Abstract

The coal seams in the Zhaogu mining area are characterized by great burial depth, hard coal quality, and difficulty in fracturing the top coal. To address the challenges of top-coal drawing in the working face, this study focuses on the external coal pillar working face in the Second Panel. Through laboratory experiments, field tests, and PFC numerical simulations, the coal drawing parameters and top-coal caving techniques were systematically investigated to provide technical support for on-site production. Key findings include: (1) Borehole observations revealed that adjacent goaf mining activities induced stress redistribution toward deeper zones, promoting full fragmentation of top coal. (2) Numerical simulations demonstrated the significant influence of mining-to-drawing ratio (MDR) on top-coal failure characteristics, with optimal recovery rate (TCRR) achieved at 1:1 MDR. (3) Parameter analysis showed the lowest gangue content occurred at 0.8 m drawing step distance, while single-round multi-opening interval drawing strategy delivered superior economic benefits and higher recovery compared to traditional multi-round approaches. (4) Similarity simulation tests uncovered funnel interaction patterns between adjacent drawing openings, with peak efficiency during initial drawing phases and an overall simulated recovery rate of 86.23%. Field applications confirmed the method’s effectiveness, showing no significant fluctuations in support pressure during operation. The research results provide critical parameter optimization schemes and technical implementation pathways for efficient extraction of deep-buried hard coal seams under complex geological conditions.

Similar content being viewed by others

Introduction

In recent years, with the rapid economic development of China, the energy industry has undergone profound reforms1,2; however, coal continues to hold a steadfast core position3. In the Xinxiang area of Henan Province, the II1 coal seam exhibits complex occurrence conditions and a significant burial depth. Top coal caving technology4,5 is extensively employed in mining operations. Nevertheless, the recovery rate of top coal is not consistently guaranteed6,7. Therefore, it is of great significance to study the process parameters of top coal caving to achieve efficient mining of thick coal seams.

Considering the research on coal caving technology within fully mechanized caving faces, numerous scholars have conducted extensive studies8,9,10. Wang11,12 has conducted in-depth research on the law of top coal release, proposing the BBR research system, which comprises four key elements. The achievements of China in fully mechanized caving mining over the past 40 years are summarized. He highlighted that the future development of fully mechanized caving mining technology should focus on the advancement of intelligence and the exploration of low-carbon technology applications. Targeting the shallow-buried double-hard and extra-thick coal seam in the Xinjiang region, Sun et al.13 employed FLAC3D to simulate the caving characteristics of the working face, utilized PFC for the analysis of the top coal caving law, and determined the caving method and the caving step distance. Adopting the control variable method and adhering to the principle of ' observing gangue and closing the window,' Ruan et al.14 analyzed the flow behavior of coal gangue in the 12,309 thick coal seam working face of the Baode Coal Mine using PFC numerical simulation software. Liu et al.15 employed CDEM simulation software to investigate the top coal caving process across various thicknesses and discussed the alterations in the coal-gangue interface and the recovery rate of the top coal. Liu et al.16 utilized PFC simulation software to evaluate five different coal caving techniques and identified the optimal strategy, thereby enhancing the top coal recovery rate for the 108 working face at the Suancigou Coal Mine. Wenli, Zhang, and Lu et al.17,18,19 employed numerical simulation techniques and field applications to investigate the caving technology of fully mechanized caving faces across various coal mines. They analyzed the influencing factors on the caving of the top coal, aiming to significantly enhance the economic profitability of the mines. Through the application of top coal thickness detection, GDEM numerical simulation, and engineering practice, Huang et al.20 established the geological model for the bifurcation and merging zones of extra-thick coal seams. Subsequently, he conducted a statistical analysis of the top coal recovery rates under various coal caving techniques. Vakili21 developed a new criterion for evaluating the recoverability of top coal and improved the overall understanding of the recoverability mechanism of longwall top coal mining (LTCC) technology. Suzuki Morales et al.22 explored the challenges faced in predicting the rock mass caving rate in the caving mining method. Orellana et al.23 conducted simulation experiments of block caving mining method by establishing an axisymmetric physical model and obtained a steady-state productivity model. Alehossein and Poulsen24 carried out a comparative experiment on the prediction models for top coal mining using two numerical simulation software, UDEC and PFC, and verified the feasibility of Longwall Top Coal Caving (LTCC). Elik25 obtained the important relationships that affect the caving of top coal in longwall mining by studying the critical top coal loss rate and the critical rock mixing ratio. Wang et al.26 summarized the relevant literature on the longwall top coal caving method within twenty years and put forward the unsolved problems in the implementation of this method. Cao et al.27, Du et al.28 used methods such as numerical simulation to study the evolution law of the stress arch during the fracture process of a thick and hard roof. Huang et al.29 revealed the mechanical mechanism of overlying rock fracture through methods such as mechanical modeling. Lin et al.30 studied the weakening of the mechanical properties of rocks under dynamic loading through laboratory experiments. Cao et al.31 and Jia et al.32 revealed the water-inrush disaster mechanism of the collapse column through similar simulation and numerical simulation. The information of different researchers is summarized in Table 1.

