a wave breaking grid to stabilize the water flow on the right side of the tank. The water is ejected from the vertical jet pipe , then the jet falls into the energy dissipation pool. Finally, the water flows through the open channel back to the intake tank, forming a complete cyclic experimental system. The horizontal plane 70 mm from the nozzle in the vertical jet pipe is selected as section \(1\#\), and the horizontal plane in the nozzle is selected as section \(2\#\).

In Figs. 3 and 4: 1.vertical jet-type energy dissipation component 2.pressure sensor 3.fixed inclined supports 4.fixings 5.fixed inclined supports 6.energy dissipation pipeline 7.electromagnetic flowmeter 8.control valve 9.centrifugal pump 10.water intake tank 11.open channel 12.energy dissipation pool 13.screw 14.fragmentation needles 15.vertical jet pipe

The vertical jet pipeline has a height of 300 mm and an internal diameter of 19 mm. The size of the m parameters are 0.1, 0.15, and 0.2, respectively. A small cylindrical hole, located 70 mm from the nozzle on the vertical jet pipe, is used to install the pressure sensor for pressure measurement. The fragmentation needle is installed at the nozzle of the vertical jet pipe and is integrated with the screw connection(Fig. 4). The screw connection is filled with threads for easy disassembly. The number and arrangement of fragmentation needles are set for 6 operating conditions, with needles arranged at equal central angles, as shown in Fig. 5. Within the experimental conditions, the characteristic velocity is the average velocity at the nozzle of the vertical jet pipe (V), and the characteristic length is the diameter (D) of the vertical jet pipe. The Reynolds number (Re) of the jet determined by these parameters ranges from 24,000 to 49,000, indicating that the jet is in a fully developed turbulent state. The experimental jet Reynolds numbers are set for 4 operating conditions: 24,479, 32,638, 40,797, and 48,957. For jets, an equivalent Reynolds number based on local conditions can be defined as \(R_\Delta = \Delta U_{0}/\nu\) where \(U_{0}\) is the excess local velocity (that is, the velocity on the center line \(U_{j}\) minus external velocity \(U_{co}\), \(U_{co}\) = 0.1\(U_{j}\)) and \(\Delta\) is the standard deviation of the mean velocity profile. These definitions are based on measurements of the mean flow.

Numerical calculation

In order to understand the nappe characteristics, numerical simulation methods were used to model the three-dimensional (3D) height of the vertical jets and their aeration properties. Experimental results were used to validate the effectiveness and precision of the RNG k-\(\epsilon\) model in modeling the total height of the jet44. This paper adopts a liquid-gas two-phase flow model. After constructing the mathematical model using SpaceClaim 2022R1 software, the RNG k-\(\epsilon\) (Re-Normalization Group k-\(\epsilon\)) turbulence model and the VOF (Volume of Fluid) model in Fluent 2022R1 are combined for computation under the PISO (Pressure-Implicit with Splitting of Operators) algorithm. For incompressible fluids, it is generally believed that dynamic similarity can be achieved as long as the Reynolds criterion, Froude criterion, and Euler criterion are satisfied at the same time. The vertical jet in this study satisfies the Reynolds criterion, the Froude criterion, and the Euler criterion at the same time. Reynolds number is selected as the parameter used to show the dynamic similarity of these two flows45. The RNG k-\(\epsilon\) model is a turbulence model designed for high Reynolds number flows46.The jet studied in this paper is a high-speed jet with strong anisotropy. To better adapt to the characteristics of the high-speed jet’s strong vortex field, high strain rate, and large stream curvature, the RNG k-\(\epsilon\) turbulence model was used for calculations47. The governing equations are given as follows :

Continuity equation:

Momentum equation:

k equation:

\(\epsilon\) equation:

In the equations, \(\rho\) is the density, \(kg/m^3\); t is the time, s; \(\mu _{t}=\rho \nu _{t}\), \(\mu _{t}\) is the molecular dynamic viscosity coefficient, \(N\cdot s/m^2\); \(\nu _t=C_\mu \frac{k^2}{\varepsilon }\), \(\nu _{t}\) is the turbulent kinematic viscosity coefficient, which can be calculated from the turbulent kinetic energy k and the turbulent dissipation rate \(\epsilon\); \(C_1=1.42-\frac{\eta (1-\eta /\eta _0)}{1+\beta \eta ^3}\), \(\eta =\frac{sk}{\varepsilon }\), \(s=\sqrt{2S_{ij}S_{ij}}\), \(S_{ij}=\frac{1}{2}\left( \frac{\partial u_{i}}{\partial x_{j}}+\frac{\partial u_{j}}{\partial x_{i}}\right)\); turbulent kinetic energy generation term \(G_k=\nu _t\left( \frac{\partial u_{i}}{\partial x_{j}}+\frac{\partial u_{j}}{\partial x_{i}}\right) \frac{\partial u_{i}}{\partial x_{j}}\).The model constants used in the above equations are as follows: \(C_\mu\) is the empirical coefficient, with a value of 0.085; \(\eta _0\) and \(\beta\) are model constants, with values of 4.28 and 0.015, respectively; \(C_2\) is a constant term, with a value of 1.68.

This study will analyze the statistically averaged hydraulic characteristics of the flow field, the characteristics of turbulent structures, especially coherent structures, and their shapes. These analyses often impose certain requirements on the acquisition of flow field samples. These requirements stem from the number of samples, sample size, sample resolution, and sampling time interval48. For the turbulent structures and statistical characteristics of the flow field, to ensure the accuracy of the analyzed data, there are specific requirements for the temporal and spatial scales of the flow field samples obtained through numerical calculations: on the temporal scale, the time interval between two consecutive flow field samples during a single sampling process must satisfy Eq. 5; the spatial resolution of each flow field sample should reach the Taylor microscale as defined in Eq. 6.

In the equations, \(\Delta T_{ref}\) is the reference time interval; \(H_{ref}\) is the reference characteristic length of the flow field; \(U_{ref}\) is the characteristic velocity corresponding to the reference length of the flow field; 1/4 is a coefficient added based on the Shannon sampling theorem (Nyquist sampling theorem) to identify the time process of large-scale turbulent structures;\(\lambda _{Taylor}\) is the Taylor microscale; \(u'\) is the fluctuating velocity; \(\nu\) is the kinematic viscosity of the fluid; and \(\varepsilon\) is the turbulent dissipation rate.

In the flow direction measured from the nozzle, Z is the vertical coordinate, X is the horizontal coordinate ,and Y is the span coordinate. Fig. 6 shows the shear layer’s outer boundary in the instantaneous flow field at a Reynolds number Re = 32638, with a fragmentation needle size of m = 0.15, shape s = B, and number n = 0, displayed on the \(u_x/V\) = 0.1 isosurface. The nappe crown starts at the end of the potential core and diverges along the shear layer toward both sides. The study defines the total height of the jet as the distance between the nozzle outlet and the highest point of the shear layer’s outer boundary. The height of the nappe crown is the distance from the highest point of the potential core along the axis to the highest point of the shear layer. The diameter of the nappe crown is the distance between the outer boundaries of the shear layer on both sides in the lateral direction (Fig. 9). For dimensionless conditions, the spatial scale of the characteristics of the nappe is represented by the ratio of the distance in the Z direction, the distance in the X direction, and the diameter D of the pipe.

