Abstract

The controlled permeable formwork (CPF) liner is an innovative approach to enhance the quality of the concrete cover zone. This novel technique facilitates the drain of excess water and entrapped air from the freshly laid concrete’s near-surface region, while retaining tiny particles like cement and other fine constituents. Therefore, the concrete becomes denser and less porous as a result of a decrease in the water-to-cement ratio at the surface zone. This strategic manipulation of the concrete’s surface composition yields more robust and durable cover zone, enhancing the overall performance and longevity of the structural element. The effect of incorporating glass fiber (GF) into concrete with a CPF liner was investigated in this research. Different percentages of glass fiber (0.5, 1.0, 1.5, and 2.0) were added to the CPF concrete mix to prepare the samples, and tested at various ages. The Rockwell hardness, rebound number, dynamic hardness, split tensile, flexural strength, compressive strength, and superficial pore measurement tests were conducted. The results indicated that the dynamic and rebound hardness, split, and flexural strength of the CPF liner concrete with 1.5% of GF were significantly enhanced at a range of 74, 69, 49, and 47% correspondingly.

Similar content being viewed by others

Introduction

The durability and longevity of concrete structures are significantly influenced by the level of porosity, or pin holes, present on the surface of the concrete. The reducing surface porosity is crucial, and this can be achieved by reducing the water-to-cement ratio, promoting cement hydration process, and enhancing the quality of the interfacial transition zone (ITZ) between aggregates and cement paste. While lowering the water-to-cement ratio and incorporating chemical admixtures can improve the quality of core concrete, these methods have a limited impact on the quality of the surface zone of concrete. The outer surface skin, which serves as the primary barrier against environmental exposure and damaging substances, plays a vital role in determining the overall durability and longevity of concrete structures. Moreover, the performance of the surface skin is significantly affected by the type of formwork used during the construction1,2,3.

Traditional formwork (steel, plastic, or plywood) is almost completely impervious to air and water. While the fresh concrete is subjected to vibration, the surplus water and entrapped air migrate toward the formed surface. A mixture of water and air is draped at the concrete/formwork interface zone because the wood or steel formwork is impermeable. The water which reaches the interface increases the effective water-cement (w-c) ratio in the cover region. Visually, this may be evident on all concrete surfaces through the presence of blowholes and pin holes following formwork removal4,5,6,7,8. This is really a serious problem because the first line of defence of all structural elements against carbonation, chlorides, frost and abrasion, is the cover zone, which incidentally poor in quality compared to core concrete. Therefore, a surface zone of concrete with low diffusivity, low permeability, and no surface porosity is required for long-term durability.

Controlled permeable formwork (CPF) liners are the formwork system essentially intended to improve the quality of the surface zone of concrete. CPF system consists of a textile liner affixed on usual formwork as shown in Fig. 1. The CPF liner allows the surplus water and entrapped air to drain out from the concrete surface whilst retaining cement and other fine particles5,6,7,8. This enables to lower the w-c ratio and enrich of cement content in the near surface zone of concrete. This action creates a uniform and smooth surface without blowholes, pinholes and surface blemishes9,10,11,12. Further, surface zone of concrete hydrates to a high degree and makes dense surface skin as the CPF liner maintains sufficient moisture which offers a conducive ambiance for effective cement hydration13,14,15,16,17. The reduction in w-c ratio, increased cement content and effective cement hydration in the surface zone of concrete are reported to increase surface strength, abrasion, and resistance to freezing and thawing, as well as reduced water and air permeability, water absorption, depth of carbonation, and chloride and oxygen diffusion18,19,20,21. In addition, they have reported that the tensile strength of CPF concretes was increased by about 25% and mechanism responsible for such high improvement in tensile strength has also been explained22,23,24. Numerous researchers claimed that by use of CPF liner the quality of concrete cover enhanced by 5–30 mm25,26,27.

