Abstract

Rapid sand filtration is typically used at water treatment plants to remove the fine suspended solid particles from the raw water. Backwashing of exhausted filter beds inevitably generates large volume of filtration sludge in water treatment plants. In this study, filtration sludge is collected, dried and crushed to powder, then passed through 90 µm sieve to get powdered filtration sludge (PFS) which is then characterized and utilized without energy intensive process of calcination. The PFS is blended with cement up to 20% and investigated for various properties to assess the possibility of its utilization in construction industry. Ordinary Portland cement (OPC) mortar or control mortar when substituted with up to 15% PFS has compressive strength above 33 MPa at 28 days and above 41 MPa at 90 days and setting times within prescribed limits. OPC blended with PFS up to 15% conforms various specifications desired for use in different construction practices especially where early strength is not essential. Utilization of filtration sludge as partial cement replacement in mortar would provide a beneficial and sustainable disposal alternative. Simultaneously it will reduce the cement consumption depending on the extent of its utilization. Consequently, it would help in conserving the natural resources, reducing the carbon emission and its related impact on the environment.

Similar content being viewed by others

Introduction

Conventionally, all the water treatment plants (WTPs) include filtration in the treatment process to treat surface water for potable use. Surface water from lakes, rivers, reservoirs etc. carries contaminants such as clay, sand, silt, plant fibers, microorganisms, and pollutants from municipal and industrial discharge. The coagulation-flocculation, followed by sedimentation in a clarriflocculation tank, remove larger and colloidal impurities. Finer particles that escape the clarriflocculation tank are collected on the filter beds during filtration. Due to continuous deposition of fine particles, the filtration beds get exhausted and are cleaned through backwashing. The backwashing process generates residuals called as spent filter backwash water (SFBW) which contains finer solid particles. The total residuals generated from the backwashing of filter beds and in the coagulation-flocculation process are known as water treatment sludge (WTS). Typically, a water treatment plant (WTP) generates over 100 thousand tonnes of WTS in a year1. Zhao et al.2 reported that WTS typically accounts for about 1–3% of the total raw water treated at WTPs. Although, global data on WTS production is limited, China leads in total generation of WTS with approximately 2.3 million tonnes annually. On the other hand, Korea produces the highest WTS on per capita basis, whereas Denmark has the lowest overall as well as per capita production at around 10,000 tonnes per year. Krause and Bronstein3 estimated the sludge generation in United States WTPs and reported that 35–40 million metric tonne dry sludge/year was produced from 2000 to 2015, yielding to 150 kg dry sludge/person-year. In many countries WTS is discharged directly into nearby hydric bodies or disposed on open lands after dewatering. In UK and US, about 9% and 25% respectively of the total WTS is discharged into the sewers to be treated with sewage sludge4. It is however not a safe and sustainable disposal practice. Disposal of the voluminous sludge is difficult task under strict environmental legislations which are likely to be enforced in many countries soon.

Construction industry plays a crucial role in the infrastructure development and economic growth of a country. Moreover, construction industry revolves around the production of cement, as it is the main ingredient which is used as binder. But production of cement clinker has negative impact on the environment as it is causing the depletion of natural lime deposits and emitting huge CO2 into the atmosphere5 Due to growing environmental concern and resource depletion, reuse and recycling of several industrial waste in construction have been investigated6,7. It may reduce the reliance on natural materials, valorize the waste materials under circular economy and lower the carbon footprint of the construction projects. Similarly, to valorize the WTS and dispose it sustainably, several reuse and recycling options have been identified globally1. Yen et al.8 utilized WTS, marble slurry and basic oxygen furnace slag as raw material in cement production and reported better compressive strength at 28 days when compared with control paste produced from conventional raw material. Properties similar to ordinary Portland cement (OPC) were observed in the eco cement. Chen et al.9 partially substituted shale with WTS as raw material in manufacturing cement and found that 3, 7 and 28-days strength are higher than the control specimen, when WTS up to 5% was used as raw material. Gomes et al.10 replaced cement with WTS and investigated the heat evaluation and compressive strength of the mix. Results were close to reference specimen for the cement mixed with WTS up to 2%. Rodríguez et al.11 used WTS to replace 10–30% cement to prepare mortar and reported that the replacement has decreased the mechanical strength, reduced the rate of hydration, and altered the setting time of mortar. Sales and De Souza12 prepared the concrete and mortar with joint addition of WTS and construction and demolition waste. They found that partial replacement of fine aggregate with WTS is feasible in different construction activity. Pham et al.13 replaced sand with non-calcined and calcined WTS to prepare mortar and found that bond strength of mortar and bricks increased significantly with 10% calcined WTS. Huang et al.14 mixed 15–30% WTS with waste excavation soil for producing bricks and reported that up to 15% WTS can be incorporated in the production of first-class construction bricks at the temperature commonly attained in brick kiln. Yang et al.15 heated WTS at optimum temperature of 800 °C and incorporated 30% WTS in the mortar samples and compared with the standard mortar samples. Heating of WTS at 800 °C, led to the formation of highly active γ-Al2O3 and active SiO2. The addition of WTS significantly promoted the formation of ettringite and C–(A)–S–H gel, which contributed to improved compressive strength of 44.86 MPa at 90 days, demonstrating its effectiveness as a cementitious material. Nontananandh et al.16 investigated the sustainable use of WTS and seabed dredged sediments as construction material by combined dewatering and cement stabilization method. Results demonstrated a clear relationship between lower w/c ratios and higher unconfined compressive strength, supporting the utilization of treated sludge as landfill liners and a subbase layer for roads. Kina17 investigated the possibility of utilizing WTS with fly ash and ground-granulated blast furnace slag as ternary binders. Mortars were produced with WTS substituted for 0–30% of the cement as binary blends and also mixed with fly ash/blast furnace slag as ternary blends. Mortars with 10% WTS as binary blend have higher strengths with lower porosity and denser microstructures. Moreover, by adding fly ash/blast furnace slag with similar strength values, the drawbacks of substituting cement with WTS on the rheological characteristics and environmental-economical issues were also mitigated. Consequently, developing more economical and environmentally friendly cement-based products from WTS recycling. Xia et al.18 critically reviewed the status of recycling sludge and sludge ash into low-carbon construction materials. To address the global issue of sludge production and the associated challenges of safely and economically treating this waste, authors emphasized the potential of utilization of sludge in the construction industry due to its chemical composition, which is similar to that of cementitious materials. Additionally, heavy metals present in WTS can get immobilized, ensuring that their use in construction does not pose risks to human health or the environment.

