Abstract

In recent years, ultra-high-performance concrete (UHPC) has been widely used in bridge engineering owing to its high strength and toughness and excellent durability. UHPC can improve the stiffness of composite slabs and solve fatigue cracking and failure problems. However, the mechanical properties of UHPC are susceptible to curing conditions. Moreover, the bonding between steel and UHPC is affected by curing conditions owing to the large difference in their thermal expansion coefficients. Therefore, this study investigates the bending performance of steel-UHPC composite slabs under different curing conditions. Three steel-UHPC composite slab specimens were designed and fabricated under different curing conditions (28 days of standard curing, 48 h of curing at 70 °C and 90 °C), and subjected to bending tests to analyze their failure process, failure mode, load deflection response and load-strain curve. A finite element model was established to study the influence of the number of studs, thickness of the UHPC plate, and thickness of the steel plate on the flexural performance of the steel-UHPC composite slab. The results show that the failure mode of the steel-UHPC composite slabs under different curing conditions is complete flexural failure, and the failure process is divided into three primary stages: elastic stage, crack development stage, and yield stage. Compared with standard curing conditions, high-temperature curing can effectively inhibit the development of cracks and improve the ductility and flexural bearing capacity of steel-UHPC composite slabs. The ultimate bearing capacity of steel-UHPC composite slabs under the action of a positive bending moment is significantly influenced by the curing condition, whereas it is less affected by the action of a negative bending moment. The morphological patterns of the interface slip curves along the longitudinal axis of symmetry of the steel-UHPC composite slabs and the strain distribution laws along the height direction of the mid-span section are consistent under different curing conditions. The curing conditions had a significant impact on the interface slip within the shear bending section. Under all curing conditions, the flexural bearing capacities of the steel-UHPC composite slabs increase with the parameters, such as the number of shear studs, thickness of the steel plate, and thickness of the UHPC, but the degrees of influence of these parameters are different.

Similar content being viewed by others

Introduction

As a critical component of the structure of a bridge, the bridge slab directly bears the wheel pressure of a vehicle, and its working state directly affects the performance of the bridge1; therefore, it is of great significance to select the appropriate bridge slab structure when designing the bridge structure. Currently, the commonly used forms of bridge slabs include reinforced concrete and steel bridge slabs. Concrete bridge slabs are often constructed via on-site pouring. It requires setting up scaffolding and vertical formwork, which can cause some interference with urban traffic, and the removal cost is also high. Concrete bridge slabs have relatively large thickness and weight; however, it is difficult to fulfill the design requirements of long-span bridge slabs. Steel bridge slabs can realize the design and application of large span; however, several problems, such as prominent fatigue disease, low stiffness, easy damage to asphalt pavement, and high maintenance cost, exist. To effectively solve the above-mentioned problems, scholars have fully utilized the mechanical and physical characteristics of steel and concrete materials, complemented each other, and leveraged their respective material advantages to propose steel–concrete composite slabs2. Steel concrete composite slabs are a new type of bridge slab composed of steel bottom plates and upper concrete plates connected by shear connectors, such as bolts or perforated steel plates (PBLs)3. Steel–concrete composite slabs are widely used owing to their high bearing capacity, high stiffness, and relatively low section height.

Ultra-high-performance concrete (UHPC), a new type of ultra-high-performance cement-based composite material, has the characteristics of high strength, high modulus, good toughness, durability, and excellent crack resistance. Moreover, the early mechanical properties of UHPC can be rapidly improved by high-temperature curing4. Therefore, an increasing number of researchers have applied it to composite slabs and called them steel-UHPC composite slabs. Steel-UHPC composite slabs can reduce the self-weight, improve structural stiffness, reduce the live load stress amplitude, and solve the fatigue cracking problem of traditional orthotropic steel slab structures. The structural form of steel-UHPC is shown in Fig. 1. Steel-UHPC composite slabs are widely used in girder bridges, arch bridges, cable-stayed bridges, and suspension bridges5, such as the slab pavement of the Tarim River Bridge, slab pavement reconstruction of the Wuhan Junshan Yangtze River Bridge, and slab pavement of the Baigou River Steel Arch Bridge of the Jingxiong Expressway.

To date, scholars at home and abroad have conducted extensive research on the mechanical properties of steel-UHPC composite slabs via experiments, theoretical analyses, numerical simulations, and other methods, primarily including the static and fatigue properties of steel-UHPC composite slabs, design of shear connectors, and influence of factors such as steel plate type and UHPC strength on the mechanical properties of steel-UHPC composite slabs. Yizhi et al.6 conducted static loading tests on four steel-UHPC composite slabs, examined the influence of fiber content on UHPC cracking and the mechanical properties of composite slabs under transverse and longitudinal negative bending moments and deduced the bending calculation formula of steel-UHPC composite slabs based on the crack width. The results indicate that the calculation formula can fully predict the bending behavior of composite slabs. Wenguang et al.4 obtained the failure mode, load–deflection, and crack width of steel-UHPC composite slabs under positive and negative bending moments via a bending performance test of steel-UHPC and calculated the cracking strength and flexural bearing capacity. Zhou et al.7 conducted experimental research and numerical simulations on the bending of steel-UHPC composite slabs with perforated plate shear keys. The test results indicated that the specimen with more perforated plate shear keys exhibited the best mechanical performance. Junyuan et al.8 proposed a steel-UHPC composite slab with a fabricated stud connection. They showed that the failure mode of a steel-UHPC composite slab with a fabricated connection is longitudinal horizontal shear bond failure. A calculation method for the ultimate bearing capacity and a calculation formula for the bending stiffness of the structure were derived. Jinben et al.9 studied the flexural performance of a structure by testing a detachable steel-UHPC composite slab. The test results of the failure modes of specimens with different types of steel plates show that the combination mode of a steel plate with a negative Poisson’s ratio has better bending performance. Zhenyu et al.10 studied the flexural behavior of corrugated steel and concrete composite slabs with modified studs (MCL-shaped) and the effects of the steel plate thickness, UHPC thickness, and shear span length on the flexural behavior. The results show that studs can provide longitudinal and transverse shear strengths, and increasing the thickness of the steel plate and UHPC can increase the yield and ultimate loads. In addition, a formula to calculate the bearing capacity was provided. Zongxuan et al.11 compared and analyzed the bending performance of a steel bar-UHPC composite slab and a steel plate-UHPC composite slab and established a method to analyze bending. The results show that steel plates can improve the crack resistance and stiffness of composite slabs more than steel bars, and narrow-height composite slabs have superior bending performance.