Two major limitations of concrete are its tendency to experience stresses and its inherent brittleness. Even before the concrete fully cures and gains strength, cracks begin to manifest soon after placement. These cracks compromise the durability as well as the service life of the concrete structures28,29,30. To address cracking issues, recent advancements in concrete technology have focused on incorporating fiber reinforcements, especially glass fibers, with the aim of better controlling and mitigating crack formation and propagation31,32,33,34,35. The GF has good tensile strength, high stiffness-to-weight ratio, excellent dimensional stability under varying loads, excellent resistance to chemicals and corrosive environments36,37,38,39.

Previous research has shown that using a CPF liner enhances the quality of the concrete surface through allowing the surplus water and air to drain out from the concrete surface, particularly increasing its splitting and flexural strength properties. Incorporating glass fibers (GF) has also demonstrated improvements in split tensile and flexural strength of concrete. However, no research has investigated the combined synergistic effects of GF and CPF liner on concrete. GF reinforced concrete has different water requirements and setting behaviors compared to conventional concrete. The glass fiber distribution and orientation near formwork surfaces present unique considerations. Also, the interaction between fiber distribution and the water removal mechanism of permeable formwork might produce unique mechanical behavior not observed in either system alone. This experimental study proposes to examine the impacts on surface characterization, compressive strength, rebound number, splitting tensile strength, flexural strength, Rockwell hardness, and dynamic hardness when using glass fiber reinforced concrete cast against CPF liners.

Experimental program

Materials

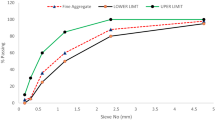

This study employed an Ordinary Portland Cement (OPC) of grade 43, conforming to IS: 8112-201340 was used. The fine aggregate (FA) utilized was Zone-II river sand, compliant with IS: 383-201641. The coarse aggregate (CA) was 20 mm in size and also met the specifications outlined in IS: 383-201641. The water used for concrete mixing in the laboratory adhered to the standards prescribed in IS: 456-202142. Furthermore, a naphthalene formaldehyde condensate-based superplasticizer admixture was used and conforming to IS: 9103-201843.

Concrete mix composition

As per the guidelines of IS: 10,262–201944, the mix proportions are displayed precisely in Table 1.

Permeable formwork liner

For this investigation, the CPF liner used was Type II. It is a single layer system. It had two sides, one side actedas filter and other side acted as drain6. Table 2 displayed the primary specifications of the permeable liner.

Glass fiber (GF)

Figure 2 represents the glass fibers, which can be purchased commercially from Zart, India. These glass fibers are added to the concrete mixtures as a ratio of the total concrete volume. Table 3 displayed the GF’s properties.

Sample preparation and curing

As shown in Fig. 3a,b, the concrete samples were casted by means of steel mould (150 mm size) and the CPF liner was fastened to the plate.

In order to guarantee even dispersion, the superplasticizer is first combined with water. After blending the dry ingredients for a minute, half of the water is added. Glass fibers are gradually added while the water is still running to prevent clumping after three minutes of constant mixing. The fibers are thoroughly distributed during mixing for about five minutes. After that, the concrete is poured into the mould. After one day in the mould, the concrete specimen is removed and left to cure in water until the testing date. The casted concrete specimens are shown in Fig. 4.

Testing of specimen

The surface quality was assessed using a superficial pore measurement test following ASTM B 276-201545 standards. According to IS: 516-201846 guidelines, the compressive strength were conducted on the specimens of cube (150 mm size). For splitting tensile strength length of 200 mm and diameter of 100 mm cylindrical specimen were used according to IS: 5816-201847. Prism specimens of size 100 × 100 × 500 mm were used to find the flexural tensile tests in accordance with IS: 516-201846 guidelines. On 100 mm cube specimens, the following tests were performed: dynamic hardness, Rockwell hardness, and rebound hammer, as specified in ASTM A 956-202248, ASTM E 18-202249, and IS: 13,311: Part 2-201850 respectively.

