Abstract

This study introduces a novel application of non-contact computer vision technology to simulate and analyse the impact of traffic loads on deformation in soft soil foundation pits, using vehicle flow data captured by roadside cameras. The research employs the YOLO (You Only Look Once) detector coupled with a multi-object tracking algorithm for vehicle classification and tracking. Following statistical analysis of traffic parameters, Monte Carlo sampling is utilised to simulate actual traffic loads. These loads are then input into a PLAXIS 3D finite element model to examine their effects on support structures and soil deformation. The comparison of measured and simulated data confirms the accuracy of the traffic load simulation model. Results demonstrate that vehicular loading can increase pit deformation by up to 48.7%, with significant impacts extending over 101.3 m along the site, significantly influencing engineering planning and construction management. This study provides a scientific basis for safety assessments in urban infrastructure projects, demonstrating the potential of non-contact machine vision technology for analysing the impact of traffic loads on the safety of adjacent excavation projects.

Similar content being viewed by others

Introduction

As urban development accelerates, the exploitation of underground spaces is increasingly vital, leading to the increment of the excavation pit projects. Urban pit projects are typically conducted in complex environments influenced by municipal infrastructure, buildings, and vehicle loads from surrounding roads. These factors can adversely affect the stability of excavations and the safety of construction operations, and thus warrant significant attention1,2,3.

Unlike the static loads from surrounding structures, traffic loads are highly correlated with actual traffic flow characteristics, exhibiting substantial spatial randomness and temporal variability1,2,4. Excavation of foundation pits disrupts the initial stress balance of the soil, leading to the generation of active and passive earth pressures on the support structures5,6,7. However, traffic loads on nearby roads will impact the existing stress states of the excavation soil, causing a series of mechanical behavioural changes8,9,10. If these are not promptly addressed, unexpected deformations may occur, posing threats to the safety of the pit’s support structures11. Therefore, the risks associated with traffic loads on excavation projects demand heightened attention.

Currently, scholars commonly employ field measurements, theoretical vehicle load models, or simulations using finite element software to study the impact of vehicle loads on foundation pits12,13,14,15,16,17,18,19,20,21,22. In field testing, Sulaiman et al.18 developed an empirical model based on field data using multivariate regression analysis that considers soil dynamics, pavement characteristics, and traffic parameters as independent variables to assess the impact of nearby lane loads on the deformation characteristics of soft ground. Liu et al.15 constructed a test box frame in the laboratory, measuring 1.76 m in length, 0.3 m in width, and 1.48 m in height, with wheels to simulate the impact of vehicle loads on backfill settlement and analyse their mechanisms. Zhang et al.21 observed that changes in soil pressure in deep excavation projects in silty clay foundations are related to vehicle speed and load, with traffic loads potentially increasing the soil pressure behind the retaining piles by up to 10% within a depth of 0–3 m.

In theoretical modelling, Li et al.14 treated vehicle loads as static concentrated loads and used Boussinesq’s solutions and the method of layers to determine the impact depth of vehicular dynamic and overload conditions. Singh and Chatterjee17 simulated the effects of vehicle loads using a pseudo-static approach, utilising finite difference software to analyse the settlement and deflection of cantilever sheet piles under vehicle loading. Tang et al.19 divided vehicle loads into static and dynamic components, representing the dynamic vehicle loads as harmonic loads based on the differential equations of motion for a two-degree-of-freedom vibratory system. Rao et al.16 introduced a dynamic load coefficient and revised the initial rupture angle specified in the standards to propose an improved equivalent thickness method for vehicle load modelling, to analyse the anti-tilting stability of unsaturated soil pits under vehicle loads.

Finite element analysis technology offers an efficient and accurate approach for underground excavation projects and is commonly used to assess the reliability and stability of soft soil pit engineering23,24,25. In finite element analysis, Xu et al.20 employed Midas/GTS software to analyse the impact of vehicle loads on the support system of foundation pits, discovering significant effects during construction, necessitating timely reports on vehicle load impacts. Ding et al.13 compared actual monitoring data with simulations performed using Midas GTS software, finding that the closer the vehicle load to the edge of the pit, the greater its impact. Bao et al.12 simulated the characteristics of soil deformation under train dynamic loads using ABAQUS, noting that considering vehicle loads increased the surface settlement of the pit by 49% and the maximum horizontal displacement at the pile top by 51%. Zhao et al.22 introduced a vehicular harmonic wave model in finite element simulations, discovering that vehicle loads significantly affect the axial force of the anchor rods within a 7 m range outside the pit, with different vehicle speeds causing additional deformations of up to 12 mm in the support piles. Based on the aforementioned research, it is evident that considerable studies have been conducted on the impacts of vehicular loads on excavation projects. However, field-based studies on the impact of traffic loads on excavation projects are resource-intensive and time-consuming. Due to the high correlation between traffic loads and actual traffic flow parameters, theoretical models often struggle to align effectively with real conditions, and the simulated results of theoretical vehicle load models input into finite element software often differ from actual outcomes. Particularly given the heavy loads from construction vehicles often near foundation pit sites, this discrepancy can be even more pronounced.

Non-contact machine vision technology offers a new potential method for the statistical analysis of traffic parameters26. Specifically, vehicle datasets captured via monitoring cameras can be utilised to train detectors using deep learning algorithms27. Once trained, these detectors facilitate vehicle detection and target tracking28. This method eliminates the need for laborious manual counts and field measurements, allowing for the accurate determination of the real-time spatial distribution of vehicle loads. It has already been successfully implemented in the analysis of bridge vehicle loads and deformation monitoring29,30,31,32. Consequently, utilizing non-contact machine vision technology, based on data collected from roadside surveillance cameras to generate real-time traffic load data, undoubtedly enables a more accurate analysis of the impact of vehicle loads on excavation projects. However, current literature on the application of non-contact machine vision technology to analyse the stability and safety of excavation projects in soft soil areas adjacent to roads is scarce. Existing analytical approaches often rely on static data or traditional standard models, which do not accurately depict the real-time traffic conditions on roads.