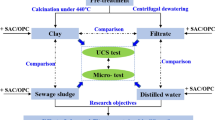

As an identified gap, most of the earlier studies have investigated the characteristics of WTS as a whole and its utilization for safe disposal. However, WTS includes waste generated from clarriflocculation tank as well as filtration units and physicochemical properties of the two waste varies. The physicochemical properties govern the selection of reuse options. Therefore, separate characterization of the two waste and investigation for their sustainable disposal may emanate new idea of innovative research and better reuse options. Present study deals with the characterization of filtration sludge (FS) and its utilization in construction industry without energy intensive calcination process. Ordinary Portland cement (OPC) 43 grade is partially substituted with varying percentage of powdered filtration sludge (PFS) to prepare mortar and mechanical as well as physicochemical properties of the prepared mortar have been assessed. This study is a novel effort to promote sustainable disposal of FS and reducing the adverse environmental impact caused due to huge production and consumption of cement worldwide.

Methodology

Collection of filtration sludge

Filtration sludge (FS) is collected from a WTP where rapid sand filtration is used to remove the finer solid particles escaping from the clariflocculation tank. The WTP was using PACl (Polyaluminium Chloride) as coagulant to agglomerate the colloidal impurities causing turbidity in the raw water. The agglomerated colloidal particles settle under gravity in clariflocculator tank and are drawn as clarifier sludge from the bottom. The overflowing clear water from clariflocculator tank is then passed over filter beds where finer and lighter particles present in the water get retained. The exhausted filtration beds are cleaned by backwashing and during the cleaning process large volume of FS is generated. The FS was collected, dewatered, and dried to obtain cakes. These cakes were crushed to powder and characterized for various physicochemical properties. Figure 1a,b shows the dried FS cakes and crushing of the cakes respectively, whereas Fig. 1c shows the obtained PFS.

PFS characterization

The representative sample of PFS was analyzed for particle size distribution, pH, moisture, organic content, fixed solids, and loss on ignition. Sieve analysis and hydrometer test was carried out to measure the particle size distribution in PFS. The pH value was measured as per IS 2720 (Part 26)19. Moisture, organic matter, and fixed solids have been determined according to standard procedures20. Volatile organic fraction was found by heating the sample at 550 ± 5 °C for 2 h whereas the loss on ignition was measured gravimetrically by heating PFS at 1000 ± 5 °C for 2 h. Chemical composition of the PFS and OPC cement was analyzed by X-ray fluorescence spectroscopy (XRF) technique. Surface morphology of the PFS was studied by using Jeol model JSM 6510 LV scanning electron microscope (SEM). X-ray diffraction (XRD) analysis was carried out using Rigaku X-ray diffractometer, (copper radiation, K-beta filter, 0.05°step, 40 kV, 30 mA) and scanning for 2θ ranging from 10 to 85°. The crystalline phases were identified using International Center for Diffraction Data database (JCPDS–ICDD). SDT Q600 TA apparatus is used to perform thermogravimetric analysis (TGA) and differential thermal analysis (DTA) for understanding the thermal behavior of PFS. A nitrogen flow of 100 mL per minute is maintained to heat the PFS sample up to 1000 °C at a rate of 10 °C per minute. Using Micromeritics Gemini V apparatus, the BET (Brunauer, Emmett, and Teller) specific surface area of the PFS is determined by nitrogen adsorption–desorption isotherms at 77 K.

