Abstract

Hot-mix asphalt (HMA) fatigue cracking is governed by external factors, including temperature, precipitation, and traffic loading, alongside internal factors, such as bitumen type, bitumen percent, air void, and the aggregate’s mineralogy and physical properties. As a critical external factor, moisture, particularly runoff with varying acidity, exacerbates fatigue cracking through physical and chemical interactions. The use of advanced additives such as nanomaterials in HMAs enhances their performance against various types of distress. Carbon nanotubes (CNTs) and nano-graphene oxide (NGO) are nanomaterials that exhibit exceptionally high elastic resistance and desirable hydrophobic properties. Their application has shown promising results in the contaminated water treatment industry. Given that the providing solutions to mitigate the negative effects of acidic and alkaline waters on the intermediate-temperature performance of HMAs has not been widely discussed, this study employs CNTs and NGO to mitigate the damaging effects of acidic and alkaline runoff from surface pollutants on the fatigue performance of bitumen and HMAs. This study employed dynamic shear rheometer (DSR) and semi-circular bending (SCB) tests under dry, neutral wet, acidic wet (pH = 5 and 6), and alkaline wet (pH = 8 and 9) conditions to evaluate the fatigue cracking potential in different bitumens and asphalt mixtures. Limestone and siliceous aggregates, differing in moisture susceptibility, were combined with PG 58–22 bitumen to fabricate HMA. Carbon nanotubes (CNTs) and nano-graphene oxide (NGO) were also incorporated at 0.3% and 0.6% by the bitumen’s weight. Test results on the bitumen and HMAs under different moisture conditions show that altering the pH of pure water significantly degrades the bitumen’s rheological properties and the mixture’s mechanical fracture resistance. Conversely, CNTs and NGO substantially reduced G*Sinδ while boosting fracture energy and toughness. In other words, these two nanomaterials reduced the fatigue parameter of the bitumen under dry, acidic, and alkaline moisture conditions, demonstrating their outstanding performance in enhancing the fatigue resistance of the modified bitumen against intermediate temperature cracking under various moisture exposures. Furthermore, the mixtures modified with CNTs and NGO withstood higher energy for cracking at intermediate temperatures when exposed to acidic and alkaline moisture conditions, while also increasing the critical stress threshold required for final failure. This indicates that CNTs and NGO, even when the detrimental effects of acidic and alkaline runoff dominate their properties, improve the performance of both the bitumen and the mixture against intermediate-temperature cracking. The specimens with 0.6% NGO exhibited exceptional fatigue resistance across all conditions. These findings highlight NGO at 0.6% concentration as a superior enhancer of asphalt resilience against runoff-induced fatigue deterioration.

Similar content being viewed by others

Introduction

Fatigue cracks, rutting, and low-temperature cracking represent the primary distresses in flexible pavements. Fatigue cracking in asphalt pavements can significantly elevate repair and maintenance costs while reducing the pavement structure’s service life. Traffic loading on the pavement surface occurs periodically, with load intensities typically below the hot mix asphalt (HMA) fracture strength. However, over the long term, the combined effects of repeated loading and environmental factors create conditions conducive to the development of fatigue cracks1. Fatigue cracking in HMA generally arises through two mechanisms; the first involves the failure of adhesion between the bitumen and aggregate, while the second pertains to the failure of cohesion within the bitumen itself2. Fatigue cracks initially manifest as microcracks, which evolve into macrocracks within the HMA with continued loading. These macrocracks eventually propagate to the pavement surface, potentially compromising the pavement structure’s integrity and strength1,3.

Several factors, including environmental conditions, loading characteristics, and material properties, influence HMA’s fatigue performance. Among environmental factors, moisture is widely recognized as a critical contributor to extensive pavement deterioration4. Moisture in asphalt pavements may originate from internal or external sources. Complete exclusion remains challenging despite measures implemented to prevent moisture infiltration into the pavement layers5. When conditions allow water to accumulate on the HMA layer’s surface, moisture can penetrate the mixture due to air voids (AV). This infiltration disrupts adhesion between the bitumen and aggregate, subsequently weakening the HMA’s structural integrity. Furthermore, moisture exposure hardens the bitumen, increasing its susceptibility to fatigue and thermal cracking6,7.

The detrimental impact of moisture on HMA performance is influenced by multiple factors, including HMA permeability, aggregate composition, and chemical alterations in infiltrating water. Moisture primarily infiltrates HMA through surface runoff, whose chemical composition varies significantly due to environmental contaminants. These include airborne particulates, vehicular exhaust emissions, and other surface pollutants. Among these chemical changes, variations in water pH (acidity or alkalinity) prove particularly consequential8,9. Field and laboratory studies show that runoff flowing onto the pavement surface has acidic and alkaline properties. In areas with heavy traffic where soot accumulation is dominant and in regions with light traffic where dust particles are more likely, the runoff has basic and acidic properties, respectively. Exposure to moisture with differing pH levels degrades both bitumen and asphalt concrete properties, ultimately compromising their resistance to various failure mechanisms10,11,12,13.

Given the significant deterioration of asphalt mixtures caused by exposure to acidic and alkaline waters, developing effective mitigation strategies to enhance mixture durability has become imperative. Recent advances in material science suggest that nanomaterial additives can substantially improve HMA resistance to various distress mechanisms. Among these, carbon nanotubes (CNTs) and nano-graphene oxide (NGO) demonstrate particularly promising characteristics, including exceptional elastic modulus and superior hydrophobicity. These nanomaterials have already proven their efficacy in water purification applications, suggesting strong potential for asphalt performance enhancement8,9. Accordingly, this study employs CNTs and NGO to mitigate the damaging effects of acidic and alkaline runoff from surface pollutants on the fatigue performance of bitumen and HMAs.

Previous studies

Effects of moisture on HMA performance

Water flow on road surfaces, commonly referred to as runoff, constitutes a primary source of moisture in pavement structures. Amini et al6. (2014) investigated the performance of two HMAs with different gradations under runoff by measuring Marshall stability and specimen weight loss. Surface water flows created conditions conducive to various forms of deterioration in HMA, ultimately reducing the service life of pavements. In 2019, Junior et al14. assessed the influence of adhesion between the bitumen and aggregate on moisture damage and fatigue cracking in various HMAs. Employing image processing techniques to evaluate adhesion, the researchers reported that moisture-induced bond failure between the bitumen and aggregate weakened HMA’s structural integrity.

Scott et al.15 (1978) demonstrated that variations and instability in water acidity affect the quality of chemical bonding at material surfaces and adhesion between the bitumen and aggregate. Yoon and Tarrer16 (1988) conducted a laboratory study investigating adhesion between the bitumen and aggregate under diverse conditions. They prepared specimens using aggregates with varying physical and chemical properties and employed the boiling water test to assess moisture effects. Their results highlighted the significant influence of water acidity on bitumen-aggregate adhesion16. Studies by Zhang et al.17,18,19 in 2004 and 2005 explored the impact of acidic moisture on HMA. To simulate the effects of acid rain, they used combinations of water with H₂SO₄ and HNO₃ solutions to achieve acidity levels of pH 1, 3, and 6.5. The findings indicated that wet specimens exhibited increased AV, weight loss, and reduced Marshall stability compared to dry specimens.

