Abstract

Water is a clean and pollution-free medium, making it an excellent alternative to hydraulic oil as a transmission medium. However, the widespread application of water hydraulic systems is currently hindered by poor sealing performance and the complex structure of control components. To address these challenges, this study introduces an innovative 4/3 water hydraulic directional valve. The proposed valve adopts a contact-type dynamic sealing structure, which offers superior sealing performance and the ability to withstand a wider range of high pressures. Additionally, it features a simple structure and low manufacturing cost. A prototype was developed and subjected to rigorous performance testing. The experimental results demonstrate that the valve realizes reliable directional control functions, exhibits excellent dynamic characteristics, and ensures safe and reliable control of hydraulic cylinders. Under different pressure conditions, the valve maintains ideal sealing performance both in the neutral and working positions after directional switching. The development of the novel 4/3 water hydraulic directional valve not only enriches the range and application scope of water hydraulic components but also shows significant potential for advancing hydraulic transmission technology from oil-based to water-based systems.

Similar content being viewed by others

Introduction

Pascal formulated the famous Pascal’s Law in 1653, laying the foundation for the development of hydraulic technology. In 1795, British engineer Joseph Bramah built the world’s first hydraulic press based on Pascal’s principle, marking the true birth of hydraulic transmission technology. In 1906, Williams and Jenny proposed the idea of using oil as a substitute for water-based fluids, thus avoiding issues related to corrosion, lubrication, and water-related leakage. The subsequent years witnessed a significant increase in the application of oil hydraulics. However, the extensive use of hydraulic oil inevitably leads to oil leakage during production, transportation, and storage, which can result in contamination of water and soil with harmful substances1, posing serious threats to human health2,3,4,5, plants, animals, and ecosystems6,7. With the increasing depletion of energy resources and growing awareness of environmental protection, water hydraulics, using water as a clean, non-polluting, and sustainable transmission medium, gained renewed interest at the end of the 20th century8.

Water hydraulic systems employ filtered, additive-free natural freshwater or seawater as the transmission medium. These systems offer several advantages, including environmental friendliness, low cost, and non-flammability. They are particularly useful in specialized applications, such as water hydraulic manipulators in high-radiation zones of nuclear reactors for dismantling, handling, cleaning, and maintenance9; underwater robotic arms for seabed resource exploration10; and hydraulic supports for underground mining11. These devices rely on water hydraulic valve-controlled cylinder systems to perform complex movements, often in combination with various mechanical mechanisms.

A key component of water hydraulic systems, the three-position four-way (4/3) water hydraulic directional valve, is crucial for controlling actuators. However, the development of these valves is challenged by several factors, including the low viscosity of water, its tendency to leak, corrosive nature, and the risk of cavitation. Among these challenges, sealing is the most critical. The performance of seals determines not only the stability of the hydraulic system but also the ability of the valve to withstand high-pressure conditions.

Currently, most water hydraulic directional valves primarily adopt seat-type configurations. In these designs, the spool maintains minimal contact area with the valve seat, where sealing is achieved through linear or areal contact mechanisms. The application of adequate sealing force generates elevated sealing pressure, thereby enhancing sealing efficacy in aqueous environments. However, a seat-type valve can only realize the two-position two-way (2/2) control though single valve core configuration. To control actuator movement, multiple 2/2 valves must be combined. For instance, Han et al.12 developed a water hydraulic proportional directional valve for die-casting machines, where the main valve is a 2/2 seat-type valve, and each core of the main valve is controlled by two 2/2 pilot valves. Liu et al.13 developed a 4/3 cartridge directional valve for seawater hydraulic systems by integrating four 2/2 switching valves into a single block. Yang et al.9 used four 2/2 high-speed switching valves to control the hydraulic cylinders of a robotic arm, with the principle of the hydraulic system shown in Fig. 1. Similarly, Zhang et al.14 designed a three-core follower-type water hydraulic valve for hydraulic support column control. Zhao et al.15 employed two two-positions three-way (3/2) cone sliding valve directional valves to control the hydraulic support columns, as shown in Fig. 2.

Spool valves, compared to seat-type valves, offer simpler structures. A single valve spool can realize 4/3 function, and the valve spool’s geometry can be adjusted to realize specific functions16,17,18. Majdic et al.19 developed a 4/3 water hydraulic spool valve and established an experimental platform to test its lifetime. This valve uses a gap-sealing structure and operates of 16 MPa with the flow rate of 0–30 L/min. Ebara, a Japanese company, has recently developed a proportional water pressure control valve with a rated pressure of 7 MPa and the maximum flow of 35 L/min. Meanwhile, the British company WATER HYDRAULICS20 developed a similar valve using a flat sealing method, achieving a rated pressure of 16 MPa and the flow rate of 0–30 L/min.

In oil hydraulic systems, mineral oils form an oil film between the gap of valve spool and valve body, creating a sealing area and providing lubrication, as shown in Fig. 3. However, spool valves are less effective in water hydraulic systems due to water’s high leakage tendency through the gaps in the valves. Leakage in water hydraulic systems can be approximately dozens of times higher than in oil hydraulic systems. Although reducing the gap between the valve spool and the valve bore can somewhat reduce leakage, overly tight gaps increase friction and wear, potentially causing system failure19,21. Zum Gahr et al.22 have explored the frictional properties of materials under water lubrication about ceramic materials. Additionally, Guo et al.23 investigated the effect of break-in processes on the friction coefficient of graphite and tungsten carbide in deionized water. Other studies have also examined the tribological behavior of polymer-metal material pairs24,25 to improve the performance and lifespan of water hydraulic systems26. However, the lack of comprehensive design parameters poses significant challenges for the practical application of new engineering materials. Therefore, the maintenance, repair, and operation markets look for a high-performance product with long-term operation.

