Abstract

Crop harvesting, a crucial part of cultivation, has traditionally depended on manually, and despite technological advancements benefiting most crops through mechanical harvesting, the manual method of harvesting of shorter crops (one foot in height) continues to persist. Recognizing this challenge, an innovative solution has emerged a self-propelled battery-operated leafy-vegetable harvester specifically designed for leafy vegetables, integrating battery technology to mechanize the harvesting. Design Expert statistical software was used to identify optimal solutions for the laboratory analysis harvester using the Response Analysis and Multi-Parameter Simulation (RAMPS) model. The analysis revealed that the highest cutting efficiency was achieved at a cutter bar speed of 370.67 strokes/min with a forward speed of 2 km/h. Further optimization showed that a reel speed of 0.32 m per second at a forward speed of 1.65 km/h, with a driven pulley size of 558 mm (level 6 of B), resulted in highest harvesting efficiency. Additionally, the optimal conveyor performance was observed at a speed of 0.86 m/s, with a forward speed of 1.857 km/h and a driving pulley size of 101.6 mm (level 3 of A). The harvester was tested across speeds ranging from 1.5 to 5 km/h, with power requirements between 157 and 542 watts. Within this range, the battery-powered harvester provided an operating time of 2.25 to 7.8 h and the total energy required as 107.36 MJ/ha. By integrating battery technology, the harvester influences to sustainable agricultural practices, supporting with global efforts to minimize carbon emissions. This innovative attempt provides a viable solution for smallholder farmers, developing agricultural productivity and supporting the transition to more sustainable farming methods.

Similar content being viewed by others

Introduction

Agriculture has played an important role in human health and welfare by producing large amounts of food to feed a growing world population, but this has also placed substantial pressures on natural resources1 and the sustainability of environment2. In that agriculture field most probably, all operations are still depending on traditionally. In that traditional approach facing challenges are labor shortage3, if labours are available, they are Bottlenecks4, Musculoskeletal Disorders (MSDs) risk factors such as repetitive motion and awkward postures while working5 and less production efficiency6. The sustainable intensification of agricultural systems offers synergistic opportunities for the co-production of agricultural and natural capital outcomes7. Efficiency and substitution are steps towards sustainable intensification, but system redesign is essential to deliver optimum outcomes as ecological7, economic and technological conditions change. With rising labour costs and a scarcity of labour, mechanization8 is required for agriculture.

Tractors and agricultural equipment run on non-renewable energy sources has led to a scarcity9 of conventional sources of energy like fossil fuels10, which can be harmful to the environment, climate, human health11, rising oil price, insufficient indigenous fossil fuel reserve, heavy expenditure on oil import and energy insecurity, etc.12. At present, the global agricultural emits about 20% of the total carbon dioxide emissions due to internal combustion engines used by agricultural machinery13. The linked problems of energy sustainability14 and climate change is among the biggest challenges humanity faces in the next century15 and it impacts on crop yields are inherently uncertain16. In recent years, countries committed to green agricultural development have taken a number of measures to improve the energy conservation, efficiency and environmental protection of related machinery in all aspects of agricultural production17. Closer attention to a broader spectrum of adaptation options is urgently needed. In particular, ecosystem-based adaptation approaches provide flexible, cost-effective and broadly applicable alternatives for buffering the impacts of climate change, while overcoming many drawbacks of hard infrastructure15. So, electric agriculture machinery has emerged as a more efficient alternative and these machineries have been a great step forward to help positively the environment with zero emissions and total energy consumption in their lifecycle18.

Leafy vegetables are perennial plants cultivated worldwide. India owns a rich flora comprising 6000 plant species, one-third of which, approximately, are green leafy vegetables used for consumption19. Due to their significant nutrient, vitamin, and mineral content, leafy vegetables are an essential part of the human diet20, especially where malnutrition is on the rise21. The cutting, uprooting and hand-picking of leafy vegetables are primarily carried out manually, often using a sickle while adopting a sitting or squatting posture. Choosing to cut leafy vegetables rather than uprooting them offers several advantages. This method ensures a continuous vegetable supply over an extended period after sowing seeds at once. Moreover, adopting the cut-and-come-again practice proves to be a profitable source of income for small landholders. Over a period of about 6–7 months, this practice allows for multiple cuttings, yielding a considerable amount of good-quality seeds and productivity22. The cut-and-come-again approach not only saves time, energy, and seed costs but also addresses certain drawbacks associated with uprooting crops. Uprooting leafy crops presents challenges for consumers as they may find crop roots in their cuisine, and each uprooting event results in soil loss along with the roots. Retaining stubble, however, mitigates these issues by reducing soil erosion, decreasing evaporation of existing soil moisture through lower wind speed at the soil surface, minimizing raindrop impact, providing soil shading, increasing soil water content by decreasing runoff, enhancing infiltration, and improving soil biological fertility, among other benefits23,24,25.

By achieving these objectives, CAE, JNKVV, Jabalpur developed a self-propelled battery-operated ergonomic leafy vegetable harvester, taking into account the drawbacks of existing leafy vegetable harvesting and findings from previous studies on leafy vegetable harvesters. The proposed harvester seeks to improve agricultural productivity and profitability, offering a more viable alternative to traditional methods. With these innovations, the harvester not only addresses the immediate needs of farmers but also contributes to the broader goal of sustainable agriculture, where economic viability, environmental stewardship, and social responsibility are all integral components. Olowojola et al.26 developed a tractor-mounted leafy vegetable harvester for cutting amaranthus crops using a reciprocating cutter knife at a crank speed of 447 rpm and operated at 3.27 km/h forward speed. Packaging of harvested vegetables into sizes is done alongside 3–5 labor/day. The developed machine had an effective field capacity of 0.27 ha/h and an efficiency of 92%. Jin et al.27 developed a 4gcd-600 leafy vegetables harvester and the experimental results in the field showed that the advance speed of the harvester was 0.85 km/h, the leafy vegetables integrity rate was 92.79%, miss cutting rate was 1.04%, miss picking rate was 2.60% and the harvesting efficiency was 0.085 hm2/h. Kolgiri et al.28 developed a prototype harvester is developed for head lettuce production. This harvester consists of a cutting blade that cuts the vegetable head at the desired location. Then this cut vegetable is lifted in a container by using a conveyor belt. A cutting component is a band saw belt is used. The cutter and transport belt are driven by electric power so we used the power unit for this harvester. For cutting and lifting 12 V DC motor will be used. Movement of this harvester manually. There is a provision to position the cutter height according to the type of vegetable. Singh et al.29 developed a battery-assisted offset rotary cutter for leafy green spinach and coriander. It consists of a frame, 250 W geared DC motor, two 12 V-12 ah batteries, power transmission, cutting unit and handle. A worker with the developed cutter provided the output of 145 m2/h for green spinach and 153 m2/h for coriander. The leftover leaves rate after manual and machine cut per m2 area were 0.35 and 1.4% respectively. Time taken in the collection of cut crops by the developed cutter and making bundles manually was incorporated in getting overall output with this system was found 2.56 times more than the traditional system of harvesting the crops. Yin and Wang30 focus on the engine-driven harvester for stem and leaf vegetables. When used for harvesting with roots, install the harvesting device with roots, and the single-acting cutter is driven by the vegetable cutting motor for reciprocating plane movement; when used for harvesting without roots, when roots are harvested, a harvesting device without roots is installed, and the cutter motor drives the upper and lower cutters to reciprocate through two cutter eccentric wheels. The various parameters of the harvester followed by harvest rate is ≥ 95%, cleanliness is ≥ 90%, supporting power is 18 kW, driving speed is 0.2–0.3 m s−1, harvesting efficiency is 0.33–0.40 hm2/h.