Testing of cement and PFS mixture

The PFS as shown in Fig. 1c was passed through 90 µm Indian standard (IS) sieve and the portion that passed the sieve have been separated out. In this study, only the PFS which passed through 90 µm IS sieve was used for replacement of OPC; therefore, fineness PFS was comparable to that of fineness of OPC cement as per IS 26921. OPC 43 Grade conforming to IS 811222 was mixed with PFS in the ratio of 0, 10, 15, 20 percent and assessed for various parameters essential for determining the suitability and possible uses of the cement-PFS mix in different construction practices. Figure 2 shows the mixing of PFS with the OPC cement. Normal consistency, setting time, hydration behavior, compressive strength, permeable voids, water absorption, and microstructure characteristics of the OPC cement and cement-PFS mix were determined in this study as per the standard procedure. Normal consistency of the cement and cement-PFS mix was determined as per IS 4031(Part 4)23 to find the water content required for achieving a standard consistency of the paste. The initial and final setting times were then measured as per IS 4031(Part 5)24 whereas hydration test was conducted using isothermal calorimetry as per the procedure mentioned in ASTM C1679-0825. In order to measure the heat released during the exothermic hydration reaction, firstly the calorimeter is set at 27 °C then, a sample holder containing around 30 g of cement/cement-PFS paste is placed inside the calorimeter. Water-to-cement/cement-PFS ratios that were previously determined during the standard consistency test were used to prepare paste. Heat released during the hydration reaction was recorded at one-minute intervals over the period of three days. Sand and water mixture was used as a reference sample to reduce baseline errors.

Mortar mixes were prepared, including a control mix without PFS (MM0) and mixes with varying percentages of PFS (MM10, MM15, and MM20). 70.6 mm mortar cubes were cast as per the method specified in IS 4031(Part 6)26. For each mix, twelve cubes were cast and subjected to triplicate tests for compressive strength, water absorption, and permeable voids. An automated compression testing machine was used to determine the compressive strength at 3, 7, 28, and 90 days. Water absorption and permeable voids were measured at 28 days according to ASTM C642-0627. The cubes having maximum 28-day compressive strength have been analyzed for microstructure using SEM and XRD techniques by taking small fragments from the center.

Furthermore, Portland pozzolana cement (PPC) was also tested in this study for initial setting time, final setting time, and compressive strength as PPC is commonly used in India for making masonry mortar and plastering mortar. Test results of PPC were compared with that of OPC and OPC-PFS mix. Table 1 shows the constituent of the mortar mix prepared in this study.

Results

Characteristics of PFS

During the filtration process generally, finer particles get deposited on the filter bed that are removed through filter backwashing. The FS typically constitutes fine sand, silt, clay, chemical precipitates, plant fibers other organic and inorganic particles. Figure 3 shows the particle size distribution of PFS. It is observed that PFS constitute 44% fine sand ranging 75–150 µm. About 40% silt is present whereas clay constitute about 16% of PFS. Thus, 56% of the PFS particles are finer than 75 µm constituting silt and clay. Some of the physicochemical characteristics of the PFS is shown in Table 2. PFS is observed to be slightly alkaline in nature. The pH of PFS is found to be 7.25 as it was collected from the drinking water treatment plant where pH of raw water ranges between 6 and 8. Volatile matter is found to be only 2.84% showing the presence of low organic content and predominantly inorganic nature of the PFS. About 7.42% loss on ignition is found attributing the oxidation–reduction, dissociation/arrangement of function groups and bonds in organic as well as inorganic compounds at higher temperature. Decarbonation of carbonates, dehydroxylation of phyllosilicates and aluminium hydroxides, and dissociation of other inorganic minerals take place between 800 and 1000 °C11. Fixed solids constitute about 89.86% of the PFS.

Chemical composition of PFS and OPC cement is shown in Table 3. Silica (50.89%) and alumina (17.81%) constitute the major portion of PFS followed by iron oxide, calcium oxide, magnesium oxide, potassium oxide, and sodium oxide. The WTP from where the FS was collected, uses polyaluminium chloride as coagulant for the treatment of raw water and thus produces aluminium based sludge. Iron, calcium, magnesium and other metals are also found in the PFS as they were present in the raw water or present as impurities in the chemical coagulants that get precipitated and removed in clariflocculation and filtration as sludge1. These impurities get concentrated into small mass of sludge and if discharged untreated may cause environmental degradation, therefore require proper treatment and sustainable disposal. The total percentage of silica, alumina and iron oxide present in the PFS is above 70% thus, satisfy the requirement for natural pozzolana that can be used for cement preparation as per IS 1344 and ASTM C618-8928,29. OPC cement has 58.2% lime, 22.8% silica, 5.2% alumina and 3.59% iron oxide, satisfying the required chemical composition of OPC cement.

Surface structure of the PFS was assessed using SEM and shown in Fig. 4. Although SEM analysis of the material gives the qualitative idea of a material, it is visible from the SEM images that the PFS particles do not have much crystalline structure. Laminar flakes are more evident on the surface of the PFS sample. The XRD diffractogram of PFS as observed over 2-theta, 10–85° is displayed in Fig. 5. XRD diffractogram indicates that quartz (SiO2, PDF#046–1045) is the predominant crystalline phase present in PFS30. Relatively low intensity peaks of albite (NaAlSi3O8, PDF#009-0466) and calcite (CaCO3, PDF#01-086-2339) are also visible. Peaks of the kaolinite mineral (Al2Si2O5(OH)4, PDF#01-078-1996)30, which shows pozzolanic properties upon calcination, can be also seen in the XRD diffractogram of PFS. However, calcination is an energy intensive process and may increase the cost and carbon footprint of FS disposal.

