Abstract

In light of the existing carbon imbalance and environmental risks linked to cement manufacturing, diverse forms of biochar materials have been integrated into cement composites. This approach presents a mutually beneficial solution, effectively mitigating CO2 emissions while concurrently yielding economic benefits. This paper focused on replacing 0.1–24% of cement with apricot shells, along with biochar from palm, date, and peach shells at an 8% replacement rate. A nearly linear decline in workability and density was observed in biochar-mortar admixtures, as indicated by the results. With the addition of 1% biochar, the UHPC matrix achieved a peak compressive strength, surpassing that of the control by 2.65%, subsequent increments weakened it. Biochar-added UHPC mortars exhibited a diminished drying shrinkage, and the improvement in anti-permeability was confined to biochar additions ranging from 0.1 to 2%. Inclusion of 0.1–1% biochar in UHPC mortars reduced electrical flux, attributed to their “micro densification” effect. With 1% biochar substitution for cement, MIP analysis disclosed minimal porosity, complemented by SEM imagery showcasing abundant hydration products, underscoring the superior modification achieved in UHPC mortar. Deployed as an additive in UHPC mortar, biochar demonstrates potential success, fostering waste recycling while sequestering carbon within building materials.

Similar content being viewed by others

Introduction

Ultra high performance concrete (UHPC) represents a groundbreaking construction material characterized by its exceptional strength, durability, and remarkable workability1,2. The exceptional durability of UHPC can be attributed to its dense microstructure, resulting in extended service life and reduced maintenance requirements compared to structures made with conventional cement-based materials. In order to attain its exceptional strength, UHPC is engineered to achieve a remarkable packing density, thus, UHPC mixes incorporate a substantial amount of fine materials, including cement and specially processed micro-fillers like silica fume (SF)1,3. Concrete maintains its pivotal significance in construction projects4,5. Powdered cement, in particular, remains an indispensable component of concrete5. Cement production, regrettably, is also a bane to the environment, responsible for emitting approximately 1 ton of CO2 for every ton of cement manufactured6. Consequently, challenges such as high emissions, material cost, and energy consumption continue to hinder the widespread adoption and acceptance of UHPC in large-scale engineering structures3,7.

In order to alleviate these challenges, extensive researches are being conducted on the implementation of alternative materials as partial substitutes for traditional raw materials in UHPC mixtures3,8,9. In accordance with a study conducted by Asadi Zeidabadi et al.10, agricultural wastes are commonly incinerated in open fields, lacking proper control. This practice leads to the direct release of combustion gases, primarily CO2, into the atmosphere, thereby engendering a multitude of environmental concerns1,10. Consequently, numerous academics have endeavored to investigate the potential for repurposing and harnessing agricultural waste. A variety of renewable and plentiful agricultural residues, including wood shavings, bamboo fibers, corn cob remnants, food scraps, and rice husks, are frequently employed in the manufacture of biochar4,11. Biochar, a carbonaceous porous solid material, is generated through pyrolysis process, either in the absence of oxygen or under controlled oxygen levels12. Based on estimations, roughly 1.0 ton of deceased wooden material can yield around 0.3 tons of biochar during the production process13. Applying biochar in concrete facilitates the efficient utilization of agricultural waste and promotes carbon sequestration. Hence, this approach also proves to be a viable method for utilizing agricultural waste in construction applications.

Multiple research endeavors have highlighted the promise of utilizing agricultural residues to convert biochar into a partial replacement for cement in concrete. Aman et al.14 performed an analysis on the characteristics of biochar, revealing that efficacy mortar and concrete composites formulated with biochar as a constituent material. Research findings had revealed that the incorporation of 1–2 wt% food waste biochar and rice waste biochar into mortar yielded mechanical strengths that were comparable to those of the control. Biochar derived from mixed wood sawdust, in turn, exhibited superior performance with regard to both mechanical and permeability properties15. Study investigated biochar particles derived from woody biomass pyrolyzed at 300 °C (BC300) and 500 °C (BC500), where the incorporation of 1–2 wt% BC500 into concrete was shown to mitigate thermal degradation while retaining 20% and 11% greater compressive strength16. Maljaee et al.17 investigated the impact of biochar as a cement filler and substitute on various properties of cement-based composites, including workability, mechanical strength, and transmission characteristics, and emphasized that biochar content of 2% was optimal for enhancing mechanical performance. Research had shown that the incorporation of biochar derived from rice husks, at a rate of 5%, yielded in optimal compressive strength, surpassing other mortar mixtures11. Danish et al.18 determined that adding biochar, up to a 10% dosage, in cement-based composites does not adversely affect their engineering performance. It had been reported that the addition of biochar generally has a minimal impact on the tensile behavior and cracking behavior of cement-based composites19. Despite this, there remains a dearth of systematic research on the UHPC matrix, specifically in terms of its comprehensive dosage change as a substitute for cement. The utilization of biochar in the UHPC matrix is still relatively limited in research. Specifically, there is a lack of investigation into the microstructure and durability of UHPC mortar when biochar is used as a cement replacement. Furthermore, exploration is warranted to investigate the effects of different types of biochar and varying fractions of biochar content on modifying the properties of the UHPC matrix.

The objective of this study is to explore application of apricot shells biochar, derived from agricultural waste through pyrolysis, as a partial cement replacement in UHPC mortar, which replacement was carried spanning from 0.1 to 24%. Since performance of biochar is contingent upon the choice of feedstock and production techniques employed, as such, our research entails to opt for the calibration of four distinct types of biochar, namely apricot shells, palm shells, date shells, and peach shells. Our investigation explored the effects of varying biochar substitution levels and types on a range of properties, encompassing workability, compressive strength, water absorption capacity at saturation, as well as chloride ion penetration resistance. Furthermore, microstructure tests, such as SEM and MIP analysis, were carried out to elucidate the underlying mechanisms behind the enhancement or degradation of the mechanical and durability properties of the UHPC mortar samples.

Materials and methods

Cement, sand and silica fume

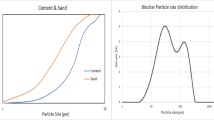

Among concrete components, cement variations stands out, exerting a greater influence than any other individual element. In this research, Ordinary Portland cement P.O 42.5R was employed in UHPC mortar samples, which complied with the Chinese standard and boasted a density of 3.15 g/cm3. Additionally, this cement exhibits a loss on ignition of 5.6%. Its chemical composition by X-ray fluorescence spectroscopy, is further elaborated in Table 1. The particle size distribution data of cement, depicted in Fig. 1, are derived from tests conducted by Daqian Testing Agency, which employed a Laser Particle Size Analyzer for analysis.

Silica fume, consisting of exceedingly fine amorphous silica micro-particles, is a component in UHPC mixes. Being highly reactive and pozzolanic, it augments both the durability and strength of the concrete16,20.

River sand, harnessed in UHPC mortar, was readily obtainable, economically viable, and demonstrated remarkable stability. Maximum size of sand used is 4 mm, and the gradation conforms to ASTM C33, and the particle distribution of river sand is illustrated in Fig. 1.

A superplasticizer (SP), obtained from Laiyang Hongyang Construction Admixture Factory, was incorporated into UHPC matrix, thereby enhancing its properties. They enhance the fluidity of the mortar considerably, facilitating smoother handling during pouring and vibrating processes. Moreover, they effectively decrease water usage while maintaining concrete strength. The solid content spans a range of 40–70%, with a permissible deviation of ± 1.0%. Concurrently, the dry solid content fluctuates ranging from 0.1 to 0.4%. Moreover, the water reduction rate can escalate to between 25% and 45%.

Preparation of Biochar

Biochar particle, procured from Zhengzhou City in Henan Province, was the focus of this study. Specifically, four varied types were obtained, derived from apricot shells, palm shells, date shells, and peach shells. Different kinds of biochar powders, prior to analysis, were processed using a ball mill, and the grinding time was set to 6 h. Composed of granular activated carbon, these biochars demonstrated an iodine number of 600, distinguishing them from other materials. Figure 1 illustrates the particle size distribution of various biochar types. Concurrently, Table 2 presents a detailed chemical characterization, obtained through X-ray fluorescence spectroscopy, while density are concurrently provided. Silicon, potassium and calcium content were detected in biochar, which was inherited from feedstock during pyrolysis. However, silicon in the form of amorphous SiO2 was found to enhance the pozzolanic reactivity of biochar composites20. The sample incorporating apricot shell in place of cement is referred to as 1BC. Similarly, the samples substituting cement with palm, date, and peach shells are designated as 2BC, 3BC, and 4BC, respectively.

