Abstract

This study proposes a multidimensional reinforcement framework integrating three mechanisms: nano-silica (SiO2) interfacial reconfiguration, fiber toughening, and dynamic response regulation. The effects of pre-soaking recycled aggregates in nano-SiO2 solutions at concentrations of 0%, 1.0%, and 2.0% and incorporating steel fibers (0%, 1.0%, 2.0%) or polyvinyl alcohol (PVA) fibers (0%, 0.1%, 0.2%) into recycled aggregate concrete (RAC). The impact resistance of treated specimens was evaluated under different strain rates using the split Hopkinson pressure bar (SHPB) method. Fracture patterns were analyzed, and dynamic stress-strain relationships were examined to assess the evolution of dynamic compressive strength and dynamic growth factor. Results indicated that higher impact velocities led to greater specimen damage, while increased nano-SiO2 concentrations and fiber reinforcement enhanced structural integrity. Pre-treatment with nano-SiO2 accelerated the peak stress occurrence in the dynamic stress-strain response, whereas fiber incorporation substantially increased peak stress. Both dynamic compressive strength and dynamic growth factor exhibited a linear relationship with strain rate, suggesting that nano-SiO2 and steel fibers collectively enhanced impact resistance.The application of RAC in protective engineering relies on nanoscale pretreatment and fiber reinforcement technologies to enhance the recycling of construction and demolition waste (CDW), enabling its conversion into high-value applications.

Similar content being viewed by others

Introduction

The volume of construction and demolition waste (CDW) in China has risen steadily in recent years, with projections estimating 3 billion metric tons by 2023. CDW constitutes over 40% of China’s municipal waste, yet its resource utilization rate remains below 10%. Globally, the United States generates over 530 million metric tons of CDW annually, while the European Union produces approximately 850 million metric tons, constituting 35% of the EU’s total waste1. By 2050, global construction and demolition waste is projected to reach 27 billion metric tons annually2, highlighting the urgency of effective waste management strategies. Recycled aggregate concrete (RAC), manufactured by replacing natural aggregates (NA) with recycled aggregates (RA) in concrete mixtures, offers a viable solution to mitigate CDW accumulation and reduce natural resource consumption3. This approach aligns with global sustainability objectives and carbon reduction strategies4.

Compared to normal aggregate concrete (NA), recycled aggregate concrete (RAC) exhibits more porous and inhomogeneous characteristics, resulting in relatively lower mechanical properties. To enhance the mechanical properties of RAC, researchers have investigated the addition of various fibers, including steel5, basalt6, and polymer fibers7. Studies indicate that the “bridging effect” of these fibers significantly inhibits stress propagation and crack initiation in RAC, thereby improving its flexural and tensile strengths8,9. However, the traditional approach of incorporating single-type fibers has limitations in enhancing the mechanical properties of RAC. Consequently, some researchers have explored the use of a combination of steel and polyvinyl alcohol (PVA) fibers in RAC, leveraging the high strength of steel fibers alongside the excellent toughness of PVA fibers10,11,12.

An effective approach to improving the properties of RAC involves incorporating nanomaterials and mineral additives during production, such as nano-CaCO313, silica fume14, nano-silica (SiO2)15, and fly ash16. Nano-SiO2, in particular, exhibits high pozzolanic reactivity and a large specific surface area, which accelerates cement hydration and enhances its efficiency17. Additionally, it synergizes with other materials to amplify their performance. For instance, nano-SiO2 reacts with calcium hydroxide (CH) crystals to form high-strength gels that fill mortar pores, thereby increasing concrete densification. However, excessive nano-SiO2 may cause particle agglomeration, reducing surface area and dispersion efficacy, which compromises concrete strength and compatibility18. To address this, researchers have optimized the pre-treatment of RA by soaking them in nano-SiO2 solutions. A 2% nano-SiO2 solution reduced the RA crushing index by 28% compared to untreated RA, and concrete incorporating these treated aggregates demonstrated a 20% increase in compressive strength19. Similarly, Rezaei et al.20 investigated the effect of nano-SiO2 content (1.5–6%) on RAC mechanical properties. After 28 days, samples with 4.5% nano-SiO2 exhibited 21%, 29%, and 17% improvements in compressive strength, splitting tensile strength, and elastic modulus.