In conclusion, the low viscosity and high leakage propensity of water create significant challenges for the sealing performance of water hydraulic valves. Most existing water hydraulic directional valves belong to the seat-type valve. While effective in sealing, they can only realize 2/2 function with a single valve core. In practice, a 4/3 valve is often employed to control actuators in practice. This typically involves combining multiple 2/2 valves, increasing the complexity and size of the valve system. Such configurations raise production and maintenance costs and limit system flexibility, especially in compact or confined spaces. These issues highlight the need for valves with multiple control functions and simplified structures27. In contrast, spool valves offer simpler designs, with a single spool capable of achieving multiple control functions. However, the gap-sealing structure limits the pressure tolerance, and reducing the gap to minimize leakage increases friction, wear, and noise. Although advanced materials such as high-performance plastics and ceramics can reduce wear, they also introduce challenges related to brittleness, manufacturing precision, and cleanliness of the water medium. Maintenance and cost considerations further constrain the widespread use of spool valves in water hydraulic systems28. Consequently, the development of water hydraulic valves combining superior sealing integrity, enhanced pressure rating, simplified structural configuration, and cost-effectiveness has emerged as a critical technical bottleneck in modern hydro-pneumatic engineering.

With the improvement of sealing technology in recent years, the research related to the sealing vice under the condition of water medium has also made rapid development. For the sealing needs of water medium, Wu et al.29 studied the sealing performance of reciprocating rod seals under high-pressure water lubrication conditions. Tao et al.30 investigated the effects of different concentrations of water-based emulsion and pure water on the frictional resistance of reciprocating seal O-rings. Liu et al.31 investigated different materials of moving pairs under seawater lubrication, and concluded that the materials used for moving pairs need to be selected according to the actual working conditions. Due to their high-strength and abrasion-resistance polyurethane materials are widely used in high-pressure aqueous environments32,33.

In response to the leakage susceptibility of spool valves in water hydraulic systems, Professor Zhang Xi from China University of Mining and Technology (Beijing) proposed a novel contact-seal-type three-position four-way directional water hydraulic spool valve, which has been designated as the Zhang Xi Valve (ZXV). The novel ZXV employs a contact-seal mechanism to ensure reliable sealing in water hydraulic systems. It retains the simplicity of traditional spool valves while enhancing their adaptability and pressure tolerance in water hydraulic systems. This advancement has significant implications for the development and application of water hydraulic systems. The following sections will explore the operational performance of ZXV, focusing on its structure, working principle, and experimental evaluation.

Structure, components and mathematical model

The structure of the novel ZXV

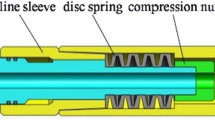

The structure of ZXV proposed in this paper is shown in Fig. 4(a). It mainly consists of a valve body, a spool, two bonnets, sealing rings, reset springs, and other components. Specifically, sealing rings are positioned between the flow passages in the valve bore. The No.1 sealing ring is installed between port A and port T1, No.2 sealing ring is installed between port A and port P, No.3 sealing ring is installed between port P and port B, and No.4 sealing ring is installed between port B and port T2. The spool features three shoulders—referred to as the left shoulder, the middle shoulder, and the right shoulder - based on their relative positions. Each shoulder is equipped with a combination of rounded and beveled edges to minimize the risk of the spool damaging the seals during directional changes.

Working principle

The working principle of ZXV is as follows:

At the beginning of the process, there is no fluid pressure in the control cavities Q1 and Q2. As a result, the spool of ZXV remains in the neutral position due to the opposing forces from the respective springs. In this state, the inlet port P is closed, the A-T1 channel is connected, and the B-T2 channel is also connected, with the outlet ports T1 and T2 open, as shown in Fig. 4(a).

1) Opening Process (P to B):

As illustrated in Fig. 4(b), when fluid pressure is applied to cavity Q2, the combined action of fluid pressure and spring force pushes the spool to the left of the valve. During this movement, the middle shoulder gradually separates from No. 3 sealing ring, while No. 2 sealing ring remains in contact with the middle shoulder. This results in port P being connected to port B, while the right shoulder gradually makes contact with No. 4 sealing ring. The spring in cavity Q1 is compressed, allowing fluid to flow out of cavity Q1. As a result, port P connects to port B, and port A is connected to port T1. The middle shoulder and right shoulder of the spool come into contact with No. 2 sealing ring and No. 4 sealing ring, respectively, preventing fluid leakage at port A and port T2.

2) Closing Process:

When no fluid pressure is applied to both cavities Q1 and Q2, the spool returns to the neutral position under the spring force. During this process, the right shoulder gradually separates from the No. 4 sealing ring, while the middle shoulder makes contact with No. 3 sealing ring. The port P is closed, and the B-T2 channel is connected, while ports T1 and T2 remain open.

3) Opening Process (P to A):

As shown in Fig. 4(c), when fluid pressure is applied to cavity Q1, the spool moves to the right. During this process, the middle shoulder gradually separates from No. 2 sealing ring, while No. 3 sealing ring remains in contact with the middle shoulder. This causes port P to connect to port A, while the left shoulder gradually makes contact with No. 1 sealing ring. The spring in cavity Q2 is compressed, allowing fluid to flow out of cavity Q2. As a result, port P is connected to port A, and port B connects to port T2. The left and middle shoulders of the spool come into contact with No. 1 and No. 3 sealing rings, respectively, preventing fluid leakage at port T1 and port B.

4) Closing Process:

When there is no fluid pressure in both cavities Q1 and Q2, the spool returns to the neutral position under the spring force. During this return movement, the left shoulder gradually separates from No. 1 sealing ring, while the middle shoulder makes contact with No. 2 sealing ring. In this state, port P is closed, and A to T1 channel is connected, while ports T1 and T2 remain open.