Materials and methods

The design of the self-propelled battery-operated leafy vegetable harvester is a comprehensive process that involves agronomical considerations, functional requirements, and detailed component specifications. A survey of the leafy vegetable crop at the Agricultural Farm of the Department of Agriculture, JNKVV, Jabalpur was conducted to collect the information on agronomical characteristics of leafy vegetable plants. The agronomical characteristics of leafy vegetables were measured, in the field at the harvesting stage, and on the standing crop with the help of suitable devices and suitable methods for various parameters. All the measurements and tests related to the agronomical properties of leaves were conducted within 24 h from the harvesting of leaves kept at room temperature (25–28 °C in the month of November). Observations were taken on the characteristic dimensions of the leafy vegetable plants which were relevant to the study. These considerations ensure that the harvester is efficient, user-friendly, and suitable for various field conditions.

-

a.

Agronomical Considerations for the Design of the Harvesting Unit: The design of the harvesting unit takes into account the agronomical properties of leafy vegetables, such as plant height, spacing, and stem strength. These properties are crucial for determining the optimal cutting height, blade design, and conveyor dimensions. The harvester must be adaptable to different row and plant spacing to accommodate various cultivation methods. The goal is to minimize damage to the plants while maximizing yield and maintaining the quality of the harvested vegetables.

-

b.

Functional Requirements and Theoretical Power Calculations: The harvester’s functional requirements include precise cutting, efficient conveyance of harvested crops, and ease of manoeuvrability. The design should incorporate lightweight materials to reduce the overall weight and optimize power usage. Theoretical power calculations are essential to ensure that the harvester operates efficiently. These calculations consider the average walking speed of the operator, the power needed for the cutting blades, reel unit, conveyor system, and drive wheels. By understanding the power requirements at each stage of the harvesting process, the components can be appropriately sized and selected to maximize performance.

-

c.

Detailed Description of Components and Their Specifications: The harvester is composed of various components, each designed to fulfill specific roles in the harvesting process. Key components include:

-

Cutting Unit: Designed for precise and efficient cutting of leafy vegetables, with adjustable height and a reciprocating blade mechanism.

-

Conveying Unit: Ensures smooth transfer of cut crops from the cutting unit to the collection bag, minimizing losses.

-

Power Source: A BLDC motor powered by lead-acid batteries provides the necessary energy for all operations.

-

Main Frame and Wheels: The robust frame supports all components, while the wheels ensure stability and ease of movement across different terrains.

-

Reel Unit and Controller: These facilitate crop feeding into the conveyor and regulate power distribution across the harvester.

-

To develop the battery-operated leafy vegetable harvester various components were designed/selected as per the requirement in the Workshop of Farm Machinery and Power Engineering, College of Agricultural Engineering, JNKVV, Jabalpur during the year 2020 to 2023. The following Table 1 provides a detailed overview of the components and specifications of the self-propelled battery-operated leafy vegetable harvester:

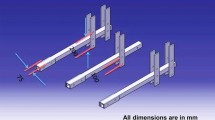

The design of the self-propelled battery-operated leafy vegetable harvester, depicted in Fig. 1a and b, showcases a well-engineered solution tailored to the specific needs of harvesting leafy vegetables. This innovative harvester is meticulously crafted to address key challenges faced by farmers, including labor intensity, efficiency, environmental impact, and user ergonomics. The harvester’s design begins with careful agronomical considerations, taking into account the unique properties of leafy vegetables, such as plant height, stem strength, and spacing. These factors are crucial in determining the optimal design of the cutting unit and the overall dimensions of the harvester. The cutting unit features reciprocating blades that are designed to precisely and gently cut the leafy vegetables at the optimal point, minimizing damage and maximizing yield. Adjustable cutting height options ensure adaptability to various crop conditions and farming practices, accommodating different row and plant spacing. The functional requirements of the harvester focus on efficiency and ease of operation. The machine is powered by a Brushless Direct Current (BLDC) motor, which provides consistent and reliable performance while minimizing emissions. The motor’s power is calculated to meet the demands of the cutting blades, reel unit, conveyor system, and drive wheels, ensuring smooth and efficient operation. The use of lead-acid batteries provides a stable and sustainable power source, supporting the harvester’s functions while reducing the reliance on fossil fuels and decreasing greenhouse gas emissions.

Ergonomic design is a key consideration in the harvester’s development, ensuring that it is user-friendly and reduces physical strain on operators. The handle is designed with adjustable height and an ergonomic grip to accommodate various users and enhance comfort during operation. This focus on ergonomics not only improves user experience but also promotes wider adoption among farmers by making the machine accessible and easy to use. The conveying unit of the harvester is engineered to efficiently transport cut crops from the cutting unit to the collection area. It utilizes a well-designed conveyor belt system, positioned at a slight incline, to ensure smooth and consistent conveyance of materials. This minimizes losses and maintains the quality of the harvested vegetables. The harvester’s main frame and wheels are built to withstand the challenges of uneven terrain, providing stability and durability. The robust construction ensures that the harvester can navigate different field conditions, from soft soil to rough ground, without compromising performance. In terms of environmental considerations, the harvester is designed to be environmentally friendly by utilizing battery-operated technology, which significantly reduces emissions compared to traditional diesel-powered machines. This design choice aligns with global efforts to promote sustainable agricultural practices and reduce the environmental impact of farming activities.