Moreover, diverse impact forces can inflict significant damage on concrete structures. Consequently, an increasing number of researchers have been focusing on enhancing the impact resistance of concrete by exploring appropriate materials. The combined utilization of nano-SiO2 and fibers synergistically improves their properties, resulting in RAC that is more suitable for practical applications. Wang et al.15 and Li et al.21 have discovered that adding nano-SiO2 to RAC boosts its impact strength and diminishes its strain rate sensitivity. The influence of strain rates and the existence of nano-SiO2 on RAC varies according to peak strain and energy dissipation values. Additionally, the incorporation of steel fibers increases the impact energy of concrete at the failure point by a factor of 5–622. Likewise, the application of PVA fibers improves the dynamic peak strain of RAC, thus facilitating material deformation23. The inclusion of a ternary blend of nano-SiO2, soft and hard fibers leads to an overall improvement in the static and dynamic mechanical properties of concrete.

Recent studies have increasingly focused on the role of nano-SiO2 in enhancing the mechanical properties and durability of RAC. Concurrently, researchers have explored the influence of blended fiber systems on improving crack resistance and long-term performance. However, a critical gap remains in understanding the synergistic effects of combining nano-SiO2 pretreatment and multi-fiber reinforcement on the systematic impact resistance of RAC. In this study, RA were pretreated with nano-SiO2 and then combined with hybrid fibers, including steel and PVA fibers. Impact resistance testing evaluated the effects of varying nano-SiO2 concentrations and fiber blend ratios on RAC performance. The research aims to investigate the multifunctional mechanisms of nano-SiO2, including interfacial reconfiguration, fiber toughening, and dynamic response regulation, and to establish a theoretical foundation for optimizing its application in protective engineering and high-stress environments.

Materials and methods

Raw materials

The study utilized P·O 42.5 ordinary portland cement (properties detailed in Table 1). Natural river sand (0–5 mm particle size, fineness modulus 2.9) classified as Zone II medium sand served as the fine aggregate. Natural coarse aggregate consisted of locally sourced Jiaozuo limestone (5–10 mm particle size, apparent density 2796 kg/m2, water absorption 1.05%). Recycled coarse aggregate (5–10 mm particle size, bulk density 2657 kg/m2, water absorption 4.81%) was derived from crushed waste concrete pavement and subbase materials. Steel fibers (end-hooked type: density 7.8 g/cm2, diameter 0.25 mm, length 16 mm, tensile strength 2,800 MPa) and PVA fibers (density 1.3 g/cm2, diameter 15 μm, length 18 mm, tensile strength 1830 MPa) were used (Fig. 1). Nano-SiO2 colloids diluted to 1 wt% and 2 wt% concentrations (Table 2) were applied as surface treatments. A polycarboxylate-based high-performance water reducer ensured workability, and municipal tap water served as mixing water.

Mix proportions

RA were pre-treated with nano-SiO2 solutions at concentrations of 0%, 1.0%, and 2.0%. Steel fiber content was varied at 0%, 1.0%, and 2.0%, while PVA fiber content was tested at 0%, 0.1%, and 0.2%, with all mixes incorporating 100% recycled aggregate replacement. Table 3 outlines the experimental design matrix for RAC specimens. In the coding system, “RA” denotes unmodified recycled aggregate, and “SRA” refers to silica-modified recycled aggregate. Specimen nomenclature follows a standardized format: identifiers combine material codes with numerical values representing dosage percentages. For example, “N2R100S2P0.2” corresponds to a mix containing 2.0% nano-SiO2 solution, 100% RA replacement, 2.0% steel fiber, and 0.2% PVA fiber.

Specimen preparation and curing

The preparation process is divided into several stages. Initially, the coarse aggregate and sieved natural river sand are carefully weighed and added to the mixer, followed by the incorporation of cement. The mixer is activated to perform a dry mix for 1 min to achieve a dry mixture. Thereafter, steel fiber and PVA fiber are uniformly sprinkled into the mixer to prevent adhesion and aggregation during mixing. Following an additional 1-minute mixing period, the appropriate quantity of mixing water and polycarboxylic acid water-reducing agent are thoroughly diluted and slowly added to the mixer. The mixture is then stirred for 2 min. Subsequently, the mixture is poured into molds that have been treated with a release agent. After vibration, the molds are wrapped with cling film and stored in a cool, well-ventilated area for 1 day to allow for initial curing before demolding. The demolded specimens are then transferred to a standard humidity and temperature incubator set at 20 ± 2 ℃ and a relative humidity of 90 ± 5% for 28 days to ensure proper curing of the RAC specimens.