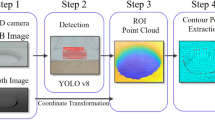

Therefore, this paper proposes a computer vision detection technique, utilising the roadside camera set by our team to collect data on vehicle types, numbers, and speeds on roads adjacent to the foundation pit project, which were statistically analysed to establish the probability distribution of different traffic load parameters. A vehicular load model based on real traffic data and constructed using Monte Carlo sampling is then input into finite element software to analyse the effects of traffic loads on the deformation of support structures and soil during the excavation of a long soft soil foundation pits. The novelty of our study is to apply non-contact machine vision technology to the analysis of stability and safety during excavation processes near roadways. This technology enables the real-time capture and analysis of road traffic loads, enhancing the accuracy of simulations of traffic load responses on pit deformation. By comparing with traditional methods, our new model demonstrates advantages in predicting deformations caused by traffic on the ground and structures, providing a reference for application in related engineering fields. The framework of this paper is depicted in Fig. 1, and the content is organised as follows:

-

1.

Section II introduces the combined YOLO-v5 and Deep SORT algorithms for vehicle recognition and tracking, specifically using the YOLO (You Only Look Once) detector for vehicle type detection and the Deep SORT (Deep Simple Online and Realtime Tracking) algorithm for simple online and real-time multi-target tracking, vehicle number, and vehicle speed estimation.

-

2.

Section III introduces the correlation between actual measured vehicle weights and vehicle types, performing statistical analysis on the probability distribution of vehicle weight and speed for different vehicle types. A Monte Carlo sampling technique is used to simulate the temporal variation of vehicle load based on real traffic flow data.

-

3.

Sections IV and V detail the establishment of the finite element model for the foundation pit of a real excavation project using PLAXIS 3D and analyse the deformation responses of both the pit soil and its support structures before and after the introduction of the actual traffic load.

Traffic flow Estimation using YOLOv5 and DeepSORT algorithms

Vehicle detection with YOLOv5 algorithm

Structure of YOLO-v5

Real-time vehicle detection is crucial for acquiring spatio-temporal information of vehicles. The YOLO model, the pioneer in single-stage detectors, has seen significant enhancements in accuracy and speed with its latest version33. In choosing the version of YOLO, the requirements of the engineering site must be considered: it should provide high accuracy and fast detection performance with limited computing resources. Therefore, this study employs YOLO-v5 as the foundational technology for vehicle detection. The primary features of YOLO-v5 are its excellent real-time processing capabilities, lower hardware requirements, and since its introduction in 2020, its codebase has been extensively tested and continuously improved, minimizing the risk of unforeseen issues34,35,36. Its maturity and stability can ensure the smooth progression of engineering projects. Therefore, this study employs YOLO-v5 as the foundational technology for vehicle detection. Figure 2 illustrates the architecture of YOLO-v5, which is divided into three main components: the Backbone, the Neck, and the Prediction network. The input data were derived from video captured by the traffic monitoring camera strategically positioned adjacent to the roadway by our team. The cameras used were manufactured by Hikvision, model DS-2CD2T46XM-LGLE, capable of capturing video at a resolution of 1080p. The Backbone network incorporates the Focus and CSPDarknet modules to efficiently extract features from input data. The Neck network utilizes various convolution blocks and upsampling techniques to merge and process feature maps of different scales. The Prediction network processes features from the Neck, outputting the category and bounding box coordinates for each detected object. Detailly, the Focus module enhances the backbone’s capability to extract data features more effectively. The CSPDarknet module, developed within the Darknet framework using the Cross-Stage Partial (CSP) strategy, includes the CSB and C3 components32. The CSB component, consisting of convolutional neural networks, batch normalisation, and SiLU activation functions, extracts vehicle features from feature maps37. As feature maps enter the C3 component, part of them undergo convolution to form new feature maps while the rest merge directly with these new feature maps. Additionally, the Spatial Pyramid Pooling (SPP) module enables significant traffic background features to be extracted without noticeably reducing network speed. Thus, the CSPDarknet module efficiently reduces the dimensionality of feature maps.

In the prediction phase of YOLO-v5, multi-class classification and bounding box regression occur at various scales. Calculating the loss function is critical to address the differences between predicted outcomes and actual ground truth and to adjust weights accordingly. The YOLO-v5 loss function is divided into three components: bounding box regression loss, classification loss, and confidence loss, expressed as follows:

.

Here, Symbols K, S², and B represent the output feature maps, the number of cells in each feature map, and the number of anchors per cell, respectively. The term α* indicates the weights for respective terms, with values set at αbox=0.05, αobj=0.7, and αcls = 0.3. IIobj kij denotes the output sample from the k-th feature map; tp and tt refer to the predicted and actual vectors, respectively; and αbalance k adjusts the weighting of output feature maps across different scales.

In bounding box regression, the Complete Intersection over Union (CIoU) loss is utilised instead of the Mean Squared Error (MSE) method traditionally used in previous YOLO versions38. The CIoU loss accounts for overlap, centroid distance, and aspect ratio, providing better convergence speed and accuracy:

.

Here, do represents the Euclidean distance between the centroids of the actual and predicted boxes, dc is the diagonal distance of the smallest enclosing box covering both the actual and predicted boxes, IoU stands for the intersection over union, and v measures the consistency of the aspect ratio39. After performing multi-class classification and bounding box regression in the feature maps, multiple prediction boxes are generated for the detected objects. Non-Maximum Suppression (NMS) is used to filter these prediction boxes.

Establishment of the database

For training the YOLO-v5 detector to achieve the desired detection performance, a dataset with an abundant variety of categories and labels is important. This study utilised a dataset containing 2,000 vehicle images, which were extracted from video footage captured by the roadside camera we installed at the construction site of the foundation pit. The dataset is randomly divided into a training set (80% of the total data) and a test set (20% of the total data). As shown in Table 1, vehicles are classified into four types based on the actual road traffic flow: Type 1, Type 2, Type 3, and Type 4. Additionally, to enhance the generalisation capability of the detection model, mosaic data augmentation techniques were applied to preprocess the vehicle images.

During the training process of YOLO-v5, the model underwent 60,000 iterations, with Stochastic Gradient Descent (SGD) employed as the primary optimisation strategy to adjust parameters. The momentum was set at 0.9, the batch size was fixed at 15, and the initial learning rate was set at 0.001. Figure 3 (a) displays the precision-recall curves for the four vehicle types, and Fig. 3 (b) presents the Average Precision (AP) for each vehicle type, indicating an overall AP of 86.67%. verifying the accuracy of the model. Table 2 provides data recorded over a three-month period using the trained model, detailing the changes in the number and proportions of different types of vehicles. It reveals that Type 1 vehicles are the most common, while heavy vehicles (Type 3 and Type 4) account for approximately 10% of the total. The YOLO-v5 model runs on a computational setup that includes Pytorch 1.10 as the deep learning framework, CUDA version 11.4, and OpenCV version 4.5.1. The hardware utilised for this study comprises an Intel(R) Core i7-10750 H processor at 2.6 GHz, paired with an NVIDIA GEFORCE RTX 2070 8 GB graphics card.