In summary, the self-propelled battery-operated leafy vegetable harvester, as illustrated in Fig. 1, is a thoughtfully designed machine that integrates agronomical insights, functional efficiency, ergonomic comfort, and environmental sustainability. It stands as a practical and innovative solution to the challenges of leafy vegetable harvesting, offering significant benefits in terms of cost-effectiveness, productivity, and ecological responsibility. All experimental data were analyzed using Design-Expert Software Version 13.0.5.0. The software was used for designing experiments, analyzing variance (ANOVA), and optimizing process parameters (https://www.statease.com/software/design-expert/).

Results and discussion

In this phase of the study, rigorous laboratory tests were conducted to assess the technical and functional aspects of the self-propelled battery-operated leafy vegetable harvester. This methodology involved a series of controlled experiments and detailed measurements that provided valuable insights into the harvester’s performance in terms of precision, efficiency, power management, and speed control of its various components, while also ensuring adherence to safety standards.

The study focused on evaluating the effects of different independent variables, specifically the sizes of the pulley and forward speeds (1.5, 2, and 2.5 km/h), which served as the dependent variables. This comprehensive analysis aimed to identify optimal operational conditions and settings that enhance the harvester’s performance. The results obtained were analyzed through a factorial experiment utilizing analysis of variance (ANOVA), a statistical method that allowed for precise evaluation of the relationships between the independent and dependent variables. The findings from the study are discussed under various key headings:

Cutter bar speed at different forward speeds

Effect of forward speed of harvester on cutter bar speed

The optimization of harvesting efficiency in a leafy vegetable harvester hinge significantly on the interplay between forward speed and cutter bar speed. As illustrated in Fig. 2, there is a noticeable increase in the cutting unit’s speed corresponding with the forward speed. This is achieved through the strategic arrangement of the main shaft, cutter bar, and wheels within an interconnected power transmission system. The system is designed to enhance cutting precision and productivity by aligning values with various parameters, such as strokes per minute and forward speed, for a given apparatus. From Fig. 2, it is evident that at a forward speed of 1.5 km/h, the cutter bar’s minimum number of strokes was 275, reaching a maximum of 286, with a mean speed of 281 strokes per minute. When the forward speed increased to 2 km/h, the cutter bar speed ranged from a minimum of 360 strokes per minute to a maximum of 382 strokes per minute, averaging 371 strokes per minute. At a higher forward speed of 2.5 km/h, the minimum and maximum cutter bar speeds rose to 450 and 478 strokes per minute, respectively, with a mean speed of 462 strokes per minute. The cutter bar is capable of achieving a maximum of 780 cutting strokes per minute. These findings align with past studies, indicating a consistent trend of increasing cutter bar speed with forward speed.

This data provides a clear demonstration of the intricate relationship between forward speed and cutter bar speed in optimizing the harvesting process for leafy vegetables. The effectiveness of this relationship is further influenced by several crop-related factors, which must be considered to maximize efficiency:

-

Crop Characteristics: Different leafy vegetables may vary in density, size, and structure. The optimal forward speed and cutter bar speed must be adjusted according to the specific crop being harvested to ensure precision and effectiveness.

-

Stem Thickness: The thickness of the stems can significantly impact the cutter bar speed. Thicker stems may require a slower, more deliberate cutting approach compared to thinner stems to avoid damage and ensure a clean cut.

-

Crop Density: The spacing and density of the crop can affect cutting efficiency. High-density crops may necessitate adjustments in cutter bar speed to prevent clogging and maintain uniform harvesting across the field.

-

Moisture Content: The moisture level in leafy vegetables influences the cutting process. Wet conditions may require different cutter bar speeds to accommodate the increased resistance compared to dry conditions.

-

Harvesting Height: Leafy vegetables are harvested at varying heights depending on the type. Some may be closer to the ground, while others require higher cuts. Adjusting the cutter bar height is essential to match the specific harvesting requirements of each crop.

These factors highlight the need for a dynamic approach to adjusting forward and cutter bar speeds, ensuring that the harvester operates efficiently under diverse agricultural conditions. By understanding and adapting to these variables, the harvester can achieve optimal performance, minimizing labour and maximizing yield quality and quantity.

Data analysis of harvester performance using design expert software

The data analysis for this study was conducted using Design Expert software, utilizing a factorial study design with a randomized full factorial approach. This design involved testing three different forward speeds (1.5, 2, and 2.5 km/h), with each speed replicated three times, resulting in a total of nine experimental runs. The primary objective was to assess the impact of the independent variable, forward speed, on the dependent variable, which was the cutter bar speed measured in strokes per minute. The analysis revealed a standard deviation of 11.13 and a mean cutter bar speed of 370.44 strokes per minute. The coefficient of variation was calculated at 3%, indicating a high level of consistency across the replications. The predicted R2 value of 0.9678 demonstrated strong predictive accuracy and was in reasonable agreement with the adjusted R2 of 0.9809, as the difference between them was less than 0.2, suggesting that the model effectively fits the data.

Adequate precision is a measure used to evaluate the signal-to-noise ratio of the model, where a ratio greater than 4 is considered desirable. In this study, an adequate precision ratio of 28.736 was observed, indicating a robust signal and confirming that the model provides a reliable basis for predicting the effects of forward speed on cutter bar performance. The findings from this analysis underscore the reliability and accuracy of the experimental design and data analysis, demonstrating that forward speed is a significant factor influencing cutter bar speed in the leafy vegetable harvester. This insight is crucial for optimizing the harvester’s performance and achieving efficient and effective harvesting operations.

The ANOVA results presented in Table 2 highlight the statistical analysis of the cutter bar speed, indicating that the model is highly significant with an F-value of 206.45. This F-value suggests that there is only a 0.01% chance that such a large F-value could occur due to random noise, underscoring the robustness of the model. The analysis also utilizes p-values to determine the significance of individual model terms. P-values less than 0.0500 denote statistically significant model terms, indicating that these factors have a substantial effect on the response variable. In this study, the term A was identified as a significant model term, demonstrating its influence on the cutter bar speed. Conversely, values greater than 0.1000 suggest that certain model terms do not significantly impact the response variable. Overall, these results underscore the reliability of the model in predicting the cutter bar speed based on the independent variable of forward speed, and they provide a clear understanding of which factors are most influential in optimizing the performance of the leafy vegetable harvester. The cutter bar was evaluated at different forward speeds to determine the optimal values that would maximize the harvester’s performance during field operations. Table 3 illustrates the optimization of various cutter bar speeds, highlighting the most effective settings for efficient operation. Using the Response Analysis and Multi-Parameter Simulation (RAMPS) model, as depicted in Fig. 3, the optimal solution for the harvester was identified. The analysis indicated that operating the harvester at a cutter bar speed of 370.667 strokes per minute while maintaining a forward speed of 2 km/h resulted in the highest cutting efficiency. This finding underscores the importance of achieving the precise combination of stroke count and forward speed to enhance the overall performance of the harvester. By optimizing these variables, the harvester can deliver superior cutting efficiency, ensuring effective and consistent harvesting of leafy vegetables. This optimization not only improves productivity but also contributes to reduced labor costs and increased profitability for farmers.