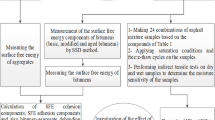

Feng and Johnson20 (2017) conducted a laboratory study on bitumen specimens to evaluate changes in rheological properties under moisture conditions with acidity levels of pH 2 and 4. Rheological properties were assessed through viscosity, softening point, and ductility tests. The results from specimens exposed to acidic moisture showed reduced viscosity, increased softening points, and decreased ductility compared to those in neutral moisture conditions. Yang et al.21 investigated the effects of varying water acidity levels on the bitumen-aggregate rheological properties, cohesion, and adhesion. The findings revealed that acidic, alkaline, or saline solutions altered bitumen structure and diminished its elasticity. Moreover, bitumen specimens exposed to acidic or alkaline water exhibited a substantial reduction in fatigue life. Using surface free energy (SFE) theory, Arabani et al.12 (2020) examined adhesion between the bitumen and aggregate under runoff with varying acidity levels. Acidic or alkaline runoff increased the free energy at interface between the bitumen and aggregate, significantly weakening adhesion quality. Additionally, shifts in water acidity increased the work of adhesion between the bitumen and water, enhancing the bitumen’s affinity for water, which led to its separation from aggregates and a loss of cohesion in the HMA. Arabani et al.22 also conducted a laboratory study to assess the moisture susceptibility of HMA under runoff with different acidity levels using mechanical and thermodynamic methods. Their analysis revealed that increases or decreases in runoff acidity significantly heightened the moisture susceptibility of HMA.

In 2022, Wei et al.23 studied the fatigue life of HMA under acidic moisture conditions. Based on four-point bending test results, they reported reduced fatigue life when HMA was exposed to acidic moisture. Chen et al.24 (2023) examined the effects of saline solutions and acid rain (pH = 3) on the moisture resistance of HMA using a multiscale analysis approach. The investigation assessed impacts at three scales: bitumen, interface between the bitumen and aggregate, and HMA. Acidic moisture (pH = 3) caused more pronounced damage across all scales compared to saline solutions, with interface between the bitumen and aggregate exhibiting the greatest vulnerability. Li et al.25 (2023) investigated the effects of alkaline, acidic, saline, and pure water solutions on asphalt deterioration using molecular dynamics (MD) simulation and dynamic shear rheometer (DSR) tests. Alkaline solutions exerted the most detrimental effect on bitumen-aggregate adhesion, reducing the performance of the bitumen-aggregate system. Additionally, exposure to alkaline and acidic solutions induced premature aging in asphalt.

Zhou et al.26 (2024) evaluated the effects of moisture with acidity levels of pH 3, 5, 7, 9, and 11 on the properties of base PG 70–22 bitumen and styrene–butadiene–styrene (SBS) modified bitumen. Both acidic and alkaline solutions caused significant declines in the physical and mechanical properties of bitumen by 25.5% in acidic solutions and 23.2% in alkaline solutions. Mehdinazar et al.27 (2024) evaluated the effects of zeolite on HMA under dry, acidic (pH 5 and 6), and alkaline conditions (pH 8 and 9). The semi-circular bending (SCB) test was used to assess mechanical performance, while SFE theory analyzed the thermodynamic behavior of the HMA. Under severe moisture conditions, adding zeolite at 1% and 2% by the bitumen’s weight improved the HMA’s fracture energy and fracture toughness by up to 25%. Additionally, zeolite enhanced the mixtures’ thermodynamic stability, effectively reducing the risk of cracking in acidic and alkaline environments.

Effects of nanomaterials on bitumen and HMA performance

In recent years, enhancing the properties of HMA by using various additives has garnered significant research attention. Incorporating nanomaterials as additives substantially improves the performance of HMA, including increased resistance to fatigue damage, moisture damage, and aging28,29,30.

In a laboratory study, Ameri et al.31 (2016) examined the fatigue and fracture properties of HMA modified with CNT. CNTs were added to base bitumen at five weight percentages ranging from 0.2% to 1.5%. The performance of the HMA specimens was evaluated using the SCB test and the beam fatigue test. The results demonstrated that bitumen modification with CNTs enhanced the fatigue life and fracture resistance of the HMA. Ashish et al.32 (2018) also utilized CNTs at concentrations of 0.4%, 0.75%, 1.5%, and 2.25% by the bitumen’s weight as an additive. Rheological tests on the modified bitumen revealed increased viscosity and failure temperature. Additionally, mechanical tests on HMA specimens indicated improved resistance to moisture and fatigue damage.

Latifi et al.33 (2018) incorporated CNTs into bitumen at 0.5%, 1%, and 2% by weight. The researchers assessed the properties of both the bitumen and HMA specimens through mechanical testing. The findings reported enhanced stiffness, rutting resistance, fatigue resistance, and thermal cracking resistance. Furthermore, Bach et al.34 utilized CNTs at various concentrations (0.05%, 0.1%, 0.15%, 0.2%, and 0.25% by the bitumen’s weight) as a bitumen modifier. Analysis of mechanical test results on HMA specimens confirmed that the CNTs increased fatigue resistance.

Liu et al.35 (2018) conducted a laboratory study on bitumen modified with graphene oxide (GO). They reported a chemical reaction between GO and bitumen particles, which improved the modified bitumen’s performance against rutting and low temperature cracking. In a laboratory study, Zhou et al.36 (2019) employed GO alongside Sasobit and waste cooking oil to modify bitumen and enhance HMA properties. The laboratory results indicated that adding 0.05% GO by the bitumen’s weight significantly reduced the HMA’s susceptibility to moisture damage. In 2019, Liu et al.37 demonstrated that combining GO and waste cooking oil markedly improved the fatigue properties of modified bitumen.

Adnan et al.38 (2020) incorporated GO into bitumen at varying concentrations (0.5%, 1%, 1.5%, 2%, and 2.5% by weight) as an additive. Chemical analysis using Fourier-transform infrared (FTIR) spectroscopy confirmed a reaction between carbon and bitumen particles. Durability and mechanical tests on HMA specimens further revealed that GO enhanced bitumen cohesion and resistance to moisture damage. In 2023, An et al.39 investigated the fatigue performance of GO-modified bitumen, examining both linear and nonlinear viscoelastic behaviors and considering long term aging effects induced by ultraviolet radiation. Based on laboratory results and analyses using a simplified viscoelastic continuum damage model, they reported that GO addition extended the fatigue life of bitumen.

Hamedi et al.40 (2024) examined the efficacy of NGO in mitigating the effects of runoff acidity variations on HMA. They used PG 64–16 bitumen modified with NGO at 0.3% and 0.5% by weight. Acidic and alkaline conditions were simulated using hydrochloric acid and sodium oxide, and specimen performance was evaluated through the indirect tensile strength (ITS) test and SFE theory. The ITS test results indicated that NGO improved the tensile strength ratio (TSR) of HMA, particularly under acidic and alkaline conditions, enhancing their moisture resistance. Furthermore, SFE analysis revealed that NGO reduced separation energy, with more pronounced effects in acidic and alkaline environments, signifying improved adhesion and moisture resistance in the HMA.