The TGA-DTA analysis was used to study the thermal behavior of the PFS. Figure 6 displays the TGA-DTA curve for PFS. The first endothermic peak visible around 75 °C can be associated to the release of hygroscopic water from PFS. The weight loss is less than 1% as the PFS was prepared from dry FS cakes. A wide exothermic peak with maxima at around 315 °C is associated with the beginning of oxidation of organic matter. The PFS start losing weight rapidly at 550 °C which can be attributed to the expulsion of volatile organic matter and the associated weight loss is about 2.5% at 550 °C as indicated in the TGA curve. This weight loss is also in agreement with the results found in Table 2. At 705 °C, there is another endothermic peak that is mainly due to oxidation of inorganic materials and transformation of crystalline phases31. Total weight loss at 990 °C is around 7.2%, which is comparable to the value of loss on ignition. Similar thermal properties of the FS were also reported in previous studies31,32.

BET analysis was carried to find the surface properties of the PFS particles. It was found that PFS has very high BET surface area of 6.99 m2/g and single point total pore volume of pores less than 420.38 Å diameter is 0.014506 cm3/g. Average pore width of the PFS particles was observed to be 83.0 Å. Therefore, it has been inferred that PFS particles are finer than minimum required Blain fineness of 0.32 m2/g for the calcined clay if used for producing Portland pozzolana cement or using in unblended cement mortar and concrete and lime-pozzolana mixture28. However, in this study PFS is directly mixed with OPC 43 grade cement and used to prepare mortar.

Effects of PFS substitution on standard consistency and setting time

Table 4 illustrates the effect of partially substituting cement with PFS on the standard consistency and setting time. The amount of water needed to make cement paste that will allow the Vicat plunger to penetrate to a point 5–7 mm from the bottom of the Vicat mold is known as the standard consistency of cement paste. Standard consistency of OPC and PPC was 33% and 36% respectively whereas OPC cement with 10%, 15% and 20% PFS were having standard consistency of 35.5%, 37% and 38.5% respectively. It was observed that the standard consistency of the cement and PFS mix increased as the percentage of PFS was increased. Reason for the increasing trend of standard consistency can be understood from the need of additional water to moisten the fine PFS particles having higher surface area and adsorption pores. Some of the water had been absorbed by the PFS particles while making a consistent paste of cement-PFS mix33. Initial setting time as well as final setting time of OPC get affected due to partial blending of PFS. Initial setting time should not be shorter than 30 min, and the duration of final setting should not exceed 600 min34. It can be seen in the Table 4 that all the cement-PFS mix has higher setting times but lies within the prescribed limits and thus can be used for preparing mortar or concrete where delayed setting is not an issue.

Effects of PFS on hydration

Hydration of cement is an exothermic chemical reaction which takes place when water is mixed with cement, and it provide strength and binding properties to concrete and mortar. Cement hydrates mainly in two ways. In the first, anhydrous cement compounds dissolve into their ionic constituents to create hydrates in solution and because of their limited solubility, these hydrates eventually precipitate, generating hydration products. In the second method the hydration take place right at the anhydrous cement compounds’ surface without going into solution. The exothermic reaction between cement and water produces hydration products and the heat of hydration. The amount of hydrated cement cannot be measured directly, but it can be inferred indirectly by tracking the amount of heat generated during hydration over the time. Rate of hydration in OPC cement and OPC-PFS mix containing 10% and 20% PFS is shown in Fig. 7. Initial setting time and final setting time found above also matches with the results of heat of hydration test. OPC and OPC-PFS mix have similar patterns in the release of heat of hydration however, time lag and lowering in the rate of hydration can be seen from Fig. 7. Gomes et al. and Rodriguez et al.10,11 also reported delay in hydration reaction and this delay increases the setting times and decreases the gain of early strength. Addition of PFS to the cement has decreased the rate of hydration reaction in the present study and can be attributed to physical interaction of the PFS with the cement particles. These interactions may have hindered the movement of water and reactants, thus reduced their contact and slow down the hydration process.

Effects of PFS incorporation on compressive strength

Different sets of mortar cubes were prepared using standard sand and different binder such as OPC, OPC-PFS mix and PPC. Compressive strength of the prepared mortar specimens was found as per IS 4031(Part 6)26. Compressive strength of the mortar cubes having different percentage of PFS and tested at 3, 7, 28 and 90 days are shown in Fig. 8. It can be seen that compressive strength decreases with increase in the percentage of PFS in the mortar cubes. It can be attributed to the fact that cement content decreases and thus the quantity of C3S (Tricalcium silicate) and C2S (Dicalcium silicate) which are mainly responsible for strength development get reduced35. The rate of heat evolution during cement hydration also provides insights into strength development. Reduction in the heat evolution rate as visible in Fig. 7 corresponds to decrease in the strength development in PFS blended mortar specimens. Furthermore, PFS blended mortar tends to have higher water content (water-to-cement/binder ratio) compared to that of control mortar, for maintaining the same consistency during casting. The higher water content can contribute to reduction in the strength by diluting the cementitious components and affecting the overall hydration process36. 3-day compressive strength of mortar cubes (MM10, MM15, and MM20) having 10, 15 and 20 percent PFS were around 21 MPa, 19 MPa and 15 MPa respectively. PPC had also 3-day compressive strength around 15 MPa, lower than that of MM10 and MM15, however 7-day and 28-day compressive strength were around 26 MPa and 41 MPa respectively. MM10 and MM15 had mean compressive strength of about 28 MPa and 27 MPa respectively at 7 days whereas, around 36 MPa and 34 MPa respectively at 28 days. Both MM10 and MM15 had 28-day compressive strength higher than the required minimum compressive strength of 33 MPa as per IS 1489 (Part 2) and IS 26937,38. Moreover, 90-day compressive strength MM10, MM15 and MMppc were almost same around 42 MPa. Therefore, the compressive strength test supports the incorporation of up to 15 percent PFS with OPC and can be used similar to PPC in construction practices. PPC is commonly used in India to prepare mortar and concrete. Similarly, OPC-PFS mix can be used where delayed strength is not a bar and could be utilized to prepare masonry mortar, plastering mortar and non-structural elements especially those having lower strength.

