Abstract

This study examines how rock properties affect the production of fines and chips during rock cutting, a crucial aspect of mechanized excavation science that dictates cutting efficiency and excavator performance. Small-scale linear cutting tests using a conical tool were conducted on thirteen rock specimens made up of sedimentary and metamorphic rocks. Unrelieved mode cutting depths ranged from 0.5 to 6 mm, with fines production quantified through sieve analysis. Mechanical properties, including uniaxial compressive strength (UCS), significantly affected fines: the greater the UCS, the lower the fines due to microcrack extension. At greater strengths and cutting depths, however, the force to break rock resistance enlarged the crushed zone, sometimes contributing to an enhancement in fines production. Also, among the physical properties of rocks, an increase in density and a decrease in porosity lead to a reduction in fine grains, greater rock compaction, and an increase in the amount of chips. Microscopic properties indicated texture coefficient to be the most influential factor, with greater texture coefficient making the rock stronger and favoring crack propagation to the free surface to minimize fines. Shape factor was the least contributing factor. The study shows how rock properties control cutting behavior, giving insight into the optimization of excavation performance through a better understanding of fines, chips, and crack growth mechanisms.

Similar content being viewed by others

Introduction

The efficiency of the rock cutting process plays a crucial role in shaping the economic aspects of mechanized excavation. The size distribution of the particles (fine material and chip) generated during excavation in competent rock formations exhibits a direct correlation with cutting efficiency. This distribution can also provide valuable insights into the excavation process and the mechanisms involved in rock breaking1. In the field of mechanized excavation research, numerous comprehensive studies have been undertaken to investigate the production of fine material (FM) and chip material (CH) resulting from rock cutting. These studies investigate the characteristics of FM and CH and analyze their influence on excavation performance1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24. Jeong and Jeon (2018) found that, in linear cutting tests of sandstone, the chip size distribution (analyzed using sieving and image processing) peaks at the optimal cut spacing and shows a strong correlation with cutter forces and specific energy19. Mohammadi et al. (2019) revealed that chip geometry, characterized by very platy and bladed shapes and an inverse exponential correlation between specific energy and particle size indicators (e.g., median size, coarseness index), significantly influences rock cutting efficiency2. Hou et al. (2021) demonstrated that mechanical specific energy in PDC bit rock cutting decreases exponentially with increased cuttings size, with the coarseness index significantly influenced by depth of cut and rake angle17. Bejari and Khademi Hamidi (2023) demonstrated that water saturation reduces chisel pick production capacity, decreases chip size, and increases fine material production in rock cutting, highlighting the need for further investigation into environmental effects on excavation performance in the present study13. Kadkhodaei et al. (2024) investigated the ductile-to-brittle transition in rock cutting using a conical tool on sedimentary and metamorphic rocks, demonstrating that cutting depths below the critical value produce high fines under ductile failure mode and developing a support vector machine model to accurately evaluate the fines-to-chip transition zone25. Kadkhodaei et al. (2024) found that uniaxial compressive strength, Schmidt rebound number, and density significantly influence total force and specific energy, while brittleness index primarily affects fine material production in rock cutting26.

These studies have provided valuable insights into how the composition and quantity of FM and CH generated during the cutting process can influence the overall efficiency of excavation operations. Calculating specific energy is a technique used to assess the efficiency of rock cutting in mechanical excavation operations. Based on the definition of specific energy (which refers to the energy or work needed to cut a unit volume of rock), the volume of fine materials and chips is one of the parameters that affect the efficiency of cutting operations27,28. Figure 1 shows the relationship between specific energy and the size of rock particles based on Bond’s, Kick’s, and Rittinger’s laws29. Based on this figure, an increase in the size of the particles results in a decrease in specific energy. In other words, the majority of the energy expended during rock cutting is dedicated to producing fine materials. The size distribution of particles from various laboratory rock cutting experiments conducted by Rad and Olson30 revealed that the quantity of fines and chips generated can serve as an indicator of cutting efficiency.

the relationship between specific energy and the size of rock particles based on Bond’s, Kick’s, and Rittinger’s laws29.

Conical picks are essential cutting tools, primarily utilized on roadheaders, shearers, and continuous miners. Their cutting performance directly influences excavation efficiency and cost. Evaluating fines production in this type of cutting tool is imperative due to its impact on production dust levels, ventilation costs, tool vibration, and energy consumption. This necessity arises because of the range of rock cutting conditions (from weak to medium strength and low brittleness) and the conical geometry of these tools, which sets them apart from disc cutting tools.