Structural advantages

In summary, the novel ZXV offers several key features and advantages:

1) Improved Sealing Performance:

Unlike traditional spool valves with gap sealing structures, ZXV adopts a contact-type dynamic sealing method. Sealing rings fill the gap between the spool and valve chamber, ensuring superior sealing performance in water hydraulic systems. This design represents a significant improvement over existing water hydraulic spool valves. The sealing rings not only provide excellent sealing performance but also demonstrate high wear resistance, ensuring long-term, reliable operation of the valve.

2) Simplified Structure:

For water hydraulic seat-type valves, controlling one actuator typically requires two 3/2 seat-type valves or four 2/2 seat-type valves to manage the actuator’s two working ports. In contrast, ZXV features a compact structure, with a single spool capable of achieving three-position four-way functionality to control an actuator. With the same specifications, the novel valve is more compact, allowing for a more streamlined hydraulic system and saving installation space for components.

3) Ease of Manufacturing and Assembly:

From a manufacturing and assembly perspective, the gap between the valve spool and the valve chamber in ZXV can be relatively wider, allowing for looser manufacturing tolerances. This design facilitates easier assembly and simplifies maintenance procedures.

4) Expanded Range and Enhanced Pressure Tolerance:

The new water hydraulic directional valve features a spool valve structure, expanding the range and versatility of existing water hydraulic valves. It effectively eliminates the pressure limitations typically associated with traditional spool valves, enabling better performance at high-pressure conditions.

Kinetic equation of spool valve

When the spool moves to the right position, causing port P to open and connect with port A, the spool is influenced by hydraulic pressure, spring force, viscous resistance, hydrodynamic force, and seal resistance. At this point, the dynamic equilibrium equation of the sliding spool is expressed as:

Simplified as:

where m is the mass of the spool, x1 is the displacement of the spool, which is also the displacement of the spring, b is the viscous resistance acting on the spool, k is the stiffness of the spring, x0 is the pre-compression of the spring, Fs is the hydrodynamic force acting on the spool, Fm is the frictional resistance from the sealing ring acting on the spool, Fp is the pressure acting on the left side of the spool.

The pressure acting on the left side of the spool is:

where p is the pressure acting on the left side of the main spool, Sz is the effective area on the left side of the main spool.

The steady-state hydrodynamic force acting on the spool is:

where FsPA is the steady-state hydrodynamic force at the P-A port, FsBT is the steady-state hydrodynamic force at the B-T2 port;

When the valve opening remains constant, changes in fluid velocity and direction generate steady-state hydrodynamic forces. The steady-state hydrodynamic forces for fluid flowing through P-A and B-T2 are expressed as:

where Cd is the flow coefficient of the valve port, Cv is the velocity coefficient of the valve port, S1 is the flow area of the P-A valve port, S2 is the flow area of the B-T2 valve port, ∆p1 is the pressure difference across the P-A valve port, ∆p2 is the pressure difference across the B-T2 valve port, φ1 is the jet angle of the P-A valve port, φ2 is the jet angle of the B-T2 valve port.

When sealing rings are installed in the sealing groove, they undergo compressive deformation due to squeezing. During the movement of the spool, it is subjected to frictional resistance from the sealing rings:

where f is the friction coefficient, Fn is the normal force exerted by the sealing rings on the spool.

Calculation of the flow area of ZXV

When the P-A valve port opens, the spool disengages from No.2 sealing ring. This process occurs though two distinct operational phases. As illustrated in Fig. 5, the initial phase is characterized by the radial clearance between the spool and valve bore. Due to the low viscosity of the water medium, the leakage through the annular gap should not be neglected, and the valve port can be considered open at this point. The length of the annular gap is l. As the spool moves, the length l of the annular gap decreases to zero, after which the valve port transitions into the second phase.

In the initial phase, it is assumed that the spool and the valve bore of ZXV are coaxial in their positional relationship. At this point, the gap between the spool and the valve bore forms a concentric annular clearance. Therefore, the flow rate of water through the concentric annular gap is given by:

where q₀ is the flow rate through the annular gap, r is the radius of the valve spool shoulder, l is the length of the annular gap, h is the height of the annular gap, µ is the absolute viscosity of the fluid, u₀ is the relative velocity between the spool and the valve port.

In the second phase, the effective width of the valve port is determined by the distance y between the edge of the spool shoulder and the edge of the annular cavity:

Since the valve port is annular, the size of the valve opening is given by:

where S₀ is the area of the valve port, α is the angle between the vertical line from the center of the spool shoulder arc and the line segment OM, y is the distance between the line segment OM and the radius of the arc.

At this point, the flow rate through the valve port is:

Sealing mechanism

In the ZXV, a sealing interface is established between the spool and the sealing rings to prevent water leakage. The sealing ring is a self-tightening extrusion-type seal, and its working principle relies on the elastic deformation of the sealing element to generate contact pressure between the spool and the sealing ring, thereby achieving a sealing effect. The contact pressure of the sealing element is determined by the pre-compression force from assembly and the pressure of the working medium. It primarily consists of two components:

When the sealing ring is installed in the sealing groove, the initial compression causes elastic deformation of the sealing ring, generating pre-compression stress σ0 on the sealing surface where the spool and the sealing ring are in contact, achieving the initial sealing effect.

As the fluid medium pressure p increases, the fluid pressure acts on the sealing element’s working surface, causing it to deform and be squeezed into the sealing gap, thereby enhancing the sealing performance.

Therefore, the contact pressure on the sealing surface between the spool and the sealing ring consists of the pre-compression stress and the working medium pressure, which can be expressed as:

where (σx)max is the maximum contact stress of the sealing ring under the corresponding working conditions; β is the contact pressure transfer coefficient or lateral pressure coefficient.

