Abstract

Ecological slope restoration is crucial for environmental balance, disaster mitigation, and sustainable development. This study evaluates a novel vegetation-growing material with high strength, plant growth performance, and cost efficiency. The key innovation lies in the introduction of a composite ecological regulator (CER), which synergistically balances mechanical strength and ecological functionality by addressing the limitations of conventional materials (e.g., high cement content, pH imbalance). Using orthogonal and secondary optimization tests, we systematically resolved the conflicting effects of cement, CER, microsilica powder, rice husk, and farmyard manure on vegetative characteristics (germination rate, plant height) and physicochemical properties (compressive strength, pH, porosity). Results demonstrate that cement enhances bond strength but increases pH and reduces porosity, with an optimal dosage of 4%. CER improves nutrients and microbial activity but inhibits growth when excessive, with an optimal dosage of 7.5% of cement. Microsilica powder lowers pH and enhances strength, but exceeding 50% of cement reduces porosity. Rice husk improves pore distribution, while 6% organic matter optimizes water retention, germination rate, and plant height, increasing them by 130% and 163%, respectively. The optimal mix ratio was determined as soil:cement:CER:microsilica powder:rice husk:farmyard manure = 100:4:0.3:2:6:2. Research results provide new ideas for material-vegetation synergistic slope protection and ecological restoration.

Similar content being viewed by others

Introduction

With rapid socio-economic development, municipal, water conservancy, transportation, and other infrastructure construction activities have become increasingly frequent, resulting in the formation of a large number of slopes, which not only changes the original topography and geomorphology but also triggers the destruction of vegetation, soil erosion, decline of biodiversity and other types of serious ecological problems1,2,3. Annual soil erosion caused by slope ecological damage reaches billions of tons4, resulting in soil degradation and intensifying natural disasters such as debris flows and landslides5,6, threatening socio-economic stability and human safety. Therefore, restoring slope ecosystems is essential for maintaining ecological balance, mitigating natural disaster risks, and supporting sustainable development7.

A common method for slope ecological restoration is the direct planting of trees, grasses, or sod8. However, in harsh environments and poor soil quality, this approach often results in low vegetation survival rates and slow growth9,10,11. To enhance the efficiency and quality of slope restoration, various sprayed planting substrate technologies have been developed, including thick substrate slope greening12, guest soil spraying13, and hydraulic spraying greening technologies14. These technologies improve plant growth and coverage by spraying substrates containing plant seeds and organic matter, improving slope stability and vegetation survival rates. Although thick substrate-slope greening and guest soil spraying are cost-effective, they provide lower erosion resistance and adaptability under extreme weather conditions. To address these shortcomings, research has increasingly focused on vegetated concrete spraying technology, which offers high strength and superior erosion resistance15,16. Vegetated concrete is a composite substrate composed of soil, cement, greening additives, and organic matter. It provides a growth medium for plants while also improving slope stability through structural reinforcement. Extensive research has been conducted on the mechanical strength of vegetated concrete17, vegetative environment18, and chemical properties19. Studies demonstrate that the mechanical strength, durability, and erosion resistance of the substrate improve with higher cement content and longer curing times but diminish as organic matter, greening additives, and biochar content increase20,21,22. While a higher cement content is necessary for ensuring mechanical strength and erosion resistance, it can lead to substrate salinization, increased pH, nutrient loss, and soil sloughing, thereby significantly reducing plant germination and growth rates17,23,24. To improve the vegetation environment, greening additives, ecological regulators and soil bacteria, which account for about 50% of the cement mass are added. However, this weakens the mechanical properties of the cement and significantly increases costs25. For instance, bacterial additives require annual replenishment due to microbial activity degradation, costing approximately RMB 8000 per ton. In contrast, supplementary materials such as microsilica (RMB 900 per ton) and rice husk (RMB 120/m3) provide stable performance with lower economic input26,27. Given the conflicting roles of cement and greening additives, the introduction of an efficient, low-dose multifunctional regulator may establish a beneficial cycle, enhancing mechanical strength, reducing cement content, and improving vegetative properties. Recent studies highlight the potential of calcined clay and fly ash in vegetation concrete to enhance strength and pH regulation28, as well as polyurethane-modified substrates for improved plant adaptability29. However, these approaches often require high additive dosages or lack multifunctionality, underscoring the need for a balanced solution. Additionally, vegetated concrete is a composite substrate made from various materials, where both mechanical strength and vegetative properties must be balanced30. The components are interrelated, and most existing research focuses on single-factor analysis, failing to account for the synergistic or antagonistic effects between factors31,32,33.

Existing studies fail to address the synergistic optimization of mechanical and vegetative properties due to conflicting roles of cement and additives. To address these issues, this paper proposes a novel vegetation-growing material for slope protection composed of soil, cement, composite ecological regulator (CER), microsilica powder, rice husk, and farmyard manure. While rice husk and microsilica powder have seen isolated applications, their combined use in vegetation-growing substrates remains unexplored, particularly in balancing pH and porosity under varying cement content. Rice husk and farmyard manure enhance pore distribution and water retention, while microsilica powder improves mechanical strength and pH regulation. These materials outperform alternatives like biochar or fly ash in balancing strength and vegetative properties under cost constraints. The effects of cement, CER, rice husk, and farmyard manure on vegetative characteristics (germination rate and plant height) and physicochemical properties were evaluated through orthogonal and secondary optimization tests. The optimal mix ratio was determined to be soil:cement:CER:microsilica powder:rice husk:farmyard manure = 100:4:0.3:2:6:2. This study fills a research gap by offering a novel vegetation-growing material for slope protection and CER for ecological slope restoration. The synergistic development of materials and vegetation provides novel insights into environmental restoration and long-term protective strategies.