Quasi-static compressive strength test

Mechanical property tests were carried out according to the Chinese National Standard GB/T50081-2019. The quasi-static tests were conducted at strain rates ranging from 10− 5 to 10− 2 s− 1. Under micro-strain control, the specimens maintained equilibrium throughout failure. The quasi-static strength serves as a reference for calculating the dynamic growth factor, a ratio commonly used to quantify the strain rate effect on concrete material performance. Testing employed a 600 kN rigid servo-hydraulic testing machine, with the loading strain rate maintained at 10− 2 s− 1. A cylindrical sample with a diameter of 50 mm (matched with the impact sample ) was made, with a length-diameter ratio of 2, and 3 samples were made for each mix ratio.

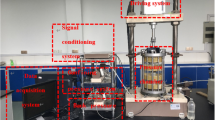

Impact resistance test

The impact resistance test was carried out in accordance with the Chinese National Standard CECS 13-2009. The experiment was conducted in the vibration laboratory of Henan Polytechnic University utilizing a Φ50 mm split Hopkinson pressure bar (SHPB) apparatus with a separable variable cross-section. This apparatus comprises a pressure device, a pressure rod system, and a data acquisition and processing system. Figure 2 illustrates the overall structure of the experimental apparatus. The pressure rod system includes an incident rod, a transmission rod, and a buffer rod, each with a tapered end of Φ37 mm in diameter and a specimen contact end of Φ50 mm in diameter. All rods are constructed from high-strength alloy steel, possessing a density of 7,800 kg/m³ and an elastic modulus of 210 × 102 MPa. Notably, the buffer rod is fabricated from aluminum alloy and integrated with a damper to constitute the final energy absorption and dissipation mechanism. Compressed nitrogen served as the pressurized power source, with two sets of control air pressures employed: 0.2 MPa, 0.3 MPa, and 0.4 MPa for lower strain rates, and 0.6 MPa, 0.9 MPa, and 1.2 MPa for higher strain rates. The initial impact velocity of the incident rod was measured using a parallel-source laser velocimeter, resulting in impact velocities ranging from 4.34 to 12.64 m/s.

The striker rod impacts the pre-accelerated incident rod, generating a stress pulse. The specimen is positioned at the interface between the incident and transmission rods. At the rod-specimen interface, impedance mismatch induces partial reflection of the pulse signal, producing a tensile pulse. The remaining compressive wave propagates through the specimen before being transmitted to the transmission rod. Strain gauges were mounted on the incident rod to record the reflected signals, while those on the transmission rod captured the transmitted wave. A wave propagation velocity of 5.19 km/s was recorded in the rods. Both sets of strain gauges were positioned symmetrically at one-third of the specimen’s length. To minimize friction, petroleum jelly was evenly applied to the contact surfaces between the specimen and rods. Additionally, a 2 cm2 brass sheet, coated with petroleum jelly, was attached to the tapered end of the incident rod to shape the incident pulse and reduce waveform oscillations, thereby stabilizing the strain rate during testing.

In a standard split Hopkinson pressure bar (SHPB) test, strain gauges on the incident bar record the incident wave εi(t) and reflected wave εr(t), while the transmission bar strain gauge captures the transmitted wave εt(t). Upon transferring kinetic energy from the impact bar to the incident bar, Contact Surface I (between the incident bar and specimen) generates force FΙ(t) and particle velocity VΙ(t). Simultaneously, Contact Surface II (between the specimen and transmission bar) produces force FII(t) and particle velocity VII(t). Based on one-dimensional elastic wave theory, the specimen’s internal average stress σs(t), average strain εs(t), and average strain rate εs(t) are calculated as follows:

In the above formula:

Here, A0 and AS denote the cross-sectional areas of the compression bar and specimen, respectively; C0 and Ls represent the elastic wave velocity in the compression bar and the specimen length, respectively; and E0 is the elastic modulus of the compression bar. Substituting FΙ(t), VΙ(t), FII(t), and VII(t) into Eqs. (1), (2), and (3), the stress wave formulation based on the three-wave method is derived as follows:

The calculation of the three-wave method formula is complicated, but the calculation results have high accuracy and effectiveness. The data processing of this test is carried out by the three-wave method formula.The dynamic balance test of the wave signal based on the typical waveform curves in the actual test is shown in Fig. 3.