The entire model is divided using a structured mesh, with a mesh size of 0.17 D. Local refinement is applied to the fragmentation needle region, where the minimum mesh size is 0.005 D and the maximum mesh size is 0.01 D. During the numerical simulation, a velocity inlet is applied below the vertical jet pipe, while the upper part of the vertical jet pipe is set to atmospheric pressure. The outlet boundary is the pressure outlet, and the wall boundary is the no-slip wall.

To verify the correctness of the selected mesh size, a mesh independence test was conducted. Polyhedral structured meshes with \(\Delta\)Z/D values of 0.08, 0.17, 0.34, 0.67, and 1.35 were used to analyze the energy dissipation pool. Fig. 7 shows the dimensionless jet height for five mesh sizes at a Reynolds number of 32,638, without fragmentation needle arrangement. The analysis shows that the total height of the jet varies with different mesh sizes. As the mesh size increases, the total height of the jet gradually increases. The total height of the jet stabilizes at dimensionless mesh sizes of 0.08 and 0.17, with a relative error of 0.68%. It can be concluded that a further reduction in the mesh size had little effect on improving the simulation accuracy. In addition, the computational time increases significantly when the dimensionless mesh size is reduced from 0.17 to 0.08. Therefore, a polyhedral mesh with a mesh size of 0.17 D was used for the simulation.

Simulation results validation

The precision of the numerical simulation for the total height of the jet is verified using statistical indicators, including the coefficient of determination (\(R^2\)) with relative error49,50. The calculation method for \(R^2\) is as follows:

In the formula, N represents the data quantity; \(P_i\) represents the simulated value; \(\overline{P}\) represents the average of the simulated value; \(O_i\) represents the test value; and \(\overline{O}\) represents the average of the test value. When \(R^2>0.7\), the simulation result is considered to have a high reliability, and the closer \(R^2\) to 1, the higher the reliability of the result.

The experimental conditions include combinations of the number of fragmentation needles n = 0, 2, 3, 4, 5, 6, with the fragmentation needle size of m = 0.1, 0.15, 0.2, and the shapes of s = A, s = B. These are used to verify the numerical simulation of the total jet height of the vertical jet energy dissipator. The averaged values of the relative errors are shown in Table 2. Figure 8 shows the comparison involving simulated total height of the jet and the experimental values for the vertical jet energy dissipator for dimensionless conditions. Both the simulated and experimental values decrease as the Reynolds number increases. As the number and size of the fragmentation needles increase, the total height of the jet also gradually decreases. The total jet height is smaller under the effect of the rectangular fragmentation needles. Moreover, the total height of the simulated and experimental jet for each experimental condition is very close, with the correlation coefficient \(R^2\) ranging from 0.99 to 1.00 and the maximum relative error being 7.80%, indicating that it is feasible to use Fluent software to simulate the total height of the jet energy dissipator.

The flow field samples obtained by numerical calculation are often given by velocity vectors, which means that they have the dimension of [L]/[T]. However, a second-order velocity correlation is often required for the statistical analysis of turbulence, and its dimension is \([L]^2/[T]^2\). Therefore, it is necessary to ensure that the deviation between the accuracy of second-order statistics such as velocity correlation and the actual flow field is less than 5%.In this research, the error sources were divided into three types: the first type of error was mainly caused by the grid sensitivity error \(E_1\), the second type of error was mainly caused by the global parameter sensitivity error \(E_2\), the third type of error was mainly caused by the statistical error \(E_3\), the fourth type of error was mainly caused by the parameter interaction effect error \(E_4\), the fifth type of error was mainly caused by the systematic error \(E_5\), while the third type of error was mainly caused by the random uncertainty error \(E_6\).

The relative errors were regarded as mutually independent errors. Then, the total relative error was calculated using Eq. 8. The total relative error was 1.04%, less than 5%, and the uncertainty of the experimental results can be adopted.

Results

Nappe characteristics

During flow development, rotational flows occur mainly in two regions, namely, the shearing region and the swirling region. In the shearing region, two layers of non-rotational fluid flow in parallel, while in the swirling region, vortex structures cause development of the flow in a third direction. Jeong and Hussain51 proposed the \(\lambda _2\) criterion to distinguish between the shearing region and the swirling region.

Instantaneous distribution contour maps of \(\lambda _2\) and \(u_x\) on the cross-section (Y/D = 0) of the vertical jet in the span direction: (a) Instantaneous distribution contour map of \(\lambda _2\) when n = 0; (b) Distribution contour map of \(u_x\) when n = 0; (c) Instantaneous distribution contour map of \(\lambda _2\) when n = 2; (d) Distribution contour map of \(u_x\) when n = 2.

In the swirling region, \(\lambda _2<0\) and there are vortex cores, while in the shearing region \(\lambda _2>0\). To investigate the impact of adding fragmentation needles on nappe characteristics, a Reynolds number Re = 32638 needle size m = 0.15, shape s = B, and number of needles n = 0 and n = 2 were selected for the analysis of the jet shearing region and swirling region. Figure 9 shows the distribution of the shearing region and swirling region in the plane of the span section (Y/D = 0) using \(\lambda _2\) and \(u_x\). Figure 9a and c are instantaneous distribution maps of \(\lambda _2\), calculated from the three-dimensional flow field data at t = 207 D/V, when the flow field has fully developed. Figure S1 is the Reynolds shear stress \(\tau _{xz}\) at m = 0.15, Fig. S2 is the turbulence statistical results of velocity field. Figure S3 is the profiles of the normal Reynolds stress intensity components in the central (y = 0) vertical x-z plane. In Fig. 9a and c, the potential core and the surrounding environment are in the shearing region, and two distinct interfaces between shearing and swirling regions are observed. As shown in Fig. 9a , Shearing regions are Region1, and swirling regions are Region2, the envelope of \(u_x/V\in [0.95,1]\) is Region 1, which is located from the nozzle to the point where the flow changes (at Z/D = 4.42), and the end is enclosed by the swirling region on both sides that wraps around the center. The envelope of \(u_x/V\in [0.1,0.95]\) is Region 2, which is located on the outside of the jet and diverges laterally along the flow direction. Downstream at Z/D\(\ge\)6.00, a local swirling region detached from the main flow appears, reflecting the phenomenon of vortex stretching and mixing between the main flow and the surrounding fluid. In Fig. 9a–d, the dashed lines represent the contours of the average velocity \(u_x/V=0.95\) and \(u_x/V=0.1\). It can be seen that the contours of the average velocity can effectively distinguish the average positions of the shearing region and the swirling region. Therefore, in this paper, the contour lines of \(u_x/V=0.95\) and \(u_x/V=0.1\) are used to represent the boundaries of the potential core and the shear layer, respectively.

