Abstract

Asphalt concrete core rockfill dam utilizes an asphalt concrete core as anti-seepage structure. Uneven deformation could produce at core wall-transition interface due to differences in material stiffness, potentially leading to crack formation in the core wall. Shear behavior of the interface is more complex under seepage effect. This study investigates the shear behavior of the asphalt concrete core-transition material interface under seepage effects. Shear tests were conducted across five seepage pressure, three shear rates, and five normal stress levels. A nuclear magnetic resonance system was employed to analyze internal pore distribution in the asphalt concrete core within shear-affected region. Additionally, high-pressure permeability tests were conducted to explore the effects of shear action on asphalt concrete core permeability. Findings revealed that the interface exhibited a shear hardening phenomenon, with normal displacement rising in response to increased seepage pressure, while the internal friction angle and cohesive strength diminished. The observed damage patterns primarily involved particle embedding, aggregate cracking, and surface cracking, with damage severity increasing with both normal stress and seepage pressure. Despite shear action leading to increased porosity, the asphalt concrete core remained compliant with porosity control standards.

Similar content being viewed by others

Introduction

The ACCD utilizes an asphalt concrete core as its seepage control measurement. The ACCD has the characteristics of good anti-seepage performance, strong deformation adaptability, and good seismic performance, which is the preferred dam type for areas with scarce soil anti-seepage materials1. Along the river direction, the asphalt core is positioned between two transition layers made of coarse granular material on both sides. In the contact area between cohesive asphalt concrete and unbonded transition material, interlocking occurs. Notably, the transition material on the upstream side of the core is subjected to saturated seepage conditions during the water storage period. This seepage significantly influences the interface’s performance. Due to complex stress conditions and differences in deformation modulus of the core and transition, the interface is susceptible to uneven deformation, potentially leading to arch effects on the core and resulting in shear-tensile cracks. Consequently, investigating the shear mechanisms at the core-transition interface is vital for ensuring the safety of ACCDs.

Numerous scholars have conducted relevant researches on shear behavior of soil-rigid structure interfaces2,3. Early experimental studies by Hu and Pu4,5 focused on the mechanical behavior of these interfaces. Subsequent investigations by Chen et al.6 and Li et al.7 examined the shearing performance of various interfaces, including frozen soil-structure, silty clay-concrete, and sand-concrete under differing loading and normal stress. However, these studies predominantly addressed the interfaces between sand or clay and concrete, leaving gaps in their applicability to coarse-grained soils. Feng et al.8,9,10 and Zhang et al.11 conducted monotonic and cyclic shear tests on coarse granular material-structure interfaces. These tests provided insights into fundamental mechanical behaviors and their influencing factors, leading to the establishment of an elastic–plastic damage model for the interface. Research by Martinez et al.12, Guo et al.13, and Attal et al.14 investigated how structural type, roughness, soil properties, shear paths, and cyclic loading affect the shear behavior of coarse granular material-concrete interfaces. The impact of particle sizes on interface shear behavior was analyzed by Wang et al.15, while Macaro et al.16 utilized the discrete element method to study the impact of gravel content and shape on the shear properties of soil-rock mixtures. Additionally, Donna et al.17 and Rehman et al.18 conducted shear tests to investigate the interface between cushion layers and concrete face slabs in rockfill dam, revealing that particle breakage and shear compaction were primary reasons for shear dilation. Saberi et al.19 and Liu et al.20 analyzed effect of discontinuous deformation of the interface on damage and cracking characteristics of concrete face slab considering contact effect between face slab and cushion layer. Other studies, such as those by Yu et al.21, Ke et al.22, and Wen et al.23, discussed the interaction between concrete cut-off walls in dam foundations and adjacent soil. Macaro et al.16 applied particle flow methods to investigate the contact dynamics between soil and structures. Although significant insights have been gained, the effect of seepage on the shear action of coarse granular material-structure interfaces have yet to be thoroughly investigated.

In addition, relevant scholars have conducted research on the shear performance of the flexible interface formed between granular material. Compared with conventional concrete and other rigid structure, asphalt concrete has a low deformation modulus and will also produce a flexible interface between it and the transition material. Studies, including those by Wang et al.24,25 and Baziar et al.26 have analyzed the inharmonious deformation at the asphalt core-transition interface of Quxue, Yele and Meijaran ACCD based on observational data and numerical analysis. Their findings reveal a substantial difference in vertical deformation between the two materials. Hu et al.27 explored the interface behavior of anti-seepage and filter materials in conjunction with coarse-grained soil through direct shear testing, analyzing the failure characteristics under significant shear deformations. Hu and Walubita28 investigated the interaction between asphalt pavement and gravel materials. Tajdini et al.29 performed shear tests using small-scale shear equipment, albeit without addressing the characteristics of rough contact surfaces, which limits the applicability of their results. Wang et al.25 executed shear tests on the flexible asphalt core-transition interface, utilizing a ring shear test apparatus to discuss the relation between shear stress and displacement. Despite these efforts, there is still a limitation of research regarding the mechanisms and affecting elements that interact between transition material and asphalt core. Meanwhile, the effect of seepage on interface behavior has not been sufficiently addressed. Further in-depth studies on the shear behavior of the interface under seepage conditions are needed to fill this gap.