Influence of forward speed and pulley size on reel speed in a self-propelled battery-operated leafy vegetable harvester

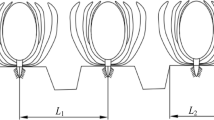

The results obtained from the self-propelled battery-operated leafy vegetable harvester, as detailed in Fig. 4, focus on the reel speed and reel speed index under various conditions of pulley sizes with a forward speed set at 1.5 km/h. A 50.8 mm drive pulley affixed to the main shaft was used alongside pulleys of 304, 355, 381, 431, 457, and 558 mm attached to the reel unit shaft to investigate reel speed across different configurations. The reel shaft rotations were recorded at 41.8, 38.3, 35.3, 32.8, 30.6, 27, 25, and 21 rpm, with corresponding reel speeds of 0.59, 0.49, 0.47, 0.40, 0.39, and 0.30 m/s for the respective pulley sizes. The reel speed indexes were calculated as 1.58, 1.46, 1.34, 1.24, 1.17, 0.97, 0.95, and 0.73, respectively.

When the forward speed of the harvester was increased to 2 km/h, as shown in Fig. 4, the reel shaft rotations for the same pulley sizes were quantified at 55.8, 51, 47.2, 43.8, 41, 36, 34, and 27 rpm, with observed reel speeds of 0.80, 0.66, 0.64, 0.55, 0.53, and 0.39 m/s. The reel speed indexes for these settings were calculated as 1.55, 1.42, 1.32, 1.21, 1.14, 0.98, 0.94, and 0.69. This data is detailed in Table 4, which offers insights into the relationship between pulley sizes and reel speed at this specific forward speed. At a higher forward speed of 2.5 km/h, the RPM of the reel shaft, reel speed, and reel speed index were evaluated for the pulley sizes of 304, 355, 381, 431, 457, and 558 mm. The reel shaft rotations were recorded at 87, 79.6, 73.5, 68.2, 63.7, 56, 53, and 43 rpm, with reel speeds observed at 1.21, 1.03, 0.95, 0.83, 0.81, and 0.64 m/s. The reel speed indexes for these conditions were 1.94, 1.77, 1.64, 1.52, 1.42, 1.18, 1.15, and 0.91.

Figure 4 demonstrates that an increase in reel speed is concurrent with increased forward speed, achieved through the strategic arrangement of the main shaft and reel unit in an interconnected power transmission system. The reel speed in this harvester is influenced by a combination of machine parameters and crop-specific factors, providing valuable insights into optimizing performance. Here are some key parameters affecting reel speed under various conditions of forward speed and pulley sizes:

-

Forward Speed: The speed at which the harvester moves forward significantly influences reel speed. An increase in forward speed typically results in a higher reel speed. Adjustments to the driving pulley of the reel shaft may be necessary to optimize the harvesting process.

-

Pulley Size: The size of the pulleys attached to the reel shaft plays a crucial role. Smaller pulleys tend to result in higher reel speeds. Typically, the reel speed is set 1 to 1.5 times higher than the forward speed to reduce clogging and jamming of the crop, achieved by selecting a larger pulley ratio.

-

Crop Density: The density of the leafy vegetable crop impacts the engagement between the reel and vegetation. Higher crop densities may require increased reel speeds to maintain efficiency.

-

Crop Height: The height of the leafy vegetables is a critical factor. The reel speed must be adjusted to effectively engage and cut crops at the desired height. The developed harvester can cut crops less than 300 mm in height, but for crops taller than 300 mm, adjustments may be needed to prevent jamming.

-

Crop Type and Structure: Different types of leafy vegetables have varying structures and textures. Bulky structures like spinach may require higher reel speeds, while less bulky crops like coriander and fenugreek may require lower speeds.

-

Stem Thickness: The thickness of the stems can influence cutting ease. Lighter stems like coriander require less reel power, while thicker stems like spinach necessitate higher reel power.

-

Moisture Content: The moisture content of the crop can impact the cutting process. Wet conditions may require adjustments in reel speed to accommodate increased resistance.

These findings provide valuable insights into the nuanced relationship between forward speed and pulley sizes of reel shafts, offering a comprehensive understanding of how these variables impact the harvester’s performance. By optimizing these parameters, the harvester can achieve superior cutting efficiency, ultimately enhancing productivity and profitability for farmers.

Data analysis and model evaluation using design expert software

The data analysis for this study was conducted using Design Expert software, employing a response surface methodology characterized as a randomized subtype. The design model utilized was a two-factor interaction (2FI) employing an I-optimal design, which is particularly effective for optimizing experimental designs with continuous variables. This design included three forward speeds and six distinct sizes of driven pulleys for the reel, each replicated three times, resulting in a total of 22 experimental runs. The primary focus of this investigation was to assess the combined influence of the independent variables—forward speeds (1.5, 2, and 2.5 km/h) and six levels of pulley sizes (304, 355, 381, 431, 457, and 558 mm)—on the dependent variable, which is the reel speed. This approach aimed to provide a nuanced understanding of how variations in forward speed and pulley sizes collectively impact speed performance.

In analyzing the reel speed under various conditions of forward speed and pulley sizes, the standard deviation was 0.0197, the mean was 0.6445, and the coefficient of variation (CV %) was 3.06%. These statistical measures provide insights into the variability and central tendency of the reel speed across different combinations of forward speed and pulley sizes. The results show a strong consistency in reel speed, with low variability, indicating reliable performance across different experimental conditions. The predicted R2 value of 0.9720 was in reasonable agreement with the adjusted R2 value of 0.9928, with the difference being less than 0.2. This indicates that the model has a high predictive capability and effectively fits the data. Additionally, adequate precision, which measures the signal-to-noise ratio, yielded a value of 59.531, significantly above the desired threshold of 4, indicating a robust signal and confirming the model’s reliability for navigating the design space.