Based on existing research findings, studies related to the flexural performance of steel-UHPC composite slabs primarily focus on specimens cured under high-temperature conditions, whereas relatively few studies exist on specimens cured under standard conditions. Different curing conditions have a profound impact on the mechanical properties of UHPC12,13,14,15,16,17. Under standard curing conditions, the hydration reaction of the UHPC is stable, and its strength gradually increases. It takes a long time to reach a high strength, and its performance is limited. Contrastingly, high-temperature curing can rapidly improve the early strength of UHPC, promote the development of late strength, optimize the microstructure, and enhance durability18. Additionally, the thermal expansion coefficients of steel and UHPC differ greatly, and the bonding between them is easily affected by the curing conditions. Therefore, it can be inferred that the curing condition has a certain impact on the flexural performance of steel-UHPC composite slabs. In engineering applications, steel-UHPC composite slabs are mostly cured under high-temperature conditions, but the process is costly and the construction process is cumbersome. In comparison, standard curing can reduce the construction costs and simplify the construction process. However, the mechanical performance of steel-UHPC composite slabs under standard curing relative to that under high-temperature curing conditions needs to be further studied.

This study aims to investigate the bending performance of steel-UHPC composite slabs under different curing conditions. Accordingly, three scaled specimens of steel-UHPC composite slab are designed and fabricated under different curing conditions (standard curing for 28 days and curing at 70 °C and 90 °C for 48 h), and bending tests are conducted to analyze their failure process, failure mode, load–deflection response, and load-strain curve. On this basis, a finite element model was used to study the effects of three parameters, namely, the number of bolts, thickness of the UHPC plates, and thickness of the steel plates, on the bending performance of the steel-UHPC composite slabs. The accuracy of the finite element method was verified based on the experimental data obtained in this study and the literature. The conclusions drawn from this study provide guidance for the design and application of steel-UHPC composite slabs in bridge engineering.

Test overview

Design and manufacture of specimen

Three different curing conditions (standard curing for 28 days, curing at 70 °C for 48 h, curing at 90 °C for 48 h) of steel UHPC composite slab scaled specimens were designed and fabricated according to the dimensions of orthotropic steel slabs in practical engineering in recent years, and taking into account laboratory conditions. The details of specimens are displayed in Fig. 2. The specimens were mainly composed of a steel plate with a size of 1400 mm × 100 mm × 14 mm, a UHPC plate with a size of 1200 mm × 200 mm × 50 mm and seven bolts. Three different curing conditions were set up in the test, which were standard curing for 28 days, curing at 70 °C for 48 h and curing at 90 °C for 48 h, and the corresponding specimens were numbered as SU-standard, SU-70 and SU-90.

The design strength of the UHPC plate in the specimens is 100 MPa, and the steel type is Q345. The reinforcement in the UHPC layer, which is of grade HRB400 with all diameters of 10 mm, has a longitudinal and transversal spacing of 50 mm. The bolts between the UHPC layer and the steel plate have a diameter of 13 mm, an initial height of 38 mm which becomes 35 mm after welding, and are spaced 250 mm apart. The reinforcement arrangement of the three specimens is kept the same.

Figure 3 shows the fabrication process of the steel-UHPC composite slab, including binding steel bars, erecting steel mesh, pouring UHPC, standard and high temperature curing, and pasting strain gauges.

Material properties

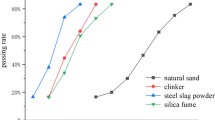

According to the national standard of Reactive Powder Concrete (GB/T31387-2015)19 and the existing research, the UHPC material in this test is designed according to the design strength grade of 100 MPa, and steel fibers with a specification of 0.16 mm in diameter and 13 mm in length are incorporated, with a volume content of 2%. The composition and mix proportion are shown in Table 1.

Specimens for testing UHPC properties are poured and cured together with test pieces. The material properties test specimens were divided into 4 groups, each having 12 specimens. Specifically, these four groups respectively consist of 150 mm × 150 mm × 150 mm standard cubic test blocks used for testing the compressive strength of UHPC cubes, 100 mm × 100 mm × 300 mm prismatic test blocks employed to test the axial compressive strength, 150 mm × 150 mm × 150 mm standard cubic test blocks utilized for testing the splitting tensile strength of UHPC, and 100 mm × 100 mm × 400 mm prismatic test blocks applied to test the flexural strength.

The basic mechanical property parameters of UHPC measured in the test are shown in Table 2. The steel plate and stud shear keys are made of Q345 steel, and the reinforcing bar is made of HRB400 grade steel, and its mechanical property parameters are shown in Table 3.

Loading method and measuring point arrangement

The loading techniques for the three specimens use four-point bending static loading, as illustrated in Fig. 4. The net distance between the two seats is 1000 mm, the computed span is 1000 mm, and a pure bending section measuring 400 mm in length is formed at the midpoint of the span via the distribution beam. A fixed hinge support and a sliding hinge support are positioned at each end of the specimen to establish a simply supported border. The test employs a hydraulic jack for loading, with the load monitored by a pressure sensor accurate to 0.1 kN.

The vertical deflection of the pure bending section of the specimen was measured by setting up a displacement meter at the bottom of the plate. The three measured positions were below the center point and 100 mm and − 100 mm away from the center point, respectively, as shown in Fig. 4. Strain gauges were attached to the pure bend section in the span of the specimen to measure the strain of UHPC, steel bar and steel plate. The specific strain measuring points were arranged as shown in Fig. 5. The strain and displacement data are automatically collected by the static signal acquisition system, as shown in Fig. 6.

