Abstract

The impact of nanoparticles (NP) mixtures (Fe + Ni + Co, Fe + Ni, Fe + Co, and Ni + Co) on the anaerobic digestion (AD) of cow manure was examined through kinetic modelling (Modified Gompertz, Logistic, and First-order kinetic) and experimental observations. The NPs mixture significantly enhanced biogas production rate and yield potential. The variation between predicted and actual biogas yields was smaller with the Modified Gompertz model (1.37% to 5.30%) and First-order kinetic model (0.04% to 3.83%) compared to the Logistic model (1.99% to 7.04%). Additionally, digestates containing NPs showed strong fertility properties (5.16% to 5.36%). The combined use of kinetic models and experiments offers an effective way to quantify the influence of NPs mixture on AD performance, aiding in industrial application.

Similar content being viewed by others

Introduction

Livestock contributes approximately 40% of the global agricultural product value and supports the livelihoods of nearly 1.3 billion people worldwide1. However, livestock farming also generates significant amount of waste, particularly from cow and poultry manure, with cow manure alone making up over 50% of total manure production in European2. Traditionally, cow manure is applied directly to land as fertilizer. This can cause environmental problems such as soil and water pollution, greenhouse gas emissions, and inefficient nutrient utilization3. Therefore, it is essential to develop methods to reduce the resource waste and environmental impacts associated with excess livestock manure4.

Anaerobic digestion (AD) has become a popular solution on dairy farms, offering a way to manage waste while producing biogas and harnessing the energy potential of cow manure2,3. Additionally, the digestate from AD can be used as a nutrient-rich fertilizer with lower greenhouse gas emission potential5,6,7.

The AD process consists of four stages, i.e., hydrolysis, acidogenesis, acetogenesis, and methanogenesis, each is carried out by different groups of bacteria, including hydrolytic, acidogenic, acetogenic, and methanogenic bacteria8. Many researchers have noted that hydrolysis is the rate-limiting step in the AD of lignocellulosic substrates like cow manure9,10. Consequently, several efforts have been made to boost microbial and enzymatic activity using trace elements such as iron (Fe), nickel (Ni), and cobalt (Co) in nanoparticle (NP) form to enhance methane production11,12,13,14,15.

Adequate levels of Fe, Ni, and Co are considered essential for the microbial communities involved in AD16,17,18. For Fe NPs, Wang et al. (2019)19 reported that 10 mg/g total solids (TS) of Fe NPs increased the number of microorganisms, bacteria, and archaea, as well as the activity of the F420 coenzyme, which is crucial for methanogen growth20. Abdelsalam et al. (2016)11 found that 20 mg/L of Fe NPs increased methane production by 59% compared to the control, while Abdelwahab et al. (2022b)13 observed a 118.8% increase with 30 mg/L of Fe NPs. For Ni NPs, Tsapekos et al. (2018)21 noted that 5 mg/Kg VS of Ni NPs increased methane production in the AD of sewage sludge by 10% compared to the control. Abdelsalam et al. (2017)12 found a 101% increase in methane production using 2 mg/L of Ni NPs. The finding aligns with Abdelwahab et al. (2023a)14, who reported a 71% improvement with the same concentration. Cobalt NPs have also been shown to promote acetogenesis during the startup of AD15, and Abdelsalam et al. (2017)12 observed a 186% increase in methane production with 1 mg/L of Co NPs compared to the control.

Mixtures of multiple NPs tend to be more beneficial for the AD process than individual NPs22,23. Zhang et al. (2015)24 found that the combination of Fe, Ni, and Co NPs increased biomass content in the AD system. Additionally, Zhang et al. (2011)25 showed that a mixture of Fe, Ni, Co, and Mo resulted in minimal accumulation of volatile fatty acids (VFAs), low soluble chemical oxygen demand (COD), and high solid degradation during the AD of piggery wastewater and food waste. Generally, the use of NPs (either single or combined) can enhance the AD process22. However, the interaction of Fe, Ni, and Co NPs on methane production and digestate quality is still not clear. Furthermore, an overestimation of NPs mixture addition may increase the operating costs. Therefore, gaining insight into the relation between using NPs mixture supplementation with minimal cost and methane production is crucial.

Kinetic analysis is essential for optimizing AD processes at a larger scale. Kinetic models help identify optimal variables, such as the lag phase and hydrolysis constant, while also assessing biogas production rates, AD potential, and the activation energy required for digestate pyrolysis4,26,27. Biogas production potential, lag phase, and hydrolysis rate constant parameters are key to understanding reaction mechanisms, optimizing process conditions, and predicting biogas yield, hydraulic retention time, and energy consumption in real-world applications. Despite the benefits of kinetic model fitting, the impact of NPs mixtures on AD, especially in terms of kinetic models and experimental data, has not been widely explored. Although NPs have been shown to improve biogas production in AD systems11,12,13,14,15,28, their influence on kinetic models for biogas production and digestate utilization remains understudied, distinguishing this research from prior work.

