Abstract

Agarwood is a kind of valuable traditional Chinese medicine. However, natural agarwood has a long formation cycle and is in short supply. Herein, the complex inducer of artificial agarwood was screened and optimised based on design of experiments (DoE). Single factor design experiments were conducted to evaluate the effects of different concentrations of methyl jasmonate (A-MeJA), formic acid (B-FA) and Botryosphaeria rhodina A13(C-A13) on the in vitro branches of A. sinensis at different induction times (D-Time). The 2k factorial design was used to further optimise the screening of the complex inducer. Single factor experiments determined the concentration of the inducers acting on the branches of A. sinensis. The order of the four factors obtained by 2k factorial experiment was D-Time > A-MeJA > B-FA > C-A13. The optimal complex inducer was 1%MeJA + 1%FA + A13. Verification through an in vivo field experiment of 18 batches of A. sinensis, artificial agarwood met the requirements of the Pharmacopoeia of People’s Republic of China 2020 (ChP 2020), an indication that the complex inducer could efficiently promote the formation of agarwood (in 9 months). These findings provide essential data and new ideas for the efficient induction of agarwood and the production of high-quality substitutes for natural agarwood.

Similar content being viewed by others

Introduction

Herbal and medicinal plants play a vital role on the life of human beings and have unique compartment in their lifestyles. humanity faces numerous persistent diseases and illnesses, for which medicinal and herbal plants offer promising therapeutic options. Evidence for the effectiveness of herbal drugs has been obtained using extracts from aromatic and medicinal plants including essential oils, alcoholic, hydrolyzed and other solvent-based extracts along with fruit juices and extracts obtained from resins1. The plants Aquilaria spp. belong to the Thymelaeaceous family and are the typical wounding-induced medicinal plants primarily distributed throughout Southeast Asia. Depending on the region agarwood (also called Chen-Xiang, agar, gaharu, eaglewood, or aloeswood) is a resinous part of the non-timber Aquilaria tree. The chemical composition of agarwood mainly consists of sesquiterpenoids, 2-(2-phenylethyl) chromones and aromatics. Agarwood is a precious product for perfumes, incenses, and traditional Chinese medicine. In China, agarwood originates from aromatic resinous portion of A. sinensis (Lour.) Gilg and is generally used as a spiritual healing drug, digestive, sedative, and antiemetic drug2,3,4. Through its medicinal value, aroma healing and cultural and economic significance, agarwood contributes to human health and quality of life in many ways. With the deepening of modern scientific research, the potential of agarwood is expected to be further explored, bringing more benefits to human health.

In general, the fragrant resin is not produced in healthy A. sinensis and requires a long period of time to be produced under natural conditions (e.g., moth-eaten, thunderstruck, typhoon, and so on)5,6,7. Over decades, people pondered on how natural agarwood is formed. Indeed, agarwood is a typical injury-induced plant. Common physical and traditional agarwood-inducing methods are trunk wounding through a knife cut, hammering nails into A. sinensis tree trunks, drilling, and heat shock, all of which are mechanical injuries; and the formation is usually in the proximity of the wounded or decaying parts of the trunk8,9. Chemicals are potent agarwood inducers. Examples of these chemicals can be phytohormone such as hydrogen peroxide (H2O2), MeJA, and salicylic acid (SA), or chemicals such as sodium chloride (NaCl), FA, and so on10,11,12,13. Research has shown that exogenous MeJA can induce the formation and accumulation of sesquiterpenoids and when combined with SA in A. sinensis, can improve the stress tolerance14,15,16. The chemical inducer acts by causing severe damage to the cellular structure of the trunk of the Aquilaria spp., and as a result, callusing to cover up the wound cannot take place. Physical and chemical damage can weaken the A. sinensis and in turn become vulnerable to fungal infection13,14,17. Over the years, many researchers believe that microbes play an important role in agarwood formation and thus have isolated endophytic fungi from agarwood zones18,19,20. Furthermore, biological inoculation using specific fungi as inoculants has been conducted, and some of these fungi are members of the genera Fusarium, Colletotrichum, Botryosphaeria and many others13,21,22,23,24,25. However, natural agarwood is formed by four induction modes: physical injury, chemical damage, fungal infection, and comprehensive stimulation26.

Main compounds in agarwood are sesquiterpenes and 2-(2-phenylethyl) chromones, and the former is the main determinant of the unique aroma and important pharmacodynamic ingredient in agarwood27,28,29. Agarwood chips can cost from US$6,000 to US$20,000 per kilogram30. China has its own system for grading agarwood, which has started hundreds of years ago. Formerly, the classification of quality grades of agarwood in China was based on its sinking ability (i.e., the specific density of sinking in water, half floating or floating) and appearance characteristics (i.e., the sensory evaluation of aroma characteristics, color characteristics, and the resin area of agarwood). For the moment, whether it is commercial agarwood collected in the Forestry Industry Standard of the People’s Republic of China (2017 edition), or medicinal agarwood collected in the Pharmacopoeia of the People’s Republic of China (2020 edition), the quality of agarwood was evaluated by description (the characteristics of appearance, aroma, and taste), microscopic identification (microscopic characteristics of transverse section and interxylary phloem), physicochemical reaction identification of terpenoids, TLC identification, determination of the contents of ethanol-soluble extractives (EEC%) (mainly composed of sesquiterpenes and 2-(2-phenylethyl) chromones) and agaroretrol (one of the 2-(2-phenylethyl) chromones) content, and HPLC characteristic chromatogram (identification of 2-(2-phenylethyl) chromones). The above standard requires that EEC% not less than 10.0%, and the content of agaroretrol not less than 0.1%. Among them, EEC% is one of the important indexes of quality evaluation and quality classification of agarwood. Besides China, some Southeast Asian countries (e.g., Indonesia) also use this classification method. However, there is no uniform standard. Some regions in China (e.g., Dongguan and Hainan) divide agarwood into five quality grades based on EEC%, e.g., special Grade: extractives ≥ 30.0%; Grade I: 25.0% ≥ extractives > 30.0%; Grade II: 20.0% ≥ extractives > 25.0%, Grade III: 15.0% ≥ extractives > 20.0%, Grade IV: 10.0% ≥ extractives > 15.0%31,32,33.

The aims of this paper are to evaluate the effects of different factors of complex inducer (comprehensive method) based on design of experiments (DoE) and to select an effective agarwood-inducing agent34,35,36. with a view to improving the agarwood-inducing efficiency and reducing the cost of agarwood-induction. Technology for artificial agarwood induction is mainly inspired by the natural agarwood formation process37. Nevertheless, the chemical composition and proportion of artificial agarwood are largely different from those of natural ones, and their quality and price are far less than those of natural agarwood37,38,39. For these reasons, it is of great importance to continuously improve the method and quality of artificial agarwood.

