Abstract

This study investigates the mechanical behavior of alkali-activated concrete (AAC) subjected to triaxial compression under different confining pressures and freeze-thaw cycles. A series of triaxial compression tests were performed on cylindrical AAC specimens under confining pressures of 0, 3, and 6 MPa, combined with up to 200 freeze-thaw cycles, to evaluate the effects on failure mode, stress-strain response, peak strength, and elastic modulus. The experimental procedure involved specimen preparation, controlled freeze-thaw exposure, and triaxial loading using a servo-controlled testing system. Test results show that increasing confining pressure changes the failure mode from tensile cracking to shear-compression failure, significantly improving load-bearing capacity. Both peak strength and elastic modulus decrease with the number of freeze-thaw cycles, with the most severe degradation observed at 3 MPa, while 6 MPa confining pressure effectively mitigates deterioration. Based on the experimental data, predictive models for the triaxial compressive strength and elastic modulus after freeze-thaw cycles are proposed, and a constitutive model is developed to describe the stress-strain relationship. These findings enhance understanding of AAC durability and provide design references for its application in cold regions and harsh environments.

Similar content being viewed by others

Introduction

With the growing urgency of global environmental issues, the construction industry faces increasing demand for low-carbon and sustainable materials. Alkali-activated concrete (AAC) has emerged as a promising alternative to traditional cement-based concrete, owing to its low carbon emissions, superior mechanical properties, and enhanced durability1,2,3. In cold regions, however, concrete structures are frequently exposed to prolonged freeze–thaw cycles, which can induce the formation and propagation of microcracks, ultimately leading to strength degradation and reduced durability. This significantly affects the safety and service life of infrastructure4.

Previous studies have shown that alkali-activated cementitious materials exhibit remarkable freeze–thaw resistance, withstanding up to 300 cycles or more5,6. For example, Fu et al.7 reported that alkali-activated slag materials exhibited a mass loss of less than 0.7% and a relative dynamic modulus reduction of under 10% after 300 cycles. Similarly, Zhao et al.8 demonstrated that AAC containing 50% slag could endure 225 cycles, while alkali-activated fly ash materials maintained compressive strength loss rates below 20% after 100 cycles9,10. These findings suggest that the frost resistance of AAC largely depends on its chemical composition and pore structure. The dense hydration products formed by alkali activation, coupled with reduced interfacial transition zones, contribute to a compact microstructure that limits fluid movement and ion diffusion, thereby enhancing frost resistance. Krivenko11 further demonstrated that water glass-activated slag concrete, with its lower porosity, could withstand at least 300 freeze–thaw cycles12.

However, despite the excellent freeze–thaw resistance exhibited by many AAC systems, substantial variability exists in the durability of different alkali-activated binders. For instance, Temuu et al.13 reported that fly ash-based geopolymer concrete failed within 40 cycles, while Slavik14 observed a 20% strength reduction after 50 cycles in low-calcium fluidized bed ash-based geopolymer concrete15. In contrast, slag-based alkali-activated binders generally demonstrate superior frost resistance but exhibit lower carbonation resistance. Therefore, improving the freeze–thaw durability of fly ash-based AAC is not only beneficial for enhancing the resource utilization of fly ash but also holds considerable potential for advancing green building materials in cold regions16,17.

In addition to durability concerns, it is important to note that concrete structures in cold regions are often subjected not only to environmental freeze–thaw actions but also to complex multi-axial stress states induced by overburden loads, lateral pressures, and seismic forces. Such stress conditions cannot be accurately represented by simple uniaxial compression tests. Compared with ordinary Portland cement (OPC) concrete, AAC exhibits distinct mechanical characteristics under triaxial compression, including higher compressive strength, improved ductility, and greater energy absorption capacity, primarily due to its dense microstructure and the formation of strong C–A–S–H or N–A–S–H gels18,19. These features delay crack initiation, enhance deformation resistance, and strengthen the aggregate–matrix interface, making AAC highly resilient under complex stress states.