Statement of the problem and significance of the study

The HMA layer, as the pavement’s uppermost layer, is directly exposed to traffic loading and environmental conditions. Environmental factors significantly influence the stability and durability of HMA. Among various environmental conditions, moisture notably affects the performance of HMA. Moisture infiltrates HMA through diverse sources and processes, weakening its structural integrity. As an external moisture source, surface runoff is consistently available on pavements. As runoff moves across the pavement surface, it interacts with dust and surface contaminants, which alter its properties compared to potable water. One approach to investigating these changes in runoff characteristics is to study its acidity level. As a chemical indicator, acidity provides a framework for examining runoff properties and their impact on fatigue damage. Using nanomaterials as additives represents an innovative strategy to enhance various performance aspects of HMA. As highlighted in the literature review, CNTs and NGO have been shown to improve HMA performance, particularly in terms of fatigue and moisture resistance. However, prior research has primarily evaluated the effects of CNTs and NGO on fatigue performance under dry conditions or moisture susceptibility without considering the influence of acidity variations. Therefore, the present study investigated the effects of CNTs and NGO on fatigue damage under wet conditions, considering changes in runoff acidity. The current research pursued the following objectives:

-

Assessing the influence of runoff acidity variations on the rheological properties of base and modified bitumen at intermediate temperatures,

-

Studying the effect of runoff pH variation on the fatigue cracking potential of base, and modified HMA by CNT and NGO at intermediate temperatures,

-

Conducting statistical analysis to examine the impact of aggregate type, nanomaterial type, and concentration on the bitumen’s rheological properties and the HMA’s fatigue performance under runoff with different acidity levels.

Materials and methods

Materials

The materials consisted of aggregates, bitumen, and additives, each described in detail below.

Aggregates

The aggregates used to prepare the HMA specimens comprised limestone and siliceous. These two aggregate types were selected based on fundamental differences in their mineralogical characteristics and hydrophilic/hydrophobic behavior, which directly influenced the asphalt mixture’s performance. Table 1 and Table 2 present the mineralogical and physical properties of the limestone and siliceous aggregates, respectively.

The gradation of the aggregates was determined in accordance with ASTM D3515, with a maximum aggregate size of 19 mm and a nominal maximum size of 12.5 mm. Figure 1 depicts the gradation limits. The filler utilized in this research was cement.

Bitumen

Pure bitumen with a performance grade of PG 58–22 was used. This bitumen was sourced from the Jey Esfahan Oil Refinery (Iran), and its performance characteristics are presented in Table 3.

Additives

CNTs and NGO were utilized at two weight percentages, 0.3% and 0.6%, by weight of the bitumen. The nanomaterials were sourced from US Nanomaterials (US NANO). Figure 2 displays SEM images of the nanomaterials, and technical specifications of CNTs and NGO are presented in Table 4 and Table 5, respectively.

Bitumen modification with nanomaterials

CNTs and NGO were utilized as additives for bitumen modification. Each nanomaterial has been added at two different concentrations of 0.3% and 0.6% by weight of the bitumen. The quantity of nanomaterials in the modified bitumen influences its rheological properties, and the selected percentages were determined based on previous studies32,38. A high shear mixer was employed to blend the bitumen with CNTs and NGO. The bitumen was heated to 160 °C, and the powders of CNTs and NGO were gradually and slowly added. The high shear mixer operated at 12,000 rpm for 30 min to ensure thorough mixing of the bitumen and nanomaterials. A heating element surrounding the mixing container maintained the bitumen temperature during the blending process. The modified bitumen samples underwent aging due to the elevated temperature and prolonged mixing duration. To enhance the accuracy of data comparison and conclusions, the same heating and mixing process (30 min at elevated temperature) was applied to the control samples without adding nanomaterials.

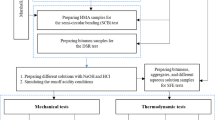

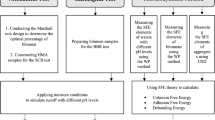

Laboratory program

The DSR and SCB tests evaluated the rheological properties of bitumen and the mechanical properties of HMA, respectively. Three replicates were conducted for each test to ensure the reliability and improve the precision of the results. Figure 3 presents the flowchart of the laboratory program. As illustrated in Fig. 3, bitumen and HMA specimens were fabricated after preparing and processing the required materials. Following the research objectives, these specimens were tested under dry and wet conditions. The wet specimens were subjected to various moisture conditions, including neutral, acidic, and alkaline environments; subsequently, the DSR test was performed on the bitumen samples, and the SCB test was conducted on the HMA samples.

As outlined in the previous section, two types of aggregates and two types of nanomaterials, each at two concentrations, were utilized in this study. Consequently, various combinations were considered to prepare the laboratory specimens, as detailed in Table 6. The samples were tested under four conditions to align with the research objectives and evaluate the effects of moisture with varying properties on the fatigue cracking of bitumen and HMA specimen: dry, neutral wet (pH = 7), acidic wet (pH = 5 and 6), and alkaline wet (pH = 8 and 9).

Mix design

The mix design and optimal bitumen content significantly influence the mechanical properties, durability, and service life of asphalt pavements. The method employed to determine the appropriate mix design in this study adhered to the MS-2 guidelines41. Given the distinct properties of limestone and siliceous aggregates, particularly their bitumen absorption characteristics, separate mix designs were developed for HMA containing limestone or siliceous aggregates. The Marshall mixing design was carried out for different bitumen (PG 58–22) and aggregate (limestone and granite) compositions used in this study. The Marshall specimens were prepared in three series of mixtures with a constant aggregate weight of 1200 g. Each set of samples was prepared with six different bitumen percentages (4%, 4.5%, 5%, 5.5%, 6%, and 6.5%). A summary table showing the proportions of the different components for each mix has been presented in Table 7. The mixtures were fabricated with 75 blows applied to each side of the cylindrical specimens to simulate heavy traffic conditions. The mixing and compaction temperatures were established based on the temperature-viscosity relationship of the respective bitumens. To determine the optimal bitumen content, key parameters (stability, flow, bulk specific gravity, air voids in the mineral aggregate (VMA), air voids in the compacted mix (AV), and voids filled with asphalt (VFA)) were plotted against the bitumen percentages.

The optimal percentage of bitumen was calculated in the following steps:

-

1

. After plotting the Marshall diagrams, the percentage of bitumen was obtained corresponding to the following:

-

• Maximum stability.

-

• Maximum bulk specific gravity.

-

• Average AV range, which is 3–5 (with an average of 4 in this study).

-

-

2

. The average of three percentages of the bitumens were calculated.

-

3

. On the diagrams, the values of the parameters corresponding to the average amount of bitumen in the previous step were calculated:

-

a. Stability.

-

b. Flow.

-

c. AV.

-

d. VMA

-

DSR test

The DSR test was conducted per AASHTO T31542. Two key parameters characterizing bitumen properties are derived from the DSR test: the complex shear modulus (G*) and the phase angle (δ). G* is calculated using Eq. 1, while δ is determined using Eq. 2:

where τmax is the maximum amplitude of applied sinusoidal shear stress (Pa), γmax is the maximum amplitude of applied sinusoidal shear strain, and G* is the complex shear modulus (Pa).

where δ is the phase angle (rad), and f is the loading frequency (rad/s).