Results

Single factor experiment

Induction samples were collected for 5, 7 and 10 days, and GC–MS compared the total peak area of each induction sample (Table 1), and XCMS online platform was used to identify the common secondary metabolites of the samples induced by the same inducer (Table 2). Based on GC–MS analysis, the total peak area of the three induction formulations with different concentrations was 10% MeJA-D5 with the largest and 0.1% MeJA-D5 with the smallest. The results of the identification of different inducer groups, as shown in Table 2, showed that the common secondary metabolite in the MeJA group was MeJA, and the common secondary metabolite in the FA and A13 groups was benzaldehyde, 4-hydroxy-3,5-dimethoxy. For inducer containing 10% MeJA, although the total peak area was the largest in the GC–MS analysis results, the preparation of MeJA inducers required a large amount of alcohol as a solvent, which would cause greater harm to the A. sinensis. Dripped with large amounts of ethanol, it can cause them to dehydrate, dry out, and then die.

Identification and screening of secondary metabolites

We used 16 combinations of MeJA (0.1%, 1%), FA (0.05%, 1%), A13 (5%, 15%) and time (7d, 15d) to treat the in vitro branches of A. sinensis, respectively. GC–MS analysis was performed on agarwood samples with different treatments, followed by chromatographic peak alignment using XCMS online and retrieval from the NIST 17 standard spectral library to identify common secondary metabolites in the samples (Table 3). The full spectrum data information was extracted through the XCMS online platform, and the components with difference in peak signal intensity of inducer treated samples for 7 and 15 days were screened based on OPLS-DA analysis. The arrangement experiment is an external model verification method to verify the fitting degree of OPLS-DA. By changing the arrangement order of the categorical variable y randomly multiple times (n = 200), various random Q2 values were produced. The results indicate that the model is effective and there is no overfitting phenomenon (Fig. 1B). According to the OPLS-DA scatter plots (R2X: 0.936, R2Y: 0.962, and Q2: 0.756) (Fig. 1A), samples with different processing times can be clearly distinguished. Based on the corresponding VIP values (Fig. 1C), the variable with VIP value > 1 was selected, and the result showed that the component with difference between the two types of samples was MeJA.

(A) Scatter plot, (B) Orthogonal Partial Least Squares-Discriminant Analysis (OPLS-DA) arranges the model verification diagram, and (C) Variable Importance in Projection (VIP) scores of peak signal intensities were compared between samples treated with inducers for 7 and 15 days. VIP values exceeding 1 are in green.

24 factorial design experiment

Model fitting and ANOVA analysis

The 24 factorial design was carried out using Design-Expert software (Version 8.0.6.1). Sixteen design experiments were performed to find the optimal complex inducer formulation by varying the concentrations of MeJA (A), FA (B), and A13 (C) and time (D).

Their lower and higher levels were designated as -1 and 1, respectively. The relative content of MeJA (%, Y1) and total peak area (× 108, Y2) were used as response values. The Y1 and Y2 were normalised, and the geometric mean of normalised values of each index was calculated to obtain the total normalised value (OD, maximum) (Table 4).

Therefore, a 24 factorial design was employed to study the impact of the four factors, and a total of 16 runs were performed (Table 5). The results obtained were statistically evaluated using Design-Expert software (Version 8.0.6.1).

The Model F-value of 21.58 implies the model is significant. There is only a 0.06% chance that a "Model F-Value" this large could occur due to noise (Table 6). Values of "Prob > F" less than 0.0500 indicate model terms are significant. In this case A, B, D, AB, AD, BD, ABC, BCD are significant model terms. This means that the main effects of A, B, D and the interactions of AB, AD, BD, ABC, BCD have significant effects on the response variable -OD values.

In addition, the determination coefficient R2 value was 0.9805, the Adj. R2 value was 0.9351 and the Adeq. Precision value was 16.667 (> 4.0). These values indicate that the regression model has a high fitting degree and low error value. Additionally, it accurately reflects the actual change rule of the experimental group. The R2 value showed that 98.05% of the test data could be explained by the regression model. The R2 value was close to the Adj. R2 value and approached 1. This reflects that the high fitting degree of the factors to the total normalised value (OD). The CV value of 26.6% (> 15%) indicated that the response index varied greatly among different samples, suggesting that the induction effects of samples were different to a certain extent.

After analysing and calculating each factor and interaction between the effect of the response value by Design Expert 8.0.6.1 software, an equation for the data were obtained as follows:

where OD represents the response, and A, B, C and D are the mathematical model terms for the four factors, including MeJA concentration, FA concentration, A13 concentration and time, respectively. The correlation coefficient of the Eq. (1) shows that the model fitted well and can be used to analyze and predict the screening of the complex inducer.

In Eq. (1), the mean value of the total normalised value (OD) was 0.26 for 2k factorial test. For each factor, the most important factor influencing the OD values was induction time, and its effect estimation was − 0.15, an indication of a negative effect on the OD value. The second most important factor was the concentration of MeJA, and its effect estimation was + 0.095, an indication of a positive effect on the OD value. However, formic acid had less influence on the OD value; its effect estimation was + 0.059, which is indicative of a positive effect on the OD value. For interaction factors with influential effects, the factors AB, AC, ACD, BCD had a positive effect on the OD value, whereas the factors AD, BC, BD, CD, ABC and ABD had a negative effect.

Pareto analysis

To compare the contribution ratio of each single factor and interaction to the OD value, pareto analysis method, was used (Fig. 2).

The contribution ratios between the main influencing factors in descending order was D > A > B > C. Then, the contribution ratio of two-factor interaction in descending order was BD > AD > AB > CD > AC > BC. The contribution ratios of the multiple interacting factors in descending order was ABC > BCD > ACD > ABD (Fig. 2.). The calculation showed that the total contribution percentage of A (13.92%), B (5.37%), and D (34.70%) was more than 50%, while that of C (0.26%) was only 0.30%. Therefore, the effect of A-MeJA and B-FA concentrations and D-Time on the OD value was significant, as calculated from the relative content of MeJA and total peak area. The influence of C-A13 inducer at a concentration range of 5–15% on the OD value was low; however, it was a positive influence.

In the table showing the results from 2k factorial design optimisation using Design Expert 8.0.6, the first row is the optimised complex inducer subschema (Table 7). Comprehensive analysis of the above ANOVA analysis and Pareto analysis, the complex inducer was found to be “1% MeJA + 1% FA + A13” and this complex inducer was used in the field experiment.

Verification of factorial experimental results

In this study, we used in vitro branches of A. sinensis as experimental materials and evaluated the induction effects of various single inducers and complex inducers. The relative content of MeJA and the total peak area of the samples were employed as assessment indicators. The induction results were evaluated using two algorithms: TOPSIS and the calculation of OD values (Table 8). Both algorithms consistently demonstrated that the combination of 1% MeJA + 1% FA + A13 yielded the best induction effect, which is in agreement with the screening results from the factorial experiment. For the single inducer MeJA, a concentration of 10% MeJA was found to cause dehydration and death of the tree, as also mentioned in this paper. Unfortunately, after 7 days of induction with MeJA, we were unable to obtain experimental data from the sample due to an experimental error. Nevertheless, based on the2k factorial screening results and extensive in vitro branch experiments, we have confirmed that the most effective inducer is the combination of 1% MeJA + 1% FA + A13.