Multi-target tracking with deep SORT algorithm

Multi-vehicle tracking

As previously discussed, the YOLO-v5 detector is capable of identifying vehicle types in every frame of the surveillance video. To track vehicle trajectories, it employs multi-target tracking technology to calculate the match degree between consecutive frames. In this study, the Deep SORT algorithm was utilised40. The algorithm employs Matching Cascade to match newly detected vehicles with existing tracked vehicles and utilises a Kalman Filter to predict the likely positions of the tracking targets in the next frame. Unmatched tracks are either deleted or identified as new vehicles. The entire framework is depicted in Fig. 4.

The Deep SORT algorithm employs two distinct metrics for tracking: the Mahalanobis distance, which offers a short-term prediction of object positions using their movement patterns to indicate motion correlation; and the cosine distance, which incorporates visual attributes into the tracking mechanism to effectively handle long-term occlusions by matching the appearance characteristics of objects. The formulation of the Mahalanobis distance is as follows:

.

where dj represents the position of the j-th detection box, yi indicates the position predicted by the i-th tracker, and Si is the covariance matrix between the predicted position and average tracking position. The cosine distance calculation is expressed as:

.

where rj is a normalised appearance descriptor with |rj| = 1. Given the Kalman filter’s role in only providing a rough estimate of object positions within the image space, the cosine distance complements the Mahalanobis distance in various aspects of Deep SORT. A linear weighted sum of these two metrics is employed:

.

Here, the weighting parameter λ is set to zero in this study. This method effectively merges motion and appearance information to optimise tracking performance.

Calculation of the vehicle speed

The conversion of pixel coordinates in surveillance videos to real-world coordinates enables the acquisition of spatio-temporal data of vehicles. This coordinate transformation encompasses pixel, image, camera, and world coordinate systems, and is articulated as follows32:

.

Here, Zc represents the distance between the world coordinate system and the camera coordinate system. The pixel coordinates u and v indicate the row and column positions, respectively, while dx and dy denote the actual pixel dimensions along the u-axis and v-axis. The camera’s focal length is represented by f. The coordinates Xc, Yc, Zc in the camera system and Xw, Yw, Zw in the world system are defined respectively. R is a three-dimensional orthogonal matrix, T is a translation matrix, and M is a projection transformation matrix. The matrix M, derived from image coordinates and world reference points, incorporates twelve parameters, setting m34 to 1 and leaving eleven as unknowns. As the road surface is approximated as a planar in the world coordinate system, Zw is considered constant, reducing the unknown variables from eleven to eight. This optimisation simplifies the transformation relation as follows31:

.

Figure 5 illustrates the use of four pairs of reference points, A1, A2, A3, and A4, to establish the projection transformation matrix M. Additional points, A5 and A6, are used to validate the accuracy of M. Thus, the pixel and world coordinates of these six reference points enable precise determination of vehicle positions within the world coordinate system.

The method for calculating vehicle speed from the position changes of vehicles across consecutive video frames is as follows31:

.

Here, Fn represents the total number of frames capturing the vehicle’s movement, F1 is the initial frame, and fFPS is the frame rate of the video, set to twelve frames per second. The world coordinates of each frame’s vehicle are Xwi,Ywi . To validate the model’s accuracy, radar speed measurement is used in practice to gauge vehicle speed. Figure 6 compares the calculated vehicle speeds with those measured by radar. Table 3 records a comparison between actual measurements and calculated values for 1,000 vehicles (with an equal number of each vehicle type), demonstrating minimal discrepancies between them and confirming the accuracy required for engineering applications.

Dynamic vehicle load model of traffic flow based on measured data

Distribution of different vehicle parameters

To accurately simulate time-varying traffic loads caused by vehicles, it is crucial to obtain statistical distributions of vehicle speed and weight for different types. Due to the high correlation between vehicle types and vehicle weights41it is necessary to obtain the weight distribution for different types of vehicles. This allows for the association of vehicle weight with vehicle type information. For measuring vehicle weight, a trench measuring 0.5 m × 0.1 m is pre-dug on the side of the road near the excavation pit, and a soil pressure box is buried to measure the weight of passing vehicles. The top of the pressure sensors is covered with soil and protected with an iron plate. Note that the pre-buried pressure sensors are solely for acquiring the weight distribution of different types of vehicles, allowing the association of vehicle type with weight based solely on video information in practical engineering applications, eliminating the need for pre-arranged contact sensors. The weight data of 1,000 vehicles (with an equal number of each vehicle type) are selected for fitting different probability distribution types, as shown in Fig. 7. The results of the Kolmogorov-Smirnov (K-S) hypothesis tests for different distribution types are recorded in Table 4, and the best-fitting vehicle weight distribution for each vehicle type is selected based on the smallest D-statistic.

For vehicle speed, the data are obtained from surveillance video using Deep SORT and coordinate transformation techniques. Similar to the analysis of vehicle weight, different probability distributions are used to fit the distribution of vehicle speeds of 1,000 vehicles, as shown in Fig. 8.

Table 5 records the K-S test results for vehicle speeds of different vehicle types.

Table 6 summarises the statistical distribution of vehicle weight and speed for different vehicle types along with their parameters. In this study, the road adjacent to the excavation pit is not a main artery and experiences low traffic volumes, with vehicle spacings showing high variability and extended tail distributions. The Gamma distribution is particularly effective at capturing these features under sparse traffic conditions42,43. Additionally, the flexibility of the Gamma distribution to adjust its shape and scale parameters allows it to effectively fit various data distributions, especially in scenarios with significant traffic flow fluctuations. This choice is substantiated by existing research confirming the appropriateness of using the Gamma distribution to describe vehicle spacings44,45,46. Therefore, the Gamma distribution has been adopted in this study to represent vehicle spacing distributions. Moreover, relevant studies indicate that vehicle spacing is largely independent of vehicle type47,48hence the same Gamma distribution is applied to describe the spacing for all four vehicle types. Given that the road adjacent to the excavation site is on the urban fringe with sparse traffic, the spacing distribution of the sparse state is selected based on established coefficients from previous research48using a Gamma distribution with a shape parameter k = 1.06 and a scale parameter θ = 0.00143. With the above-mentioned information, the temporal variation of vehicle loads at the measurement section can be calculated, and the process is completed using Monte Carlo sampling in the subsequent sections.