Effects of PFS on permeable voids and water absorption

Permeable voids as well as water absorption found in the mortar cubes prepared from OPC, OPC-PFS mix and PPC have been shown in Fig. 9. Permeable voids as well as water absorption were found to increase with increase in the percentage of PFS in the mortar. However, difference in permeable voids of control mortar cubes and the cubes having PFS up to 15% is not much high. Control mortar cubes (MM0) have mean permeable voids of 11.41% whereas mortar cubes with 10% and 15% PFS have permeable voids of 11.42% and 11.89% respectively, whereas MM20 having 20% PFS has the mean permeable voids of 12.91%. MMppc has 11.49% permeable voids which is same as that of MM10 and MM15. Similar trend can be seen in the variation of water absorption in different mortar specimen. MM0 MM10, MM15, and MM20 has 4.47%, 5.17%, 5.27%, and 5.81% water absorption respectively. MMPPC has water absorption of 5.21% and about same as that of mortar specimen containing up to 15% PFS. The OPC cement when partially substituted by PFS which has high specific surface area and irregular shape require more water to have a consistent cement-PFS paste. Thus, the mortar specimens with PFS have higher water to cement/binder ratio and therefore, led to increased formation of permeable pores and capillary voids within the cementitious matrix39. The increased porosity and pore connectivity created more permeable microstructure in the hardened OPC-PFS mortar specimens which resulted in higher water absorption. It also contributed to the reduction in compressive strength by creating weak points and stress concentrations within the material. However, hydration products of C3S and C2S continuously deposits into the water-filled capillary pores thus, decreasing the pore volume and increasing the compressive strength40.

Microstructural properties of mortar

Microstructural properties of the mortar cubes containing OPC and OPC-PFS mix were investigated by SEM and XRD analysis. SEM images of the mortar specimen having maximum strength at 28 days are shown in Fig. 10. C–S–H (calcium silicate hydrate) gel, portlandite also called CH (calcium hydroxide) and Ettringite (hydrous calcium aluminium sulphate) are known as hydration products of cement. Microstructure of these hydration product are extremely intricate and sometimes challenging to comprehend. The main product phase that imparts strength is C–S–H, which can have an amorphous or weakly crystalline structure. Scrivener et al.41 reported in their book that the structure and mechanical properties of C–S–H gel in hardened cement concrete or mortar depend on concentration as well as distribution of particles, composition of phases and orientation of particles in the matrix, their shape and size. The SEM micrograph of the OPC and OPC-PFS mortar specimen (Fig. 10) shows the aggregation of microscopic fibrous crystals of C–S–H and long whisker-like crystals of ettringite. It also shows the crystals of CH or portlandite with hexagonal-prism morphology. The MM10 and MM20 mortar specimens having 10% and 20% PFS respectively also exhibit PFS particles trapped between the hydration products. SEM images also show the larger voids in MM10 and MM20 specimen supporting the results of comparatively lower compressive strength and higher permeability when compared to control mortar.

The XRD diffractogram of the hydration products formed in OPC and OPC-PFS mortar specimens are displayed in Fig. 11. The intensity and position of peaks provide valuable information about the interactions between the cement hydration products and PFS particles. Furthermore, the relative intensities of peaks can give insights into the degree of incorporation and influence of the PFS particles within the cementitious matrix. Crystallite phases of ettringite (3CaO·Al2O3·3CaSO4·32H2O, PDF#39-1381), and portlandite or CH (Ca(OH)2, PDF#04-0733) are present in the XRD pattern of all the mortars; however, the intensity of the peaks decreases as the percentage of PFS increases. C–S–H ((CaO)x(SiO2)y(H2O)z, PDF#29-0373) is amorphous or weakly crystalline and the presence of broad peak (or halo) in the range of approximately 25–35° (2θ) is indicative of C–S–H. However, the XRD identification of C–S–H, as the main cementitious reaction product, seems complicated as its weak peak overlaps with that of the calcite nonetheless, the strength attained is an indirect indicator of its formation42. Tkaczewska and Rajamma et al.43,44 also carried out the XRD analysis of cement paste at 28 days and found similar hydration products. Strong peaks of quartz (SiO2, PDF#11-0252) were observed due to the presence of sand particles in the powdered sample and calcite (CaCO3, PDF#47-1743) peaks were also found which may be the result of carbonation of CH present in the mortar. The peaks of the various hydration products can be easily seen in Fig. 11, indicating that the cement has significantly hydrated in 28 days in the mortar specimens of OPC and OPC-PFS and thus supports the achieved results of compressive strength.

XRD of mortar specimens at 28 days, (a) Quartz (SiO2; PDF#11-0252), (b) Calcite (CaCO3; PDF#47-1743), (c) C–S–H gel ((CaO)x(SiO2)y(H2O)z; PDF#29-0373), (d) Portlandite (Ca(OH)2; PDF#04-0733), (e) Ettringite (3CaO·Al2O3·3CaSO4·32H2O; PDF#39-1381), (f) C2S (2CaO·SiO2, PDF#39-0298)30.