Test results and analysis

Failure process and failure modes

The failure mode of each specimen in the test is bending failure, which can be categorized into three stages: elastic stage, crack development stage, and yield stage. Throughout the examination, the failure characteristics of the three specimens exhibit similarity; however, the loads sustained at each phase differ. Table 4 records the main failure phenomena at the three stages during the loading process.

Figure 7 shows the failure mode of the steel-UHPC composite slab of standard curing 28d. It can be seen from the figure that the cracks of the steel-UHPC composite slab are mainly distributed in the pure bend section, and the cracks are dense and obvious in the middle. Because UHPC has ultra-high compressive strength, there are no obvious cracks at the top of UHPC. In addition, when the steel-UHPC composite slab is destroyed, the steel plate at the left end is separated from the UHPC interface, and the separation length extends from the end of the plate to the middle of the span. After unloading, the steel plate has obvious rebound, while the UHPC plate at the end is obviously raised and the degree of recovery is small.

Figure 8 is the failure mode of steel-UHPC composite slab cured at 70°C for 48 h. It can be seen from the diagram that the cracks of the steel-UHPC composite slab are mainly distributed in the pure bending section, and the dense cracks are at the end of the separation near the interface and the cracks are thin and short. In addition, when the steel-UHPC composite slab is damaged, the interface between the right end steel plate and UHPC is separated, the separation length does not extend to the pure bending section, the interface separation is not obvious during loading, the steel plate has obvious rebound after unloading, and the UHPC recovery degree is small, and the UHPC plate at the end is obviously warped but the degree is less than that of standard curing.

Figure 9 shows the failure mode of steel-UHPC composite slab cured at 90 °C for 48 h. It can be seen from the figure that the cracks of the steel-UHPC composite slab are also distributed in the pure bend section, and the crack distribution is relatively uniform with only small cracks. In addition, when the steel-UHPC composite board is damaged, the bolts are cut due to excessive interface slip. After the bolts are cut off, the steel plate at the left end is separated from the UHPC interface, and the separation length extends from the end to the mid-span. At the late loading stage, it can be clearly seen that the deflection of the steel-UHPC composite slab is greater than that of the composite slab cured for 28 days, indicating that high temperature curing can improve the ductility of the steel-UHPC composite slab.

The analysis of the failure modes of the steel-UHPC composite slab under the three specified curing conditions reveals that all specimens exhibit the same failure mode. However, the ductility and ultimate bearing capacity of the specimens are enhanced following curing at 70 °C for 48 h and 90 °C for 48 h at elevated temperatures. In the early stage of loading, the steel-UHPC composite slabs with standard curing and high temperature curing have good cooperative working ability. During the development of cracks, the ductility of the specimens cured at high temperature is better than that of the standard curing, and the ultimate bearing capacity is also increased by 14.9%, indicating that high temperature curing can effectively inhibit the development of cracks, improve the ductility of steel-UHPC composite slabs, and thus improve the flexural bearing capacity.

Load–deflection

The load–deflection curves of steel-UHPC composite slabs with three curing conditions obtained from the test are shown in Fig. 10. It can be seen from the figure that the load–deflection curves of the three specimens have similar development rules, which can be divided into three stages: (1) In the linear elastic stage, the load and deflection increase linearly, while the stiffness of each specimen remains unchanged. (2) In the crack development stage, the load continues to increase, and it can be observed that the interface between the steel plate and the UHPC plate slips, and small cracks appear in the middle of the specimen. The loading continues until the failure load of the bolts in the shear section reaches the peak value. (3) During the yield stage, the cracking load experiences a sudden decline due to the shearing of the stud bolts in the preceding stage. The pure bending section exhibits pronounced bending, and the interface separation between the UHPC plate and the steel plate progressively extends from the end towards the mid-span, while the cracks persist in their propagation. At this time, the reinforcing bars in the tension zone and the steel plate jointly bear the load, and the load rises gently. As the load increases, after the stud bolts at the end are damaged, the steel plate bears the load, and the load still rises steadily until the steel plate yields. Finally, after the steel plate yields, the bearing capacity remains unchanged, but the deflection increases continuously, and there is obvious interface separation between the steel plate and the UHPC plate at one end of the steel-UHPC composite slab.

In the elastic stage, the stiffness of the specimen cured at 70 °C for 48h is slightly higher than that of the specimen cured at 90 °C and the standard curing. By comparing the specimens of the three curing conditions, it can be found that the crack development stage will be extended with the curing temperature increasing, indicating that high temperature curing can improve the ductility and bending bearing capacity of steel-UHPC composite plate.

Load–strain

Figure 11 shows the development of UHPC surface tensile strain, surface reinforcement strain and steel plate strain in the mid-span section during the loading process of each specimen. Combined with the test data, when the elastic limit load is reached, the UHPC compressive strains on the top of the three specimens cured at standard curing 28 d, 70 °C and 90 °C for 48 h are-263.3 με, − 587.4 με and − 702.7 με, respectively.

As can be seen from Fig. 11a, the UHPC top surface strain of the specimen under standard curing increased by 324 με ~ 440 με in the elastic stage compared with that under high temperature curing. The main reason is that the longitudinal reinforcement in the UHPC slab limits the shrinkage of UHPC, so that the initial tensile stress appears inside the UHPC after high temperature curing. Secondly, the ultimate compressive strain of UHPC given in the yield stage according to the specification20 is 4000 με, while the test results show that the compressive strain of the upper surface of the UHPC in the middle span during the failure of the three specimens after standard curing for 28d, 70 °C and 90 °C curing for 48h is 862 με, 2142 με and 2115 με, respectively. It is indicated that the high temperature curing at 70 °C and 90 °C improves the ductility of UHPC in steel-UHPC composite slabs.