Results and discussion

Measurement of superficial pores

The surface and superficial pores found in the concrete samples are shown in Fig. 5. The average percentage of surface pores in the concrete specimens with IMF, CPF, and CPF with GF was 24%, 3%, and 3% respectively. The use of a CPF liner resulted in an eight-fold improvement in surface pores. Also, it was observed that the surface pore was almost similar in both CPF and CPF with GF concrete mixtures. The surface of the CPF specimen appears a smooth and fine-grained texture, as shown in the typical picture (Fig. 5).

Compressive strength

Figure 6 presents the compressive strength results. The findings revealed that CPF specimens exhibited higher compressive strengths than IMF specimens at all ages, with improvements ranging from approximately 3–6%, which is considered marginal. These findings are consistent with previous research outcomes18. Compressive strength reflects the characteristics of the entire volume of the concrete specimen. By improving the quality of concrete superficially the physical behaviour of the entire mass cannot be modified18. Furthermore, a comparative analysis with IMF specimens revealed that the incorporation of GF in CPF concrete resulted in notable increases in compressive strength, 10% increase with the addition of 0.5% GF, 14% increase with the addition of 1.0% GF and 18% increase with the addition of 1.5% GF. The substantial improvement in compressive strength, particularly when the GF percentage increased from 0.5 to 1.5%, can be attributed to the presence of glass fibers in the CPF concrete specimens delayed the onset of early cracks. With a GF of 2.0% addition in CPF concrete, the improvement over IMF specimens were about 9%. It was discovered that compressive strength started to decrease when the percentage of GF about 2.0%. This reduction is credited to the reduced adhesion between the fibers and cement paste/gel29,34, as well as the increased air gaps and consolidation/compaction issues caused by the higher fiber content29,34. Consequently, no further improvements were observed beyond 1.5% GF addition.

Split tensile strength

Figure 7 presents the split tensile strength results. The findings revealed that CPF specimens exhibited higher split tensile strengths than IMF specimens at all ages, with improvements ranging from approximately 9–18%. These findings align with previous research18. The usage of a CPF liner had a more noticeable impact on the tensile strength of concrete than compressive strength. As a cylindrical specimen undergoes longitudinal compressive force, a consistent transverse tensile stress is generated throughout the vertical diameter. However, compressive stress dominates at a depth of around 0.1 times the specimen’s diameter in the area of the load point51. The usage of CPF liner a thin, strong and impervious layer was created, once this layer fracture, the specimens breaks quickly. The split tensile strength is greatly increased by this failure process. Additionally, compared to IMF specimens, CPF concrete’s split tensile strength increased by roughly 28%, 34%, and 49%, respectively, with the addition of 0.5%, 1.0%, and 1.5% GF. The split tensile strength significantly increased when the GF percentage increased from 0.5 to 1.5%, most likely because the glass fibers in the CPF concrete specimens delayed the onset of early cracks. In fiber-reinforced concrete (FRC), specimens did not break into two splits exactly under the loaded section and its flexibility prohibited sudden failure. With a GF of 2.0% addition in CPF concrete, the improvement over IMF specimens were about 23%. It was discovered that split tensile strength started to decrease when the percentage of GF about 2.0%. This reduction is credited to the reduced adhesion between the fibers and cement paste/gel29,34. as well as the increased air gaps and consolidation/compaction issues caused by the higher fiber content20,25. Consequently, no further improvements were observed beyond 1.5% GF addition.