Sample collection in field experiment

Due to the complex environmental factors in the field experiment, the growth conditions of A. sinensis trees was different. Three parallel samples were prepared for each group. For the wood sample collection, the A. sinensis of four months (F1-1–F1-3, F2-1–F2-3, F3-1–F3-3) and nine months (N1-1–N1-3, N2-1–N2-3, N3-1–N3-3) in the field experiment were cut down, and the resinous heartwood were shaved and used as test items. A total of 18 batches of A. sinensis wood samples were collected, and the detailed information is presented in Table 9. The geographic map of the sampling area is shown in Fig. 3.

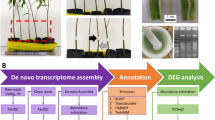

The growth condition of the experimental A. sinensis was good. The area of incense part of the experimental group samples was bigger than that of the control group, and comparing the 9-month samples with the 4-month samples, the brownish-black resin part was more thickened. In the second group, in which 25% ethanol was used as the negative control solvent, the A. sinensis trees were largely damaged and in turn had fewer leaves and rottenly xylem. In the third group, in which distilled water was used as the blank control, the A. sinensis trees grew well and could be used for subsequent incense making process (Fig. 4).

Analysis of quality evaluation

Moisture content, EEC%, and colour reaction

As shown in Table 10, the moisture contents of the experimental group, negative control group, and blank group were 4.35–5.94%, 4.09–6.29%, and 5.75–6.17%, respectively. EEC% of the experimental group, negative control group, and blank control group were 4.63–14.80%, 6.90–10.85%, and 3.51–5.03%, respectively. The colour reaction of the 4-month wood samples did not conform to ChP 2020, but that of the 9-month samples of the experimental group was cherry red, which fits with ChP 2020.

Content of agarotetrol

Solutions of 18 batches of wood samples, one batch of agarwood reference drugs (Sample tag: DZYC), and agarotetrol reference substance were analyzed by HPLC. The contents of agarotetrol of the experimental group, negative control group, and blank group were 0.02–0.86%, 0.09–0.18%, and 0.01–0.05%, respectively. The content of agarotetrol in DZYC was 0.38% (Table 10).

Analysis of fingerprint and chromatogram

HPLC chromatogram

Test solutions of 18 batches of wood samples and two batches of DZYC were subjected to HPLC analysis. The samples from both the experimental group and negative control group showed the six characteristic peaks of ChP 2020 and agarwood reference drug. Using the chromatogram of DZYC as the reference, the similarity of the experimental group, negative control group, and blank control group was found to be 0.885–0.960, 0.694–0.835, and 0.039–0.638, respectively (Table 10). The overlapped HPLC chromatogram of 18 batches of samples is shown in Fig. 5.

Overlapped HPLC chromatogram for A. sinensis wood samples and reference: (a) 9 batches of 4 M samples; and (b) 9 batches of 9 M samples. 1In the six characteristic peaks, peak 1: agarotetrol; peak 3: 8-chloro-2-(2-phenylethyl)-5,6,7-trihydroxy-5,6,7,8-tetrahydrochromone; and peak 5: 6,4′-dihydroxy-3’-methoxy-2-(2-phenylethyl) chromone. 2DZYC: agarwood reference drug.

Chromatographic fingerprint analysis by GC–MS

Chromatographic fingerprint can be used to evaluate the similarity among samples and obtained by calculating the correlation coefficient of the original data. The test sample solutions were prepared and analyzed by GC–MS.

The GC–MS analysis results for each sample were normalised by the peak area, and the obtained data files were then imported into the Traditional Chinese Medicine Fingerprint (2012 version) software. Similarity between a set of chromatographic fingerprints of the samples and the agarwood reference drug was evaluated and calculated. The GC–MS chromatographic fingerprint of the samples was established (Fig. 6). Obtaining the total ion chromatogram (TIC) of a sample took a long period of time; thus, after automatic matching with multi-point correction in Traditional Chinese Medicine Fingerprint (2012 version) software, three characteristic peaks of three compounds, including benzyl acetone (Rt = 12.352 min), baimuxinal (Rt = 58.547 min) and 2-(2-phenylethyl) chromone (Rt = 140.734 min), were used as the reference peaks in subsequently matching. Due to their good separation and high response values, they are suitable to be used as the reference peaks (these peaks were marked in Fig. 6a as TIC of DZYC). With the control fingerprint as the reference, the similarity for the experimental group, negative control group, and blank control group were found to be 0.640–0.943, 0.659–0.911, and 0.019–0.205, respectively (Table 10). In addition, the size of total peak area of the three groups could be ranked as follows: experimental group > negative control group > blank group. It could be seen that the experimental group and the blank group were obviously different (Fig. 6b, c, and d).

GC–MS fingerprint of (a) agarwood reference drug and (b)–(d) overlap of fingerprint for 6 batches of experimental group (b), negative control group (c), and blank control group (d) and that for 1 batch of agarwood reference drug. Peak 1: benzylacetone; peak 2: baimuxinal; and peak 3: 2-(2-phenylethyl) chromone.

The ratio (R) of the sum peak area at the 139–220 min range of individual agarwood to that at the 0–139 min range was determined and used as the apparent abundance of GC–MS fingerprints. The ratios of the experimental group, negative control group, and blank control group were found to be 1.42–4.76, 0.80–1.64, and 2.60–5.80, respectively (Table 10), and the ratio of DZYC was 1.05. In addition, the secondary metabolites in the agarwood samples in the experimental group were identified (Table 11).

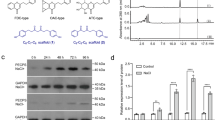

Correlation between EEC% and total HPLC total peak area and agarwood formation time

Multiple comparison tests on EEC (%) and total HPLC peak area (× 104) of artificial agarwood samples induced by complex inducer for 4 and 9 months were performed using GraphPad Prism 8.4.0. Compared to the control group, EEC% and total HPLC peak area (× 104) of the experimental group significantly increased with increasing induction time (P < 0.05, Fig. 7). This indicates that the induction by complex inducer could lead to the accumulation of 2-(2-phenylethyl) chromones.