This work aimed to: (1) explore the effect of NPs mixtures on the biogas yield, TS and volatile solids (VS) removal rates, and pH variation; (2) to investigate the feasibility of digestate utilization by fertilizer analysis; (3) to predict the kinetic parameters (maximum biogas production rate and potential, lag phase, and hydrolysis constant) of biogas yield using the first-order kinetic model, logistic model, and modified Gompertz model. To the best of the authors’ knowledge, the effect of NPs mixture on the kinetic parameters of biogas yield and digestate is investigated for the first time.

Materials and methods

Experimental set-up

The batch mode was used with 15 laboratory-scale digesters in this study as shown in Fig. 1. Each digester consisted of a 1000-mL Borosil bottle with an effective working volume of 500 mL served as the digester and a 1000-mL clear plastic graduate cylinder served as the gas collecting unit. The graduated cylinder was placed upside down in another cylinder (2000 mL) filled with saturated sodium chloride (NaCl) solution. Both the digester and the gas collection cylinder were connected by rubber tubes. The experiments were conducted under mesophilic condition (33 ± 1℃). A complete explanation of the experimental devices can be found in our previous work13,14,15. Each digester was manually shaken three times a day, and its biogas volume was measured once a day.

Substrate, inoculum, and nanoparticles

The digested cow dung was collected from a dairy farm in Benha City, Qalyubiyya, Egypt. Inoculant sludge was taken from a cow manure anaerobic digestion plant in Benha city, Qalyubiyya, Egypt. The detailed characteristic parameters of cow manure and inoculant sludge are summarized in Table 1. Cow manure 50 wt% and inoculant sludge 50 wt% were mixed well for each assay to make sure an optimal TS at 8–10% in the digester4. Nanoparticles Fe NPs, Ni NPs, Co NPs (99.9% metals basis) were obtained from Sigma scientific services Co. (Cairo, Egypt).

Experimental design

Based on our previous work13,14,15, optimal concentrations of Fe NPs, Ni NPs, and Co NPs were selected at 30 mg/L, 2 mg/L, and 1 mg/L, respectively. The composition of different NPs mixture is presented in Table 2. The digesters in each group were triplicated. All digesters included 47.0 g dry (9.13 g VS) cow dung and 49.5 g dry (9.09 g VS) inoculant sludge. All batches were triplicated, and the results were repeatable.

Analytical method

During the digestion period, the daily biogas production was determined using a simple water displacement method. Biogas production was expressed in unit of mL/g VS, which represented the volume of biogas when per gram of feedstock VS added to the digester. The APHA recommended standard procedures for determining TS and VS29. A digital pH meter (XL600, Germany) was used to measure the pH values before and after digestion. The contents of VFAs in each digester were determined using a titration method that combined the acidity (Method 2310B) and alkalinity (Method 2320B) titration methods29. The total levels of carbon, nitrogen, sulfide, and hydrogen (C, N, and S) were assessed using a micro elemental analyzer with simultaneous CHNS determination to evaluate the influence of NPs mixture on the chemical composition of the digestate (UNICUBE, Germany). After the experiments, Fourier transform infrared spectroscopy was used to characterise the organic content in the digestate samples (dry samples) (FTIR, Perkin Elmer Spectrum, version 10.4.3., USA). The total contents of phosphorus and potassium (TP and TK) were measured with an inductively coupled plasma optical emission spectrometer to examine the effect of NPs mixture on digestate fertility (ICP-OES, Perkin Elmer, Avio 200, USA).

Kinetic model

Different process parameters such as biogas production potential, lag phase, and hydrolysis rate constant may be predicted by fitting the kinetic model to the biogas productin and digestate quality. This is crucial when assessing the beneficial effects of NPs mixture supplementation.

The modified Gompertz model (MGM) (Eq. (1)) depicts a standard sigmoidal curve that is used to explain microbial growth, and biogas production is considered a function of microbial growth in general30. The logistic model (LM) (Eq. (2)) assumes that the rate of biogas production is proportional to the quantity of biogas previously produced, the maximum production rate, and the biogas production potential, and that it can fit the fast growth in the beginning stage and eventually reach a stable level26. As a result, the MGM and LM were used in this study to calculate the biogas yield kinetic parameters. These two kinetic models were also used to determine the lag phase and maximum biogas production rate and evaluate the AD process, in addition to the biogas production potential.

where P(t) cumulative biogas production (mL/g VS) at time t (30 days); Pm is the maximum biogas potential production (mL/g VS); Rm is the maximum biogas production rate (mL/g VS/d); λ is the lag phase (d); t is the total digestion time (d); e is 2.71828.

The first-order kinetic model (FOM) is typically used to characterize the kinetics of AD fermentation process. Thus, the hydrolysis rate constant (k) of slurry can be fitted using Eq. (3)31:

where k is the hydrolysis rate constant (d-1); t is time (d).