Discussion

Physicochemical properties of PFS satisfies the specification of natural pozzolana as per ASTM C618-8929 for mixing in concrete as mineral admixture. It also conforms to the properties of raw clay material required to manufacture calcined clay pozzolana according to IS 134428. The calcined clay pozzolana can be further incorporated in lime-pozzolana mixture and in unblended cement mortar or concrete and used for manufacturing of PPC (calcined clay based) cement having specification as per IS 1489 (Part 2)37. However, in this study PFS is directly utilized without calcination and up to 15% replacement of OPC 43 grade cement with PFS gave satisfactory results. Setting times of OPC-PFS get delayed but were within prescribed limits. The compressive strength at 28-day of OPC-PFS was also above 33 N/mm2 as required for PPC (fly ash based) as per IS 1489 (Part 1)34 and PPC (calcined clay based) as per IS 1489 (Part 2)37. PPC (fly ash based) is commonly available in the market and used for construction and repair. 90-day compressive strength of the OPC-PFS mortar having up to 15% PFS was found to be same as that of PPC mortar tested in this study and close to that of OPC mortar. Comparison of physical and mechanical properties between OPC, PPC, OPC-PFS mortars clearly indicated that incorporating PFS in unblended OPC cement will produce similar strength, but only limitation is that the gain of strength will be delayed. However, lots of opportunities of using PFS in construction practices can be explored where delayed strength is not a limitation.

Therefore, construction industry may find sustainable disposal options by recycling PFS into concrete, mortar, and unblended cement. Furthermore, the amount of PFS recycled into concrete and mortar could be engineered, which may provide better options to recycle PFS even greater than 15%, depending upon the strength need and type of construction activity. PFS can be easily incorporated into non-load bearing concrete or masonry structures. In masonry, mortar does play a significant role in influencing the bond strength and deformability of masonry, but it does not have much effect on the compressive strength of masonry45. Masonry structure is composed of anisotropic materials and mortar ensures that the stress is distributed uniformly by accounting for deformations and uneven block shapes. Therefore, richer mortar is not needed in the construction of masonry as it experiences triaxial stress in masonry. Cement partially replaced with PFS would be most appropriate for preparing masonry mortars of various grades as per IS 2250, code of practice for the preparation and use of masonry mortars46. In the case of non-structural elements, PFS can be easily added to the concrete mix as an additive thus, offering a sustainable disposal of water treatment waste.

Cement production significantly impacts the environment, primarily through the exploitation of natural limestone deposits and the release of substantial amounts of carbon dioxide (CO2) into the atmosphere. Limestone (CaCO3) being a principal raw material when heated at around 1450 °C in the kiln dissociates into lime (CaO) and CO₂. Furthermore, to this temperature in the kiln, fossil fuels such as coal, oil, or natural gas are burnt, releasing CO₂ and other greenhouse gases directly into the atmosphere. Globally, the cement industry is one of the largest contributors of CO2 emissions, accounting to approximately 8% of the total emissions worldwide47,48. According to Amran et al.49, cement production is experiencing a steady growth at the rate of about 9% annually. Therefore, it is crucial to enhance fuel efficiency, lower the clinker-to-cement ratio, incorporate supplementary cementitious materials, and explore alternative binders without compromising cementitious properties50. These strategies can significantly reduce the carbon footprint of the cement industry while supporting sustainability efforts. Therefore, utilizing the FS from the WTPs as partial cement substitute in construction industry could be a beneficial and sustainable disposal option which would otherwise adversely affect the environment. Partial replacement of cement with PFS would also reduce the demand for cement production however, it will depend on the extent to which such mixtures are accepted in construction industry. But utilization of cement-PFS mixture would help in lowering the adverse impact of increasing cement production on the environment. Environmental and economic benefits of utilizing FS are far more than the cost of collection and processing of FS to produce PFS.

Conclusions

The study has investigated the potential application of filtration sludge produced at WTPs for sustainable disposal. Partial replacement of cement with PFS for preparing concrete and mortar would promote sustainability and reduce the cement production as well as their related environmental impact. PFS blended with cement requires more water to prepare standard consistent paste and have delayed initial and final setting time but are within the prescribed limits. Adding PFS decreases the hydration rate which resulted in delayed strength. However, compressive strength of OPC-PFS mortar having 15% PFS is above 33 MPa which is more than the minimum compressive strength required at 28 days for PPC and OPC 33 grade cement. 90-day compressive strength of OPC-PFS mortar up to 15% PFS is almost same as that PPC available in the market and commonly used for construction. Depending on the required strength for masonry and plastering mortar, PFS can be easily recycled in the preparation of mortar and OPC cement can be further replaced by PFS even more than 15%. PFS can be further investigated with other waste materials such as fly ash, blast furnace slag, marble slurry, silica fumes etc. as binary or ternary mix. Engineered mix of PFS with cement and/or other industrial waste may enhance the potential utilization of PFS in construction industry.

Data availability

All data generated or analyzed during this study are included in this manuscript.