This paper aims to investigate shear performance of the core-transition material interface under seepage effect. Shear tests were conducted at the interface across five seepage pressure levels, three shear rates, and five normal stress levels. The surface damage patterns were analyzed, and the shear mechanism at the interface influenced by seepage pressure was examined. Furthermore, the study assessed the impact of seepage on shear behavior. A nuclear magnetic resonance (NMR) system was employed to analyze the internal pore distribution in the asphalt core within the shear-affected region. Additionally, high-pressure permeability tests were conducted to explore the effects of shear on asphalt core permeability in the presence of seepage.

Test method

Core-transition interface shear test

Figure 1 shows diagram of the interface deformation between asphalt concrete core and transition material. Uneven deformation could produce at core wall-transition interface due to differences in material stiffness, potentially leading to crack formation in the core wall. Shear behavior of the interface is more complex under seepage effect.

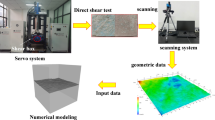

A contact surface shear testing procedure is adopted to perform shear tests on the asphalt core-transition interface. Figure 2 provides an overview of the testing equipment, testing principles, and testing procedures. The apparatus includes a shearing box, loading module, monitoring module, and seepage control module, with a maximum loading capacity of 600 kN and a load indication accuracy of ± 1%. Stresses during the shearing process are measured using pressure resistance sensors. The shearing box is composed of upper and lower compartments sealed with rubber rings. During testing, the lower part remains stationary while the upper one is moved. Coarse-grained soil is positioned in the lower box, with asphalt core placed in the upper box. A water inlet located at the bottom of the lower shearing box allows for stable seepage pressure application during the experiment, facilitated by a water tank connected to a nitrogen bottle and pressure valve. The maximum stroke of normal displacement and shear displacement is 75 mm and 20 mm respectively, both monitored via displacement sensors. The specific steps for conducting the shear tests at the interface are as follows:

-

1.

Asphalt core samples are extracted from actual engineering projects and processed into specimens fitting the dimensions of shearing box (75 mm in height and 200 mm in diameter). To prevent damage during the cutting process, a low-speed cutting method utilizing cold water cooling is employed. Subsequently, the prepared asphalt core specimen is positioned in the upper shearing box.

-

2.

Transition material specimens were prepared according to the designed gradation. To ensure uniformity in the transition material specimen, the transition material is mixed in 5 batches for each test. This mixed material is then filled into the lower shearing box. Each layer is compacted through vibration to achieve consistent grading throughout. After filling the lower shearing box with the transition material, the specimens and shearing box are sealed in preparation for the test.

-

3.

A predetermined normal load is first applied to the upper box. Following stabilization of the normal stress and displacement, seepage pressure is introduced at the interface via the seepage inlet and pressure valves. Shearing load is subsequently applied once the seepage pressure reached stability. The shear test is conducted at a predetermined shear rate, concluding when the shear displacement reached a maximum of 20 mm.

-

4.

Shear strength parameters of the interface are determined by both the shear stress and displacement. Post-test, the damage patterns in the asphalt core due to shearing is examined. Additionally, the porosity and permeability of the asphalt core are evaluated by examining the pore distribution and permeability in the affected areas of the specimens.

NMR test

In order to examine the impact of shearing on the extent of damage and the pore distribution in asphalt core specimens, low-field nuclear magnetic resonance tests are performed on these specimens after shearing. The NMR testing process is illustrated in Fig. 3. Given that shearing affects only a specific depth within the specimen, this research focuses on evaluating pore characteristics and damage within the impacted area, following the identification of the shearing effective depth.

A rock core drilling rig is utilized to extract core samples from the central positions of specimens, both those subjected to shearing and those in the control group. In order to avoid secondary damage to the core samples during the sampling process, cold water was used to cool down the core drilling position and low-speed core drilling was adopted. Four samples are taken from each specimen, ensuring they are evenly distributed within the middle section of the asphalt specimen (see Fig. 3). One sample is designated for analyzing the affected-depth, while the remaining three samples are intended to examine alterations in pore distribution within the affected depth zone of the asphalt cores. The sample diameter and height are both 50 mm. Before conducting nuclear magnetic resonance testing, an intelligent vacuum saturation machine is used to perform vacuum saturation treatment on the specimens. The saturated samples are wrapped with plastic wrap to prevent moisture loss before further testing. A low field nuclear magnetic resonance instrument is used to test the characteristics and variation patterns of the internal pore structure of the sample. The core sample size used for nuclear magnetic resonance testing is Φ50 mm × H50 mm. The parameters for the NMR sequence are detailed in Table 1. After the test is completed, porosity and corresponding spectral curve information can be obtained by processing the test data.

