Abstract

Road repair materials employed in the seasonal frozen regions of Northeastern China always often demonstrate poor long-term performance under extreme climate conditions. This is primarily attributed to the detrimental effects of short-term aging and frequent freeze–thaw cycles on the adhesive properties of sealants. Existing standards fail to adequately account for these complex environmental factors, leading to unsatisfactory repair outcomes. This study evaluated the changes in adhesive performance of eight commonly used sealants under conditions simulating short-term high-temperature aging, low-temperature water immersion, and repeated freeze–thaw cycles. The mechanical properties of the materials under different conditions were assessed using low-temperature tensile tests and an improved energy dissipation method. The results indicated that short-term high-temperature aging caused a significant reduction in the adhesive strength of the sealants, while freeze–thaw cycles further exacerbated performance degradation. Conversely, low-temperature water immersion improved adhesive strength by 48.1%. Compared to conventional assessment methods, the improved energy dissipation method provided a more precise evaluation of changes in adhesive performance under complex environmental conditions. This study offers valuable theoretical insights for the selection and optimization of repair materials in cold regions and addresses limitations in current standards.

Similar content being viewed by others

Introduction

Hot-poured sealants are widely utilized in the maintenance of asphalt pavements in cold regions due to their excellent adhesive properties1,2. While these sealants are effective at sealing cracks in the short term, their adhesive strength often deteriorates significantly within 1–2 years of application, particularly under the low-temperature conditions prevalent in seasonal frozen regions3,4. Current standards in China, such as the JT/T 740 Standard for Hot-Poured Sealants for Pavements, primarily rely on indicators like softening point, penetration, and flowability to assess sealant quality. However, these indicators only determine whether a product meets minimum requirements and fail to capture the long-term performance of sealants. It is evident that the existing evaluation system lacks the capacity to address the long-term performance of sealants under cold environmental conditions. This evaluation gap prevents road maintenance departments from accurately predicting the durability of sealants in low-temperature environments, particularly under the combined effects of repeated freeze–thaw cycles and prolonged water immersion—two common phenomena in seasonal frozen regions.

To address these limitations, some researchers have proposed advanced evaluation methods aimed to better assessing the adhesive properties of sealants. Among these, the Direct Tension Tester (DTT) has emerged as a key tool for evaluating the stress–strain behavior of sealants under low-temperature tensile conditions. This method allows for the differentiation of materials based on their resistance to thermal stress, providing a basis for selecting sealant materials in cold regions5. Building on the DTT, the Crack Sealant Adhesion Test (CSADT) was developed to more accurately simulate the crack propagation behavior of sealants in cold environments6. Sawalha et al.7 further refined methods for adhesion testing, emphasizing the critical roles of both cohesion and adhesion properties in determining sealant performance. Additionally, dynamic mechanical analyzers (DMA) have been used to investigate the dynamic mechanical properties of sealants. The findings indicated that sealants with lower glass transition temperatures (Tg) and lower stiffness moduli perform better under cold climate conditions8. Similarly, the combined use of the Bending Beam Rheometer (BBR) and the Dynamic Shear Rheometer (DSR) has provided insights into the correlation between laboratory test results and field performance9. These advances have significantly expanded sealant performance evaluation approaches, providing valuable references for assessing sealant performance under low-temperature conditions.

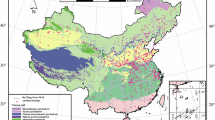

Despite growing attention to the tensile performance of sealants under low-temperature conditions, the impact of high-temperature short-term aging during the construction process on their long-term performance remains under-researched. High-temperature short-term aging is likely a critical factor contributing to the premature failure of sealants in practical applications. During construction, sealants are typically heated to approximately 190 °C for several hours, a process that may cause material degradation, thereby affecting their subsequent durability10. Masson et al.11,12 studied the aging mechanisms during construction and found that high-temperature heating might cause uneven aging of sealants. They also noted that overheating caused by a hot-air lance (HAL) could reduce the adhesive properties of sealants13. Laboratory methods have been developed to simulate construction-related aging, such as stirring sealants in a small kettle at the recommended maximum temperature for 4 h to replicate the aging effects during heating14, or employing the Thin Film Oven Test (TFOT) to simulate short-term aging during construction15. While these methods can characterize the aging behavior of sealants under high-temperature conditions to some extent, they have yet to fully address performance degradation under freeze–thaw cycles. In Northeast China’s seasonal frozen regions, severe winter temperature fluctuations and heavy snowfall subject road cracks to intense freeze–thaw cycles16,17,18,19,20. During these cycles, water infiltrates cracks and freezes, expanding and causing damage to the sealant-pavement interface. This accelerates the aging and failure of the material, as shown in Fig. 1. However, traditional sealant performance evaluation systems do not sufficiently account for the impact of freeze–thaw cycles on material performance. Therefore, both construction aging and freeze–thaw cycles should be incorporated into the evaluation system.