Although numerous studies have examined the triaxial compression performance of OPC concrete after freeze–thaw exposure, limited research has addressed AAC under similar conditions. In particular, the mechanisms by which freeze–thaw cycles influence the triaxial compressive strength, deformation behavior, and failure modes of AAC remain insufficiently understood. Given AAC’s potential application in cold regions where both freeze–thaw deterioration and multi-axial stresses coexist, it is crucial to clarify how freeze–thaw cycles affect its performance under triaxial compression. The triaxial compression test, which better simulates the in-situ stress conditions encountered in practical engineering applications compared to uniaxial testing, serves as an effective tool for assessing material strength evolution under varying confinement levels. Therefore, this study aims to investigate the triaxial compression behavior of AAC after freeze–thaw cycles, to elucidate its micro-damage evolution mechanisms and provide theoretical guidance and practical support for the application of this sustainable material in cold-region engineering.

Experimental program

Raw materials and mix ratio

The bonding materials consist of S95 slag powder from Gongyi Longze Water Purification Materials Co., Ltd. and fly ash with a density of 2.55 g/cm³. The fly ash was first grade with a moisture content of 0.85% and a fineness of 13%. The coarse aggregate is gravel ranging from 5 to 20 mm in particle size, while the fine aggregates were river sand with a fineness modulus of 2.71. The alkali activator used in this study was a mixture of sodium silicate solution and sodium hydroxide solution. The modulus m represents the molar ratio of SiO2 to Na2O in the sodium silicate solution (m = SiO2/Na2O), which was adjusted by adding sodium hydroxide. In this study, m was set as 0.8. The sodium silicate solution was prepared using commercially available sodium silicate (modulus of 2.2) and sodium hydroxide (purity of 99%) as alkaline activators. AAC was prepared using the above materials, and the mixing method of the materials is detailed in Reference20. Table 1 provides the mix proportions of AAC.

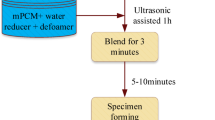

Specimen preparation

For this study, 15 sets of AAC cylindrical specimens with a diameter of 100 mm and a height of 200 mm were designed based on the number of freeze-thaw cycles (0, 50, 100, 150, 200) and confining pressures (0 MPa, 3 MPa, 6 MPa). The variation parameters and test results of the specimens are shown in Table 2. The naming convention for specimen numbers is that the first number represents the number of freeze-thaw cycles, and the second number represents the magnitude of confining pressure. For example, F50-3 represents 50 freeze-thaw cycles and a triaxial confining pressure of 3 MPa.

Test methods

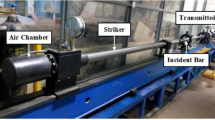

Mechanical properties

The loading device for the triaxial compressive strength test adopts the GCTS rock concrete triaxial apparatus, as shown in Fig. 1. This instrument was introduced by GCTS Corporation in the United States, and the entire system consists of a three-axis pressure chamber, a high-temperature and high-pressure axial/radial deformation measurement device, a silent hydraulic source, a pressure head, and an SCON-3000 digital acquisition and controller. This instrument can accommodate solid cylindrical specimens ranging from 25 to 150 mm, with a maximum axial loading force of 2000 kN, a maximum axial travel of 100 mm, a temperature of up to 150 °C, and a maximum confining and pore pressure of 140 MPa. With reference to the recommendations of Akbarpour et al.21,22 for unconfined and triaxial tests on cohesive soils, and considering the similarities between brittle cemented materials and concrete, an axial strain rate of no more than 0.005 min− 1 was adopted in this study. Accordingly, for the cylindrical specimens with a height of 200 mm, the corresponding axial loading rate was set at 0.08 mm/min. This relatively low loading rate was selected to minimize pore pressure generation within the specimens and to ensure quasi-static loading conditions, thereby reducing any potential damping effects during the test.

Freeze-thaw test

According to the Standard for test methods of long-term performance and durability of ordinary concrete(GB/T 50082-2009)23, the rapid freezing method is used for freeze-thaw cycle testing. The freeze-thaw cycle includes a 4-hour freezing state (− 18 to − 20°C) and a 4-hour thawing state (18—20 °C). Take appearance photos, weigh, and test the elastic modulus and compressive strength of the samples every 50 cycles. The rapid freeze-thaw testing machine (TDR-28, maximum power 7 kW) was adopted, as shown in Fig. 2.