A second order Akaike Information Criterion (AIC) test was used to determine the model best matches the experimental results26. An AIC value can be positive or negative and the sign doesn’t have a meaning since it can be changed using different units to express data. Models were compared by evaluating the difference between the AIC values in which the model with the smallest AIC values was taken as the most likely to be correct. Equation (4) was used to calculate the AIC value31.

where N number of points; RSS residual sum of square; n number of model parameters. The parameters for the models were determined by using SPSS IBM 20 software.

Statistical analysis

Analysis of variance (ANOVA) test was performed on the cumulative biogas production with a significance level of 0.05 to analyze the statistical significance of the results. The statistical analyses were conducted using SPSS software, version 20 (IBM Co.).

Results and discussion

Effect of nanoparticle mixture on biogas production

Measured daily and cumulative biogas production

The daily and cumulative biogas production over 32 days of AD are shown in Fig. 2. The trends in daily biogas yields with different additives showed similar patterns, with two peaks observed around day 3 and day 8. These peaks correspond to the degradation of carbohydrates and the breakdown of more complex organic materials such as crude protein and lignocelluloses16,32. Han et al. (2019)33 reported similar results, indicating that adding steel slag could boost biogas production and enhance digestate stability. In the current study, the two biogas production peaks for the Fe + Co + Ni group, measuring 49.43 and 47.36 mL/g VS, were not significantly different from the other groups: 50.10 and 49.82 mL/g VS for Fe + Ni, 49.12 and 46.08 mL/g VS for Fe + Co, 45.31 and 47.31 mL/g VS for Ni + Co, and 46.08 and 45.57 mL/g VS for cow manure only (p = 0.357).

As shown in Fig. 2 and Table 3, the Fe + Co + Ni group achieved the highest cumulative biogas yield at 933.42 mL/g VS, representing a 25.34% increase compared with cow manure alone. This was followed by the groups of Fe + Ni (928.89 mL/g VS, 24.73%, increase), Fe + Co (891.29 mL/g VS, 19.68%, increase), Ni + Co (775.22 mL/g VS, 4.10%, increase), and cow manure only (744.70 mL/g VS) (p < 0.05).

Previous studies have demonstrated that combining 500 mg/L nano zero-valent iron (nZVI) with 4 g/L of zeolite boosted biogas production by 130.87% compared to the control34. Similarly, Abdallah et al. (2019)35 found that using Ni-Ferrite nanoparticles at concentrations of 20, 70, and 130 mg/L increased biogas yields by 30.8%, 28.5%, and 17.9%, respectively, relative to cattle manure—only. Additionally, Karlsson et al. (2012)36 reported that adding a mixture of Fe, Co, and Ni chloride salts at concentrations of 500, 0.5, and 0.25 mg/L, respectively, to a semi-continuous biogas reactor enhanced biogas production by 23.91% compared to the control. These findings align with Farghali et al. (2019)37 who observed that mixtures of 20 mg/L Fe2O3 and 500 mg/L TiO2 nanoparticles, as well as 100 mg/L Fe2O3 and 500 mg/L TiO2, increased biogas production by 10.07% and 13.08%, respectively, compared to the control.

The use of NPs mixtures significantly increased biogas production compared to cow manure only, indicating that enhanced microbial activity in the digester accelerated the breakdown of organic matter. These results align with previous studies that demonstrated how supplementing methanogenic systems with micronutrients like Fe NPs, Co NPs, and Ni NPs improved key fermentation stages (hydrolysis and acidogenesis) and supported enzyme function38,39,40.

Furthermore, biogas production reached its highest level when Fe, Co, and Ni NPs were added together, consistent with the findings of18. Wang et al. (2021)4 also noted that digesters supplemented with a greater variety of trace elements, such as Fe, Ni, and Co, produced more biogas than those with fewer types.

The significant increase in biogas yield with the addition of NPs mixture can be attributed to the availability of additional micronutrients, which support microbial growth and enhance the activity of anaerobic bacteria. These results suggest that using a mixture of NPs could be an effective approach to improving AD performance.

Kinetic study of biogas production

Figure S1 (supplementary material) presents the fitting results of the three kinetic models (MGM, LM, and FOM) for biogas production, with Table 3 detailing the corresponding kinetic parameters. From Fig. S1a–c, it is evident that the MGM and FOM models align more closely with the measured data compared to the LM model. As shown in Table 3, the deviation between the fitted and measured biogas yields was higher for the LM model (1.99–7.04%) than for the MGM (0.32–5.30%) and FOM models (0.043–1.79%). Additionally, the R2 values for LM (0.982–0.986) were lower than those for MGM (0.992–0.995) and FOM (0.994–0.997). The results for Akaike Information Criterion (AIC) test for the MGM, FOM, and LM models are shown in Table 3. The MGM and FOM models have a lower AIC value than LM, indicating that they are better models to use in this case.