Generation of the random traffic flow based on Monte Carlo sampling

During the simulation process, initially, vehicles are randomly generated in proportion to the measured vehicle types (as shown in Table 2). Subsequently, based on the vehicle type information, the distribution parameters for vehicle weight, speed, and spacing are determined, generated by Monte Carlo sampling. These operations are repeated multiple times to simulate the fundamental characteristics of real traffic flows. The distribution of vehicle weight directly influences the load level of each randomly generated vehicle, while differences in vehicle speed and spacing affect the timing, frequency, and duration of the load application as each vehicle travels along the edge of the excavation pit. Additionally, these variations also impact the overall smoothness and continuity of the traffic flow. The variation in vehicle type and vehicle load over time, illustrated over a 100-second interval, is shown in Fig. 9. It can be seen that the figure reflects the vehicle type information through the measurement section and also illustrates the corresponding vehicle loads and the timing of the loads (i.e., load-time varying information). It is observed that most vehicle loads are distributed within the 0-600kN range, with Type 1 vehicles being the most numerous but generating the lowest vehicle loads. Heavy vehicles (Type 3 and Type 4) are present in a significant number, and their vehicle loads are mostly distributed between 200-600kN, possibly due to the frequent passage of construction vehicles near the excavation project. Consequently, in the finite element model, the aforementioned vehicle model can be applied along the road at the edge of the excavation to simulate the impact of vehicle loads on the pit construction. Specifically, vehicles are randomly generated at one edge of the road (random vehicle type + speed + spacing) and then move across to the opposite side. This process is repeated several times until internal forces and deformations stabilize, after which the effect of vehicle loads on the excavation project can be analysed. The following sections will focus on the establishment and analysis process of the finite element model.

Modelling of foundation pits in highway tunnels

Project overview

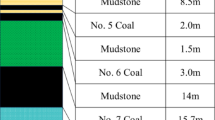

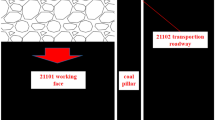

The engineering project is located near the West Station Junction in Hangzhou, China. The main tunnel line starts west of East-West Avenue and ends east of Liangmu Road, running east-west with a total length of 3630 m. The focus of this study is on the “narrow-type” Pit No. 12, as a long soft soil pit, near the North-south road, which measures 477 m in length and varies in width from 31.5 to 35.9 m. The depth of excavation ranges from 7.74 to 10.49 m. The retaining structures utilise bored piles combined with a waterproof curtain, and the pit is equipped with two levels of internal support: the first comprising reinforced concrete and the second consisting of steel pipe supports, as depicted in Fig. 10.

The Hardening Soil Model with Small Strain Stiffness (HSS model) has been proven effective in simulating the deformation characteristics of soft soils in related studies49,50and is therefore employed in the finite element simulations of this study. The soil parameters are derived from a series of tests on undisturbed soil samples collected at various depths from the project site. Specifically, thin-walled samplers were used for soil sampling, followed by a series of laboratory tests conducted in accordance with relevant standards51. These tests include standard consolidation tests, consolidated undrained triaxial shear tests, and load-unload-reload triaxial tests. The soil characteristic analyses were conducted through in-situ drilling around the excavation project. Table 7 presents the actual stratigraphic distribution and soil parameters.

During excavation, Pit No. 12 is divided into 29 structural segments, arranged in an axially symmetrical distribution. Due to their proximity to roads, structural segments A34 to A37 were selected for installing measurement points to monitor surface settlement and the horizontal displacement distribution of the retaining piles, as shown in Fig. 11. Each measuring section was equipped with five surface settlement monitoring points at distances of 2 m, 5 m, 10 m, 20 m, and 30 m apart. The spacing of the pile deformation monitoring points is 0.5 m.

Modelling of the foundation pit

As shown in Fig. 12 (a)-(d), simulations were performed using the finite element software PLAXIS 3D (2020 version)52. According to the geotechnical report, there is significant variability in soil layers along the long side of the excavation pit, while variations along the short side are minimal. Therefore, in the finite element model construction, non-uniform soil layers are established based on the actual soil layer distribution along the long side, whereas the soil layer thickness at the same depth along the short side remains consistent. The distribution of the model’s soil layers is shown in Fig. 12 (a). The bottom of the model is constrained in both horizontal and vertical directions, the sides are fixed horizontally and free vertically, and the surface is free. Hardening soil model with small strain stiffness (HSS model) is employed to accurately reflect the true deformation characteristics of the soft soil excavation pit. Drained analysis was employed in the modelling process, and the computational parameters for the HSS model were derived from geotechnical tests, detailed in Table 7. Given the implementation of a robust support structure using Soil Mixing Wall (SMW) method piles and a water-blocking curtain, coupled with water extraction from deeper soil layers via the deep well system, groundwater levels were maintained at 2–3 m below the pit base. Consequently, groundwater influence was not considered in the model. In PLAXIS 3D, five densities corresponding to different element sizes are defined for mesh division: high coarseness, coarse, medium, fine, and ultra-fine. For general model computations, the default mesh suffices; thus, a fine mesh division was employed for this study, with a total of 85,631 elements. Due to the east-west symmetry of the excavation pit, only half of the pit was modelled during the simulation. The pit’s support structures, comprising SMW method and bored piles, primarily exhibit elastic deformation under load, hence a uniform strength plate element model was used for both pile types. The pit base was reinforced with cement mixing piles to a depth of 3 m and a skirt reinforcement depth of 4 m, simulated using elastic solid elements. All supports were modelled using uniform strength elastic beam elements. Details of the finite element model parameters are listed in Table 8.

In practical engineering projects, a sequential operation is adopted, involving stepwise excavation from both ends towards the middle of the foundation pit. Consequently, to closely simulate the actual engineering conditions, the process is divided into nine stages, as outlined in Table 9. Figure 13 illustrates the sequence of the excavation process, during which the vehicle load model obtained in Sect. 3 is applied to the road adjacent to the pit.