Flexural strength

Figure 8 presents the flexural strength results. The findings revealed that CPF specimens exhibited higher flexural strengths than IMF specimens at all ages, with improvements ranging from approximately 19–26%. These findings support earlier research18. The lowermost part of the prism is subjected to the peak tensile stresses during the flexural test. In order to boost the flexural strength of the CPF concrete and postpone the beginning of initial cracks, CPF specimens form a strong and thin shell layer. By adding GF at 0.5%, 1.0%, and 1.5% to CPF concrete led to approximately 35%, 40%, and 47% improvements in flexural strength, respectively, compared to IMF specimens. Since GF stopped early cracks in CPF concrete specimens from forming, flexural strength significantly increased when GF percentage increased from 0.5 to 1.5%. With a GF of 2.0% addition in CPF concrete, the improvement over IMF specimens were about 29%. It was discovered that flexural strength started to decrease when the percentage of GF about 2.0%. As was seen in earlier research, when more than 1.5% of GF was added, the flexural strength decreased.

Rebound number

Figure 9 presents the rebound number results, that indicates a noteworthy rise of rebound number for CPF specimens than IMF specimens at all ages. The development of a robust and thin shell layer on CPF specimens may have contributed to the improvement, which varied from 39 to 50%. These findings support earlier research18. Adding GF at 0.5%, 1.0%, and 1.5% to CPF concrete led to approximately 52%, 61%, and 69% improvements in rebound number, respectively, on comparing to IMF specimens. It was revealed that the rebound number value significantly improved as the GF percentage increased from 0.5 to 1.5%. Nevertheless, only a 56% improvement over the IMF sample was obtained by adding 2% GF to CPF concrete. It was discovered that rebound number started to decrease when the percentage of GF about 2.0%.

Dynamic hardness number

The dynamic hardness numbers of different mixtures of concrete are shown in Fig. 10. These results demonstrate that higher dynamic hardness numbers were found in permeable formwork specimens compared to IMF specimens at all age, with a significant improvement ranging from roughly 31–50%. By adding 0.5%, 1.0%, and 1.5% GF to CPF concrete resulted in a further improvement in the dynamical hardness value of roughly 56%, 64%, and 74% when compared to IMF specimens. As the GF percentage increased from 0.5 to 1.5%, there was a noticeable increase in the dynamic hardness number. By adding 2.0% of GF to CPF concrete, the improvement over IMF specimens was only 56%, it was indicated that the dynamical hardness value begins to decline when GF percentage adding 2.0%.

Superficial Rockwell hardness number

The superficial Rockwell hardness numbers of different mixtures of concrete are shown in Fig. 11. According to the findings, on comparing with IMF specimens at all ages, CPF specimens showed a significant improvement in Rockwell hardness numbers, ranging from roughly 21 to 31%. When glass fiber was added to permeable formwork concrete at 0.5%, 1.0%, and 1.5%, there was an further improvement in the Rockwell hardness number of about 36%, 49%, and 64% when compared to IMF specimens. As the GF percentage increased from 0.5 to 1.5%, there was a noticeable increase in the Rockwell hardness number. By adding 2.0% of GF to CPF concrete, the improvement over IMF specimens was only 53%, it was indicated that the Rockwell hardness number begins to decline when GF percentage adding 2.0%.

Conclusions

The experimental analysis of the present study produced the subsequent conclusions.

-

1.

The workability of concrete decreased when glass fiber was added, and the percentage of glass fiber increased, resulting in stiffer and more challenging to compaction of concrete. Doses exceeding 1.5% resulted in significant stiffness and compaction difficulties.

-

2.

The quality of concrete surfaces was much enhanced by the application of CPF liner, particularly in terms of the reduction of surface defects and pores. The surface pores in the CPF specimens were about 3% smaller than that of IMF specimens, a difference of eight times.

-

3.

There was a marginal improvement in compressive strength (3–6%) in CPF concrete compared to IMF concrete. CPF concrete with GF showed considerable performance gains of 10–18%.

-

4.

The split tensile strength of CPF concrete was significantly increased by 9–18% in comparison with conventional concrete. In the CPF concrete with 0.5–1.5% of GF, the additional improvement was observed in the range of 28–49%.

-

5.

The flexural tensile strength of CPF concrete was significantly increased by 19–26% when compared to IMF concrete. The improvement of CPF concrete with 0.5–1.5% of GF was in the range of 35–47%.