The prismatic concrete specimens, measuring 100 mm × 100 mm × 300 mm, were cast and cured for 28 days to ensure uniformity, and 3 samples were made for each mix ratio. Subsequently, the specimens underwent processing utilizing a coring machine and ball mill, following which impact specimens were prepared, featuring dimensions of Φ50 mm × 25 mm and a L/D of 1/2. Post-grinding, the surface flatness of the specimens was maintained at ± 0.02 mm. Figure 4 illustrates the specimens for each group.

Experimental results and discussion

Slump

The specimens were divided into two groups: a nano-SiO2 control group and a composite fiber control group. The slump values for each group are summarized in Fig. 5. In the nano-SiO2 group, the R100-W sample (recycled concrete without a water-reducing agent) exhibited a slump of 120 mm. The grey bar chart represents the slump of R100 and serves as a reference.

Figure 5a demonstrates that adding a 1.0% water-reducing agent significantly increased the slump of recycled concrete. However, incorporating nano-SiO2 improved plasticity while reducing slump values. This reduction is attributed to the high specific surface area of nano-SiO2 particles, which adsorb interlayer and gel-pore water, increasing viscosity and lowering slump. Figure 5b reveals that the slump of specimens with 2.0% steel fiber was lower than those with 0.2% PVA fiber. Additionally, hybrid fiber mixtures (steel and PVA) consistently produced lower slump values than single-fiber specimens. The lowest slump occurred in the 2.0% steel fiber + 0.2% PVA fiber combination. Notably, increasing the concentration of hybrid fibers enhanced concrete plasticity.

Impact failure pattern

Figure 6 illustrates the failure modes of specimens subjected to low strain rates, with corresponding impact air pressures of 0.2 MPa, 0.3 MPa, and 0.4 MPa for impact velocities of 4.34 m/s, 6.08 m/s, and 7.36 m/s, respectively. The strain rates were confined within the range of 20–50 s− 1. Notably, at a constant impact velocity of 4.34 m/s, all specimen groups exhibited a uniform pattern of complete failure, accompanied by minimal edge penetration cracks. Conversely, at an impact velocity of 6.08 m/s, a significant change in failure mode was observed; only the specimens reinforced with PVA fibers maintained their integrity upon failure. As the impact velocity increased to 7.36 m/s, the failure mode intensified, resulting in the specimens fragmenting into smaller particles. Furthermore, the strength of the specimens progressively increased with higher concentrations of nano-SiO2 solution at constant impact velocities. The incorporation of PVA fibers acted as a bridging mechanism at the crack interface, mitigating further damage to the specimens. This bridging action led to the dispersion of crack propagation in multiple directions, enabling the specimens to retain a certain level of strength despite higher impact velocities24.

Figure 7 illustrates the failure patterns observed in specimens subjected to high strain rates. The corresponding impact air pressures, at velocities of 8.06 m/s, 10.44 m/s, and 12.64 m/s, were measured as 0.6 MPa, 0.9 MPa, and 1.2 MPa, respectively, with strain rates confined to the range of 70 s− 1 to 110 s− 1. At an impact velocity of 10.44 m/s, specimens exhibited edge shedding with considerable damage occurring at a steel fiber volume fraction of 0.1%. As the impact velocity was elevated to 12.64 m/s, a more pronounced failure pattern became apparent, featuring increased damage and enhanced stripping of aggregates, especially in the transition zone of the interface. Notably, specimens fortified with a 2% admixture of steel fibers demonstrated higher integrity at the same impact velocity. In contrast, specimens that incorporated a blend of 1% steel fiber and 0.2% PVA fiber exhibited more significant damage. This suggests that the strategic use of steel fiber admixtures can effectively mitigate penetration cracks and improve the buffering capacity of the specimens against high-impact forces.