Abbreviations

- WTP:

-

Water treatment plant

- WTS:

-

Water treatment sludge

- PFS:

-

Powdered filtration sludge

- SFBW:

-

Spent filter backwash water

- FS:

-

Filtration sludge

- OPC:

-

Ordinary Portland cement

- SEM:

-

Scanning electron microscope

- PPC:

-

Portland pozzolana cement

- MM:

-

Mortar mix

- XRF:

-

X-ray fluorescence

- XRD:

-

X-ray diffraction

- TGA:

-

Thermogravimetric analysis

- DTA:

-

Differential thermal analysis

- IS:

-

Indian standard

- ASTM:

-

American society for testing and materials

- MPa:

-

Mega pascal

- C3S:

-

Tricalcium silicate

- C2S:

-

Dicalcium silicate

- C–S–H:

-

Calcium silicate hydrate

- CH:

-

Calcium hydroxide

References

Ahmad, T., Ahmad, K. & Alam, M. Sustainable management of water treatment sludge through 3 ‘R’ concept. J. Clean. Prod. 124, 1–13 (2016).

Zhao, Y. et al. Waterworks sludge: An underrated material for beneficial reuse in water and environmental engineering. Waste Biomass Valoriz. 12, 4239–4251 (2021).

Krause, M. J. & Bronstein, K. E. Estimating national sludge generation and disposal from US drinking water and wastewater treatment plants. J. Clean. Prod. 453, 142121 (2024).

Nguyen, M. D., Thomas, M., Surapaneni, A., Moon, E. M. & Milne, N. A. Beneficial reuse of water treatment sludge in the context of circular economy. Environ. Technol. Innov. 28, 102651 (2022).

Akhtar, N. et al. Ecological footprint and economic assessment of conventional and geopolymer concrete for sustainable construction. J. Clean. Prod. 380, 134910 (2022).

Bella, N. et al. Formulation of alkali-activated slag binder destined for use in developing countries. Appl. Sci. 10(24), 9088 (2020).

Ally, A. N. et al. Substitution of aggregates in concrete and mortar with coltan mining waste: Mechanical, environmental, and economic impact case study. J. Miner. Mater. Charact. Eng. 12(2), 139–163 (2024).

Yen, C.-L., Tseng, D.-H. & Lin, T.-T. Characterization of eco-cement paste produced from waste sludges. Chemosphere 84, 220–226 (2011).

Chen, H., Ma, X. & Dai, H. Reuse of water purification sludge as raw material in cement production. Cem. Concr. Compos. 32, 436–439 (2010).

Gomes, S. D. C., Zhou, J. L., Li, W. & Qu, F. Recycling of raw water treatment sludge in cementitious composites: Effects on heat evolution, compressive strength and microstructure. Resour. Conserv. Recycl. 161, 104970 (2020).

Rodríguez, N. H. et al. Re-use of drinking water treatment plant (DWTP) sludge: Characterization and technological behaviour of cement mortars with atomized sludge additions. Cem. Concr. Res. 40, 778–786 (2010).

Sales, A. & De Souza, F. R. Concretes and mortars recycled with water treatment sludge and construction and demolition rubble. Constr. Build. Mater. 23, 2362–2370 (2009).

Pham, P. N., Duan, W., Zhuge, Y., Liu, Y. & Tormo, I. E. S. Properties of mortar incorporating untreated and treated drinking water treatment sludge. Constr. Build. Mater. 280, 122558 (2021).

Huang, C., Pan, J. R. & Liu, Y. Mixing water treatment residual with excavation waste soil in brick and artificial aggregate making. J. Environ. Eng. 131, 272–277 (2005).

Yang, J., Chen, C., Chen, S., Ren, Y. & Jinsuo, Lu. Resource utilization of drinking water treatment aluminum sludge in green cementing materials: Hydration characteristics and hydration kinetics. J. Environ. Sci. 144, 236–248 (2024).

Nontananandh, S. et al. Sustainable utilization of dredged sediments and water treatment sludges as construction materials through combined dewatering and cement stabilization techniques. Recycling 10(1), 22 (2025).

Kina, C. Sustainable binary/ternary blended mortars with recycled water treatment sludge using fly ash or blast slag: Characterization and environmental-economical impacts. Environ. Sci. Pollut. Res. 31, 15126–15152 (2024).

Xia, Y. et al. Value-added recycling of sludge and sludge ash into low-carbon construction materials: Current status and perspectives. Low-Carbon Mater. Green Constr. 1, 1–19 (2023).

Bureau of Indian Standards (BIS). Method of test for soils: Determination of pH value, IS 2720 (Part 26) (BIS, 1987).

American Public Health Association (APHA). Standard methods for the examination of water and wastewater, twentieth ed. (APHA, 1998).

Bureau of Indian Standards (BIS). Indian standard specification for ordinary Portland cement, IS 269 (Bureau of Indian Standards, 2015).

Bureau of Indian Standards (BIS). Specification for 43 grade ordinary Portland, IS 8112 (BIS, 1989).

Bureau of Indian Standards (BIS). Methods of physical tests for hydraulic cement: Determination of consistency of standard cement paste, IS 4031(Part 4) (BIS, 1988).

Bureau of Indian Standards (BIS). Methods of physical tests for hydraulic cement: Determination of initial and final setting times, IS 4031(Part 5) (BIS, 1988).

ASTM designation: C 1679-08. Standard practice for measuring hydration kinetics of hydraulic cementitious mixtures using isothermal calorimetry. Annu. Book ASTM Stand. (2008).

Bureau of Indian Standards (BIS). Methods of physical tests for hydraulic cement: Determination of compressive strength of hydraulic cement (other than masonry cement), IS 4031(Part 6) (BIS, 1988).