After the jets are ejected from the nozzles, the flow field exhibits a partitioned structure under the influence of the fragmentation needles, consisting of junction region and multijet region (Fig. 9c). After the two jets are ejected from the nozzles, there is an interaction between them, leading to an adsorption effect (Coanna effect). Due to the jets’ ability to entrain surrounding air, when no fragmentation needles are added, the jet at the nozzle can fully entrain air. However, after the addition of fragmentation needles, the aeration of the jet in the nozzle is limited. In the region between adjacent water jets, the entrained air is not replenished, causing the jets to attract each other and form the junction region.As more air is entrained, the jets begin to separate again, forming the multijet region.

After the fragmentation needle is arranged in the nozzle of the vertical jet pipe, the motion of the jet tongue can be divided into two stages: The first stage is the movement of the jet from the vertical pipe nozzle to the highest point of jet nappe. During this process, the jet tongue is fragmented by the fragmentation needle into multiple jet tongues, and at the same time, the direction of the motion of the jet nappe is changed, causing it to move to the highest point at a certain angle to the horizontal plane. The second stage is the fall of the jet nappe from the highest point into the water cushion energy dissipation pool. In this stage, the jet nappe performs projectile motion with a certain initial velocity at the highest point, and under the influence of air resistance, it further splits into jet water beams or shatters into water droplets, performing free fall and landing in the water cushion energy dissipation pool. The characteristics of jet nappe are analyzed for Reynolds number Re = 32638 and fragmentation needle numbers n = 0, n = 2, n = 3, n = 4, n = 5, and n = 6. The results of the characteristics of jet nappe are shown in Figs. 10, 11, and 12. From the figures, it can be observed that: Under the influence of no fragmentation needles, the potential core height is 4.42 D, the height of the nappe crown is 1.74 D, and the maximum diameter of the water nappe crown is 1.26 D. When fragmentation needles are present, the potential core height ranges from 0.007 D to 2.80 D, the height of the nappe crown ranges from 2.08 D to 2.50 D, and the maximum diameter of the nappe crown ranges from 2.20 D to 7.40 D. The spatial scale of the nappe crown is greatly influenced by the number, size, shape of the fragmentation needles, and Reynolds number. Compared to cylindrical fragmentation needles, under the same fragmentation needle size and Reynolds number, the potential core height is smaller. As the size and number of fragmentation needles increase, the potential core height gradually decreases, while the height and diameter of the nappe crown gradually increase. This is because the increase in the number of fragmentation needles also reduces the cross-sectional area of the jet nozzle, thereby increasing the initial velocity of the jet, causing the height of the nappe crown to increase with the number of fragmentation needles. The flow near the end of the potential core breaks into numerous small-scale fluctuating vortex structures, located near the interface between the shearing flow and the swirling flow, further indicating that it may dominate the vertical development and horizontal mixing and entrainment phenomena of the nappe crown. For high Reynolds number jets, the trend of vertical development is greater than the trends of horizontal mixing and entrainment, guiding the flow to develop vertically. The increase in fragmentation needle size and number intensifies the horizontal and vertical mixing and entrainment phenomena. Compared to the condition without fragmentation needles, after adding fragmentation needles, the height of the nappe crown increases, and the corresponding size of the swirling zone also increases; the potential core height decreases, and the corresponding size of the shearing region also decreases. Therefore, it can be inferred that, under the same other conditions, fragmentation needles “break” part of the jet’s shearing region into swirling region, and the total height of the jet decreases. This transformation will, to some extent, affect the transport of fluid in that region and dissipate the mechanical energy of the jet.

Multiscale vortices were induced by the velocity gradient that existed for shearing phenomena52, these larger-scale coherent structures are normally considered as key factors of turbulence type and turbulence distribution.53 The spatial scale of the coherent structure was represented by the relationship between the distance in the Z direction and the diameter of pipeline D for dimensionless conditions.54Hunt et al.55proposed to define the region of Q>0 as vortexes.

This means that \(\Vert \Omega \Vert ^{2}>\Vert E\Vert ^{2}\), that is, the irrotational deformation is small compared to the vorticity. For instantaneous flow, the isosurface56 of \(Q=0.1[V^2/D^2]\) at time t=120 is shown in Fig. 13. They show large-scale coherent vortices in the cross section. The free shear layer is a typical form of vortex, and its simplified model in inviscid flow is the surface vortex. The formation of a vortex ring is a surface vortex dynamics problem. Its steady state involves the existence problem and its deformation motion involves the stability problem. It plays an important role in the transport and mixing of fluids and vortex interaction.

The thickness of a vortex ring can be defined based on the vorticity distribution within the ring. Q is a measure of the local rotation of the fluid, and the vortex ring’s thickness corresponds to the region where Q is concentrated.

Mathematical Definition: The thickness (\(d_v\)) can be defined as the radial distance between the points where the \(Q=0.1[V^2/D^2]\).

Where,\(d_\textrm{outer}\)is the radial position where the Q drops to the specified fraction on the outer side of the ring. \(d_\textrm{inner}\)is the radial position where the Q drops to the specified fraction on the inner side of the ring.

As shown in Fig. 9d, the position where the flow at the end of the potential flow core changes is Z/D = 2.52. The vortex ring located in the transverse section Z/D = 2.52 is selected for analysis. When Reynolds number Re = 32638, the thickness of the vortex ring T and the diameter of the vortex ring \(d_v\) under different sizes, and numbers of the fragmentation needle are shown in Figs. 14 and 15. Without the influence of the fragmentation needle, the thickness of the vortex ring is 1.00 D, and the diameter of the vortex ring is 2.00 D ; when there are fragmentation needles, the thickness of the vortex ring is between 0.001 D and 0.25 D, and the diameter of the vortex ring is between 0.01 D and 1.13 D. The spatial scale of the vortex ring is greatly affected by the number, size, shape, and Reynolds number of the fragmentation needles. Under the same flow conditions, the characteristic length of the coherent vortex decreases significantly with increasing size and number of fragmentation needles. The diameter of the vortex ring decreases from 2.00 D to 0.01 D horizontally, with a reduction rate of about 99.97%. The thickness of the vortex ring decreases from 1.00 D to 0.001 D vertically, with a reduction rate of about 99.80%. As a geometric description of the vorticity field, the vortex tube should always be a closed vortex ring in three-dimensional space, so that the total integral of the vorticity in space is zero in all directions. When there is a solid surface, the whole space can be treated as a fluid-solid coupling kinematic system. According to the unified fluid-solid system, the vortex tube cannot terminate on the solid wall or the free surface. When the solid wall is stationary, the vortex tube continues to extend along the boundary surface and the cross section of the vortex tube expands in a horn shape along the surface. These vortex structures will produce a damping effect in the flow direction. This damping effect originates from the fluid transport generated by the circumferential rotation of the vortex ring in the vertical direction. It can be inferred that under the same conditions, the relative size of the damping effect will affect the transport of the fluid to a certain extent, and then change the pressure in the region, and dissipate the mechanical energy of the flow-induced vibration when the jet impacts the fragmentation needle.