For the FOM model, the potential biogas production (Pm) increased with the addition of NPs mixtures, suggesting that incorporating NPs can enhance the biogas production potential in AD. Although Pm differed from the actual biogas yield, the R2 value remained within 0.994–0.997. The hydrolysis rate constant (k) for cow manure-only treatment, and the groups with Fe + Ni + Co, Fe + Ni, and Fe + Co NP mixtures, showed a reduction in the hydrolysis rate by 47.50%, 43.90%, and 34.09%, respectively. However, there was little difference in the k value between the Ni + Co group, which contained 2 mg/L of Ni NPs and 1 mg/L of Co NPs, and cow manure-only. These findings highlight the critical role of NPs mixture in affecting the hydrolysis rate.

For the MGM and LM models, biogas production potential (Pm) and the maximum biogas production rate (Rm) were improved by adding NPs mixture. For the Fe + Ni NP group, compared to cow manure-only, Pm increased by 32.73% for MGM and 7.31% for LM, while Rm increased by 30.02% for MGM and 9.80% for LM.

However, both models indicated that the NPs mixture had no significant impact on the lag phase (λ), a result consistent with Wang et al. (2021)4 and Zhang et al. (2019)40, who noted that trace element supplementation typically showed minimal short-term effects, with more pronounced benefits after extended operation.

These results suggest that the NPs mixture significantly enhanced biogas production potential and rates. Although FOM and MGM start from different theoretical assumptions, both models were successfully used to predict the impact of NP mixtures on biogas production, fitting well with the experimental data (R2 > 0.992). Thus, these models provide a reliable way to compare AD systems with and without NP mixtures.

However, when the substrate contains similar amounts of readily and poorly biodegradable components, two peaks in the cumulative biogas production curve may appear, reducing the fitting accuracy of classical models like FOM and MGM41,42. In such cases, classical kinetic models may need modification, or a more accurate model may need to be developed in the future to address these complexities.

pH, removal rate of VFAs, TS, VS

The pH, VFAs, total alkalinity (TA), TS, and VS are all critical factors influencing the fermentation process43,44. The pH plays a crucial role in influencing the growth rate of microorganisms in AD systems45,46. In this study, the pH levels across all digesters ranged from 6.70 to 7.50 (Table 4), staying within the optimal range of 6.0 to 8.545,46. This indicated that microbial activities within the AD systems were functioning properly.

The VFAs with short carboxylic chains (C2-C6) play a crucial role as intermediate products in the progression of AD47,48. During AD, VFAs are a key measure of the degradation of organic matter in substrates49,50. The varying rates of VFAs removal suggest that organic matter in the substrates was broken down by microorganisms to different extents, leading to biogas production51,52. As presented in Table 4, the group supplemented with Fe NPs, Ni NPs, and Co NPs achieved the highest VFAs removal rate of 74.10%, indicating more complete degradation and digestion of substrates compared to other experimental groups. This effect could be attributed to the Fe NPs, Ni NPs, and Co NPs additions, which supplied essential micronutrients for microbial growth.

The removal rates of TS and VS, which are key indicators for assessing the degradation of cow manure, were calculated and shown in Table 4. Compared to the cow manure-only group, the groups supplemented with Fe + Co + Ni, Fe + Ni, Fe + Co, and Ni + Co exhibited lower residual TS and VS after digestion. The Fe + Co + Ni group achieved the highest TS removal rate (41.53%) and VS removal rate (20.54%), which can be attributed to the combined addition of the NPs mixture. These findings are consistent with Wang et al. (2021)4, who reported that a trace element mixture of Fe, Ni, and Co improved TS and VS removal rate by 37.00% and 41.60%, respectively. However, the results of this study were lower than those reported by Farghail et al. (2019)37, who found that NPs mixture of 20 mg/L Fe2O3 and 500 mg/L TiO2 increased VS decomposition by 54.16% and 54.26%, respectively, compared to control conditions. This variation may be due to differences in the type and concentration of NPs mixture used in each study. Although the use of NPs mixture has shown promising results in enhancing biogas production, further research is needed to confirm its effectiveness for large-scale AD of cattle manure.

Effects of NPs mixture on the characterization of organic material, chemical composition and fertility evaluation of digestate

The analysis of the organic material and chemical composition of the digestate is crucial for determining its quality53. The organic matter content and nutrient levels should support the soil microbial ecosystem and meet crop requirements when the digestate is applied as fertilizer in agricultural systems54,55.

Characterization of organic material and chemical composition of digestate

The FTIR method was used to detect the characteristic vibrations of chemical bonds and functional groups. The FTIR spectrum of digestate, where the substrate was treated with a mixture of NPs, compared to untreated cattle manure, is shown in Fig. 3. The key absorption peaks identified, based on previous studies, include: (i) O – H stretching of carboxylic and alcoholic groups around 3450 cm−1, (ii) C–H stretching of aliphatic groups near 2900 cm−1, (iii) – COO − stretching of carboxylic acids around 1600 cm−1, and (iv) C – O stretching of carbohydrates near 1100 cm−155,56.