The yield strain of Q345 steel is 2378 με according to the calculation, and the strain of the steel plate at yield measured by the test is 1066με, 1255.9 με and 1675.5 με, respectively. As can be seen from Fig. 11b, when the ultimate load is reached, the steel plate of the specimen cured at 90 °C reaches the yield strain, while the steel plate strain of the specimen cured at 70 °C and standard curing reaches 74% and 64% of the yield strain, indicating that the specimen cured at high temperature curing can better exert the ability of steel plate and UHPC to work together in the crack development stage.

In order to clarify the stress state and role of steel bars in the bending of steel-UHPC composite slab, the strain of longitudinal tensile steel bars in the pure bending section of UHPC plate was measured, and the results are shown in Fig. 12. It can be seen from the diagram that the steel bar is in the elastic stage before reaching the ultimate load. The steel bar strain shows an obvious inflection point after the cracking of UHPC, indicating that the cracking of the bottom surface of UHPC has a great impact on the steel bar. The specimens of standard curing 28d, 70°C curing 48 h and 90°C curing 48h yield when the strain of steel bar reaches 1100 με, 1255 με and 1623 με, respectively. This shows that after curing at 70°C and 90°C for 48h, the ability of steel plate, steel bar and UHPC to work together is better than that of standard curing specimens and improves the ductility of steel-UHPC composite slabs.

Comparative analysis of the test data

The experimental results on the flexural performance of steel-UHPC composite plates under different curing conditions are shown in Table 5. From the data in the table, it can be seen that in the elastic stage, the elastic ultimate loads of both SU-Standard and SU-90 are 33.7 kN, while the elastic ultimate load of SU-70 reaches 35.5 kN, indicating that curing at 70 °C for 48 h can, to a certain extent, enhance the load resistance capacity of the specimens in the elastic stage. The absolute value of the compressive strain on the upper surface of the UHPC slab increases with the rise of the curing temperature, suggesting that high-temperature curing may enable the UHPC slab to bear greater compressive stress in the elastic stage. By analyzing the steel bar strains of the specimens, it is found that the steel bar strain of the SU-Standard specimen is the largest, and that of the SU-70 specimen is the smallest, indicating that the steel bars under the curing condition of 70 °C are subjected to relatively small forces in the elastic stage. In the yield stage, the ultimate load, mid-span deflection, strain on the upper surface of the UHPC slab, and strain on the bottom surface of the steel plate of the specimens increase with the rise of the curing temperature, indicating that high-temperature curing can enhance the deformation capacity of the specimens in the yield stage, but it may reduce the structural stiffness. In addition, high-temperature curing also makes the UHPC slab and the steel plate bear greater stress.

In summary, the specimens cured at 70 °C for 48 h exhibit good load-bearing capacity in both the elastic stage and the yield stage. However, as the curing temperature increases to 90 °C, the elastic ultimate load of the specimens decreases to a certain extent, while the ultimate load corresponding to the yield stage increases significantly. This phenomenon indicates that the change in curing temperature has a differential impact on the load-bearing characteristics of the specimens at different stress stages. Although a higher curing temperature is not conducive to the improvement of the load-bearing capacity in the elastic stage, it can enhance the load-bearing capacity in the yield stage. Therefore, when designing the specimens, if the performance of the steel-UHPC composite slab in the elastic stage is emphasized, it is recommended to adopt the curing method of curing at 70 °C for 48 h; if the performance of the steel-UHPC composite slab in the plastic stage is emphasized, it is recommended to adopt the curing method of curing at 90 °C for 48 h.

Finite element analysis

Finite element modelling

The finite element model of steel-UHPC slab composite slab was established by software ABAQUS to study the bending performance of composite slab under different curing conditions.

The UHPC plate, steel plate and stud were simulated by a three-dimensional eight-node reduced integral solid element (C3D8R). Compared with the complete integral element, the integral element reduces a certain number of integral points, thus greatly reducing the calculation time and improving the calculation efficiency. The three-dimensional two-node linear interpolation truss element T3D2 is used to simulate reinforcement. After the sensitivity analysis of mesh size, different mesh sizes are adopted for different components in the model. The mesh size of UHPC plate, steel plate and steel bar is set to 20 mm, and the studs need to be divided into regular blocks and then divided into 3 mm grids before grid division. The grid division result is shown in Fig. 13.

The mechanical behavior of UHPC is described by the concrete damage plasticity (CDP) model. The stress–strain relationship of UHPC under compression and tension is based on the UHPC constitutive model proposed by Yang et al.21 and Zhang et al.21 respectively, as shown in Fig. 14, which can be calculated by Eqs. (1) and (2):

where, fc is the compressive strength of the cylinder, reference23 fc = 0.95 fcu; ε0 is the peak strain, ξ = ε/ε0; n = Ec/Es, Ec is the initial elastic modulus, Es is the secant modulus of the peak point, Es = fc/ε0; fct is the average stress of UHPC yield stage; εca is the peak strain of UHPC tensile elastic stage; εpc is the ultimate strain.

The CDP model in ABAQUS involves five plastic parameters. Among them, eccentricity (e), the ratio of initial equal biaxial compression yield stress to initial uniaxial compression yield stress (fb0/fc0) and the ratio of the second stress invariant on the tensile meridian Kc are the default values, which are 0.1, 2/3 and 1.16, respectively23. The expansion angle (ψ) and the viscosity coefficient (λ) are determined by referring to the existing numerical simulation studies20,25,26,27,28 and numerical analysis experience, which are set to 30° and 0.0005, respectively.

The constitutive model of the steel plate is represented by a three-segment stress–strain curve, as depicted in Fig. 15. The constitutive model of the reinforcing bar is characterized by a two-segment stress–strain curve, as illustrated in Fig. 16. The mechanical behavior of the steel plate and reinforcing bar can be quantitatively determined using Eqs. (3) and (4), respectively.

where, fy is the yield strength of the material; εy is the yield strain of the material; Es is the elastic modulus of the material; fu = 510MPa; εu is the tensile ultimate strength of the steel plate and its corresponding ultimate strain; E's is the elastic modulus of the strengthening section.