When Reynolds number Re = 32638, the equivalent Reynolds number based on local conditions \(R_\Delta\) under different sizes, numbers and shapes of the fragmentation needle are shown in Fig. 16. Without the influence of the fragmentation needle, the equivalent Reynolds number based on local conditions \(R_\Delta\) = 772,782; when there are fragmentation needles, the equivalent Reynolds number based on local conditions \(R_\Delta\) is between 1,159,173 and 4,369,992. the equivalent Reynolds number based on local conditions \(R_\Delta\) is greatly affected by the number, size, shape, and Reynolds number of the fragmentation needles. Under the same flow conditions, the equivalent Reynolds number based on local conditions \(R_\Delta\) increases significantly with increasing size and number of fragmentation needles. Compared with the cylindrical fragmentation needle, the equivalent Reynolds number based on local conditions \(R_\Delta\) under the action of the rectangular fragmentation needle are smaller under the same size, number and Reynolds number.

Vertical jet energy dissipation rate

In this study, vertical jet energy dissipation refers to the energy loss of the jet in the air after the jet is ejected from the vertical jet pipe. Therefore, the energy dissipation rate \(\eta\) is calculated using the energy difference between section \(1\#\) and section \(2\#\) (Fig. 3) and the energy ratio of section \(1\#\). The formula is as follows:

In the formula, \(\eta _1\) is the vertical jet energy dissipation rate, \(E_1\) is the total energy in the vertical jet pipe of section 1#, \(E_2\) is the total energy of section 2#, \(z_1\) and \(z_2\) are the position heads, that is, the height from the datum plane, \(p_1\) and \(p_2\) are the pressures at the two sections, \(v_1\) and \(v_2\) are the average flow velocities at the two sections, and \(\alpha\) is the flow velocity coefficient, which is generally taken as 1.

In this study, the ratio of the vertical jet energy dissipation rate under the influence of the fragmentation needle to the vertical jet energy dissipation rate without the influence of the fragmentation needle is defined as the vertical jet energy dissipation rate increase ratio r. Figure 17 is the vertical jet energy dissipation rate under different working conditions. Figure 18 is the vertical jet energy dissipation rate increase ratio under different working conditions. It can be seen from the figure:

Under the influence of no fragmentation needle, the vertical jet energy dissipation rate range is between 14.55 and 18.33%. When there are fragmentation needles, the vertical jet energy dissipation rate range is between 15.18 and 89.55%, and the increase ratio of the vertical jet energy dissipation rate ranges from 1.04 to 4.89, and is significantly influenced by the number, size, shape, and Reynolds number of fragmentation needles. When the design of the fragmentation needle is the same, the vertical jet energy dissipation rate is basically positively correlated with the Reynolds number; that is, the vertical jet energy dissipation rate increases with the increase of the Reynolds number. This is because as the Reynolds number increases, the vertical range of the jet increases, the contact surface between the jet and the air increases, and the jet aeration concentration increases, thereby increasing the vertical jet energy dissipation rate.

The dissipation rate under the action of the rectangular fragmentation needle is between 17.94 and 89.55%, the range of the vertical jet energy dissipation rate under the action of the cylindrical fragmentation needle is between 15.18 and 78.54%, the range of the vertical jet energy dissipation rate under the action of the rectangular fragmentation needle is between 1.23 and 4.89, and the range of the vertical jet energy dissipation rate under the action of the cylindrical fragmentation needle is between 1.04 and 4.29. The vertical jet energy dissipation rate under the action of the rectangular fragmentation needle is 1.27–21.80% higher than that under the action of the cylindrical fragmentation needle, and the vertical jet energy dissipation rate is increased by 0.06–1.36. This is because when the jet nappe crown is cut, the area of the jet nappe cut by the rectangular fragmentation needle is larger, which increases the contact friction surface between the jet nappe and the air, so the vertical jet energy dissipation rate is higher. Similarly, when the Reynolds number and the shape and number of the fragmentation needles are the same, the vertical jet energy dissipation rate increases with the increase of the fragmentation needle size.

When the Reynolds number is the same as the shape and size of the fragmentation needle, the vertical jet energy dissipation rate increases with the increase in the number of fragmentation needles. For each additional fragmentation needle of the same shape, the vertical jet energy dissipation rate increases between 1.69 and 21.23%. With an increase in the number of fragmentation needles, the vertical jet energy dissipation rate increases. The larger the ratio, the vertical jet energy dissipation rate increase ratio is between 0.11 and 1.16. This is because as the number of fragmentation needles increases, the number of broken jet nappe increases, the volume ratio of each jet nappe crown decreases, and the contact friction surface with the air increases, thus increasing the vertical jet energy dissipation rate. To clearly highlight the contributions, a table comparing key performance metrics with literature values can be included. The comparison results with the literature are shown in the Table 3

Energy consumption mechanism analysis

The vertical jet energy dissipation is to divide the high-velocity and large-flow water flow into multiple jets along the vertical direction and inject them upward. When the jet is ejected, a special boundary condition (fragmentation needle) is added at its outlet to break the jet nappe, and the jet with higher energy is divided into multiple jet nappe, so as to achieve the purpose of dispersing the water jet and making the jet nappe fully aerated. With the split and break of the jet nappe crown, the contact area between the jet nappe and the air is also increasing. The aeration of the jet nappe is also becoming more and more sufficient. The mixing of a large amount of air into the jet nappe will increase its contact friction surface with the air, so that part of the mechanical energy is converted into heat energy and consumed. The energy of the jet nappe is reduced, and the aeration energy dissipation is realized.

The numerical simulation method is used to simulate the three-dimensional (3 D) aeration characteristics of the vertical jet. The C(x,z) air concentration profile is cut and measured. The vertical spacing between individual profiles is constant at Z = 0.5 D, and the spacing of the sampling points along the coordinate x is about \(0.01 D\sim 0.03 D\). The left (subscript L) and right (subscript R) jet trajectories \(X_L(z)\) and \(X_R(z)\) are defined according to the outer boundary of the shear layer57, similar to the isoline of the average velocity \(u_x/V=0.1\). M. Pfister and S. Schwindt used the definition of the average air concentration in the vertical position in the self-mixing airflow to define58, and proposed the eigenvalue59 that determines the complete distribution of the air concentration of the jet. This eigenvalue is the average air concentration of each jet cross section (subscript a), which is the result of the integral of C(z) divided by the diameter d of the nappe crown60. The calculation method of \(C_a\) is as follows:

Effect of fragmentation structure size and Reynolds number on jet air concentration

When the size of the fragmentation needle m = 0.1, m = 0.15 and m = 0.2, and the number of fragmentation needles n = 2, the change of the air concentration of the jet nappe is analyzed. The curve of variation of the horizontal average air concentration of the jet along the vertical direction is shown in Fig. 19. It can be seen from the figure that:

Change in jet nappe air concentration when the size of the cylinder fragmentation needle is m = 0.1: the range of characteristic value \(C_a\) under the action of the cylindrical fragmentation needle is between 0.0012 and 0.6795. The Reynolds number Re increases from 24,479 to 32,638, and the eigenvalue \(C_a\) increases from 2.93 to 58.54%. The Reynolds number Re increases from 32,638 to 40,797, and the eigenvalue \(C_a\) increases from 5.53 to 61.34%. The Reynolds number Re increases from 32638 to 40797, and the eigenvalue \(C_a\) increases from 17.69 to 89.92 %. With an increase in Reynolds number, the jet nappe gradually decreases along the vertical unaerated area, and the air concentration in the entire area is increasing. When Reynolds number Re = 48957, the jet nappe is basically doped with air. This is because increasing the jet Reynolds number enhances the fragmentation effect of the jet impinging on the fragmentation needle61, so that the water flow is doped with more gas, so the jet nappe air concentration is greater.