Materials and methods

Materials

-

1.

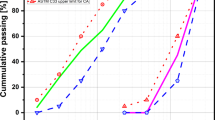

Soil: Soil for the experiment was collected from a management project along the Yellow River in Zhengzhou, China. It consists of recent river channel sedimentary deposits, primarily composed of gray-brown powdery fine sand. The soil particle size distribution is illustrated in Fig. 1.

-

2.

Cement: The cement used is Ordinary Portland Cement (P·O 42.5), manufactured in Zhengzhou, Henan Province. Its 3-day and 28-day compressive strengths are 18 MPa and 44.6 MPa, respectively, with initial and final setting times of 51 min and 650 min. The chemical composition is provided in Table 1.

-

3.

Microsilica powder: Microsilica powder (SF96) has a density of 2.2 g/cm3, a bulk density of 0.26 g/m3, and a specific surface area of 22 m2/g. Table 1 shows its chemical composition.

-

4.

CER: A composite blend formulated to reduce substrate alkalinity, supply nutrients, and enhance the microbial environment.

-

5.

Rice husks: The rice husks used are air-dried after fermentation, with a moisture content of 8.2%, a bulk density of 0.13 g/m3, and a length of approximately 10 mm width of 3 mm.

-

6.

Farmyard manure: The farmyard manure was derived from air-dried, fermented sheep dung, with an organic matter content of 28%, 0.76% nitrogen, 0.55% phosphorus, and 0.43% potassium.

-

7.

Tall fescue: Tall fescue seeds were supplied by Tung Shing Landscape Co. Weak and empty hulled seeds were eliminated for uniformity; seeds were soaked in water for 2 h before planting.

Test program

This study first employs orthogonal experimental design to analyze the effects of multiple factors on the physico-mechanical properties and vegetative growth performance of a novel vegetation-growing slope protection material. Subsequently, secondary optimization of the composite ecological regulator (CER) was implemented based on experimental outcomes, ultimately establishing the optimal mix ratio for the vegetation-growing material and the optimal CER dosage. The experimental procedure is schematically illustrated in Fig. 2.

The orthogonal test method efficiently evaluates multiple factors and their interactions, minimizing required tests and optimizing the design. In this study, cement, CER/cement, microsilica powder/cement, rice husks, and farmyard manure were selected as variables. Evaluation criteria included germination rate, plant height, compressive strength, pH, porosity, and water-holding capacity. Each factor was tested at five levels using the standard orthogonal table L25, yielding 25 test groups. The factor levels are outlined in Table 2, and the orthogonal test scheme is presented in Table 3. To match the dry density of the specimens to actual field conditions and ensure comparable results, soil samples were collected from the surface of a vegetated embankment slope along the Yellow River in Zhengzhou. The average dry density of these samples was 1.286 g/cm3. For consistency, the dry density of the test specimens was maintained at 1.30 g/cm3. After multiple adjustments, the moisture content of the substrate was finalized at 20%.

Specimen preparation

Physical and mechanical properties specimen

Specimen preparation adhered to ASTM D2166, with two-layer compaction to replicate field density. According to the proportions in Table 3, dry soil, cement, microsilica powder, rice husk, and farmyard manure were combined in a planetary mixer and blended at high speed for 2 min. CER was then dissolved in water and gradually added to the dry mixture, which was further mixed for 3 min to create the base material20,21.

The compressive strength test used cube specimens measuring 70.7 × 70.7 × 70.7 mm3. The mixture was weighed according to its dry density and pressed into the test mold in two layers, with the surface brushed between layers. Following molding, the specimens were cured for 1 day, then removed and placed in a standard curing chamber for 7 days. The water-holding rate and porosity tests used ring knife specimens with a diameter of 61.8 mm and a height of 40 mm. The specimens were molded in a single step with a ring knife press, cured for 7 days in a standard maintenance environment.

Planting specimen

Vegetation specimens were produced in transparent planting pots with an upper surface size of 15 × 15 cm and a height of 16 cm. To ensure that the substrate is breathable and that the fine particles are not easily lost during watering, the bottom 5 cm of the pots was filled with gravel overlaid with geotextile fabric. The remaining pot volume was determined using the water-filling method. Substrate mixtures weighed to match a dry density of 1.30 g/cm3 were evenly distributed across three layers in the pots. The surface of the substrate was leveled, and a custom-made planting hole template was used to create a 7 × 7 grid of uniformly spaced holes. Festuca arundinacea seeds were placed in each hole using tweezers, and the holes were then covered, resulting in a total of 49 seeds per pot. After planting, an absorbent blanket was placed over the substrate surface, and the pots were placed outdoors under well-lit conditions. The plants were watered every morning and evening. The vegetation growth specimen fabrication process is shown in Fig. 3.