The ANOVA analysis presented in Table 5 further supports the significance of the model, with the cutter bar speed yielding a model F-value of 243.81. This high F-value suggests that there is only a 0.01% chance that such a large value could occur due to noise, underscoring the model’s robustness and significance. P-values less than 0.0500 indicate significant model terms, and in this case, terms A (forward speed), B (pulley size), AB (interaction between forward speed and pulley size), and A2 (quadratic effect of forward speed) were identified as significant. Conversely, values greater than 0.1000 suggest that some model terms are not significant. If many insignificant model terms are present (excluding those necessary for model hierarchy), model reduction may enhance model accuracy. The lack of fit F-value of 0.70 implies that the lack of fit was not significant relative to the pure error, with a 62.44% chance that such a large lack of fit F-value could occur due to noise. A non-significant lack of fit is desirable, as it indicates that the model adequately fits the data, ensuring reliable predictions and insights into the harvester’s performance. Overall, the analysis demonstrates that the chosen model effectively captures the relationship between forward speed, pulley size, and reel speed, providing a comprehensive understanding of the factors influencing the performance of the self-propelled battery-operated leafy vegetable harvester. This model serves as a valuable tool for optimizing the design and operation of the harvester, ultimately enhancing its efficiency and effectiveness in the field.

Effect of forward speed and pulley size on reel speed of harvester

Figure 5a illustrates the relationship between forward speed and reel speed, demonstrating that an increase in forward speed leads to a corresponding elevation in reel speed. This correlation is primarily attributed to the interconnected power transmission between the reel shaft and the wheel shaft. The lowest reel speed recorded was 0.59 m/s at a forward speed of 1.5 km/h, while the highest reel speed was 1.25 m/s at a forward speed of 2.5 km/h, both observed with the same pulley size. As depicted in Fig. 5b, reel speed decreases as the reel-driven pulley size increases. Specifically, the observed average minimum reel speed was 0.39 m/s when the reel-driven pulley size reached its maximum of 558 mm (level 6 of B). Conversely, the average maximum reel speed was 0.83 m/s with the reel-driven pulley size at its minimum of 304 mm (level 1 of B). This inverse relationship between pulley size and reel speed highlights the importance of selecting appropriate pulley sizes for optimal performance. Figure 6, further emphasizes this dynamic relationship. The lowest reel speed was observed at a forward speed of 1.5 km/h, where the reel-driven shaft equipped with a 558 mm (level 6 of B) pulley registered a speed of 0.3 m/s. In contrast, the highest reel speed was recorded at a forward speed of 2.5 km/h, with the reel-driven shaft featuring a 304 mm (level 1 of B) pulley, achieving a reel speed of 1.204 m/s.

These observations underscore the intricate interplay between forward speed, pulley size, and reel speed, which are critical for the effective functioning of the harvester. By adjusting these parameters, operators can optimize the harvester’s performance, ensuring efficient and precise cutting of leafy vegetables. Understanding this relationship is vital for maximizing the harvester’s productivity and adapting to different crop conditions, ultimately enhancing the overall efficiency of the harvesting process.

The reel of the self-propelled battery-operated leafy vegetable harvester was evaluated at various forward speeds and pulley sizes to determine the optimal combination of these variables for improved performance during field operation. The optimization of five different reel speeds out of a possible 100 configurations is detailed in Table 6. Using the Response Analysis and Multi-Parameter Simulation (RAMPS) model, as depicted in Fig. 7, the optimal solution for achieving higher harvesting efficiency was identified. The analysis determined that a reel speed of 0.32 m/s at a forward speed of 1.65 km/h, with a driven pulley size of 558 mm (level 6 of B), results in the highest cutting efficiency. This finding suggests that achieving this specific combination of forward speed and reel speed, along with the appropriate pulley size, significantly enhances the overall performance of the harvester. By optimizing these parameters, the harvester can operate more efficiently, providing precise and consistent cutting of leafy vegetables. This optimization not only improves the harvester’s productivity but also reduces labor costs and increases profitability for farmers by ensuring a higher quality of harvested crops.

Analysis of conveyor speed in relation to forward speed and pulley configurations

Figure 8 describes the conveyor speed under various conditions of forward speed, taking into account different pulley configurations in the self-propelled battery-operated leafy vegetable harvester. In this setup, a 50.8 mm pulley was positioned at the conveyor driving roller. Pulleys of sizes 50.8 mm (level 1 of A), 76.2 mm (level 2 of A), and 101.6 mm (level 3 of A) were affixed to the gear output shaft to assess the conveyor speed associated with each selected pulley size. The observed data reveals a clear trend where conveyor speed increases proportionally with the augmentation of pulley size at the gear output shaft. Additionally, there was a notable correlation between conveyor speed and the increasing forward speed of the harvester, highlighting the dynamic interplay between these variables.

Several machine and crop parameters can influence the conveyor speed in a self-propelled battery-operated leafy vegetable harvester under varying conditions of forward speed and pulley sizes:

-

Transmission System Design: The efficiency of the transmission system, including gear ratios and belt mechanisms, can significantly impact conveyor speed. Proper alignment and calibration are crucial for optimal performance.

-

Weight Distribution: The distribution of weight across the harvester, particularly within the conveyor system, can affect its overall stability and conveyor speed. Balanced weight distribution ensures smoother operation and consistent speed.

-

Crop Density: The density of the leafy vegetables in the field can influence the load on the conveyor system, affecting its speed. Denser crops may require adjustments to maintain efficient operation.

-

Moisture Content: Higher moisture content in the harvested crop can affect the friction on the conveyor, potentially influencing speed. Adjustments may be needed to compensate for varying moisture levels.

Figure 8 reveals the conveyor speed relative to the harvester’s forward speed set at 1.5 km/h, considering pulley sizes of 50.8, 76.2, and 101.6 mm for the conveyor driving shaft. The corresponding conveyor roller rotations were measured at 230, 345, and 460 rpm, with observed conveyor speeds of 0.39, 0.54, and 0.71 m/s for the 50.8, 76.2, and 101.6 mm pulleys on the gear output shaft, respectively. When the forward speed of the harvester increased to 2 km/h, as shown in Fig. 8, the conveyor roller rotations for the same pulley sizes were quantified at 307, 461, and 614 rpm, with observed conveyor speeds of 0.46, 0.70, and 0.92 m/s for the gear output shaft pulleys, respectively. At a forward speed of 2.5 km/h, the conveyor roller rotations were measured at 478, 717, and 956 rpm, corresponding to conveyor speeds of 0.68, 1.08, and 1.47 m/s for the 50.8, 76.2 and 101.6-mm pulleys on the gear output shaft, respectively. This finding further validates the observed relationship between forward speed, pulley size, and conveyor speed, underscoring the importance of optimizing these parameters for efficient harvesting operations. These results highlight the intricate relationship between forward speed, pulley size, and conveyor speed, which are critical for the effective operation of the harvester. By understanding and adjusting these parameters, operators can enhance the harvester’s performance, ensuring efficient and consistent crop handling and transport.