To overcome these challenges, the present study systematically investigated the performance of hot-poured sealants used in Northeast China by simulating the effects of short-term aging, freeze–thaw cycles, and water immersion during the construction process. It analyzed the changes in adhesive performance of sealants under short-term aging and low-temperature conditions and identified the key mechanisms responsible for adhesive failure. Furthermore, a novel quantitative evaluation method based on the energy dissipation method was developed to complement and strengthen existing standards. These findings provide a more scientific and practical reference for the selection and use of crack repair materials in Northeast China.

Materials and test design

Experimental materials

Eight commonly used sealants for road maintenance in Northeastern China were selected as experimental samples. Among these, four were designed for use at temperatures as low as − 20 °C, while the remaining four were suitable for use at − 30 °C. Key indicators such as low-temperature tensile strength, penetration, softening point, and elastic recovery rate were tested for these sealants. All sealants met the standard requirements to ensure their suitability for road maintenance under the harsh climate conditions in Northeastern China. The performance indicators of the samples are presented in Table 1.

Experimental methods

Considering that sealants typically undergo 2–4 h of heating at 190 °C during construction, the sealant samples were placed in an oven at 190 °C for 4 h to simulate the short-term aging. After aging, tensile tests were conducted under conditions of low temperature, low-temperature water immersion, and freeze–thaw cycles to analyze changes in the adhesive performance of the sealants.

Given the harsh cold and seasonal freeze–thaw cycles in Northeastern China, sealants must possess excellent interfacial adhesive and tensile strengths under low-temperature conditions. Therefore, low-temperature cyclic tensile tests and low-temperature fracture tests were performed on the samples measuring 50 mm × 50 mm × 15 mm. The test blocks were prepared using AC-16 asphalt mixture (dimensions of 75 mm × 50 mm × 25 mm) and metal blocks. The eight groups of sealant samples were conditioned at -30 °C (Groups A, B, C, D) and − 20 °C (Groups E, F, G, H) for 4 h. Subsequently, they were subjected to cyclic tensile tests at a speed of 0.05 mm/min using a UTM-100 tensile testing machine, which can provide a maximum displacement of 50 mm, Following these tests, fracture tests were performed. The adhesive performance and maximum tensile force of the sealant samples were measured during the tests. The testing equipment is illustrated in Fig. 2.

To accurately evaluate the adhesive performance of the sealants after low-temperature water immersion, the sealant samples were first immersed in water at 25 °C for 96 h. Then, they were subjected to three sets of cyclic tensile tests at -20 °C and − 30 °C in accordance with ASTM D5329 and D6690 standards to analyze the changes in the maximum tensile force of the sealants.

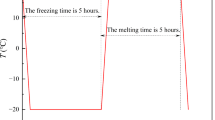

To simulate the freeze–thaw cycles in Northeastern China, the test samples underwent both heat treatment and cold treatment21. For each heat treatment cycle, the layered samples were placed in an oven at 60 °C for no less than 4 h, and then compressed under their own weight before being cooled at room temperature for 6 h. For the cold treatment, the heat-treated samples were placed in an environmental chamber at − 15 °C for no less than 4 h. Tensile tests were conducted on an UTM machine to stretch the samples to 150% of the sample width (i.e., 22.5 mm). For each freeze–thaw cycle, tensile positioning blocks were placed between the substrates to maintain the sealant’s tensile length, and the samples were kept at room temperature for 6 h. The freeze–thaw cycle was repeated for three times, after which low-temperature fracture tests were performed to measure the maximum tensile force of the samples. These tests allow for the analysis of the effect of freeze–thaw cycles on the adhesive performance and maximum tensile force of the sealant. The procedure of the freeze–thaw cycle test is illustrated in Fig. 3.