If the contact pressure on the sealing surface between the spool and the sealing ring is less than the working medium pressure in the sealing cavity, it will lead to sealing failure, resulting in leakage. Therefore, the maximum contact pressure criterion is used to determine whether the sealing has failed:

During the operation of the sealing structure, the fluid pressure p = σx acts on the exposed surface of the sealing element and increases the contact pressure to a higher value σp. This contact pressure σp must exceed the sealed fluid pressure p; otherwise, the fluid may enter the gap between the seal and the mating surface, leading to leakage.

Performance tests

The contact-type contact sealing structure of the spool valve proposed in this paper has not been documented in public reports to date, and its sealing structure constitutes the key distinguishing feature of the valve, which plays a vital role in the valve characteristics. Therefore, functional validation of the newly developed valve must first be conducted, and secondly, the valve’s dynamic characteristics and sealing performance should be experimentally evaluated.

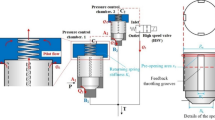

Measurement system

Figure 6 illustrates the schematic diagram of the test system for a water hydraulic directional valve. The measurement system is divided into the water hydraulic system and the measurement and control system. The water hydraulic system includes “a hydraulic pump - a directional valve - a hydraulic cylinder”. The system is powered by a water hydraulic reciprocating piston pump with a rated pressure of 25 MPa. The ZXV is used as the control element to control the action of the actuator’s hydraulic cylinder. The ZXV requires a pilot stage for control, so two 3/2 electromagnetic pilot valves (EPVs) are used to control the commutation of ZXV. The key components of ZXV are shown in the upper right corner of Fig. 6, labelled with the same numbers as in Fig. 4. The ZXV has a simple structure, few parts and low manufacturing cost. The valve body, bonnet and spool are made of 316 stainless steel, No.1 - No.4 sealing rings are made of polyurethane with high hardness and excellent friction performance. In addition, the measurement system contains a filter for removing fluid impurities, an accumulator for reducing system pressure fluctuations, a regulator for adjusting system pressure, and a shut-off valve for shutting off the flow of fluid in the pipeline. The hydraulic test system uses water as the transmission medium with a viscosity of 8.94 × 10− 4 Pa·s. The tests were conducted at a constant temperature of approximately 25 °C. In order to ensure a constant temperature, an air-cooled hydraulic cooler for fluid cooling was installed in the hydraulic system. Due to equipment limitations in the laboratory, the maximum pressure currently achievable by the water hydraulic system is 25 MPa. Therefore, the experimental validation of ZXV was conducted within a pressure range not exceeding this threshold under controlled operational conditions.

The measurement and control system consists of test elements and an industrial control computer. Four pressure sensors measure the pressure of each valve port, with a measuring range of 0–25 MPa, the LVDT displacement sensor measures ZXV spool’s displacement, with a measuring range of 0–30 mm and an accuracy of ± 1 μm. The hydraulic cylinder incorporates a piston rod-mounted displacement sensor, enabling real-time tracking of axial movement during operation. The system controls ZXV by powering electromagnetic pilot valve1 (EPV1) and electromagnetic pilot valve2 (EPV2) respectively from a 12 V DC supply. The industrial control computer integrates modules such as the upper computer, lower computer, power amplifier, and signal collector, which collect test data and control the power-supply and power-off of EPVs. Figure 7 shows a photograph of on-site testing as well as the test elements and sensors.

Experimental procedures

The loading procedure for the tested valve follows these steps: first, close Shut-off Valve 7 to isolate ZXV’s port P. The pressure regulator is then set to 0 MPa, and the pumping station is started. After several minutes of idle operation, the regulator is adjusted to the test pressure. Once Pressure sensor 6 confirms attainment of the preset pressure, Shut-off Valve 7 is opened to direct system pressure to ZXV’s port P. By activating EPVs via the industrial control computer, the commutation of ZXV is controlled, thereby regulating the displacement of the hydraulic cylinder’s piston rod. Throughout the process, real-time data is displayed and saved on the industrial control computer.

Results analysis

Dynamic characteristics

The spool of ZXV features a symmetric cylindrical structure, which is equivalent to a double-acting cylinder. The valve spool’s left and right working positions are structurally symmetric. In this experiment, ZXV’s P-B port connection is controlled by modulating the power supply of EPV2. This enabled precise control of the movement of the piston rod of the hydraulic cylinder.

Figure 8(a) - (e) illustrate the dynamic characteristics of ZXV at different pressures. Each test comprise three phases:

Phase I (0–10 s):

In this phase, EPV1 and EPV2 were de-energized, and no fluid or pressure actuated control cavities Q1 and Q2. Under the influence of spring force, the spool remained in the neutral position. Consequently, the inlet port P of ZXV remained closed.

Phase II (10 s onwards):

At the 10-second mark, EPV2 was energized, causing the spool of ZXV to move to the right position. This connects port P to port B, while port A was connected to port T1. Consequently, the piston rod of the hydraulic cylinder began moving. During this phase, the pressure at port P decreased, while the pressure at port B increased. When the hydraulic cylinder piston rod extended, the pressure at port A rose slightly, while the pressure at port T1 remained at 0 MPa.

Phase III (Transition to Phase III):

When the piston rod had moved a specified distance, deactivation of EPV2 triggered Phase III. At this point, pressures in cavities Q1 and Q2 were released, and the spool was centered by spring force. Port A and port B were simultaneously connected to port T1 and port T2, halting the movement of the piston rod. The pressure at port P returned to system pressure, while the pressures at ports A and B rapidly dropped to 0 MPa.