-

6.

CPF concrete showed a significant increase by 39–50% in rebound numbers compared to IMF concrete specimens. The additional improvement was observed in the range of 52–69% for CPF concrete with 0.5–1.5% of GF.

-

7.

The dynamic hardness number of CPF concrete was significantly increased by 31–50% when compared to IMF concrete. The improvement of CPF concrete with 0.5–1.5% of GF was in the range of 56–74%.

-

8.

CPF concrete showed a significant increase by 21–31% in Rockwell hardness numbers compared to IMF concrete specimens. The additional improvement was observed in the range of 36–64% for CPF concrete with 0.5–1.5% of GF.

Recommendations for future research

The following recommendations are made to supplement the present study:

-

A study on cement content and w/c at covercrete region of concretes may be carried out.

-

Efficiency of CPF liner on horizontal members, like slab elements may be studied.

-

A study the influence of CPF liner on structural behaviour of concrete is important one.

-

Studies of rebar corrosion in CPF concrete exposed to actual marine conditions may be carried out.

-

Comparative study of various types of cements may be carried out.

-

A study on the effect of CPF liner on high performance concrete/high strength concrete.

-

Development of cost effective CPF liner may be worth an important study.

Data availability

The data provided for the results presented in this study is available through the corresponding author upon request.

References

Alexander, M. & Beushausen, H. Durability, service life prediction, and modelling for reinforced concrete structures - review and critique. Cem. Concr Res. 122, 17–29 (2019).

Kandasamy, S. & Kothandaraman, S. Influence of controlled permeable formwork liner on surface quality of self-compacting concrete. Constr. Build. Mater. 260, 1–7 (2020).

Kandasamy, S., Gowthaman, M., Gowdhamramkarthik, P., Venkatesh Marshall Raman, J. & Magenthiran, B. Strength and durability performance of concrete cast using permeable formwork liner. J Buil Patho & Rehabili 9(86). (2022).

Kandasamy, S., Gowdhamramkarthik, P., Syed Ibrahim, S., Chandra Bose, S., Thulasirajan, K. & R. & The effect of permeable formwork on durability and corrosion performance of concrete. Case Stud. Constru Mater. 16, e00838 (2022).

Shyha, I., Richardson, A., Coventry, K. & Ponton, H. Mould release technologies with regard to concrete surface finish. Magaz Concr Res. 68 (2), 87–98 (2016).

Krishnan, T. & Telkar, S. K. Influence of nonwoven fabric as controlled permeable formwork liner in concrete. Mater. Today: Proceed. 64 (2), 1048–1053 (2022).

Price, W. F. Controlled permeability formwork, CIRIA Report, C 511 (2000).

Ambad, V., Narwadeb, R. & Nagarajanc, K. Impact of controlled permeable formwork liner against chloride penetration on the concrete structures. J. Res. Eng. Struct. Mater. 8 (1), 117–126 (2021).

Law, D. W., Molyneaux, T. & Aly, T. Long term performance of controlled permeability formwork. Aust J. Civ. Engg. 15, 117–125 (2017).

Herrmann, M. et al. Flexible formwork technologies–a state of the Art. Struct. Concr. 17 (6), 1–48 (2016).

Kandasamy, S. & Kothandaraman, S. The effect of formwork liner on the service life of self-compacting concrete. Asian J. Civ. Eng. 21 (7), 1239–1247 (2020).

Adam, A. A., Molyneaux, T. C., Patnaikuni, I. & Law, D. The effect of controlled permeability formwork on the curing of concrete. Prog Mecha Struct. & Mater. CRC Press 611–615 (2020).

Kandasamy, S. & Kothandaraman, S. Effect of formwork liner on durability and corrosion characteristics of self-compacting concrete. KSCE J. Civ. Eng. 25 (6), 2046–2052 (2021).