The bolt adopts three-fold stress–strain relationship29, which can be calculated by Eq. (5) below:

where, fsy is the yield strength of the bolt; Ess is the elastic modulus; εsy is the strain of the stud at yield, εsy = fsy/Ess = 1.82 × 10–3; εsu is the strain when the stud reaches the ultimate strength, and the value is εsu = 21εsy, εsu = 3.822 × 10–2 according to literature24.

The interface contact and friction between the steel plate and the UHPC plate are simulated by surface-to-surface contact. The upper surface of the steel plate is used as the main surface, and the lower surface of the UHPC plate is used as the slave surface. The “hard contact” and “penalty function” algorithms with a friction coefficient of 0.4 were used respectively for normal and tangential interactions between the main and slave surfaces. Tie contact simulation is used between the stud and the steel plate, and the studs and steel bars are embedded in the UHPC plate in a built-in manner. The reference points RP3 and RP4 are established at the center of the pad block, and the coupling constraints are set up to make RP3 simulate the rolling hinge support and RP4 simulate the fixed hinge support. In the finite element analysis, the load is applied by displacement loading method. Reference points RP1 and RP2 are established at the center point of the cushion blockand, and 25 mm vertical displacement is applied to the reference points. Figure 17 is the established finite element model.

Model validation

Figure 18 shows the comparison between the tensile damage diagram of UHPC plate and the test failure mode. It can be seen from the figure that the tensile area of the steel-UHPC composite slab under load is mainly concentrated in the pure bend section, which is consistent with the crack location of the UHPC plate in the test. In the finite element analysis, the tensile damage of UHPC extends from the bottom of UHPC plate to the top and decreases gradually. In the test, the crack extends upward from the joint of UHPC plate and steel plate to the middle of UHPC plate.

Figure 19 shows the load–deflection relationship curve of the steel-UHPC composite slab at the mid-span position. The load–deflection curves obtained by simulation are similar to those obtained by test and are divided into three stages: linear elastic stage, crack development stage and yield stage, which are represented by 1, 2, and 3 respectively in the figure. As can be seen from the figure, the finite element simulation results are close to the test results in the overall trend, and the bearing capacity of the two is 67 kN and 65.2 kN respectively, with a difference of only 2.8%. In the elastic stage, the finite element simulation curve approaches the test curve, while in the crack development stage, the finite element model cannot accurately simulate the real stress state when the stud is cut off, so the curve at this stage is quite different from the test.

In general, the finite element analysis results are close to the experimental results, and the model can better simulate the mechanical properties of steel-UHPC composite slabs. Therefore, the model can be used for subsequent research.

Results of FEA

Flexural failure modes of steel-UHPC composite slabs with different curing conditions

Figure 20 shows the stress distribution of the steel-UHPC composite slab with three different curing conditions under the positive bending moment limit state. It can be seen from the diagram that the failure mode of the finite element model of the steel-UHPC composite slab is flexural failure. With the increase of curing temperature, the strength of UHPC increases, the compressive stress and tensile stress of UHPC increase. At the same time, the compressive stress of the steel plate decreases, but the tensile stress changes little. The maximum compressive stress is concentrated on the top of the pure bending section of the UHPC plate.

In the test, it is found that the stud plays a crucial role in the failure form and bearing capacity of the steel-UHPC composite board, so it is necessary to analyze the stress state of the stud in the finite element simulation. Figure 21 shows the stress distribution of the stud in the limit state. From the figure, the stress of the stud in the limit state is much larger than the yield strength, mainly because the finite element simulation is biased towards the ideal state. In the actual test, due to the high strength of UHPC, the deformation of the stud will be limited, and the stud will be cut under the interaction between the steel plate and the UHPC plate.

Flexural deflection of steel-UHPC composite slabs with different curing conditions

Figures 22 and 23 show the load–deflection curves of the steel-UHPC composite slabs at the mid-span position under the three curing conditions under positive and negative bending moments, respectively. The figure shows that the load–deflection curve of the steel-UHPC composite slab under positive and negative bending moments can be divided into three stages, which are represented by 1, 2, and 3, respectively, in the Fig. (1) Linear elastic stage: The slope of the load–deflection curve is unchanged, and the elastic load value of the composite slab is higher than 43% and 35% of the ultimate load under the action of positive and negative bending moments, respectively, indicating that the steel-UHPC composite slab has good stiffness at this stage, and the overall working performance is good. (2) Crack development stage: When the positive bending moment exceeds the load in the linear elastic stage, cracks in UHPC continue to increase and slip occurs between the steel and UHPC plates. Under the interaction of the steel and UHPC plates, the shear force increases continuously, while the UHPC limits the deformation of the studs; thus, the studs in the shear-bending section are first destroyed, and as the load continues to increase, the end studs are destroyed, resulting in the steel and UHPC plates not working well together. The stiffness of the composite slab decreases under the action of a negative bending moment, with cracks forming at the bottom of the UHPC and developing continuously. (3) Yield stage: The main load of the steel-UHPC composite slab under a positive bending moment is borne by the steel plate, which is eventually destroyed owing to the yielding of the steel plate; under the action of a negative bending moment, the composite slab fails owing to the continuous development and expansion of cracks in the UHPC plate.

When the steel-UHPC composite slabs under different curing conditions are in the elastic stage under a positive bending moment, the slope of the load–deflection curve is small. It indicates that the curing conditions had little effect on the overall stiffness of the steel-UHPC composite slabs. Under the action of a positive bending moment, the ultimate bearing capacities of SU-standard, SU-70, and SU-90 are 46.3, 57.1, and 67 kN, respectively. Among them, curing at 70 °C and 90 °C for 4 h resulted in 23% and 45% higher than standard curing. The ultimate bearing capacities of the SU-standard, SU-70, and SU-90 specimens under a negative bending moment were 40.5, 42, and 43 kN, respectively. The results indicate that high-temperature curing has a significant influence on the ultimate bearing capacity of the specimens under a positive bending moment and has little effect on the ultimate bearing capacity under a negative bending moment. This is primarily because the UHPC in the specimens mainly bears the tensile stress, and the difference in the tensile strength of the UHPC under different curing conditions is small. When the specimens were subjected to a positive bending moment, the distribution and magnitude of the tensile stress differed significantly from those under the action of a negative bending moment. The performance variations of UHPC were significantly enhanced under different curing conditions when subjected to a positive bending moment, which resulted in significant alterations in the ultimate bearing capacity. Nevertheless, under the action of a negative bending moment, the influence of the different curing conditions on the ultimate bearing capacity is not obvious owing to the small difference in the tensile strength of the UHPC.