Test methods

Compressive strength test

Compressive strength test was conducted using a 30 kN servo-controlled pressure tester, and the average value of three specimens was recorded as the test result.

Water-holding rate and porosity

Water-holding rate and porosity test procedure is as follows:

-

1.

Dry the specimen in an oven at 105 °C for 8 h, and its mass is recorded after drying \({\text{W}}_{{\text{s}}}\).

-

2.

Submerge the dried specimen in pure water for 24 h, remove it, pat the surface dry with a wet towel, and record its saturated mass Wω.

-

3.

Submerge the saturated specimen in water again and measure its mass in water using a hydrostatic balance.

-

4.

Calculate the water-holding capacity and porosity using the formulas in Eqs. (1) and (2).

$${\text{W}}_{{\text{c}}} = {{\left( {{\text{W}}_{\omega } - {\text{W}}_{{\text{s}}} } \right)} \mathord{\left/ {\vphantom {{\left( {{\text{W}}_{\omega } - {\text{W}}_{{\text{s}}} } \right)} {{\text{W}}_{{\text{s}}} }}} \right. \kern-0pt} {{\text{W}}_{{\text{s}}} }}$$(1)$$P_{n} = {{1 - \left( {{\text{W}}_{s} - {\text{W}}_{{\text{p}}} } \right)} \mathord{\left/ {\vphantom {{1 - \left( {{\text{W}}_{s} - {\text{W}}_{{\text{p}}} } \right)} {\rho V}}} \right. \kern-0pt} {\rho V}}$$(2)where Wc, Pn, ρ, and V refer to the water holding capacity of the specimen, porosity, density of water, and volume of the specimen, respectively.

pH value determination

After the compressive strength test, the crushed sample was dried and spread onto a plexiglass plate. The sample was further pulverized using a wooden stick and mixed thoroughly. The fragments were passed through a 0.25 mm nylon sieve, and 10 g of the sieved sample was weighed and then transferred into a 50 mL beaker. Next, 25 g of distilled water was added, and the mixture was stirred with a magnetic stirrer for 2 min. The beaker was then covered with cling film and left undisturbed for 30 min. A calibrated pH meter was inserted into the beaker at a depth of 1/3 to 2/3 below the liquid surface. Once the readings stabilized, the test was completed. The electrode was rinsed with clean water, dried with filter paper, and prepared for testing the next sample. The process was repeated for all subsequent specimens34.

Germination and plant height tests

The number of germinated seeds and plant height were recorded every 2 days until stabilization of the germination rate. Germination rate was calculated as the ratio of germinated seeds to the total number of seeds (49), while plant height was the average per pot. Measurements for germination rate and plant height were taken on the 20th day of planting.

Determination of nutrient elements and effective colony counts

Soil water, carbon, and nutrients are essential for healthy plant growth. The nutrients assessed in this study are available nitrogen (AN), available phosphorus (AP), and available potassium (AK), which are easily absorbed by plants. AN was determined using the alkaline diffusion method. AP was measured through sodium bicarbonate leaching followed by molybdenum-antimony spectrophotometry. AK was analyzed using the ammonium acetate leaching method in conjunction with a flame photometer. The effective number of microbial colonies in the soil was assessed using the plate colony counting method (CFU method) in a biochemical incubator.

Sensitivity analysis of factors affecting Festuca arundinacea growth characteristics

Overview of test results

Physicochemical and vegetative properties of 25 orthogonal test groups were analyzed. The results included measurements of compressive strength, pH, porosity, water-holding capacity (WHC), germination rate, and plant height across configurations. Detailed results are presented in Table 3.

To achieve effective ecological restoration and slope protection, the vegetation-growing slope protection material must possess adequate air permeability, water retention, a suitable pH range, and high strength. Analysis of the test results demonstrates that the compressive strength of the substrate ranged from 0.087 to 0.992 MPa, pH values ranged from 7.99 to 11.55, porosity ranged from 35.67 to 45%, water retention ranged from 24.7 to 36.3%, germination rates ranged from 18.3 to 95.9%, and plant heights ranged from 6 to 79 mm. These results suggest that the composition and mix ratio of the substrate have a significant impact on its physicochemical and vegetative properties. Referring to the provisions of the relevant specifications, when the vegetated concrete has good vegetation growth and slope protection performance when the unconfined compressive strength is ≥ 0.25 MPa, the aeration porosity is ≥ 25%, and the water content is ≥ 15%, the new vegetated material proposed in this paper can well meet the requirements of the relevant specifications32.

Sensitivity analysis of factors affecting the germination rate of Festuca arundinacea

Figure 4 illustrates the impact of each factor on germination rates. As illustrated in Fig. 4a, cement has a significant inhibitory effect on germination rate. With increasing cement content, two distinct trends emerge: a gradual decline followed by a sharp drop. When cement content increases from 2 to 4%, the germination rate decreases slightly from 66 to 62%, a modest 6% reduction indicating the gradual decline phase. However, when cement content increases from 4 to 6%, the germination rate drops sharply from 62 to 33%, a steep 47% decrease. To maintain acceptable germination rates, the cement content should not exceed 4%.