Li, W., Lin, X., Bao, D. W. & Xie, Y. M. A review of formwork systems for modern concrete construction. Structures 38, 52–63 (2022).

Schulte Holthausen, R., Merkel, M., Breit, W. & Raupach, M. Monitoring the microstructural deterioration of concrete exposed to leaching in purified water. Civ. Engg Des. 4 (4), 99–109 (2022).

Ye, J., Yu, L. & Chen, Y. Study on the mitigative effect of controlled permeability formwork liner on early-age shrinkage of box-girder concrete. J. Adv. Mater. Sci. Engg. 4150279, 1–8 (2019).

Aissoun, B. M., Gallias, J. L. & Khayat, K. H. Influence of formwork material on transport properties of self-consolidating concrete near formed surfaces. Constr. Build. Mater. 146, 329–337 (2017).

Garg, S., Nim, K. S., Bajpai, K. K. & Misra, S. Enhancement in the quality of near surface concrete using some formwork liners. Constr. Build. Mater. 207, 722–733 (2019).

Guo, B. L., Wang, B. M., Han, Y. & Jiang, R. Improvement of concrete property with controlled permeability formwork. Revista Romana De Mater. 50, 379–386 (2020).

Megid, W. A. & Khayat, K. H. Variations in surface quality of self-consolidation and highly workable concretes with formwork material. Constr. Build. Mater. 238, 117638 (2020).

Sørensen, H. E. & Poulsen, S. L. Effect of curing regime and controlled permeability formwork on early chloride penetration into fly Ash concrete, in book: High Tech Concrete: where Technology and Engineering Meet, Springer, Cham, January. (2018).

Menaka, B., Sundari, S. & Kumar, G. A. A review on effect of controlled permeable formwork (Cpf) liner on concrete. Inter J. Adv. Engg Managt. 4 (1), 527–532 (2022).

Tahmoorian, F., Nemati, S. & Soleimani, A. A state of the Art on the structural performance of fabric formwork systems. Eng. Sol Mech. 8, 49–62 (2020).

Kandasamy, S. & Kothandaraman, S. Influence of controlled permeable formwork liner on the service life of reinforced concrete. J. Mater. Civ. Eng. 33 (6), 04021103 (2021).

Kothandaraman, S. & Kandasamy, S. The effect of controlled permeable formwork (CPF) liner on the surface quality of concrete. Cem. Conc Comp. 76, 48–56 (2017).

Kothandaraman, S. & Kandasamy, S. The effect of controlled permeable formwork liner on the mechanical properties of concrete. Mater. Structur. 49, 4737–4747 (2016).

Kothandaraman, S., Kandasamy, S. & Sivaraman, K. Studies on the effect of controlled permeable formwork liner on the properties of self-compacting concrete. Constru Build. Materi. 118, 319–326 (2016).

Qureshi, A. & Ahmed, A. An investigation on strength properties of glass fiber reinforced concrete. Inter J. Eng. Res. Tech. 2 (4), 2567–2572 (2013).

Chandramouli, K., Srinivasa Rao, P., Pannirselvam, N., Sekhar, S., Sravana, P. & T. & Strength properties of glass fiber concrete. ARPN J. Eng. Appl. Sci. 5 (4), 1–6 (2010).

Afroughsabet, V., Biolzi, L. & Özbakkaloğlu, T. High–Performance Fiber–Reinforced concrete: A review. J. Mater. Sci. 51, 6517–6551 (2016).

Asokan, P., Osmani, M. & Price, A. D. F. Improvement of the mechanical properties of glass fibre reinforced plastic waste powder filled concrete. Constr. Build. Mater. 24, 448–460 (2010).

Alam, M. D., Ahmad, I. & Rahman, F. Experimental study on properties of glass fibre reinforced concrete. Inter J. Eng. Tren Tech. 24 (6), 297–301 (2015).