Dynamic stress–strain curve

Table 4; Fig. 8 display the impact test results and dynamic stress-strain curves of various specimens.

The incorporation of nano-SiO2 into RAC significantly enhances its impact strength at low strain rates, as evidenced by the study. Specifically, within the 20 s− 1 strain rate group, the impact strength increased by 9.6% and 48.3% with increasing nano-SiO2 concentrations, as depicted in Fig. 6. This enhancement is corroborated by a discernible increase in strength, as observed in the failure patterns. Furthermore, the impact strength exhibited an ascending trend with increasing strain rate, accompanied by greater curve similarity, indicating significant strain rate sensitivity25,26. Notably, the effects of nano-SiO2 concentration and fiber addition on the impact properties of RAC samples were relatively consistent, with strain rate emerging as the pivotal regulatory factor. At high strain rates, the steep rise in the slope of the ascending section of the dynamic stress-strain curve and the substantial increase in peak stress are attributed to the synergistic effects of viscosity, crack propagation, and inertia27. Of particular note is the enhanced strain resistance demonstrated by specimens containing 2% steel fibers and 0.2% PVA fibers, suggesting that increasing fiber reinforcement can substantially improve the specimens’ deformation resistance.

Under high strain rate loading, nano-SiO2 enhances the ITZ through pore-filling and pozzolanic reactions, forming calcium silicate hydrate (C-S-H) gel. This structural optimization reduces the crushing index, suppresses microcrack initiation, and improves interfacial bonding strength, establishing a uniform stress transfer pathway for fiber reinforcement28,29. Steel fibers absorb kinetic energy via macroscopic crack bridging, while their high elastic modulus imparts inertial resistance under dynamic loading, extending the stress plateau phase (Fig. 8)30. PVA fibers mitigate brittle matrix failure through hydrogen bond formation31, synergizing with steel fibers to create a multiscale “macro-micro” energy dissipation network. Furthermore, nanoparticles strengthen the fiber-matrix interface and mitigate agglomeration risks, collectively forming a composite system characterized by a dense matrix, toughened interface, and hierarchically structured fibers32.

Dynamic impact strength

Figure 9 illustrates the variations in dynamic compressive strength of RAC specimens under different strain rates. As shown in Table 4; Fig. 9a, RAC specimens exhibit increased dynamic compressive strength with higher nano-SiO2 concentrations at low strain rates (20–50 s− 1). The most significant enhancement occurs at 20 s− 1, with strength improvements of 9.56% (1.0% nano-SiO2) and 48.28% (2.0% nano-SiO2) compared to the control group (0% nano-SiO2). Conversely, the beneficial effect of nano-SiO2 diminishes at elevated strain rates. At 40 s− 1, strength increments reduced to 21.13% (1.0%) and 24.06% (2.0%), and further declined to 5.43% (1.0%) and 8.39% (2.0%) at 50 s− 1. These findings align with Li et al.21, who observed that increased strain rates induce greater crushing of recycled aggregates, beyond which aggregate strength becomes independent of nano-SiO2 concentration. Consequently, the efficacy of nano-SiO2 in enhancing dynamic compressive strength diminishes at higher strain rates.

Fig. 9b exhibits a broader distribution of dynamic compressive strength values in the high strain rate group for the specimens. Notably, specimens reinforced with 1% steel fibers and 0.2% PVA fibers exhibited higher dynamic compressive strengths, contrasted with those containing 2% steel fibers and 0.1% PVA fibers, which displayed lower strengths. The ideal blend of steel and PVA fibers has been identified as a significant factor in enhancing the dynamic compressive strength of RAC. This improvement arises from the complementary mechanical roles of the two fiber types: steel fibers provide high tensile strength and crack-bridging capabilities, while PVA fibers enhance energy absorption and microcrack resistance through their flexibility and bond strength with the cement matrix. Steel fibers with high modulus and tensile strength bridge macro-cracks, delaying crack propagation through mechanical interlocking and inertial resistance at high strain rates. PVA fibers’ flexibility and strong interfacial bonding via hydrogen bonds suppress micro-crack initiation and disperse stress concentrations, enhancing ductility. Together, these fibers create a synergistic reinforcement mechanism, forming a multilayered composite structure that redistributes stress and delays fracture propagation under dynamic loading conditions33.