Data analysis and model evaluation of conveyor speed using design expert software

Further the data analysis was conducted using Design Expert software, employing a response surface study type with a randomized subtype and utilizing an I-optimal coordinate exchange design model (2FI). This experimental design was selected to comprehensively assess the relationship between forward speed, pulley size, and conveyor speed in a self-propelled battery-operated leafy vegetable harvester. The study incorporated three distinct forward speeds: 1.5 km/h, 2 km/h, and 2.5 km/h. Additionally, three different sizes of conveyor driving pulleys were considered, measuring 50.8 mm (level 3 of A), 76.2 mm (level 2 of A), and 101.6 mm (level 1 of A) in diameter. Each combination of forward speed and pulley size was replicated three times, resulting in a total of 15 experimental runs. The primary focus of the investigation was to assess the impact of the independent variables—forward speed and pulley size—on the dependent variable, specifically the conveyor speed of the developed leafy harvester.

The statistical analysis of the conveyor speed data revealed a standard deviation of 0.0230, indicating the spread of data points around the mean conveyor speed. The mean conveyor speed was 0.7973 m/s, representing the central average around which the data points were distributed. Additionally, the coefficient of variation (CV %) was calculated at 2.89%, providing a relative measure of the standard deviation relative to the mean. This percentage offers valuable insights into the relative variability of conveyor speed data, considering the magnitude of the mean. The model’s predictive capability was demonstrated with a predicted R2 value of 0.9917, which was in reasonable agreement with the adjusted R2 value of 0.9958, indicating a minimal difference of less than 0.2. This close agreement suggests that the model effectively captures the variability in the data and provides accurate predictions. Adequate precision, which measures the signal-to-noise ratio, yielded a value of 69.345, significantly exceeding the desirable threshold of 4, indicating a robust signal and confirming the model’s reliability for navigating the design space.

The ANOVA analysis, as presented in Table 7, further substantiates the significance of the model, with a model F-value of 560.14. This high F-value implies that there is only a 0.01% chance that such a large value could occur due to random noise, underscoring the model’s robustness and statistical significance. The P-values indicate that model terms A (forward speed), B (pulley size), AB (interaction between forward speed and pulley size), and A2 (quadratic effect of forward speed) were significant, as they were less than 0.0500. Conversely, values greater than 0.1000 suggest that certain model terms are not significant, and model reduction could improve the model if there are many insignificant terms not required to support hierarchy. The lack of fit F-value was 3.53, which implies there was a 9.70% chance that such a large lack of fit F-value could occur due to noise. This relatively low probability (< 10%) indicates a concerning fit of the model to the data, suggesting that further refinement may be necessary to ensure the model’s accuracy and reliability. A significant lack of fit is generally undesirable, as it suggests that the model does not adequately capture the variability in the data. Overall, the analysis demonstrates that the chosen model effectively captures the relationship between forward speed, pulley size, and conveyor speed, providing a comprehensive understanding of the factors influencing the performance of the self-propelled battery-operated leafy vegetable harvester. Despite the lack of fit issue, the model serves as a valuable tool for optimizing the design and operation of the harvester, enhancing its efficiency and effectiveness in the field. Further investigation and model refinement may be necessary to address the lack of fit and improve predictive accuracy.

Effect of forward speed and pulley size on conveyor speed of harvester

Figure 9a provides insights into the relationship between the forward speed of the developed leafy vegetable harvester and the speed of its conveyor system. A clear positive correlation exists between the harvester’s forward speed and the conveyor speed. When the harvester’s forward speed was lower, at 1.5 km/h, the conveyor speed was measured at 0.38 m/s. However, as the forward speed increased to 2.5 km/h, the conveyor speed correspondingly rose to 0.68 m/s. This demonstrates a proportional relationship where increasing the forward speed results in an increase in conveyor speed.

Additionally, Fig. 9b reveals that the conveyor speed is also influenced by the size of the conveyor driving pulley. The smallest recorded conveyor speed, 0.42 m/s, was associated with a level 1 of A pulley, which has a diameter of 50.8 mm. Conversely, the largest observed conveyor speed, reaching 0.96 m/s, corresponds to a level 3 of A pulley, which has a larger diameter of 101.6 mm. This indicates that larger pulley sizes facilitate higher conveyor speeds, highlighting the importance of selecting appropriate pulley sizes for optimal performance.

In Fig. 9c, the data illustrates how pulley size influences the conveyor speed of the developed leafy vegetable harvester. The graph’s blue line denotes the conveyor’s top speed of 1.4 m/s, achieved when the harvester was traveling at a speed of 2.5 km/h with a pulley diameter of 101.6 mm (level 3 of A). On the other hand, the red line represents the minimum conveyor speed of 0.38 m/s, which occurred when the harvester was traveling at a slower speed of 1.5 km/h with a smaller pulley diameter of 50.8 mm. These results underscore the dynamic interaction between pulley size and the harvester’s forward speed in determining the conveyor speed within the harvester system. Conveyor speed can be significantly affected by adjusting either the forward speed or the pulley size. Therefore, careful consideration and optimization of these parameters are crucial when designing and operating the leafy vegetable harvester. The examination of the data reveals interesting patterns that suggest an interaction between increased forward speed and larger conveyor driving pulley size, both contributing to elevated conveyor speeds. The conveyor speed increases in tandem with the harvester’s forward speed, while larger conveyor driving pulley diameters also correlate with higher conveyor speeds. The synergy between these two factors higher forward speed and larger pulley size generates a combined effect that significantly enhances conveyor speed. This interdependence emphasizes their collective influence on the overall performance of the developed harvester’s conveyor system. Understanding and leveraging this relationship is essential for optimizing the harvester’s efficiency and effectiveness, ensuring a more productive and streamlined harvesting process.

The conveyor was evaluated for different forward speeds and different pulley sizes to find the suitable values of these variables at which the harvester would give a better performance during field operation. The optimization of five different reel speeds out of 100 is shown in Table 8 Based on RAMPS presented in Fig. 10, the optimal solution for the harvester, resulting in higher harvesting efficiency, was identified at conveyor speed was 0.86 m/s, when operating at a forward speed of 1.857 km/h with the driving pulley of the conveyor was level 3 of A.

Effect of forward speed on battery discharging time of the harvester

The analysis of power requirements for the self-propelled leafy vegetable harvester reveals critical insights into its operational efficiency across various conditions. When the harvester is in its rest position and not accelerated, the power requirement is approximately 1.22 W, with a minimum range spanning from 1.19 to 1.24 W. The voltage at rest is expected to be within 49.4–49.9 V, and the current required ranges from 24 to 25 mA. These parameters provide a baseline for understanding the harvester’s energy consumption in idle states. According to the data presented in Fig. 11, the power requirements for the harvester at a forward speed of 1.5 km/h fluctuate between 149 and 168 W, with an average power demand of 157 W. Under these conditions, the harvester maintains an average running time of 7–8 h, resulting in an operational duration of 7.80 h at this speed. This efficiency highlights the harvester’s capability to perform effectively over extended periods at lower speeds.