Experimental results and discussion

Failed modes

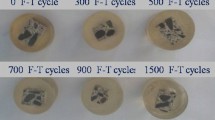

Figure 3 shows the failure modes of all specimens. Based on different confining pressures and freeze-thaw cycles, the following conclusions can be drawn:

-

(1)

Under the same confining pressure, the failure mode of AAC subjected to triaxial compression after varying freeze-thaw cycles is similar, primarily characterized by crack formation and propagation along the loading direction when there is minimal or no confining pressure. The absence of external constraints results in significant lateral expansion and fragment separation during the failure process. Observations indicate that cracks propagate along the weakest path, ultimately leading to shear slip or diagonal cracking of the concrete cylinder. At a confining pressure of 3 MPa, the failure mode of AAC typically accompanied by reduced lateral expansion and a more uniform crack distribution. The confining pressure of 3 MPa imposes a certain degree of constraint, limiting the lateral expansion of the material and increasing the likelihood of crack formation within a specific compression zone, resulting in a more concentrated failure mode. Conversely, at a confining pressure of 6 MPa, the failure mode of AAC demonstrates dense failure, characterized by negligible lateral expansion and challenges in crack formation and propagation. The damage manifests as internal compaction and material crushing rather than pronounced crack penetration. This failure mode generally necessitates greater stress to be achieved, indicating that AAC possesses a higher bearing capacity under elevated confining pressures.

-

(2)

After the same number of freeze-thaw cycles, the triaxial compression failure mode of AAC under different confining pressures exhibits similarities. When subjected to zero freeze-thaw cycles, the failure mode of the concrete cylinder is primarily influenced by its original material properties and preparation processes. This is evidenced by a relatively uniform distribution of cracks and fracture surfaces, with cracks predominantly occurring along the loading direction. Following 50 freeze-thaw cycles, initial formation and propagation of microcracks can be observed, characterized by small surface cracks or slight peeling. Nevertheless, the overall structural performance remains relatively intact, and the failure mode continues to exhibit regularity. Upon reaching 100 freeze-thaw cycles, an increase in the number of cycles leads to further crack development and accumulation of internal damage within the concrete. Consequently, a greater number of cracks and small-scale peeling may manifest, resulting in a transition towards a more irregular failure mode. At 150 and 200 freeze-thaw cycles, the internal structure of the concrete is significantly compromised, with more pronounced surface peeling and penetrating internal cracks, culminating in a broader spectrum of failure modes.

Triaxial stress-strain curve

Figure 4 illustrates the impact of varying freeze-thaw cycles on the triaxial stress (σ1 -σ3) -strain (ε) curve of AAC. As the number of freeze-thaw cycles increases, the peak stress observed in the stress-strain curve under triaxial compression significantly decreases, while the strain increases more gradually after reaching the peak stress. This observation suggests a trend of decreasing strength coupled with increasing ductility. The increase in ductility can be attributed to the formation and propagation of microcracks induced by freeze-thaw cycles, which reduce the effective bearing area of the concrete and, consequently, its load-bearing capacity. While increased ductility might indicate enhanced deformability, it could also point to excessive damage accumulation within the material, as the formation of microcracks compromises its structural integrity. Therefore, although ductility is generally considered beneficial, in this case, it might also signify the onset of material degradation.

Figure 5 illustrates the stress-strain curves of AAC subjected to varying confining pressures after 0, 50, 100, 150, and 200 freeze-thaw cycles. The data show that, at a consistent number of freeze-thaw cycles, an increase in confining pressure (from 0 to 3 MPa, and subsequently to 6 MPa) correlates with an increase in the peak stress of AAC. This phenomenon can be attributed to the confining pressure effect, which enhances the compactness and strength of concrete structures. However, the influence of confining pressure on ductility appears to be minimal after the peak stress is reached. This can be explained by the fact that freeze-thaw cycles compromise the pore structure of AAC, leading to microcrack formation and exacerbating material degradation. Confining pressure can compact these microcracks to some extent, improving compressive strength, but its effect on ductility is relatively limited. Consequently, while confining pressure may mitigate some of the strength reduction due to freeze-thaw cycles, the overall damage to the AAC structure remains irreversible as the number of freeze-thaw cycles increases.