From Fig. 4b, the germination rate initially increases and then decreases with a rising CER-to-cement ratio. The germination rate peaks at 67.35% when the ratio is 10%, representing a 22.2% improvement compared to the absence of CER. However, when the ratio reaches 20%, the germination rate drops to 41.63%. According to Fig. 4d, rice husk content is the most critical factor in enhancing germination. The germination rate rises almost linearly with rising rice husk content. When rice husk content increases from 0 to 8%, the germination rate rises significantly from 29.8 to 76.73%, a 157.5% increase. Thus, increasing rice husk content is an effective strategy for promoting seed germination. Figure 4e illustrates that the seed germination rate initially increases with rising agricultural fertilizer dosage and then stabilizes. The highest germination rate occurs at 2% fertilizer content. Overall, the fluctuations are minimal, indicating that agricultural fertilizer has a relatively small impact on germination rates.

Sensitivity analysis of factors affecting plant height

Figure 5 illustrates the trends in plant height corresponding to each factor. As cement content increased, plant height declined nearly linearly, decreasing from 52.4 mm at 2% to 18.6 mm at 6%, highlighting its strong inhibitory effect on plant growth. For the CER/cement, plant height initially rose, peaking at 46.2 mm at 10%, before decreasing. A similar pattern emerged with the microsilica powder/cement ratio, where plant height reached a maximum of 44.6 mm at 50% and then declined. Rice husk content emerged as the most significant factor affecting plant height. Plant height increased from 18.4 to 47.6 mm when rice husk content rose from 0 to 4%, with minimal changes at higher levels. Farmyard manure showed a modest positive effect on plant height. Increasing its content from 0 to 1%, the plant height increased from 31.8 to 39.6 mm (a 25% increase), but further increments had minimal impact.

Analyzing the effects of various factors on the vegetative characteristics of Festuca arundinacea reveals that cement substantially inhibits seed germination and plant growth. When the cement content exceeds 4%, the germination rate drops steeply, suggesting that the cement dosage should be limited to 4% or less. In contrast, rice husk content enhances both germination and plant height, with increasing effects observed at higher levels; however, the optimal dosage must be balanced with other indicators. The germination rate and plant height reached their optimal levels when the CER/cement, microsilica powder/cement ratios, and farmyard manure content were 10%, 50%, and 2%, respectively. These findings indicate that appropriate amounts of CER, microsilica powder, and farmyard manure can promote germination and growth, while excessive additions inhibit them.

Sensitivity analysis of factors affecting the physicochemical properties of substrates

Sensitivity analysis of factors affecting compressive strength

To further analyze how each factor level influences compressive strength, Fig. 6 illustrates the trends in substrate compressive strength relative to each factor. The compressive strength increases nearly linearly with higher cement content but decreases as farmyard manure content rises. It initially increases with greater rice husk content, reaching a peak at 4–6% before declining. Similarly, compressive strength increases with a higher microsilica powder-to-cement ratio. In contrast, as the CER-to-cement ratio exceeds 5%, the compressive strength drops sharply before stabilizing. These findings indicate that cement, microsilica powder, and rice husks enhance compressive strength, while CER and farmyard manure diminish it.

Sensitivity analysis of factors affecting pH of substrates

As illustrated in Fig. 7, the substrate pH rises sharply and linearly with an increase in cement content, while it declines with higher levels of rice husk, farmyard manure, and CER/cement. This indicates that the rise in pH is primarily due to cement hydration. When cement content increases from 2 to 6%, the pH rises from 9.08 to 11.11, representing a 22.4% increase. Conversely, the pH decreased progressively with higher CER/cement, suggesting that CER reacts with calcium hydroxide to lower pH. Rice husk and farmyard manure significantly reduce pH, with levels exceeding 6% and 2%, respectively, capable of bringing the substrate pH below 10.

Sensitivity analysis of factors affecting porosity and water holding capacity

As illustrated in Figs. 8 and 9, substrate porosity and water-holding capacity decrease as cement content increases. When cement content rises from 2 to 6%, porosity drops from 42.63 to 40.13%, and water-holding capacity declines from 32.94 to 29.70%, representing 5.8% and 9.8% reductions, respectively. Conversely, increasing rice husk content reduces porosity. In contrast, water-holding capacity initially increases and then decreases, peaking at 33.92% with a rice husk dosage of 6%, an 18.27% improvement compared to substrates without rice husk. Water-holding capacity reflects the ability of the substrate to absorb and store water, which is influenced by porosity and the characteristics of the pore structure. Higher porosity enhances the hydrophilicity of the substrate, while a well-connected network of fine pores enhances water absorption and retention. These factors collectively support better plant growth.

Discussion

The hydration products of cement, such as silicate gel (C-S-H) and calcium hydroxide, primarily contribute to the bonding strength of the substrate. Higher cement content enhances stability yet introduces challenges. Notably, our findings align with prior studies that report pH elevation (9.0–11.5) and reduced porosity (35–45%) in cement-dominated substrates35,36,37. However, unlike conventional vegetated concrete formulations using 8–10% cement21,22,23, our optimized mix (4% cement) achieves comparable compressive strength (0.37 MPa) while mitigating pH-induced vegetation suppression. This reduction in cement dependency represents a significant advancement, as excessive cement (> 6%) has been shown to decrease germination rates by 47%21, a trend corroborated in our orthogonal tests (Fig. 4a).