Research history shows that extensive studies have been conducted on the effect of CH production and the dimensions of the particles on the cutting performance. Among these studies, the effect of the comprehensive properties of the rock being cut on the amount of fines production has not been investigated. In this research, the effect of the physical, mechanical, and microscopic properties of the rocks on the fines produced and the cutting rate during rock cutting using a conical cutting tool has been discussed. For this purpose, cutting with a conical pick at various depths was performed on 13 laboratory-scale rock samples with weak to medium strength based on Bieniawski31 classification. After each cutting, the fines produced and the cutting rate of the samples were determined and their behavior compared to the properties of the rock samples was investigated.

Fine materials

Rock cutting is defined as the removal of a layer from the free surface of the rock using a tool that moves parallel to the free surface of the rock. A better understanding of the behavior of cutting operations and the examination of the fragments resulting from cutting are among the primary objectives of cutting research, and these aspects have been extensively investigated in both experimental and theoretical domains32. In the meantime, investigating the production behavior of fine-grained materials is more important due to its direct impact on the energy consumption of cutting. Fine materials are obtained during the cutting process under the following conditions32,33:

1) Depending on the conical cutting tool: During the contact of the conical pick with the rock, the rock in front of the tip of the tool is crushed due to the concentration of compressive stress and fine materials (rock powder) are created.

2) Depending on the depth of cut and the type of rock: Based on the depth of cut and the type of rock being cut, the cutting mode is divided into ductile and brittle. Ductile mode is often created in low cutting depths and the amount of fine materials is dominant (in front of the tip of the conical cutting tool and the scratch on the rock surface).

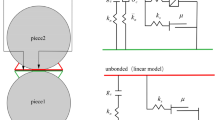

When the cutting tool impacts the rock, it results in an increase in the force applied to the tool. An increase in force results in pressure being applied to the rock in front of the cutting tool. This, in addition to creating a crushed zone, induces cracks in the rock. When the increase in force exceeds the strength of the rock, it yields rock fragments. At this point, a drop in cutting force is observed in the time-domain signal. This reduction in cutting force is directly proportional to the cutting time and provides information about the dimensions of the rock pieces34,35,36. Figure 2 shows an example illustrating changes in cutting force in the time domain at two cutting depths: 1 mm and 5 mm, for sample S4. According to this figure, an increase in cutting depth not only results in higher cutting forces but also yields larger rock pieces.

Laboratory testing

Rock properties tests

In this study, 13 types of rock samples that can be excavated with the conical pick (weak to medium strength) have been collected from different parts of Iran. Physico-mechanical properties of all rock samples have been determined from the laboratory tests according to the relevant standard37,38,39,40. These properties include uniaxial compressive strength (UCS), Brazilian tensile strength (BTS), density (D), porosity (P), and Schmidt rebound number (Sch). Each test was repeated five times per sample to ensure statistical reliability, and the mean values were reported. To minimize environmental effects, the samples were prepared under controlled conditions (temperature: 25 ± 2 °C; relative humidity: 20 ± 5%).

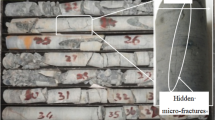

The textural properties of the rocks also play a crucial role in determining the cuttability of the rock. They affect the rock’s strength against crack development, thereby influencing its overall cuttability and structure of the fines and chips formation41. Microscopic properties, including texture coefficient (TC), interlocking index (g), shape factor (SF), and grain size homogeneity (t), were evaluated by analyzing thin sections under a polarized microscope equipped with image analysis software (Fig. 3)42. Table 1 presents the studied rock samples. Figure 4 shows the relationship between the physical, mechanical, and microscopic properties of the studied samples.

Fine material

In order to investigate the behavior of fines production in rock cutting with conical picks, the cutting operation was done using a small-scale linear cutting machine (LCM) at cutting depths of 0.5, 0.8, 1, 2, 3, 4, 5, and 6 mm under unrelieved cutting conditions. In rock cutting with conical picks, two primary cutting modes are distinguished: unrelieved and relieved cutting. Unrelieved cutting refers to the process in which a single conical pick penetrates the rock without adjacent grooves or prior cuts, resulting in a fully confined rock mass around the pick. In contrast, relieved cutting occurs when the pick operates in the presence of pre-existing grooves or adjacent cuts, created through sequential or simultaneous pick interactions with controlled line spacing. These grooves provide free or semi-free surfaces, reducing the rock’s confinement and facilitating easier fracture propagation. As a result, relieved cutting is associated with lower cutting forces, reduced specific energy, and the production of larger rock chips, thereby enhancing overall cutting efficiency43. In this study, unrelieved cutting conditions were adopted to investigate the baseline behavior of fines production, while the influence of cutting depth was analyzed to assess its impact on cutting performance.