The loading frequency influences the determination of G* and δ values. The test was performed at a loading frequency of 10 rad/s. To align with the research objectives of evaluating fatigue cracking at intermediate temperatures, the test temperature was set to 22 °C, and the specimens aged in a pressure aging vessel (PAV) were selected for testing. Given the bitumen’s PG 58–22 performance grade, testing was conducted at 22 °C to consider the under strain-controlled conditions. The test temperature has been selected based on the climatic intermediate temperature performance grade temperature as defined in specification AASHTO M320 (Eq. 3):

where, PG IT = intermediate performance grade temperature (°C), PG HT = climatic high performance grade temperature, and PG LT = climatic low performance grade temperature. Selecting the test temperature according to the AASHTO M320 standard method ensures the mid-temperature performance of the selected bitumen under actual pavement conditions.

The specimen dimensions depend on the test temperature; a thickness of 2 mm and a diameter of 8 mm were adopted in this study. The prepared specimens were then subjected to various moisture conditions before testing. For bitumen specimens in the DSR test, the samples were immersed in distilled water or the designated solutions at 60 °C for 1 h before testing to simulate moisture conditions27,43,44. To adjust the pH of distilled water to acidic levels, hydrochloric acid was added dropwise using a dropper until reaching pH values of 5 and 6. For alkaline conditions, sodium hydroxide was added dropwise to achieve pH values of 8 and 9.

Bitumen with a lower G* exhibits reduced stiffness, enabling deformation without significant stress accumulation. Conversely, a lower δ indicates greater elasticity, allowing the bitumen to recover its initial state more rapidly. Thus, lower G* and δ values are desirable for improved fatigue performance. The fatigue criterion at intermediate temperatures in this test is the parameter \({G}^{*}\mathit{sin}\delta\), with a maximum limit of 5,000 kPa for PAV-aged specimens. This threshold was selected to restrict dissipated energy, thereby minimizing fatigue cracking.

SCB test

The SCB test was conducted per ASTM 804445. The SCB test is a widely recognized and reliable method for evaluating the cracking resistance of HMA. This test emphasizes the relationship between the elastoplastic and viscoelastic properties of HMA and fracture mechanics, employing established models to investigate the behavior of these mixtures. The SCB test can accurately apply stresses to specimens that closely resemble the real-world stresses experienced by pavements. Fracture energy represents the energy required to propagate a crack with unit area in HMA, while the fracture toughness corresponds to the critical stress intensity factor at crack initiation in Mode I fracture. The SCB test specimens were prepared with dimensions of 150 ± 9 mm diameter and 24.2 ± 7 mm thickness. Each specimen featured a centered 15 ± 0.5 mm deep notch (1.5 mm width) oriented at 0° to the vertical axis, specifically designed to induce pure Mode I fracture conditions. Figure 4 illustrates the specifications of the semicircular specimens.

Given the bitumen’s PG 58–22 performance grade, testing was conducted at 22 °C to consider the under strain-controlled conditions. The test temperature has been selected based on the climatic intermediate temperature performance grade temperature as defined in specification D8044 (Eq. 3). Selecting the test temperature according to the ASTM D8044 standard method ensures the mid-temperature performance of the selected bitumen under actual pavement conditions.

A constant displacement rate of 0.05 mm/min was maintained until complete specimen failure. This loading rate has been empirically correlated with a crack mouth opening displacement (CMOD) rate of 0.03 mm/min.

In the subsequent step, for evaluating the influence of water acidity on the HMA, the SCB sampleswere exposed to different moisture conditions. Moisture conditioning was performed in accordance with AASHTO T28346, with the following procedures:

-

Saturation Phase: Specimens were vacuum saturated (13–67 kPa absolute pressure) for 5 min in the respective solutions, achieving 70–80% saturation, followed by 5–10 min of soaking without vacuum.

-

Freeze–Thaw Cycle: Saturated specimens were:

-

a) Placed in plastic bags with 10 mL of solution.

-

b) Frozen at −18 °C for 16 h.

-

c) Thawed in 60 °C solution for 24 hours (Fig. 5)

-

pH-adjusted solutions were carefully prepared by titrating distilled water with hydrochloric acid (HCl) or sodium hydroxide (NaOH) using a dropper until reaching target pH values. These acidity levels were selected based on findings reported by Arabani12.

-

Acidic conditions (pH = 5 and pH = 6) representing industrial/urban pollution

-

Neutral conditions (pH 7) for baseline comparison

-

Alkaline conditions (pH = 8 and pH = 9) simulating certain natural runoff scenarios

After preparing the semicircular specimens, they were subjected to loading, and the fracture energy and fracture toughness were calculated using the following equations:

where Gf is fracture energy (J/m2), Wf is the work of fracture (J), and Alig is the area of the cracked region (m2).

Fracture toughness was calculated using Eq. 5:

where k1c is the fracture toughness (MPa.m⁰·5), σ0 is the applied stress (MN/m2), and Y1(0.8) is the normalized stress intensity factor.

Results and discussion

Mix design results

Table 8 lists the results of the mix design for HMA containing limestone and siliceous aggregates. In Table 9, five key parameters (Marshall stability, flow, AV, voids in mineral aggregate (VMA), and voids filled with bitumen (VFA)) were evaluated following the MS-2 manual.

DSR test results

The DSR test was utilized to evaluate the rheological performance of base bitumen and bitumen modified with CNTs and NGO. Figures 6 and 7 present the results, encompassing the parameters G* (complex shear modulus) and δ (phase angle). These parameters were measured under various moisture conditions, including dry, neutral wet (pH = 7), acidic wet (pH = 5 and 6), and alkaline wet (pH = 8 and 9). The findings indicate that runoff acidity, nanomaterial type, and nanomaterial concentration significantly influenced the G* and δ values, thereby affecting the rheological behavior of bitumen.

Comparing the results obtained under dry conditions reveals that CNTs and NGO reduced the G* parameter, particularly at a concentration of 0.3% by the bitumen’s weight. Moreover, CNTs and NGO impacted G* under different moisture conditions. CNTs and NGO, in addition to their high tensile strength and stiffness, possess an exceptionally high specific surface area due to their nanoscale particle size, enabling greater interaction with bitumen particles. At higher concentrations, these nanomaterials disperse more extensively within the bitumen, forming a reinforcing network within the bitumen matrix. For this reason, in some samples, increasing the percentage of nanomaterials causes an increase in G* because they form a matrix with higher hardness. Comparing G* values across all conditions demonstrates that samples modified with 0.3% CNTs exhibited the lowest G* values, indicating the best performance against fatigue cracking.

As shown in Fig. 6, variations in the intensity of acidity or alkalinity significantly increased G*. Specifically, for samples modified with 0.6% CNTs, G* reached 1,427 kPa in strongly alkaline wet conditions (pH = 9) and 1,471 kPa in strongly acidic wet conditions (pH = 5). In other words, when bitumen is exposed to acidic or alkaline moisture conditions, its G* increases by an average of 17%, indicating increased brittleness of bitumen at intermediate temperatures and causing premature cracking. Bitumen, composed of hydrocarbon compounds, is profoundly influenced by acidic or alkaline conditions, which can alter the ratios of paraffinic and aromatic components, subsequently impacting G*43. A consistent pattern of G* increase with rising acidity or alkalinity intensity was observed across all the samples, with the highest G* values recorded under strongly acidic wet conditions (pH = 5).