Results and discussion

Comparative analysis of finite element calculations and measuring data

Figures 14 and 15 show the deformation cloud maps for the soil settlement and retaining structures during key stages of excavation — specifically, “Excavate to the bottom of the foundation pit (stage S5)” and “Construct the top slab (stage S9)”. Due to the unloading effects of excavation, the surrounding soil exhibits downward settlement deformation, while the retaining structures deform horizontally towards the inside of the pit. As the stages progress, the deformation propagates from the excavation start point (east or right side) towards the direction of excavation, with both the displacement of the retaining structures and the deformation of the surrounding soil gradually increasing. Moreover, it is observed that under the influence of traffic loads, the deformation of the retaining structures on the east side of the pit, as well as the soil settlement, are more pronounced.

The maximum deformation values observed at different monitoring cross-sections vary as the stages of work progress, as shown in Fig. 16. It is apparent that as the project advances, both the surrounding soil settlement and the deformation of the retaining structures’ piles continue to increase. Similar trends are observed across different construction segments, with the greatest increase in deformation occurring during soil excavation. This is attributed to the excavation altering the stress balance inside and outside the pit, resulting in the external active earth pressure exceeding the internal passive earth pressure, thus causing significant soil deformation and inward deformation of the retaining piles.

Monitoring section near the road on the short side cross-section (ZQT326 + DBC350, Fig. 17) and the long side cross-section (ZQT286 + DBC295, Fig. 18) were selected to observe the patterns of cross-sectional deformation during various stages. It was found that both the absolute values of surface settlement and pile displacement progressively increase during different constructing stages, yet the distribution patterns remain similar, with the positions of maximum values consistently aligning. The soil settlement around the foundation pit increases and then decreases with distance from the pit, forming a “spoon-shaped” curve. This is primarily due to the unloading effect of soil excavation within the pit, which causes the external soil to move diagonally downwards towards the pit, resulting in surface settlement around the pit. The soil within the pit concurrently undergoes heaving, thereby inducing vertical upward displacement of the surrounding retaining structures and the adjacent soil16,19. Due to differences in materials between the road and the surrounding soil used in the simulations, a significant abrupt change in surface settlement was observed (Fig. 17). Observing the deformation of the retaining structure’s piles reveals a “bulging” shape, with larger deformations in the middle and smaller at both ends. This is because the top of the retaining structure is supported by reinforced concrete internal struts, while the bottom is embedded in the soil layer, resulting in smaller displacements at the top and bottom of the structure. These simulation results are consistent with actual project conditions, validating the effectiveness of the finite element model.

To compare the impact of the non-contact machine vision-based vehicular load simulation model proposed in this study with theoretical vehicular load models on simulated pit deformation, the theoretical calculations are conducted using formulas recommended in the literature. The sinusoidal wave model, widely applied in existing studies for analysing the impact of vehicle loads on structures, assumes the vehicle load as a sinusoidal waveform53,54,55with the formula provided as follows:

.

Here, the vehicle load is described in the form of a sine wave, where P0 is the static load of the vehicle, taken as 80 kN according to the literature56,57. The load amplitude P is calculated as P = M0αω2, where ω is the vehicle vibration frequency, M0 is the sprung mass, and α is the road surface irregularity height, with values for ω, M0, and α taken from the standards58. In this research, the equivalent soil layer thickness method was employed to uniformly apply the aforementioned vehicle loads across the road surface56,57. A comparison between simulated and monitored values was conducted for the construction segment near the roadside (A37), using both the vehicular load model based on actual measured data (VL2) proposed in this study and a theoretical vehicle load model (VL1), as shown in Figs. 19 and 20. It was observed that all simulated values exhibited trends consistent with the monitoring data. However, deformations simulated using the vehicular load model proposed in this paper were closer to the monitored deformations. This closer alignment is attributed to the proposed model being derived from actual measured data, which more accurately reflects the traffic flow conditions beside the excavation pit. In contrast, the theoretical model does not account for the frequent passage of heavy vehicles, resulting in smaller simulated values. Comparative analysis with traditional models reveals that the real-time traffic flow-based vehicular load model proposed in this paper can more accurately reflect the true traffic load conditions. Consequently, this enables a more precise prediction of the actual deformations of excavation pits and their support structures in real engineering projects.

Analysis of the impact of vehicle load on foundation pit deformation

The impact of vehicular load presence on the deformation characteristics of the excavation pit is analysed using the vehicle simulation model proposed in this paper. Comparisons between deformations at monitoring points near the road (DBC350, ZQT326) with and without vehicular loads are illustrated in Fig. 21. It is observed from Fig. 21 (a) and (b) that the morphology of simulated pit deformation distributions within the section remains similar whether vehicular loads are applied or not. However, deformations are notably larger when vehicular loads are considered, with the differences in deformation growing as the working conditions progress, especially during the soil layer excavation stage, as shown in Fig. 21 (c). By the final stage, the increment of the surface soil settlement can reach up to 19.4 mm, and the horizontal displacement of the pile can increase by up to 6.5 mm, which are 48.7% and 22.3% of the origin deformation, respectively. These simulation results underscore the significant impact of vehicular load on pit deformation. While the vehicular load does not alter the distribution of deformation, it significantly enhances the absolute deformation values, underscoring the importance of considering vehicular loads near excavation sites in simulations.

Measuring sections near the road (measurement points: DBC350, ZQT326) were selected to calculate the distribution of the deformation increment after applying vehicle load within the section under different working conditions, as shown in Fig. 22. It can be found that the distribution of the incremental deformation at the section is similar to the morphology of the deformation distribution. As the location moves away from the edge of the pit, the deformation increment initially increases, then decreases, and eventually approaches zero. As the working conditions progress, the difference in surface settlement and pile displacement with and without vehicle loads becomes greater, and the influence range of the vehicle load gradually increases. The impact boundary of the vehicle load is determined at the value of 1% of the maximum increment value. It can be seen that the impact range of the vehicle load on surface settlement is 16.3 m, and the impact depth on pile deformation is 21.8 m.