ASTM designation: C 642-06. Standard test method for density, absorption, and voids in hardened concrete, Annu. Book ASTM Stand. (2006).

Bureau of Indian Standards (BIS). Specification for Calcined Clay Pozzolana, IS 1344 (BIS, 1981).

ASTM designation: C 618-89. Standard specification for coal fly ash and raw or calcined natural pozzolana for use as a mineral admixture in concrete, Annu. Book ASTM Stand. (1989).

McMurdie, H. F. et al. Standard X-ray diffraction powder patterns from the JCPDS Research associateship. Powder Diffr. 1, 64 (1986).

Xu, G. R., Zou, J. L. & Li, G. B. Effect of sintering temperature on the characteristics of sludge ceramsite. J. Hazard. Mater. 150, 394–400 (2008).

Ahmad, T., Ahmad, K. & Alam, M. Investigating calcined filter backwash solids as supplementary cementitious material for recycling in construction practices. Constr. Build. Mater. 175, 664–671 (2018).

Puertas, F., Blanco-Varela, M. T. & Vazquez, T. Behaviour of cement mortars containing an industrial waste from aluminium refining: Stability in Ca(OH)2 solutions. Cem. Concr. Res. 29, 1673–1680 (1999).

Bureau of Indian Standards (BIS). Portland Pozzolana Cement—Specification Part 1 Fly Ash Based (Fourth Revision), IS 1489: Part 1 (BIS, 2015).

Neville, A. M. & Brooks, J. J. Concrete Technology 2nd edn. (Longman Scientific and Technical, 2010).

Singh, S. B., Munjal, P. & Thammishetti, N. Role of water/cement ratio on strength development of cement mortar. J. Build. Eng. 4, 94–100 (2015).

Bureau of Indian Standards (BIS). Portland-pozzolana cement specification (calcined clay based), IS 1489 (Part 2) (BIS, 1991).

Bureau of Indian Standards (BIS). Specification for Ordinary Portland Cement, 33 Grade, IS 269 (BIS, 1989).

Kim, Y. Y., Lee, K. M., Bang, J. W. & Kwon, S. J. Effect of w/c ratio on durability and porosity in cement mortar with constant cement amount. Adv. Mater. Sci. Eng. 2014, 273460 (2014).

Chen, X. & Wu, S. Influence of water-to-cement ratio and curing period on pore structure of cement mortar. Constr. Build. Mater. 38, 804–812 (2013).

Scrivener, K., Bazzoni, A., Mota, B. & Rossen, J. E. Electron microscopy. In A Practical Guide to Microstructural Analysis of Cementitious Materials (eds Scrivener, K. et al.) 351–417 (CRC Press, 2016).

Rodriguez-Morales, J. & Escalante-Garcia, J. I. Recycling pulverized concrete as cementitious precursor in alkaline one-part cements, with a waste glass-based sodium silicate. J. Clean. Prod. 482, 144229 (2024).

Tkaczewska, E. Mechanical properties of cement mortar containing fine-grained fraction of fly ashes. Open J. Civ. Eng. 3, 54–68 (2013).

Rajamma, R. et al. Characterisation and use of biomass fly ash in cement-based materials. J. Hazard. Mater. 172(2–3), 1049–1060 (2009).

Haach, V. G., Vasconcelos, G. & Lourenço, P. B. Influence of aggregates grading and water/cement ratio in workability and hardened properties of mortars. Constr. Build. Mater. 25(6), 2980–2987 (2011).

Bureau of Indian Standards (BIS). Code of practice for preparation and use of masonry mortars, IS 2250 (BIS, 1981).

Shah, I. H. et al. Cement substitution with secondary materials can reduce annual global CO2 emissions by up to 1.3 gigatons. Nat. Commun. 13, 5758 (2022).

Farooq, F. et al. Geopolymer concrete as sustainable material: A state of the art review. Constr. Build. Mater. 306, 124762 (2021).

Amran, Y. M., Alyousef, R., Alabduljabbar, H. & El-Zeadani, M. Clean production and properties of geopolymer concrete: A review. J. Clean. Prod. 251, 119679 (2020).

Singh, N. B. & Middendorf, B. Geopolymers as an alternative to Portland cement: An overview. Constr. Build. Mater. 237, 117455 (2020).

Acknowledgements

The authors gratefully acknowledge the funding of the Deanship of Graduate Studies and Scientific Research, Jazan University, Saudi Arabia, through project number: RG24-S0133.

Funding

The Deanship of Graduate Studies and Scientific Research, Jazan University, Saudi Arabia, has financially supported through project number: RG24-S0133 to carry out this study.

Author information

Authors and Affiliations

Contributions

All authors have conceptualized the present study. Formal analysis and investigations are done by Tarique Ahmad. All authors have contributed to writing the original draft of the manuscript. Reviewing and editing of the draft manuscript is carried out by Tarique Ahmad.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical approval

Present research work does not involve human or animal and therefore approval from any ethics committee is not required. The work has been accomplished with research ethics.

Consent to participate

No human or animal participation therefore any statement of consent is not required.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ahmad, T., Magbool, H.M. & Rasooly, S.S. Characterization and experimental investigation of powdered filtration sludge for potential utilization in construction industry. Sci Rep 15, 32398 (2025). https://doi.org/10.1038/s41598-025-05448-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-05448-5