Further examination of the data reveals varying power requirements at different forward speeds. At a moderate forward speed of 2 km/h, the power demand ranges from 180 to 201 W, demonstrating the harvester’s adaptability to efficiently handle tasks within this speed range. The average power demand is calculated to be 193 W, providing a benchmark for operational considerations and optimizing performance in moderate working conditions. As the forward speed increases to 2.5 km/h, the power requirements rise, ranging from 239 to 263 W. The average power demand at this speed is 248 W, with a consistent operational time of 4.70 to 5.20 h. This indicates the harvester’s capacity to navigate and function effectively at higher speeds while balancing power consumption and running time. At the maximum forward speed, as illustrated in Fig. 11, the power requirements exhibit a dynamic range from 521 to 566 W. The harvester’s ability to withstand more challenging conditions is evidenced by its higher average power consumption of 542 W. However, this results in a shorter operational period of 2.20 to 2.40 h, reflecting a common trend observed in past studies where increased power utilization corresponds with decreased battery working time.

These insights into power requirements, average power demands, and running times at various speeds offer valuable information for optimizing the operation of the self-propelled leafy vegetable harvester across different scenarios. By understanding and managing these parameters, operators can enhance the harvester’s performance, ensuring efficient and sustainable agricultural practices.

Effect of forward speed on the energy requirement of the cutter bar of the harvester

The energy consumption for harvesting selected leafy crops using the developed self-propelled battery-operated leafy vegetable harvester was evaluated through the use of both direct and indirect energy sources, including labor, battery power, and the machine itself. The total energy required to harvest one hectare of leafy vegetable crops with the developed harvester was calculated to be 107.36 MJ/ha. This total comprises 42.05 MJ/ha from direct energy sources and 65.31 MJ/ha from indirect energy sources. Direct energy, amounting to 42.05 MJ/ha, includes 19.6 MJ/ha attributed to human labor and 22.45 MJ/ha from battery energy. This demonstrates the efficiency and reduced reliance on human labor compared to traditional methods, with the battery-operated system contributing significantly to the harvesting process. Indirect energy, representing 65.31 MJ/ha, involves the energy equivalent coefficient of the harvester itself. This figure captures the embodied energy related to the machinery’s production, maintenance, and operation, reflecting the comprehensive energy use in the harvesting process. In stark contrast, the total energy required for manual harvesting of leafy vegetable crops was calculated at 392 MJ/ha, utilizing 25 man-days per hectare. This comparison highlights the substantial energy savings achieved by the developed harvester, offering a more sustainable and efficient alternative to traditional manual harvesting methods.

Figure 12 illustrates the comparative harvesting processes between manual and mechanized methods, emphasizing the advantages of the developed harvester in terms of reduced energy consumption and enhanced productivity. By leveraging advanced technology, the harvester not only lowers energy requirements but also mitigates the physical strain on laborers, contributing to a more sustainable agricultural practice. Overall, these findings underscore the significant benefits of adopting the self-propelled battery-operated leafy vegetable harvester, which offers a viable solution for increasing efficiency and sustainability in crop harvesting. This innovative approach aligns with broader environmental goals and the need for modern agricultural systems to reduce their carbon footprint while maintaining high productivity levels.

Conclusions

The development of the self-propelled battery-operated leafy vegetable harvester implies a significant improvement in agricultural technology, addressing the significant challenges faced by farmers in the efficient harvesting of leafy vegetables. This study effectively demonstrates the harvester’s ability to decrease labor costs, improve productivity, and reduce environmental impact, making it an ideal solution for smallholder farmers.

-

1.

Enhanced Efficiency: The harvester works with great effectiveness; the maximum configurative power is provided in the forward speed 1. 857 km/h, and the conveyor speed is 0. 86 m/s with the pulley size of 558 mm. This has the added advantage of enhancing the crop collection and reducing on wastage, hence increasing productivity.

-

2.

Energy Consumption: The harvester substantially reduces energy consumption compared to traditional manual methods, requiring only 107.36 MJ/ha for harvesting, compared to 392 MJ/ha for manual labor. This exhibits the harvester’s capability to provide a more environmental and cost-effective solution for leafy vegetable harvesting.

-

3.

Environmental Impact: By utilizing battery-operated technology, the harvester eliminates direct emissions associated with diesel-powered machinery, aligning with global sustainability goals and contributing to the reduction of greenhouse gas emissions in agriculture.

-

4.

Ergonomic Design: The harvester’s design features ergonomic principles, confirming ease of use and reducing physical strain on operators. This user-friendly approach encourages broader adoption among farmers, enhancing the overall accessibility and usability of the machine.

-

5.

Robust Performance: Through severe laboratory testing and field assessments, the harvester has confirmed to be a reliable and robust results, capable of directing numerous field conditions and delivering consistent performance.

Altogether, this study may lead to improvements in the self-propelled battery-operated harvester of leafy vegetables and thus change the existing conventional techniques in harvesting, providing the farmers a better option which is efficient, sustainable, and economically viable in the long run. The successful integration of advanced technology and ergonomic design principles positions the harvester as a key innovation in modern agriculture, promoting sustainable practices and supporting the needs of smallholder farmers.

Data availability

All data generated or analysed during this study are included in this published article.

References

Yang, L. N. et al. Enhanced agricultural sustainability through within-species diversification. Nat. Sustain. 2, 46–52. https://doi.org/10.1038/s41893-018-0201-2 (2019).

Patel, S. K., Sharma, A. & Singh, G. S. Traditional agricultural practices in India: An approach for environmental sustainability and food security. Energy Ecol. Environ. 5, 253–271. https://doi.org/10.1007/s40974-020-00158-2 (2020).

Umeda, S. et al. Cost and workload assessment of agricultural drone sprayer: A case study of rice production in Japan. Sustainability 14, 10850. https://doi.org/10.3390/su141710850 (2022).

Sinébou, V. C. O. et al. Toward the Reshaping of an endogenous Leafy Vegetable value chain: The Case Study of Vitex doniana in the Republic of Benin. Econ. Bot. 77, 455–475. https://doi.org/10.1007/s12231-023-09591-w (2023).