The maximum deformation increments caused by vehicle loads along the longitudinal length of the pit were extracted, and the distribution of these deformation increments under the influence of vehicle loads along the long side of the pit (i.e., the construction direction) was plotted, as shown in Fig. 23. Similarly, 1% of the maximum deformation increment is used as the boundary of vehicle load influence range. It is observed that as the section position moves further from the road, the deformation increment caused by the vehicle load gradually decreases. As the working conditions advance, the range of influence of the vehicle load gradually expands along the construction direction. Due to the variability in soil distribution and the effect of horizontal support, fluctuations in the distribution of deformation increments under specific conditions are observed, but the overall trend remains: as the conditions progress, the differences in deformation caused by vehicle loads become increasingly significant. Eventually, the influence range of vehicle loads along the longitudinal long side of the pit on surface settlement and pile deformation is 87.5 m and 101.3 m, respectively. The lesser impact on pile deformation may be due to the horizontal support limiting the displacement of the piles. From the above analysis, it is evident that the influence of vehicle loads on nearby roads on excavation pits is significant and should not be overlooked.

Conclusion

To assess the impact of traffic loads from nearby roads on the excavation process of pit projects, this study collected real traffic flow data using non-contact machine vision technique. After statistical analysis of the collected data, Monte Carlo sampling was utilised to simulate vehicular loads, which were then input into the PLAXIS 3D finite element model to evaluate the effects of traffic loads on pit deformation. This approach allows for a comprehensive analysis of the influence of real-world vehicular activities on structural integrity during excavation operations. The following conclusions can be drawn:

-

1.

The traffic load simulation model framework utilises YOLO-v5 for detecting vehicle types and the Deep SORT algorithm for obtaining vehicle speed information. Comparisons with field test results show an 86.67% accuracy in vehicle type recognition, with a speed recognition error ranging between 2 and 6%, confirming that the established model effectively reflects real traffic flow information.

-

2.

By using measured data from weight sensors, vehicle weight information is correlated with vehicle types. Subsequently, statistical distribution analysis was employed to derive vehicle speed and weight distributions. Monte Carlo sampling is used to obtain time-varying simulated vehicle load profiles. The simulation model developed effectively captures the categorizes of vehicles passing through and temporal variations in load across the monitored sections.

-

3.

A finite element simulation of a long soft soil pit is conducted using PLAXIS 3D finite element software, with simulated vehicle loads added on the road adjacent to the foundation pit. Comparisons between deformation monitoring results at the pit section and simulation results validate the accuracy of both the finite element model and the traffic load simulation model. The traffic load simulation model based on real traffic flow information could reflect the impact of nearby road traffic on pit deformation more accurately compared to theoretical vehicle load model.

-

4.

Following the application of vehicular loads, significant increases in both the deformation of the pit support and the surface soil settlement are observed, with increments growing as the conditions progress. The maximum increase in surface soil settlement and horizontal displacement of the support structures can reach 48.7% and 22.3%, respectively. This underscores the significant impact of nearby vehicle loads on pit deformation, which should not be overlooked in practical engineering applications.

-

5.

At the edge of the pit nearby the road, the impact depth of vehicular loads on the support structure reaches 21.8 m, and the range of impact on surface soil settlement by vehicular loads extends up to 101.3 m along the construction direction. The impact of vehicular loads from nearby roads should not be overlooked during the excavation of foundation pits adjacent to the roads. In practice, to enhance the safety of foundation pit construction, we recommend maintaining a minimum distance of at least 150 m between the vehicles and the edge of the excavation pit.

In urban areas where road networks are dense, vehicular loads have a significant impact on pit excavation. The traffic load simulation methodology established in this paper based on non-contact machine vision offers a new approach for safety assessments in foundation pit projects during urban construction. However, as the model only collected data during cloudy and clear weather conditions, its accuracy was observed to decrease during rainy and snowy conditions. Additionally, considering that the model’s training dataset was exclusively derived from a specific road in a particular Chinese city, the transferability and universality of the model need further validation. Future research could involve integrating more scenarios and expanding the training dataset, along with employing more effective deep learning algorithms to optimize the model. We are also continuing this line of research and invite the readers to stay tuned for further developments.

Data availability

The datasets generated during and analysed during the current study are available from the corresponding author on reasonable request.

References

Hettelingh, R. & Puzrin, A. M. Construction on slow-moving landslides: effects of excavation on neighboring structures. J. Geotech. Geoenviron. https://doi.org/10.1061/JGGEFK.GTENG-11318 (2023).

Li, H., Huang, M., Yu, J., Li, Y. & Guo, Y. Three-dimensional solution for braced excavation-induced ground settlement. Comput. Geotech. https://doi.org/10.1016/j.compgeo.2024.106460 (2024).

Liu, C., Yan, C., Zheng, G., Liu, T. & Yang, Y. Field testing and numerical analysis of supporting performance of oblique piles used in pit excavation. Int. J. Geomech. https://doi.org/10.1061/IJGNAI.GMENG-8487 (2023).

Wang, C., Zhai, M. & Wang, Y. Research progresses on fatigue in steel bridges. J. Traffic Transp. Eng. 24, 9. https://doi.org/10.19818/j.cnki.1671-1637.2024.01.002 (2024). (in Chinese).

Lei, H., Zhan, B., Feng, S. & Amin, M. Influence of foundation pit groups’ excavation on the deformation characteristics of adjacent railway subgrade and protection measures. Geotech. Geol. Eng. 41, 3877. https://doi.org/10.1007/s10706-023-02493-7 (2023).

Lu, T., Liu, S., Cai, G., Wu, K. & Xia, W. Study on the disturbance and recompression settlement of soft soil induced by foundation pit excavation. Rock. Soil. Mech. 42, 565. https://doi.org/10.16285/j.rsm.2020.0980 (2021).

Sun, Y., Zhou, S. & Luo, Z. Basal-heave analysis of pit-in-pit braced excavations in soft clays. Comput. Geotech. 81, 294. https://doi.org/10.1016/j.compgeo.2016.09.003 (2017).

Qian, J., Wang, Q., Jiang, J., Cai, Y. & Huang, M. Centrifuge modeling of a saturated clay ground under cyclic loading. Int. J. Geomech. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001166 (2018).

Tian, Z., Gong, Q., Di, H., Zhao, Y. & Zhou, S. What causes the excessive metro tunnel settlement in soft deposits: learned from a detailed case with factor decomposition. B Eng. Geol. Environ. 81, 212. https://doi.org/10.1007/s10064-022-02713-z (2022).

Yang, Q., Tang, Y., Yuan, B. & Zhou, J. Cyclic stress-strain behaviour of soft clay under traffic loading through hollow cylinder apparatus: effect of loading frequency. Road. Mater. Pavement. 20, 1026. https://doi.org/10.1080/14680629.2018.1428219 (2019).