Adhesive and hydrophobic properties of C-S-H result in agglomeration, reducing porosity and water retention. Here, the incorporation of rice husk (6%) addresses this limitation by dispersing pore clusters and enhancing water-holding capacity (33.92%, Fig. 10). Compared to biochar-amended substrates38,39,40, which improve porosity but lack structural stability, rice husk provides dual benefits: (1) acting as a skeletal framework to resist crack propagation, and (2) decomposing gradually to release organic nutrients. This dual functionality aligns with the findings of Ding et al.33, who observed a 25% increase in plant height with rice husk addition, though our study achieves a more pronounced improvement (163%) due to synergistic effects with CER.

The novel CER plays a pivotal role in balancing mechanical and ecological performance. While traditional regulators like phosphogypsum23 or biochar focus solely on pH reduction or nutrient supply, CER integrates three functions: pH regulation (via ammonium and phosphate hydrolysis), nutrient enrichment (AN: 63.9 mg/kg, AP: 53.8 mg/kg, AK: 205.2 mg/kg), and microbial activation (CFU: 1.2 × 10⁶/g). This multifunctionality resolves the trade-off between strength and vegetation growth observed in prior studies41. For instance, Liu et al.20 reported a 30% decline in germination rates when cement content exceeded 5%, whereas our CER-enabled formulation maintains > 90% germination even at 4% cement (Fig. 11).

Microsilica powder further enhances the system by reacting with calcium hydroxide to form additional C-S–H gel, thereby improving strength without exacerbating alkalinity. This mechanism diverges from fly ash-based approaches42, which require higher dosages (20–30%) to achieve similar pH reduction. Our results demonstrate that microsilica at 50% of cement mass optimizes both strength (0.35 MPa) and pore structure (42.6% porosity), outperforming silica fume-modified substrates that often suffer from pore clogging.

Optimal slope restoration transitions from artificial to natural processes, requiring substrates to provide sustainable nutrients. Farmyard manure offers balanced nutrients, long-lasting effects, and supports soil microorganisms, enhancing substrate nutrient retention and supply. Given its loose, porous nature, farmyard manure significantly affects substrate strength and vegetation properties. A 2% mixing ratio balances these impacts.

Despite these advances, limitations remain. Long-term field validation is needed to assess CER’s durability under weathering and microbial competition. Additionally, the vegetative and physicochemical (pH, shear strength, nutrient retention) properties of the material are also the focus of attention at a later stage, as are the patterns of long-term evolution and the factors influencing them.

In conclusion, the design of the novel vegetation-growing material for slope protection must balance strength and vegetative properties, ensuring rapid ecological recovery and a sustainable transition from artificial to natural restoration. Based on orthogonal test analysis, the optimal mixing ratio is soil:cement:CER:microsilica powder:rice husk:farmyard manure = 100:4:X:2:6:2, with further tests needed to determine the precise CER content.

Secondary optimization of base material ratios

Experimental design

To determine the optimal CER content, the substrate composition was set at a soil:cement:CER:microsilica powder:rice husk:farmyard manure = 100:4:X:2:6:2, with microsilica powder at 50% of the cement content. Single factor analysis of CER was conducted, testing mixing levels of 5%, 7.5%, 10%, 12.5%, and 15% relative to the cement content baseline. The growth conditions and physicochemical properties of Festuca arundinacea were evaluated at each CER level. To ensure consistent dry density and accuracy in subsequent testing, planting specimens were prepared using a ring-knife mold with a diameter of 61.8 mm and a height of 40 mm. Three specimens were created for each mixing ratio, and the germination rates and plant heights of Festuca arundinacea were recorded after 20 days of growth. AN, AP, AK, viable bacterial counts, and shear strength were measured using ring-knife specimens after standard curing for 7 days.

Results of the secondary optimization experiment

Figures 10, 11, 12 and 13 depict the effects of varying CER dosages on plant growth and substrate properties. Figure 9 illustrates plant growth at 10, 20, and 40 days. Figure 11 presents the germination rate and plant height trends at 20 days. Figure 12 highlights changes in substrate nutrient composition and viable bacterial counts, while Fig. 13 shows the shear strength variations of the substrate with CER dosage.

Figures 10 and 11 illustrate that higher CER levels initially improved the growth of Festuca arundinacea, but excessive levels inhibited it. Optimal growth occurred at 7.5% CER doping (group b), with a germination rate of 96% within 20 days and a plant height of 13.5 cm. This stage was characterized by a high early germination rate and robust late-stage growth, suggesting that 7.5% CER doping effectively met the nutrient requirements of the plant throughout its growth cycle. At a CER dosage of 5% (group a), the early growth of Festuca arundinacea was favorable, with a germination rate of 91% and a plant height of 12.6 cm. However, by 40 days, the plants appeared stunted and yellowed, exhibiting noticeable growth stagnation. At 15% CER doping (group d), plant growth dropped considerably across all stages, with a germination rate of 55% and a plant height of 12.2 cm. These values were 42.3% and 9.7% lower than the respective maximums, indicating that the appropriate amount of CER could significantly promote seed germination and plant growth; however, the doping was extremely high and inhibited the plant.