Figures 17, 18, 19, 20 and 21 in the Appendix present the repeated step test characteristics of ZXV at system pressures of 5, 10, 15, 20, and 25 MPa, respectively. The experimental results presented in Figs. 8(a)-(e) and Figs. 17, 18, 19, 20 and 21 collectively demonstrate that the newly developed ZXV prototype exhibits proper commutation functionality, achieving reliable directional switching operations within the 25 MPa pressure range. The ZXV can effectively control the operation of the hydraulic cylinder in the valve-controlled cylinder system. It successfully implements the Y-shaped neutral position function, whereby both ports A and B interface with return ports T1 and T2 when the spool is in the neutral position. Moreover, the displacement curves of the hydraulic cylinder piston rod in Figs. 8(a)-(e) demonstrate that the piston rod maintained a constant velocity during operation, indicating stable operation of ZXV under working conditions. The switching characteristics of ZXV are not significantly different from those traditional water hydraulic seat-type valves15.

Sealing performance in neutral position

To evaluate the sealing performance of ZXV when the inlet port P was closed, the spool was positioned in the neutral position. In this configuration, No. 2 and No. 3 sealing rings engaged with the middle shoulder, forming a sealed interface that effectively prevented pressure leakage from port P to ports A and B. The system pressures were sequentially set to 5, 10, 15, 20, and 25 MPa, with a 120-second hold time at each pressure level. Throughout the test, the pressure at port P remained stable.

Figure 9 demonstrates that the newly designed sealing structure maintains reliable sealing performance when the valve spool is in the neutral position. This ensures the stable operation of ZXV in the closed configuration, thereby ensuring system reliability and stability at varying operating pressures.

Sealing performance in working positions

To assess the sealing performance of ZXV when the valve ports were open, EPV2 was energized, causing the spool of the main valve to move to the left position. In this state, port P was connected to port B, and port A was connected to port T1. When the piston rod reached its limit position, the pressure at port P equaled that at port B, with EPV2 remaining energized. The No. 2 and No. 4 sealing rings engaged with the middle and right shoulders of the spool respectively, forming a sealing area to prevent pressure leakage. The pressure was maintained for 120 s, with stable pressure at port P and no observable drop, as demonstrated in Fig. 10.

When EPV1 was energized, the spool moved right to connect port P with port A, and port B with port T2. Upon the piston rod reaching its limit position, the pressure at port P was equivalent to that at port A, while EPV1 stays energized. The No. 1 and No. 3 sealing rings contacted the left and middle shoulders respectively, forming a secondary sealing interface. The pressure was held constant for 120 s, as shown in Fig. 11.

Results demonstrate that ZXV effectively prevents pressure leakage and maintains excellent sealing performance in both operating positions at varied pressure conditions.

Step response characteristics

After adjusting the spool of the main valve to the neutral position, the actuation sequences of EPV1 and EPV2 were controlled to achieve incremental spool actuation. The displacement of the spool at the neutral position was set to 0 mm (zero-reference position), with its reciprocating stroke ranging from − 10 mm (left position) to + 10 mm (right position). System pressures of 5, 10, 15, 20, and 25 MPa were applied during testing. Table 1 documents the energized and de-energized states of EPVs over a 20 s interval.

Figure 12 depicts the step response characteristics of ZXV. The results indicate that at the 2-s mark, EPV2 was energized. At a system pressure of 5 MPa, the spool moved from the 0 mm to -10 mm, with a full stroke opening time of approximately 0.4 s. At pressures of 10, 15, 20, and 25 MPa, the valve opened in approximately 0.25 s.

At the 5-s mark, EPV2 was de-energized, and the valve spool returned from the − 10 mm position to the neutral position. However, observations show that the spool exhibits an incomplete return to the zero-reference position at all pressure levels. When the system pressure is 5 MPa, the deviation from the neutral position is about 0.4 mm; at 10 MPa, approximately 0.8 mm; at 15 MPa, around 1.5 mm; and at 20 MPa and 25 MPa, about 2.7 mm. This correlation demonstrates that increased system pressure directly amplifies the deviation of the spool from the neutral position after returning from the working position.

At the 10-s mark, EPV1 was energized, and the spool moved from its current position to + 10 mm. At 5 MPa, the full stroke opening time is around 0.4 s; at 10, 15, 20, and 25 MPa, the opening time is about 0.25 s.

At the 13-mark, EPV1 was de-energized, and the valve spool returned from the + 10 mm to the neutral position. Similarly, the spool exhibited incomplete return to the neutral position at all pressure levels. The mechanism governing this phenomenon is illustrated in Fig. 13.

When the spool is in the neutral position, No. 2 sealing ring and No. 3 sealing ring make contact with the middle shoulder surface of the spool, effectively sealing the passage between port P and ports A and B. The valve port of ZXV features a negative opening, with the width z of the middle shoulder on the valve spool exceeding the width D of the undercut groove at port P. This design ensures sufficient contact area between the middle shoulder and both No. 2 and No. 3 sealing rings, guaranteeing an effective seal in the neutral position.

For instance, when ZXV is opened and the spool switches to the right position from its neutral position, it initially travels a distance Xs, during which port P remains close. This distance34known as the “dead zone” or “sealing area”, persists until the middle shoulder of the spool separates from No. 2 sealing ring. At this point, port P is connected to port A, and port B is connected to port T2. During this motion, No. 1 sealing ring forms a sealing pair with the left shoulder of the spool, while No. 3 sealing ring remains in contact with the middle shoulder, and No. 4 sealing ring does not engage any spool shoulder.

When the valve spool moves from the right position toward the neutral position, the middle shoulder gradually approaches and contacts No. 2 sealing ring, entering the sealing area. Simultaneously, No. 1 sealing ring separates from the left shoulder, and port A connects to port T1. Since the sealing rings are composed of nonlinear hyperelastic materials, their deformation depends on fluid pressure. The No. 2 sealing ring deforms under both fluid pressure and spool force, increasing return resistance.