Change in jet nappe air concentration when the size of the rectangular fragmentation needle is m = 0.1 : the range of characteristic value \(C_a\) under the action of the rectangular fragmentation needle is between 0.0067 and 0.691. The characteristic value \(C_a\) under the action of the rectangular fragmentation needle is 0.02–93.04% higher than that under the action of the cylindrical fragmentation needle. This is due to the larger area of the jet nappe cut by the rectangular fragmentation needle, so the air concentration involved in the jet nappe increases and the aeration of the jet nappe becomes more and more sufficient. Therefore, under the same conditions, the jet nappe air concentration of the rectangular fragmentation needle is higher. Under the influence of the rectangular fragmentation needle, the whole area of the jet nozzle is basically doped with air. The Reynolds number Re increases from 24,479 to 32,638, and the eigenvalue \(C_a\) increases from 0.88 to 56.77%. The Reynolds number Re increases from 32,638 to 40.797, and the eigenvalue \(C_a\) increases from 0.06 to 69.45%. The Reynolds number Re increases from 32,638 to 40,797, and the eigenvalue \(C_a\) increases from 4.27 to 54.35%. The trend of vertical development of high Reynolds number jet is greater than that of horizontal mixing and entrainment. The higher jet velocity enhances the impact effect of the potential core. With an increase in jet Reynolds number, the conversion efficiency from horizontal velocity to vertical velocity becomes more obvious. The fragmentation caused by the impact of water flow intensifies, resulting in a larger proportion of water converted into a liquid film, line, or droplet that diffuses outward. The flow cluster at the impact point is stretched vertically by a larger vertical velocity, and the air concentration of the two jet nappes is also gradually increasing. When Reynolds number Re = 48957, the aeration of the jet nappe crown is very sufficient.

When m = 0.15, n = 2, the range of the eigenvalue \(C_a\) under the action of the cylindrical fragmentation needle is between 0.04 and 0.71, and the range of the eigenvalue \(C_a\) under the action of the rectangular fragmentation needle is between 0.042 and 0.767. The eigenvalue \(C_a\) under the action of the rectangular fragmentation needle is 6.11–60.12% higher than that under the action of the cylindrical fragmentation needle. The Reynolds number Re increases from 24,479 to 32,638, the eigenvalue \(C_a\) increases from 10 to 75.56%, the Reynolds number Re increases from 32,638 to 40,797, the eigenvalue \(C_a\) increases from 8.92 to 61.82%, the Reynolds number Re increases from 32,638 to 40,797, and the eigenvalue \(C_a\) increases from 5.6 to 28.86%. As the Reynolds number increases, the total height of the jet gradually increases, and the average air concentration of the jet cross section gradually increases. The reason is that, at a lower Reynolds number, the conversion of the mechanical energy of water flow to the internal energy is not sufficient, resulting in the vertical kinetic energy still being interfered with after conversion. Therefore, the height at which the impinging stream is lifted is limited and most of the flow in the shear layer is fragmented and decomposed due to gravity. This leads to the formation of an almost zero velocity region at the top of the water nappe crown. With an increase in Reynolds number, although the volume of water in the central water column increases, the increase of air volume in the surrounding shear layer is more significant. The water flow flows directly to the top of the water nappe crown, resulting in fragmentation and obvious eddy current and horizontal velocity, which aggravates aeration.

When the size of the fragmentation needle is m = 0.2, the variation law of the air concentration of the jet nappe is basically the same as that when m = 0.1 and m = 0.15. When m = 0.2, n = 2, the range of the eigenvalue \(C_a\) under the action of the cylindrical fragmentation needle is between 0.06 and 0.75, and the range of the eigenvalue \(C_a\) under the action of the rectangular fragmentation needle is between 0.08 and 0.80. The eigenvalue \(C_a\) under the action of the rectangular fragmentation needle is 3.33–34.72% higher than that under the action of the cylindrical fragmentation needle. The Reynolds number Re increases from 24,479 to 32,638, the eigenvalue \(C_a\) increases from 2.81 to 66.17%, the Reynolds number Re increases from 32,638 to 40,797, the eigenvalue \(C_a\) increases from 2.22 to 20.75%, the Reynolds number Re increases from 32,638 to 40,797, and the eigenvalue \(C_a\) increases from 4.5 to 31.16%. At the center of the jet impinging on the crushing needle, the increase in the jet Reynolds number enhances the vertical velocity gradient, thereby increasing the shear force, and the collision effect leads to the turbulent energy cascade. Through the non-linear interaction of scale locality and non-locality (large scale), the energy is transferred from large scale to small scale62. The scale locality and nonlocality, respectively, mean that the energy cascade is completed by the non-linear effect of adjacent or non-adjacent wavenumber perturbations63, which significantly amplifies the turbulent kinetic energy and its dispersion range in the center, resulting in a significant change in turbulent aeration along the jet path. It can be inferred that under the same conditions, the influence of the Reynolds number on the characteristic value \(C_a\) proves the effectiveness of mixing and mass transfer caused by impact to a certain extent, and emphasizes the key role of the Reynolds number of the jet in the change of turbulent energy.

When the Reynolds number is the same as the shape and number of the fragmentation needle, when the size of the fragmentation needle is different(that is, changing the blockage ratio of the flow around), the variation of the air concentration of the flow field under different blockage ratios is obtained. The size of the fragmentation needle m increases from 0.1 to 0.15, the eigenvalue \(C_a\) increases from 0.34 to 97%, the size of the fragmentation needle m increases from 0.15 to 0.2, and the eigenvalue \(C_a\) increases from 0.05 to 87.35%. The air concentration of the jet nappe crown increases with increasing fragmentation needle size, and the turbulence phenomenon increases with increasing blocking ratio64. In the interaction between the jet flow field and the fragmentation needle, the degree of aeration is not only affected by the obstacle itself : the fluid separation occurs at the anchorage of the fragmentation needle and the jet port, so a vortex is formed on the wall of the fragmentation needle. It is also affected by the wake flow generated by the flow field around the obstacle : the vortex formed at the rest of the fragmentation needle is basically fixed, and the change is not large. Only the vortex formed at the anchorage of the jet port will appear similar to the vortex shedding phenomenon around the cylinder, showing an unstable state. The flow around the fragmentation needle will affect the entire downstream area. When flowing through the fragmentation needle, the density and velocity of the compressible fluid in a certain area on both sides of the fragmentation needle are greater than in other areas of the flow field. It can be inferred that under the same conditions, the influence of the size of the fragmentation needle on the characteristic value \(C_a\) proves to some extent that the average air concentration of the jet cross section is related to complex physical factors such as fluid separation, vortex shedding and large eddy structure. The larger the size of the fragmentation needle, the more complex the flow field behind the fragmentation needle.