Theoretical analysis of porosity in asphalt core sample

Because the excellent impermeability, incomplete saturation of the sample may introduce errors in the sample’s pore structure observed in NMR testing. Thus, this study also uses a theoretical method to calculate the sample’s porosity. Porosity can be determined from the sample’s density and maximum density, following the method described by Lian et al.30. The sample’s density is measured using the water displacement method, which is suitable for both laboratory-prepared samples and those collected in the field. To minimize water absorption errors from prolonged contact with water, samples should only be submerged for a maximum of 1 min. The sample’s maximum density ρ0, representing the highest density achievable after maximum compaction, is determined by the following equation:

where m1, m2, m3, and m4 refer to the mass of coarse aggregate, fine aggregate, mineral powder and asphalt. ρ1, ρ2, ρ3, and ρ4 represent the densities of coarse aggregate, fine aggregate, mineral powder and asphalt.

Impermeability test

The permeability coefficient of asphalt concrete in hydraulic engineering must typically be not exceed 1 × 10–8 cm/s. Using a constant water head high-pressure permeameter, impermeability tests are carried out on samples from the affected area in order to further examine the impact of shearing on the permeability. The procedure for the impermeability test is shown in Fig. 4. The test is designed in accordance with the technical specifications for hydraulic asphalt concrete testing in China, and it is based on Darcy’s law and constant water head under pressure permeability tests. The diameter of penetration sample is 175 mm and the height is 75 mm. The sample is placed in pressure chamber of the permeameter. The plastic wrapping film sealing method is used to address sealing issue between specimen and mold. After the installation of the sample is completed, the set osmotic pressure is applied from the bottom of the pressure chamber. For 2 h, 3 specimens underwent parallel testing. A complete absence of water leakage indicates an effective anti-seepage performance.

Test materials and scheme

Test material

Transition material

The transition layer plays a crucial role in facilitating the deformation coordination between the asphalt core and dam. Transition materials could use screened and processed sand and gravel, artificial sand and gravel materials, or their blending ingredients. The particle size of transition material should smaller than 80 mm, with 25%-40% of the particles being smaller than 5 mm and no more than 5% smaller than 0.075 mm.

This study utilized the actual design gradation of the transition material from a specific ACCD engineering project. To comply with the size requirements pertinent to the testing instruments, the gradation is scaled down using a hybrid scaling method. Firstly, the design gradation was reduced by an appropriate scale factor, and then replacing any particles that still exceeded specified size limit. In the tests, the maximum particle size is established at 16 mm, resulting in four categorized groups: 16–10 mm (36%), 10–5 mm (36%), 5–0.075 mm (28%), and < 0.075 mm (4%). The test gradation curve is showed in Fig. 5. Processed gravel is used as the transition material, exhibiting characteristics such as a shear strength of 2.816 MPa, an internal friction angle of 41.3°, porosity of 18%, and permeability coefficient of 3.77 × 10–2 cm/s.

Asphalt core material

The asphalt core specimens are extracted from an actual project. Gradation indexes of the asphalt concrete consist of maximum aggregate size (Dmax), gradation index (r), and filler content (P0.075). The mix proportions for the asphalt concrete are established through orthogonal experiments, resulting in r of 0.40, a filler, fine aggregate, coarse aggregate and asphalt content of 13%, 30%, 57%, and 6.6%, respectively. Limestone block stone serves as the coarse aggregate, while artificial sand is used as the fine aggregate. Limestone mineral powder is used as the filler, and Karamay 70 Grade A asphalt is adopted. To prepare the asphalt core samples, a 200 mm diameter core drilling equipment is employed, resulting in core samples with a total length of 350 mm. A cutting equipment is then utilized to slice these samples into test specimens, each with a height of 75 mm, conforming to testing requirements. The process of asphalt core sample preparation is illustrated in Fig. 6.

Test scheme

Table 2 shows the test scheme. In total, 75 test sets are performed. Considering the current dam height of ACCDs, 5 levels of seepage pressures are selected for the interface shear tests, corresponding to 0 MPa, 0.29 MPa, 0.59 MPa, 0.88 MPa, and 1.18 MPa, simulating the stress conditions of the core under water head of 0 m, 30 m, 60 m, 90 m, and 120 m, respectively. Shear tests are carried out at 3 shear rates (γ) of 2.4 mm/min, 3.0 mm/min, and 3.6 mm/min under each seepage pressure condition, according to geotechnical testing standards. Shear tests were conducted under 5 normal pressures for each seepage pressure and shear rate condition. To reflect the lateral earth pressure on the core at varying dam heights, 5 normal stress levels (σ) of 1.41 MPa, 2.12 MPa, 2.35 MPa, 2.82 MPa, and 3.53 MPa are applied to simulate the stress state at different depths of the core. In total, 75 test sets are performed. Since the asphalt core is located inside the dam body, which is less affected by external environment. In subtropical regions, the temperature of the core remains stable at around 20 °C31. Therefore, all tests in this paper are conducted under ambient temperature of 20 °C.