Dynamic increase factor

The dynamic increase factor (DIF) is the ratio of dynamic compressive strength to quasi-static compressive strength of a specimen, as defined in the CEB specification34. It quantitatively reflects the effect of strain rate on concrete material properties and is calculated using the formula:

where ,\(\:{F}_{ds}\) and \(\:{F}_{qs}\) represent the dynamic compressive strength and quasi-static compressive strength of the specimen, respectively.

The DIF values, calculated using dynamic and quasi-static compressive strengths in Eq. (11), are summarized in Table 4; Fig. 10. DIF values increase with strain rate across all groups. Figure 10a shows that incorporating 0.2% PVA fibers reduces DIF values within the 20–50 s− 1 strain rate range, indicating diminished strain rate sensitivity. The R100 specimens exhibit the highest DIF growth rate, aligning with findings by Wang et al.23, likely due to extensive damage localization in RAC under equivalent loading, where cracks predominantly form in the interfacial transition zone. Figure 10b highlights significant dispersion of DIF values (70–110 s− 1) in steel fiber-modified specimens. The lowest DIF occurs in the 2% steel fiber-only group, while hybrid fiber incorporation (e.g., N2R100S2P0.2) elevates DIF values, demonstrating synergistic reinforcement.

The relationship between the DIF value of the specimen and the strain rate is linear. The fitting equation for this relationship is provided below:

Where a, b, and c represent the fitting parameters, and \(\:\stackrel{-}{\epsilon\:}\) is the average strain rate of the specimen.

Figure 11 presents the fitted relationship between DIF values and strain rate for each group of specimens. The DIF values exhibit a significant index growth relationship with an increasing strain rate, with the DIF showing a more rapid rate of change. Moreover, Table 5 provides the parameters (a, b, and c) for each group of specimens, along with their corresponding correlation coefficient R2 derived from the fitted linear relationship. The index relationship between the DIF of each specimen and strain rate is clearly observed.

Conclusion

The study demonstrated that the incorporation of PVA fibers significantly enhanced the deformation capacity of the specimens. Concurrently, the addition of steel fibers resulted in an increase in impact strength. Furthermore, the utilization of nano-SiO2 solution-modified RA yielded a more substantial improvement in the mechanical properties of RAC. Based on these findings, the following conclusions were derived:

-

(1)

As strain rates increased from 20 s− 1 to 110 s− 1, untreated specimens degraded significantly, culminating in complete fragmentation at 110 s− 1. In contrast, specimens modified with 2% nano-SiO2 and hybrid fibers containing 2% steel and 0.2% PVA retained 80% structural integrity at 110 s− 1, reducing fragmentation by 60%. This marked improvement in failure modes underscores the synergistic role of nano-fiber systems in mitigating dynamic damage.

-

(2)

The stress and strain values of the specimens increased proportionally with the increasing strain rate, exhibiting a clear upward trend in peak stress. At a mean strain rate of 20 s− 1, increasing nano-SiO2 concentration from 0 to 2% elevated impact strength by 9.6% and 48.3%, reaching 44.7 MPa and 60.5 MPa, respectively. Under high strain rates of 70–110 s− 1, dynamic stress-strain curves for hybrid fiber-reinforced specimens exhibited steeper ascending slopes than controls, confirming enhanced deformation resistance via multi-scale crack bridging.

-

(3)

The dynamic compressive strength of the specimens increased with the strain rate. At high strain rates of 70–110 s− 1, the N2R100S1P0.2 group, which included 1% steel and 0.2% PVA fibers, reached a peak dynamic strength of 191.7 MPa, exceeding the control group by 111%. The attributed to the synergistic interplay of steel fibers in bridging macro-cracks and PVA fibers in suppressing micro-crack propagation through hydrogen bonding.

-

(4)

The DIF value exhibits an increase with increasing strain rates, as evidenced by the strong linear correlation demonstrated by the fitted curve. At low strain rates, specimens exhibit reduced variability and lower strain sensitivity; however, at high strain rates, there is a significant rise in DIF values with the incorporation of PVA fiber doping.

Data availability

All data generated or analysed during this study are included in this published article.