Triaxial peak stress

(1) The influence of freeze-thaw cycles on triaxial peak stress.

To normalize the peak stress in the experimental results, the values were calculated relative to the peak stress observed in specimens without any freeze–thaw cycles. As shown in Fig. 6, under varying confining pressures, the peak stress of AAC exhibits distinct degradation trends as the number of freeze–thaw cycles increases. For the specimen subjected to a confining pressure of 3 MPa, the peak stress decreased by 11.8%, 17.6%, 20.9%, and 23.6% compared to the specimen tested at room temperature. In contrast, under a confining pressure of 6 MPa, the peak stress decreased by only 2.1%, 6.9%, 20.7%, and 22.4% after the corresponding number of cycles. Notably, the peak stress degrades more rapidly under 3 MPa confinement, particularly in the early stages of freeze–thaw cycling. This phenomenon can be attributed to the interplay between freeze–thaw-induced microstructural damage and the effect of confining pressure. Under 3 MPa confinement, the external restraint is insufficient to suppress the expansive stresses generated by ice crystallization within the pore structure. The cyclic freezing and thawing of internal moisture produces volumetric expansion that exceeds the local tensile strength of the matrix, initiating microcracks and promoting their propagation. This progressive microcracking reduces the effective load-bearing cross-sectional area and compromises the material’s integrity, leading to a faster reduction in strength. In contrast, at a higher confining pressure of 6 MPa, the external pressure provides more effective restraint against crack opening and propagation. The higher confinement limits the volumetric expansion of ice and maintains the closure of existing defects, thereby mitigating microcrack development and delaying microstructural deterioration. Consequently, the degradation in peak stress is less severe under higher confinement, especially during the early freeze–thaw cycles.

(2) The influence of confining pressure on triaxial peak stress.

Figure 7a illustrates the relationship between the peak stress of AAC and the confining pressure, while Fig. 7b presents the normalized curve. The data indicate that as confining pressure increases, the peak stress of AAC gradually rises. This behavior can be attributed to the research results of Akbarpour et al.24: higher confining pressure enhances the compaction of materials, reduces the size and volume of pores and voids in concrete. This densification leads to a more refined microstructure with fewer pathways for moisture migration, thus improving the material’s resistance to external pressure and increasing its compressive strength25. In particular, the reduction of porosity under higher confining pressure ensures a more uniform and dense structure, which enhances the overall structural integrity and the material’s ability to resist deformation.

Conversely, under identical confining pressure, the peak stress of AAC decreases with an increase in freeze-thaw cycles. This degradation can be primarily attributed to the freeze-thaw cycles inducing continuous freezing and thawing of moisture within the material. The freeze-thaw process causes ice crystals to form within the pores, exerting expansive forces that initiate and propagate microcracks. These microcracks act as stress concentrators, weakening the material and compromising its overall integrity. As the freeze-thaw cycles progress, the material’s porosity increases due to the formation and expansion of these cracks, exacerbating the reduction in compressive performance.

Regarding the growth rate of peak stress, at constant confining pressure, the growth rate initially decreases and then increases as the number of freeze-thaw cycles rises. This behavior can be explained by the rapid accumulation of internal damage during the initial freeze-thaw cycles. The early formation of microcracks leads to a sharp reduction in compressive strength and slows down the strength gain. However, as the number of freeze-thaw cycles continues to increase, the material may undergo a process of structural adaptation. During this phase, a relatively uniform distribution of microcracks may develop, which helps alleviate the concentration of damage and mitigates the rate of decline in compressive strength. As a result, within a specific range of freeze-thaw cycles, the peak stress growth rate exhibits a pattern of first decreasing and then increasing, reflecting the material’s gradual adaptation to the environmental conditions.

Based on the measured data, the existing literature adopts the calculation formula form of triaxial peak stress of concrete under different confining pressures (such as Eq. 1), and fits the measured data:

where, σw represents the magnitude of the lateral confining pressure value, and σ0 is the peak stress of the specimen when the confining pressure value is zero. The fitting parameter results are shown in Table 3.