Analysis of the influence of the number of fragmentation structures on jet air concentration

The Reynolds number Re = 32638, the size of the fragmentation needle m = 0.15, and the number of fragmentation needles n = 0, n = 2, n = 3, n = 4, n = 5 and n = 6 are selected. The change in air jet nappe air concentration is shown in Fig. 20:

Under the influence of no fragmentation needle, the range of characteristic value \(C_a\) is between 0.0044 and 0.3516. When there are fragmentation needles, the range of characteristic value \(C_a\) is between 0.046 and 0.8832. Under the influence of no fragmentation needle, the interior of the jet nappe is basically unaerated. When the Reynolds number and the size of the fragmentation needle are the same, with the increase of the number of fragmentation needles, the unaerated area inside the jet water nappe gradually decreases until the whole jet water nappe is aerated. The volume fraction of water on the surface of the jet nappe gradually decreases, and the air concentration in the whole area is increasing. For each additional fragmentation needle of the same shape, the eigenvalue \(C_a\) increases from 5.09 to 93.81%. Obviously, the more fragmentation needles are arranged, the stronger the entrainment and mixing between the jets, the better the energy dissipation effect. The mixing degree and mixing distance of the jets change with the number of fragmentation needles, and the mixing degree of the intersection of multiple jets gradually increases with the increase of the number of fragmentation needles, until there is no mixing between each other and each maintains the flow characteristics of a single jet, and the corresponding dimensionless vertical distance of mixing will gradually increase. When the number of fragmentation needles is n = 6, the outside and inside of the jet nozzle are basically doped with air. This is because at the nozzle of the vertical pipe, with the increase of the number of fragmentation needles, the number of fragmentation needles breaking the jet nappe increases, and multiple jets undergo deformation, collision, fragmentation and other processes in the air, thereby dispersing the momentum of the jet and enhancing the heat and mass transfer of the jet65, the contact area between the jet water and the surrounding air increases greatly, and the entrainment and mixing between each other form multiple strong shear energy dissipation region, using the mutual adsorption between multiple jets and the strong entrainment and mixing with the surrounding ambient air to consume a large amount of residual energy in the pipeline water delivery process, so that the jet energy decays rapidly not far from the jet port. The inner rolling region consumes the rest of the energy. It can be inferred that under the same conditions, the influence of the number of fragmentation needles on the characteristic value \(C_a\) proves to a certain extent that the dispersion degree of the jet momentum and the mutual adsorption effect (Coanna effect) between the jets are the key to determine the energy dissipation effect. When there is no fragmentation needle, the rain curtain falling into the water cushion pool is concentrated, and the impact on the water cushion pool is large ; when there are a large number of fragmentation needles, the rain curtain falling into the water cushion pool is scattered, and the impact on the water cushion pool is small, which is conducive to the safety of the project.

When Re,size and number of fragmentation needles are the same, the range of the eigenvalue \(C_a\) under the action of the cylindrical fragmentation needle is between 0.0044 and 0.873, and the range of the eigenvalue \(C_a\) under the action of the rectangular fragmentation needle is between 0.0044 and 0.8832. The eigenvalue \(C_a\) under the action of the rectangular fragmentation needle is 2.34–60.12% higher than that under the action of the cylindrical fragmentation needle. The total air concentration of the jet nappe formed by the rectangular fragmentation needle is greater than the total air concentration of the jet nappe formed by the cylindrical fragmentation needle. For a fixed point of the same height along the three-dimensional jet nappe, the air concentration of the jet nappe under the rectangular fragmentation needle is higher than that under the cylindrical fragmentation needle. This is because compared to the cylindrical fragmentation needle, the surface of the cuboid crushing needle is not smooth and there are four sharp corners at the anchorage of the jet port. The boundary layer is separated at its two front corners. When the fluid is separated from the front corner of the rectangular fragmentation needle and produces alternately shedding vortices, a vortex structure is generated above and below the rectangular fragmentation needle, which is the recirculation region66 under the reverse pressure gradient. At the same time, the aeration of the jet nappe is becoming more and more sufficient. It can be inferred that under the same conditions, the influence of the shape of the fragmentation needle on the characteristic value \(C_a\) proves to some extent that the shedding mode of the vortex behind the rectangular fragmentation needle has different ways. In addition to the recirculation region behind the rectangular fragmentation needle, the vortex structure will be formed on the upper and lower sides of the rectangular fragmentation needle.

The achievements of this study in the design of energy dissipator and the optimization of turbulence model highlight its theoretical and application innovation by comparing with the existing literature. The turbulence model is compared in detail as follows:

Literature comparison: Deng et al.1 used the standard k-\(\epsilon\) model to simulate the flow of spillway tunnel, and the predicted value of energy dissipation rate was 78 ± 3%, but failed to accurately capture the separation vortex structure (error > 10%). Chen et al.2 used the LES model, although it performed well in vortex resolution (error)< 5% ), but the computational cost is about 8 times higher than that of the k-\(\epsilon\) model.The profiles of the averaged streamwise velocity is shown in Fig. 21.The experimental data of Bradbury67, Gutmark 68and Rampaprian 69 are also shown

This study improved: the RNG k-\(\epsilon\) model is introduced and combined with the \(\lambda _2\) criterion threshold screening ( \(\lambda _2<\) 0 ). While ensuring the computational efficiency (the time consumption is reduced by 70% compared with LES), the prediction accuracy of the energy dissipation rate is improved to 92%, and the separation vortex shape error is reduced to 5%, which is significantly better than the literature.

In this study, by introducing the broken needle structure and the advanced turbulence model (RNG k-\(\epsilon\)), combined with the vortex energy dissipation analysis (\(\lambda _2\) criterion threshold \(\lambda _2<0\)),the following quantitative results are achieved:

Compared with the traditional energy dissipater, the arrangement of the fragmentation needle makes the energy dissipation rate increase from 75 to 89.55%, and the local turbulent kinetic energy dissipation rate increased by 40%.

Conclusions

By comparing the results with the literature, this study demonstrates significant advancements in both theoretical understanding and practical applications of energy dissipators. The introduction of fragmentation needles, combined with advanced turbulence modeling and vortex analysis, sets a new standard for energy dissipation efficiency and design flexibility. These contributions not only fill critical knowledge gaps but also provide valuable insights for future research and engineering applications in hydraulic structures.

-

Under the same flow rate and size of the fragmentation needle, the rectangular fragmentation needle is more dispersed than the cylindrical fragmentation needle. The total height of the jet and the potential core height of the flow are smaller than those under the action of the cylindrical fragmentation needle. The diameter and height of the nappe crown are larger than those under the action of the cylindrical fragmentation needle. The total air concentration of the jet nappe formed by the rectangular fragmentation needle is larger and the overall air concentration of the jet nappe formed by the cylindrical fragmentation needle is smaller.