Results and discussion

Results of short-term aging test

The test results of the sealant samples following short-term aging are summarized in Table 2. It was observed that cone penetration, flowability, and elastic recovery rate exhibited a significant decrease across all sealants. The softening points of sealants A, C, D, and F increased, which was primarily due to the evaporation of oils during the heating process. In contrast, the softening points of the remaining sealants decreased, which was primarily attributed to the degradation of the rubber powder. The low-temperature tensile curves of the sealants are depicted in Fig. 4. Although the cone penetration, softening point, and elastic recovery rate of the sealants after short-term aging still met current standard requirements, these indicators mainly reflected the initial performance without considering potential long-term deterioration. While the mechanical properties of the sealants experienced a slight decline after short-term aging, prolonged factors such as freeze–thaw cycles and water infiltration were likely to accelerate the sealants’ performance over time.

As depicted in Fig. 4, the adhesion of the crack sealant increased with deformation during low-temperature tensile testing. However, after short-term aging, the tensile force of the sealant decreased significantly compared to the unaged sealant. Specifically, at − 30 °C, the tensile force in the first cycle of the aged sealant sample decreased by an average of 64.30% relative to the unaged samples. At − 20 °C, the average reduction was 20.14%. Furthermore, the stage of force equilibrium was either significantly shortened or completely absent in aged samples. This indicated that short-term aging not only initiated damage to the sealant but also progressively impaired its mechanical properties over its service life.

Further analysis revealed significant changes in the surface porosity of the crack sealant following short-term aging. Compared to the unaged sealant, the surface porosity of the aged sealant decreased noticeably, resulting in a more compact and smoother surface texture. The transformation was primarily attributed to the volatilization or degradation of some plasticizers and solubilizers in the sealant during the short-term aging process, which led to the release of gases from the material. The volatilization of plasticizers was particularly critical, as they were essential for maintaining the flexibility and adaptability of the sealant at low temperatures. The loss of these components not only weakened the key bonding sites that helped maintain polymer chain connectivity—making the material more compact and smooth—but also reduced the sealant’s low-temperature flexibility.This led to brittle fracture of the sealant under low-temperature conditions, particularly when subjected to tensile forces, causing a sharp decline in its tensile properties and severely impairing its low-temperature performance. Test results further indicated that the sealant at − 30 °C, which contains a higher proportion of plasticizer, experienced a more pronounced degradation in low-temperature performance.

Results of low-temperature fracture test

Figure 5 compares the tensile force–deformation curves of the sealant samples before and after short-term aging. It was observed that all eight sealants exhibited a notable increase in adhesive force as the tensile displacement increased during the initial stretching stage. However, sealants A, E, and F demonstrated an increasing trend in adhesive force even after reaching the maximum stretching distance, demonstrating good performance. The other sealants, which met the required tensile distance specified by established standards, also exhibited an increase in adhesive force over a certain distance before the adhesive force began to decline. In contrast, the adhesive force of the short-term aged sealants was significantly lower than that of the unaged sealants and dropped sharply after reaching a certain amount of deformation. This suggested that short-term thermal aging exerted a substantial impact on the long-term performance of the sealants.

The primary factors contributing to this performance degradation include the deterioration of key components, such as SBS (styrene–butadiene–styrene) and rubber powder, which are essential for maintaining the sealant’s elasticity and adhesion. During the aging process, the volatilization of plasticizers further reduced the material’s flexibility and increased its brittleness under low temperature conditions. For example, sealant H exhibited nearly zero adhesive force at its maximum stretching distance, signifying a complete loss of functional performance. Given its relatively higher elastic recovery rate, it could be inferred that the higher SBS content in sealant H provided better elasticity at ambient temperatures. However, after short-term aging, the combined effect of plasticizer volatilization and SBS degradation made the sealant more prone to brittleness at low temperatures. Additionally, the propagation of micro-cracks further accelerated the mechanical degradation of sealant H.