The LCM is equipped with a 95 mm-long conical pick (90 degrees tip angle), set at an attack angle of 50 degrees and a clearance angle of 5 degrees. The maximum cutting depth was limited to 6 mm to prevent contact between the pick body and the rock surface, ensuring that only the pick tip interacted with the rock. The cutting speed was maintained at 25 cm/s. Figure 5 shows the view of the linear rock cutting machine along with its components.

The rock samples (dimensions 30 × 35 × 30 cm) were securely seated in the clamp and held in place with hydraulic jacks to prevent movement during cutting. Each cutting pass was performed on a fresh rock surface to avoid cumulative damage effects. Before the cutting operation, the rock block is placed in a plastic container. After the cutting operation, all the resulting rock fragments (fines and chips) are collected and spread inside the container. More details about the testing process can be found in previous research25,26. After the cutting operation in each step, the rock fragments were collected and then segregated and classified in different dimensions using sieves based on the ASTM standard for a duration of 5 min (using 11 sets of sieves including 3/4'', 1/2'', 3/8'', and mesh sizes of 4, 10, 14, 20, 35, 50, 100, and 200)44. Finally, based on Wentworth45 classification, the sieved fragments were classified into three categories: fines, moderates, and chips according to Table 2. For example, for the Bookan travertine rock sample, a sedimentary rock (No. 9 in Table 1), at a cutting depth of 4 mm, the percentages of fine, moderate, and chip production are 32.20%, 20.79%, and 47.01%, respectively. Similarly, for the Marvdasht rock sample, a metamorphic rock (No. 13 in Table 1), at the same cutting depth, the percentages of fine, moderate, and chip production are 14.47%, 24.63%, and 60.90%, respectively.

Results and discussion

Mechanical properties

The relationship between the mechanical properties of the samples and the percentage of fines at each cutting depth is shown in Fig. 6. According to this figure, an increase in rock strength leads to a decrease in fines production compared to the excavated volume. Furthermore, as the cutting depth increases, the percentage of fines production decreases. The greater the rock’s strength, the higher its resistance to failure. When the conical pick impacts the rock, the force required to overcome the rock’s strength initiates crack expansion, resulting in a reduced propensity for failure compared to rocks with low strength. Therefore, the ratio of chips to fines increases. As evident from the figures, an increase in cutting depth leads to a departure from the linear trend in the reduction of fines production relative to rock strength. This deviation occurs because, with increasing cutting depth, the cutting behavior transitions from ductile to brittle. In this case, at a high cutting depth, with the increase of rock strength in a region, the decrease in the percentage of the fines takes on a constant behavior. If the ratio of cutting depth to rock strength exceeds a specific threshold, the decreasing trend in fines can stop and even increase. When both cutting depth and rock strength are high, the tendency of the rock to failure significantly diminishes. Consequently, with the increase of the force applied to the rock in front of the conical pick, the crushed zone increases compared to before and leads to an increase in the amount of fines in the rock. Figure 7 shows the fines sensitivity to the mechanical properties of the rock. To determine the sensitivity and relative impact of these properties on the amount of fines produced, the ratio of the correlation coefficients determined at each cutting depth (see Fig. 6) was used. In this analysis, fines production was considered the dependent variable, and mechanical properties were treated as the independent variables. According to this figure, among the mechanical properties, the uniaxial compressive strength has the greatest effect on the production of fines.

Physical properties

The relationship between the physical properties of the samples and the percentage of fines at each cutting depth is shown in Fig. 8. The experimental results indicate a clear correlation between fines content and two key physical properties: porosity and density. Specifically, there is a direct relationship between fines content and porosity, and an inverse relationship between fines content and density.