Mix proportions and specimen preparation

During the entire experiment, a uniform water-cement ratio, specifically 0.24, was upheld. Furthermore, each mixture contained identical quantities of sand, water, silica fume, as well as superplasticizer. A range of mix ratios was developed to evaluate biochar’s influence on UHPC mortar. Altogether, 14 distinct formulations were compiled and assessed, including a control without biochar (‘B0 (control)’), as detailed in Table 3.

Four types of biochar were employed in this study: apricot shells (1BC), palm shells (2BC), date shells (3BC), and peach shells (4BC). Apricot shells (1BC) were exclusively tested across a wide range of experiments, with their inclusion ranging from 0.1 to 24% by weight as substitutes for cement, considering palm, date, and peach shells biochar at an 8% replacement level. In this study, the UHPC mortar samples are labeled according to a convention: 1BC1 denotes 1% cement substitution with apricot shells biochar, while 2BC8 indicates an 8% palm shells replacement by weight. The remaining samples are labeled in a similar manner following the mentioned format.

The process of sample preparation commenced with the pouring of water, mixed with SP, into the mixing vessel. Cement and silica fume were introduced, followed by stirring at low speed for 1 min. Subsequently, sand and biochar were introduced into the mixing pot. Following this, the mixture underwent stirring at a high speed for a duration of 2–3 min, until a uniform blend was ultimately achieved. After finishing the mixing process, a slump test was promptly conducted. Following this, the mortar was cast into a mold of a specified dimension to produce samples for dry shrinkage analysis. The freshly mixed mortar was poured into a 4 cm cubes mold placed on a vibrating table. Encased in polythene sheets, the cast specimens were left to set at room temperature for up to 24 h before demolding. Upon hardening, the UHPC mortar samples were ultimately conveyed to a fog room. There, they underwent a wet curing process maintained at a temperature ranging from 18 to 22 °C, accompanied by a relative humidity of 95 ± 2%, and this curing process lasted for durations of 3-day and 28-day. Under standard curing conditions, cement hydration is optimized, which promotes the formation of calcium-silicate-hydrate gels and ettringite, thereby densifying the microstructure, while the controlled humidity minimizes moisture loss, thus reducing drying shrinkage.

Test methods

Slump

The UHPC mortar workability was assessed using the slump test, in accordance with GB/T 50,080 − 2016. A slump cone was placed on a non-absorbent glass plate and moistened before three layers of mortar are added and compacted. After leveling the surface, the cone was lifted swiftly and the slump value was determined by measuring the height difference post-slumping.

Saturated water absorption

After undergoing standard curing processes for durations of 3 and 28 days, samples of dimensions with a 4 cm cubic shape were prepared for the tests. Subsequently, the water absorption of these samples was calculated utilizing the formula provided in (1)5.

Here, the notation mw (g) signifies the weight of the sample when it is in a wet condition, whereas md (g) indicates its weight in a dry state. To ascertain mw, the sample was thoroughly immersed in a water bath for a period of 24 h. Conversely, the weight of the sample in its dry form, md, was determined by subjecting it to drying in an oven maintained at a temperature of 110 ± 5 °C for a duration of 24 h21.

Permeability

To evaluate the bottom permeability of UHPC mortar, the capillary water absorption method was utilized. Before conducting the test, the specimen underwent a drying process at 60 °C for 48 h to eliminate any traces of residual water. Ensuring complete sealing, the specimens were coated on all four sides with melted candle wax prior to their immersion in water, reaching a depth of 5 mm. Ultimately, the capillary water absorption rate, kc, for UHPC mortar was calculated using Eq. (2)22,23.

In this formula, the water absorption of the specimen, measured in grams (g), is represented by △m; ρ denotes the density of water, g/mm3; A denotes the submerged cross-sectional area measured in square millimeters, while t indicates the duration of immersion in minutes.

Compressive strength

Samples, shaped as 4 cm cubes, underwent compressive strength testing at both 3 and 28 days using a computer-controlled electro-hydraulic cement pressure testing machine, specifically the YAW-300B model manufactured by Jinan Times Gold Testing Machine Co., Ltd. The testing procedure was conducted in accordance with GB/T 17,671 − 2021. To guarantee precision and accuracy, the UHPC mortar samples were positioned securely between the bearing blocks, and the load was then applied in a gradual and controlled manner, increasing at a steady rate of 2 mm/min24. Subsequently, the average compressive strength was calculated based on an assessment of three separate specimens.

Density

For density analysis purposes, three 40 mm cubic samples were selected from each mixture. The density measurements were conducted at both 3-day and 28-day, when the specimens were taken out of the fog room for mass assessment. Before measurement, the surfaces of the samples were cleaned by wiping them down with a towel20.

Drying shrinkage

To explore the effect of biochar on the drying shrinkage properties of UHPC mortar, prismatic samples were employed25. The assessment of free linear shrinkage was conducted using steel molds measuring 25 mm × 25 mm × 285 mm, with rivets embedded at both ends, compliance with ASTM C157. Once the casting process was completed, a duration of 24 h elapsed before the specimens were removed from their molds. Thereafter, the initial length of each individual specimen underwent measurement, and the definitive result was established by computing the average value of the readings collected from three separate specimens. Periodically, measurements were taken across a period spanning from 24 h19 up until 28 days under ambient temperature condition.

Rapid chloride permeability test

Monitoring current transmission during testing is a method employed for assessing the chloride level in the samples26. After a 28-day curing, standardized testing procedures is in ASTM C1202, and cylindrical specimens are measured, with 100 mm in diameter and 50 mm in height, involving the monitoring of electrical current that traverses the specimen for a duration of 6 h, and a voltage of 60 V is maintained across the ends of the sample throughout the test. One lead was immersed in a 3.0% salt (NaCl) solution and the other in a 0.3 M sodium hydroxide (NaOH) solution, whereupon electrical connection was established and experimental data were recorded.

SEM experiments

To gauge an understanding of the surface morphological characteristics of the specimen, a TESCAN MIRA LMS scanner was conducted, providing a resolution of 1.2 nm at 30 keV and 3.5 nm at 1 keV, and test samples was sprayed with gold for 60s before experiment. Following a 28-day curing, the specimens were subjected to cutting and sampling procedures. To halt further hydration, once the sampling was done, they were immersed in alcohol during 48 h. Subsequently, the specimens were placed in an oven and subjected to drying at a temperature of 60 °C for a duration of 48 h, ready for testing27.

Mercury intrusion porosimeter (MIP)

After a curing period of 28 days, Mercury Intrusion Porosimetry (MIP) was utilized to assess the pore size distribution within the cement mortar28. Prior to measurement, core samples extracted from the center of the specimens were treated with alcohol to halt hydration, and these selected samples were then subjected to oven-drying at a temperature of 60 °C for a period of 48 h. A Micromeritics AutoPore IV 9500 instrument, characterized by its impressive maximum mercury intrusion pressure of 413 MPa and a chosen contact angle of 130°, was utilized to carry out the measurement.

Results and discussion

Macroscopic characteristics

Workability

Slump test proves indispensable, evaluating UHPC workability that governs self-compaction. Insufficient workability of cementitious composites is a key factor leading to poor mechanical strength and durability28,29. In the study, addition biochar to the UHPC paste showed no signs of segregation or bleeding. Figure 2 illustrates the slump values of UHPC mortar, indicating the impact of biochar replacement dosage on the fluidity of freshly mixed mortar. The test uncovered a trend, as the proportion of biochar increased, the slump fresh UHPC mortar diminished in an almost linear fashion. Up to 16% of biochar replacement, no marginal differences in the consistency of the UHPC mortar was reported. However, a lost in workability was observed at substitution rates of 24%, leading to a reduction by 5.38%, compared to the control. Danish et al.18 mentioned a reduction in mortar flow rate, and this effect was magnified when the biochar content was increased beyond 5%. Moreover, the impact of varying biochar types on the slump value was found to be exiguous, when maintained a consistent dosage, 8%, as illustrated in Fig. 3. The reduction in 1BC8 was somewhat evident, which could be explained by the finer granularity of this biochar, compared to other varieties.

When biochar replaced a portion of cement, its higher surface area, in contrast to traditional cement particles, led to elevated water absorption30. The higher water absorption diminished the water quantity available for lubrication during the mixing process, consequently augmenting friction levels and impeding particles movement31. Owing to biochar’s highly permeable structure and its affinity for water, resulting in a gradual moisture was absorbed within its pores, there necessitating increased water intake28, so a diminished slump values was appeared. Gupta & Kua20 suggested a outcome, attributing the decrease in workability to biochar particles’ irregular shape, which limited lubrication, and their high carbon content, which boosted water retention.