Steel-UHPC composite slab slips under different curing conditions

Interface slip curve along the longitudinal symmetry axis of the steel-UHPC composite

The bolts in the steel-UHPC composite slab can make the steel and UHPC plates play a synergistic role, but the slip phenomenon occurs between the two plates as the load increases. Under the interaction between the higher compressive strength of UHPC and higher tensile strength of the steel plate, the shear force produced by the bolts increases continuously, and the slip also increases continuously. The interface slip curve along the longitudinal position of the steel-UHPC composite slab was obtained using finite element analysis, as shown in Figs. 24 and 25. The abscissa in the figure represents the longitudinal position of the steel-UHPC composite slab, x = 100 indicates the starting point of the interface between the steel plate and UHPC composite slab, x = 700 indicates the mid-span position of the steel-UHPC composite slab; the ordinate represents the slip value, the arrow indicates the loading position and direction, and Pu represents the load corresponding to the maximum displacement applied.

As shown in Fig. 24, under the action of a positive bending moment, the forms of the interface slip curves along the longitudinal axis of symmetry of the steel-UHPC composite slabs under different curing systems are basically consistent. The interface slip amounts at the end part, support, loading point, and mid-span area of the specimen are close to zero, and the slip amount in the shear-bending section is greater than that in the pure bending section. As the load increases, the amount of interface slip of the steel-UHPC composite slabs increases significantly. When the load is less than 0.5Pu, the interface slip is primarily concentrated in the shear-bending section; when the load is greater than or equal to 0.5Pu, it is largely concentrated in the shear-bending and pure bending sections.

As shown in Fig. 25, under the action of a negative bending moment, the forms of the interface slip curves along the longitudinal axis of symmetry of the steel-UHPC composite slabs under different curing systems are basically consistent. Specifically, the interface slip amounts at the end, support, loading point, and mid-span areas of the specimen are close to zero, and the slip amount in the shear-bending section is significantly greater than that in the pure bending section. Concurrently, the influence of the curing system on the interface slip is primarily concentrated in the shear-bending section. As the load increases, the interface slip amount of the steel-UHPC composite slabs increases significantly, and it is primarily concentrated in the shear-bending and pure bending sections.

Load-slip curve at 1/3 of the specimen

From the above analysis, it is evident that the interface slip of the steel-UHPC composite slab in the shear-bending section is significantly greater than that in the pure bending section. Therefore, the load-slip curve within the shear-bending section of the steel-UHPC composite slab (at 1/3 position of the specimen) is further analyzed.

Figure 26 illustrates the load-slip curve of the steel-UHPC composite slab within the shear-bending section (at 1/3 position of the specimen) under the action of a positive bending moment. Evidently, in the elastic stage, the curing system has minimal influence on the load-slip curve of the steel-UHPC composite slab. As the load increases, a slight slip occurs between the steel plate and UHPC, and the slip amount exhibits a linear growth trend, indicating that the interface bonding performance of the steel-UHPC composite slab is in a relatively stable state. The curing system substantially affects the load-slip curve of the steel-UHPC composite slab during the plastic stage. When the slip amounts between the steel plate and UHPC are equivalent, the specimens cured at elevated temperatures (SU-70 and SU-90) can withstand loads that are much higher than those of the specimen cured under standard conditions (SU-standard). This suggests that high-temperature curing can, to a certain degree, enhance the load-bearing capacity of the steel-UHPC composite slab.

Figure 27 illustrates the load-slip curve of the steel-UHPC composite slab within the shear-bending section (at 1/3 position of the specimen) under the action of a negative bending moment. Evidently, the interface slip amounts of the steel-UHPC composite slab are almost the same in the elastic stage, and small differences exist in the interface slip amounts of the steel-UHPC composite slab in the plastic stage, which indicates that the curing system has little influence on the load-slip curve of the steel-UHPC composite slab.

Flexural strain of steel-UHPC composite slabs under different curing conditions

Under the action of positive bending moment, the strain distribution along the height of the mid-span section of the steel-UHPC composite slab under different curing conditions is shown in Fig. 28. The abscissa in the figure represents the longitudinal strain of the section; the ordinate represents the height of the section, where y = 0 is the bottom surface of the UHPC slab, y = 50 is the top surface of the UHPC slab, and Pu is the load corresponding to the maximum applied displacement. It can be seen from the figure that in the initial stage of loading (0.15 Pu) of the specimen, the strain distribution along the height direction of the mid-span cross-section conforms to the plane section assumption, and the strain curves of the steel-UHPC composite slabs under different curing conditions distributed along the height almost coincide; as the load increases, the strain growth rate in the compression zone above the neutral axis is obvious, and the tensile strain below the neutral axis increases. Under the same load, the compressive strain of the specimen SU-standard is greater than that of SU-70 and SU-90.

Under the action of negative bending moment, the strain distribution of steel-UHPC composite slabs with 3 curing conditions along the mid-span section height is shown in Fig. 29. It can be seen from the figure that the UHPC plate is mainly subjected to tensile stress under the action of negative bending moment, and the curing condition has little influence on the force of the UHPC plate of steel-UHPC composite slab.

Parameter analysis

The above verified finite element analysis model is used to carry out the parameter analysis of steel-UHPC composite slab, mainly exploring the influence of the number of bolts, the thickness of UHPC plate and the thickness of steel plate on the mechanical performance of the composite slab. Only the analyzed parameters are changed during the analysis, and other parameters remain unchanged.