Porosity significantly influences the mechanical behavior of rocks during cutting. As porosity increases, the rate of crack propagation decreases due to the presence of void spaces that dissipate the energy applied by the cutting tool. Figure 8a shows that samples with higher porosity (> 10%) produced up to 50% more fines compared to low-porosity samples (< 10%). In highly porous rocks, cracks tend to re-emerge as the cutting pick advances along the groove (at constant cutting depth), often before reaching the free surface or merging with side cracks formed between adjacent cutters. This behavior delays the formation of large chips and promotes the generation of fine particles. When these cracks eventually intersect or reach the free surface, the resulting fragments are predominantly fines, with particle sizes typically below 1.2 mm, as confirmed by sieve analysis.

In contrast, rock density exhibits an inverse relationship with fines production. Denser rocks, characterized by a more compact structure, facilitate faster crack propagation when subjected to cutting forces. Figure 8b shows that samples with density values above 2.25 g/cm3 produced significantly fewer fines compared to less dense samples (density < 2.25 g/cm3), which yielded up to 35% fines. In denser rocks, the cutting tool induces rapid crack growth, allowing cracks to coalesce and reach the free surface more efficiently. The increased compactness of denser rocks reduces energy dissipation within the rock matrix, thereby enhancing the efficiency of chip formation. The results of this section are consistent with the findings of other researchers13.

Microscopic properties

The phrase “rock texture” refers to the arrangement, size, and composition of mineral grains and the matrix within rocks. When assessing the textural characteristics of rocks, it is important to thoroughly investigate the geometric aspects of the mineral grains and their interaction with the matrix46. The relationship between the textural properties of rocks and the fines produced during rock cutting is shown in Fig. 9. According to this figure, as TC, g, and t increase and SF decrease, the amount of fines decreases. As mentioned, the principle of creating fines and chips, as well as their dimensions, depends on the expansion of microcracks in the rock during the cutting operation. According to Fig. 9c, with the increase in SF, the amount of fines increases. SF represents the circularity of the grains (the degree of deviation of the grains from being circular)47, and with the increase of this deviation (which may be due to the increase in the peripheral roughness of the grains or the elongation of their shape), the amount of SF decreases, ultimately leading to an increase in the compactness of the grains. This result can also be analyzed from a mechanical perspective. Samples with complex shapes (low SF) exhibit higher strength due to an increase in the internal friction angle48. Consequently, as discussed in section "Mechanical properties", there is a relationship between crack growth during the cutting operation and a decrease in the amount of fines. This finding is consistent with studies conducted in this field49,50. According to the mentioned contents and the relationship between SF and g, it is evident that as g increases, the amount of fines decreases (Fig. 9b). This observation justifies the linear relationship between these two parameters and fines. According to Fig. 9d, as the grain size homogeneity increases, the amount of fines produced decreases. An increase in "t" leads to an increase in the homogeneity of the entire rock mass structure51, which in turn increases its resistance to penetration. Consequently, as "t" increases, the rock structure becomes denser and less porosity. This results in higher rock strength and a decrease in the production of fines. According to Fig. 9a, as the texture coefficient increases, the amount of fines decreases. The TC index is the most exhaustive and dependable measure for quantifying the texture of a rock. TC was developed by Howarth and Rowlands52 to quantify rock texture and predict the strength properties of rocks. As TC increases, rock strength also increases. When pressure is applied to the rock, a high-stress area is created. When the stress exceeds the material’s strength, cracks begin to form and spread to the free surface. Once the cracks reach the free surface of the rock, macroscopic failure occurs, and a chip is formed. Consequently, as the TC value increases, the amount of fines decreases. Figure 10 shows the fines sensitivity to the microscopic properties of the rock. According to this figure, among the microscopic properties, the texture coefficient has the greatest effect on the production of fines.

Summary and conclusions

This study investigated the effects of the physical, mechanical, and microscopic properties of rocks on the amount of fines produced during cutting with a conical tool. A total of thirteen rock samples, consisting of both metamorphic and sedimentary rocks, were prepared and then tested at various cutting depths ranging from 0.5 to 6 mm. The fragments are carefully collected at each cutting stage, and the amount of fines produced is measured using sieve analysis. Finally, according to the existing standards, the physical, mechanical, and microscopic properties of each sample were determined, and the production process of fines was analyzed based on these properties. The study’s findings can be summarized as follows:

-

The results of examining the mechanical properties on the amount of fines showed that uniaxial compressive strength has the greatest effect on fines production during cutting with a conical tool. As rock strength increases, resistance to failure also increases, which reduces the amount of fines compared to rocks with low strength (due to the expansion of microcracks). Additionally, as the cutting depth increases, the cutting behavior tends toward brittle failure. Therefore, at a high cutting depth, with an increase in rock strength in a specific region, the behavior becomes constant. If this strength surpasses a certain threshold, the additional force required to overcome resistance against failure leads to more crushing in front of the tool’s tip. This can halt the downward trend of fines production and instead cause an increase.