Density

The crucial density of building components impacts the structural integrity and, consequently, the support capacity. As biochar dosage escalated, the density of mortar underwent a decrement, exemplified in a marked drop of roughly 100 kg/m³, particularly when biochar content transitions from 0–5%32. The research by Gupta et al.33 demonstrated that a modest 1–2% incorporation of biochar enhanced the hardened density of mortar, however, a noteworthy reduction in hardening density was discernible, with the incorporation of 5% and 8% biochar substitutions.

As depicted in Fig. 4, density of the specimens is linked to the percentage of biochar. The impact of biochar dosage on the density of UHPC hardened mortar evolves dynamically, with fluctuating according to both time and dosage levels. An apparent trend emerged with increasing biochar dosage, a virtually gradual decrease in density. Notably, upon 28 days of curing, a marginal enhancement in sample density was discerned, within a biochar addition of 0.75–2%. When biochar incorporation surpassed 4%, a pronounced decline became evident. After 3 and 28 days, incorporating 24% biochar into UHPC mortar samples resulted evident density reductions, peaking at approximately 7.80% and 6.17% respectively, in comparison to the control. In Fig. 5, the reported hardened density values of mortar, with various biochar types incorporated, are compared against those of the plain mortar, B0. The comparison revealed that the effect on density exerted by the different biochar types utilized in the study is comparatively subtle (p = 0.406 > 0.05, 95% confidence level), as evidenced by the modest variations observed.

Augment in density by 0.75–2% biochar addition could be linked to its water retentive property. Biochar, by being integrated into the mortar, was capable to absorb and sequester a portion of the mixing water, consequently diminishing the availability of free water. The evaporable water content, which governed capillary porosity, was decreased. Consequently, the application of low biochar dosages exerted a densifying influence on the hardened mortar33. Upon exceeding 2% incorporation, the decrease in mixture density could be multifaceted. Primarily, the substantial inclusion of low-density, porous biochar enhanced void formation, driven by its inherently lower envelope density compared to cement, contributing to an overall density reduction. Subsequently, the higher biochar content diminished mix flowability, negatively impacting mortar compactness and fostering void development in the hardened paste. Additionally, the integration of biochar into the UHPC matrix promoted porosity around its particles, further decreasing the density12,34.

Compressive strength

Compressive strength influenced by Biochar dosage

Mechanical behavior of cementitious composites hinges critically on the Interfacial Transition Zone (ITZ), which can be modulated by biochar inclusion17. Biochar incorporation into normal concrete had yielded favorable outcomes, as evidenced in published research. Experimental findings indicated reduced damage in the ITZ of cement composites fortified with 1% biochar, contrasting to the without biochar16. In the study of Restuccia et al.35 revealed a notable boost in compressive strength, attributed to the incorporation of 0.5–0.8% biochar. Several studies have documented an enhancement in compressive strength, achieved by incorporating up to 2% biochar15,33,36,37.

When varying proportions of apricot shell biochar is added, the compressive strength tests conducted on cube samples, as illustrated in Fig. 6, reveal the mean of three specimens per mix, derived from peak loads in load-displacement. As biochar content rose from 0 to 24%, compressive strength exhibited a declining trend, evident at both 3 days and 28days. Remarkably, at 1% biochar addition, the compressive strength surpassed by 1.76% and 2.65% that of the control, respectively, indicating an enhancement. Upon adding 2% biochar dosage, it remained comparable to B0 (control) specimen. Evaluating UHPC mortar, it was found that incorporating over 4% biochar caused considerable modifications. Among these, 1BC16 demonstrated 6.32% and 2.32% reductions at 3 and 28 days, respectively, compared to the plain. Furthermore, the 3-day compressive strength of 1BC24 decreased by 29.86%, amounting to 46.07 MPa, in comparison to the plain. Meanwhile, 1BC24 exhibited significant declines of 22.34% at 28 days, versus the biochar-free counterpart.

To ascertain the influence of biochar on the strength properties of UHPC mortar, SEM analysis was employed, zeroing in on the intricate interactions between biochar and the matrix21. The inclusion of up to 1% biochar was found to be both viable and contribute to a subtle increase in compressive strength. This enhancement could be elucidated by the SEM image (Fig. 7a), revealing an abundance of hydration products, likely facilitated by a heightened degree of hydration. Biochar surfaces and pores might serve as nucleation sites, and heterogeneous nucleation promoted the preferential formation of for hydration products on biochar interfaces, which enhanced the spatial uniformity of hydration products, refined the microstructure, and, in the end, improved the overall compressive strength. Remarkably, Fig. 7b showcased 1BC24, which hydration products volume fell short of pore size, affecting compressive strength negatively. When biochar was incorporated in excess, a multitude of interfacial voids were introduced into the UHPC matrix, which functioned as stress concentration zones that induce crack propagation, thereby reducing compressive strength.

Developed during high-temperature pyrolysis38,39, the porous structure of biochar particles generates porosity, imparting adsorption and water retention abilities40, thereby surpassing that of cement and sand. From the particle distribution curve (Fig. 1), it is discernible that apricot shells biochar particles exhibited finer granularity than cement, implying a capacity to refine pore structure of cement mortar. This refinement stemmed either from the micro-filler effect or the biochar’s role as nucleation sites, aiding cement hydration37. Consequently, upon 1% biochar substitution, which maximized compressive strength, potentially due to optimizing microstructure of UHPC mortar, enhancing hydration reactions, and internal curing exerting effects, achieved through moderate incorporation41. In minimal dosages, under 1%, which failed to induce an effective micro-aggregate filling, thus leading to insignificant or marginal strength attenuation. When the incorporation of biochar exceeded 2%, hydration products failed to adequately fill pores, resulting in a disparity with the higher biochar pore dimensions5. At elevated dosages, the decrease in compressive strength was likely attributable to biochar particles, inherently less potent than UHPC matrix components, functioning as localized ‘soft zones’, thereby breaked within the dense C–S–H gel matrix25. Furthermore, the elastic modulus of UHPC matrix, surpassed 40–50 GPa, while biochar exhibited a significantly lower value, approximately an order of magnitude less, at roughly 8 GPa42.

Compressive strength influenced by types of Biochar

The compressive strength results of cube samples, incorporating various biochar types at an identical dosage, are presented in Fig. 8. The results are comprised of averages, calculated from three samples per mix, with error bars illustrating the deviations from the mean values. The decline in compressive strength was more pronounced after 3 days of incorporation of various biochar types, compared to that observed after 28 days. At an 8% biochar dosage, the inclusion of 1BC diminished compressive strength by 13.70% and 11.66% at 3-day and 28-day, respectively. Conversely, following a three-day curing duration, the addition of 3BC8 significantly reduced compressive strength by 16.86% (p = 0.169 > 0.05, 95% confidence level) compared to the control. Across the board, 2BC8 and 4BC8 consistently caused a roughly 20% decrement in compressive strength. following the 28-day curing process, specimen 3BC8 exhibited 11.76% (p = 0.53 > 0.05, 95% confidence level) lower compressive strength values than the control, B0. Similarly, both 2BC8 and 4BC8 underwent notable strength reductions compared to the control. Various biochar types were characterized by distinct pore structures and specific surface areas, which were influenced to alter their water absorption and retention capabilities. Subsequently, when incorporated into the UHPC matrix, they imparted diverse effects on the strength. As depicted in Fig. 1 through the particle size distribution curve, the finer particle size of 1BC, in comparison to other biochar types, then enhanced the hydration processes and heat release43.

Durability

Drying shrinkage

Apart from the economic and environmental concerns, UHPC mixtures still grapple with a formidable challenge, heightened cracking. Gupta et al.33revealed that incorporating biochar as a cement substitute initially (within 1–4 days) prompted an augmentation in drying shrinkage of UHPC mortar, yet as the curing process advanced, a reduction in this shrinkage was observed with 1% biochar. The lack of modified additives, such as biochar, in the reference mixture restricted the potential benefits for shrinkage reduction. Research indicated that the incorporation of 25% biochar into samples augmented shrinkage values, yet these samples demonstrated a noteworthy 46–55% reduction in shrinkage, relative to the reference mixture31. Based on the research conducted by Dixit et al.25 noted a prominence of shrinkage, which strengthened with the elevation of biochar content. Gupta & Kashani44 further revealed that the drying shrinkage at 7 days in mortar intensified with the escalated dosage of biochar, ranging from 1 to 3%.

Utilizing biochar as a cement substitute, as depicted in Fig. 9, exerts a profound influence on drying shrinkage across different maturity stages, with an outcome being the significant reduction in shrinkage, attributable to the addition of biochar. In this investigation, biochar-added mortars exhibited a reduced drying shrinkage, marked by an accelerated rate during initial stages (1–4 days), regardless of the biochar dosage. However, beyond 7 days, a subsequent deceleration in drying shrinkage was observed, compared with plain mortar. At 1% and 2% inclusion levels, biochar visibly minimized the drying shrinkage of UHPC mortar, with 1BC1 and 1BC2 exhibiting 53.02% and 53.69% lower shrinkage, respectively, compared to plain mortar (control) after 28 days, underscored by their favorable impact on mitigating shrinkage. Even at a 24% substitution level, a modest reduction was evident, in contrast to the control. Drying shrinkage of UHPC mortar was not linearly correlated with the quantity of biochar incorporated, as evidenced by Fig. 9.