To explore the mechanisms underlying plant growth changes with CER dosage, AN, AP, AK levels, and viable bacterial counts in the substrate were analyzed (Fig. 12). Results demonstrated rapid increases in AP, AK, and bacterial counts with higher CER dosages, while AN levels remained essentially unchanged. Substrates with AN, AP, and AK levels of 60–90 mg/kg, 30–40 mg/kg, and 100–200 mg/kg, respectively, were deemed nutrient-rich. However, AP levels above 65 mg/kg and AK levels exceeding 400 mg/kg hinder plant growth43,44. At 7.5% CER dosage, the substrate contained 63.904 mg/kg of nitrogen, 53.78 mg/kg of phosphorus, and 205.186 mg/kg of potassium, providing an optimal nutrient balance for plant growth. However, at 10% CER, AP exceeded favorable levels (80.257 mg/kg), and at 15%, it doubled the threshold (136.605 mg/kg), severely inhibiting germination and growth. Therefore, the germination rate is the lowest, and plant growth is the poorest at this dosage, which is consistent with existing research findings19. In conclusion, CER enhances substrate nutrients and microbial content, improving vegetative conditions. However, excessive CER increases AP to inhibitory levels, negatively impacting seed germination and late-stage plant growth.

As illustrated in Fig. 13, increasing CER content does not significantly affect the internal friction angle, which remains stable at approximately 23°; however, it causes a gradual decrease in cohesion. When the substrate cohesion is at least 15 kPa, and the internal friction angle is around 30°, shear slip between the substrate and surface of the steep slopes can be prevented. Due to its thin application layer on the slope surface, the novel vegetation-growing material for slope protection relies heavily on cohesion for shear strength and slope stability, as indicated by the Moore‒Coulomb criterion. At a CER content of 7.5%, the cohesion reaches 62.25 kPa, and the internal friction angle is 26°, which meets the requirements, with cohesion significantly exceeding the safety threshold. However, when CER content increases to 12.5%, cohesion drops to 41 kPa—a 44.9% reduction from the peak value of 74.34 kPa. This indicates that excessive CER content significantly reduces cohesion, likely due to the alkaline modifiers and active microorganisms in CER, which disrupt the hydration environment of the cement and alter its hydration products.

In summary, with the increase of CER dosage, the growth of Festuca arundinacea was first enhanced and then weakened; when the CER dosage accounted for 7.5% of the cement mass, the plant growth was optimal and had good shear strength. However, excessive CER caused the AP content in the substrate to exceed the tolerance limit of the plant, inhibiting seed germination and growth while significantly lowering substrate cohesion. Thus, the optimal CER dosage is 7.5% of the cement mass, and the ideal substrate mixing ratio is soil:cement:CER:microsilica powder:rice husk:agricultural fertilizer = 100:4:0.3:2:6:2.

Conclusion

To develop a novel vegetation-growing material for slope protection with high strength, strong erosion resistance, excellent vegetative performance, and ease of construction, this study examined the effects of cement, CER, rice husk, and farmyard manure on the vegetative performance and physicochemical properties of substrates. Using orthogonal testing and secondary optimization of CER, the optimal mix ratio was determined as soil:cement:CER:microsilica powder:rice husk:farmyard manure = 100:4:0.225:2:6:2. The main findings are summarized below:

-

1.

Cement hydration products provide bonding strength to the substrate but increase pH and reduce porosity and water-holding capacity, thereby hindering seed germination and plant growth. An optimal cement dosage of 4% effectively balances the physical properties of the substrate and plant growth requirements.

-

2.

Rice husks act as reinforcements, skeleton builders, and pore dispersers in the substrate. When organic matter is incorporated at 6%, the substrate achieves optimal strength and water-holding capacity. This results in a seed germination rate of 68.57% and an average plant height of 48.4 mm—improvements of 130% and 163%, respectively, compared to a germination rate of 29.80% and plant height of 18.4 mm without rice husk.

-

3.

Proper CER supplementation enhances substrate nutrient levels, regulates pH, and boosts microbial activity. However, excessive CER can result in available phosphorus levels exceeding plant tolerance, inhibiting seed germination and late-stage growth. The optimal CER dosage is 7.5% of the cement weight.

-

4.

Microsilica powder lowers substrate pH and improves structural strength. However, when its proportion exceeds 50% of the cement dosage, the pore ratio decreases, restricting root respiration and plant growth.

This study achieves the dual role of revegetation and slope protection by integrating industrial and agricultural wastes into a low-carbon matrix, in line with the United Nations Sustainable Development Goals. Future research should focus on the long-term evolution of substrate properties under field conditions, particularly the persistence of CER-mediated pH regulation and nutrient retention mechanisms. For example, multi-year monitoring of pH stability, nutrient leaching patterns, and microbial community dynamics under weathering (e.g., freeze–thaw cycles, rainfall erosion) conditions is essential to validate material sustainability.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Li, D., Chen, X., Tao, T., Tan, W. & Ma, L. Quantifying the sheet-rill erosion process along a saturated soil slope. CATENA https://doi.org/10.1016/j.catena.2022.106631 (2022).

Dong, L. et al. Effects of vegetation restoration types on soil nutrients and soil erodibility regulated by slope positions on the Loess Plateau. J. Environ. Manag. https://doi.org/10.1016/j.jenvman.2021.113985 (2021).