Results of low-temperature fracture test after water immersion

The short-term aged sealant samples, following water immersion, were subjected to low-temperature tensile and fracture tests. The tensile force–deformation curves are depicted in Fig. 6. After undergoing three low-temperature tensile tests, the relationship between adhesive force and deformation for the immersed samples was nearly identical to that of the non-immersed samples. However, at − 30 °C, the curves for all sealants did not consistently exhibit a clear peak value. Except for sealant A, the curves at − 30 °C experienced a gradual upward trend, whereas at − 20 °C, they typically showed a rapid decline after reaching the maximum tensile force. Analysis revealed that the plasticizers in the sealants at -30 °C contributed to improved low-temperature performance, while water immersion did not significantly affect the adhesive force of the sealants. On the contrary, water immersion resulted in a slight increase in adhesive force. Specifically, the average adhesive force of the immersed sealants increased by 48.1% compared to the un-immersed sealants. This enhancement could be attributed to the infiltration of water into the asphalt mixture. Under low-temperature conditions, water molecules migrated and crystallized into ice, which subsequently interacted with the asphalt interface to form adhesion. The combined effect of ice crystal toughening and the optimization of low-temperature performance by the plasticizers enhanced the low-temperature adhesive properties of the sealant, as illustrated in Fig. 722,23,24.

Results of freeze–thaw cycle test

The tensile force–deformation curves of the sealants after freeze–thaw cycles, obtained from the fracture tests, are presented in Fig. 8. Overall, the adhesive force increased with increasing deformation. However, at − 20 °C the adhesive force of the sealants decreased significantly during the later stages, while at − 30 °C, the sealants exhibited a more pronounced linear increase in adhesive force after undergoing freeze–thaw cycles. To enhance the plasticity of the sealants under low-temperature conditions, plasticizers were added into the − 30 °C sealant formulations during preparation. In contrast, the − 20 °C sealants were prepared with a higher content of elastomers, such as SBS and rubber powder. After multiple freeze–thaw cycles, some degradations of these elastomers, particularly SBS, were observed, which contributed to a reduction in their elasticity. It was evident that freeze–thaw cycles influenced the performance of the sealants.

Adhesion evaluation based on the energy dissipation method

Basic principle

Aging can cause significant and irregular fluctuations in the mechanical properties of sealants6, which necessitates the pursuit of a more stable evaluation metric to assess the cohesive strength of sealants.

Traditional evaluation methods struggle to quantify the adhesion and low-temperature performance of sealants under complex conditions, particularly when adhesive strength deteriorates due to temperature fluctuations and prolonged loading. While indicators such as cone penetration and softening point can provide insights into initial performance, they cannot accurately characterize the long-term mechanical behavior and durability of the material, particularly in extreme environments. To address this limitation, this study introduced the energy dissipation method, which evaluates the mechanical performance of sealants by calculating the energy dissipated during the tensile process. This approach involves calculating the area under the force–deformation curve obtained from tensile tests, which reflects the adhesive performance under various stress conditions. The energy dissipation method overcomes the shortcomings of traditional evaluation methods in assessing long-term adhesive performance at extreme low temperatures and under prolonged service conditions, which makes it particularly suitable for assessing the performance of sealants under complex service conditions in cold regions in Northeast China. The calculation method is expressed in Eq. (1).

where E represents the energy dissipated during the tensile process of the sample, with a unit of J/m2; ω is the work done during the tensile process, with a unit of J, which is calculated as the area under the force–deformation curve as depicted in Fig. 9; A is the contact area between the sealant and the asphalt mixture substrate, m2.

Adhesion evaluation of short-term aging based on the energy method

The principle of the energy dissipation method is illustrated in Fig. 9, where the E values after short-term aging were calculated using Eq. (1). The calculation results are displayed in Fig. 10.

As revealed in Fig. 10, the energy dissipation of the sealants after short-term aging significantly decreased. However, as the number of cycles increased, while there was a gradual decline in adhesive energy, it became difficult to identify a specific energy value to serve as a reference or to determine which cycle’s energy value should represent the performance status. The deformation-adhesion curves of many sealants displayed inconsistencies. For some sealant samples, the maximum adhesive force was achieved at a certain level of deformation; however, as the deformation continued to increase, the adhesive force gradually decreased. Conversely, other sealants were able to maintain satisfactory adhesive performance even after reaching their maximum allowable tensile deformation. Furthermore, certain sealants that followed typical deformation-adhesion curves did not exhibit cracks beyond the specification requirements during tensile testing. However, minor cracks were observed at the bonding interface, which could severely compromise the long-term performance of the sealants, as illustrated in Fig. 11. These factors significantly affected the long-term usage of sealants. The original energy dissipation method, which is based on a single cycle,failed to account for the actual working conditions experienced by the sealants during the tensile process.