Ye, S., Zhao, Z. & Wang, D. Deformation analysis and safety assessment of existing metro tunnels affected by excavation of a foundation pit. Undergr. Space. 6, 421. https://doi.org/10.1016/j.undsp.2020.06.002 (2021).

Bao, X. et al. Analysis of the influence of deep foundation excavation on adjacent viaduct pile foundation considering train dynamic loads. Appl. Sci. 13, 1572. https://doi.org/10.3390/app13031572 (2023).

Ding, S., Qian, D., Dai, Q. & Bao, S. Analysis on the stability of deep foundation pit excavation under vehicle loads. J. Hefei Univ. Technol. (Natural Science). 42, 671. https://doi.org/10.3969/j.issn.1003-5060.2019.05.016 (2019). (in Chinese).

Li, B., Gao, Y., Wei, D. & Liu, H. Research on influential depth of vehicle loads and its influencing factors. Roak Soil. Mechanies. 26, 310 (2005).

Liu, H., Han, J. & Parsons, R. L. Geosynthetic reinforcement of backfill behind integral abutments to mitigate approach slab distresses. Eng. Struct. 269, 114772. https://doi.org/10.1016/j.engstruct.2022.114772 (2022).

Rao, P. et al. Stability analysis of unsaturated soil pit under vehicle load. Geotech. Geol. Eng. https://doi.org/10.1007/s10706-024-02825-1 (2024).

Singh, A. P. & Chatterjee, K. Ground settlement and deflection response of cantilever sheet pile wall subjected to surcharge loading. Indian Geotech. J. 50, 540. https://doi.org/10.1007/s40098-019-00387-1 (2020).

Sulaiman, N. & Adnan, M. A. Empirical model of ground-borne vibration imposed by road traffic on soft ground. Cham https://doi.org/10.1007/978-3-030-65181-7_45 (2021).

Tang, L., Qiu, P., Yang, G., Xi, J. & Wu, D. An approach to simplify the vehicle load in excavation-supporting structures design. Eur. J. Environ. Civ. En. 24, 1589. https://doi.org/10.1080/19648189.2018.1476269 (2020).

Xu, C. J., Xu, Y. L., Lin, H. H. & Sun, F. M. Influences of vehicle loads on braced excavation in soft clay. Appl. Mech. Mater. 353–356, 146. https://doi.org/10.4028/www.scientific.net/AMM.353-356.146 (2013).

Zhang, X., Chen, J., Wan, L., Luo, W. & Xu, C. Field test and analysis of vehicle load and its influence on the retaining structure of adjacent foundation pits. China Earthq. Eng. J. 42, 490. https://doi.org/10.3969/j.issn.1000-0844.2020.02.490 (2020). (in Chinese).

Zhao, T. et al. Study on dynamic response of the foundation pit supporting structure under dynamic load. J. Earthq. Eng. Eng. Vib. 40, 216. https://doi.org/10.13197/j.eeev.2020.03.216.zhaotd.022 (2020).

Nguyen, T., Phan, T. N., Likitlersuang, S. & Bergado, D. Characterization of stationary and nonstationary random fields with different copulas on undrained shear strength of soils: probabilistic analysis of embankment stability on soft ground. Int. J. Geomech. https://doi.org/10.1061/(ASCE)GM.1943-5622.0002444 (2022).

Hsiung, B. B., Likitlersuang, S., Phan, K. H. & Pisitsopon, P. Impacts of the plane strain ratio on excavations in soft alluvium deposits. Acta Geotech. 16, 1923. https://doi.org/10.1007/s11440-020-01115-3 (2021).

Roeun, D., Sukkarak, R. & Likitlersuang, S. Influences of subsoil modelling on underground deep excavation behaviour in Phnom Penh city, Cambodia. Int. J. Geosynthetics Ground Eng. 10, 27. https://doi.org/10.1007/s40891-024-00534-6 (2024).

Hou, R., Jeong, S., Lynch, J. P. & Law, K. H. Cyber-physical system architecture for automating the mapping of truck loads to bridge behavior using computer vision in connected highway corridors. Transp. Res. Part. C: Emerg. Technol. 111, 547. https://doi.org/10.1016/j.trc.2019.11.024 (2020).

Zhang, B., Zhou, L. & Zhang, J. A methodology for obtaining spatiotemporal information of the vehicles on bridges based on computer vision. Comput-Aided Civ. Inf. 34, 471. https://doi.org/10.1111/mice.12434 (2019).

Yang, G. et al. Automatic generation of fine-grained traffic load spectrum via fusion of weigh-in-motion and vehicle spatial–temporal information. Comput-Aided Civ. Inf. 37, 485. https://doi.org/10.1111/mice.12746 (2022).

Dan, D., Ying, Y. & Ge, L. Digital twin system of bridges group based on machine vision fusion monitoring of bridge traffic load. IEEE Trans. Intell. Transp. 23, 22190. https://doi.org/10.1109/TITS.2021.3130025 (2022).

Xu, Z., Wei, B. & Zhang, J. Reproduction of spatial–temporal distribution of traffic loads on freeway bridges via fusion of camera video and ETC data. Structures 53, 1476. https://doi.org/10.1016/j.istruc.2023.05.023 (2023).

Yin, X., Huang, Z. & Liu, Y. Traffic load simulation on bridges based on improved non-contact machine vision technique and multi-source information fusion. Measurement 213, 112754. https://doi.org/10.1016/j.measurement.2023.112754 (2023).

Zhu, J., Li, X., Zhang, C. & Shi, T. An accurate approach for obtaining spatiotemporal information of vehicle loads on bridges based on 3D bounding box reconstruction with computer vision. Measurement 181, 109657. https://doi.org/10.1016/j.measurement.2021.109657 (2021).

Redmon, J. et al. You Only Look Once: unified, real-time object detection. In Presented at the 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Seattle, WA. https://doi.org/10.1109/CVPR.2016.91 (IEEE, 2016).

Kushwaha, P. & Murmu, M. K. Suspicious activity monitoring system using YOLOv5. In Presented at the 2024 15th International Conference on Computing Communication and Networking Technologies (ICCCNT) https://doi.org/10.1109/ICCCNT61001.2024.10724525 (2024).