Discussion

Up to now, a variety of artificial inducer have been used to induce agarwood formation in A. sinensis. MeJA, as a plant hormone, plays an important role in the formation of agarwood. The content of agarotetrol reached 1.78 mg/g, which was 14.8–21.8 times higher than that of the control group after induction of A. sinensis with exogenous MeJA (10 g/L)10. Injecting appropriate amounts of acidic or alkaline inducing agents, such as salicylic acid, ethylene glycol, formic acid, and sodium dihydrogen phosphate, into the xylem of A. sinensis can promote the production of resin, with the EEC% reaching over 10.0%, and the highest reaching up to 32.4%, in compliance with the pharmacopeial standards for medicinal use in the Chinese Pharmacopoeia40. After one year of induction treatment with sulfuric acid and sodium methylbisulfate, the content of agarwood oil produced by A. crassna was 0.038–0.039%, and the sesquiterpenes accounted for 15.80–20.80% of the total oil41. B. rhodina is a plant pathogenic fungus, which can infect more than 500 kinds of tropical and subtropical forests42 and cause a variety of plant diseases43. B. rhodina A13 is an endophytic fungus isolated from the resinous xylem of A. sinensis, can induce A. sinensis excised twigs to produce 5,9-dimethyl-2-(1-methylethylidene) cyclodecanol, sesquiterpene of agarwood44. Using sawdust of A. sinensis as the culture substrate, solid fermentation culture was performed on B. rhodina A13. Seven 2-(2-phenylethyl) chromone analogues and ten steroid compounds, as well as flavonoid compounds, were isolated from B. rhodina A13. Among these, the steroid compounds exhibited good cytotoxic activity45. After 12 months of induction with FA + B. rhodina A13 in A. sinensis, EEC% of agarwood could reach a maximum of 40.60%, with a median value of 15.54% across 45 batches46. Therefore, we selected MeJA, FA and A13 as candidate inducers. Based on the survival rate of trees and continuous testing39,46, the appropriate concentration is obtained for single-factor experiments. Because the in vitro branches of A. sinensis were induced for a short time and did not produce large amounts of sesquiterpenes and 2-(2-phenylethyl) chromones, we assessed the degree of stress by changes in the accumulation of secondary metabolites. Therefore, the total peak area of the sample is used as the evaluation index. Based on GC–MS analysis, in the MeJA group, the total peak area of samples induced by 10%MeJA was the largest, but the preparation of MeJA inducer required a large amount of alcohol as a solvent, which would cause greater harm to the A. sinensis. A. sinensis will be affected by the alcohol as a solvent, causing dehydration, drying out, and then death47. In subsequent field experiments, when 25% ethanol was used as the negative control solvent, most of the A. sinensis trees were damaged, the leaves became less, and the xylem rotted, which also showed the harm of a large amount of alcohol acting on the A. sinensis. In the FA group, samples treated with FA (0.05%, 1%) showed higher total peak areas than those treated with 0.5% FA. Similarly, in the A13 group, samples treated with A13 (5%, 15%) had greater total peak areas than those treated with 10% B. rhodina A13. Therefore, we used MeJA (0.1%, 1%), FA (0.05%, 1%) and A13 (5%, 15%) for the subsequent experiments.

Design of experiments (DoE) systematically evaluates multiple factors’ effects. Both Taguchi’s method and factorial design fall under the category of DOE. When dealing with numerous factors, Taguchi’s method can be prioritized. It utilizes orthogonal arrays combined with Signal-to-Noise Ratio (S/N Ratio) analysis to identify optimal parameter combinations while mitigating the effects of noise factors. However, Taguchi’s method has limitations in interpreting main effects and interaction effects48. Factorial design can comprehensively analyze main effects and interactions at all levels49. However, as the number of factors increases, the number of required experiments grows exponentially, leading to computational complexity and difficulties in interpreting the numerous interactions50. 24 factorial design serves as an efficient and systematic multi-factor optimization tool for situations with limited resources and few factors (≤ 4), but where a comprehensive analysis of main effects and interactions and efficient screening of key influences are required. This method can simultaneously analyze four factors (A, B, C, D) and all their possible main effects and interactions (such as AB, AC, ABC). Each factor is horizontally and evenly distributed, which can effectively avoid data bias and omission of key influencing factors. Meanwhile, only 16 experiments (24 = 16) are needed to examine all factor combinations. While quantifying the contribution of each factor to the results through statistical models (such as ANOVA), the synergy or antagonistic effects among the factors can also be revealed, thereby accurately identifying the optimal parameter combinations51. This study aims to systematically investigate the contributions of A-MeJA, B-FA, C-A13, and D-Time to agarwood formation and identify the key factors influencing agarwood production. Additionally, GC–MS and HPLC were employed for multi-index validation to compensate for the limitations of a simple two-level analysis. Therefore, this study employed 24 factorial design to optimize controllable factors, thereby simplifying the complexity of field experiments while improving agarwood induction efficiency and reducing costs.

The common secondary metabolite in the 16 samples of factorial design experiments was MeJA, in addition to phenolic and fatty acid compounds (Table 5). Their accumulation provides the chemical basis for the special aroma and medicinal value of incense. According to the OPLS-DA analysis results (Fig. 1), the relative contents of MeJA in the chemical compounds of 16 the in vitro branches of A. sinensis showed differences at different induction times. It can be seen from Table 4 that the relative contents of MeJA in samples induced for 7 days was higher than that in samples induced for 15 days. In the early stages of induction, the content of MeJA increased rapidly to activate plant defence responses and secondary metabolic pathways. The rapid accumulation of JA in response to wounding has been demonstrated to be essential for the direct defenses at the attack site and during systemic defense signaling52. After injury, A. sinensis exhibited an early increase in endogenous jasmonic acid compounds, followed by a significant rise in sesquiterpene content10,53. It had been further demonstrated that MeJA significantly induced the expression of the sesquiterpene synthase (ASS) gene, which led to an increase in the production of sesquiterpenes54. These findings indicated that the JA pathway played a key role in regulating the biosynthesis of sesquiterpene defences in A. sinensis. Although only the accumulation and change of JAs were detected due to the short induction time of in vitro branches of A. sinensis, the results also suggested that the biosynthesis of sesquiterpene of A. sinensis may be promoted at the early stage of inducer treatment. Sesquiterpenes are one of the main chemical components of agarwood, and sesquiterpene content has typically been regarded as an important criterion for the evaluation of agarwood quality11,55。

Therefore, in the 2k factorial design analysis, the relative content of MeJA and the total peak area of each sample were used as indicators to evaluate the effect of inducers. We found that the optimal complex inducer was “1%MeJA + 1%FA + 5%A13 + 7days”. However, the effect of A13 at the concentration range of 5%-15% was not significant (Table 6), likely due to that the con-centration was too low. To simplify operating procedures in the field, we used the stock solution of A13 in the field experiment. Moreover, because the in vitro branch of A. sinensis was used as a material, the induction time range used in the field experiment was not sufficient. To verify the results of the factorial experiment, we used in vitro branches of A. sinensis as experimental materials and evaluated the induction effects of various single inducers and complex inducers. The two algorithms TOPSIS and OD value combined the relative content of MeJA and the total peak area of the sample to avoid the bias of single-parameter evaluation (Table 8). The accuracy and reliability of the screening results of 2k factorial experiments are improved. According to the discriminant analysis of the natural agarwood formation mode, the analysis results show that 57.1% of the natural agarwood formation mode may be integrated (physical injury + chemical damage + fungal induction), and long-term induction factors (fungal induction) are required26. Thus, “1%MeJA + 1% FA + A13” was selected as the complex inducer in the field experiments.