Based on Fig. 7, under dry conditions, the δ value for the control sample reduced by 20% due to modifing with 0.3% CNTs. With an increase in CNT concentration to 0.6% by the bitumen’s weight, δ further decreased by 27%. Similarly, adding NGO reduced δ under dry conditions. Across all the evaluated wet conditions, incorporating CNTs and NGO, particularly 0.6% NGO, led to a significant reduction in δ. CNTs and NGO significantly improve the elasticity of bitumen due to their nanoscale size and unique properties. They disperse evenly within the bitumen, increasing surface contact and promoting 3D elastic networks. This reduces stress buildup and enhances the bitumen’s elastic performance.

According to Fig. 7, On average, acidic moisture conditions (pH < 7) led to a 15% increase in the bitumen’s delta, while alkaline moisture conditions (pH > 7) resulted in an average 22% rise. These findings suggest that δ increased notably as moisture acidity or alkalinity intensifies, especially in alkaline environments. Previous studies have also shown that acidic or alkaline water hardens bitumen and diminishes its elastic properties, potentially due to the dissolution and ionization of polar or ionic chemical groups in asphaltenes and resins at the bitumen surface21.

By measuring G* and δ, the DSR test enables the evaluation of bitumen samples’ fatigue cracking performance through the fatigue cracking parameter (G*sinδ). Figure 8 presents the fatigue cracking index for control and modified bitumen samples under various moisture conditions. On average, 0.3% and 0.6% CNT led to a 14% and 16% decrease in the bitumen’s fatigue parameter, respectively. Also, 0.3% and 0.6% NGO resulted an average 15% and 18% reduction in the bitumen’s fatigue parameter. These reductions demonstrate that adding either nanomaterial, particularly at 0.6% NGO, significantly enhanced the bitumen’s resistance to fatigue cracking across various moisture conditions.

According to Fig. 8, acidic or alkaline moisture adversely affected the bitumen’s elastic properties, reducing its fatigue cracking resistance. Beyond the presence of acidity or alkalinity, the intensity of these conditions also influenced the fatigue cracking index. In strongly acidic conditions (pH = 5), the fatigue index reduced by an average of 36%, and in strongly alkaline conditions (pH = 9), it decreased by an average of 33%. These changes indicate that under severe moisture conditions, whether acidic or alkaline, the fatigue performance of bitumen declined considerably.

An independent t-test of the data obtained from the DSR test was conducted to further investigate the effects of CNTs and NGO on the fatigue cracking parameter of bitumen. The results are presented in Table 9. Four groups were considered: samples modified with 0.3% and 0.6% CNTs and NGO, which were compared against control samples. The comparisons evaluated the influence of CNTs and NGO as intervening factors on the fatigue cracking parameter.

According to Table 10, the assumption of equal variances is upheld if the significance value (sig.) of Levene’s test exceeds the predetermined confidence level (0.05). Under this assumption, the data from the first row of the t-test are analyzed. A sig. value for the t-test less than the confidence level (0.05) indicates a statistically significant relationship between the intervening factor and the studied parameter. In the first case, the effect of 0.3% CNTs on the fatigue cracking parameter was examined. With a Levene’s test sig. value of 0.809, the assumption of equal variances held, and the first row of the t-test data was evaluated. The sig. value of the t-test was 0.016, which is below the confidence level (0.05), confirming a significant relationship between using 0.3% CNTs and the fatigue cracking parameter of bitumen. Similarly, in the other comparison cases, a statistically significant relationship was observed between utilizing the specified nanomaterials and the fatigue cracking parameter of bitumen.

SCB test results

The SCB test evaluates the performance of HMA against cracking by providing two key parameters: fracture energy and fracture toughness. Fracture energy represents the ability of an HMA to withstand applied stresses before failure; higher values indicate greater resistance to cracking and improved performance. Fracture toughness indicates the resistance of the HMA to brittle failure upon crack initiation. It is noteworthy that three repetitions were performed for each sample, and their average was reported to enhance the accuracy and reliability of the results. Additionally, to illustrate the variations and dispersion of the data used in determining the average, the standard deviation of the data has been calculated and represented on the graphs using error bars, and the values related to the coefficient of variation (COV) for the data in each column have been written on it. Based on the observed data, the maximum COV for fracture energy and fracture toughness parameters is 7.5% and 7.1%, respectively. These values indicate relatively low variability, supporting the reliability and consistency of the experimental results. Given that COV values below 10% generally denote high repeatability, this reinforces the validity of the findings. A smaller COV indicates less variability and therefore, a more reliable measurement47.

Figures 9 and 10 present the fracture energy results for HMA containing limestone and siliceous aggregates. In dry conditions, adding CNTs and NGO, especially at 0.6% by the bitumen’s weight, increased the fracture energy of HMA, thereby improving their fatigue performance.

Following the research objectives, the effects of nanomaterials on the fracture energy of HMA under various moisture conditions were investigated. In strongly alkaline wet conditions (pH = 9), the control sample of the HMA with limestone aggregates exhibited a fracture energy of 658 J/m2. A significant improvement was observed with the addition of CNTs, with the fracture energy of the sample modified with 0.3% CNTs increasing by an average of 43%. Increasing the CNT concentration to 0.6% by the bitumen’s weight further elevated the fracture energy by an average of 68%. Consequently, using CNTs and NGO, particularly at 0.6% by the bitumen’s weight, significantly enhanced the fracture energy parameter across various moisture conditions, leading to improved fatigue performance of the HMA.

CNTs and NGO possess exceptional mechanical properties, including high tensile strength, stiffness, and elasticity. In samples modified with these nanomaterials, they act as reinforcing agents, enhancing mechanical properties.

Bitumen acts as a binder in HMA, and moisture reduces its stiffness and elasticity. Consequently, in wet conditions, bitumen’s ability to bind aggregates and maintain a cohesive, stress-resistant structure diminishes. Owing to the unique properties of CNTs and NGO and their positive impact on the mechanical properties of modified bitumen, these nanomaterials mitigate the samples’ susceptibility to moisture damage. By forming a denser network within the bitumen structure, they impede water molecule penetration, thereby reducing the loss of fracture energy in wet conditions. Besides bitumen properties, aggregate characteristics also significantly influence the performance of HMA under wet conditions. Due to their silicon-oxygen bonds, siliceous aggregates are chemically more inert and less reactive than limestone aggregates. However, they exhibit greater hydrophilicity, showing a higher tendency to absorb moisture in wet conditions. As a result, the bitumen-aggregate bond in siliceous mixtures weakens more significantly in wet conditions compared to limestone mixtures, enabling the latter to better preserve structural integrity8,9.

According to Fig. 11, control HMA samples with limestone and siliceous aggregates experienced a 27% and 44% reduction in fracture energy, respectively, in neutral wet conditions compared to dry conditions. Figure 11 indicates that HMA with limestone aggregates demonstrated greater resistance to fracture energy reduction in neutral, acidic and alkaline wet conditions compared to those with siliceous aggregates. Ultimately, the HMA containing limestone aggregates and bitumen modified with 0.6% CNTs exhibited the least reduction in fracture energy in neutral wet conditions compared to dry conditions.

Figures 12 and 13 display the changes in fracture energy under various moisture conditions, including acidic and alkaline wet states relative to neutral wet conditions.