Number of bolts

In the shear bending section of the steel-UHPC composite slab, one row, two rows of bolts and no bolts are arranged in the transverse to make a comparison, and the mechanical performance of the steel-UHPC composite slabs with three curing conditions is analyzed. The load–deflection curve obtained is shown in Fig. 30. When the transverse stud row of the specimen was increased from 1 to 2 rows, the ultimate bearing capacity of standard curing 28d, 70 °C curing 48h and 90 °C curing 48h increased by 33%, 21% and 20%, respectively. With the increase of curing temperature, the influence of stud on flexural capacity decreases. The bearing capacity of steel-UHPC composite slabs without studs under three curing conditions is reduced by about 50%, indicating that increasing the number of studs in the shear-bending section can reduce the interface slip between the steel plate and the UHPC slab, thereby improving the ultimate bearing capacity of the steel-UHPC composite slab. While the lack of stud will reduce the collaborative working ability of the steel plate and the UHPC plate, resulting in a reduction of the bearing capacity of steel-UHPC composite slab.

UHPC plate thickness

In order to study the influence of UHPC plate thickness on the mechanical properties of steel-UHPC composite slab under three curing conditions, three kinds of thickness were set up, which were 45 mm, 50 mm and 55 mm respectively. The analysis results are shown in Fig. 31. It can be seen from the figure that increasing the thickness of UHPC plate can improve the ultimate bearing capacity of the specimens. When the thickness of the UHPC plate increases from 45 to 50 mm and 50 mm to 55 mm, the ultimate bearing capacity of the specimen SU-standard increases by 40% and 30% respectively. The ultimate bearing capacity of SU-70 and SU-90 increased by 20% and 18% step by step with the increase of plate thickness, respectively. Therefore, the increase of UHPC thickness can improve the stiffness and bearing capacity of steel-UHPC composite slabs. Compared with standard curing, the ultimate bearing capacity of specimens under high temperature curing is less affected by UHPC thickness.

Steel plate thickness

In order to explore the influence of steel plate thickness on the bending performance of steel-UHPC composite slab under three curing conditions, specimens with steel plate thickness of 12 mm, 14 mm and 16 mm were set for analysis, and the load deflection curve of steel-UHPC composite slab obtained was shown in Fig. 32. It can be seen from the figure that when the thickness of the steel plate increases from 12 to 14 mm, the ultimate bearing capacity of the SU-standard, SU-70, and SU-90 specimens increases by 34.7%, 24.2%, and 27.9%, respectively. When the thickness of the steel plate increases from 14 to 16 mm, the ultimate bearing capacity of the specimens SU-standard, SU-70 and SU-90 increases by 16.5%, 15.5% and 13%, respectively. Compared with standard curing, the thickness of the steel plate under high temperature curing has little effect on the ultimate bearing capacity. In addition, the increase of steel plate thickness has little effect on the stiffness of steel-UHPC composite slabs, but it has a greater effect on the bearing capacity of steel-UHPC composite slabs in the inelastic stage.

Parameter impact analysis

Table 6 shows the ultimate loads obtained from the parametric analysis of the steel-UHPC composite slabs under different curing regimes. By analyzing the data in the table, it can be seen that the flexural bearing capacities of the steel-UHPC composite slabs all increase with the increase in the number of shear studs, the thickness of the steel plate, and the thickness of the UHPC. However, the degrees of influence of these parameters on the flexural bearing capacity of the steel-UHPC composite slabs are different. Among them, the thickness of the UHPC slab has a relatively large impact on the ultimate load of the specimens cured under the standard curing regime, with a maximum increase of 78.5%. The thickness of the steel plate has a relatively large impact on the ultimate load of the specimens cured at 90°C for 48 h, with a maximum increase of 57.1%.

Conclusion

The failure process, morphology, and load deflection curves of steel-UHPC composite slabs were analyzed under different curing conditions to investigate their flexural performance. On this basis, a finite element model was established to analyze the flexural performance of the composite slab and study its parameters. The main conclusions are as follows:

-

Bending failure constitutes the failure mode of steel-UHPC composite plates under different curing conditions. The bending failure process can be divided into three stages: elastic, crack development, and yield. Compared with standard curing, high-temperature curing can enhance both the ductility and flexural bearing capacity of steel-UHPC composite slabs. Moreover, once the shear studs experience failure, a substantial decrease in the bearing capacity of the steel-UHPC composite slabs was observed.

-

The curing condition has a significant impact on the ultimate bearing capacity of the steel-UHPC composite slabs under a positive bending moment. Compared with the standard curing condition, the ultimate bearing capacities of the steel-UHPC composite slabs cured at 70 °C and 90 °C were increased by 23% and 45%, respectively. The curing condition has a relatively minor influence on the ultimate bearing capacity of the steel-UHPC composite slabs under a negative bending moment. This is because, under the action of a negative bending moment, UHPC primarily bears tensile stress, and the tensile strengths of UHPC under different curing conditions are approximately the same.

-

The interface slip curve of the steel-UHPC composite plate along the longitudinal axis of symmetry under different curing conditions was basically consistent and primarily manifested as almost no interface slip at the end of the specimen, support, loading point, and mid-span position. The slip amount in the shear bending section was greater than that in the pure bending section. The curing conditions had a significant impact on the interfacial slip of the steel-UHPC composite plates in the shear bending section.

-

The strain distribution laws along the height direction of the mid-span section of the steel-UHPC composite slabs under different curing conditions were consistent. When the load was relatively small, the strain distribution basically conformed to the plane section assumption, whereas the strain distribution did not conform to the plane section assumption when the load was relatively large. The curing condition had a significant influence on the slope of the strain distribution curve of the steel-UHPC composite slabs under the action of a positive bending moment.

-

The flexural bearing capacities of the steel-UHPC composite slabs under different curing conditions increased with parameters such as the number of shear studs, thickness of the steel plate, and thickness of the UHPC. However, the degrees of influence of these parameters on the flexural bearing capacity of the steel-UHPC composite slabs varied.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Fan, L. Bridge Engineering (China Communication Press, 2004).