-

The investigation into physical properties revealed that porosity and density significantly affect fines and chip formation during rock cutting. Higher porosity promotes the production of fines by providing micro-pores that disrupt crack growth, leading to localized failure. In contrast, higher density increases rock compactness, facilitating crack coalescence and chip formation, thereby reducing fines. Overall, porosity exerts a stronger influence on fines production due to its role in interrupting crack paths.

-

The investigation into the microscopic properties affecting the amount of fines showed that the texture coefficient has the greatest impact on fines production during cutting with a conical tool. The results showed that as the texture coefficient increased, the rock strength also increased. When pressure is applied to the rock, if the texture coefficient is high, a pressure zone is created in front of the tool, causing cracks to develop and spread towards the free surface, and consequently, the ratio of fines production decreases.

Despite these findings, certain limitations of the study must be acknowledged to properly contextualize the results. The rock cutting tests were conducted under controlled laboratory conditions, which may not fully replicate the complexities of excavation work in the field. Factors such as rock mass properties (e.g., jointing, fracturing, and heterogeneity) significantly influence cutting performance in real-world scenarios and were not considered in this study. These differences suggest that the results may vary when applied to field excavation, highlighting the need for further research to bridge the gap between laboratory and field outcomes.

The mechanism of fines and chips production during cutting, as well as the production process based on rock properties, is a fundamental topic in the science of mechanized excavation. A detailed investigation on a microscale, focusing on the recognition and examination of the crack initiation and propagation process, can provide vital insights for performance evaluation.

References

Tuncdemir, H., Bilgin, N., Copur, H. & Balci, C. Control of rock cutting efficiency by muck size. Int. J. Rock Mech. Min. Sci. 1997(45), 278–288 (2008).

Mohammadi, M., Khademi Hamidi, J., Rostami, J. & Goshtasbi, K. A closer look into chip shape/size and efficiency of rock cutting with a simple chisel pick: A laboratory scale investigation. Rock Mech. Rock Eng. 53, 1375–1392 (2020).

Altindag, R. Evaluation of drill cuttings in prediction of penetration rate by using coarseness index and mean particle size in percussive drilling. Geotech. Geol. Eng. 22, 417–425 (2004).

Altındag, R. Estimation of penetration rate in percussive drilling by means of coarseness index and mean particle size. Rock Mech. Rock Eng. 36, 323–332 (2003).

Rispoli, A., Ferrero, A. M., Cardu, M. & Farinetti, A. Determining the particle size of debris from a tunnel boring machine through photographic analysis and comparison between excavation performance and rock mass properties. Rock Mech. Rock Eng. 50, 2805–2816 (2017).

Pan, Y., Liu, Q., Liu, J., Liu, Q. & Kong, X. Full-scale linear cutting tests in Chongqing Sandstone to study the influence of confining stress on rock cutting efficiency by TBM disc cutter. Tunn. Undergr. Space Technol. 80, 197–210 (2018).

Rostami, J., Gertsch, R. & Gertsch, L. Rock fragmentation by disc cutter: A critical review and an update. In Proceedings, North American Rock Mechanics Symposium (NARMS) (Tunneling Association of Canada (TAC) meeting, 2002).

Rostami, K., Hamidi, J. K. & Nejati, H. R. Use of rock microscale properties for introducing a cuttability index in rock cutting with a chisel pick. Arab. J. Geosci. 13, 1–12 (2020).

Roxborough, F. Cutting rocks with picks. Mining Eng. 445–455 (1973).

Bruland, A. Hard rock tunnel boring: vol. 1–10. (Norwegian University of Science and Technology (NTNU), Trondheim, Norway, 2000).

Gong, Q. M., Zhao, J. & Jiang, Y. S. In situ TBM penetration tests and rock mass boreability analysis in hard rock tunnels. Tunn. Undergr. Space Technol. 22, 303–316 (2007).