As shown in these figures, the percentage reduction in fracture energy of moisture-conditioned samples with distilled water is significantly higher under acidic conditions than under alkaline conditions. Additionally, as the acidity or alkalinity of the distilled water increases, the reduction in fracture energy becomes more pronounced. This indicates that acidic moisture conditions (pH = 5) have a more damaging effect on the mixture’s fracture energy compared to alkaline conditions. The fracture energy results reveal that HMA with limestone aggregates experienced the greatest reduction in fracture energy under strongly acidic wet conditions (pH = 5) compared to other moisture states. Comparative data suggest that samples modified with 0.6% NGO exhibited the least reduction in fracture energy under the two critical moisture conditions: strongly acidic (pH = 5) and strongly alkaline (pH = 9).

Across most conditions examined, the percentage reduction in fracture energy for modified samples, particularly at a 0.6% concentration by the bitumen’s weight, was lower than that of the control sample. NGO, owing to its two dimensional structure, provided a larger contact surface for interaction with bitumen. The oxygen-containing functional groups on NGO’s surface might have neutralized the adverse effects of moisture with varying properties, mitigating severe chemical degradation. However, the concentration of NGO played a critical role in its effectiveness. At a lower concentration (0.3% by the bitumen’s weight), the contact surface between NGO and bitumen decreased, and the dispersion of nanomaterial particles might have been insufficient to form a continuous reinforcing network. This created localized weak points in the bitumen, rendering it more susceptible to damage under wet conditions and mechanical loading. Beyond concentration, acidity levels also influenced the effect of nanomaterials on the percentage reduction in fracture energy. The greater reduction in fracture energy for modified samples in mildly alkaline wet conditions (pH = 8) suggests the negative impacts of nanomaterials under these specific conditions. In mildly alkaline wet environments, nanomaterials might exhibit unfavorable interactions with bitumen, leading to suboptimal performance in modified samples. This behavior could stem from adverse chemical interactions between the nanomaterials and bitumen or inadequate dispersion of the nanomaterials.

Table 10 presents the t-test results. Eight groups were considered: samples modified with 0.3% and 0.6% CNTs and NGO, compared against control samples. This comparison evaluated the influence of nanomaterials as an intervening factor on the fracture energy parameter of HMA containing limestone or siliceous aggregates.

Table 11 provides the results of the t-test applied to HMA’s fracture energy data. A significance confidence level of 0.05 was adopted in this test. If the significance value (sig.) of Levene’s test exceeds 0.05, the assumption of equal variances is deemed valid, and the data from the first row of the t-test are utilized. A sig. value for the t-test less than 0.05 indicates a statistically significant relationship between the intervening factor and the fracture energy parameter. In the first comparison examining the effect of 0.3% CNTs by the bitumen’s weight, the sig. value of Levene’s test was 0.988. In the first row of the t-test data, the sig. value was 0.011, confirming a statistically significant relationship between the additive and the fracture energy of the HMA. Across the other comparison groups, except for one specific case, a significant relationship was observed between the use of CNTs and NGO and the fracture energy of HMA. However, in comparing the control sample and the HMA containing siliceous aggregates modified with 0.3% CNTs, no statistically significant relationship was detected between the use of the additive and the fracture energy parameter. Therefore, based on the majority of cases, it can be concluded that a statistically significant relationship existed between the intervening factor (use of nanomaterials) and the fracture energy parameter.

Figures 14 and 15 present the fracture toughness results for HMA containing limestone and siliceous aggregates. Comparative analysis across various moisture conditions reveals that CNTs and NGO significantly influenced the fracture toughness parameter of HMA. Examining the fracture toughness values for HMA with limestone aggregates under dry conditions shows that 0.3% CNTs increased fracture toughness by 32% compared to the control sample. Increasing the CNT concentration to 0.6% by the bitumen’s weight resulted in a 55% increase in fracture toughness for mixtures with limestone aggregates. For HMA with siliceous aggregates, using CNTs at concentrations of 0.3% and 0.6% by the bitumen’s weight increased fracture toughness by 30% and 35%, respectively. Similarly, adding NGO under dry conditions enhanced the fracture toughness of modified HMA samples. Comparable results were observed under other moisture conditions, where these nanomaterials increased the fracture toughness of HMA. Thus, CNTs and NGO, particularly at a concentration of 0.6% by the bitumen’s weight, had a substantial positive effect on enhancing the fracture toughness of HMA. Among the combinations evaluated, the sample containing 0.6% NGO exhibited the highest fracture toughness value.

By forming a structural network within the bitumen, CNTs and NGO significantly improve the mechanical properties of HMA. These nanomaterials effectively enhance load distribution throughout the bitumen matrix, thereby increasing the mixture’s load-bearing capacity. Additionally, when microcracks form within the asphalt structure, these nanomaterials act as crack-bridging agents, preventing crack propagation.

Figures 14 and 15 indicate that due to moisture-induced damage and weakened bitumen-aggregate bonding, fracture toughness values across all wet conditions were lower than those recorded under dry conditions. Figure 16 illustrates the reduction in fracture toughness for HMA samples containing limestone aggregates under neutral wet conditions compared to dry conditions. According to Fig. 16, the control sample exhibited a 34% reduction in fracture toughness. In contrast, using CNTs at concentrations of 0.3% and 0.6% by weight of the bitumen reduced this decrease to 26% and 16%, respectively. Similarly, NGO at 0.3% and 0.6% by weight of the bitumen resulted in 19% and 13% reductions, respectively. Likewise, incorporating CNTs and NGO at 0.3% and 0.6% by the bitumen’s weight significantly mitigated the reduction in fracture toughness for HMA with siliceous aggregates under neutral wet conditions compared to dry conditions. Therefore, CNTs and NGO, particularly at 0.6% by weight of the bitumen, minimized the adverse effects of moisture on fracture toughness reduction, thereby improving the performance of HMA under neutral wet conditions. Furthermore, HMA with limestone aggregates experienced a lesser reduction in fracture toughness under neutral wet conditions compared to those with siliceous aggregates. This difference is primarily attributed to siliceous aggregates’ chemical properties and surface texture, which result in weaker bonding between the bitumen and aggregate under wet conditions compared to limestone aggregates.

Figures 17 and 18 present the percentage reduction in fracture toughness under acidic and alkaline wet conditions relative to neutral wet conditions.

Examining the the reduction in fracture toughness of HMA samples with limestone and granite aggregates revealed that the percentage reduction in fracture toughness increased significantly under acidic or alkaline wet conditions, particularly at higher intensities. Notably, while some samples modified with CNTs and NGO might have experienced a greater percentage reduction in fracture toughness than the control, this did not negate their overall positive impact. Although these nanomaterials substantially enhanced the absolute fracture toughness values of HMA, their effectiveness might have diminished under acidic or alkaline wet conditions. Nevertheless, the absolute fracture toughness of modified samples remained higher than that of the control across all moisture conditions.

The observed increase in the percentage reduction of fracture toughness under acidic or alkaline wet conditions, especially at higher intensities, is attributed to chemical degradation.

processes affecting the bitumen. Acidic moisture can accelerate bitumen oxidation by breaking chemical bonds and attacking functional groups, weakening the bitumen structure and its adhesion properties. In alkaline wet conditions, hydroxide ions target polar bonds within the bitumen structure, fragmenting long hydrocarbon chains into smaller segments. These smaller fragments alter the bitumen’s properties, reducing its flexibility and adhesion. Additionally, the neutralization or decomposition of acidic components in bitumen under alkaline conditions may further diminish its adhesive strength. In summary, exposure to strongly acidic or alkaline environments induces chemical degradation of bitumen, compromising its structural integrity, elasticity, and adhesion properties, which in turn reduces fracture toughness.