Most researchers believe that the longer the duration of artificially induced accumulation, the better the quality of agarwood. However, our previous dynamic study showed that after more than 10 months of artificial induction, EEC% has begun to have a downward trend38. We therefore adopted the 9-month time period and retained part of the A. sinensis for follow-up observation. In our experiment, we used agarwood reference drug (standard substances verified by the National Institute for Food and Drug Control to meet the specified requirements) as references. According to the requirements of ChP 2020, we conducted a comprehensive evaluation of wood samples (agarwood) collected from in vivo field experiments. The evaluation includes the description, moisture content, identification, characteristic chromatogram, EEC% and agaroretrol required by ChP 2020. In addition to meeting the requirements of ChP 2020, the similarity of GC–MS and HPLC fingerprints in the experimental group was the highest compared with the agarwood reference drug. Meanwhile, when comparing total peak areas across the three groups, the experimental group also showed the highest total peak area and abundance of compounds. The experimental group’s samples are closer to the agarwood reference drug. Therefore, the artificial agarwood induced by complex inducer produced in this study met the requirement of ChP 2020 for medicinal agarwood, and the resin quality reaches the grade IV of agarwood quality31.

As we know, agarwood primarily contains sesquiterpenes, 2-(2-phenylethyl) chromones, and aromatic compounds. One of the main bases of agarwood’s medicinal effects is agarwood essential oil, which chemical composition is mainly sesquiterpenes. Jayachandran et al. analyzed the volatile oil of different grades of A. malaccensis and found that the higher the grade of volatile oil, the higher the relative content of sesquiterpenes56. Previous studies have shown that natural agarwood is mainly composed of 2-(2-phenylethyl) chromones and sesquiterpenes with their relative content ratio (apparent abundance, R) close to 1:1. The ratio of artificial agarwood is between 1.1 and 10.5. The closer the ratio is to 1:1, the more artificial incense can achieve similar levels of chemical composition as natural agarwood37. However, the average ratio of blank group samples was 4.28:1, whereas that of the experimental group was 2.28:1. The decrease in ratio may be due to the decrease in 2-(2-phenylethyl) chromones abundance or the increase in sesquiterpenes abundance. However, the EEC% and HPLC results showed that the 2-(2-phenylethyl) chromones content of samples in the experimental group was significantly increased compared to that of samples in the blank group. The content also significantly increased with the increase of induction time (Fig. 7). Therefore, the decrease in the ratio is likely due to an increase in the abundance of sesquiterpenes rather than a reduction of the abundance of 2-(2-phenylethyl) chromones, which suggests that the complex inducer can increase the abundance of sesquiterpenes compounds in agarwood to a certain extent.

We suggest that the complex inducer to produce agarwood not only can satisfy the high demand for natural agarwood, but also can help preserve and protect wild A. sinensis tree. At the same time, this provides new ideas for developing efficient artificial agarwood formation technologies and producing high-quality artificial agarwood that closely resembles natural agarwood.

Materials and methods

Materials

Robust and insect-free branches of A. sinensis planted in the experimental base of the Tropical Forestry Research Institute, Guangzhou Plantation Base (40° 0′ N, 116° 15′ E) were picked and used in single factor and factorial design experiment for the screening of complex inducer. Resinous parts of wood chips of A. sinensis planted in Wugui Mountain (22° 26′ N, 113° 24′ E), Zhongshan, China were collected for in vivo confirmatory experiment. The experimental area belongs to the planting land of Zhongshan Woxianglin Agricultural Development Co., Ltd. The experiments involving the artificial induction of A. sinensis and the collection of incense resin were authorized by the company. A. sinensis cultivation and agarwood production complied with the Forestry Industry Code of the People’s Republic of China (LY/T 3374-2024) issued by the National Forestry and Grassland Administration. All A. sinensis trees were identified as A. sinensis by Prof. Yan (College of Traditional Medicine, Guangdong Pharmaceutical University, China). Botryosphaeria rhodina A13 (EU781670), isolated and provided by associate Prof. Li (Institute of Microbiology, Guangdong Academy of Sciences, China), was used to inoculate on A. sinensis trees57. Agarwood reference drug (DZYC) was purchased from National Institutes for Food and Drug Control (121222-201203, 121222–202104, Beijing, China). MeJA was purchased from Sigma-Aldrich (#392707, St. Louis, MO). FA, ethanol (EtOH), and trichloromethane (THMS) were purchased from Guangzhou Chemical Reagent Factory (Guangdong, China).

The strain A13 (stored at 4 °C) was cultured on potato glucose agar at 28 °C for 7 days and then inoculated into 500 mL Erlenmeyer flasks, which contained 250 mL potato dextrose broth (potato 20%, glucose 2%, K2HPO4 0.3%, MgSO4·7H2O 0.15%, vitamin B 10 mg/L). After 7 days of cultivation on a 120 r/min rotating shaker at 28 °C, the liquid fermentation broth of the strain A13 was filtered through sterile double-layer gauze fabrics to prepare the stock solution. MeJA, weigh it precisely, add 50% ethanol to dissolve it, and dissolve it to 2% (w/v) at room temperature as inducer I. FA was pipette accurately, and dissolved by adding A13 to give a concentration of 2% (w/v). Finally, A13 was added to 1500 mL and the solution was stirred until evenly mixed to result in inducer II. Then, it was mixed with inducer I, and the final concentration of ethanol, MeJA, FA was adjusted to 25%, 1%, 1% respectively. The final liquid was the complex inducer for in vivo field experiment.

Methods

Establishment of in vitro branch model of A. sinensis

Complex inducers were screened through the use of the in vitro branch model of A. sinensis established by a previous study44. Under aseptic conditions, fresh branches with a thickness of about 0.5 cm were cut into small sections with a length of about 5 cm. The sections were soaked in 0.1% HgCl2 solution for 5 min and then rinsed 3 times with sterile water. After that, they were soaked in 75% ethanol solution for 5 min and then rinsed with sterilised water to remove residual ethanol. A sterile puncher was used to drill the branches before being placed on a petri dish filled with moist sterile filter paper (Fig. 8).

Single factor experimental design

MeJA, FA, and A13 were employed to induce the in vitro branches of A. sinensis. Solutions of MeJA (0.1%, 1%, 10% w/v), FA (0.05%, 0.5%, 1% w/v) and A13 (5%, 10%, 15% w/v) were prepared. The solutions were injected into the in vitro branches, which were then sealed with a plastic wrap. The branches were placed in darkness at 28 °C for 5, 7 and 10 days (Table 12).

24 factorial experiment design and statistical optimisation

The ak factorial design was adopted, where k is the experimental factor, and a is the factor level, to optimize the design scheme further. The established regression model and multiple regression equation were employed to screen out the best complex inducer more accurately.

According to the results from single factorial analysis and preliminary experiment, MeJA concentration (A; 0.1%, 1%), FA concentration (B; 0.05%, 1%), A13 concentration (C; 5%, 15%) and induction time (D; 7d, 15d) were considered the investigate factors.

Infusion process of complex inducer into A. sinensis

Artificial agarwood from A. sinensis was induced by complex inducer through pinhole instillation17. A total of 18 batches of A. sinensis trees were used in the field experiment and were randomly divided into three groups: experimental group, negative control group, and blank control group. The holes of incense were drilled at 50 and 100 cm from the ground, and the trunk of each A. sinensis tree was marked with a label paper (Fig. 9a). After the inducer permeated the A. sinensis, they were transported upward through the xylem by transpiration and transported downward through the xylem by gravity. After four and nine months, the trunk was cut down at the hole of incense and then cut horizontally at every 50 cm along the longitudinal axis (Fig. 9b).