Traditional mining methods are difficult to fully recover coal pillar resources in deep coal seams due to complex geological conditions and high ground pressure. By mining the whole height at one time or releasing the roof in sections, the roof-placing technology can effectively recover the coal pillars that may have been left behind and significantly improve the utilization rate of resources33,34,35. Despite significant advancements in the research of top coal caving technology, the occurrence conditions of coal seams vary significantly across different mining regions due to regional differences. Consequently, the same caving technology may not yield optimal results in various mining areas. At the outer coal pillar working face of the second panel in Zhaogu No.2 Coal Mine, top coal caving mining is employed. Coal seam samples are taken, and uniaxial compression tests are conducted. Drilling observations are made in the working face to study the caving behavior of the coal body. The PFC numerical simulation software is utilized to simulate the mining and caving ratio, caving step distance, and caving method of the fully mechanized caving face. The law of top coal recovery in coal drawing process was studied by similar simulation test, determining the optimal mining ratio for hard roof coal release in long arm workings.This simulation aims to determine the rational caving technology, optimize the safety mining guarantees for the working face, and facilitate engineering applications.

Working face profile and caving analysis

Working face profile

The II1 coal seam is the primary coal seam in the Zhaogu No.2 Coal Mine. The seam thickness ranges from 4.73 to 6.87 m, with an average thickness of 6.16 m. The gangue layer predominantly consists of mudstone, with an average thickness of 0.19 m. The coal seam exhibits a relatively simple structural configuration, with coal sample compressive strength measuring 12.7 MPa. The working face of the outer coal pillar in the second panel is situated in the northwest section of the panel. The layout of the working face is depicted in Fig. 1.

The dip length extends to 257.6 m, the coal seam is buried at depths ranging from 650.1 to 696.9 m, and the thickness of the coal seam in the working face varies between 5.1 and 6.6 m, with an average thickness of 6.0 m. The average dip angle of the coal seam is 5°. The working face of the outer coal pillar in the second panel traverses three primary roadways and connecting roads during its advancement. To ensure mining safety, no coal is extracted as the working face passes through unreinforced roadways. This measure is taken to prevent the overhanging roof area from becoming excessively large, which could prematurely fracture the basic roof and lead to crushing accidents in the working face. The immediate roof of the working face is composed of gray-black sandy mudstone and gray mudstone. The main roof is made up of light gray and dark gray fine-coarse sandstone, with the composition primarily consisting of quartz and feldspar. It exhibits good stability. The columnar shape of the 12,800 boreholes near the outer coal pillar working face of the second panel is illustrated in Fig. 2.

The ZF18000/21/38D hydraulic support is employed in the top coal caving operations at the working face of the outer coal pillar in the second panel. Due to the improper adjustment of the coal caving process, issues such as a high gangue content or inadequate top coal caving may arise. To address these challenges, through the comparison and study of various mining and caving ratios, coal caving steps, and caving methods, the optimal coal caving process parameters are ultimately determined.

Mining scheme

At the 11,050 working face of the first panel in Zhaogu No.2 Coal Mine, the full-thickness mining method was utilized, incorporating a large mining height, to extract the II1 coal seam from the 11,050 working face of the first panel. The coal wall of the mining face often experiences rib spalling disasters, which pose a significant threat to the safety and efficiency of production in the working face. The outer coal pillar working face of the second panel has been fully extracted. Under the mining action on both sides, the coal pillar forms a stress concentration zone, resulting in more extensive fracture development. If the large mining height mining technology is implemented, the plastic failure zone ahead of the working face increases, and the coal wall spalling disaster is likely to worsen. The thickness of the coal seam in the outer coal pillar working face of the second panel varies, and fully mechanized caving mining is capable of adapting to the actual changes in coal seam thickness at the working face. The investment cost for fully mechanized caving mining equipment is lower, the consumption of working face materials and electricity is reduced, and the direct costs associated with the working face are significantly decreased. The selection of the main coal mining equipment in the working face is presented in Table 2.

The impact risk index for the outer coal pillar working face in the second panel is low (Wt = 0.190), indicating a negligible risk of rock burst. The measured original gas content ranges from 1.75 to 4.16 m3/t, with a relative gas pressure between 0 and 0.1 MPa, thus ruling out the risk of outburst. The thickness of the bedrock in the working face varies between 123.8 m and 156.29 m. Under conditions where roof cutting is not performed, large-scale roof caving occurs, mining height is increased, and bedrock thickness is reduced, there will be no occurrence of water inrush in the working face. According to the Coal Mine Safety Regulations, the spontaneous combustion tendency grade of the II1 coal seam is Grade III, and the spontaneous combustion tendency of the coal seam in the outburst coal pillar working face of the second group of coal seams is low.

Therefore, the use of top coal caving mining is more suitable for the outer coal pillar working face of the second panel.

Caving analysis

caving analysis of working face

The success of top coal caving mining hinges on the smooth release of the top coal with a high recovery rate, which is contingent upon the effective crushing and caving of the top coal. The caving of the top coal is governed by numerous geological factors, including mining depth, coal seam strength, and the lithology of the direct roof, among others.

Evaluation of the influence of buried depth on top coal caving

The buried depth has a direct impact on the magnitude of the original rock stress and abutment pressure. As the buried depth increases, the stress within the coal body intensifies, resulting in a more pronounced crushing effect on the top coal. Furthermore, a greater buried depth facilitates the occurrence of the critical failure condition for the top coal. The mining face has a buried depth ranging from 653.9 m to 670.4 m, which is conducive to the premature failure of the top coal.