Elastic modulus

(1) The influence of freeze-thaw cycles on elastic modulus.

This study normalizes the triaxial compression elastic modulus of AAC and calculates it based on the modulus with zero freeze-thaw cycles. The relationship between the triaxial compression elastic modulus of AAC and the number of freeze-thaw cycles has been shown in Fig. 8. As illustrated in the figure, with an increase in freeze-thaw cycles, the triaxial compressive elastic modulus of AAC gradually decreases. Specifically, for AAC subjected to confining pressures of 0 MPa, 3 MPa, and 6 MPa, the maximum triaxial compressive elastic modulus decreases by 39.5%, 42.1%, and 34.6%, respectively. Notably, at a confining pressure of 3 MPa, the degradation amplitude of the three-axis elastic modulus of AAC is the largest, whereas it is the smallest at a confining pressure of 6 MPa. This phenomenon may be attributed to the fact that an increase in confining pressure can lead to the closure of internal micropores within the material to a certain extent, thereby enhancing the density and overall compressive strength of the material. At higher confining pressures (e.g., 6 MPa), the microstructural damage experienced by the material during freeze-thaw cycles may be comparatively minor, resulting in a smaller degradation amplitude of the elastic modulus. During the freeze-thaw cycle, the movement of water within the pores and the formation of ice crystals can inflict damage on the material. When the confining pressure is lower (3 MPa), the migration of water and the formation of ice crystals may generate larger internal stresses within the material, leading to increased microscopic damage and degradation of the elastic modulus.

(2) The influence of confining pressure on elastic modulus.

Figure 9a illustrates the relationship between the triaxial compressive elastic modulus and confining pressure of AAC, while Fig. 9b presents the normalized curve. The data indicate that, with an increasing number of freeze-thaw cycles, the triaxial compressive elastic modulus of AAC progressively increases as confining pressure rises. This behavior can be attributed to the fact that higher confining pressure enhances the material’s density, reduces the presence of pores and microcracks, and leads to a more compact microstructure. As a result, the material is better able to withstand and distribute external forces, thereby improving both its compressive performance and elastic modulus. Furthermore, the increased confining pressure helps to limit the migration of water and the formation of ice crystals during freeze-thaw cycles, thus reducing the detrimental effects of freeze-thaw cycles on the material’s microstructure. Consequently, the triaxial compressive elastic modulus of AAC shows an overall increase after exposure to freeze-thaw cycles.

Similarly, the existing literature adopts the calculation formula for the elastic modulus of concrete under different confining pressures (such as Eq. 2), and fits the measured data:

where, σw represents the magnitude of the lateral confining pressure value, and E0 is the elastic modulus of the specimen when the confining pressure value is zero. The fitting parameter results are shown in Table 4.

Compressive strain energy and brittleness index of AAC

The axial stress-strain curve of AAC is divided into an ascending section and a descending Sects.26,27. Based on the experimental results and previous experience, the area enclosed by the ascending section of the stress-strain relationship curve and the horizontal axis (0 < ε < ε0) is defined as the compressive strain energy absorbed by the AAC specimen during the failure process, denoted as EcompI. EcompI reflects the amount of energy required for the failure of AAC, as shown in Eq. 3:

Similarly, the area enclosed by the descending section of the stress-strain curve and the horizontal axis (0 < ε < εu) is defined as the compressive strain energy EcompII released by the AAC specimen in this interval, as shown in Eq. 4:

The toughness or brittleness of a material is an important indicator of its properties. Generally speaking, the toughness and brittleness of a material are corresponding concepts. There are many methods to describe the brittleness of a material, among which the brittleness index is the most common. AAC is a quasi brittle material. Combining the AAC stress-strain curve, the brittleness index is defined based on the compressive strain energy mentioned above to describe the toughness of AAC. The brittleness index is defined as the ratio of the compressive strain energy between the rising segment and the area enclosed by the horizontal axis, and the falling segment and the area enclosed by the horizontal axis of the AAC stress-strain curve. The specific expression is as follows:

According to Eq. 5, the compressive strain energy (Ecomp) and brittleness index (B) of AAC are calculated and presented in Table 5. The data reveals the relationship between freeze-thaw cycles, lateral confining pressure, and the brittleness index of AAC. As the number of freeze-thaw cycles increases, the brittleness index generally rises, indicating a gradual increase in brittleness. Specifically, at 0 MPa confining pressure, the brittleness index increases from 1.445 to 1.671 as freeze-thaw cycles progress from 0 to 200, highlighting a significant deterioration in material integrity. However, the effect of confining pressure on the brittleness index becomes evident as pressure increases. At 3 MPa confining pressure, the brittleness index rises from 0.451 to 0.537, with a relatively smaller increase compared to 0 MPa. At 6 MPa, the change in brittleness index becomes minimal, from 0.382 to 0.299. This indicates that beyond a certain threshold of confining pressure, the ductility of AAC remains relatively unchanged. Based on the data, the threshold pressure is approximately 3 MPa, where the brittleness index stabilizes and further increases in confining pressure have a diminished impact on improving ductility. This suggests that while confining pressure significantly mitigates brittleness, its effect diminishes beyond this point.

The triaxial compression constitutive model of AAC after freeze-thaw cycles

When ε/ε0 (ε0 is the strain at the peak stress) is x and σ/fcu is y, the stress-strain curve can be inversed to a dimensionless form28,29. Similar to the curve characteristics observed under uniaxial loading, the complete stress-strain curve of AAC under a triaxial stress state comprises both an ascending segment and a descending segment, however, notable differences exist. As the lateral confining pressure increases from 0 MPa to 6 MPa, the slope of stress growth in the triaxial state becomes steeper, resulting in a sharper decline in the descending segment. Based on the characteristics of the curve shape under AAC triaxial loading, and in conjunction with the research methods applied to ordinary concrete, the constitutive relationship is expressed in distinct segments. For the ascending segment, the same expression as that used for the uniaxial loading scenario is adopted for the single-axis curve form:

where a and b are fitting constants, represented as the initial elastic modulus and related to shape of descending branch of the stress-strain curve, respectively.

Compared to the rising segment of the curve, the decreasing segment of the AAC stress-strain curve in the triaxial state shows significant changes compared to the uniaxial state. Therefore, the constitutive model expression in the uniaxial state is no longer applicable. This article draws on the rational fraction proposed by Yang et al.30:

The experimental data were fitted and analyzed using Eq. 6 and Eq. 7, and the values of each parameter in the descending section of the curve are shown in Table 6. As shown in the table, both confining pressure and freeze-thaw cycles have a significant impact on the parameters, indicating that both confining pressure and freeze-thaw cycles have a substantial effect on the AAC failure stage. To further enhance the predictive capability of these experimental findings, machine learning techniques could be employed31. For example, regression models or neural networks could be trained using the experimental data to predict the material’s behavior under varying confining pressures and freeze-thaw cycles. This approach could offer more accurate and efficient predictions, enabling the optimization of AAC material design based on real-time data and conditions. The use of machine learning in this context allows for the identification of complex patterns and relationships that may not be immediately apparent through traditional analytical methods, potentially improving both the design and durability of AAC in real-world applications.

Conclusions

This chapter delves into the effects of different confining pressures and freeze-thaw cycles on the failure mode, stress-strain relationship, peak strength, and elastic modulus of AAC. The main conclusions are as follows:

-

The failure mode of AAC changes with confining pressure: under 0 MPa, the failure is characterized by crack propagation along the loading direction with significant lateral expansion and fragment separation. At 3 MPa, the failure mode shifts to compressive failure with less lateral expansion and a more uniform crack distribution. Under 6 MPa, the failure mode becomes dense, with almost no lateral expansion, indicating a notable improvement in the material’s bearing capacity under high confining pressure.

-

Freeze-thaw cycles lead to a significant reduction in peak stress, with the most substantial degradation occurring at 3 MPa. Specifically, the peak stress of specimens subjected to freeze-thaw cycles decreases by 20.1% at 0 MPa, 23.6% at 3 MPa, and 22.4% at 6 MPa after 200 cycles. This suggests that while freeze-thaw cycles degrade the material’s compressive strength, the degradation rate is faster at lower confining pressures.