In this study, the addition of various NPs mixture resulted in changes in both the intensity and shifts of these peaks compared to the untreated manure spectrum. Notably, a strong peak around 1100–950 cm−1, corresponding to C–O stretching of carbohydrates (Fig. 3), showed decreased intensity in the treated sample, indicating reduced carbohydrate content. This suggests that the NPs mixture may enhance methanogenic communities, promoting carbohydrate decomposition, VFA formation, and increased biogas production. Additionally, the peaks at 1600 cm−1 and 1509 cm−1 (N–H deformation vibration of amide II) were lower in the NPs treated groups, indicating enhanced organic matter degradation57. The FTIR analysis also revealed a slight shift to higher wave numbers due to NPs mixture addition. This may be attributed to interactions between soluble organic compounds and the NPs surface58,59.

Fertility evaluation of digestate

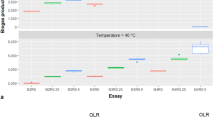

Microbial degradation during AD increases the availability of nitrogen (N), phosphorus (P), and potassium (K) in organic matter, making digestates suitable for direct use as fertilizers or as components in commercial fertilizers60,61. The higher the concentration of these nutrients in digestates, the more effective they are as fertilizers. To assess the potential of digestates containing NPs as fertilizers, the total nitrogen (TN), total phosphorus (TP), and total potassium (TK) levels were measured for the Fe + Co + Ni, Fe + Ni, Fe + Co, and Ni + Co groups. As shown in Fig. 4, the NPK content was 5.35% for the Fe + Co + Ni group, 5.36% for the Fe + Ni group, 5.16% for the Fe + Co group, and 5.32% for the Ni + Co group. Since the NPK concentration for bioorganic fertilizers should exceed 5%, these digestates show promise as effective components of organic fertilizers.

Additionally, Fig. 4 compares the NPK content of these digestates with that of soil and commercial bioorganic fertilizers. The total nutrient content in the Fe + Co + Ni, Fe + Ni, Fe + Co, and Ni + Co groups was significantly higher than in soil, indicating their potential for soil enrichment. The nutrient levels of the digestates were also comparable to those in commercial bioorganic fertilizers, with the TN of the digestates exceeding that of the commercial products, making them particularly beneficial for nitrogen-deficient soils. However, the TP content in these digestates was lower than that of commercial fertilizers, a result consistent with other studies on digestates derived from cattle manure40,62. Further research is needed to develop phosphorus-rich additives for anaerobic digestion to improve the TP content in digestates.

Cost analysis from nanoparticles input for biogas production

Analyze the costs was performed to investigate the impact of various NPs mixture on biogas yield. The cost calculation is based on the amount of CH4 produced (L) from one liter of substrate. As shown in Table 5, the highest net profit was attended with the group Ni + Co NPs, and was 0.51 USD over the cattle manure-only. Additionally, the groups of Fe + Ni + Co, Fi + Ni, and Fe + Co achieved net profit of 0.49, 0.38, 0.18 USD, respectively over the cattle manure-only. These results indicated that not only the supplementation of bio-digesters with NPs mixture of Fe, Ni, and Co boosted CH4 production, but also gained more profits from the commercial aspect of view. As a result, NPs mixtures may be a sustainable and cost-effective way to boost CH4 production from AD of cow manure.

Conclusions

The effect of a nanoparticles (NPs) mixture of Fe, Ni, and Co on the anaerobic digestion (AD) performance was investigated in a mesophilic AD process. The addition of NPs mixture significantly enhanced the AD of cow manure. The Fe + Co + Ni group achieved the highest volatile fatty acids (VFAs) removal rate (74.10%) and cumulative biogas yield (933.42 mL/g VS). Both the Modified Gompertz Model (MGM) and First-order Model (FOM) closely matched the experimental data, outperforming the Logistic Model (LM). The total solids (TS) removal rate of digestates in the NPs-treated groups also improved. The fertilizer potential of these digestates was comparable to that of commercial NPK fertilizers. Using a combination of kinetic models and experimental data can be an effective approach to evaluate the impact of NPs mixtures on AD performance.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

WHO. FAO’s Global Animal Diseases Surveillance and Early Warning System (2017).

Scarlat, N., Fahl, F., Dallemand, J. F., Monforti, F. & Motola, V. A spatial analysis of biogas potential from manure in Europe. Renew. Sustain. Energy Rev. 94, 915–930 (2018).

Yao, Y., Huang, G., An, C., Chen, X., Zhang, P., Xin, X., & Agnew, J. Anaerobic digestion of livestock manure in cold regions: Technological advancements and global impacts. Renew. Sustain. Energy Rev. 119, 109494 (2020).