Once the force acting on the sealing ring—sealing resistance, fluid pressure, and spring force reaches equilibrium, the spool stops moving, preventing it from fully returning to the neutral position after switching. Moreover, as system pressure increases, the fluid force on the sealing ring also increases, leading to greater deformation of the sealing ring, which further hinders the spool from returning to its neutral position. Under dynamic sealing conditions, elevated pressure may extrude the sealing ring33. The extrusion will cause the seal deformation, producing the resistance to the movement of the spool.

It is worth noting that at pressure conditions of 20 and 25 MPa, the displacement curves of the spool show a high degree of consistency, as shown in Fig. 12. This phenomenon indicates that as the system pressure increases, the influence of the deformation of the sealing ring caused by the fluid pressure on the movement resistance of the valve spool is significantly weakened, reflecting that this sealing structure can still maintain a stable form under high-pressure conditions.

As shown in Fig. 14, the mean deviation of ZXV spool returning to the neutral position from lateral positions is measured under pressures ranging from 5 to 25 MPa. Tables 3 and 4 in the Appendix summarize the mean, maximum, and minimum values of the spool’s lateral-to-neutral deviation during 100 repeated directional valve cycling tests. Error bars (representing the full range of deviation) are added to the mean values, showing a range of approximately 0.1 mm (± 0.05 mm). The deviation values for the left-to-neutral (L-Neu) and right-to-neutral (R-Neu) positions show statistically insignificant variations.

These differences can be attributed to dimensional tolerances in valve port machining and sealing ring production. Furthermore, to facilitate sealing ring installation within the groove dimensions. the axial length of the sealing rings is intentionally reduced relative to the groove dimensions. This design provides axial clearance to the sealing rings, contributing to slight observed deviations.

Importantly, the time required for the spool to move from the working positions to the neutral position is statistically equivalent to the return time from the initial position. This demonstrates consistent stability in system response time during switching operations.

The sealing performance of the spool when offset from neutral position

Figure 15 illustrates the movement of the spool from the neutral position to the right position and then back to the neutral position. The purpose is to test the sealing performance as the spool returns from working to neutral position while not fully maintaining neutral alignment under varying pressure conditions.

The spool was initially adjusted to the neutral position, at which time port P was closed, set the system pressure to 5, 10, 15, 20, and 25 MPa respectively, each pressure level was maintained for 10 s with stable system pressure. At the 10-s mark, EPV1 was energized, liquid filled the cavity Q1, the left side of the valve spool was pushed by the liquid pressure (causing it to move to right), port P and port A were connected, and the system pressure decreases due to the hydraulic circuit being connected. At the 20-s mark, EPV1 was de-energized, cavity Q1 depressurized, and the spool returned to the neutral position via spring actuation.

Under five system pressure conditions, the main valve spool does not return to zero-reference position. At this stage, the system pressure recovers to the level equivalent to the 0–10 s phase; this pressure level maintains stability for the subsequent 120 s, showing no downward trend. This phenomenon occurs because when the spool is in the right position, No. 1 sealing ring and the No. 3 sealing ring establish dynamic sealing interfaces with the spool surface, creating redundant sealing zones; the resultant pressure differential maintains positive pressure locking through system hydraulic forces. During cavity Q2 depressurization, the spool is driven to the left position by spring force to regain neutral position, a process wherein No. 1 sealing ring disengages from the spool surface while the central shoulder’s left flank gradually establishes contact with No. 2 sealing ring. This contact interface develops elastic deformation under port P’s fluid pressure, ultimately generating friction resistance through contact between the deformed sealing element and the spool’s medial shoulder.

As derived from Formula (12), with the increase of fluid pressure, the sealing ring deformation variable increases, thereby increasing friction, which directly elevates spool reset resistance. According to the static equilibrium conditions, when the spool reaches static equilibrium, it will no longer move. At this point, although the spool has deviated from the initial position, pressurized contact between the spool and the sealing rings is established. Under fluid pressure, the sealing rings interface between the spool and the sealing rings that exceeds the fluid pressure. This prevents fluid leakage while ensuring that the valve maintains sealing even when the spool is not in the neutral position. Therefore, excellent sealing performance is guaranteed despite the spool being displaced from the initial position.

Figure 16 illustrates the movement of the spool from the neutral position to the left position and then back to the neutral position. The spool was positioned in the neutral configuration, effectively isolating port P. System pressure was sequentially calibrated to 5, 10, 15, 20, and 25 MPa through controlled adjustments, with each pressure level sustained for a 10-seconds stabilization interval. Throughout all test phases, the system maintained strict pressure integrity with no observable deviation from set parameters.

The spool was initially positioned in the neutral position. After a 10-seconds stabilization period, EPV2 was energized, inducing leftward displacement of the spool that established hydraulic connection between port P and port B of ZXV. At the 20-s mark, EPV2 de-energization triggered spring-driven spool return. However, complete return to the initial position was not achieved. This coincided with a gradual pressure increase in the system. Throughout the subsequent 120 s monitoring phase, the system pressure maintained stable values without demonstrating any pressure decay characteristics.

During the spool’s motion, sequential disengagement from No. 4 sealing ring and subsequent engagement with No. 3 sealing ring are observed. The sealing interface demonstrates effective leakage prevention performance, with no detectable fluid pressure loss. This behavior aligns with the sealing principles previously described as Fig. 15, thereby requiring no reiteration.

These experimental results confirm that the reciprocating seal configuration developed in this study maintains reliable sealing integrity under specified operational conditions, effectively preventing fluid pressure loss throughout the test duration.

Discussions

Comparison of the new ZXV with existing water hydraulic directional valves

Table 2 shows comparison of the structure and performance parameters of the existing water hydraulic directional valves. At present, there are two main structures of water hydraulic directional valves: one is the seat-type valve structure, whose valve core is a ball valve structure or cone valve structure; the other is the spool valve structure.