Interface shear performance under seepage impact

Surface damage pattern

Figure 7 presents the surface damage of asphalt core samples subjected to a shear rate of 3.0 mm/min. To quantify the damage, the damage degree index is defined as the ratio of the damaged area to the total surface area of the sample. Figure 8 depicts the correlation between the damage degree, normal stress, and shear rate.

The surface damage patterns observed in the asphalt core primarily consist of three types: particle embedding, aggregate cracking and detachment, and surface cracking. Under conditions of low seepage pressure and normal stress, the specimens mainly exhibited shear scratches and particle embedding, along with limited aggregate cracking and detachment. With the increase of normal stress, the incidence of particle embedding damage decreased, while the occurrences of aggregate cracking and detachment, and surface cracking intensified. In scenarios with high seepage pressure, the predominant surface damage at low normal stresses was characterized by aggregate cracking and detachment. As the normal stress rose, the levels of aggregate cracking, detachment, and surface cracking also increased. Overall, the damage degree of the samples escalated with rising normal stresses and seepage pressures. Specifically, as seepage pressure rises from 0.29 to 1.18 MPa, the damage degree range shifted from 30–59% to 39–69% under varying normal stresses. Furthermore, the damage degree is found to increase with higher shear rates.

The phenomenon outlined can be attributed to the shearing mechanism. Figure 9 exhibited a schematic diagram of shear mechanism of the interface under seepage effect. During the normal stress loading phase, the transition material becomes embedded in the surface of the asphalt core sample due to the application of normal stress. As normal stress increases, both particle embedding and surface damage intensify. When seepage pressure is applied, it exerts a relatively uniform distribution across the flat surface of the asphalt core sample. In the initial phase of shearing, the shear stress on the surface particles of the transition material remains below the maximum static friction between these particles, causing them to remain fixed and resulting in interlocking at the core-transition interface. Concurrently, the application of seepage pressure on the asphalt core surface facilitates water infiltration into the small pores at the interface, which reduces the frictional resistance. This phase exhibited partial aggregate cracking phenomena. In middle phase of shearing, due to limited maximum static friction force between transition material particles, transition material particles begin to slide and rotate along the interface due to shear action. As the accumulation of particles increases, particles on the interface were difficult to break and flip, thus forming a self-locking phenomenon. When the shear stress exceeded the bonding strength between asphalt and aggregate, the interface experienced shear slip, aggregate cracking and detachment failure. Water infiltration weakened bonding strength between aggregates and asphalt, further exacerbating separation or peeling phenomenon between asphalt and aggregates. In later phase of shearing, under the self-locking effect between the transition material particles, physical interlocking between the contact surface particles and asphalt concrete generated interlocking effect. The interface is more vulnerable to shear damage as shear displacement increases. This phase primarily leads to surface and aggregate cracking damage. Furthermore, the extent of this damage intensifies with rising seepage pressure, normal stress, and shear rate.

Correlation between interface stress and displacement

Figure 10 presents the correlation between shear stress and shear displacement of the interface under various normal stresses and seepage pressures at a shear rate of 3.0 mm/min. The shearing process can be categorized into three distinct phases: initial shearing phase (A-B), middle shearing phase (B-C), and final shearing phase (C-D). During the initial shearing phase (A-B), there is a rapid increase in shear stress with increasing shear displacement, culminating in a transient peak stress. Notably, shear stress tends to decrease as seepage pressure rises. In this phase, the interaction between asphalt core and transition materials creates a shear sliding zone, and the friction coefficient at the interface reaches its peak. Higher seepage pressure contributes to a reduction in frictional resistance, thereby leading to a drop in shear stress. In the middle shearing phase (B-C), the curve flattens, and the duration of this phase shortens with increasing normal stress. This may be due to the rapid plastic deformation of the asphalt core under shearing. At this stage, failure has occurred and the shear stress shows a decreasing trend with shear displacement. Similar to the initial shearing phase, higher seepage pressure corresponds to lower shear stress. During the shear test, an abnormal final shearing phase (C-D) was observed. In this phase, the shear stress increases with the shear displacement. This may be caused by inherent defects in the testing equipment. Meanwhile the cohesive force of the transition material particles in sliding zone increases with displacement leading to a self-locking effect that enhances friction at the interface. At this point, the shear stress exceeded interface yield strength, causing further plastic deformation and an increase in shear stress with displacement. Overall, the shear test results at this phase cannot accurately reflect the actual working behaviors of the interface.