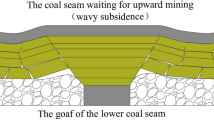

Evaluation of the influence of immediate roof on top coal cavability

If the roof is hard and the structure is sound, it is less prone to collapse during mining, which can lead to the formation of a suspended roof at the rear, thereby enhancing the crushing effect on the top coal. Conversely, if the rock strata are relatively soft, they are more susceptible to caving, causing the roof to collapse rapidly and fill the entire goaf. Under such circumstances, the liberation process of the top coal becomes relatively straightforward. However, this condition may not be favorable for the crushing effect of the top coal. Due to the mining influence on both sides of the goaf, the degree of fragmentation of the coal mass in the outer coal pillar working face of the second panel is more pronounced than that in the general working face. Additionally, in comparison to the normal working face, the goaf on both sides induces fracture failure in the overlying strata within the outer coal pillar working face of the second panel, which can fall during mining, creating a roof that is prone to caving. This condition is conducive to the breaking of the top coal.

Evaluation of the influence of coal strength on top coal cavability

Uniaxial compression tests were conducted at three sampling locations: 29 m (the first group), 125 m (the second group), and 233 m (the third group) from the air intake roadway in the outer coal pillar working face of the second panel. These samples were divided into three groups, with each group consisting of three samples, as depicted in Fig. 3. The stress–strain curves from the uniaxial compression tests are presented in Fig. 4.

From Fig. 4, it is evident that the uniaxial compressive strength of the first group of coal samples ranges from 10.399 to 21.179 MPa, with an average value of 15.924 MPa. For the second group, the uniaxial compressive strength spans from 15.455 to 24.291 MPa, with an average of 19.761 MPa. The third group of coal samples exhibits a uniaxial compressive strength between 5.754 and 10.588 MPa, averaging 8.337 MPa. The average compressive strength across the three groups is 14.674 MPa. The hardness coefficient of the coal seam is less than 2 (f = Rc / 10, where Rc is the uniaxial compressive strength of the coal, in MPa), indicating good caving characteristics of the top coal.

Evaluation of the influence of fracture development degree on cavability

To accurately assess the caving characteristics of the top coal and to observe its fracture progression, the fracture development characteristics of the top coal in the working face are measured and investigated using borehole peeping technology. This is done to ascertain the integrity of the top coal. The results of the peeping are presented in Fig. 5.

Figure 5 illustrates that at a drilling depth of 3.34 m, the hole wall exhibits a rough texture, suggesting that the cracks on the surface of the coal body have reached a relatively mature stage of development. As the drilling depth continues to increase, the structure of the hole wall undergoes substantial changes, with the emergence of longitudinal cracks and a noticeable trend of increased crack propagation length. These sequential changes indicate that the coal body in the working face is significantly influenced by the mining activity of the adjacent goaf within a specific depth range. Under this influence, the coal body experiences substantial abutment pressures. The increase in this pressure further facilitates the expansion and interconnection of cracks within the coal body, thus creating favorable conditions for the caving of the overlying coal.

By analyzing the impact of the aforementioned four factors on the caving of the overlying coal, it is observed that the burial depth of the working face is considerable, and the coal body is subjected to the influence of high ground stress, which is favorable for the caving of the overlying coal. The average compressive strength of the coal seam is 14.674 MPa, and its hardness coefficient is less than 2, suggesting that the overlying coal possesses good caving properties. The mining activity on both sides of the goaf has caused the fracturing of certain hard rock strata, resulting in a roof that is prone to collapse, which also enhances the caving of the overlying coal. Drilling peeping observations reveal that the internal cracks within the coal body are fully developed, further contributing to the caving of the overlying coal. The caving of the overlying coal in the outer coal pillar working face of the second panel is effective, and mining utilizing the caving of the overlying coal can be employed.

Determination of coal caving parameters in fully mechanized caving face

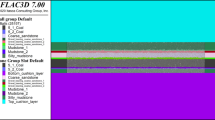

In accordance with the movement law of the overlying strata in the outer coal pillar working face of the second panel, the top coal and the immediate roof are identified as the loose medium in the ideal state. The numerical calculation model was established using the PFC2D discrete element simulation software, the numerical simulation uses a parallel bonded contact model to simulate the gradual fragmentation of intact materials, and the simulation process is consistent with the progressive fragmentation behavior of intact rock formations, as depicted in Fig. 6.The physical and mechanical parameters of coal—measure strata obtained from indoor tests are calibrated by using the mechanical strength unit model test. The left and right sides of the model are set as horizontal displacement constraint boundaries. In order to eliminate the boundary influence, the open—off cut is set at a position 5 m away from the model boundary.

The model dimensions are 65 m by 28.7 m, with overlying strata consisting of 5.9 m of sandy mudstone, 2.3 m of siltstone, 13.9 m of sandy mudstone, and 6.6 m of II1 coal from top to bottom. To mitigate the effect of boundary conditions, a 5.0 m thickness of top coal was maintained at both ends of the model. A normal stress of 15 MPa was applied to the top of the model to simulate the load exerted by the overlying strata. The physical and mechanical parameters are presented in Table 3.

The PFC wall was utilized to simulate the hydraulic support of the working face, and a corresponding height of bottom coal was removed to replicate the coal cutting process by the shearer. During the coal caving process, the wall beneath the overlying coal is removed to simulate the caving mouth. Once the coal caving is complete, the caving mouth advances by a caving step and initiates a new cycle. By simulating and analyzing the coal flow patterns under various mining and caving ratios, caving steps, and caving methods, and comparing the gangue content and recovery rates at different process parameters, the most rational caving process parameters are determined.

Caving ratio

By investigating the impact of varying heights of the overlying coal on the recovery rate of the overlying coal and the gangue content, the most appropriate mining and caving ratio is determined. During the simulation of coal caving, the height ratio between the bottom coal and the overlying coal is adjusted to replicate different mining and caving ratios.