HPLC and quality evaluation

High performance liquid chromatography (HPLC) was carried out following the method of Xu et al.58 and EEC%, agarotetrol content and colour reaction were examined according to the ChP 20202 determination of agarwood requirements. GraphPad Prism 8.4.0 and Origin 2021 software were used for significance analysis and to create plots, respectively.

GC–MS fingerprinting and identification of secondary metabolites

GC–MS fingerprinting37 was employed to determine the content of MeJA in agarwood. Preparation method of test product solution, branches of A. sinensis in each test group were placed in a tapered flask with a stopper, in which they were soaked in THMS for 24 h. The extract solution was removed using a rotary evaporator, and the residual was dissolved with THMS before being transferred to a 1 mL volumetric flask. After THMS was dropped to the mark the solution was shaken vigorously and then filtered through a 0.22 μm microporous membrane; and the filtrate was collected. For field verification experiment, all samples were collected and dried at room temperature. Wood samples were ground to powder and then filtered through a 50-mesh sieve. The powder samples of agarwood (0.2 g) were extracted with THMS (10 mL, 24 h) at room temperature. The solvent was evaporated in a water bath (70 °C) until viscous semi-solid masses were obtained. The semi-solid masses were dissolved in the THMS and adjusted to a 2 mL volume. The liquid was shaken vigorously and then filtered through a 0.22 μm microporous membrane. The filtrate was collected and stored in darkness in an air-tight sealed vial at 4 °C. DZYC (0.2 g) was accurately weighed and then subjected to the above steps. The obtained test solutions and standard solution were subjected to subsequent GC–MS analyzes, respectively.

The GC–MS experimental conditions were as follows: GC analysis was performed using the following conditions: For the in vitro branches experiment, GC–MS 7890A-5957C (Agilent) and equipped with a capillary fused silica column HP-5MS (30 m × 0.25 mm × 0.25 µm film thickness, Agilent Technologies); injector temperature: 260 °C; carrier gas (He, 99.999%) flow rate, 1.0 mL min−1; programmed oven temperature, 90 °C for 2 min, then rose at 2.5 °C min−1 to 160 °C for 5 min, then rose at 2 °C min−1 to 180 °C for 5 min, and last rose at 5 °C ·min−1 to 230 °C for 15 min. The split ratio of 1/30; a sample of 1 µL was injected. For field verification experiment, injector temperature: 260 °C; carrier gas (He, 99.999%) flow rate, 1.0 mL min−1; programmed oven temperature, 90 °C for 4 min, then rose at 2 °C min−1 to 135 °C for 5 min, then rose at 0.2 °C min−1 to 153 °C then 3 °C min−1 to 210 °C for 10 min, then rose at 0.5 °C min−1 to 230 °C for 20 min, and last rose at 2 °C min−1 to 280 °C for 10 min; injections of 1 µL were performed in splitless mode. MS analysis was performed under the following conditions: The samples were operated in the electron ionization (EI) mode (70 eV); ionization voltage, 1 kV; injection port temperature, 250 °C; ion source temperature, 230 °C; solvent delay time, 5 min; quality scan range, m/z 50–500.

Mass spectral information of TIC of the samples was obtained using Automated Mass Spectral Deconvolution and Identification System (AMDIS). The information was then compared with the mass spectral information and the retention index (RI) value in the National Institute of Standards and Technology Mass Spectral Library (NIST 17). The relative percentage of agarwood compounds was calculated by the area normalisation method using the GC–MS Postrun Analysis workstation.

Conclusions

In this study, we established the in vitro branch model of A. sinensis, which was a simple method compared with the field plant experiments, and was able to screen different inducers at the same time, which greatly shortened the experimental period. Moreover, the in vitro branches of A. sinensis were closer to the natural growth condition of the plant. The factorial experimental design is a multi-factor, multi-level, single-effect crossover design, it can accurately evaluate the effect of each independent factor and the interaction between the factors. The complex inducer was optimized by the factor design experiment, and the best complex inducer was determined to be 1%MeJA + 1%FA + A13. Field experiments proved that the complex inducer could effectively promote the formation of agarwood. This work provides a theoretical basis for optimizing the existing production methods and improving the quality of artificial agarwood. The agarwood formation process is complex, and due to individual differences in each tree, the effectiveness of agarwood-inducing agents can be affected by these factors. In the future, with the application of biotechnology, the optimization of chemical induction technology, and the development of digitalization and intelligence, the problems of unstable quality of agarwood will be solved, and the quality and market recognition of agarwood will be improved, and the standardization and industrialization of agarwood industry will be promoted.

Data availability

The data presented in this study are available on request from the corresponding author.

References

El Jabboury, Z. et al. Ammi visnaga (L.) Lam.: An overview of phytochemistry and biological functionalities. Trends Phytochem. Res. https://doi.org/10.30495/tpr.2023.1987739.1347 (2023).

China Pharmacopoeia Committee. The Pharmacopoeia of People’s Republic of China (I) (Chemical Industry Press, NY, 2020).

Baldovini, N. The chemistry of agarwood odorants. Prog. Chem. Org. Nat. Prod. 118, 47–100. https://doi.org/10.1007/978-3-030-92030-2_2 (2022).

Xie, B. et al. Pharmacokinetic studies of six major 2-(2-phenylethyl) chromones in rat plasma using ultra high performance liquid chromatography with tandem mass spectrometry after oral administration of agarwood ethanol extract. J. Sep. Sci. 44(12), 2418–2426. https://doi.org/10.1002/jssc.202100053 (2021).

Wang, Y. C. et al. Aquilaria species (Thymelaeaceae) distribution, volatile and non-volatile phytochemicals, pharmacological uses, agarwood grading system, and induction methods. Molecules 26(24), 7708. https://doi.org/10.3390/molecules26247708 (2021).

Naziz, P. S., Das, R. & Sen, S. The scent of stress: Evidence from the unique fragrance of agarwood. Front. Plant Sci. 16(10), 840. https://doi.org/10.3389/fpls.2019.00840 (2019).

Shivanand, P., Arbie, N. F., Krishnamoorthy, S. & Ahmad, N. Agarwood-the fragrant molecules of a wounded tree. Molecules 27(11), 3386. https://doi.org/10.3390/molecules27113386 (2022).

Pojanagaroon, S. & Kaewrak, C. Mechanical methods to stimulate aloes wood formation in Aquilaria crassna Pierre ex H. Lec. (Kritsana) trees. Acta Hort. 676, 161–166. https://doi.org/10.17660/ActaHortic.2005.676.20 (2005).

Liu, Y. et al. Whole-tree agarwood-inducing technique: An efficient novel technique for producing high-quality agarwood in cultivated Aquilaria sinensis trees. Molecules 18(3), 3086–3106. https://doi.org/10.3390/molecules18033086 (2013).