Lowe, M.-A., McGrath, G. & Leopold, M. The impact of soil water repellency and slope upon runoff and erosion. Soil Tillage Res. https://doi.org/10.1016/j.still.2020.104756 (2020).

Li, D. et al. Response of erosion rate to hydrodynamic parameters in sheet and rill erosion process on saturated soil slopes. Soil Tillage Res. https://doi.org/10.1016/j.still.2023.105996 (2024).

Guo, S. et al. Enhancing plant resilience: Arbuscular mycorrhizal fungi’s role in alleviating drought stress in vegetation concrete. Front. Plant Sci. https://doi.org/10.3389/fpls.2024.1401050 (2024).

Jien, S.-H., Chen, C.-N., Dabo, L. M., Tfwala, S. S. & Kunene, N. H. Impact assessment of land use and land cover change on soil erosion at Laonung watershed in Taiwan. Environ. Earth Sci. https://doi.org/10.1007/s12665-023-11287-2 (2023).

Xia, D., Shao, G., Li, X., Yao, J. & Li, F. Research status and trend of soil reconstruction based on rock slope ecological restoration. Coal Sci. Technol. 1–24 (2024).

Zhang, M. et al. Research progress and prospect slope greening in China—Bibliometric analysis based on cite space and VOS viewer. Bull. Soil Water Conserv. 43, 248–255. https://doi.org/10.13961/j.cnki.stbctb.2023.06.030 (2023).

Wu, Y. et al. Response of soil nutrients and erodibility to slope aspect in the northern agro-pastoral ecotone, China. Soil https://doi.org/10.5194/soil-10-61-2024 (2024).

Zhao, G. et al. Microbial fertilizers and shading contribute to the vegetation assembly and restoration of steep-slope after soil spray-sowing in the Yuanjiang dry-hot valley region. Forests https://doi.org/10.3390/f15060973 (2024).

Wang, G., Dong, Y., Rong, L., Yang, W. & Duan, X. The influence of vegetation restoration on soil quality in abandoned farmlands in the Yuanjiang dry-hot valley. CATENA https://doi.org/10.1016/j.catena.2024.108109 (2024).

Xing, H., Wang, Y. & Yang, L. Research on the construction technology of thick layer substrate spraying for slope protection and greening protection. Highway 59, 146–149 (2014).

Zhang, M., Hu, D. & Fan, J. Study on the application of vegetation protection and ecological restoration technology in stone slope. IOP Cond. Se. Earth Environ. Sci. https://doi.org/10.1088/1755-1315/510/4/042024 (2020).

Liu, D., Ma, Y. & Han, L. Selection of grass species and combinations for slope hydraulic spraying greening. J. Beiing For. Univ. https://doi.org/10.13332/j.1000-1522.2000.02.010 (2000).

Cui, Z., Chen, G., Zhu, Y., Xu, Z. & Liu, R. Research progress on the influence of admixture to the planting concrete used for slope protection. Concrete 352, 124–127 (2019).

Tang, W., Mohseni, E. & Wang, Z. Development of vegetation concrete technology for slope protection and greening. Constr. Build. Mater. https://doi.org/10.1016/j.conbuildmat.2018.05.207 (2018).

Liu, L. et al. Research progress on ecological restoration technology of vegetation concrete. J. Environ. Eng. Technol. 12, 916–927 (2022).

Li, C. et al. Effects of mineral-solubilizing microbial strains on the mechanical responses of roots and root-reinforced soil in external-soil spray seeding substrate. Sci. Total Environ. https://doi.org/10.1016/j.scitotenv.2020.138079 (2020).

Xia, D., Xu, W.-N., Zhao, J. & Zhu, S. Analysis of pH soil organic matter and the correlation to available nutrients in substrate of vegetation-growing concrete gunning. Res. Soil Water Conserv. 17, 224–227 (2010).

Liu, D. et al. Influence of addition of two typical activated carbons on fertility properties and mechanical strength of vegetation concrete under freeze-thaw conditions. Sci. Total Environ. https://doi.org/10.1016/j.scitotenv.2022.156446 (2022).

Liu, D. et al. Influence of biochar addition amount on physicochemical properties of vegetation concrete and biomass of Cynodon dactylon. J. Basic Sci. Eng. 29, 1–14. https://doi.org/10.16058/j.issn.1005-0930.2021.01.001 (2021).

Liu, D., Li, S.-L., Xu, W.-N. & Cheng, Z.-L. Selection tests for type and ratio of organic matter in vegetation concrete. Adv. Sci. Technol. Water Resour. 32, 37–40+54 (2012).

Liu, Z. et al. Research on vegetative performance of externally mixed phosphogypsum modified vegetative concrete slope protection. Yangtze River 55, 239–245. https://doi.org/10.16232/j.cnki.1001-4179.2024.10.032 (2024).

Shu, Q. et al. Response of physiological characteristics of ecological restoration plants to substrate cement content under exogenous arbuscular mycorrhizal fungal inoculation. Front. Plant Sci. https://doi.org/10.3389/fpls.2022.1028553 (2022).

Chang, Z. et al. Ecological protection technology of spraying vegetation concrete on carbonaceous rock slope experimental research and application. Adv. Civ. Eng. https://doi.org/10.1155/2022/2557131 (2022).