Improved energy dissipation method

To address the aforementioned issues and the complex conditions encountered during sealant usage, the following recommendations were proposed. When applying the energy dissipation method for evaluation, different scenarios should be considered to ensure accurate assessment. In the first scenario, if no distinct peak is observed within the maximum tensile stroke of the testing instrument (at least 5 cm), it indicates that the material has not reach its ultimate strength throughout the tensile process. In such cases, the maximum deformation should be taken into account, and the energy dissipation must still be calculated, as depicted in Fig. 12A. In the second scenario, when a distinct peak is observed, the energy dissipation should be calculated only for the deformation range from the initial stage to the peak. Beyond the peak, the adhesive force gradually diminishes, and any further deformation no longer reflects the material’s actual performance. This is still illustrated in Fig. 12B. These distinctions account for the different mechanical behaviors exhibited by sealants during the tensile process and enable a more accurate assessment of the material’s adhesive performance.

The dissipated energy of the test samples was calculated using the improved energy dissipation method, and the results are presented in Fig. 13. The dissipated energy of the short-term aged sealants was generally lower than that of the unaged sealants. Moreover, these results differed from those obtained using the original testing method. In previous tests, the dissipated energy of the aged sealants—particularly for A, B, C, and D at -30 °C—was nearly identical, as illustrated in Fig. 10. However, fracture test results demonstrated that the performance of sealants after aging followed the order of C > B > A > D. The finding demonstrated that the improved energy dissipation method effectively mitigated the instability in evaluating sealants caused by aging and long-term use. To verify the effectiveness of this improved method, a significance test was conducted to compare the performance differences of the sealants before and after aging. A t-test was employed to evaluate the statistical significance of these performance differences, with the t-test results presented in Table 3. The t-test results revealed a significant difference in the dissipated energy of the sealants before and after aging, as indicated by a p-value of 0.0217 (< 0.05), confirming statistical significance. This suggested that the improved energy dissipation method could reliably distinguish the performance changes in sealants before and after aging. Compared to the conventional evaluation method, the improved energy dissipation method provides more stable and accurate evaluation results. Therefore, the refined energy dissipation method can serves as a reliable performance evaluation metric for sealants.

Low-temperature fracture tests were conducted on the short-term aged sealants after water immersion, and the improved energy dissipation method was utilized for analysis. As presented in Fig. 14a, the maximum adhesive strength was ranked as A > C > D > B. However, the working performance of the sealants was ranked as D > C > B > A when the energy dissipation method was combined with the fracture test. The sealants subjected to water immersion exhibited increased adhesion to the asphalt mixture at low temperatures. Compared to the variability observed in multiple cyclic tests, a combination of the fracture test and the improved energy dissipation method proved advantageous by reducing the number of required tests while yielding more consistent and stable data.

Furthermore, fracture tests were conducted on the short-term aged sealants after undergoing freeze–thaw cycles, and the improved energy dissipation method was also employed for analysis, as presented in Fig. 14b. It was observed that freeze–thaw cycles remained the most critical factor influencing the working performance of the sealants, as the energy decreased markedly. Additionally, sealants used at − 30 °C generally exhibited greater stability compared to those used at − 20 °C. This suggested that the − 30 °C sealants demonstrated better long-term performance.

Comparative analysis of evaluation results

The evaluation results of this study were compared with the findings from low-temperature tensile tests and the traditional energy dissipation method, as listed in Table 4. To better assess the applicability of the sealants commonly used in Northeastern China, supplementary testing methods, conventional tests, and a series of adhesion fracture tests were established for short-term aged sealants at − 30 °C and − 20 °C, which are frequently encountered in Northeastern China. The performance of the eight sealants was initially evaluated using tensile cyclic tests in accordance with the current standard JT/T740. All eight sealants successfully passed the three required cycles under both unaged and aged conditions, confirming that they meet the qualification criteria specified by the standard. However, it was evident that the standard tests outlined in the current specifications are insufficient for providing a comprehensive evaluation of the working performance of these sealants in cold regions. This underscores the limitations of the existing standards in addressing the specific challenges posed by such extreme environments.

The traditional energy dissipation method was limited to calculating the energy from a single cycle. However, as the number of cycles increased, the energy for each cycle remained relatively consistent, which rendered this method ineffective in capturing the long-term performance of sealants. In contrast, the improved energy dissipation method provided a more detailed characterization of each sealant’s performance. This finding effectively highlights its ability to detect the degradation of adhesive performance under extreme conditions, particularly over extended periods of use. Consequently, the results obtained through the improved energy dissipation method better aligned with real-world conditions, making it a more reliable tool for evaluate the long-term performance and durability of sealants.