Given that the support height of the ZF18000/21/38D hydraulic support ranges from 2.3 to 3.8 m, and based on the previous experience with mining the overlying coal, the height of the bottom coal is considered to be excessively high, which can readily result in the spalling of the working face. Conversely, coal with a low overlying height may not be fully released. To address this, numerical calculation models with bottom coal heights of 2.9 m, 3.1 m, 3.3 m, and 3.5 m were established individually to simulate the release of the overlying coal at various heights. The influence of different mining and caving ratios on the recovery rate of the overlying coal was then investigated. The simulation results are presented in Fig. 7.

Figure 7 illustrates that the interface morphology of the coal gangue with four different caving thicknesses appears relatively similar, exhibiting an irregular pattern of development. During the caving process, the interaction forces between the top coal at the caving mouth result in varying caving rates between adjacent supports, and some top coal may remain trapped between them. Different mining-caving ratios exert diverse effects on the failure characteristics of the top coal within the working face. An excessive mining height can readily lead to the connection between the tensile-shear failure area above the top coal and the compressive-shear failure area below it, potentially causing roof falls. Consequently, the selection of a reasonable mining ratio is crucial for the recovery rate of the top coal. The statistics of the top coal and gangue released from the simulation results are depicted in Fig. 8.

Figure 8 reveals that at bottom coal heights of 2.9 m, 3.1 m, 3.3 m, and 3.5 m, the corresponding top coal recovery rates are 76.6%, 73.8%, 83.1%, and 80.8%, respectively, with gangue contents of 3.7%, 2.4%, 7%, and 7.9%, respectively. The top coal recovery rates and gangue content rates at different bottom coal heights are compared and analyzed. It is observed that at a bottom coal height of 3.3 m, the top coal recovery rate is the highest, achieving the maximum recovery potential, while the gangue content rate remains low. Considering the mine’s operational conditions, the bottom coal height is determined to be 3.3 m, and accordingly, the top coal height is also set at 3.3 m, resulting in a mining ratio of 1:1.

Coal drawing interval

The caving step in coal mining significantly impacts the recovery rate of the top coal and the gangue content in the working face. By investigating the effects of various caving step sizes, optimal parameters are identified to enhance production efficiency. As a result of the study presented in the preceding section, a mining-caving ratio of 1:1 is determined to achieve the highest recovery of the top coal, corresponding to a bottom coal height of 3.3 m and a top coal height of 3.3 m, respectively. Based on this model, the width between the coal outlets in the middle section is adjusted, with caving step distances set at 0.8 m (one cut and one caving), 1.6 m (two cuts and one caving), and 2.4 m (three cuts and one caving). The simulation results, which study the top coal recovery rate and gangue content under these three scenarios, are presented in Fig. 9.

Figure 9 indicates that when the caving step is excessively large, the gangue above the top coal may reach the caving mouth prior to the coal, leading to a significant loss of the back ridge coal. Conversely, when the caving step is too small, the gangue within the goaf may first reach the coal drawing port, causing some top coal to remain outside of the drawing port, thereby affecting the top coal recovery rate. The top coal recovery rates and gangue contents from the statistical simulation results are depicted in Fig. 9.

Figure 10 illustrates that the recovery rate of the top coal and the gangue content rate exhibit a similar trend in relation to the caving step, indicating a positive correlation. Specifically, when the caving interval is set at 0.8 m, 1.6 m, and 2.4 m, respectively, the top coal recovery rate is 83.1%, 84.2%, and 84.8%, respectively, while the gangue content is 7%, 22.5%, and 27.8%, respectively. The comparative study of the top coal recovery rate and the gangue content rate across different caving step distances reveals that, overall, the change in the top coal recovery rate between these distances is not significantly different. However, when the caving step distance is 0.8 m, the gangue content rate is considerably lower than that observed at the distances of 1.6 m and 2.4 m. Consequently, to enhance the recovery rate of coal resources, taking into account the differences in top coal recovery rate and gangue content, the caving step distance is determined to be 0.8 m, which also results in a lower gangue content.

Coal caving method

Based on actual engineering conditions and the working face borehole histogram, a 2D numerical coal drawing model perpendicular to the working face advance direction was established with appropriate simplifications considering simulation software limitations. The model dimensions are 45 m (length) × 25 m (height), featuring 49 drawing openings (0.8 m width each) arranged along the advance direction.

The coal caving technique significantly influences both the top coal recovery rate and the gangue content within the working face. Additionally, this technique is directly associated with the overall caving speed and the production efficiency of the working face. In light of the specific mine conditions, simulations have been conducted to analyze the top coal recovery rate and gangue content under four different coal caving methods: (1) multi-round, multi-stage, sequential, and uniform coal caving; (2) multiple rounds, interval, sequential, and uniform coal drawing; (3) single-wheel, multi-hole, sequential coal drawing; and (4) single wheel, multiple outlets, interval coal drawing.

-

(1)

Multi-round, segmented, sequential, and uniform coal caving: The working face is divided into two sections (Odd-numbered coal discharge openings and even-numbered coal discharge openings), with both sections undergoing coal caving simultaneously. Each section opens a caving portal, and half of the top coal is extracted in each cycle, with caving operations being carried out sequentially.

-

(2)

Multi-round, interval, uniform coal caving: In accordance with the sequence of single coal caving, half of the top coal quantity is released each time, completing one cycle. Subsequently, the top coal is released in an order of double coal outlets, thereby extending the cycle to two rounds.

-

(3)

Single-wheel, multi-port, sequential coal caving: Open two adjacent caving ports simultaneously, close the caving port upon observing the gangue, and then proceed to the next cycle in sequence.