António, J., Tadeu, A., Marques, B., Almeida, J. A. S. & Pinto, V. Application of rice husk in the development of new composite boards. Constr. Build. Mater. https://doi.org/10.1016/j.conbuildmat.2018.05.028 (2018).

Gao, J. et al. Effects of two types of activated carbon on the properties of vegetation concrete and Cynodon dactylon growth. Sci. Rep. https://doi.org/10.1038/s41598-020-71440-w (2020).

Niyomukiza, J. B., Eisazadeh, A. & Tangtermsirikul, S. Synergistic effect of calcined clay and fly ash on the performance of porous vegetation concrete. Constr. Build. Mater. https://doi.org/10.1016/j.conbuildmat.2024.139749 (2024).

Zhang, X. et al. Research on physical properties and plant adaptability of polyurethane modified cement based planting concrete. Constr. Build. Mater. https://doi.org/10.1016/j.conbuildmat.2025.140222 (2025).

Zhou, M. et al. Study on the mix proportions of substrate for vegetated concrete habitats based on the improved GAWOA-XGBoost model. China Civ. Eng. J. https://doi.org/10.15951/j.tmgcxb.23110969 (2024).

Yang, Y. et al. Effects of freeze-thaw cycling on the engineering properties of vegetation concrete. J. Environ. Manag. https://doi.org/10.1016/j.jenvman.2023.118810 (2023).

Liu, D. et al. Effect of soil quality on physical and chemical properties of vegetation concrete and plant growth. J. Environ. Eng. Technol. 13, 2271–2278 (2023).

Ding, Y. et al. Statistical damage model for fiber-reinforced vegetation concrete substrate. Chin. J. Geotech. Eng. 44, 652–659 (2022).

Fraser, T. D., Duddigan, S., Diaz, A., Green, I. & Tibbett, M. Optimizing pH for soil enzyme assays reveals important biochemical functions in low pH soil. J. Soil Sci. Plant Nutr. https://doi.org/10.1007/s42729-024-01866-y (2024).

Wu, F., Chen, X. & Brouwers, H. J. H. Application of miscanthus to enhance plant growth adaptability of bio-based vegetal concrete. Constr. Build. Mater. https://doi.org/10.1016/j.conbuildmat.2024.136096 (2024).

Hamid, F. et al. Carbon dioxide emission evaluation of biochar based vegetation concrete for ecological restoration projects. Case Stud. Constr. Mater. https://doi.org/10.1016/j.cscm.2024.e03874 (2024).

Abedi, M. et al. Influence of cement and water content on the multifaceted capabilities of a self-sensing cement-based geocomposite: A comprehensive analysis. Meas. Sci. Technol. https://doi.org/10.1088/1361-6501/ad4c89 (2024).

Senadheera, S. S. et al. Application of biochar in concrete—A review. Cem. Concr. Compos. https://doi.org/10.1016/j.cemconcomp.2023.105204 (2023).

Kuoppamäki, K., Prass, M. & Hagner, M. Crushed concrete and biochar: A sustainable solution for vegetated roofs. Urban For. Urban Green. https://doi.org/10.1016/j.ufug.2023.128082 (2023).

Guo, H., Zhang, Q., Chen, Y. & Lu, H. Effects of biochar on plant growth and hydro-chemical properties of recycled concrete aggregate. Sci. Total Environ. https://doi.org/10.1016/j.scitotenv.2023.163557 (2023).

Chen, F., Xu, Y., Wang, C. & Mao, J. Effects of concrete content on seed germination and seedling establishment in vegetation concrete matrix in slope restoration. Ecol. Eng. https://doi.org/10.1016/j.ecoleng.2013.06.016 (2013).

Zhang, Q.-L. et al. Effects of temperatures and pH values on rheological properties of cemented paste backfill. J. Cent. South Univ. https://doi.org/10.1007/s11771-021-4728-4 (2021).

Feng, Z. et al. The effect of phosphorus content on wheat root-associated prokaryotic community depends on growth stage and variety. Soil Sci. Soc. Am. J. https://doi.org/10.1002/saj2.20613 (2023).

Saritha, M., Kumar, P., Panwar, N. R. & Burman, U. Plant response to novel organo-mineral fertilizers based on selective enrichment of P- and K-solubilizing microorganisms in soil. J. Soil Sci. Plant Nutr. https://doi.org/10.1007/s42729-021-00530-z (2021).

Acknowledgements

We would like to thank Editage (www.editage.cn) for English language editing.

Funding

This study was supported by the National Natural Science Foundation of China (No. U1704243).

Author information

Authors and Affiliations

Contributions

Liu provided guidance on research direction, experimental design, and manuscript revision. Fan* contributed to the overall study design, methodology development, data analysis, and manuscript preparation. Luo conducted experiments, data collection, and initial analysis. Chang assisted in data interpretation, visualization, and manuscript editing. All authors reviewed and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Liu, HD., Fan, L., Luo, J. et al. Synergistic optimization of mechanical strength and vegetative growth in ecological slope restoration materials through mix ratio design. Sci Rep 15, 20374 (2025). https://doi.org/10.1038/s41598-025-05754-y

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-05754-y