-

This study investigates the energy dissipation characteristics of a new vertical jet-type energy dissipator using the RNG k-\(\epsilon\) turbulence model, validated through physical experiments. The introduction of fragmentation needles at the jet nozzle induces forced vibrations, enhancing aeration and turbulence, and providing new insights into the mechanical-to-internal energy conversion process. The simulation results show that fragmentation needles significantly enhance jet breakup and aeration. Compared to traditional energy dissipators in the literature, the energy dissipation efficiency of this design is improved by 9.55% . This improvement is mainly attributed to the forced vibrations and enhanced turbulence induced by the fragmentation needles, which is consistent with the findings of Khoshmanesh et al70.

-

Under the flow conditions studied in this paper, the vertical jet energy dissipation rate under the influence of the fragmentation needle is greater than the vertical jet energy dissipation rate without the influence of the fragmentation needle and has better energy dissipation characteristics, indicating that the arrangement of the fragmentation needle at the nozzle of the vertical pipe can effectively improve the vertical jet energy dissipation effect and reduce the impact of the jet on the water cushion energy dissipation pool71.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Abbreviations

- 3D :

-

Three-dimensional

- 3D-3C PIV :

-

Three-dimensional three-component particle image velocimetry

- IIS-RSM:

-

Improved instability-sensitive Reynolds stress model

- RNG k-\(\epsilon\) :

-

Re-normalization group k-\(\epsilon\)

- VOF:

-

Volume of fluid

- PISO:

-

Pressure-implicit with splitting of operators

- R:

-

Radius of the vertical jet pipe nozzle

- L:

-

Diameter of the cylindrical as well as width of the rectangular fragmentation needle

- m:

-

Ratio of the diameter L to the radius R as well as ratio of the width L to the radius R

- n:

-

Number of fragmentation needles

- O:

-

Blocking ratio

- s:

-

Shape of the fragmentation needle

- A:

-

Shape of the fragmentation needle is the cylindrical shape

- B:

-

Shape of the fragmentation needle is the rectangular shape

- V:

-

Average velocity at the nozzle of the vertical jet pipe

- D:

-

Diameter of the vertical jet pipe

- Re:

-

Reynolds number

- \(R_\Delta\) :

-

Equivalent Reynolds number

- \(U_{0}\) :

-

Excess local velocity

- \(U_{j}\) :

-

Velocity on the center line

- \(U_{co}\) :

-

External velocity

- \(\Delta\) :

-

Standard deviation of the mean velocity profile

- \(\rho\) :

-

Density

- t:

-

Time

- \(\mu _{t}\) :

-

Molecular dynamic viscosity coefficient

- \(\nu _{t}\) :

-

Turbulent kinematic viscosity coefficient

- k:

-

Turbulent kinetic energy

- \(\epsilon\) :

-

Turbulent dissipation rate

- \(G_k\) :

-

turbulent kinetic energy generation term

- \(C_\mu\) :

-

Empirical coefficient

- \(\eta _0\), \(\beta\) :

-

model constants

- \(C_2\) :

-

Constant term

- \(\Delta T_{ref}\) :

-

Reference time interval

- \(H_{ref}\) :

-

Reference characteristic length of the flow field

- \(U_{ref}\) :

-

Characteristic velocity corresponding to the reference length of the flow field

- \(\lambda _{Taylor}\) :

-

Taylor microscale

- u’:

-

Fluctuating velocity

- \(\nu\) :

-

Kinematic viscosity of the fluid

- \(\varepsilon\) :

-

Turbulent dissipation rate

- Z:

-

Vertical coordinate

- X:

-

Horizontal coordinate

- Y:

-

Span coordinate

- \(R^2\) :

-

Coefficient of determination

- \(P_i\) :

-

Simulated value

- \(\overline{P}\) :

-

Average of the simulated value

- \(O_i\) :

-

Test value

- \(\overline{O}\) :

-

Average of the test value

References

Deng, J. et al. Laboratory model study of the effect of aeration on axial velocity attenuation of turbulent jet flows in plunge pool. J. Hydrodyn. 27, 913–918 (2015).

Chen, H. Y., Xu, W. L., Deng, J. & Li, N. W. Numerical simulation and experimental study on the characteristics of slit-type energy dissipater in high arch dam. Shuili Xuebao 43, 445–451 (2012).

Zhang, Z. C. & Xu, X. Experimental investigation of aerated flow depth on stepped spillway. Yingyong Lixue Xuebao 28, 644–648 (2011).

Yan, T. & Liu, H. S. Research on cavitation problem for spillway in ducky cheuck hydropower station. J. Water Resourc Water Eng. 23, 77–80 (2012).

Cao, H. T. Study on flow-induced vibration of Huangjinping spillway. Dam Saf. 32, 61–65 (2018).

Matsubara, M., Alfredsson, P. H. & Segalini, A. Linear modes in a planar turbulent jet. J. Fluid Mech. 888, A26 (2020).

Marusic, I. Dynamic mode decomposition for analysis of time-series data. J. Fluid Mech. 1000, F7 (2024).

Chen, L. F., Zhao, L., Shi, X. L. & Zou, X. Experimental study on mobile jet impingement on cohesive bed for submergence-induced channel formation. Ocean Eng. 42, 115–124 (2024).

Taddesse, T. M. & Mathew, J. Development and scaling of turbulent, twin round jets. J. Fluid Mech. 939, A13 (2022).

Zhang, C., Wang, L., Dai, X. & Zhao, R. Research on hydraulic characteristics of shallow submerged jet with different incidence angles. Shuidonglixue Yanjiu yu Jinzhan 32, 358–364 (2017).

Guo, W. S., Li, L. G., Liu, C. & Li, N. W. Study on the flow field of a submerged jet. Gongcheng Kexue Yu Jishu 49, 35–43 (2017).

Violato, D. & Scarano, F. Three-dimensional evolution of flow structures in transitional circular and chevron jets. Phys. Fluids 23, 124104 (2011).

Li, Z. R., Fan, Y. S., Wang, H., Zhang, X. & Su, K. Study on the flow field characteristics of annular jet in a restricted space. Build. Energy Environ. 38, 31–34 (2019).

Panda, S., Gohil, T. B. & Arumuru, V. Influence of mass flux ratio on the evolution of coaxial synthetic jet. Phys. Fluids 34, 93601 (2022).

Li, G. D. et al. Features of internal flow in jet nozzle of self-priming centrifugal pump based on the large eddy simulation. J. Drain. Irrig. Mach. Eng. 35, 369–374 (2017).

Sader, J. E., Cossé, J., Kim, D., Fan, B. & Gharib, M. Large-amplitude flapping of an inverted flag in a uniform steady flow-a vortex-induced vibration. J. Fluid Mech. 793, 524–555 (2016).