Xiang, D. Research on design and calculation method of steel plate-concrete composite bridge deck (Tongji University, 2022).

Liu, Y. Composite Bridges (China Communication Press, 2005).

Li, W., Shao, X., Fang, H. & Zhang, Z. Experimental study on flexural behavior of steel-UHPC composite slabs. China Civil Eng. J. 48, 93–102 (2015).

Nie, J. et al. Research on the application of steel-concrete composite structure in bridge reinforcement and reconstruction. J. Disast. Prev. Mitig. Eng. 30, 335–344 (2010).

Yi, B. et al. Experimental and analytical studies on flexural behavior of composite bridge decks with orthotropic steel deck and ultra-high-performance concrete (UHPC) slab under negative moment. Eng. Struct. https://doi.org/10.1016/J.ENGSTRUCT.2022.115190 (2023).

Zhou, M., Xiao, J., Yang, T., Nie, J. & Fan, J. Experimental and numerical investigations on the flexural behavior of steel-UHPC composite slabs with perfobond rib shear connectors. Eng. Mech. 39, 19–29 (2022).

Guo, J., Wang, J., Gao, X. & Bian, C. Flexural behavior of steel-UHPC composite slabs with demountable shear connectors. J. Harbin Ins. Tech. 56, 63–72 (2024).

Gu, J., Wang, J. & Lu, W. Flexural behavior of a novel demountable steel-UHPC composite slab. J. Harbin Ins. Tech. 56, 84–92 (2024).

Chen, Z. et al. Flexural behavior of corrugated steel-UHPC composite bridge decks. Eng. Struct. https://doi.org/10.1016/J.ENGSTRUCT.2021.113066 (2021).

Shao, Z., Huai, C., Cao, J., Li, C. & Shao, X. Experimental investigation and design optimization on flexural behavior of new UHPC deck panel with longitudinal ribs reinforced by steel plates. Structures 43, 878–895 (2022).

Zhang, Y., Zhang, W. & Chen, Z. A complete review of ultra-high performance concrete: Design and preparation, microstructure, mechanics and durability, engineering applications. Mater. Rep. 31, 1–16 (2017).

Niu, X., Peng, G., Shang, Y., Dai, L. & Ji, W. Influence of combined curing composed of precuring in hot water and heating in dry air on mechanical properties of ultra-high performance concrete. J. China Cera. Soc. 46, 1141–1148 (2018).

Peng, G. et al. Combined curing as a novel approach to improve resistance of ultra-high performance concrete to explosive spalling under high temperature and its mechanical properties. Cem. Concr. Res. 109, 147–158 (2018).

Helmi, M., Hall, R. M., Stevens, A. L. & Rigby, S. P. Effects of high-pressure/temperature curing on reactive powder concrete microstructure formation. Constr. Build. Mater. 105, 554–562 (2016).

Wu, Z., Khayat, H. K. & Shi, C. How do fiber shape and matrix composition affect fiber pullout behavior and flexural properties of UHPC?. Cement Concrete Comp. 90, 193–201 (2018).

Hiremath, P. N. & Yaragal, S. C. Effect of different curing regimes and durations on early strength development of reactive powder concrete. Constr. Build. Mater. 154, 72–87 (2017).

Zhang, J. J., Shao, H. R. & Meng, Y. X. Optimization research of mix proportion of frost resistance construction of concrete based on the MATLAB language. Appl. Mech. Mater. 3309, 1917–1921 (2014).

SAC. Reactive powder concrete. GB/T 31387–2015 (Chinese Standard Press, 2015).

He, F., Zhang, Y., Yang, J. & Qiu, J. Experimental and numerical investigation on shear performance of double-keyed epoxy UHPC joints. Railw. Build. 64, 76–82 (2024).

Yang, J. & Fang, Z. Research on stress-strain relation of ultra high performance concrete. Concrete 7, 11–15 (2008).

Zhang, Z., Shao, X., Li, W., Zhu, P. & Chen, H. Axial tensile behavior test of ultra high performance concrete. China J. Highw. Transp. 28, 50–58 (2015).

Graybeal, B. A. Characterization of the behavior of ultra-high performance concrete. Washington, DC: The University of Maryland, 300–370 (2005).

Dassault Systèmes. Documentation-ABAQUS analysis user’s manual, 2019.

Xia, J. Study on damage evolution and failure behavior of the UHPC-NC interface under cyclic loading (Chongqing Jiaotong University, 2023).

Liang, R. Experimental study and theoretical analysis on bond behavior between ultra-high performance concrete and steel bar (Hunan University, 2023).

Liu, Z., Zhou, Z., Xue, J. & Mao, D. Experimental study and finite element analysis on axial compression performance of high strength steel reinforced ultra-high performance concrete short column. Eng. Mech. 41, 211–227 (2024).

Zhu, J., Qin, Y. & Shi, T. Calculation method for flexural capacity of prestressed UHPCNC composite beams. J. Cent. South. Univ. 53, 3989–4000 (2022).

Ding, F., Ni, M., Gong, Y., Zhou, Z. & Zhou, L. Experimental study on slip behavior and calculation of shear bearing capacity for shear stud connectors. J. Build. Struct. 35, 98–106 (2014).

Acknowledgements

This study was supported by the National Natural Science Foundation of China [grant No. 51808423]. The authors also would like to thank the laboratory technicians of Xi’an Technological University for their assistance.

Author information

Authors and Affiliations

Contributions

Y.W. is responsible for methodology, initial draft review, and experimental condition support. Y.C. conceived experiments, conducted experiments and finite element analysis. H.W. participated in the experiment and wrote the original draft. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, Y., Wang, H. & Chen, Y. Flexural behavior of steel-UHPC composite bridge slab under different curing conditions. Sci Rep 15, 19977 (2025). https://doi.org/10.1038/s41598-025-03774-2

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-03774-2