Wang, K., Yun, S., Xing, T., Li, B., Abbas, Y., & Liu, X. Binary and ternary trace elements to enhance anaerobic digestion of cattle manure: Focusing on kinetic models for biogas production and digestate utilization. Bioresour. Technol. 323 (2021).

Abdelwahab, T. A. M., Mohanty, M. K., Sahoo, P. K. & Behera, D. Application of nanoparticles for biogas production: Current status and perspectives. Energy Sources Part A Recov. Utiliz. Environ. Effects 46(1), 8602–8614 (2024).

Abdelwahab, T. A. M. & Fodah, A. E. M. Utilization of nanoparticles for biogas production focusing on process stability and effluent quality. SN Appl. Sci. 4(12), 332 (2022).

Li, Y., Zhao, J., Achinas, S., Zhang, Z., Krooneman, J., & Euverink, G. J. W. The biomethanation of cow manure in a continuous anaerobic digester can be boosted via a bioaugmentation culture containing Bathyarchaeota. Sci. Total Environ. 745 (2020).

Wang, Z., Hu, Y., Wang, S., Wu, G. & Zhan, X. A critical review on dry anaerobic digestion of organic waste: Characteristics, operational conditions, and improvement strategies. Renew. Sustain. Energy Rev. 176, 113208 (2023).

Fernandes, T. V., Bos, G. K., Zeeman, G., Sanders, J. P. M. & Van Lier, J. B. Effects of thermo-chemical pre-treatment on anaerobic biodegradability and hydrolysis of lignocellulosic biomass. Biores. Technol. 100(9), 2575–2579 (2009).

Rafique, R., Poulsen, T. G., Nizami, A. S., Murphy, J. D. & Kiely, G. Effect of thermal, chemical and thermo-chemical pre-treatments to enhance methane production. Energy 35(12), 4556–4561 (2010).

Abdelsalam, E. et al. Comparison of nanoparticles effects on biogas and methane production from anaerobic digestion of cattle dung slurry. Renew. Energy 87, 592–598 (2016).

Abdelsalam, E. et al. Effects of Co and Ni nanoparticles on biogas and methane production from anaerobic digestion of slurry. Energy Convers. Manag. 141, 108–119 (2017).

Abdelwahab, T. A. M., Mohanty, M. K., Sahoo, P. K. & Behera, D. Impact of iron nanoparticles on biogas production and effluent chemical composition from anaerobic digestion of cattle manure. Biomass Convers. Biorefinery 12(12), 5583–5595 (2022).

Abdelwahab, T. A. M., Mohanty, M. K., Sahoo, P. K. & Behera, D. Impact of nickel nanoparticles on biogas production from cattle manure. Biomass Convers. Biorefinery 13(6), 5205–5218 (2023).

Abdelwahab, T. A. M., Mohanty, M. K., Sahoo, P. K., Behera, D. & Fodah, A. E. M. Cobalt nanoparticles to enhance anaerobic digestion of cow dung: Focusing on kinetic models for biogas yield and effluent utilization. Biomass Convers. Biorefinery 13(13), 11657–11669 (2023).

Chen, J., Yun, S., Shi, J., Wang, Z., Abbas, Y., Wang, K. & Li, B. Role of biomass-derived carbon-based composite accelerants in enhanced anaerobic digestion: focusing on biogas yield, fertilizer utilization, and density functional theory calculations. Bioresour. Technol. 307, 123204 (2020).

Choong, Y. Y., Norli, I., Abdullah, A. Z. & Yhaya, M. F. Impacts of trace element supplementation on the performance of anaerobic digestion process: A critical review. Biores. Technol. 209, 369–379 (2016).

Moestedt, J., Nordell, E., Yekta, S. S., Lundgren, J., Martí, M., Sundberg, C. & Björn, A. Effects of trace element addition on process stability during anaerobic co-digestion of OFMSW and slaughterhouse waste. Waste Manag. 47, 11–20 (2016).

Wang, T., Zhang, D., Dai, L., Chen, Y. & Dai, X. Effects of metal nanoparticles on methane production from waste-activated sludge and microorganism community shift in anaerobic granular sludge. Sci. Rep. 6(1), 25857 (2016).

Cui, Y. et al. Biochar enhanced high-solid mesophilic anaerobic digestion of food waste: Cell viability and methanogenic pathways. Chemosphere 272, 129863 (2021).

Tsapekos, P., Alvarado-Morales, M., Tong, J. & Angelidaki, I. Nickel spiking to improve the methane yield of sewage sludge. Biores. Technol. 270, 732–737 (2018).

Hassanein, A., Lansing, S. & Tikekar, R. Impact of metal nanoparticles on biogas production from poultry litter. Biores. Technol. 275, 200–206 (2019).