The seat-type valve adopts the sealing method of line-line contact and line-face contact, which belongs to contact sealing, and has better sealing performance in water medium35,36enabling higher pressure resistance.

In hydraulic systems, the three-position four-way function of a directional valve is often required to control actuators such as hydraulic cylinders. In the seat-type valve structure, a single valve core can only realize a 2/2 function, requiring four 2/2 seat-type valves in parallel through coordinated operation to realize 4/3 function. Alternatively, two 2/2 cores may be combined to form a 3/2 valve, with two such valves in parallel achieving 4/3 function.

When controlling an actuator, the seat-type valve structure requires combining multiple valve cores. The combination simultaneously increases control complexity, structure bulkiness, and manufacturing costs, consequently limiting the widespread application of water hydraulics.

A spool valve with simpler structure can realize three-position four-way functionality using a single spool. However, its clearance sealing design poses high leakage risks in water-based systems and restricts operational pressure ranges. Previous studies indicate that water hydraulic spool valves have maximum pressure limits of 16 MPa. Exceeding this threshold necessitates drastic clearance reduction (requiring advanced manufacturing techniques and specialized materials) which escalates production costs. Furthermore, diminished clearances may induce spool-valve sleeve sticking and wear21,37.

The novel ZXV developed in this study addresses these limitations through a 4/3 spool valve configuration with unique sealing. It combines structural simplicity, minimal leakage from contact seals, and higher pressure tolerance compared to conventional water hydraulic valves.

Benefiting from its sealing innovation, ZXV permits wider manufacturing tolerances while relaxing precision requirements between spool and valve bore. This eliminates the need for exotic materials, simplifies production and assembly processes, and enhances adaptability for diverse hydraulic applications.

Conclusions

This study proposes a novel three-position four-way water hydraulic spool valve (ZXV), whose core innovation is the contact-type dynamic sealing structure design. By arranging sealing rings between adjacent valve chamber ports, this structure utilizes the combination of different spool shoulders and sealing rings during spool movement to form matched sealing pairs, thereby achieving reliable sealing for each valve port at different working positions.

Based on this innovative design, a ZXV prototype was successfully manufactured, and a water hydraulic valve-controlled cylinder test bench was constructed for systematic testing. Dynamic test results demonstrate that ZXV features a reasonable structural design that is capable of realizing the expected directional control function and Y-type neutral position configuration, while maintaining stable operation at pressures up to 25 MPa in water hydraulic systems.

Sealing performance tests show that the valve maintains constant pressure without leakage phenomenon at both neutral and working positions, fully verifying its excellent sealing capability. Step response test data indicate an opening response time of 0.4 s at 5 MPa, while the response time shortens to 0.25 s in the 10–25 MPa pressure range. Notably, incomplete spool return to the neutral position was observed during testing. Analysis confirms this phenomenon results from elastic deformation of sealing rings under fluid pressure, but it does not affect the valve’s neutral sealing performance as the spool remains within the neutral dead zone.

The successful development of ZXV breaks through the 16 MPa pressure limitation of traditional water hydraulic spool valves, elevating operational thresholds to 25 MPa. This innovation not only expands the application scope of water hydraulic valves but also demonstrates potential to reduce manufacturing costs, providing crucial technical support for developing environmentally friendly water hydraulic systems.

Data availability

The authors declare that the data supporting the results of this study are available within the article.

References

Wang, S. Hydraulic excavator track supporting wheel oil leakage fault analysis. Engineering Failure Analysis. 164, 108680 (2024).

Bacosa, H. P. et al. Polycyclic aromatic hydrocarbons (PAHs) and putative PAH-degrading bacteria in Galveston bay, TX (USA), following hurricane Harvey (2017). Environ. Sci. Pollut Res. 27, 34987–34999 (2020).

Dominguez, J. J. A., Bacosa, H. P., Chien, M. F. & Inoue, C. Enhanced degradation of polycyclic aromatic hydrocarbons (PAHs) in the rhizosphere of Sudangrass (Sorghum × drummondii). Chemosphere 234, 789–795 (2019).

Kadri, T. et al. Biodegradation of polycyclic aromatic hydrocarbons (PAHs) by fungal enzymes: A review. J. Environ. Sci. 51, 52–74 (2017).

Montas, L., Ferguson, A. C., Mena, K. D. & Solo-Gabriele, H. M. Categorization of nearshore sampling data using oil slick trajectory predictions. Mar. Pollut. Bull. 150, 110577 (2020).

Chao, J., Liu, C., Li, Y., Lin, X. & Yan, Y. Characteristics of the sea ice reflectance spectrum polluted by oil spills based on field experiments in the Bohai sea. Acta Oceanol. Sin. 36, 73–79 (2017).

Chen, H. Numerical study of underwater fate of oil spilled from deepwater blowout. Ocean Engineering. 110, 227–243 (2015).

Lim, G. H., Chua, P. S. K. & He, Y. B. Modern water hydraulics—the new energy-transmission technology in fluid power. Appl. Energy. 76, 239–246 (2003).

Yang, X. Adaptive fuzzy PID control of high-speed on-off valve for position control system used in water hydraulic manipulators. Fusion Engineering and Design. 203, 114437 (2024).

Zhou, S. Adaptive robust control design for underwater multi-DoF hydraulic manipulator. Ocean Engineering. 248, 110822 (2022).

Ren, H. et al. Dynamic impact experiment and response characteristics analysis for 1:2 reduced-scale model of hydraulic support. Int. J. Min. Sci. Technol. 31, 347–356 (2021).

Han, M., Liu, Y., Wu, D., Tan, H. & Li, C. Numerical analysis and optimisation of the flow forces in a water hydraulic proportional cartridge valve for injection system. IEEE Access. 6, 10392–10401 (2018).