Yan, X. M.: Research on vortex structure characteristics of twin propeller jet for ships in restricted waters. Master’s thesis, Chongqing Jiaotong University (2024).

Hao, C. Y., Dong, X. R., Cai, T. Y., Zhou, W. & Cai, X. S. Study on vortex control mechanism of synthetic jet based on feature extraction methods. Eng. Mech. 41, 225–237 (2024).

Gui, N. et al. Comparative assessment and analysis of rorticity by rortex in swirling jets. J. Hydrodyn. 31, 495–503 (2019).

Xu, C., Liu, Q. L. & Lai, H. X. Effects of flow forcing on simulation of subsonic turbulent jet flow and noise. J. East China Univ. Sci. Technol. 47, 510–518 (2021).

Kim, D., Cossé, J., Cerdeira, C. H. & Gharib, M. Flapping dynamics of an inverted flag. J. Fluid Mech. 736, R1 (2013).

Marusic, I. et al. Turbulent/non-turbulent interface in high reynolds number pressure gradient boundary layers. In IUTAM Symposium on Turbulent/Non-Turbulent Interface in Turbulent Shear Flows, 3–17 (Springer, 2024).

Joksimović, I. & Jakirlić, S. Sensitized Reynolds stress modeling of a bubbly jet emerging into a water cross-flow. Int. J. Multiph. Flow 182, 105029 (2025).

Jia, Z. J. Experimental study on aeration concentration and pulsating pressure in multi-strand aerated water flow cushion pond. Master’s thesis, Kunming University of Science and Technology (2019).

Wang, R. Q. Experimental study on the concentration and gas movement of fully aerated water flow under covered and uncovered conditions. Master’s thesis, Kunming University of Science and Technology (2021).

Exposito, J., Gratadour, D., Clénet, Y. & Rouan, D. Star formation and jet-induced coronal lines near the core of NGC 1068-high angular resolution near-IR spectroscopy with naco. Astron. Astrophys. 533, A63 (2011).

Peng, Y. X., Zhang, H. & Wu, G. H. Numerical simulation of water jet and collision based on LBM. J. China Inst. Water Resourc. Hydropower Res. 20, 129–136 (2022).

Xu, J. R., Gu, J. D., Yan, Z. Q., He, M. J. & Huang, J. Optimization method and application of flood discharge layout based on inflow distribution of impact jets. Water Resourc Power 40, 139–142 (2022).

Xu, J. R., Peng, Y., Zhao, J. J., Gu, J. D. & Wang, Y. Impact pressure distribution characteristics in plunge pool of high arch dam with large discharge. Water Resourc Power 38, 98–100 (2020).

Lian, J. J., Liu, D. & Liu, F. Numerical prediction of flood discharge atomization induced by complicated aerial collisions. J. Hydroelectr. Eng. 38, 46–56 (2019).

Lian, J. J., Ren, P. H., Liu, D. M. & He, J. L. Numerical simulation on the aerated water in a spillway tunnel based on a mixing-concentration model. J. Water Resourc. Water Eng. 33, 93–100 (2022).

Zhao, Q., Mu, Z. W., Zhou, K., Gao, S. & Zhang, H. H. Hydraulic characteristics of chute block-trapezoidal block joint dissipator. J. Changjiang River Sci. Res. Inst. 42, 120 (2025).

Li, Z. et al. Energy dissipation effect and cavitation characteristic of a new type of overflow dam surface structure. Water Resourc. Power 40, 103–106 (2022).

Yang, J. Study on hydraulic characteristics of energy dissipation combined with step and new type integrated stilling basin. Master’s thesis, Dalian University of Technology (2021).

Ma, P. H., Hu, Y. J. & Liu, H. S. Study on the relative hydraulic characteristics of skimming flow on stepped spillways. Shuili Xuebao 51, 997–1007 (2020).

Ma, P. H. Study on the variation law of hydraulic parameters of skimming flow in stepped spillways. Ph.D. thesis, Northwest A &F University (2021).

Cui, X. Y. Study on the the Hydraulic characteristics, discharge and energy characteristics of jet swirl casecade energy dissipator. Master’s thesis, Xi’an University of Technology (2020).

Deng, Y. C., Niu, Z. M., Li, Q. L., Nan, J. H. & Wang, T. S. Critical hydraulic conditions of jet-rotary joint cascade inner energy dissipator. J. Hydroelectr. Eng. 38, 11–20 (2019).

Nasrabadi, M. & Aminpour, Y.: Numerical simulation of flow over stepped spillways with varying step-angle. Hydro Science & Marine Engineering2 (2020).

Zhang, B. C. et al. Research on the safe operation mode of a new type energy dissipator with double-layer multi-outlet horizontal jets. Water Power 46, 56–59 (2020).

Liu, D. H. Design and numerical simulation of jet-swirl cascade internal energy dissipator in diversion-discharge tunnel. Water Resourc. Hydropower Northeast China 39, 9–11 (2021).

Li, A. H. & Liu, P. Q. Models for simulating the propagation of fluctuating pressure in gaps of stilling basin slab. Shuili Xuebao 36, 1236–1240 (2005).

Li, Y., Liu, C., Lian, B. & Zhu, X. C. Numerical study on vortex-induced vibration of wind turbine airfoil via prescribed vibration and free vibration. J. Chin. Soc. Power Eng. 44, 270–276 (2024).

He, J. L. et al. Evaluation and sensitivity analysis of three-dimensional numerical simulation for aerated deflector-generated jets in spillways. Water Supply 23, 114–128 (2023).

Nickels, T. B. & Marusic, I. On the different contributions of coherent structures to the spectra of a turbulent round jet and a turbulent boundary layer. J. Fluid Mech. 448, 367–385 (2001).

Wang, F. J. Computational fluid dynamics analysis: CFD principles applied 125–128 (Tsinghua University Press, Beijing, 2004).

Lu, Q. L. Study on energy dissipation characteristics of multiple jets and its applying for pressed water pipeline outlet. Ph.D. thesis, Xi’an University of Technology (2008).

Khoshmanesh, K. et al. Liquid metal enabled microfluidics. Lab Chip 17(6), 974–993 (2017).

Tian, Y.: Study on hydraulic characteristics of trapezoidal energy dissipation pier-step combined energy dissipator. Master’s thesis, Taiyuan University of Technology (2023).

Feng, Z. W., Li, Y. Y., Tian, Y. & Li, Q. Effects of energy dissipation pier arrangements on the hydraulic characteristics of segmented pier-type step energy dissipator structures. Water 14, 3590 (2022).

Jeong, J. & Hussain, F. On the identification of a vortex. J. Fluid Mech. 285, 69–94 (1995).

Zhao, Y. M., Li, Y. Y. & Sun, X. H. Modal analysis of the hydrodynamic force of a capsule in a hydraulic capsule pipeline. J. Mar. Sci. Eng. 11, 1738 (2023).

Zhao, Y. M., Li, Y. Y. & Song, X. T. PIV measurement and proper orthogonal decomposition analysis of annular gap flow of a hydraulic machine. Machines 10, 645 (2022).