Hassanein, A., Keller, E. & Lansing, S. Effect of metal nanoparticles in anaerobic digestion production and plant uptake from effluent fertilizer. Biores. Technol. 321, 124455 (2021).

Zhang, W., Wu, S., Guo, J., Zhou, J. & Dong, R. Performance and kinetic evaluation of semi-continuously fed anaerobic digesters treating food waste: role of trace elements. Biores. Technol. 178, 297–305 (2015).

Zhang, L., Lee, Y. W. & Jahng, D. Anaerobic co-digestion of food waste and piggery wastewater: Focusing on the role of trace elements. Biores. Technol. 102(8), 5048–5059 (2011).

Donoso-Bravo, A., Pérez-Elvira, S. I., & Fdz-Polanco, F. Application of simplified models for anaerobic biodegradability tests. Evaluation of pre-treatment processes. Chem. Eng. J. 160(2), 607–614 (2010).

Mishra, R.K. & Mohanty, K. Pyrolysis kinetics and thermal behavior of waste sawdust biomass using thermogravimetric analysis. Bioresour. Technol. 251, 63–74 (2018).

Yusuf, H. H., Pan, X., Ye, Z. L., Abdelwahab, T. A. M., & Fodah, A. E. M. A novel strategy for enhancing high solid anaerobic digestion of fecal slag and food waste using percolate recirculation and dosage of nano zero-valent iron. Water Res. 122477 (2024).

APHA. Standard Methods for Examination of Water and Wastewater 21st edn. (APHA, 2005).

Fagbohungbe, M. O. et al. Impact of biochar on the anaerobic digestion of citrus peel waste. Biores. Technol. 216, 142–149 (2016).

Andriamanohiarisoamanana, F. J. et al. Valorizing waste iron powder in biogas production: Hydrogen sulfide control and process performances. J. Environ. Manag. 208, 134–141 (2018).

Jia, B., Yun, S., Shi, J., Han, F., Wang, Z., Chen, J. & Xing, T. Enhanced anaerobic mono-and co-digestion under mesophilic condition: Focusing on the magnetic field and Ti-sphere core–shell structured additives. Bioresour. Technol. 310, 123450 (2020).

Han, F., Yun, S., Zhang, C., Xu, H. & Wang, Z. Steel slag as accelerant in anaerobic digestion for nonhazardous treatment and digestate fertilizer utilization. Biores. Technol. 282, 331–338 (2019).

Amen, T. W., Eljamal, O., Khalil, A. M. & Matsunaga, N. Biochemical methane potential enhancement of domestic sludge digestion by adding pristine iron nanoparticles and iron nanoparticles coated zeolite compositions. J. Environ. Chem. Eng. 5(5), 5002–5013 (2017).

Abdallah, M. S., Hassaneen, F. Y., Faisal, Y., Mansour, M. S., Ibrahim, A. M., Abo-Elfadl, S. & Allam, N. K. Effect of Ni-Ferrite and Ni-Co-Ferrite nanostructures on biogas production from anaerobic digestion. Fuel 254, 115673 (2019).

Karlsson, A. et al. Impact of trace element addition on degradation efficiency of volatile fatty acids, oleic acid and phenyl acetate and on microbial populations in a biogas digester. J. Biosci. Bioeng. 114(4), 446–452 (2012).

Farghali, M. et al. Impacts of iron oxide and titanium dioxide nanoparticles on biogas production: Hydrogen sulfide mitigation, process stability, and prospective challenges. J. Environ. Manag. 240, 160–167 (2019).

FitzGerald, J. A., Wall, D. M., Jackson, S. A., Murphy, J. D. & Dobson, A. D. Trace element supplementation is associated with increases in fermenting bacteria in biogas mono-digestion of grass silage. Renew. Energy 138, 980–986 (2019).

Zhang, L. & Loh, K. C. Synergistic effect of activated carbon and encapsulated trace element additive on methane production from anaerobic digestion of food wastes—Enhanced operation stability and balanced trace nutrition. Biores. Technol. 278, 108–115 (2019).

Zhang, C. et al. Low-cost composited accelerants for anaerobic digestion of dairy manure: Focusing on methane yield, digestate utilization and energy evaluation. Biores. Technol. 263, 517–524 (2018).

Wang, Z. et al. Critical evidence for direct interspecies electron transfer with tungsten-based accelerants: An experimental and theoretical investigation. Biores. Technol. 311, 123519 (2020).

Wu, J., Hu, Y. Y., Wang, S. F., Cao, Z. P., Li, H. Z., Fu, X. M. & Zuo, J. E. Effects of thermal treatment on high solid anaerobic digestion of swine manure: Enhancement assessment and kinetic analysis. Waste Manag. 62, 69–75 (2017).

Suanon, F. et al. Application of nanoscale zero valent iron and iron powder during sludge anaerobic digestion: Impact on methane yield and pharmaceutical and personal care products degradation. J. Hazard. Mater. 321, 47–53 (2017).