Table 12 presents the results of the t-test on fracture toughness data. In this analysis, a confidence level of 0.05 was established to ensure acceptable precision in evaluating the t-test results. Samples modified with 0.3% and 0.6% CNTs and NGO were compared against control samples. This comparison assessed the influence of nanomaterials as an intervening factor on the fracture toughness parameter of HMA containing limestone or siliceous aggregates. Out of the eight comparison cases evaluated, six demonstrated statistically significant relationships between the use of CNTs and NGO and the fracture toughness of HMA. However, for samples comprising HMA with 0.3% NGO, 0.3% CNTs, and siliceous aggregates, the statistical analysis did not indicate a significant relationship between the use of nanomaterials and fracture toughness.

The statistical analysis of fracture energy and fracture toughness in asphalt mixtures indicates that while the incorporation of 0.3% CNTs or NGO showed no significant improvement in these parameters for silica based aggregates, a measurable enhancement was observed in limestone-based mixtures. This discrepancy can be attributed to the superior moisture resistance of limestone aggregates compared to their siliceous counterparts, owing to their stronger adhesion between the bitumen and aggregate. Consequently, moisture conditions significantly influence nanomaterial effectiveness, as the weak bitumen-silica interfacial bonding limits the performance enhancement achievable with 0.3% nanomaterial content. However, increasing the nanomaterial concentration to 0.6% yields a statistically significant improvement, demonstrating that the inherent properties of CNTs and NGO can effectively counteract the moisture susceptibility of silica aggregates.

Conclusions

Fatigue cracking, a primary distress in flexible pavements, is influenced by various factors. Among these, environmental conditions, particularly moisture, play a critical role in the fatigue performance of HMA. HMAs are continuously exposed to moisture from multiple sources, with surface runoff being a significant contributor. The properties of surface runoff, altered by its movement across road surfaces and interaction with environmental contaminants, differ from those of potable water. Therefore, the effect of runoff with varying acidity levels on HMA performance will be different from that of potable water.

This study investigated the effects of CNTs and NGO on the fatigue resistance of HMA under runoff conditions with varying acidity levels. To achieve this, bitumen and HMA samples were subjected to different moisture conditions before testing. The influence of CNTs and NGO on the bitumen’s rheological properties and the HMA’s mechanical properties under these moisture conditions was then evaluated. The DSR test was employed to assess the rheological properties of bitumen, while the SCB test was used to measure the mechanical properties of HMA. The findings, aligned with the research objectives, are summarized as follows:

-

1

- Runoff acidity significantly affected the G* (complex shear modulus) and δ (phase angle) parameters. The recorded data show that acidic or alkaline moisture increased G* and δ compared to neutral moisture.

-

2

- The acidic and alkaline properties of runoff elevated the fatigue cracking parameter of bitumen compared to neutral conditions, consequently impairing its fatigue performance.

-

3

- The fatigue cracking parameter of bitumen in samples modified with CNTs and NGO was significantly lower than that of the control sample. This indicates the outstanding performance of these nanomaterials in improving the fatigue performance of bitumen.

-

4

- Fracture energy and fracture toughness decreased in all wet conditions compared to dry conditions. This shows that HMAs exposed to acidic and alkaline waters are more susceptible to cracking at intermediate temperatures.

-

5

- Due to the chemical properties of siliceous aggregates, reductions in fracture energy and fracture toughness were greater in mixtures with siliceous aggregates than in those with limestone aggregates across all wet conditions.

-

6

- Comparing the fatigue cracking parameter, fracture energy and fracture toughness values reveals that greater acidity or alkalinity of water intensified chemical reactions, amplifying the negative impact on fatigue performance. Bitumen samples under strongly acidic (pH = 5) or strongly alkaline (pH = 9) conditions exhibited the highest fatigue cracking indices and the poorest fatigue performance.

-

7

- Using CNTs and NGO as bitumen additives increased the fracture energy and fracture toughness of HMA. As the weight percentage of nanomaterials in the bitumen increases, the values of fracture energy and fracture toughness also rise, further enhancing the mixture’s resistance to fatigue cracking.

-

8

- Among the evaluated combinations, the bitumen and HMA with 0.6% NGO exhibited superior fatigue performance compared to other samples.

-

9

- The t-test results generally confirmed a significant relationship between using these nanomaterials and the fatigue cracking parameter, fracture energy, and fracture toughness parameters.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Moreno-Navarro, F. & Rubio-Gámez, M. A review of fatigue damage in bituminous mixtures: Understanding the phenomenon from a new perspective. Constr. Build. Mater. 113, 927–938 (2016).

Moghadas Nejad, F. & Azarhoosh, A. Evaluating fatigue life of asphalt mixtures using surface free energy parameters. Amirkabir J. Civil Eng. 50(2), 365–376 (2018).

Zhang, B. & Jing, M. Evaluation of fatigue performance of asphalt materials based on their relaxation behavior. Sci. Rep. 15(1), 1274 (2025).

Ameri, M. & Sadeghiavaz, M. Microwave healing properties and moisture sensitivity of asphalt mixture containing iron powder filler. Sci. Rep. 14(1), 23154 (2024).

Santucci, L., Moisture Sensitivity of Asphalt Pavements, Technology Transfer Program. UC-Berkley’s Institute of Transportation Studies, (2002).

Amini, B. & Tehrani, S. S. Simultaneous effects of salted water and water flow on asphalt concrete pavement deterioration under freeze–thaw cycles. Int. J. Pavement Eng. 15(5), 383–391 (2014).

Shi, X. et al. Research on the low-temperature performance of basalt fiber-rubber powder modified asphalt mixtures under freeze-thaw in large temperature differences region. Sci. Rep. 14(1), 30580 (2024).

Asadi, A. H., Hamedi, G. H. & Azarhoosh, A. Using mechanical and thermodynamic methods to evaluate the effects of nanomaterials on thermal cracking mechanisms of asphalt mixtures under the influence of different moisture conditions. Case Stud. Constr. Mater. 22, e04310 (2025).

Asadi, A. H., Hamedi, G. H. & Azarhoosh, A. Evaluating the Effects of Nanomaterials on Thermal Cracking of HMA in the Presence of Moisture with Different Degrees of Acidity. J. Mater. Civ. Eng. 37(5), 04025096 (2025).

Mayer, T. et al. Environmental characterization of surface runoff from three highway sites in Southern Ontario, Canada: 2. Toxicology. Water Qual. Res. J. Can. 46(2), 121–136 (2011).

Yu, A. & Zhao, C. Evaluation on the highway asphalt pavement runoff with the gray correlation model. Procedia Environ. Sci. 13, 1827–1835 (2012).

Arabani, M., Ranjbar Pirbasti, Z. & Hamedi, G. H. Evaluation of the effect of dust and soot on runoff acidity and moisture sensitivity of asphalt mixtures using thermodynamic and mechanical methods. J. Mater. Civil Eng. 32(11), 04020313 (2020).

Hamedi, G. H., Asadi, A. H. & Zarrinfam, J. Investigating the effect of fundamental properties of materials on the mechanisms of thermal cracking of asphalt mixtures. Constr. Build. Mater. 411, 134426 (2024).