A combination of the fracture adhesion test and the improved energy dissipation method facilitated accurate assessment of the long-term adhesion performance of sealants. Under unaged conditions, the adhesive strength rankings of the sealants were C > A > D > B at − 30 °C and E > G > F > H at − 20 °C, respectively. After aging, the rankings shifted to C > B > A > D at − 30 °C and G > E > H > F at − 20 °C. For the low-temperature tensile performance of sealants following water immersion, the rankings were D > C > B > A at − 30 °C and F > E > H > G at − 20 °C. Similarly, after freeze–thaw cycles, the rankings were C > A > D > B at − 30 °C and G > E > H > F at − 20 °C. Notably, adhesive strength generally improved after water immersion. As a result, the primary focus was placed on the dissipated energy indicators under unaged, short-term aged, and freeze–thaw cycled conditions. Based on these indicators, sealant C performed best at − 30 °C, while sealant E performed best at − 20 °C.

In comparison to the current standard methods, the enhanced fracture adhesion tests took into account not only the actual usage conditions in Northeastern China but also certain extreme environmental scenarios. By combining these tests with the improved energy dissipation method, more specific and detailed evaluation criteria were established. This integration significantly improved the stability of sealant performance assessments under different conditions.

Conclusions

This study systematically evaluated the performance of eight commonly used sealants in seasonal frozen regions by incorporating short-term aging, low-temperature tensile tests, low-temperature water immersion tensile tests, freeze–thaw cycle tests, and the improved energy dissipation method. The following conclusions were drawn:

-

(1)

After short-term aging, the adhesive strength of the sealants decreased significantly during low-temperature tensile testing. At − 30 °C, the adhesive strength of the sealants decreased by an average of 64.3%, while at − 20 °C, the reduction was 20.14%. In contrast, when the sealants were subjected to low-temperature tensile tests after water immersion, the adhesive strength increased by an average of 48.1%. This enhancement is attributed to the toughening effect caused by water entering the pores and freezing at low temperatures, which strengthens the adhesive strength at the interface.

-

(2)

After undergoing multiple freeze–thaw cycles, the adhesive strength of the short-term aged sealants generally decreased. Specifically, at − 30 °C, the adhesive strength decreased by an average of 54.83%, while at − 20 °C, the reduction was 29.88%. This difference is primarily attributed to the higher content of SBS, rubber powder, and other modifiers present in the sealants designed for − 20 °C conditions.

-

(3)

The improved energy dissipation method, combined with fracture tests, eliminated the uncertainty associated with selecting a specific cycle as the standard for calculation in multi-cycle assessments. This approach effectively evaluated changes in adhesive strength under conditions such as short-term aging, low-temperature water immersion, and freeze–thaw cycles. As a result, it enhances the stability and reliability of long-term performance evaluations for the sealants.

In conclusion, the improved energy dissipation method holds significant practical value by delivering more accurate and reliable results for selecting sealants and evaluating their long-term performance. Its effectiveness highlights its potential for integration into industry standards. However, this method does have certain limitations, such as requiring advanced equipment and specialized technical support, as well as specific testing conditions.

Data availability

All data generated or analysed during this study are included in this published article.

References

Gong, Y., Pang, Y., He, F. & Bi, H. Investigation on preparation and properties of crack sealants based on CNTs/SBS composite-modified asphalt. Materials 14, 4569 (2021).

Li, K., Yan, X., Ai, T., Niu, Y. & Jiang, S. Study on properties and application of chloroprene rubber/polyurethane modified asphalt sealant. Constr. Build. Mater. 406, 133177 (2023).

Hu, X., Zhou, F., Hu, S. & Scullion, T. A new laboratory evaluation method for the adhesive performance of crack sealants. J. Test. Eval. 39, 177–183 (2011).

Wang, S. et al. Effects of periodically changing temperatures on the bond interface between crack sealant and repaired pavement. J. Transp. Eng. B: Pavements 150, 04024003 (2024).

Zhai, H. & Salomon, D. Evaluation of Low Temperature Properties of Asphalt Crack Sealants Using the Direct Tension Tester. (2005).

Al-Qadi, I. L. & Fini, E. H. Development of a crack sealant adhesion test (CSADT) specification for hot-poured bituminous sealants. J. Test. Eval. 39, 184–190 (2011).