Kim, N. J., Lim, S. J. & Chang, H. N. Volatile fatty acid platform: Concept and application. Emerg. Areas Bioeng. 1, 173–190 (2018).

Mao, C., Feng, Y., Wang, X. & Ren, G. Review on research achievements of biogas from anaerobic digestion. Renew. Sustain. Energy Rev. 45, 540–555 (2015).

Schmidt, T., McCabe, B. K., Harris, P. W. & Lee, S. Effect of trace element addition and increasing organic loading rates on the anaerobic digestion of cattle slaughterhouse wastewater. Biores. Technol. 264, 51–57 (2018).

Meng, X., Zhang, Y., Li, Q. & Quan, X. Adding Fe0 powder to enhance the anaerobic conversion of propionate to acetate. Biochem. Eng. J. 73, 80–85 (2013).

Wan, S., Sun, L., Douieb, Y., Sun, J. & Luo, W. Anaerobic digestion of municipal solid waste composed of food waste, wastepaper, and plastic in a single-stage system: Performance and microbial community structure characterization. Biores. Technol. 146, 619–627 (2013).

Abbas, Y. et al. Recent advances in bio-based carbon materials for anaerobic digestion: A review. Renew. Sustain. Energy Rev. 135, 110378 (2021).

Qiang, H., Niu, Q., Chi, Y. & Li, Y. Trace metals requirements for continuous thermophilic methane fermentation of high-solid food waste. Chem. Eng. J. 222, 330–336 (2013).

Wang, Z. et al. Mesophilic anaerobic co-digestion of acorn slag waste with dairy manure in a batch digester: Focusing on mixing ratios and bio-based carbon accelerants. Biores. Technol. 286, 121394 (2019).

Yang, Y. et al. Adding granular activated carbon into anaerobic sludge digestion to promote methane production and sludge decomposition. J. Clean. Prod. 149, 1101–1108 (2017).

Möller, K. & Müller, T. Effects of anaerobic digestion on digestate nutrient availability and crop growth: A review. Eng. Life Sci. 12(3), 242–257 (2012).

Abdulla, H. A., Minor, E. C., Dias, R. F. & Hatcher, P. G. Changes in the compound classes of dissolved organic matter along an estuarine transect: A study using FTIR and 13C NMR. Geochim. Cosmochim. Acta 74(13), 3815–3838 (2010).

Gamage, I. H., Jonker, A., Zhang, X. & Yu, P. Non-destructive analysis of the conformational differences among feedstock sources and their corresponding co-products from bioethanol production with molecular spectroscopy. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 118, 407–421 (2014).

Zhou, J., You, X., Jia, T., Niu, B., Gong, L., Yang, X., & Zhou, Y. Effect of nanoscale zero-valent iron on the change of sludge anaerobic digestion process. Environ. Technol. (2020).

Dai, X., Xu, Y. & Dong, B. Effect of the micron-sized silica particles (MSSP) on biogas conversion of sewage sludge. Water Res. 115, 220–228 (2017).

Dong, B. et al. The inhibitory impacts of nano-graphene oxide on methane production from waste activated sludge in anaerobic digestion. Sci. Total Environ. 646, 1376–1384 (2019).

Firer, D., Friedler, E. & Lahav, O. Control of sulfide in sewer systems by dosage of iron salts: Comparison between theoretical and experimental results, and practical implications. Sci. Total Environ. 392(1), 145–156 (2008).

Jeon, D. et al. Reducing food waste in residential complexes using a pilot-scale on-site system. Biores. Technol. 311, 123497 (2020).

Yun, S. et al. Enhanced direct interspecies electron transfer with transition metal oxide accelerants in anaerobic digestion. Biores. Technol. 320, 124294 (2021).

Li, X. et al. Application of nano-scale transition metal carbides as accelerants in anaerobic digestion. Int. J. Hydrogen Energy 43(3), 1926–1936 (2018).

Acknowledgements

The authors gratefully acknowledge Al-Azhar University, Cairo, Egypt for providing financial support to carry out the research work.

Author information

Authors and Affiliations

Contributions

Taha Abdelfattah Mohammed Abdelwahab: Writing – original draft, Data curation, Visualization, Formal analysis. Junting Pan: Data curation, Investigation, Editing. Ji-Qin Ni: Software, Investigation. Chunping Yang: Resources, Writing-review, Editing. Mahendra Kumar Mohanty: Writing – review, Editing, Elwan Ali Darwish: Writing – review. Samir Hafez Mohamed Desoky: Review, Editing. Haiping Yang: Review. Ahmed Elsayed Mahmoud Fodah: Writing – original draft, Investigation, Formal analysis, Software.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Abdelwahab, T.A.M., Pan, J., Ni, JQ. et al. Nanoparticles for improving biogas production and effluent biofertilizer. Sci Rep 15, 19233 (2025). https://doi.org/10.1038/s41598-025-04131-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-04131-z