-

(4)

Single-wheel, multi-port, interval coal drawing: The top coal is extracted through the single support, and the coal drawing port is sealed once the gangue is encountered. At this time, a certain range of ridge coal will be formed in the top coal. After a certain lag distance (the influence range of the ridge coal), the top coal drawing operation of the even-numbered supports will be carried out to discharge the ridge coal.

By analyzing the recovery rate of top coal and the gangue content under the aforementioned four coal caving methods, the optimal coal caving technique is identified. The simulation outcomes are presented in Fig. 11.

Figure 11 illustrates that distinct coal caving methods can result in significant variations in the interface between coal and gangue. Figure 11a depicts that during the multi-wheel, segmented, sequential, and uniform coal caving process, as each section simultaneously opens the caving mouth and releases the top coal in multiple rounds, the interface between coal and gangue exhibits an irregular zigzag pattern. In the final round of the coal drawing process, the coal drawing mouth encounters gangue, precipitating the premature influx of gangue into the adjacent coal drawing mouth, leading to the early closure of the coal drawing mouth. Due to the early influx of gangue, a severe issue of intercalation between coal and gangue arises, leading to considerable coal loss and a low recovery rate of the top coal. Figure 11b illustrates that during the process of multi-round, interval, and equal-volume coal caving, the top coal forms an irregular coal-rock interface at the caving mouth, resulting in the phenomenon of ‘arching’ of the coal body at this location. The top coal is compressed by the gangue and slides into the upper portion of the adjacent support, where it cannot be released smoothly. This situation contributes to significant coal loss and a reduced recovery rate of the top coal. Figure 11c demonstrates that in the single-wheel, multi-hole, and sequential coal drawing process, while the recovery rate of the top coal can be enhanced by opening multiple drawing ports simultaneously, the high fluidity of the top coal also leads to the release of gangue, thereby increasing the gangue content. Figure 11d reveals that in the single-wheel, multi-hole, and interval coal drawing process, the coal-rock interface formed at the drawing port by the top coal is relatively regular, and the coal loss is minimal. The recovery rates of the top coal and the gangue are tabulated in the simulation results, as depicted in Fig. 12.

Figure 12 presents the recovery rates and gangue contents for various coal drawing and caving techniques. Specifically, the top coal recovery rate in the multi-round, segmented, sequential, and equal-volume coal drawing process stands at 83.9%, with a gangue content of 39.1%. For the multi-round, interval, and equal-volume coal drawing, the recovery rate decreases to 75.1%, accompanied by a gangue content of 7.8%. In the case of the single-round, multi-mouth, and sequential coal drawing, the top coal recovery rate is 82.5%, with a gangue content of 28.6%. Lastly, the single-wheel, multi-port, and interval coal caving process yields a top coal recovery rate of 82.4% and a gangue content of 9%. Comparing the top coal recovery rate and gangue content under different coal caving methods, the gangue content under the sequential coal caving method is far greater than the interval coal caving, and the top coal recovery rate of single-wheel coal caving is greater than that of multi-wheel coal caving. Therefore, according to the actual situation of the mine, the coal caving method is determined to be single-wheel, multi-hole and interval coal caving. And ensure the order of releasing top coal, make sure that the top coal is released from the head of the working face, and then release coal to the tail of the machine in turn. In the coal releasing operation, when the mouth of coal releasing is blocked by the larger top coal, the churning rod on the hydraulic support can be used to churn the top coal to ensure the smooth completion of the top coal releasing operation. In order to improve the recovery rate, the transition bracket on the side of the basic bracket can be used to release coal in an appropriate amount when the top coal lump size is small.

Similar simulation study on single-wheel multi-port interval coal caving method

In order to study the evolution process of coal-rock interface and the law of coal-rock migration in the process of top coal caving, taking the fully mechanized caving face of the outer coal pillar of the second panel of Zhaogu No.2 Coal Mine as the engineering background, the top coal caving process under the single-wheel multi-port interval coal caving method currently used in the working face is simulated.

Structure of the test device

Based on the summary of the deficiencies of the existing two-dimensional coal-dumping platforms, and aiming to simulate different coal-dumping methods in fully mechanized top coal caving mining, a comprehensive coal-caving mining inclined test platform for thick coal seams has been designed, as shown in Fig. 13.

It is mainly composed of an adjustable inclined test frame, coal-dumping orifice simulation device, front and rear observation baffles, and other supporting equipment. The frame dimensions are 2000 mm × 1000 mm × 250 mm, and the rectangular frame is supported at the bottom by two fulcrums. The left fulcrum is a rotatable hinge structure, while the right fulcrum is a fixed support structure. The middle section of the test frame is connected to the base with an inclination adjustment hydraulic cylinder. The inclination angle of the upper test frame can be controlled by extending and retracting the cylinder and rotating the left fulcrum, with an adjustable range of 0° to 30°.

The coal-dumping orifice simulation device consists of a housing, a tail beam simulation inclined plane, a coal chute inclined plane, coal-dumping sliding gates, sliding gate tracks, glass plate grooves, and a coal discharge opening. Nineteen coal-dumping orifice simulation devices are sequentially numbered from left to right and placed side by side on the test frame to form the coal-dumping system. The housing is 300 mm high, 85 mm wide, and 250 mm long, made entirely of 5 mm steel plate. On the top sides of the housing, there are glass plate grooves with a 12mm inner diameter, which are used for installing and supporting the acrylic plates. The tail beam simulation inclined plane forms an angle of 30° with the horizontal plane to simulate the effect of the tail beam of the coal-dumping support on the coal-dumping efficiency. The coal-dumping sliding gates are retractable, allowing them to be fully withdrawn to achieve the maximum opening of the coal-dumping orifice, and they are equipped with scales to adjust the size of the orifice. The sliding gate tracks are composed of long iron bars welded to the inside of the housing. At the bottom of the housing, there is a coal chute inclined plane with a 20° angle. After the coal-dumping sliding gates are withdrawn, the bulk particles slide out through a coal chute opening that is 85 mm wide and 100 mm high.