Karim, S., Ibrar, M., Bilal, A., Qadir, A. & Bibi, I. Optimized flame detection using a YOLOv5 neural network. In Presented at the 2024 International Conference on Computing, Robotics and System Sciences (ICRSS). https://doi.org/10.1109/ICRSS65752.2024.00045 (2024).

Mahboob, Z., Zeb, A. & Khan, U. S. YOLO v5, v7 and v8: A performance comparison for tobacco detection in field. In Presented at the 2023 3rd International Conference on Digital Futures and Transformative Technologies (ICoDT2). https://doi.org/10.1109/ICoDT259378.2023.10325705 (2023).

Iaboni, C., Lobo, D., Choi, J. & Abichandani, P. Event-based motion capture system for online multi-quadrotor localization and tracking. Sensors 22, 3240. https://doi.org/10.3390/s22093240 (2022).

Zhang, Y. et al. Focal and efficient IOU loss for accurate bounding box regression. Neurocomputing 506, 146. https://doi.org/10.1016/j.neucom.2022.07.042 (2022).

Ren, S., He, K., Girshick, R. & Sun, J. Faster R-CNN: towards real-time object detection with region proposal networks. IEEE Trans. Pattern Anal. 39, 1137. https://doi.org/10.1109/TPAMI.2016.2577031 (2017).

Wojke, N., Bewley, A. & Paulus, D. In 24th IEEE International Conference on Image Processing (ICIP) 3645 ( IEEE, 2017).

Pan, Y., Wang, D., Dong, Y. & Peng, B. A novel vision-based framework for identifying dynamic vehicle loads on long-span bridges: a case study of Jiangyin bridge, China. IEEE Trans. Intell. Transp. 23, 10441. https://doi.org/10.1109/TITS.2021.3094504 (2022).

Kim, J. & Mahmassani, H. S. Compound gamma representation for modeling travel time variability in a traffic network. Transp. Res. Part. B: Methodological. 80, 40. https://doi.org/10.1016/j.trb.2015.06.011 (2015).

Guessous, Y., Aron, M., Bhouri, N. & Cohen, S. Estimating travel time distribution under different traffic conditions. Transp. Res. Procedia. 3, 339. https://doi.org/10.1016/j.trpro.2014.10.014 (2014).

Soriguera, F. & Robusté, F. Estimation of traffic stream space mean speed from time aggregations of double loop detector data. Transp. Res. Part. C: Emerg. Technol. 19, 115. https://doi.org/10.1016/j.trc.2010.04.004 (2011).

Pei, X., Pan, Y., Wang, H., Wong, S. C. & Choi, K. Empirical evidence and stability analysis of the linear car-following model with gamma-distributed memory effect. Phys. A: Stat. Mech. Its Appl. 449, 311. https://doi.org/10.1016/j.physa.2015.12.104 (2016).

Shoaeb, A., El-Badawy, S., Shawly, S. & Shahdah, U. E. Time headway distributions for two-lane two-way roads: case study from Dakahliya governorate, Egypt. Innovative Infrastructure Solutions. 6, 165. https://doi.org/10.1007/s41062-021-00531-y (2021).

Huang, P. et al. Improved multi-lane traffic flow simulation based on weigh-in-motion data. Measurement 188, 110408. https://doi.org/10.1016/j.measurement.2021.110408 (2022).

Yang, D., Guan, Z., Yi, T., Li, H. & Ni, Y. Fatigue evaluation of bridges based on strain influence line loaded by elaborate stochastic traffic flow. J. Bridge Eng. 27, 4022082. https://doi.org/10.1061/(ASCE)BE.1943-5592.0001929 (2022).

Surarak, C. et al. Stiffness and strength parameters for hardening soil model of soft and stiff Bangkok clays. Soils Found. 52, 682. https://doi.org/10.1016/j.sandf.2012.07.009 (2012).

Likitlersuang, S., Teachavorasinskun, S., Surarak, C., Oh, E. & Balasubramaniam, A. Small strain stiffness and stiffness degradation curve of Bangkok clays. Soils Found. 53, 498. https://doi.org/10.1016/j.sandf.2013.06.003 (2013).

Ministry of Water Resources of The people’s Republic of China. In GB/T 50123 – 2019 (China Planning, 2019).

Brinkgreve, R., Engin, E. & Swolfs, W. J. P. B. PLAXIS 3D 2020 User Manual. (PLAXIS bv, 2020).

Wang, H. & Nagayama, T. Response spectrum model of vehicle dynamic load for the prediction of Bridge vibration level due to single vehicle-passage. Eng. Struct. 260, 114180. https://doi.org/10.1016/j.engstruct.2022.114180 (2022).

Li, D. & Wang, L. Synergism analysis of bedding slope with piles and anchor cable support under sine wave vehicle load. Adv. Mater. Sci. Eng. 2016, 1 https://doi.org/10.1155/2016/5753970 (2016).

Zhang, X. et al. Dynamic response of roadbed soil under various dynamic load waveforms. Geotech. Geol. Eng. 42, 6237. https://doi.org/10.1007/s10706-024-02879-1 (2024).

Tian, F. & Chu, J. Research on traffic load characteristics and simulation methods. J. Water Resour. Architectural Eng. 66, 161. https://doi.org/10.3969/j.issn.1672-1144.2014.04.012 (2014). (in Chinese).

Zhang, J., Wu, D. & Zhu, D. Simulation study of foundation pit support under vehicle load based on PLAXIS. Low Temp. Archit. Technol. 41, 83, 99. https://doi.org/10.13905/j.cnki.dwjz.2019.03.022 (2019). (in Chinese).

Ministry of Transport of the People’s Republic of China. In JTG B01- 2014 (China Communications Press, 2014).

Acknowledgements

The authors would like to acknowledge the financial support provided by Zhejiang Provincial Natural Science Foundation (Grant Nos. LTGG23E080001 and LY20E080027), and National Natural Science Foundation of the People’s Republic of China (Grant No. 52308535).

Author information

Authors and Affiliations

Contributions

Zhi-Yu XIE and Xi WU wrote the main manuscript text, Miao-Miao SUN and Song-Qiang CHEN analysed the test data, Zhen-Yu ZHANG created the software used in the manuscript, and Xing-Lang Fan and Hai-Min Qian reviewed and substantively revised the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wu, X., Sun, MM., Xie, ZY. et al. Influence of simulated traffic on foundation pit deformation via machine vision technology. Sci Rep 15, 21242 (2025). https://doi.org/10.1038/s41598-025-05699-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-05699-2