Tajdini et al.29 conduct direct shear tests on interface of sand and asphalt concrete. The results show that the shear stress increases as the shear displacement. After reaching to a maximum shear stress, the failure occurs and then, the shear stress decreases to a final constant value. Wang et al.25 conduct stacked ring shear test on asphalt concrete core and gravel transition zone interface. The experimental results show that the shear stresses increased with the shear displacements and then reached peak strength. In this study, except for the abnormal results in the final shearing phase, the results of the first two phases are basically consistent with existing experimental results.

To deeper discuss the effects of shear rate and seepage pressure on shear stress and displacement, we conduct an analysis of both transient peak and maximum shear stress. As illustrated in Fig. 11, the relationship between shear stress, normal stress, and shear rate reveals that both the transient peak and maximum shear stress decrease as seepage pressure increases. The range of transient peak values under the minimum and maximum seepage pressures decreases from 1.37–2.65 MPa to 0.59–2.07 MPa, while the maximum shear stress decreases from 2.24–3.83 MPa to 1.55–2.78 MPa. This is because the increase in seepage pressure reduces the effective stress at the interface, leading to a decrease in both transient peak and maximum shear stress. Conversely, these stresses increase with higher normal stress. The range of transient peak under the minimum and maximum normal stress increases from 1.18–1.43 MPa to 2.39–2.83 MPa, while the range of maximum shear stress increases from 1.41–1.69981 MPa to 3.51–4.65 MPa. Higher normal stress directly correlates with increased effective stress and shear stress. Similarly, both the transient peak and maximum shear stress rise with increasing shear rate. The range of transient peak values under the minimum and maximum shear rate increases from 0.45–1.69 MPa to 1.61–2.83 MPa, while the range of maximum shear stress increases from 1.94–3.48 MPa to 2.59–4.65 MPa. This is likely due to enhanced friction and compression during rapid shearing, which locally increases effective stress and, consequently, shear stress.

Shear deformation

Figure 12 shows the relationship between normal and shear displacement under a shear rate of 3.0 mm/min. Due to the shearing effect, coarse aggregate particles were compacted, resulting in reduction in the pores of transition material. Simultaneously, the asphalt core sample undergoes compression deformation due to shear force, resulting in shear-induced shrinkage at the interface. Similarly, Wang et al.25 found that when the normal stress was relative small, the interface exhibits a phenomenon of first shear shrinkage and then shear dilation. However, when the normal stress was relative large, the interface mainly experienced shear shrinkage phenomenon. Tajdini et al.29 found that the interface mainly experienced shear shrinkage phenomenon in the direct shear experiment. The shear displacement test results in this paper are consistent with the existing direct shear test results.

In the initial shearing phase, normal shrinkage displacement increases rapidly with shear displacement, demonstrating a linear growth trend. This phenomenon can be attributed to the shear action facilitating the rearrangement of transition particles, which likely reduces the voids within the transition material. Normal displacement in this phase constitutes approximately 80%-90% of total displacement. In the middle and final shearing phase, increment of shear deformation is relatively small compared to the previous phase. The normal displacement correlates positively with seepage pressure, with the time to peak normal displacement extending as seepage pressure increases. Additionally, the normal displacement is found to increase in response to elevated normal stress and shear rate.

Figure 13 illustrates the correlation between normal displacement and factors such as seepage pressure, normal stress, and shear rate. Similar to shear stress, normal displacement increases with seepage pressure. Under different normal stress conditions, maximum normal displacement increased by 0.32–10.06 mm relatively compared to the condition without seepage pressure. The range of maximum normal displacement increased from 4.08–7.41 mm to 8.47–15.78 mm. Both initial and maximum normal displacements gradually increase with normal stress, primarily due to enhanced compression deformation in transition materials under higher normal stress. The range of maximum normal displacement increased from 4.70–6.77 mm to 10.05–14.48 mm under different shear rate conditions, likely due to uneven internal stress distribution and transient pore instability at higher shear rates.

Shear strength

The relationship between interface shear strength and normal stress is showed in Fig. 14. The data reveal that, across the testing range of normal stress, shear rate, and seepage pressure, shear strength demonstrates a clear linear correlation with normal displacement. The linear correlation coefficients of fitted Mohr–Coulomb lines are all above 87.65%. Thus, the shear strength can be characterized by the Mohr–Coulomb criterion.

Figure 15 shows the correlation between the interface cohesive force and the friction angle with seepage pressure and shear rate. The two decrease with the seepage pressure. The effect of large seepage pressure could reduce the effective stress between interfaces, which result in a decrease in the effective contact and bonding ability between the interfaces. The range of friction angles under different seepage pressures is 32.48–39.52°, decreasing by 3.83–8.11° compared to the condition without seepage pressure. The range of cohesive force under different seepage pressures is 0.55–1.03 MPa, decreasing by 0.06–0.69 MPa. On the contrary, the two parameters increase with shear rate. This is mainly due to the fact that high shear rates promote effective rearrangement between particles, which lead to a compact and stable transition material particle structure.