The outcomes of the drying shrinkage tests on UHPC mortar samples, each incorporating varying types of biochar at an equivalent addition level, are depicted in Fig. 10. Diverse biochar types significantly impact drying shrinkage, as evidenced by lower shrinkage observed in specimens containing 8% biochar addition, contrasting notably with those of plain sample. Upon 28 days of curing, 1BC and 2BC performed well, exhibiting respective reduction rates of 18% and 16% in shrinkage, outperforming the control.

UHPC mortar contractions were due to the loss of capillary water, resulting in the intensification of internal stresses45. Thus, superior retention properties of biochar was the key characteristics imparted to the mortar, enhancing its resistance against shrinkage17. Biochar, with rich micropores, efficiently absorbed water, diminishing the mortar sorption capacity and alleviating shrinkage. Additionally, it enhanced the UHPC matrix microstructure by promoting the generation of extra C-S-H gel through pozzolanic reactions. This dense structure curbed moisture migration, further diminishing shrinkage46,47. In the majority of observed cases, during the hydration process, biochar functioned as an effective internal curing agent, thereby reducing shrinkage within cementitious composites, owing to its stable porous structure48,49. The observed fluctuations in shrinkage values, which exhibited both increasing and decreasing trends, were primarily attributed to the synergistic interaction between biochar-mediated moisture regulation and delayed hydration reactions in the UHPC matrix, inducing transient swelling during curing stages. The reinforcing prowess of biochar, even in minute quantities, had been empirically validated to be efficacious.

Saturated water absorption

Both directly and indirectly, the absorption of water by cementitious composites influences their durability properties. Generally, a paste hardened with poor water absorption is conducive to improve the durability50. The substitution of 1% cement was found by Tan et al.51 to effectively curb the water absorption capacity of mortar. Gupta et al.15 examined the impact of biochar sourced from wood, food, and rice residues on mortar performance, and the findings revealed that incorporating up to 2% biochar reduced the water absorption of mortar. Analogously, optimal water absorption reduction was attained with a 2% dosage of each biochar, relative to cement, as revealed in study6.

The transformation of saturated water absorption properties in UHPC mortar is showcased in Fig. 11, incorporating biochar percentages spanning 0 to 24%. Observed at 3 days and 28 days, it unveiled discernible patterns as biochar content escalates, with different increment. The integration of 0.1-1% biochar was noted to diminish saturated water absorption, both within 3 days and subsequently at 28 days. Additionally, at 1% biochar addition was found to minimize water absorption, marking it as the optimal substitution, effectively enhancing resistance to water penetration. During saturated water absorption, exceeding 2% biochar replacement in UHPC matrix significantly altered the outcomes, with an obvious rise. At both 3-day and 28-day intervals under normal curing, UHPC mortar with 16% biochar replacement exhibited 33.02% and 20.02% higher saturated water absorption, respectively, compared to the control. In contrast, 24% biochar replacement resulted in 52.57% and 38.00% higher absorption at 3-day and 28-day marks, respectively, than the biochar-free counterpart.

Figure 12 demonstrates that, notably, incorporating four unique biochars, each substituted at an 8% rate, into the UHPC matrix results in an increase in saturated water absorption. Upon reaching the 3-day age, variations in water absorption by UHPC mortar were noted. Specifically, 1BC and 3BC exhibited an 13.49% and 9.28% increase in absorption, respectively, in contrast to the control. Meanwhile, 2BC and 4BC displayed comparable trends, with absorption enhancements of 15.18% and 15.76% compared to the control specimen, respectively. After a 28-day curing period, analogous patterns emerged, with 1BC and 3BC showcasing the slight increase, reaching a mere 9.50% and 7.32% rise (p = 0.406 > 0.05, 95% confidence level) in comparison to the control. Compared to the control, the samples of 2BC and 4BC exhibited heightened water absorption, with respective increments of 12.12% and 10.35%. Biochar’s water absorption and retention are influenced by several factors, including its total pore volume, size, and how interconnected these pores are. Larger pores, exhibiting heightened water retention, acted as bridges, linking meso-pores and micro-pores.

The observed decline in saturated water absorption underscored the effectiveness of minimal biochar addition, which diminished the prevalence of fine capillary pores, inherently linked to the initial sorptivity rate. At this moment, the densification imparted by biochar particles, acting as both filler and water-retaining agent, facilitated a reduction in UHPC matrix porosity. This effect, coupled with the gradual release of retained water during curing, yielded the advantageous outcome52. Upon surpassing 2% biochar, the observed surge in water absorption could arise from the intrinsic pores within the carbonaceous particle structure. These pores, in turn, enabled the establishment of capillary pathways within the UHPC mortar, thus augmenting secondary absorption efficacy. Furthermore, the exceptional retention capacity of biochar bolstered water absorption, thereby enabling efficient water retention in mortar. The enhanced retention capabilities can be attributed to water being absorbed into biochar pores, adsorbed onto its surface, and inter-particulately held, collectively contributing to the overall absorption capacity1.

Permeability

The gas permeability coefficient of UHPC, being less than 1.0 × 10− 19, is surpassed by three orders of magnitude in comparison to that of conventional concrete53. The minimal permeability effectively safeguards against external harm, assuring durability in structures, thus being a cornerstone performance trait in UHPC mortar. Multiple studies12,54,55 had demonstrated that biochar utilized as a cement replacement in concrete yielded maximum permeability reduction at a 5% substitution. Gupta et al.33 revealed that incorporating 1–3% biochar markedly enhanced water penetration resistance by up to 35%, whereas a 5% addition subtly diminished water permeation by 5–8%. The UHPC-NSC, crafted with nanoparticles, exhibited a 36% reduction in water penetration when compared to control. Experimental result demonstrated an inverse correlation between fly ash content and water penetration depth, where increasing replacement rates from 0 to 40% progressively reduced permeability, with the control mixture exhibiting the highest water penetration and the 40% replacement sample achieving optimal impermeability56.

As shown in Fig. 13, the biochar content in UHPC mortar samples varies, ranging from 0 to 24%, to investigate the potential impact on permeability of UHPC mortar. It was observed that the incorporation of 0.1-8% biochar enhanced water penetration resistance within 3 days. However, at the 28-day mark, the improvement was confined to biochar additions ranging from 0.1 to 2%. As the replacement percentages increased, the samples exhibited higher porosity, resulting in an enhancement of their permeability. When 1% biochar was substituted into UHPC mortar during permeability tests at 3 days and 28 days, a minimum permeability coefficient value was attained, marking a reduction of 28.87% and 30.93% respectively compared to the control, thus emphasizing its outstanding impermeability resistance. For a duration of 3 days, 1BC24 resulted in an appreciable enhancement of the permeability coefficient, achieving 41.27%, compared to biochar-absent control. Upon a 28 -day of curing period, the substitution of up to 24% biochar yielded almost twice improvement in permeability coefficient. As illustrated in Fig. 14, it is remarkable that the UHPC mortar incorporates four unique biochars, each substituted at a rate of 8%. The graph portrayed a discernible trend, with early-stage permeability (at 12 h) being robust, only to gradually weaken over time. The findings revealed that the integration of diverse biochars could elicit varying influences, attributed to their distinct performance characteristics. After 3 days of curing, 3BC was found to possess the lowest permeability coefficient. Conversely, 1BC emerged as the sample with the optimal permeability performance at 28-day. The finer particle size of 1BC potentially underpined this phenomenon, as it progressed through curing, fostering a denser concrete structure via its filling action, ultimately enhancing the resistance to permeability.

The inclusion of biochar contents significantly influenced the permeability of samples, a phenomenon likely rooted in the porosity of the UHPC matrix, which predominantly dictated its permeability. Upon incorporating 1% of biochar, its microstructure attained greater homogeneity, owing to its filling capability. In such a case, the water penetration capacity of UHPC mortar was mitigated, as biochar partially obstructed the water transportation pathways53. In the scenario of a 24% augmentation, an excessive dosage was noted, causing weakened cohesive interaction between biochar particles and cementitious paste. This, in turn, provoked an elevation in porosity and a reduction in the compactness of the UHPC matrix. The rise in permeability was plausibly explained by gaps existing between biochar particles and mortar. These gaps, a consequence of inadequate bonding, counteracted biochar’s water retention-induced compactness. Serving as water pathways, they enabled deeper percolation within the mortar during infiltration37.