Zahari, N. E., Sazali, N., Harun, Z. & Sazali, N. The analysis of risk factor repetitive motion in manufacturing activities based on ergonomics. In Proceedings of the 2nd Energy Security and Chemical Engineering Congress. Lecture Notes in Mechanical Engineering (eds Johari, N. H., Wan Hamzah, W. A., Ghazali, M. F., Setiabudi, H. D. & Kumarasamy, S.) (Springer, 2023) https://doi.org/10.1007/978-981-19-4425-3_12.

Benos, L. et al. A review on Ergonomics in agriculture. Part I: Manual operations. Appl. Sci. 10, 1905. https://doi.org/10.3390/app10061905 (2020).

Pretty, J. et al. Global assessment of agricultural system redesign for sustainable intensification. Nat. Sustain. 1, 441–446. https://doi.org/10.1038/s41893-018-0114-0 (2018).

Tesema, G. B. & Fetene, G. N. Cotton harvesting, post-harvest handling and storage. In Cotton Sector Development in Ethiopia. Textile Science and Clothing Technology (eds Murugesh Babu, K. et al.) 115–136 (Springer, 2014).

Prakash, O., Kumar, A. & Sharaf-Eldeen, Y. I. Review on Indian solar drying status. Curr. Sustain. Renew. Energy Rep. 3, 113–120. https://doi.org/10.1007/s40518-016-0058-9 (2016).

Bundschuh, J. et al. (eds) Geothermal, Wind and Solar Energy Applications in Agriculture and Aquaculture 1st edn. (CRC Press, 2017).

Ettl, J. et al. Transfer of agricultural work operation profiles to a tractor test stand for exhaust emission evaluation. Biosyst. Eng. 176, 185–197. https://doi.org/10.1016/j.biosystemseng.2018.10.016 (2018).

Das, P. K. & Bhat, M. Y. Global electric vehicle adoption: Implementation and policy implications for India. Environ. Sci. Pollut. Res. 29, 40612–40622. https://doi.org/10.1007/s11356-021-18211-w (2022).

Tubiello, F. N. Greenhouse gas emissions due to agriculture. In Encyclopedia of Food Security and Sustainability 196–205 (Elsevier, 2019).

Stern, P., Sovacool, B. & Dietz, T. Towards a science of climate and energy choices. Nat. Clim. Change 6, 547–555. https://doi.org/10.1038/nclimate3027 (2016).

Jones, H., Hole, D. & Zavaleta, E. Harnessing nature to help people adapt to climate change. Nat. Clim. Change 2, 504–509. https://doi.org/10.1038/nclimate1463 (2012).

Godfray, H. C. J. et al. Food security: The challenge of feeding 9 billion people. Science 327, 812–818. https://doi.org/10.1126/science.1185383 (2010).

Potapov, P. et al. Global maps of cropland extent and change show accelerated cropland expansion in the twenty-first century. Nat. Food 3, 19–28. https://doi.org/10.1038/s43016-021-00429-z (2022).

Hamurcu, M. & Eren, T. Multicriteria decision making and goal programming for determination of electric automobile aimed at sustainable green environment: A case study. Environ. Syst. Decis. 43, 211–231. https://doi.org/10.1007/s10669-022-09878-8 (2023).

Garande, V. K. et al. Studies on storage behaviour of primary processed leafy vegetables under different storage conditions. Int. J. Curr. Microbiol. Appl. Sci. 8, 2249–2272. https://doi.org/10.20546/ijcmas.2019.806.268 (2019).

Pathak, M., Barik, S., Dash, S. K. & Moharana, D. P. Impact of climate change on leafy and salad vegetables production. In Advances in Research on Vegetable Production Under a Changing Climate. Advances in Olericulture Vol. 2 (eds Solankey, S. S. & Kumari, M.) 109–126 (Springer, 2023).

Taiwo, K. A. & Famuwagun, A. A. New perspectives in the utilization of African Leafy Vegetables. In Food Security and Safety Volume 2: African Perspectives (eds Babalola, O. O. et al.) 215–237 (Springer, 2023).

Biswas, S. C. The benefits of the application of 'cut-and-come-again’ practice on some leafy vegetables. Project: USAID Horticulture Project CIP/AVRDC. https://doi.org/10.13140/RG.2.2.23638.73284 (2023).

Leonard. Managing for stubble retention. Department of Agriculture Western Australia. https://catalogue.nla.gov.au/catalog/2898892 (1993).

Thomas, G. A., Orange, D. N. & King, A. J. Effects of crop and pasture rotations and surface cover on rainfall infiltration on a Kandosol in south-west Queensland. Soil Res. 46, 203–209. https://doi.org/10.1071/sr07162 (2008).

Trostle, C. Remaining crop stubble after harvest—your options and a myth. https://hockley.agrilife.org/newsletters/ipm/ (2020).

Olowojola, C. O., Faleye, T. & Agbetoye, L. A. Development and performance evaluation of a leafy vegetable harvester. Int. Res. J. Agric. Sci. Soil Sci. 1, 227–233 (2011).

Jin, Y. et al. Design and experiment of 4GCD-600 leafy vegetables harvester. Int. Agric. Eng. J. 27, 86–94. https://doi.org/10.5555/20193333207 (2018).

Kolgiri, S. G., Ranaware, A., Raskar, A., Yadav, P. & Nimbalkar, A. A review on design and development of vegetables harvester. Int. Res. J. Eng. Technol. 6, 358–361 (2019).

Singh, S. P., Singh, M. K. & Ekka, U. Battery-assisted offset rotary cutter for leafy green spinach and coriander. RASSA J. Sci. Soc. 2, 187–192. https://doi.org/10.5958/2583-3715.2022.00023.5 (2020).

Yin, H. & Wang. Z. Research on the design of cutting table mechanism of leafy vegetable harvester based on computer technology. In Journal of Physics: Conference Series Vol. 1915, 022004 (IOP Publishing, 2021). https://doi.org/10.1088/1742-6596/1915/2/022004.

Acknowledgements

The work presented in this article was partially supported by the JNKVV Jabalpur.

Author information

Authors and Affiliations

Contributions

Conceptualization, K.P.; methodology, K.P.; software validation, Y.A.K; formal analysis, K.P.; investigation, A.K.S.; resources, Y.A.K.; data curation, K.P.; writing—original draft preparation, K.P.; writing—review and editing, A.K.S.; visualization, K.P.; supervision, A.K.S.; project administration, A.K.S.; All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Praveen, K., Kumar, Y.A. & Shrivastava, A.K. Development and evaluation of a battery powered harvester for sustainable leafy vegetable cultivation. Sci Rep 15, 33812 (2025). https://doi.org/10.1038/s41598-025-03594-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-03594-4