Influence of shearing effect on the asphalt core pore structure and impermeability

The shear action of the interface causes damage to the asphalt concrete at a certain depth. The porosity and permeability of asphalt concrete would increase within the depth range affected by shear. Therefore, the shear action of the interface would have a certain impact on the porosity and permeability of the asphalt concrete. Figure 16 shows the schematic diagram of the effect of interface shear action on porosity and permeability of asphalt concrete. To analyze the impact of shear effect on the asphalt concrete core porosity and impermeability, this section discuss pore distribution, porosity, and impermeability performance of the asphalt concrete after shear action on the basis of determining the shear affected-depth.

Affected-depth of the shearing effect

To analyze the impact of shearing effect on the asphalt core pore structure and impermeability, it is essential to determine the affected-depth. As illustrated in Fig. 17, surface damage is observed in the core samples following shearing under varying normal stresses and seepage pressures, with a 3.6 mm/min shear rate. A significant increase in pores and cracks is noted at the interface, particularly with higher normal stress. Cracks appears at the interface between the aggregate and asphalt. The patterns under different shear rates and seepage pressures are generally consistent. The large pores identified in the sheared samples are primarily located close to the interface. The affected region of the samples concentrated near the contact surface, indicating the affect-depth to be within the range of 43–53 mm.

In order to quantitatively determine the affect-depth, pore ratio tests by NMR are performed on core samples subjected to various seepage pressures and normal stresses. After drilling the samples, their bottom portions are sequentially removed to evaluate the remaining porosity. Figure 18 shows distribution of porosity within the samples at different depths, showing an increase in porosity closer to the interface, where shearing effect is most severe. Notably, under different seepage pressures and normal stresses, a marked inflection point in the porosity trend is identified between depth of 45–55 mm, with the inflection point occurring at 55 mm under a seepage pressure of 1.18 MPa. Consequently, this study adopts 55 mm as the maximum affect-depth.

Asphalt core pore distribution

Figure 19 showed T2 peak curve of asphalt core sample within the affected-depth range under varying seepage pressure. The T2 spectrum curve maintain a three-peak distribution, reflecting small, medium, large pores and microcracks. Small pores are predominant when normal stress is low. However, as normal stress increases, small pores gradually transformed into large pores. After shearing, the peak value of small pores decreased, while peaks for medium and large pores increase. Under different seepage pressure conditions, the T2 spectrum curve still maintain a three-peak distribution. The shifting of the pore signal intensity peaks to the right indicates an increase in pore size with rising normal stress. This phenomenon occurs as small pores, induced by shearing, expand into medium and large pores and microcracks due to the influence of seepage pressure.

Figure 20 illustrates the relationship between the peak signal strength across various pore types and normal stresses and seepage pressures.The peak value for small pores decreases with the seepage pressure, with a reduction of 61.89–88.04 noted at a seepage pressure of 1.18 MPa compared to conditions without seepage pressure. Conversely, peak values for small, medium, and large pores tend to increase with rising normal stresses and shear rates. Compared to a normal stress of 1.41 MPa, average increase in the peak values of medium and large pores is 28.85–39.55 and 45.84–72.62, respectively, at a normal stress of 3.53 MPa. Compared to a shear rate of 2.4 mm/min, average increase in the peak values of medium and large pores is 9.05–24.91 and 12.31–29.93, respectively, at a shear rate of 3.6 mm/min. The rise in the proportion of medium and large pores is primarily attributed to shear-induced damage.

Porosity and impermeability performance

This paper compares porosity results derived from NMR test with those obtained through formula-based calculations. Figure 21 showed relationship between porosity in affected region of the specimen and normal stress, seepage pressure, and shear rate. The results indicate that the porosity measured by NMR test is lower than the values calculated using formulas. But they exhibited good consistency in distribution patterns and relative variations. Under varying loading conditions, the discrepancy in porosity between the two methods is found to be between 0.1% and 0.2%.

Figure 21 indicated that the porosity increased with seepage pressure. As the seepage pressure rose from 0.29 MPa to 1.18 MPa, the NMR testing porosity under different normal stress conditions exhibits an increase of 0.48% to 0.82% compared to conditions without seepage pressure, observed at a shear rate of 3.0 mm/min. The formula-calculated porosity under different normal stress increases by 0.39–0.70% compared with that of no seepage pressure condition. The results indicate that seepage pressure further deteriorates the samples impermeability. The porosity increases with the shear rate. The NMR testing porosity under different normal stress conditions at high shear rates increases by an average of 0.25–0.41% compared to low shear rates under a seepage pressure of 0.29 MPa. Additionally, the porosity exhibits an increase in response to the applied normal stress. The NMR testing porosity under different shear rate conditions at high normal stress increases by an average of 0.35–0.51% compared to low normal stress under the seepage pressure of 0.29 MPa, while the formula calculated porosity increases by an average of 0.40–0.56%. The porosity of hydraulic asphalt concrete should not exceed 3%25. The findings suggest that while shearing effect can increase the porosity of asphalt core, it remains within the acceptable limits for porosity control.