References

Sáez, P. V. & Osmani, M. A diagnosis of construction and demolition waste generation and recovery practice in the European union. J. Clean. Prod. 241, 118400 (2019).

Singh, N. & Singh, S. Carbonation resistance and microstructural analysis of low and high volume fly ash self compacting concrete containing recycled concrete aggregates. Constr. Build. Mater. 127, 828–842 (2016).

Kim, J. Influence of quality of recycled aggregates on the mechanical properties of recycled aggregate concretes: An overview. Constr. Build. Mater. 328, 127071 (2022).

Ding, T., Xiao, J. & Tam, V. A closed-loop life cycle assessment of recycled aggregate concrete utilization in China. Waste Manag. 56, 367–375 (2016).

Jin, L. et al. Meso-analysis method for the compressive strength of steel fiber-reinforced recycled aggregate concrete: A six-phase numerical model. Archives Civil Mech. Eng. 25, 152 (2025).

Yang, W. et al. A review of the mechanical properties and durability of basalt fiber recycled concrete. Constr. Build. Mater. 412, 134882 (2024).

Alharthai, M., Ali, T., Qureshi, M. Z. & Ahmed, H. The enhancement of engineering characteristics in recycled aggregates concrete combined effect of fly ash, silica fume and PP fiber. Alex. Eng. J. 95, 363–375 (2024).

Grzymski, F., Musiał, M. & Trapko, T. Mechanical properties of fibre reinforced concrete with recycled fibres. Constr. Build. Mater. 198, 323–331 (2019).

Nam, J. et al. Effectiveness of fiber reinforcement on the mechanical properties and shrinkage cracking of recycled fine aggregate concrete. Materials 9, 131 (2016).

Feng, J. et al. Uniaxial compressive behavior of hook-end steel and macro-polypropylene hybrid fibers reinforced recycled aggregate concrete. Constr. Build. Mater. 304, 124559 (2021).

Htet, P., Chen, W., Hao, H. & Shaikh, F. Influence of micro basalt and recycled macro polypropylene hybrid fibre on physical and mechanical properties of recycled aggregate concrete. J. Build. Eng. 76, 107083 (2023).

Tahmouresi, B., Koushkbaghi, M., Monazami, M., Abbasi, M. T. & Nemati, P. Experimental and statistical analysis of hybrid-fiber-reinforced recycled aggregate concrete. Comput. Concr. Int. J. 24, 193–206 (2019).

Li, W., Huang, Z., Cao, F., Sun, Z. & Shah, S. P. Effects of nano-silica and nano-limestone on flowability and mechanical properties of ultra-high-performance concrete matrix. Constr. Build. Mater. 95, 366–374 (2015).

Limbachiya, M., Meddah, M. S. & Ouchagour, Y. Performance of Portland/Silica fume cement concrete produced with recycled concrete aggregate. ACI Mater. J. 109 (2012).

Wang, X., Cheng, F., Wang, Y., Zhang, X. & Niu, H. Impact properties of recycled aggregate concrete with nanosilica modification. Adv. Civ. Eng. 2020, 8878368 (2020).

Tangchirapat, W., Buranasing, R. & Jaturapitakkul, C. Use of high fineness of fly ash to improve properties of recycled aggregate concrete. J. Mater. Civ. Eng. 22, 565–571 (2010).

Bai, S., Guan, X., Li, H. & Ou, J. Effect of the specific surface area of nano-silica particle on the properties of cement paste. Powder Technol. 392, 680–689 (2021).

Kumar, S., Ali, N., Begum, S. & Rahman, Z. Characterization, properties and microstructure studies of cement mortar incorporating nano-SiO2. Mater. Today: Proc. 37, 425–430 (2021).

Chen, X. F. & Jiao, C. J. Microstructure and physical properties of concrete containing recycled aggregates pre-treated by a nano-silica soaking method. J. Build. Eng. 51, 104363 (2022).

Rezaei, F., Memarzadeh, A., Davoodi, M. R., Dashab, M. A. & Nematzadeh, M. Mechanical features and durability of concrete incorporating recycled coarse aggregate and nano-silica: Experimental study, prediction, and optimization. J. Build. Eng. 73, 106715 (2023).