Soong, W. H., Raghavan, J. & Rizkalla, S. H. Fundamental mechanisms of bonding of glass fibre reinforced polymer reinforcement to concrete. Constr. Build. Mater. 25, 2813–2821 (2011).

Tassew, S. T. & Lubell, A. S. Mechanical properties of glass fiber reinforced ceramic concrete. Constr. Build. Mater. 51, 215–224 (2014).

Tian, D. et al. Waste glass powder as a high temperature stabilizer in blended oil well cement pastes: hydration, microstructure and mechanical properties. Constr. Build. Mater. 439, 137359 (2024).

Xu, L., Hongwei, L., Percy, M. I. & Shao-Bo, K. Predicting the bond stress–slip behavior of steel reinforcement in concrete under static and dynamic loadings by finite element, deep learning and analytical methods. Engg Fail. Analy. 161, 108312 (2024).

Wei, Z., Xinze, Y., Jinwei, L., Benqing, L. & Yiqun, H. Experimental and numerical study on the torsional behavior of rectangular Hollow reinforced concrete columns strengthened by CFRP. Structures 70, 107690 (2024).

Zhangsong, J. et al. Synergistic Preparation and properties of ceramic foams from wolframite tailings and high-borosilicate waste glass. Constr. Build. Mater. 457, 139367 (2024).

Zhangsong, J. et al. Contrasting effects of waste glass and scheelite tailings additions upon the properties of tailings-based foam ceramics and its mechanisms. J. Clean. Produc. 450, 142025 (2024).

IS:8112:2013, Specification for ordinary portland cement – 43 Grade, Bureau of Indian Standards, New Delhi. (2013).

IS:383:. Specification for coarse and fine aggregate from natural sources for concrete, Bureau of Indian Standards, New Delhi. (2016). (2016).

IS:456. :2021, Plain and Reinforced Concrete, Code of Practice (Bureau of Indian Standards, 2021).

IS:9103:2018, Specification for concrete admixtures, Bureau of Indian Standards, New Delhi. (2018).

IS:10262. Guidelines of concrete mix proportioning, Bureau of Indian Standards, New Delhi. (2019). (2019).

ASTM B 276. :2015, Standard Test Method for Apparent Porosity in Cemented Carbides (American Society for Testing Materials, 2015).

IS:516:2018. Methods of Tests for Strength of Concrete (Bureau of Indian Standards, 2018).

IS:5816:2018. Method of Test for Splitting Tensile Strength of Concrete (Bureau of Indian Standards, 2018).

ASTM A 956. :2022, Standard Test Method for Leeb Hardness Testing of Steel Products (American Society for Testing Materials, 2022).

ASTM E 18. :2022, Standard Test Method for Rockwell Hardness of Metallic Materials (American Society for Testing Materials, 2022).

IS:13311. Part 2:2018, Methods of Test for non-destructive Testing of Concrete (Bureau of Indian Standards, 2018).

Neville, A. M. Properties of concrete, Pearson Education, India, 4th Ed. (1995).

Author information

Authors and Affiliations

Contributions

S. Kandasamy: Formal analysis, Conducting experiments, Writing & editing, Methodology and reviewing; M. Thanmanaselvi: Conceptualization, Supervision, Methodology and reviewing Project Manager; M.V.V. Thirumuruga Poiyamozhi: Conceptualization, Reviewing & editing; Sivarama Krishna Lakkaboyana: Formal analysis, Reviewing & editing; Herri Trilaksana: Reviewing & editing; Ahmad Ansari: Review & editing; N. Pannirselvam: Writing- Review & editing; J. Venkatesh Marshall Raman: Review & editing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Kandasamy, S., Thirumuruga Poiyamozhi, M.V.V., Thanmanaselvi, M. et al. Investigating the influence of permeable formwork on the mechanical characteristics of glass fiber reinforced concrete. Sci Rep 15, 31270 (2025). https://doi.org/10.1038/s41598-025-03735-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-03735-9