In order to further investigate the impact of interface shearing effect on the impermeability of the asphalt core samples, a constant head high-pressure permeameter is used to test the permeability of the affected regions. The results show that none of the samples within the applied load range experienced leakage under a continuous high-pressure water head of 50 m for 2 h. Therefore, it is believed that after shearing, the asphalt core still has good anti-seepage performance. This is mainly due to the fact that shearing effect only inflicts damage at the interface. The internal structure has not undergone significant changes, so the shearing effect has not had a remarkable impact on the anti-seepage performance.

Conclusions

Shear tests are conducted at the asphalt core-transition material interface. The shear behaviors of the interface under seepage pressure are studied. The impact of seepage pressure, shear rate, and normal stress on the surface damage and impermeability of asphalt core are examined. The following are the key findings:

-

1.

The surface damage patterns of asphalt core sample primarily involve particle embedding, aggregate cracking and detachment, and surface cracking. The extent of surface damage in samples is found to increase with higher normal stress and seepage pressure. Additionally, damage degree escalates with rising shear rates.

-

2.

The shear stress and shear displacement curves exhibit shear hardening. Notably, the initial phase constituted approximately 80–90% of the total displacement. An increase in seepage pressure results in a reduction of effective stress at the interface, which in turn leads to a decrease in shear stress. Conversely, shear normal displacement exhibits an increasing trend with higher seepage pressure. The internal friction angle and cohesive force diminish as seepage pressure increases but exhibit an increase with higher shear rates.

-

3.

The affected-depth under shearing effect is approximately 45–55 mm. The T2 spectrum curve of asphalt concrete core specimen exhibits a three-peak distribution, representing small, medium, as well as large pores and micro-cracks. At lower normal stress levels, small pores predominate; however, as normal stress increases, the presence of large pores becomes more pronounced. Under varying seepage pressure conditions, the T2 spectrum curve consistently displays a three-peak distribution. Porosity is observed to increase with rising seepage pressure. Despite the increase in porosity due to shearing effect, the asphalt core continues to satisfy porosity control requirements.

Data availability

Data is available on request. If someone has any question can contact the corresponding authors.

References

ICOLD. Asphalt cores for embankment dams. Bulletin 179, International Commission on Large Dams, (2018).

Wu, F., Ma, Y., Cao, J., Chen, A. & Li, Z. Investigation on shear behavior of the interface between engineered cementitious composites and normal-strength concrete. Structures 62, 106238 (2024).

Wang, Y., Han, M., Cao, T., Yu, X. & Song, Y. Cyclic interface behavior of non-water reactive polymer and concrete during dam restoration. Structures 34, 748–757 (2021).

Hu, L. M. & Pu, L. J. Application of damage model for soil–structure interface. Comput. Geotech. 30(2), 165–183 (2003).

Hu, L. M. & Pu, L. J. Testing and modeling of soil-structure interface. J. Geotech. Geoenviron. Eng. 130(8), 851–860 (2004).

Chen, X. B., Zhang, J. S., Xiao, Y. J. & Li, J. Effect of roughness on shear behavior of red clay—Concrete interface in large-scale direct shear tests. Can. Geotech. J. 52(8), 1122–1135 (2015).

Li, M., Li, Y. & Islam, M. R. Effects of water content and interface roughness on the shear strength of silt-cement mortar interface. Soils Found. 61(6), 1615–1629 (2021).

Feng, D. K., Zhang, J. M. & Hou, W. J. Three-dimensional direct-shear behaviors of a gravel-structure interface. J. Geotech. Geoenviron. Eng. 144(12), 04018095 (2018).

Feng, D. K., Zhang, J. M. & Hou, W. J. Three-dimensional behaviors of a gravel-steel interface considering initial shear stress. J. Geotech. Geoenviron. Eng. 147(2), 04020158 (2021).

Feng, D. K., Zhang, J. M. & Hou, W. J. Role of normal stiffness in 3D cyclic behavior of gravel-steel interface from large-scale direct shear tests. Acta Geotech. 16(1), 151–165 (2021).

Zhang, W., Seylabi, E. E. & Taciroglu, E. An ABAQUS toolbox for soil-structure interaction analysis. Comput. Geotech. 114, 103143 (2019).