Jiang, H., Wang, Z., Yang, Q., Wang, Q. & Wang, M. Content of Agarotetrol in agarwood of Aquilaria sinensis stimulated repeatedly with methyl jasmonate. Chin. J. Trop. Crops 39(9), 1834–1840. https://doi.org/10.3969/j.issn.1000-2561.2018.09.023 (2018).

Lv, F. et al. Hydrogen peroxide burst triggers accumulation of jasmonates and salicylic acid inducing sesquiterpene biosynthesis in wounded Aquilaria sinesis. J. Plant Physiol. 234–235, 167–175. https://doi.org/10.1016/j.jplph.2019.02.006 (2019).

Zhang, Z. X. et al. Five 2-(2-Phenylethyl) chromones from sodium chloride-elicited Aquilaria sinensis cell suspension cultures. Molecules 21(5), 555. https://doi.org/10.3390/molecules21050555 (2016).

Chen, X. et al. Relationship between expression of chalcone synthase genes and chromones in artificial agarwood induced by formic acid stimulation combined with Fusarium sp. A2 inoculation. Molecules 22(5), 686. https://doi.org/10.3390/molecules22050686 (2017).

Xu, Y. H. et al. Jasmonic acid is a crucial signal transducer in heat shock induced sesquiterpene formation in Aquilaria sinensis. Sci. Rep. 6(1), 21843. https://doi.org/10.1038/srep21843 (2016).

Tayyab, N. et al. Combined seed and foliar pre-treatments with exogenous methyl jasmonate and salicylic acid mitigate drought-induced stress in maize. PLoS ONE 15(5), e0232269. https://doi.org/10.1371/journal.pone.0232269 (2020).

Mahmoud, L. M., Vincent, C. I., Grosser, J. W. & Dutt, M. The response of salt-stressed Valencia sweet orange (Citrus sinensis) to salicylic acid and methyl jasmonate treatments. Plant Physiol. Rep. 26(1), 137–151. https://doi.org/10.1007/s40502-020-00563-z (2021).

Tian, J. J., Gao, X. X., Zhang, W. M., Wang, L. & Qu, L. H. Molecular identification of endophytic fungi from Aquilaria sinensis and artificial agarwood induced by pinholes-infusion technique. Afr. J. Biotechnol. https://doi.org/10.5897/AJB11.3159 (2013).

Ramli, A. N. M. et al. Production of volatile compounds by a variety of fungi in artificially inoculated and naturally infected Aquilaria malaccensis. Curr Microbiol. 79(5), 151. https://doi.org/10.1007/s00284-022-02840-6 (2022).

Islam, M. R., Chakraborty, C. & Banu, S. Isolation and characterization of bacteria and fungi associated with agarwood fermentation. Curr. Microbiol. 79(10), 313. https://doi.org/10.1007/s00284-022-02999-y (2022).

Du, T. Y. et al. Endophytic fungi associated with Aquilaria sinensis (agarwood) from china show antagonism against bacterial and fungal pathogens. J. Fungi (Basel). 8(11), 1197. https://doi.org/10.3390/jof8111197 (2022).

Guo, Y. et al. Single-cell quantitative proteomic analysis of human oocyte maturation revealed high heterogeneity in in vitro matured oocytes. Mol. Cell Proteomics. 21(8), 100267. https://doi.org/10.1016/j.mcpro.2022.100267 (2022).

Yang, H., He, R., Cui, Y., Li, Y. & Ge, X. Saprophytic Bacillus accelerates the release of effective components in agarwood by degrading cellulose. Molecules 27(4), 1428. https://doi.org/10.3390/molecules27041428 (2022).

Justin, S., Lihan, S., Elvis-Sulang, M. & Chiew, T. Formulated microbial consortium as inoculant for agarwood induction. J. Trop. For. Sci. 32(2), 161–169. https://doi.org/10.26525/jtfs32.2.161 (2020).

Liu, J. et al. Integrating multiple omics identifies phaeoacremonium rubrigenum acting as Aquilaria sinensis marker fungus to promote agarwood sesquiterpene accumulation by inducing plant host phosphorylation. Microbiol. Spectr. 10(4), e0272221. https://doi.org/10.1128/spectrum.02722-21 (2022).

Faizal, A. et al. Methyl jasmonate and crude extracts of Fusarium solani elicit agarwood compounds in shoot culture of Aquilaria malaccensis Lamk. Heliyon 7(4), e06725. https://doi.org/10.1016/j.heliyon.2021.e06725 (2021).

Zhou, X. et al. Characterization of agarwood by gas chromatography-mass spectrometry and a random forest model. Anal. Lett. 55(9), 1364–1381. https://doi.org/10.1080/00032719.2021.2005081 (2022).

Alamil, J. M. R. et al. Rediscovering the therapeutic potential of agarwood in the management of chronic inflammatory diseases. Molecules 27(9), 3038. https://doi.org/10.3390/molecules27093038 (2022).

Li, W., Chen, H. Q., Wang, H., Mei, W. L. & Dai, H. F. Natural products in agarwood and Aquilaria plants: Chemistry, biological activities and biosynthesis. Nat. Prod. Rep. 38(3), 528–565. https://doi.org/10.1039/d0np00042f (2021).

Gao, M. et al. Overview of sesquiterpenes and chromones of agarwood originating from four main species of the genus Aquilaria. RSC Adv. 9(8), 4113–4130. https://doi.org/10.1039/c8ra09409h (2019).

Tan, C. S., Isa, N. M., Ismail, I. & Zainal, Z. Agarwood induction: Current developments and future perspectives. Front. Plant Sci. 10, 122. https://doi.org/10.3389/fpls.2019.00122 (2019).

Lin, W. T., Liu, L. F., Li, B., Huang, X. & Liang, Y. L. Research progress on quality grading and related factors of agarwood. Modern Chin. Med. 25(10), 2246–2254. https://doi.org/10.13313/j.issn.1673-4890.20221128005 (2023).

Azah, M. N. et al. Classification of agarwood (gaharu) by resin content. J. Trop. For. Sci. 25(2), 213–219 (2013).

López-Sampson, A. & Page, T. History of use and trade of agarwood. Econ. Bot. 72(1), 107–129. https://doi.org/10.1007/s12231-018-9408-4 (2018).

Politis, S. N., Colombo, P., Colombo, G. & Rekkas, D. M. Design of experiments (DoE) in pharmaceutical development. Drug. Dev. Ind. Pharm. 43(6), 889–901. https://doi.org/10.1080/03639045.2017.1291672 (2017).

Zakaria, M. Y. et al. Boosting the anti MERS-CoV activity and oral bioavailability of resveratrol via PEG-stabilized emulsomal nano-carrier: Factorial design, in-vitro and in-vivo assessments. Drug Deliv. 29(1), 3155–3167. https://doi.org/10.1080/10717544.2022.2126028 (2022).

Mah, K., Yussof, H., Seman, M. A. & Mohammad, A. Separation of xylose using a thin-film composite nanofiltration membrane: Screening of interfacial polymerization factors. RSC Adv. 6(73), 69454–69464. https://doi.org/10.1039/c6ra12628f (2016).