The experimental method of simulating broken top coal with bulk materials is mostly used in three-dimensional similar simulation, which can reproduce the process of top coal caving in space and deduce the law of top coal caving.

Test plan

-

(1)

Simulated material

During the full-seam mining process, the overlying coal and the immediate roof have become fragmented under the action of supporting pressure and the repeated support of the supports, and are in a broken state above the working face, forming a loose mass. Therefore, for the experimental study of the overlying coal release law, the use of loose particles to simulate the broken overlying coal and the immediate roof is commonly adopted to mimic the process of overlying coal release. The degree of fragmentation of the overlying coal differs due to the varying force effects in the vertical direction, with the coal closer to the working face experiencing greater fragmentation. The degree of fragmentation of the overlying coal gradually decreases from bottom to top, and the particle size becomes larger accordingly. Therefore, in this experiment, different-sized granular particles are used to simulate the overlying coal and the immediate roof in layers. The granular material used is colored granite with different particle sizes, as shown in Fig. 14.

-

(2)

Model laying

In conjunction with the platform dimensions and the geological conditions of the working face, the model laying scheme is determined as follows: a coal seam 330 mm thick and a gangue layer (fragmented immediate roof) 150 mm thick are laid separately. Different-sized terrazzo is laid according to the varying degrees of fragmentation. As the terrazzo with different particle sizes comes in different colors, this allows for better observation of the movement of coal and rock in the vertical direction at different heights during the coal caving process, and analysis of the movement laws of overlying coal in different stratigraphic levels. The laying of the model is shown in Fig. 15.

Analysis of test results

The simulated coal caving method in this test is a single-pass, multi-mouth, and spaced-out caving method. Figure 16 depicts the morphological evolution process of the coal and rock on the test platform throughout the entire coal caving process. During the test, the movement of coal and rock throughout the entire coal caving process needs to be captured in real-time by monitoring equipment. In this test platform, a Nikon D7000 high-resolution DSLR camera is used for shooting and recording. The camera is fixed at a position 4000 mm in front of the test platform using an adjustable camera mount.The simulated coal caving method in this test is a single-pass, multi-mouth, and spaced-out caving method (Scenario-4).

From Fig. 16, it can be observed that in the initial stage of coal caving, the coal caving hopper above the caving outlet is basically in a symmetrical inverted triangle shape along the centerline of the caving mouth, with an angle of approximately 26°. The boundary between coal and gangue is almost a straight line inclined within a range of 290mm, and it appears as a curved parabola between 290 and 330mm. The remaining overlying coal between adjacent caving outlets is in a "hump-shaped" configuration. At a vertical height of 290 m, the width of the coal caving hopper is approximately 400mm, indicating that the influence range of the coal caving hopper changes at a greater rate towards the top compared to the vicinity of the caving outlet. During the middle stage of coal caving, the shape of the upper coal caving hopper is mostly asymmetric, and the angle between the boundary of coal and gangue on both sides of the caving hopper and the horizontal plane is more gradual than before. At the end of coal caving, the proportion of gangue discharged increases. In the field, the gangue content can be reduced by adjusting the coal caving time. Multiple remnants of overlying coal between the caving outlets form a ridge of coal, which is the result of mutual influence among the caving outlets and also a manifestation of the differences existing among different coal caving methods.

After all 19 coal caving outlets have completed the coal caving process, the discharged loose particles were statistically analyzed. The total weight of the loose particles simulating the overlying coal within the model was 664.57 kg, with a total coal output of 573.1 kg from all the caving outlets during the test process, resulting in an overall recovery rate of overlying coal of 86.23%. Figure 17 shows the statistical data of the discharge amounts of the overlying coal and gangue simulation materials from each caving outlet.

From Fig. 17a it can be observed that due to the close proximity of the influence range of the coal caving hopper to the distance between the nearby coal caving outlets, the interface shape of the coal gangue developed above the adjacent coal caving outlets is rather similar. There is not a significant difference in the coal caving quantities. Therefore, it can be inferred that reducing the distance between them would allow for a stratified difference in the amount of overlying coal discharged from the nearby coal caving outlets. Among them, the coal caving quantities of the 1st and 19th outlets are slightly higher, which is due to the fact that these two coal caving outlets are located at the model boundaries and are affected by the overlying coal on both sides. As shown in Fig. 17b, the coal recovery rate from the coal caving outlets opened during the initial stage of coal caving is significantly higher than that during the middle and late stages. The 8th and 10th coal caving outlets, due to the presence of adjacent coal caving hoppers, have a notably higher gangue content compared to the other coal caving outlets. In the field, to reduce the gangue content, the coal caving time should be shortened to ensure a high recovery rate of the overlying coal.

In summary, the single-pass, multi-outlet, and staggered coal caving methods have similar simulated tests, with the overlying coal recovery rate at the coal caving outlets around 80%, and the total recovery rate reaching 86.23%. This is in line with the field conditions and verifies the feasibility of this similar model.