Martinez, A., Palumbo, S. & Todd, B. D. Bioinspiration for anisotropic load transfer at soil-structure interfaces. J. Geotech. Geoenviron. Eng. 145(10), 04019074 (2019).

Guo, Y. et al. Experimental investigation of soil–structure interface behaviour under monotonic and cyclic thermal loading. Acta Geotech. 18, 3585–3608 (2023).

Attal, R., Grange, S., Baroth, J. & Dahmani, A. Mechanical-probabilistic formulation of the soil-structure interaction, accounting for the average shear wave velocity. Int. J. Numer. Anal. Meth. Geomech. 45(2), 175–179 (2021).

Wang, P., Yin, Z. Y., Zhou, W. H. & Chen, W. B. Micro-mechanical analysis of soil–structure interface behavior under constant normal stiffness condition with DEM. Acta Geotech. 17, 2711–2733 (2022).

Macaro, G., Utili, S. & Martin, C. M. DME simulations of transverse pipe–soil interaction on sand. Geotechnique 71(3), 189–204 (2021).

Donna, A. D., Ferrari, A. & Laloui, L. Experimental investigations of the soil–concrete interface: Physical mechanisms, cyclic mobilization, and behaviour at different temperatures. Can. Geotech. J. 53, 659–672 (2016).

Rehman, Z. & Zhang, G. Cyclic behavior of gravel-steel interface under varying rotational shear paths. Can. Geotech. J. 58(3), 505–518 (2021).

Saberi, M., Annan, C. D. & Konrad, J. M. Numerical analysis of concrete-faced rockfill dams considering effect of face slab-cushion layer interaction. Can. Geotech. J. 55, 1489–1501 (2018).

Liu, S., Sun, Y., Shen, C. & Yin, Z. Practical nonlinear constitutive model for rockfill materials with application to rockfill dam. Comput. Geotech. 119, 103383 (2020).

Yu, X., Zou, D., Kong, X. & Yu, L. Large-deformation finite element analysis of the interaction between concrete cut-off walls and high-plasticity clay in an earth core dam. Eng. Comput. 34(4), 1126–1148 (2017).

Ke, H., Tong, X., Li, Y. C., Chen, Y. M. & Wen, Y. D. Force equilibrium-based model for predicting stresses in soil-bentonite cutoff walls. J. Geotech. Geoenviron. Eng. 144(2), 04017112 (2018).

Wen, L., Chai, J., Xu, Z., Qin, Y. & Li, Y. Comparative and numerical analyses of response of concrete cutoff walls of earthen dams on alluvium foundations. J. Geotech. Geoenviron. Eng. 145(10), 04019069 (2019).

Wang, W., Hoeg, K. & Zhang, Y. Design and performance of the Yele asphalt-core rockfill dam. Can. Geotech. J. 47, 1365–1381 (2010).

Wang, W., Feng, S. & Zhang, Y. Investigation of interface between asphalt core and transition zone in embankment dams. Constr. Build. Mater. 185, 148–155 (2018).

Baziar, M. H., Salemi, S. H. & Merrifield, C. M. Dynamic centrifuge model tests on asphalt-concrete core dams. Geotechnique 59(9), 763–771 (2009).

Hu, L. M., Zhang, B. Y. & Ma, J. Mechanical characteristics for interfaces between granular materials. Mech. Res. Commun. 37(1), 42–46 (2010).

Hu, X. & Walubita, L. F. Effects of layer interfacial bonding conditions on the mechanistic responses in asphalt pavements. J. Transp. Eng. 137(1), 28–36 (2011).

Tajdini, M., Mahinroosta, R. & Taherkhani, H. An investigation on the mechanical properties of granular materials in interface with asphaltic concrete. Constr. Build. Mater. 62, 85–95 (2014).

Lian, C., Zhuge, Y. & Beecham, S. The relationship between porosity and strength for porous concrete. Constr. Build. Mater. 25(11), 4294–4298 (2011).

Wang, W. B., Zhang, Y. B., Höeg, K. & Zhu, Y. Investigation of the use of strip-prone aggregates in hydraulic asphalt concrete. Constr. Build. Mater. 24(11), 2157–2163 (2010).

Acknowledgements

This study was supported by the National Natural Science Foundation of China (Grant No. 52479132 and U2443230), Scientific Research Program Funded by Shaanxi Provincial Education Department (No.23JP113).

Author information

Authors and Affiliations

Contributions

Lifeng Wen contributed to conceptualization, supervision, writing-review & editing, and funding acquisition. Jialuo Huang contributed to experiment, writing-review & editing, methodology, formal analysis. Yu Yang contributed to conceptualization, supervision, writing-review & editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wen, L., Huang, J. & Yang, Y. Shear behavior of the interface between asphalt concrete core and transition under seepage effect. Sci Rep 15, 22660 (2025). https://doi.org/10.1038/s41598-025-07632-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-07632-z