-

The elastic modulus of AAC also decreases with freeze-thaw cycles, with reductions of 39.5%, 42.1%, and 34.6% at 0 MPa, 3 MPa, and 6 MPa, respectively. The greatest degradation occurs at 3 MPa, while higher confining pressures mitigate the negative impact of freeze-thaw cycles on the elastic modulus.

-

Based on the experimental results, a prediction method for the triaxial compressive strength and elastic modulus of AAC after freeze-thaw cycles was proposed. A constitutive model was fitted, providing a theoretical framework for the engineering application of AAC in cold regions.

These findings highlight the critical role of confining pressure in enhancing the durability and mechanical performance of AAC, offering valuable insights for its use in freeze-thaw environments.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Mounika, G., Rama, K. S. J., & Ramesh, B. An experimental investigation on the mechanical characteristics of Steel Fibre Reinforced Alkali Activated Concrete incorporating industrial and agro wastes. Innov. Infrastruct. Solutions 9(5) (2024).

Bahmani, H. & Mostofinejad, D. Microstructural characterization of alkali-activated concrete using waste-derived activators from industrial and agricultural sources: A review. Case Stud. Constr. Mater., : e04632. (2025).

Ganta, M., Baskar R, J.S. R & K. Experimental investigation on physical and mechanical properties of alkali activated concrete using industrial and agro waste. Mater. Today Proc. 33(P7) (2020).

Wang, Y. et al. Experimental study on mechanical properties of alkali activated concrete after freeze–thaw cycles[J]. AIP Adv. 14(6). (2024).

Luga, E. et al. A comparative investigation on the freeze–thaw resistance between dry-cured alkali-activated fly ash/slag and Portland cement mortars. J. Building Pathol. Rehabilitation. 10 (2), 102 (2025).

Yang, T. et al. Deterioration mechanism of alkali-activated slag and fly Ash blended recycled aggregate concrete under freeze-thaw cycles. J. Building Eng. 99, 111555 (2025).

Fu, Y. Cai l,wu Y.Freeze-thaw cycle test and damage mechanics models of alkali-activated slag concrete. Constr. Building Mater. 2011, 25(7), 3144–3148.

Zhao, R. et al. Freeze-thaw resistance of class F fly ash-based geopolymer concrete. Constr. Build. Mater. 222, 474–483 (2019).

Thomas, R. Ariyachandra e,lezamad,et al.comparison of chloride permeability methods for alkali-activated concrete. Constr. Build. Mater. 165, 104–111 (2018).

Tennakoon, C. et al. Chloride ingress and steel corrosion in geopolymer concrete based on long term tests. Materials&design 116, 287–299 (2017).

4Krivenko, P. V. Alkaline cements: structure, properties, aspects of durability. Proceedings of the second international conference on alkaline cements and concretes. Kiev, Ukraine, Oranta. : 3–43. (1999).

Fu, Y., Cai, L. & Yonggen, W. Freeze–thaw cycle test and damage mechanics models of alkali-activated slag concrete. Constr. Build. Mater. 25 (7), 3144–3148 (2011).

Temuu, J. et al. Utilization of radioactive high-calcium Mongolian flyash for the Preparation of alkali-activated geopolymers for safe use as construction materials. Ceram. Int. 40 (10), 16475–16483 (2014).

Slavik, R. et al. Preparation of geopolymer from fluidized bed combustion bottom Ash. J. Mater. Process. Technol. 200 (1–3), 265–270 (2008).

Bakharev, T., Sanjayan, J. G. & Cheng, Y. B. Resistance of alkali-activated slag concrete to carbonation. Cem. Concr. Res. 31 (9), 1277–1283 (2001).

Badar, M. S. et al. Corrosion of steel bars induced by accelerated carbonation in low and high calcium fly Ash geopolymer concretes. Constr. Build. Mater. 61, 79–89 (2014).

Zhang, J. et al. Durability of alkali-activated materials in aggressive environments: A review on recent studies. Constr. Build. Mater. 152, 598–613 (2017).