Balci, C. Correlation of rock cutting tests with field performance of a TBM in a highly fractured rock formation: A case study in Kozyatagi-Kadikoy metro tunnel, Turkey. Tunnel. Undergr. Space Technol. 24, 423–435 (2009).

Bejari, H. & Hamidi, J. K. An experimental study of water saturation effect on chipping efficiency of a chisel pick in cutting some low- and medium-strength rocks. Rock Mech. Rock Eng. 1–27 (2023) https://doi.org/10.1007/S00603-023-03267-6.

Abu Bakar, M. & Gertsch, L. Saturation efects on disc cutting of sandstone. In Proceedings of the 45th US Rock Mechanics/Geomechanics Symposium 1–9 (2011).

Abu Bakar, M. Z., Gertsch, L. S. & Rostami, J. Evaluation of fragments from disc cutting of dry and saturated sandstone. Rock Mech. Rock Eng. 47, 1891–1903 (2014).

Yin, L. J., Gong, Q. M. & Zhao, J. Study on rock mass boreability by TBM penetration test under different in situ stress conditions. Tunn. Undergr. Space Technol. 43, 413–425 (2014).

Hou, H., Liu, Z., Zhu, H., Wang, Z. & Yin, Z. An experimental study of the relationship between cutting efficiency and cuttings size in rock cutting using a PDC cutter. J. Braz. Soc. Mech. Sci. Eng. 43, 1–12 (2021).

Gertsch, L., Fjeld, A., Nilsen, B. & Gertsch, R. Use of TBM muck as construction material. Tunn. Undergr. Space Technol. 15, 379–402 (2000).

Jeong, H. & Jeon, S. Characteristic of size distribution of rock chip produced by rock cutting with a pick cutter. Geomech. Eng. 15, 811–822 (2018).

Barker, J. S. A laboratory investigation of rock cutting using large picks. Int. J. Rock Mech. Min. Sci. Geomech. Abstracts 1, 519–534 (1964).

Roxborough, F., King, P. & Pedroncelli, E. Tests on the cutting performance of a continuous miner. J. South Afr. Inst. Min. Metall. 81, 9–25 (1981).

Ip, C. Laboratory water jet assisted drag tool rock cutting studies at high traverse speeds (University of Newcastle upon Tyne, 1986).

Abu Bakar, M. Z. & Gertsch, L. S. Evaluation of saturation effects on drag pick cutting of a brittle sandstone from full scale linear cutting tests. Tunnel. Undergr. Space Technol. 34, 124–134 (2013).

Heydari, S., Khademi Hamidi, J., Monjezi, M. & Eftekhari, A. An investigation of the relationship between muck geometry, TBM performance, and operational parameters: A case study in Golab II water transfer tunnel. Tunnel. Undergr. Space Technol. 88, 73–86 (2019).

Kadkhodaei, M. H., Ghasemi, E., Hamidi, J. K. & Rostami, J. Evaluation of fine material and chip formation in rock cutting with a conical tool. Bull. Eng. Geol. Env. 83, 1–14 (2024).

Kadkhodaei, M. H., Ghasemi, E., Khademi Hamidi, J. & Rostami, J. Evaluation of rock cutting performance of conical cutting tool based on commonly measured rock properties. Transport. Geotech. 48, 101318 (2024).

Hughes, H. M. The relative cuttability of coal-measures stone. Min. Sci. Technol. 3, 95–109 (1986).

Hughes, H. M. Some aspects of rock machining. Int. J. Rock Mech. Min. Sci. Geomech. Abstracts 9, 205–211 (1972).

Hukki, R. Proposal for a solomonic settlement between the theories of von Rittinger, Kick and Bond. Trans AIME/SME 4, 403–438 (1961).

Rad, P. & Olson, R. Tunneling machine research: Size distribution of rock fragments produced by rolling disk cutters. US Department of the Interior, Bureau of Mines 7882, (1974).

Bieniawski, Z. Engineering rock mass classifications: A complete manual for engineers and geologists in mining, civil, and petroleum engineering. (John Wiley & Sons, 1989).

Rostamsowlat, I., Evans, B., Sarout, J., Rostami, J. & Kwon, H. J. Determination of internal friction angle of rocks using scratch test with a blunt PDC cutter. Rock Mech. Rock Eng. 55, 7859–7880 (2022).

Li, X., Wang, S., Ge, S., Malekian, R. & Li, Z. A theoretical model for estimating the peak cutting force of conical picks. Exp. Mech. 58, 709–720 (2018).