Engineering application

The No. 2 coal pillar face in the outer zone of the No. 2 panel at Zhao Gu No. 2 Coal Mine adopted the top coal caving technique for reclamation in October 2023, with a coal caving-to-mining ratio of 1:1 and a coal caving spacing of 0.8 m (one mining and one caving). The coal caving was carried out in a single-pass, multi-outlet, and staggered manner, resulting in good field coal caving performance and significant economic benefits. The working resistance of the supports was extracted using the mine’s electro-hydraulic control system, and the characteristics of the in-situ mining pressure manifestation on the working face were statistically analyzed, as shown in Fig. 18.

From Fig. 18, it can be observed that during the coal caving operation of the hydraulic supports at the working face, there was no significant increase in the strength of the advancing pressure. This indicates that the pressure exerted on the supports during the coal caving period remained at a relatively stable level, with no abnormality in periodic pressure surges. Given that the coal quality at Zhao Gu No. 2 Coal Mine is relatively hard, when the top coal caving mining method is employed, the degree of fragmentation of the overlying coal is limited, and the expansion of fractures is not pronounced. Therefore, there was no significant difference in the pressure exerted on the hydraulic supports between the coal caving and non-coal caving operations. This phenomenon further confirms the rationality of the top coal caving mining parameters for the coal pillar face in the outer zone of the No. 2 panel at Zhao Gu No. 2 Coal Mine.

The working face employs a single-pass, multi-outlet, and staggered coal caving method, which yields good coal caving results. During the coal caving operation, the advancing pressure in the working face did not show a significant increase, verifying the accuracy of the numerical simulation and similar model test for the coal caving parameters.

Conclusions

-

(1)

Through the analysis of geological conditions, compression strength testing, and borehole water injection tests, a comprehensive assessment of the coal seam burial depth, the nature of the direct roof, the strength of the coal body, and the degree of fracturing development within the coal body has been conducted. It has been determined that the top coal caving performance of the working face of the outer coal pillar in the second panel is favorable, making it suitable for top coal caving mining.

-

(2)

The coal-gangue interface exhibits consistent irregular morphology across varying bottom coal thicknesses. The mining-to-caving ratio critically determines top coal failure characteristics, with a 1:1 ratio selected to optimize recovery and minimize gangue content, particularly at a 0.8 m caving step distance. Coal caving methods significantly influence gangue content and recovery rates, where single-round, multi-port, and interval techniques outperform sequential and multi-round approaches, justifying their adoption.

-

(3)

Through the similar model test on top coal caving, the distribution of coal and gangue during the caving process was investigated. During coal caving, the shape of the hopper and the boundary morphology of coal and gangue change over time, and there is mutual influence among the coal caving outlets. The reduction in the spacing between the caving outlets leads to stratified release of the overlying coal. The recovery rate of the overlying coal at the initial caving outlets is high, and the total simulated overlying coal mass in the model is 664.57 kg, with an overall recovery rate of 86.23%.

-

(4)

The working face is utilizing single-pass, multi-port, and staggered coal caving techniques, which have resulted in favorable coal caving performance. During the coal caving operation, there was no significant increase in the working face pressure, thereby confirming the accuracy of the numerical simulation of coal caving parameters and the validity of similar simulation tests.

Data availability

Some or all data, models, or codes generated or used during the study are available from the corresponding authors by request.

References

Guo, P. et al. Structural analysis of “semi-circular arch” in steeply inclined thick coal seam caving mining. Min. Res. Dev. 36(11), 6–11 (2016).

Zhengzheng, C. et al. Numerical research on disastrous mechanism of seepage instability of karst collapse column considering variable mass effect. Sci. Rep. 14, 13900 (2024).

Cao, J. et al. Optimization research and supporting practice of fully mechanized caving mining in thick coal seam. Min. Res. Dev. 41(02), 1–6 (2021).

Wang, C. et al. Study on technological parameters of fully mechanized caving mining in steeply dipping and extra-thick coal seams. Min. Res. Dev. 38(01), 11–14 (2018).

Zhengzheng, C. et al. Diffusion evolution rules of grouting slurry in mining-induced cracks in overlying strata. Rock Mech. Rock Eng. https://doi.org/10.1007/s00603-025-04445-4 (2025).

Liu, C. et al. Time series law and identification method of fully-mechanized caving coal-gangue-rock caving flow in extra-thick coal seam. Coal J. 47(01), 137–151 (2022).

Wen, Z., Zhang, B. & Li, T. Study on the law of overburden fracture and coal caving technology of composite hard roof in fully mechanized caving mining. Coal Sci. Technol. 44(06), 153–157+162 (2023).

Jin, H. Measurement of mining process parameters and optimization of mining process. Shanxi Chem. Ind. 44(03), 165–166173 (2024).

Yi, Y. et al. Intelligent decision-making method of coal caving based on fuzzy deep Q network. Ind. Min. Autom. 49(04), 78–85 (2023).

Feng, D. et al. Breaking law of overburden rock and key mining technology for narrow coal pillar working face in isolated island. Sci. Rep. 14, 13045 (2024).

Wang, J. & Zhang, J. BBR study on top-coal drawing law in fully-mechanized caving mining. Coal J 40(03), 487–493 (2015).

Wang, J. 40 years and prospects of fully mechanized caving mining in China. Coal J 48(01), 83–99 (2023).

Sun, Q. et al. Analysis and parameter study of caving law in shallow buried double hard and extra thick coal seam. Ind. Min. Autom. 48(02), 61–69 (2022).

Ruan, J. et al. Study on the flow law and process parameters of fully mechanized caving coal gangue in thick coal seam. Coal Sci. Technol. 50(S2), 26–32 (2022).