Li, W. et al. Effects of nanoparticle on the dynamic behaviors of recycled aggregate concrete under impact loading. Mater. Des. 112, 58–66 (2016).

Erdem, S., Dawson, A. R. & Thom, N. H. Microstructure-linked strength properties and impact response of conventional and recycled concrete reinforced with steel and synthetic macro fibres. Constr. Build. Mater. 25, 4025–4036 (2011).

Wang, X. et al. Effects of different strain rates on the impact properties of recycled aggregate concrete modified with nanosilica solution and polyvinyl alcohol fiber. Front. Mater. 8, 662374 (2021).

Hassan, M. & Wille, K. Comparative experimental investigations on the compressive impact behavior of fiber-reinforced ultra high-performance concretes using split Hopkinson pressure bar. Constr. Build. Mater. 191, 398–410 (2018).

Lu, Y., Chen, X., Teng, X. & Zhang, S. Dynamic compressive behavior of recycled aggregate concrete based on split Hopkinson pressure bar tests. Latin Am. J. Solids Struct. 11, 131–141 (2014).

Li, L., Xiao, J. & Poon, C. S. Dynamic compressive behavior of recycled aggregate concrete. Mater. Struct. 49, 4451–4462 (2016).

Xiao, J., Li, L., Shen, L. & Poon, C. S. Compressive behaviour of recycled aggregate concrete under impact loading. Cem. Concr. Res. 71, 46–55 (2015).

Mohana, R. & Bavithra, K. Influence of nano materials on the macro and micro structural behaviour of high performance concrete using interfacial transition zone approach. Constr. Build. Mater. 397, 132465 (2023).

Wang, Z., Bai, E., Xu, J., Du, Y. & Zhu, J. Effect of nano-SiO2 and nano-CaCO3 on the static and dynamic properties of concrete. Sci. Rep. 12, 907 (2022).

Soufeiani, L. et al. Influences of the volume fraction and shape of steel fibers on fiber-reinforced concrete subjected to dynamic loading—a review. Eng. Struct. 124, 405–417 (2016).

Liu, M. et al. Mechanism of interface performance enhancement of nano-SiO2 modified polyvinyl alcohol fiber reinforced geopolymer concrete: Experiments, microscopic characterization, and molecular simulation. J. Building Eng. 98, 111062 (2024).

Ashokan, A., Rajendran, S. & Dhairiyasamy, R. A comprehensive study on enhancing of the mechanical properties of steel fiber-reinforced concrete through nano-silica integration. Sci. Rep. 13, 20092 (2023).

Liu, F., Xu, K., Ding, W., Qiao, Y. & Wang, L. Microstructural characteristics and their impact on mechanical properties of steel-PVA fiber reinforced concrete. Cem. Concr. Compos. 123, 104196 (2021).

CEB. Concrete Structures Under Impact and Impulsive Loading: No. 187 (Lausanne, 1988).

Acknowledgements

The presented work was financially supported by the Fundamental Research Funds for the Universities of Henan Province (Grants No. NSFRF200328), the NSFC Henan Joint Funds (Grants No.U1904188) and the Double First-Class Disciplines to Create Funds (Grants No.AQ20240729).

Author information

Authors and Affiliations

Contributions

X.W.: Conceptualization, Methodology, Investigation, Writing-original draft, Validation, Funding acquisition. Z.L.: Conceptualization, Writing—review & editing, Formal analysis. Yonggui Wang: Investigation, Writing—review & editing, Supervision. X.Z.: Investigation, Writing—review & editing, Validation. M.J.: Conceptualization, Writing—review & editing, Data curation, Formal analysis. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, X., Liu, Z., Wang, Y. et al. Impact behavior of recycled aggregate concrete modified with nano-silica and fiber. Sci Rep 15, 19137 (2025). https://doi.org/10.1038/s41598-025-04264-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-04264-1

Keywords

This article is cited by

-

Sustainable Development and Response Surface Methodology-Based Optimization of Self-Compacting Concrete Incorporating Innovative Nano Concrete Aggregate and Silica Fume

Iranian Journal of Science and Technology, Transactions of Civil Engineering (2025)

-

Green self-compacting mortar with nano-silica and waste materials for concrete repair

Discover Concrete and Cement (2025)