Liu, X., Nie, S., Li, G. & Yin, F. Research on the dynamic characteristics of seawater hydraulic cartridge-type 4/3 directional valve. J. Braz Soc. Mech. Sci. Eng. 40, 11 (2018).

Zhang, H., Liao, Y., Tao, Z., Lian, Z. & Zhao, R. Modeling and Dynamic Characteristics of a Novel High-Pressure and Large-Flow Water Hydraulic Proportional Valve. Machines. 10, 37 (2022).

Zhao, R. et al. Dynamics and experimental study of a novel proportional directional valve with displacement feedback groove controlled by high-speed switching valves. Flow Meas. Instrum. 100, 102711 (2024).

Ye, Y., Yin, C. B., Li, X. D., Zhou, W. & Yuan, F. Effects of groove shape of Notch on the flow characteristics of spool valve. Energy. Conv. Manag. 86, 1091–1101 (2014).

Zhang, S., Aung, N. Z. & Li, S. Reduction of undesired lateral forces acting on the flapper of a flapper–nozzle pilot valve by using an innovative flapper shape. Energy. Conv. Manag. 106, 835–848 (2015).

Lisowski, E. & Filo, G. CFD analysis of the characteristics of a proportional flow control valve with an innovative opening shape. Energy. Conv. Manag. 123, 15–28 (2016).

Majdič, F., Pezdirnik, J. & Kalin, M. Experimental validation of the lifetime performance of a proportional 4/3 hydraulic valve operating in water. Tribol. Int. 44, 2013–2021 (2011).

Yinshui, L., Yousheng, Y. & Zhuangyun, L. Research on the Flow and Cavitation Characteristics of Multi-Stage Throttle in Water-Hydraulics. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering 220, 99–108 (2006).

Zhang, K., Liu, Y., Gu, Y., Wang, J. & Ruan, X. Valve stiction detection using multitimescale feature consistent constraint for Time-Series data. IEEE/ASME Trans. Mechatron. 28, 1488–1499 (2023).

Zum Gahr, K. H., Mathieu, M. & Brylka, B. Friction control by surface engineering of ceramic sliding pairs in water. Wear 263, 920–929 (2007).

Guo, F., Tian, Y., Liu, Y. & Wang, Y. Ultralow friction between cemented carbide and graphite in water using three-step ring-on-ring friction test. Wear 352–353, 54–64 (2016).

Mallya, R., Shenoy, S. B. & Pai, R. Steady state characteristics of misaligned multiple axial groove water-lubricated journal bearing. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology 229, 712–722 (2015).

Guan, Z. et al. Friction and wear characteristics of CF/PEEK against 431 stainless steel under high hydrostatic pressure water lubrication. Mater. Design. 196, 109057 (2020).

Chengpeng, W. et al. Research status and prospects of tribological behaviors of key friction pairs of materials in marine equipment. Materials Science. 27, 148–154 (2021).

Zhang, J. Flow control of a proportional directional valve without the flow meter. Flow Measument and Instrumentation. 67, 131–141 (2019).

Park, S. H. Development of a proportional poppet-type water hydraulic valve. Proc. Institution Mech. Eng. Part. C: J. Mech. Eng. Sci. 223, 2099–2107 (2009).

Wu, D. et al. Numerical and experimental study of reciprocating seals in seawater hydraulic variable ballast components for 11,000-m operation. Tribol. Trans. 66, 92–103 (2023).

Tao, Z., Liao, Y., Zhang, Q. & Lian, Z. Friction characteristics and failure mechanisms of O-ring seals under lubrication of water-based emulsion. Eng. Fail. Anal. 169, 109226 (2025).

Liu, Y. et al. Seawater hydraulics: from the sea surface to depths of 11000 meters. Sci. China Technol. Sci. 65, 2178–2189 (2022).

Yang, J. et al. High-performance crosslinked polyurethane with fatigue resistance, anti‐wear for sealing. J. Appl. Polym. Sci. 141, e54894 (2024).

Mahankar, P. S., Dhoble, A. S. & Prabhu, R. Experimental investigation of polyurethane seal failure used in hydraulic system. Eng. Fail. Anal. 150, 107319 (2023).

Zhang, J., Pan, X., Guo, J., Bian, J. & Kang, J. Analysis of the static and dynamic characteristics of the electro-hydraulic pressure servo valve of robot. Sci. Rep. 13, 15553 (2023).

Yang, Y., Zhang, Z. M., Chen, Y. L. & Gong, Y. J. Simulation analysis and experimental research on mechanical properties of water hydraulic ball Poppet valve. J. Braz Soc. Mech. Sci. Eng. 45, 36 (2023).

Han, M. A numerical investigation in characteristics of flow force under cavitation state inside the water hydraulic Poppet valves. International Journal of Heat and Mass Transfer. 111, 1–16 (2017).

Majdič, F., Velkavrh, I. & Kalin, M. Improving the performance of a proportional 4/3 water–hydraulic valve by using a diamond-like-carbon coating. Wear 297, 1016–1024 (2013).

Author information

Authors and Affiliations

Contributions

ZX responsible for conceptualization , investigation and project administration.FXJ responsible for formal analysis, writing origination draft . LJW responsible for methodology and formal analysis.CKL responsible for software and visualization. GDY responsible for formal analysis visualization. WZQ responsible for software and visualization. XHY responsible for formal analysis and software. GMM responsible for visualization and formal analysis.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

See Figs. 17, 18, 19, 20 and 21; Tables 3 and 4.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, X., Fan, X., Liang, J. et al. Experimental study on a three-position four-way water hydraulic directional valve with a novel sealing structure. Sci Rep 15, 20561 (2025). https://doi.org/10.1038/s41598-025-05506-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-05506-y