Júnior, J. L. L., Babadopulos, L. F. & Soares, J. B. Moisture-induced damage resistance, stiffness and fatigue life of asphalt mixtures with different aggregate-binder adhesion properties. Constr. Build. Mater. 216, 166–175 (2019).

Scott, J. Adhesion and disbonding mechanisms of asphalt used in highway construction and maintenance. in Association of Asphalt Paving Technologists Proc. (1978).

Yoon, H.H. and A.R. Tarrer, Effect of aggregate properties on stripping. (1988).

Zhang, Q., Hu, J. & Peng, Y. Analysis of chemical mechanism for aggregates corroded by acid rain in asphalt mixtures. Highway 2, 104–106 (2004).

Zhang, Q., Peng, Y. & You, X. Thermodynamic analysis of corrosion of acid rain on aggregate in asphalt mixtures. J. China Foreign Highway 24(2), 71–73 (2004).

Zhang, Q. et al. Investigation of effect of acid rain on strength and void content of asphalt mixture. J. China Foreign Highway 25(1), 78–80 (2005).

Feng, X. & Johansson, A. C. CEO incentives in Chinese state-controlled firms. Econ. Dev. Cult. Change 65(2), 223–264 (2017).

Yang, H. et al. The effect of water solution erosion on rheological, cohesion and adhesion properties of asphalt. Constr. Build. Mater. 246, 118465 (2020).

Arabani, M., Pirbasti, Z. R. & Hamedi, G. H. Investigating the impact of zeolite on reducing the effects of changes in runoff acidity and the moisture sensitivity of asphalt mixtures. Constr. Build. Mater. 268, 121071 (2021).

Wei, J. et al. Study on the durability of acid rain erosion-resistant asphalt mixtures. Materials 15(5), 1849 (2022).

Chen, X. et al. Investigation on moisture damage resistance of asphalt pavement in salt and acid erosion environments based on Multi-scale analysis. Constr. Build. Mater. 366, 130177 (2023).

Li, C. et al. Comparative evaluation on decay process of asphalt-aggregate interfaces under solution erosion. Constr. Build. Mater. 400, 132698 (2023).

Zou, Y. et al. Comprehensive properties assessment of asphalt binder under aqueous solutions with different pH values and its gradient damage behaviors. Constr. Build. Mater. 414, 134938 (2024).

Mehdinazar, M., Kordani, A. A. & Arabani, M. Effects of Changes in Runoff Characteristics on Asphalt Mixtures’ Performance Against Low-Temperature Cracking. Results Eng. 24, 103246 (2024).

Li, R. et al. Developments of nano materials and technologies on asphalt materials–A review. Constr. Build. Mater. 143, 633–648 (2017).

Cheraghian, G. et al. Rheological, physicochemical, and microstructural properties of asphalt binder modified by fumed silica nanoparticles. Sci. Rep. 11(1), 11455 (2021).

Guo, T. et al. Study on the performance and mechanism of graphene oxide/polyurethane composite modified asphalt. Sci. Rep. 15(1), 2482 (2025).

Ameri, M. et al. Investigation of fatigue and fracture properties of asphalt mixtures modified with carbon nanotubes. Fatigue Fract. Eng. Mater. Struct. 39(7), 896–906 (2016).

Ashish, P. K. & Singh, D. Development of empirical model for predicting G∗/Sinδ and viscosity value for nanoclay and Carbon Nano Tube modified asphalt binder. Constr. Build. Mater. 165, 363–371 (2018).

Latifi, H. & Hayati, P. Evaluating the effects of the wet and simple processes for including carbon Nanotube modifier in hot mix asphalt. Constr. Build. Mater. 164, 326–336 (2018).

Le Bach, V. & Le Phuc, V. Performance evaluation of carbon nanotubes as a binder modifier for asphalt mixtures. Int. J. Civil Eng. 19, 1143–1153 (2021).

Liu, K., Zhang, K. & Shi, X. Performance evaluation and modification mechanism analysis of asphalt binders modified by graphene oxide. Constr. Build. Mater. 163, 880–889 (2018).

Zhu, J. et al. Performance of hot and warm mix asphalt mixtures enhanced by nano-sized graphene oxide. Constr. Build. Mater. 217, 273–282 (2019).

Liu, K. et al. Effects of mixing sequence on mechanical properties of graphene oxide and warm mix additive composite modified asphalt binder. Constr. Build. Mater. 217, 301–309 (2019).

Adnan, A. M. et al. Improving mechanics behavior of hot mix asphalt using graphene-oxide. Constr. Build. Mater. 254, 119261 (2020).

An, X. et al. A more accurate fatigue characterization of GO-modified asphalt binder considering non-linear viscoelastic behaviour and UV exposure effects. Int. J. Fatigue 168, 107396 (2023).

Hamedi, G. H., Nejad, F. M. & Azarhoosh, A. Assessing the influence of nano graphene oxide application in mitigating the adverse effects of runoff pH on the moisture susceptibility of asphalt concretes. Constr. Build. Mater. 438, 137182 (2024).

Methods, M.-A.M.D., MS-2. Vol. 7th, Lexington, Kentucky: Asphalt Institute (2015)

AASHTO, AASHTO T315 Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). AASHTO: Wasgington D.C. (2022)

Mehdinazar, M., Abdi Kordani, A. & Arabani, M. Investigation of the Impact of Zeolite on the Detrimental Effect of Changes in the Water Acidity Level on the Intermediate Properties of HMA Using Rheological, Mechanical, and Thermodynamical Tests. J. Mater. Civil Eng. 37(2), 04024501 (2025).

Azarhoosh, A., G.H. Hamedi, and M. Amiransari, The Effect of Runoff Acidity on Fatigue Cracking of Hot Mix Asphalt Using Thermodynamic Concepts. Case Studies in Construction Materials. p. e03392. (2024)

ASTM, ASTM D8044 Standard Test Method for Evaluation of Asphalt Mixture Cracking Resistance using the Semi-Circular Bend Test (SCB) at Intermediate Temperatures. American Society of Testing and Materials: Pennsylvania. (2020)

Aashto, T., 283; Standard Method of Test for Resistance of Compacted Asphalt Mixtures to Moisture-Induced Damage. American Association of State Highway and Transportation Officials: Washington, DC, USA, (2014).

Shechtman, O. The coefficient of variation as an index of measurement reliability. In Methods of clinical epidemiology 39–49 (Springer, 2013).

Author information

Authors and Affiliations

Contributions

J.Z. conducted the experiments and prepared the results in the form of figures and tables. GH.H. and A.A. wrote the main manuscript text. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zarrinfam, J., Hamedi, G.H. & Azarhoosh, A. Impacts of carbon nanotubes and nano-graphene oxide on fatigue cracking in HMA exposed to runoff with varying acidity. Sci Rep 15, 23282 (2025). https://doi.org/10.1038/s41598-025-06333-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-06333-x

Keywords

This article is cited by

-

The effects of moisture and aging conditions on the cohesive and adhesive debonding of asphalt mixture using thermodynamical and mechanical methods

Scientific Reports (2025)

-

Effects of short-term aging of base and nano-modified bitumens on surface free energy and their relationship with moisture sensitivity in warm-mix asphalt

Scientific Reports (2025)