Dai, X., Huang, Z., Shi, H., Wu, X. & Xiong, C. Cutting force as an index to identify the ductile-brittle failure modes in rock cutting. Int. J. Rock Mech. Min. Sci. 146, 104834 (2021).

Zhou, Y. & Lin, J. S. On the critical failure mode transition depth for rock cutting. Int. J. Rock Mech. Min. Sci. 62, 131–137 (2013).

Jaime, M. C., Zhou, Y., Lin, J. S. & Gamwo, I. K. Finite element modeling of rock cutting and its fragmentation process. Int. J. Rock Mech. Min. Sci. 80, 137–146 (2015).

ASTM D2938-95. Standard test method for unconfned compressive strength of intact rock core specimens. (American Society for Testing and Materials, West Conshohocken, 1995).

ASTM D3967-95. Standard test method for splitting tensile strength of intact rock core specimens. (Annual Book of ASTM Standards, American Society for Testing and Materials, West Conshohocken, 1995).

ASTM D4543-08. Standard practices for preparing rock core as cylindrical test specimens and verifying conformance to dimensional and shape tolerances. (Annual Book of ASTM Standards, American Society for Testing and Materials, West Conshohocken, 2008).

Ulusay, R. & Hudson, J. The complete ISRM suggested methods for rock characterization, testing and monitoring: 1974–2006. in Commission on Testing Methods. International Society of Rock Mechanics, Compilation Arranged by the ISRM Turkish National Group 628 (2007).

Onodera, T. & Kumara, A. H. Relation between texture and mechanical properties of crystalline rocks. Bull. Int. Assoc. Eng. Geol. 22, 173–177 (1980).

Hemmati, A., Ghafoori, M., Moomivand, H. & Lashkaripour, G. R. The effect of mineralogy and textural characteristics on the strength of crystalline igneous rocks using image-based textural quantification. Eng. Geol. 266, 105467 (2020).

Bilgin, N. et al. Dominant rock properties affecting the performance of conical picks and the comparison of some experimental and theoretical results. Int. J. Rock Mech. Min. Sci. 43, 139–156 (2006).

ASTM C136/C136 M-14. Standard test method for sieve analysis of fne and coarse aggregates. American Society for Testing and Materials (2014). https://doi.org/10.1520/C0136_C0136M-14.

Wentworth, C. K. A scale of grade and class terms for clastic sediments. J. Geol. 30, 377–392 (1922).

Lamarche, J., Lavenu, A. P. C., Gauthier, B. D. M., Guglielmi, Y. & Jayet, O. Relationships between fracture patterns, geodynamics and mechanical stratigraphy in carbonates (South-East Basin, France). Tectonophysics 581, 231–245 (2012).

Přikryl, R. Assessment of rock geomechanical quality by quantitative rock fabric coefficients: Limitations and possible source of misinterpretations. Eng. Geol. 87, 149–162 (2006).

Hoek, E. Rock fracture under static stress conditions (1965).

Cho, G.-C., Dodds, J. & Santamarina, J. C. Particle shape effects on packing density, stiffness, and strength: Natural and crushed Sands. J. Geotech. Geoenviron. Eng. 132, 591–602 (2006).

Han, Z., Zhang, L. & Zhou, J. Numerical investigation of mineral grain shape effects on strength and fracture behaviors of rock material. Appl. Sci. 9, 2855 (2019).

Wang, Y. Numerical modelling of heterogeneous rock breakage behaviour based on texture images. Miner. Eng. 74, 130–141 (2015).

Howarth, D. F. & Rowlands, J. C. Quantitative assessment of rock texture and correlation with drillability and strength properties. Rock Mech. Rock Eng. 20, 57–85 (1987).

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

Mohammad Hossein Kadkhodaei: Material preparation, Data collection, methodology, software, visualization, writing-original draft. Ebrahim Ghasemi: Conceptualization, supervision, writing-review and editing, formal analysis. Jafar Khademi Hamidi: Conceptualization, material preparation, writing-review and editing, validation. Jamal Rostami: Discussion, formal analysis, writing-review and editing. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Kadkhodaei, M.H., Ghasemi, E., Khademi Hamidi, J. et al. An experimental study on the effect of rock properties on the production of fine materials by a conical pick. Sci Rep 15, 22803 (2025). https://doi.org/10.1038/s41598-025-05140-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-05140-8