Sawalha, M., Ozer, H., Al-Qadi, I. L. & Xue, H. Development of a modified adhesion test for hot-poured asphalt crack sealants. Transp. Res. Record https://doi.org/10.3141/2612-10 (2017).

Soliman, H. & Shalaby, A. Characterizing the low-temperature performance of hot-pour bituminous sealants using glass transition temperature and dynamic stiffness modulus. J. Mater. Civ. Eng. 21, 688–693 (2009).

Soliman, H., Shalaby, A. & Kavanagh, L. Performance evaluation of joint and crack sealants in cold climates using DSR and BBR tests. J. Mater. Civ. Eng. 20, 470–477 (2008).

Masson, J.-F., Collins, P., Woods, J., Bundalo-Perc, S. & Al-Qadi, I. Degradation of bituminous sealants due to extended heating before installation: a case study. (2006).

Masson, J.-F., Collins, P., Bundalo-Perc, S., Woods, J. R. & Al-Qadi, I. L. Early thermodegradation of bituminous sealants resulting from improper installation: Field study. Transp. Res. Rec. J. Transp. Res. Board 1991, 119–123 (2007).

Masson, J.-F., Collins, P. & Lowery, M. Temperature control of hot-poured sealants during the sealing of pavement cracks. Constr. Build. Mater. 19, 423–429 (2005).

Masson, J.-F. & Lacasse, M. A. Effect of hot-air lance on crack sealant adhesion. J. Transp. Eng. 125, 357–363 (1999).

Masson, J.-F., Woods, J. R., Collins, P. & Al-Qadi, I. L. Accelerated aging of bituminous sealants: Small kettle aging. Int. J. Pavement Eng. 9, 365–371 (2008).

Li, F., Zhou, S., Cai, W., Du, Y. & Li, L. Laboratory evaluation of short and long term performance of hot-poured sealants. Constr. Build. Mater. 148, 30–37 (2017).

Montoya, M. A., Rahbar-Rastegar, R. & Haddock, J. E. Incorporating phase change materials in asphalt pavements to melt snow and ice. Int. J. Pavement Eng. 24, 2041195 (2023).

Ma, B. et al. Performance of a novel epoxy crack sealant for asphalt pavements. Int. J. Pavement Eng. 23, 3068–3081 (2022).

Ma, R., Jiang, Y., Liu, B. & Fan, H. Effects of pore structure characterized by synchrotron-based micro-computed tomography on aggregate stability of black soil under freeze-thaw cycles. Soil Tillage Res. 207, 104855 (2021).

Zhang, K., Xie, W. & Zhao, Y. Deterioration mechanism of adhesion property for SBS modified asphalt in salt-freeze-thawing environment. Int. J. Adhes. Adhes. 126, 103441 (2023).

Guo, M., Kovalskiy, V. P., Nian, T. & Li, P. Influence of deicer on water stability of asphalt mixture under freeze-thaw cycle. Sustainability 15, 13707 (2023).

Wang, S. et al. Development of a modified bond test for hot applied crack sealants by using hot-cold cycles. Road Mater. Pavement Des. 24(8), 2027–2047 (2022).

Stendardo, L. et al. Reframing ice adhesion mechanisms on a solid surface. Appl. Surf. Sci. 641, 158462 (2023).

Golovin, K., Dhyani, A., Thouless, M. D. & Tuteja, A. Low-interfacial toughness materials for effective large-scale deicing. Science 364, 371–375 (2019).

Tarpoudi Baheri, F., Poulikakos, L. D., Poulikakos, D. & Schutzius, T. M. Ice adhesion behavior of heterogeneous bituminous surfaces. Cold Reg. Sci. Technol. 192, 103405 (2021).

Author information

Authors and Affiliations

Contributions

Rongsen He and Wei Wang jointly designed the experimental protocol and wrote the main manuscript text. Liang Xu provided technical guidance on the experimental design and reviewed and revised the manuscript. Jiale Shi performed data collection and analysis and prepared the figures. Zhiguo Chen was responsible for the implementation of the experiments and the organization of the results. All authors reviewed and approved the final manuscript for submission.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

He, R., Xu, L., Wang, W. et al. Experimental study on the low-temperature performance and evaluation methods of crack sealants for asphalt pavements in seasonal frozen regions. Sci Rep 15, 18577 (2025). https://doi.org/10.1038/s41598-025-03538-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-03538-y