Liu, C. et al. Numerical simulation study on reasonable caving technology in fully mechanized caving face with different coal thicknesses. J. Henan Polytech. Univ. (Nat. Sci. Ed.) 42(04), 40–46 (2023).

Liu, J. et al. Optimization of caving technology in fully mechanized caving face of Suancigou Coal Mine. Min. Res. Dev. 44(04), 19–24 (2024).

Wenli. Optimization of process parameters in fully mechanized caving face. Shanxi Chem. Ind. 43(12), 143–144172 (2023).

Zhang, N. Numerical simulation and application of coal drawing process in thick coal seam with large dip angle. Jiangxi Coal Sci. Technol. 21(01), 48–50 (2024).

Lu, H., Wu, Z. & Wang, Y. Study on the influencing factors of top coal caving and reasonable mining and caving ratio in fully mechanized caving mining of extra-thick coal seam. Shaanxi Coal 42(04), 55–58 (2023).

Huang, H. et al. Applicability analysis and optimization of caving method in bifurcation and merging area of extra-thick coal seam. J. Min. Strata Control Eng. 5(03), 16–23 (2023).

Vakili, A. & Hebblewhite, B. K. A new cavability assessment criterion for longwall top coal caving. Int. J. Rock Mech. Min. Sci. 47(08), 1317–1329 (2010).

Suzuki Morales, K., Suorineni, F. T. & Hebblewhite, B. Orebody cavability prediction challenges in block caving mining—A review. Bull. Eng. Geol. Environ. 83(1), 23. https://doi.org/10.1007/s10064-023-03516-6 (2024).

Orellana, L. et al. Productivity of a continuous mining system for block caving mines. Rock Mech. Rock Eng. 50(3), 657–663. https://doi.org/10.1007/s00603-016-1107-9 (2017).

Alehossein, H. & Poulsen, B. A. Stress analysis of longwall top coal caving. Pergamon 47(1), 30–41. https://doi.org/10.1016/j.ijrmms.2009.07.004 (2010).

Elik, A. Investigation of LTCC efficiency in horizontal and near-horizontal thick coal seams with a 2D physical model. Rock Mech. Rock Eng. 57(10), 8381–8404. https://doi.org/10.1007/s00603-024-03967-7 (2024).

Wang, J. et al. Drawing mechanisms for top coal in longwall top coal caving (LTCC): A review of two decades of literature. Int. J. Coal Sci. Technol. 8(6), 26. https://doi.org/10.1007/s40789-021-00453-1 (2021).

Cao, Z. et al. Disaster-causing mechanism of spalling rock burst based on folding catastrophe model in coal mine. Rock Mech. Rock Eng. https://doi.org/10.1007/s00603-025-04497-6 (2025).

Feng, D. et al. Research on overburden structural characteristics and support adaptability in cooperative mining of sectional coal pillar and bottom coal seam. Sci. Rep. 14, 11458 (2024).

Cunhan, H. et al. Development rule of ground fissure and mine ground pressure in shallow burial and thin bedrock mining area. Sci. Rep. 15, 10065 (2025).

Lin, H. et al. Study on the degradation mechanism of mechanical properties of red sandstone under static and dynamic loading after different high temperatures. Sci. Rep. 15, 11611 (2025).

Cao, Z. et al. Water inrush mechanism and variable mass seepage of karst collapse columns based on a nonlinear coupling mechanical model. Mine Water Environ. https://doi.org/10.1007/s10230-025-01041-4 (2025).

Yunlong, J. et al. Nonlinear evolution characteristics and seepage mechanical model of fluids in broken rock mass based on the bifurcation theory. Sci. Rep. 14, 10982 (2024).

Ping, Xu. et al. Effect of polymeric aluminum chloride waste residue and citric acid on the properties of magnesium oxychloride cement. J. Build. Eng. 101, 111864. https://doi.org/10.1016/j.jobe.2025.111864 (2025).

Guo-Dong, L. I. et al. A new determination method of hydraulic support resistance in deep coal pillar working face. Sci. Rep. 15, 16738 (2025).

Zou, Q. et al. Mesomechanical weakening mechanism of coal modified by nanofluids with disparately sized SiO2 nanoparticles. Int. J. Rock Mech. Min. Sci. 188, 106056. https://doi.org/10.1016/j.ijrmms.2025.106056 (2025).

Author information

Authors and Affiliations

Contributions

Li Xinlei: Data curation, Methodology, Writing-original draft. Ren Ziyuan: Data curation, Writing-original draft. Cao Zhengzheng: Conceptualization, Writing-original draft, Project administration, Supervision. Ren Hao: Conceptualization, Project administration, Resources. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Xinlei, L., Ziyuan, R., Zhengzheng, C. et al. Study on coal drawing parameters of deeply buried hard coal seams based on PFC. Sci Rep 15, 21934 (2025). https://doi.org/10.1038/s41598-025-08154-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-08154-4

Keywords

This article is cited by

-

Determination method of rational position for working face entries in coordinated mining of section coal pillars and lower sub-layer

Scientific Reports (2025)

-

Overburden failure characteristics and fracture evolution rule under repeated mining with multiple key strata control

Scientific Reports (2025)

-

Study on fracture development and failure characteristics of repeated mining overlying strata in multi-coal seams with faults

Scientific Reports (2025)

-

Evolution of the roof caving and fracture zones during mining of close range coal seams

Scientific Reports (2025)

-

Research on the main controlling factors of low permeability coal seam under the action of high-pressure water jetting

Scientific Reports (2025)