Gao, X. et al. Chromatographic fingerprint analysis of metabolites in natural and artificial agarwood using gas chromatography-mass spectrometry combined with chemometric methods. J. Chromatogr. B Analyt. Technol. Biomed. Life Sci. 967, 264–273. https://doi.org/10.1016/j.jchromb.2014.07.039 (2014).

Chen, X. et al. Trunk surface agarwood-inducing technique with Rigidoporus vinctus: An efficient novel method for agarwood production. PLoS ONE 13(6), e0198111. https://doi.org/10.1371/journal.pone.0198111 (2018).

Zhuang, Z. et al. A study on the quality evaluation of agarwood of Aquilaria sinensis and Aquilaria malaccensis induced by different inducers based on gray correlation degree and TOPSIS. Pharmacogn. Mag. 18(79), 713–728. https://doi.org/10.4103/pm.pm_340_21 (2022).

Zhou, X. et al. Analysis and evaluation of chemically induced artificial agarwood. China J. Chin. Mater. Med. 42(16), 3159–3166. https://doi.org/10.19540/j.cnki.cjcmm.20170512.004 (2017).

Le, V. T., Tran, V. D., Nguyen, H. S., Sato, T. & Kozan, O. Impacts of biological, chemical and mechanical treatments on sesquiterpene content in stems of planted Aquilaria crassna trees. Agrofor. Syst. 89(6), 973–981. https://doi.org/10.1007/s10457-015-9829-3 (2015).

Burgess, T. I., Barber, P. A., Mohali, S., Pegg, G. & Wingfield, B. M. J. Three New Lasiodiplodia spp. from the tropics, recognizedbased on DNA sequence comparisons and morphology. Mycologia 98(3), 423–435. https://doi.org/10.3852/mycologia.98.3.423 (2006).

ÚrbezTorres, J. R., Leavitt, G. M., Guerrero, J. C., Guevara, J. & Gubler, W. D. Identification and pathogenicity of Lasiodiplodia theobromae and Diplodia seriata, the causal agents of bot canker disease of grapevines in mexico. Plant Dis. 92(4), 519–529. https://doi.org/10.1094/PDIS-92-4-0519 (2008).

Tao, M., Wang, L., Gao, X. & Zhang, W. Effects of Botryosphaeria rhodina A13 on agarwood formation of Aquilaria sinensis excised twig. Nat. Prod. Res. Dev. 24(12), 1719–1723. https://doi.org/10.16333/j.1001-6880.2012.12.006 (2012).

Zhang, Y. et al. 2-(2-Phenylethyl) chromones from endophytic fungal strain Botryosphaeria rhodina A13 from Aquilaria sinensis. Chin. Herb. Med. 9(1), 58–62. https://doi.org/10.1016/S1674-6384(17)60076-5 (2017).

Fan, Y. F. et al. Quality evaluation of artificial agarwood induced by formic acid stimulation combined with different fungal inoculation. Chin. J. Pharm. Anal. 36(9), 1544–1554. https://doi.org/10.16155/j.0254-1793.2016.09.05 (2016).

Perata, P., Alpi, A. & Loschiavo, F. Influence of ethanol on plant cells and tissues. J. Plant Physiol. 126, 181–188. https://doi.org/10.1016/S0176-1617(86)80019-0 (1986).

Xu, M. Z. et al. Research on the applicability of Taguchi method. Sci. Technol. Manag. Res. 41(11), 216–223. https://doi.org/10.3969/j.issn.1000-7695.2021.11.027 (2021).

Hu, C. Y. & Hu, L. P. How to use analysis of variance correctly——an analysis of variance for the univariate quantitative data collected from the factorial design. Sichuan Mental Health 35(3), 207–211. https://doi.org/10.11886/scjsws202205100052008 (2022).

Cheng, J. L., Zheng, M. & Lou, J. Q. Comparison of several common optimal experimental design methods. Lab. Res. Explor. 31(7), 7–11. https://doi.org/10.3969/j.issn.1006-7167.2012.07.003 (2012).

Montgomery, D. C. Design and Analysis of Experiments 178–180, 185–188 (Wiley, 2020).

Howe, G. & Jander, G. Plant immunity to insect herbivores. Annu. Rev. Plant Biol. 59, 41–66. https://doi.org/10.1146/annurev.arplant.59.032607.092825 (2008).

Zhang, Z. et al. Response of endogenous jasmonates and sesquiterpenes to mechanical wound in Aquilaria sinensis stem. J. Hortic. 40(1), 163–168. https://doi.org/10.16420/j.issn.0513-353x.2013.01.003 (2013).

Xu, Y. H. et al. Identification of genes related to agarwood formation: transcriptome analysis of healthy and wounded tissues of Aquilaria sinensis. BMC Genom. 14, 227. https://doi.org/10.1186/1471-2164-14-227 (2013).

Chen, H. Q. et al. Chemical constituents of agarwood originating from the endemic genus Aquilaria plants. Chem Biodivers. 9(2), 236–250. https://doi.org/10.1002/cbdv.201100077 (2012).

Jayachandran, K., Sekar, I., Parthiban, K., Amirtham, D. & Suresh, K. Analysis of different grades of agarwood (Aquilaria malaccensis Lamk.) oil through GC-MS. Indian J. Nat. Prod. Resour. 5(1), 44–47 (2014).

Wang, L. et al. Isolation and molecular identification of endophytic fungi from Aquilaria sinensis. J. Fungal Res. 1, 37–42. https://doi.org/10.13341/j.jfr.2009.01.007 (2009).

Xu, L. W. et al. Analysis and comparison of HPLC fingerprints of natural and artificial agarwood. Chin. Pharm. J. 54(23), 1980–1987. https://doi.org/10.11669/cpj.2019.23.013 (2019).

Acknowledgements

We owe our special thanks to Weiming Zhang of Guangdong Open Laboratory of Applied Microbiology for providing fungal strain A13, which were essential for this work.

Funding

This research was funded by Basic and Applied Basic Research of Guangdong Province, No. 2022A1515011268; Key Scientific Research Project of Education Department of Guangdong Province, No. 2020ZDZX1024; Guangzhou Municipal Education Bureau Higher Education Research Program, No. 202032873; Young Innovative Talents Program for General Colleges and Universities in Guangdong Province, No. 2020KQNCX201; National College Students Innovation and Entrepreneurship Training Program, No. 202310573015.

Author information

Authors and Affiliations

Contributions

Conceptualization, X.G., X.Z., W.Z. (Weiming Zhang) and X.C.; methodology, S.D., B.Q., M.L., X.Z., W.Z. (Weiping Zhou) and X.C.; formal analysis, S.D., Q.D., J.C. and Z.L.; resources, W.Z. (Weiming Zhang); writing—original draft preparation, S.D.; writing—review and editing, X.G. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ding, Q., Qin, B., Deng, S. et al. Optimization and induction effect evaluation of complex inducer of Aquilaria sinensis based on factorial design. Sci Rep 15, 19656 (2025). https://doi.org/10.1038/s41598-025-04230-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-04230-x