Banaian, M. et al. Triaxial behavior and microstructural insights of loose sandy soil stabilized with alkali activated slag. Sci. Rep. 15 (1), 3573 (2025).

Xia, W. et al. Dynamic compression mechanical behavior and strength prediction modeling of sulfate attacked concrete under triaxial static pre-loading. J. Building Eng. 100, 111784 (2025).

Wang, Y. et al. Early mechanical properties and strength calculation method of slag-based alkali activated concrete. AIP Adv., 14(2). (2024).

Akbarpour, A., Mahdikhani, M. & Ziaie Moayed, R. Mechanical behavior and permeability of plastic concrete containing natural zeolite under triaxial and uniaxial compression. J. Mater. Civ. Eng. 34 (2), 04021453 (2022).

Akbarpour, A., Mahdikhani, M. & Moayed, R. Z. Effects of natural zeolite and sulfate ions on the mechanical properties and microstructure of plastic concrete. Front. Struct. Civil Eng. 16 (1), 86–98 (2022).

Chinese Standard, G. B. T. 50082 – 2024, Standard for test methods of long-term performance and durability of ordinary concrete, Beijing, China, (2024).

Akbarpour, A. & Mahdikhani, M. Effects of natural zeolite and sulfate environment on mechanical properties and permeability of cement–bentonite cutoff wall. Eur. J. Environ. Civil Eng. 27 (3), 1165–1178 (2023).

Akbarpour, A., Volz, J. & Vemuganti, S. An experimental study incorporating carbon fiber composite bars and wraps for concrete performance and failure insight. J. Compos. Sci. 8 (5), 174 (2024).

Gong, F. & Wang, Y. A New Rock Brittleness Index Based on the Peak Elastic Strain Energy Consumption ratio[J], 551571–1582 (Rock Mechanics and Rock Engineering, 2022). 3.

Shi, X. et al. A brittleness index evaluation method for weak-brittle rock by acoustic emission technique[J]. J. Nat. Gas Sci. Eng. 95, 104160 (2021).

Xu, R. et al. The effect of NaHCO3 accelerated carbonation method on the early mechanical properties of recycled aggregate concrete. Structures 70, 107647 (2024).

Chen, Z., Xu, R. & Liang, H. Residual mechanical properties and numerical analysis of recycled pebble aggregate concrete after high temperature exposure and cooled by fire hydrant. Constr. Build. Mater. 319, 126137 (2022).

Yang, H., Meng, S. & Deng, Z. Conventional triaxial compression constitutive curve test of high-strength recycled concrete. J. Jiangsu Univ. (Natural Sci. Edition). 32 (05), 597–601 (2011). (in Chinese).

Fazel Mojtahedi, S. F. et al. Prediction of stress-dependent soil water retention using machine learning. Geotech. Geol. Eng. 42 (5), 3939–3966 (2024).

Acknowledgements

The authors would like to acknowledge the financial support provided by National-level Innovative Team of Vocational Education Teachers, Natural Science Foundation of the Jiangsu Higher Education Institutions of China (No.24KJD560003), Key research project of Nanjing Vocational Institute of Railway Technology (No.YZ240007), Qinglan Project of Jiangsu Higher Education Institutions, Tertiary Education Scientific Research Project of Guangzhou Municipal Education Bureau (No.2024311971) and Funding by Science and Technology Projects in Guangzhou (No. 2025A04J4500).

Author information

Authors and Affiliations

Contributions

1 Dr. Yuhua Wang: Data curation, Formal analysis, Software, Writing-original draft. 2 MSc. Mengjun Wang: Data curation, Formal analysis, Writing-original draft. 3 Mr. Congrang Tang: Data curation, Formal analysis. 4 Dr. Yong Yu: Conceptualization, Data curation, Writing-review & editing. 5 Mr. Shuai Chen: Data curation, Formal analysis, Software.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, Y., Wang, M., Tang, C. et al. Study on the triaxial compressive properties of alkali activated concrete after freeze-thaw cycles. Sci Rep 15, 20517 (2025). https://doi.org/10.1038/s41598-025-06337-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-06337-7