Rapid chloride penetration test (RCPT)

Durability and corrosion resistance of UHPC matrix are assessed through charge passed as measured by RCPT, serving as a critical evaluation. Chloride ions either diffuse through the pores of concrete or become chemically and physically attached to hydration products, a interaction within the cement-based material57. Ling et al.39 observed that partial substitution of cement with 1–3% biochar, a reduction of up to 32% in the chloride diffusion coefficient. Yang & Wang58 conducted experiments simulating chloride-ion penetration by biochar mortars with 3% NaCl, featuring up to 5% cement replacement, and they showed that the inclusion of biochar powder was found to enhance the compactness of the cementitious matrix through stabilized carbonation, thereby mitigating chloride diffusion. Incorporation of fibers had been demonstrated to enhance UHPC durability, where crack propagation was effectively restrained, thereby reducing permeability through microstructural densification59. Amin et al.60 demonstrated that chloride ion penetration resistance in UHPC was enhanced with increasing silica fume substitution rates, where passing charges measured 273 − 170 coulombs for 5–25% cement replacement, while the control exhibited higher permeability, demonstrating 327 coulombs.

The illustration in Fig. 15 exemplifies the charge passed characteristics of UHPC mortar, highlighting the influence of incorporating varying percentages of apricot shell biochar. With 28 days of curing completed, the charge passed of biochar-mortar underwent a remarkable augmentation as testing time progressed from 60 to 360 min, and the ultimate value achieved was assigned as the criterion for evaluation. Of significance, UHPC mortars with 0.1-1% biochar additions demonstrated reduced electrical flux values, whereas the remaining groups presented elevated values, exceeding those of the control group. It was remarkable that 1BC1 resulted a 27.27% decrease in charge passed, compared to the control, underlining the optimal content for enhancing chloride ion penetration resistance, with further additions potentially exacerbating it. Charge passed alterations in UHPC mortar were slightly evident upon exceeding 8% biochar substitution, particularly with 16% and 24% biochar content, showcasing 165.45% and 238.18% increases (p = 0.36 > 0.05, 95% confidence level), respectively, compared to the biochar-absent counterpart.

Considering the effects of lower biochar addition on chloride-ion penetration, the positive effects of biochar application was manifested. Biochar augmented hydration through internal curing, fostering denser biochar-cement by providing extra reaction sites. Additionally, refining particle size of biochar elevated its filler effectiveness, yielding a tighter microstructure in biochar-cementitious mortars61. With the addition of biochar exceeding 2%, an inverse trend was observed in charge passed, highlighting the effects of dosage. The primary attribution for this phenomenon lay in the excessive biochar doses integrated into the UHPC matrix, which fostered the emergence of additional capillaries and elevated porosity within the UHPC mortar. Subsequently, this undermined the beneficial effects of biochar as an internal curing agent, specifically its ability to offer nucleation sites and enhance filling capabilities62,63. Past research had revealed that, albeit a minute amount of biochar had the ability to physically bind chloride ions64, an excessive incorporation of biochar, due to its inherently porous nature, led to a significant rise in the porosity within the UHPC mortar.

Figure 16 portrays the outcomes stemming from charge passed evaluations undertaken at the 28 days of curing, utilizing diverse biochar types. Based on the graph, at 8% substitution, a perceptible difference in charge passed of distinct biochar types emerged. Upon inclusion biochar, 1BC yielded the lowest growth rate, registering a minimal 18.18% increase. Conversely, 2BC demonstrated the highest surge, reaching 85.45%. 3BC and 4BC exhibited comparable enhancements, with 52.73% and 47.27% increases over the control B0, respectively. The phenomenon was attributed to attributed to exquisitely fine particles of 1BC, optimal packing was achieved. In contrast, coarse particles of 2BC hindered efficient packing. Meanwhile, 3BC and 4BC shared comparable particle dimensions, connecting their roles in the process. The 1BC, finer biochar particles efficiently occupy microscopic pores and cracks within the cementitious matrix, reducing porosity and enhancing concrete compactness, so a denser structure was achieved, impeding chloride ion penetration pathways.

Microstructure of UHPC mortar containing Biochar

After completion of a 28-day curing process, microscopic analysis of the biochar-mortars is showcased in Fig. 17, against the control for comparison. It was apparent that the control specimen, designated as B0, during the mixing process, some air voids were created, and the hydration products manifested a coherent morphological configuration4, as depicted in Fig. 17a. The introduction of 0.25% biochar in Fig. 17b, this disruption the mortar homogeneity, localized in certain areas, was primarily attributed to the reactive inertia of biochar65. Drawing upon the aforementioned experimental outcomes, it was discerned that integrating 1% biochar elicited remarkable enhancements in both the mechanical and durability characteristics of UHPC matrix. When 1% biochar was added, hydration products were intricately interwoven within the interior porosity of the UHPC-biochar mortar, and among the hydration products, flaky CH, needle-like ettringite (AFt) and spongy C-S-H gels could be observed in Fig. 17c. The surface of biochar exhibited a smoother texture, in contrast to the rougher surface of the UHPC matrix. This disparity stemed from the inherent stability of carbon, which constituted the primary component of biochar. Conversely, the matrix displayed a certain degree of randomness in the shapes formed by the proliferation of diverse crystals65. As evident from Fig. 17d, the UHPC mortar incorporating 24% biochar appeared looser than the control, with the biochar’s binding to adjacent minerals lacking compactness. This was due to the porous nature of the biochar, which facilitated higher water release, subsequently elevating the local water-to-cement ratio. As a result, porosity increased, manifesting in a looser matrix with evident pores and cracks in that region. 1BC24 led to a magnification in the volume of localized pores and cracks, both in proximity to the interfacial transition zone (ITZ) and within the cement paste matrices. Cracks traversed a narrow zone adjacent to biochar particles without fracturing their shells. These pores and cracks, causing localized stress concentrations, were pivotal factors in the decline of mechanical properties, particularly with excessive biochar incorporation.

EDS analysis of sample 1BC1 (Fig. 18) revealed multiple crystalline phases, including hydrated calcium silicate (C–S–H), calcium carbonate crystals (CaCO3), and calcium hydroxide (CH), which were identified alongside unhydrated cement clinker (C2S/C3S) and AFt. In the moist environment within biochar pores, the generation of C–S–H gel, CH, and ettringite is supported, while calcium carbonate crystals are formed as a result of localized carbonation caused by the adsorbed CO2 in those pores. C–S–H, which is the principal binder in cementitious mortar, contributes to strength only when it becomes part of the matrix and bonds biochar particles to the mortar paste37.

The microstructure of UHPC mortar is influenced by the incorporation of various types of biochar. SEM of mortar samples featuring 8% biochar sourced from 1BC, 2BC, 3BC, and 4BC are presented in panels Fig. 17e, f, g, h, respectively. Following the introduction of 1BC, it was noted that a dense and uniform structure emerged, with various hydration products locally visible at the interface, intricately interwoven. In the SEM micrograph of 2BC, a uniform and densely distributed arrangement of needle-like AFt and CH were observed to be uniformly and densely dispersed, encircling the pores within, and a distinct interface was evident between the biochar and the matrix. The micrographs of UHPC mortar featuring 3BC and 4BC, where a less pronounced uniformity and abundance in their hydration products were exhibited. On the whole, the 3BC specimen featured block-like structures that maintained uniform interfaces, demonstrating structural integrity, whereas 4BC developed fibrous networks which increased porosity and created a more disordered matrix. With the incorporation of 3BC biochar, hydration yielded predominantly flocculent C–S–H, while traces of CH and cracks are also observed. Mortar with addition of 4BC (Fig. 17h), showed significantly higher fraction of pores, in stark contrast to its counterpart with 1BC, due to the finer particle size of 1BC. The C–S–H gel exhibited a less crystalline structure and a more porous nature under these conditions. This phenomenon manifested adverse repercussions, entailing localized stress accumulations and a diminution in the effective load-bearing capacity, ultimately reducing the area capable of sustaining stress effectively.

Porosity and pore size distributions

The porosity of cement-based materials, inherently porous, influences their resultant properties, alongside the distribution pattern of these pores66. Biochar displayed a stratified pore architecture, where large macro-pores, stemming from the biomass source, and functioned as “feeders”, channeling into smaller pores1,67. The study by Brewer et al.68 indicated that during biomass pyrolysis, the deposition of tars and volatiles might cause the obstruction of certain large macro-pores in the resultant biochar. Study had revealed that incorporating 5% biochar into the composites detrimentally impacted their pore structure, manifested as an augmentation in overall porosity69. Utilizing the assessments of compressive strength and durability properties, the control, 1BC0.25, 1BC1, 1BC8, and 1BC24 samples for pore structure analysis were selected. Figure 18 presents the pore volume characteristics of the UHPC mortar, as derived from MIP testing.

Presenting influence of biochar addition on porosity, was slightly pronounced, attributed to varying dosages employed during testing, as evident from Fig. 19a. After a 28-day curing process, UHPC pastes modified with biochar exhibited a marginal decrease, mere 1% incorporation, in their overall porosity. Induced by the micro-filler effect or augmented nucleation sites offered by biochar, the pore structure underwent refinement37. Furthermore, the biochar’s water absorption capability diminished the water content in fresh mortar, in an unbound state, thereby modulating the regional water-to-cement ratio and culminating in reduced porosity36. For other addition levels, an augmentation in porosity was observed within the UHPC matrix, particularly at heightened substitution rates, whereas the porosity of the BC8 and BC24 groups witnessed a surge, reaching 23.56% and 38.53% respectively, compared to control. A comparable trend emerged in the total pore area, consistently lower than porosity across nearly all tested samples, with the exception of those incorporating 24% biochar. Upon addition of up to 1%, it became evident that biochar incorporation prompted an increase in total pore area, originating from the synergistic influence of pore structure coarsening and porosity enhancement. A portrayal of the cumulative pore volume alteration is presented at Fig. 19b, with B0 serving as the benchmark, showcasing a descent in the BC1 curve, which demonstrated that the total porosity, along with the percentages of pores categorized by varying sizes, exhibited lower than that of control sample. In contrast, an ascending trend was manifested in the curves of the remaining samples. This observation signified an enhancement in pore structure, coupled with a reduction in porosity, which offered insight into the compressive strength displayed by the UHPC mortar incorporating 1% biochar replacement. Furthermore, at a 24% increase in substitution rate, the cumulative pore volume curve experienced a marked upward displacement, implying a detrimental impact upon the pore configuration of the UHPC matrix, with porosity experiencing an elevation.

Crucial in impacting the mechanical properties of cement-based materials is the pore structure. Pores are categorized into macropores exceeding 100 nm, large capillary pores ranging from 50 to 100 nm, medium capillary pores spanning 10–50 nm, and gel pores below 10 nm. Those measuring less than 10 nm demonstrate negligible impact on compressive strength, whereas pores surpassing 50 nm exert an adverse influence on this property65. It could be observed from Fig. 19c that at the same curing age, the incorporation of biochar, at a concentration of 1%, resulted in modifications to the pore size distribution within the specimens, manifesting in an augmentation of micropores (r < 50 nm) and a corresponding diminution of macropores (r > 100 nm). Incorporation of 1% biochar diminished porosity and concurrently shrinken the average pore diameter, both factors contributing to the enhancement of compressive strength. Regarding the additional samples, there was an upward trend in the count of micropores, while paralleled by a commensurate rise in macropores. Pores exceeding 50 nm predominated in governing the transport characteristics of cement mortar, subsequently eliciting a noticeable decline in the permeability of 1BC1 specimen.

Conclusions and perspectives

To tackle carbon imbalance and environmental risks linked to cement manufacturing, recycle the agricultural waste, and efficiently capture and sequester CO2 from the atmosphere, four eco-friendly biochars were employed by innovatively substituting for a segment of the cement in UHPC matrix. An exhaustive assessment was conducted on macro performance, encompassing workability and mechanical properties, and delved into durability and microstructure characteristics. Based on experimental results, the following findings were derived and compiled.

-

1.

A discernible trend emerged from the slump test, revealing a nearly linear decline in the slump of fresh UHPC mortar as the biochar content escalated. A lost in workability was observed at substitution rates of 24%, leading to a maximum reduction by 5.38%, contrasted the control sample. Irregular shape of biochar particles hindered lubrication, while their high carbon content enhanced water retention, and could collectively contribute to the observed decrease in workability.

-

2.

Biochar-mortar exhibited a gradual density reduction at 3-day. By day 28, a marginal enhancement in density was observed, within 0.75-2% biochar addition, which could be linked to its water retentive property. Incorporation of 24% biochar led to a substantial reduction of approximately 6.17% compared to the control, a phenomenon that could be attributed to the augmentation of porosity around biochar particles.

-

3.

With a 1% biochar addition, the UHPC matrix attained a peak compressive strength, exceeding that of the control by 2.65% at 28 days. This enhancement could be credited to the water present in biochar pores, which functioned as nucleation sites for hydration products, and further facilitated hydration. However, to proceed with escalation in biochar content led to a weakening effect, stemming from the fact that biochar particles, inherently weaker than other UHPC matrix components, introduced localized ‘soft zones’ and increased porosity.

-

4.

Incorporation of biochar into UHPC mortars was observed to reduce drying shrinkage, characterized by an initial acceleration in the rate, which, after seven days, was succeeded by a deceleration, contrasting without biochar sample. The reduction was attributed to biochar as a curing agent during hydration, effectively mitigating shrinkage, owing to its stable porous architecture.

-

5.

At the 28-day, the improvement in anti-permeability was confined to biochar additions ranging from 0.1 to 2%, with 1% biochar, achieving a minimum permeability coefficient value was attained, marking a reduction of 30.93%, compared to the control.

-

6.

UHPC mortars with 0.1–1% biochar additions demonstrated reduced electrical flux values, its inherent ‘micro densification’ effect is likely the underlying cause. Incorporating an elevated dosage of biochar into the UHPC mortar led to the proliferation of capillary pores, thereby exerting an adverse effect.

-

7.

SEM images were captured for the UHPC mortar that incorporated biochar, with 1% replacement showed substantial hydration product formation in UHPC matrix. Yet, the integration of 1BC24 led to a magnification in the volume of localized pores and cracks.

-

8.

MIP test showed substituting 1% cement with biochar, a minimal porosity value was exhibited. By 24% substitution rate, the cumulative pore volume curve underwent a noticeable elevation in position, adversely affecting the pore structure.

-

9.

In general, UHPC mortar featuring 1BC fine biochar exhibited superior properties among the four biochar types, which demonstrated peak compressive strength coupled with minimal permeability.

Numerous studies have progressively highlighted the potential of biochar to serve as a substitute for cement in construction materials. However, in UHPC matrix, scarce literature addresses the repercussions of replacing cement with biochar, particularly at concentrations of 8% and greater. Moreover, the varying structures of biochar, including porosity and stability, lead to distinct properties when incorporated into cement-based materials. Hence, it is imperative for future research endeavors to focus on refining the composition and variety of biochar, while evaluating its long-lasting impacts on the mechanical and durability characteristics of UHPC mortar.

Data availability

The datasets generated and/or analysed during the current study are not publicly available due making public data accessible may compromise the novelty of our research paper, thereby adversely impacting its publication prospects, but are available from the corresponding author on reasonable request.

References

Dixit, A., Gupta, S., Pang, S. D. & Kua, H. W. Waste valorisation using Biochar for cement replacement and internal curing in ultra-high performance concrete. J. Clean. Prod. 238 https://doi.org/10.1016/j.jclepro.2019.117876 (2019).

Oh, T. et al. Effect of high-volume substituted Nanosilica on the hydration and mechanical properties of ultra-high-performance concrete (UHPC). Cem. Concr. Res. 175 https://doi.org/10.1016/j.cemconres.2023.107379 (2024).

Du, J., Wang, Y., Bao, Y., Sarkar, D. & Meng, W. Valorization of wasted-derived Biochar in ultra-high-performance concrete (UHPC): Pretreatment, characterization, and environmental benefits. Constr. Build. Mater. 409 https://doi.org/10.1016/j.conbuildmat.2023.133839 (2023).

Liu, W., Li, K. N. & Xu, S. L. Utilizing bamboo Biochar in cement mortar as a bio-modifier to improve the compressive strength and crack-resistance fracture ability. Constr. Build. Mater. 327 https://doi.org/10.1016/j.conbuildmat.2022.126917 (2022).

Akhtar, A. & Sarmah, A. K. Novel biochar-concrete composites: Manufacturing, characterization and evaluation of the mechanical properties. Sci. Total Environ. 616, 408–416. https://doi.org/10.1016/j.scitotenv.2017.10.319 (2018).

Dixit, A., Gupta, S., Pang, S. D. & Kua, H. W. Cement replacement and improved hydration in ultra-high performance concrete using biochar. In 3rd International Conference on the Application of Superabsorbent Polymers (SAP) and Other New Admixtures Towards Smart Concrete, RILEM Bookseries, pp 222–229. (2020).

Yu, R., Spiesz, P. & Brouwers, H. J. H. Development of an eco-friendly ultra-high performance concrete (UHPC) with efficient cement and mineral admixtures uses. Cem. Concr. Compos. 55, 383–394. https://doi.org/10.1016/j.cemconcomp.2014.09.024 (2015).

Wang, X. et al. Characterization of sustainable ultra-high performance concrete (UHPC) including expanded perlite. Constr. Build. Mater. 303 https://doi.org/10.1016/j.conbuildmat.2021.124245 (2021).

Mahjoubi, S., Barhemat, R., Meng, W. & Bao, Y. AI-guided auto-discovery of low-carbon cost-effective ultra-high performance concrete (UHPC). Resour. Conserv. Recycl. 189 https://doi.org/10.1016/j.resconrec.2022.106741 (2023).

Zeidabadi, Z. A., Bakhtiari, S., Abbaslou, H. & Ghanizadeh, A. R. Synthesis, characterization and evaluation of Biochar from agricultural waste biomass for use in building materials. Constr. Build. Mater. 181, 301–308. https://doi.org/10.1016/j.conbuildmat.2018.05.271 (2018).

Akinyemi, B. A. & Adesina, A. Recent advancements in the use of Biochar for cementitious applications: A review. J. Build. Eng. 32 https://doi.org/10.1016/j.jobe.2020.101705 (2020).

Praneeth, S., Saavedra, L., Zeng, M., Dubey, B. K. & Sarmah, A. K. Biochar admixtured lightweight, porous and tougher cement mortars: Mechanical, durability and micro computed tomography analysis. Sci. Total Environ. 750 https://doi.org/10.1016/j.scitotenv.2020.142327 (2021).

Chen, S., Teng, Y., Zhang, Y., Leung, C. K. Y. & Pan, W. Reducing embodied carbon in concrete materials: A state-of-the-art review. Resour. Conserv. Recycl. 188 https://doi.org/10.1016/j.resconrec.2022.106653 (2023).

Aman, A. M. N., Selvarajoo, A., Lau, T. L. & Chen, W. H. Biochar as cement replacement to enhance concrete composite properties: A review. Energies 15 (20). https://doi.org/10.3390/en15207662 (2022).

Gupta, S., Kua, H. & Koh, H. J. Application of Biochar from food and wood waste as green admixture for cement mortar. Sci. Total Environ. 619, 419–435. https://doi.org/10.1016/j.scitotenv.2017.11.044 (2018).

Gupta, S., Wei, K. H. & Dai, P. S. Effect of Biochar on mechanical and permeability properties of concrete exposed to elevated temperature. Constr. Build. Mater. 234 https://doi.org/10.1016/j.conbuildmat.2019.117338 (2020).

Maljaee, H., Madadi, R., Paiva, H., Tarelho, L. & Ferreira, V. M. Incorporation of Biochar in cementitious materials: A roadmap of Biochar selection. Constr. Build. Mater. 283 https://doi.org/10.1016/j.conbuildmat.2021.122757 (2021).

Danish, A. et al. Reusing Biochar as a filler or cement replacement material in cementitious composites: A review. Constr. Build. Mater. 300 https://doi.org/10.1016/j.conbuildmat.2021.124295 (2021).

Sirico, A. et al. Biochar from wood waste as additive for structural concrete. Constr. Build. Mater. 303 https://doi.org/10.1016/j.conbuildmat.2021.124500 (2021).

Gupta, S. & Kua, H. W. Application of rice husk Biochar as filler in cenosphere modified mortar: preparation, characterization and performance under elevated temperature. Constr. Build. Mater. 253 https://doi.org/10.1016/j.conbuildmat.2020.119083 (2020).

Qin, Y. H., Pang, X. J., Tan, K. H. & Bao, T. Evaluation of pervious concrete performance with pulverized biochar as cement replacement. Cem. Concr. Compos. 119 (2021). https://doi.org/10.1016/j.cemconcomp.2021.104022

Karataş, M., Benli, A. & Ergin, A. Influence of ground pumice powder on the mechanical properties and durability of self-compacting mortars. Constr. Build. Mater. 150, 467–479. https://doi.org/10.1016/j.conbuildmat.2017.05.220 (2017).

Zhang, P., Wittmann, F. H., Vogel, M., Müller, H. S. & Zhao, T. Influence of freeze-thaw cycles on capillary absorption and chloride penetration into concrete. Cem. Concr. Res. 100, 60–67. https://doi.org/10.1016/j.cemconres.2017.05.018 (2017).

Cuthbertson, D., Berardi, U., Briens, C. & Berruti, F. Biochar from residual biomass as a concrete filler for improved thermal and acoustic properties. Biomass Bioenerg. 120, 77–83. https://doi.org/10.1016/j.biombioe.2018.11.007 (2019).

Dixit, A., Verma, A. & Pang, S. D. Dual waste utilization in ultra-high performance concrete using Biochar and marine clay. Cement Concr. Compos. 120 https://doi.org/10.1016/j.cemconcomp.2021.104049 (2021).

Du, Y., Gao, P., Yang, J. & Shi, F. Research on the chloride ion penetration resistance of magnesium phosphate cement (MPC) material as coating for reinforced concrete structures. Coatings 10 (12). https://doi.org/10.3390/coatings10121145 (2020).

Dong, S. et al. Comparative study on the effects of five Nano-Metallic oxide particles on the long-term mechanical property and durability of cement mortar. Buildings 13 (3). https://doi.org/10.3390/buildings13030619 (2023).

Sikora, P. et al. A systematic experimental study on biochar-cementitious composites: Towards carbon sequestration. Ind. Crops Prod. 184 https://doi.org/10.1016/j.indcrop.2022.115103 (2022).

Chougan, M. et al. A. A systematic study on EN-998-2 premixed mortars modified with graphene-based materials. Constr. Build. Mater. 227 https://doi.org/10.1016/j.conbuildmat.2019.116701 (2019).

Xie, C. et al. Experimental study on the water purification performance of biochar-modified pervious concrete. Constr. Build. Mater. 285 https://doi.org/10.1016/j.conbuildmat.2021.122767 (2021).

Yosri, A. M., Zaid, O. & Hamad, M. Valorization of engineered Biochar to develop ultra-high-performance fiber-reinforced concrete with low carbon emission. J. Sustain. Cem.-Based Mater. 13 (6), 865–887. https://doi.org/10.1080/21650373.2024.2333270 (2024).

Tan, K. H., Wang, T. Y., Zhou, Z. H. & Qin, Y. H. Biochar as a partial cement replacement material for developing sustainable concrete: An overview. J. Mater. Civ. Eng. 33 (12). https://doi.org/10.1061/(asce)mt.1943-5533.0003987 (2021).

Gupta, S., Kua, H. W. & Pang, S. D. Biochar-mortar composite: Manufacturing, evaluation of physical properties and economic viability. Constr. Build. Mater. 167, 874–889. https://doi.org/10.1016/j.conbuildmat.2018.02.104 (2018).

Muthukrishnan, S., Gupta, S. & Kua, H. W. Application of rice husk Biochar and thermally treated low silica rice husk Ash to improve physical properties of cement mortar. Theoret. Appl. Fract. Mech. 104 https://doi.org/10.1016/j.tafmec.2019.102376 (2019).

Restuccia, L. & Ferro, G. A. Promising low cost carbon-based materials to improve strength and toughness in cement composites. Constr. Build. Mater. 126, 1034–1043. https://doi.org/10.1016/j.conbuildmat.2016.09.101 (2016).

Gupta, S. & Kua, H. W. Effect of water entrainment by pre-soaked Biochar particles on strength and permeability of cement mortar. Constr. Build. Mater. 159, 107–125. https://doi.org/10.1016/j.conbuildmat.2017.10.095 (2018).

Gupta, S., Kua, H. W. & Low, C. Y. Use of Biochar as carbon sequestering additive in cement mortar. Cement Concr. Compos. 87, 110–129. https://doi.org/10.1016/j.cemconcomp.2017.12.009 (2018).

Liu, J. et al. Application potential analysis of Biochar as a carbon capture material in cementitious composites: A review. Constr. Build. Mater. 350 https://doi.org/10.1016/j.conbuildmat.2022.128715 (2022).

Ling, Y. F., Wu, X. H., Tan, K. H. & Zou, Z. J. Effect of Biochar dosage and fineness on the mechanical properties and durability of concrete. Materials 16 (7). https://doi.org/10.3390/ma16072809 (2023).

Mrad, R. & Chehab, G. Mechanical and microstructure properties of Biochar-Based mortar: An internal curing agent for PCC. Sustainability 11 (9). https://doi.org/10.3390/su11092491 (2019).

Song, N., Li, Z. H., Wang, S. Q. & Li, G. Biochar as internal curing material to prepare foamed concrete. Constr. Build. Mater. 377 https://doi.org/10.1016/j.conbuildmat.2023.131030 (2023).

Park, J. H. et al. Analysis of biochar-mortar composite as a humidity control material to improve the Building energy and hygrothermal performance. Sci. Total Environ. 775 https://doi.org/10.1016/j.scitotenv.2021.145552 (2021).

Gupta, S. & Kua, H. W. Carbonaceous micro-filler for cement: effect of particle size and dosage of Biochar on fresh and hardened properties of cement mortar. Sci. Total Environ. 662, 952–962. https://doi.org/10.1016/j.scitotenv.2019.01.269 (2019).

Gupta, S. & Kashani, A. Utilization of Biochar from unwashed peanut shell in cementitious Building materials-Effect on early age properties and environmental benefits. Fuel Process. Technol. 218 https://doi.org/10.1016/j.fuproc.2021.106841 (2021).

Mo, L. W., Fang, J. W., Huang, B., Wang, A. G. & Deng, M. Combined effects of Biochar and MgO expansive additive on the autogenous shrinkage, internal relative humidity and compressive strength of cement pastes. Constr. Build. Mater. 229 https://doi.org/10.1016/j.conbuildmat.2019.116877 (2019).

Yang, L., Shi, C. & Wu, Z. Mitigation techniques for autogenous shrinkage of ultra-high-performance concrete–A review. Compos. Part. B Eng. 178 https://doi.org/10.1016/j.compositesb.2019.107456 (2019).

Fang, C., Ali, M., Xie, T., Visintin, P. & Sheikh, A. H. The influence of steel fibre properties on the shrinkage of ultra-high performance fibre reinforced concrete. Constr. Build. Mater. 242 https://doi.org/10.1016/j.conbuildmat.2019.117993 (2020).

Ahmad, S., Khushnood, R. A., Jagdale, P., Tulliani, J. M. & Ferro, G. A. High performance self-consolidating cementitious composites by using micro carbonized bamboo particles. Mater. Design. 76, 223–229. https://doi.org/10.1016/j.matdes.2015.03.048 (2015).

Cosentino, I. et al. Type of materials, pyrolysis conditions, carbon content and size dimensions: The parameters that influence the mechanical properties of Biochar cement-based composites. Theor. Appl. Fract. Mech. 103 https://doi.org/10.1016/j.tafmec.2019.102261 (2019).

Gupta, S. & Kua, H. W. Combination of Biochar and silica fume as partial cement replacement in mortar: Performance evaluation under normal and elevated temperature. Waste Biomass Valoriz. 11 (6), 2807–2824. https://doi.org/10.1007/s12649-018-00573-x (2020).

Tan, K. H., Pang, X. J., Qin, Y. H. & Wang, J. S. Properties of cement mortar containing pulverized Biochar pyrolyzed at different temperatures. Constr. Build. Mater. 263 https://doi.org/10.1016/j.conbuildmat.2020.120616 (2020).

Sirico, A. et al. Effects of Biochar addition on long-term behavior of concrete. Theor. Appl. Fract. Mech. 122 https://doi.org/10.1016/j.tafmec.2022.103626 (2022).

Ullah, R., Qiang, Y., Ahmad, J., Vatin, N. I. & El-Shorbagy, M. A. Ultra-high-performance concrete (UHPC): A state-of-the-art review. Materials 15 (12). https://doi.org/10.3390/ma15124131 (2022).

Chen, T. F., Zhao, L. Y., Gao, X. J., Li, L. S. & Qin, L. Modification of carbonation-cured cement mortar using biochar and its environmental evaluation. Cem. Concr. Compos. 134 (2022). https://doi.org/10.1016/j.cemconcomp.2022.104764

Aneja, A., Sharma, R. L. & Singh, H. Mechanical and durability properties of biochar concrete. Mater. Today Proc. 65, 3724–3730. (2022). https://doi.org/10.1016/j.matpr.2022.06.371

Bahedh, M. A. & Jaafar, M. S. Ultra high-performance concrete utilizing fly ash as cement replacement under autoclaving technique. Case Stud. Constr. Mater. 9 (2018). https://doi.org/10.1016/j.cscm.2018.e00202

Yuan, Q., Shi, C., De Schutter, G., Audenaert, K. & Deng, D. Chloride binding of cement-based materials subjected to external chloride environment—A review. Constr. Build. Mater. 23 (1), 1–13. https://doi.org/10.1016/j.conbuildmat.2008.02.004 (2009).

Yang, X. & Wang, X. Y. Strength and durability improvements of biochar-blended mortar or paste using accelerated carbonation curing. J. CO2 Utilization 54 (2021). https://doi.org/10.1016/j.jcou.2021.101766

Mousavinejad, S. H. G. & Sammak, M. Strength and chloride ion penetration resistance of ultra-high-performance fiber reinforced geopolymer concrete. Structures 32, 1420–1427. https://doi.org/10.1016/j.istruc.2021.03.112 (2021).

Amin, M., Zeyad, A. M., Tayeh, B. A. & Saad Agwa, I. Effect of ferrosilicon and silica fume on mechanical, durability, and microstructure characteristics of ultra high-performance concrete. Constr. Build. Mater. 320 https://doi.org/10.1016/j.conbuildmat.2021.126233 (2022).

Lin, X. et al. Biochar-cement concrete toward decarbonisation and sustainability for construction: Characteristic, performance and perspective. J. Clean. Prod. 419 https://doi.org/10.1016/j.jclepro.2023.138219 (2023).

Song, S. Y., Liu, Z. X., Liu, G. M., Cui, X. F. & Sun, J. H. Application of Biochar cement-based materials for carbon sequestration. Constr. Build. Mater. 405 https://doi.org/10.1016/j.conbuildmat.2023.133373 (2023).

Jakubovskis, R., Ivaškė, A., Malaiškienė, J. & Urbonavičius, J. Impact of Portland cement type on bacterial viability in biological concrete. Cem. Concr. Compos. 127 https://doi.org/10.1016/j.cemconcomp.2022.104413 (2022).

Gupta, S., Muthukrishnan, S. & Kua, H. W. Comparing influence of inert Biochar and silica rich Biochar on cement mortar–Hydration kinetics and durability under chloride and sulfate environment. Constr. Build. Mater. 268 https://doi.org/10.1016/j.conbuildmat.2020.121142 (2021).

Liu, J., Liu, J. Y., Cheng, L., Jin, H. S. & Xing, F. Sustainable upcycling of artificial lightweight cold-bonded aggregates (ALCBAs) designed by Biochar and concrete slurry waste (CSW) into porous carbons materials for CO2 sequestration. Constr. Build. Mater. 412 https://doi.org/10.1016/j.conbuildmat.2023.134736 (2024).

Hanif, A., Parthasarathy, P., Ma, H., Fan, T. & Li, Z. Properties improvement of fly Ash cenosphere modified cement pastes using nano silica. Cem. Concr. Compos. 81, 35–48. https://doi.org/10.1016/j.cemconcomp.2017.04.008 (2017).

Zhao, B., Xu, X., Zeng, F., Li, H. & Chen, X. The hierarchical porous structure bio-char assessments produced by co-pyrolysis of municipal sewage sludge and hazelnut shell and Cu(II) adsorption kinetics. Environ. Sci. Pollut. Res. 25 (20), 19423–19435. https://doi.org/10.1007/s11356-018-2079-y (2018).

Brewer, C. E. et al. New approaches to measuring Biochar density and porosity. Biomass Bioenerg. 66, 176–185. https://doi.org/10.1016/j.biombioe.2014.03.059 (2014).

Qu, F. L. et al. W. Roles of wood waste Biochar for chloride immobilization in GGBS-blended cement composites. Constr. Build. Mater. 411 https://doi.org/10.1016/j.conbuildmat.2023.134389 (2024).

Acknowledgements

Sincere gratitude is extended to the reviewers and editors for their invaluable contributions to enhancing this paper’s quality. Additionally, we acknowledge the assistance rendered by researchers at Shiyanjia Lab (www.shiyanjia.com), who played a pivotal role in facilitating SEM and MIP analyses.

Funding

This research was supported by Guizhou Provincial Basic Research Program (Natural Science) (Qiankehe Foundation MS[2025]250).

Author information

Authors and Affiliations

Contributions

F.W, Q. Z: Methodology, Investigation, Funding acquisition, Writing - original draft. S. D: Formal analysis, Supervision, Writing - review & editing. Y. C, P. L, S. Y: Experimental design, Data processing. F. Xu, J. J: Drawing, Compilation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wu, F., Zhang, Q., Dong, S. et al. Biochar modification enhances mechanical and durability properties of cement-based materials. Sci Rep 15, 22174 (2025). https://doi.org/10.1038/s41598-025-06968-w

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-06968-w